Recent Advances in the Preparation and Application of Biochar Derived from Lignocellulosic Biomass: A Mini Review

Abstract

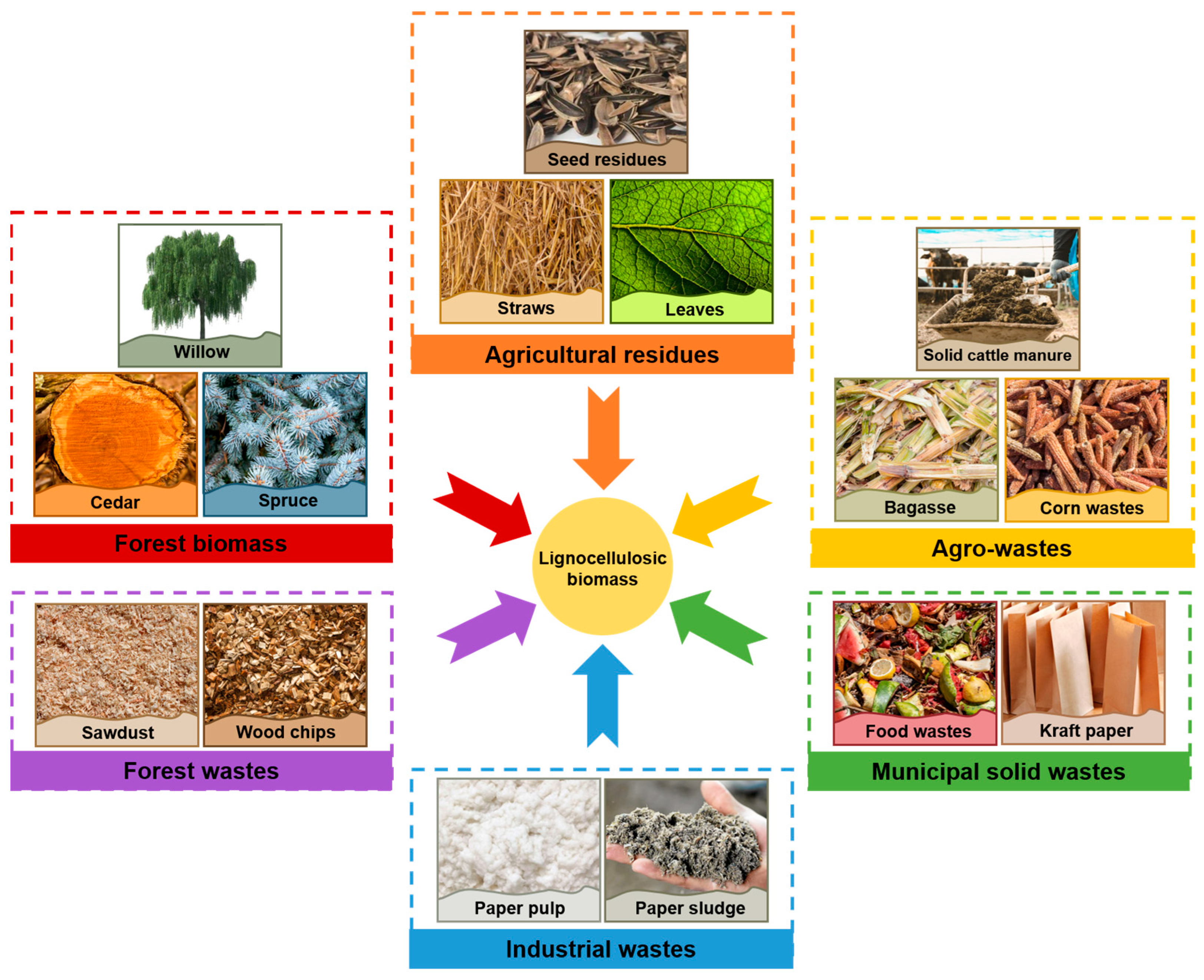

1. Introduction

2. Preparation of Lignocellulosic Biomass-Derived Biochar

2.1. Carbonization Methods

2.1.1. Direct Carbonization

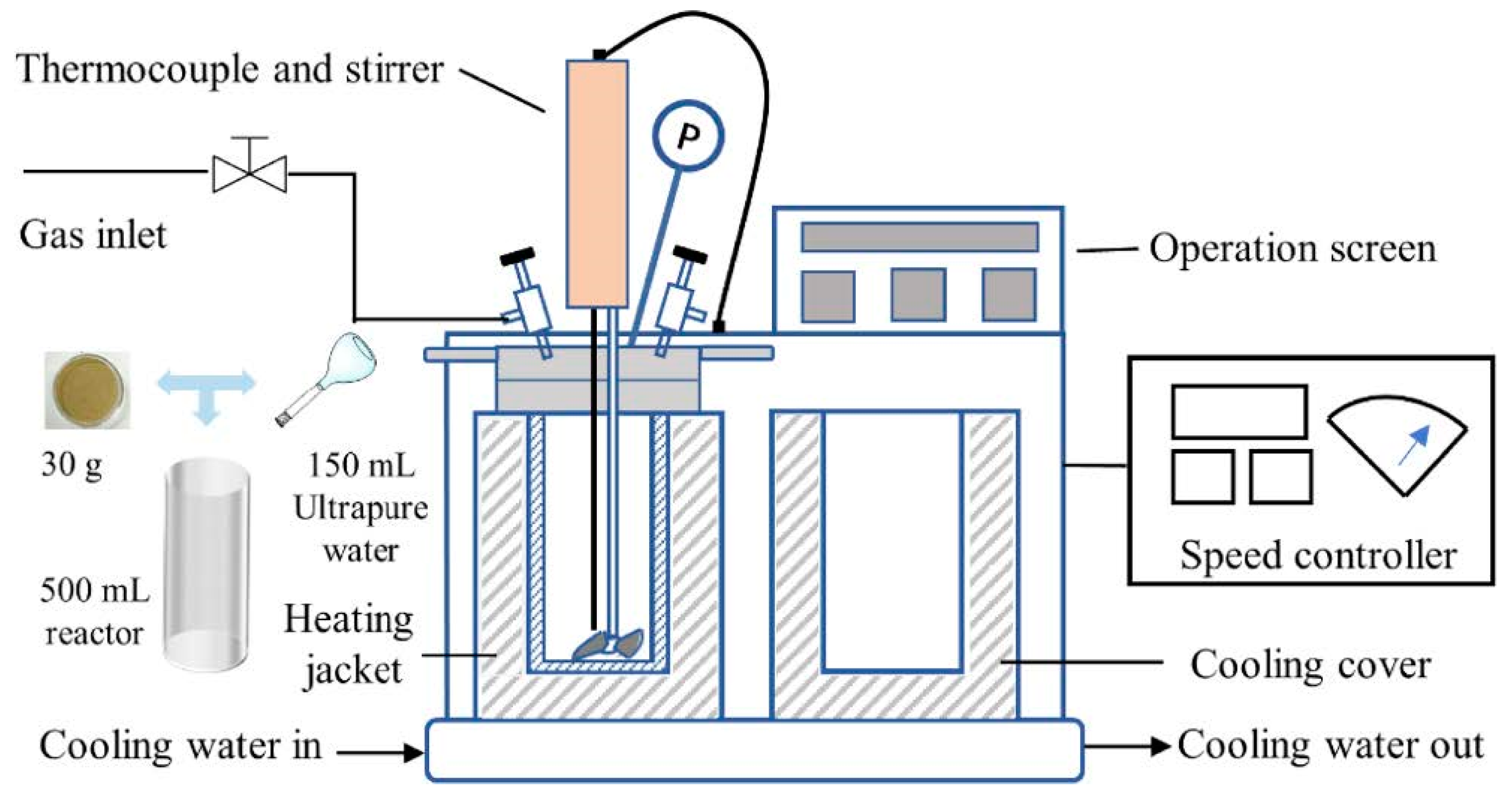

2.1.2. Hydrothermal Carbonization

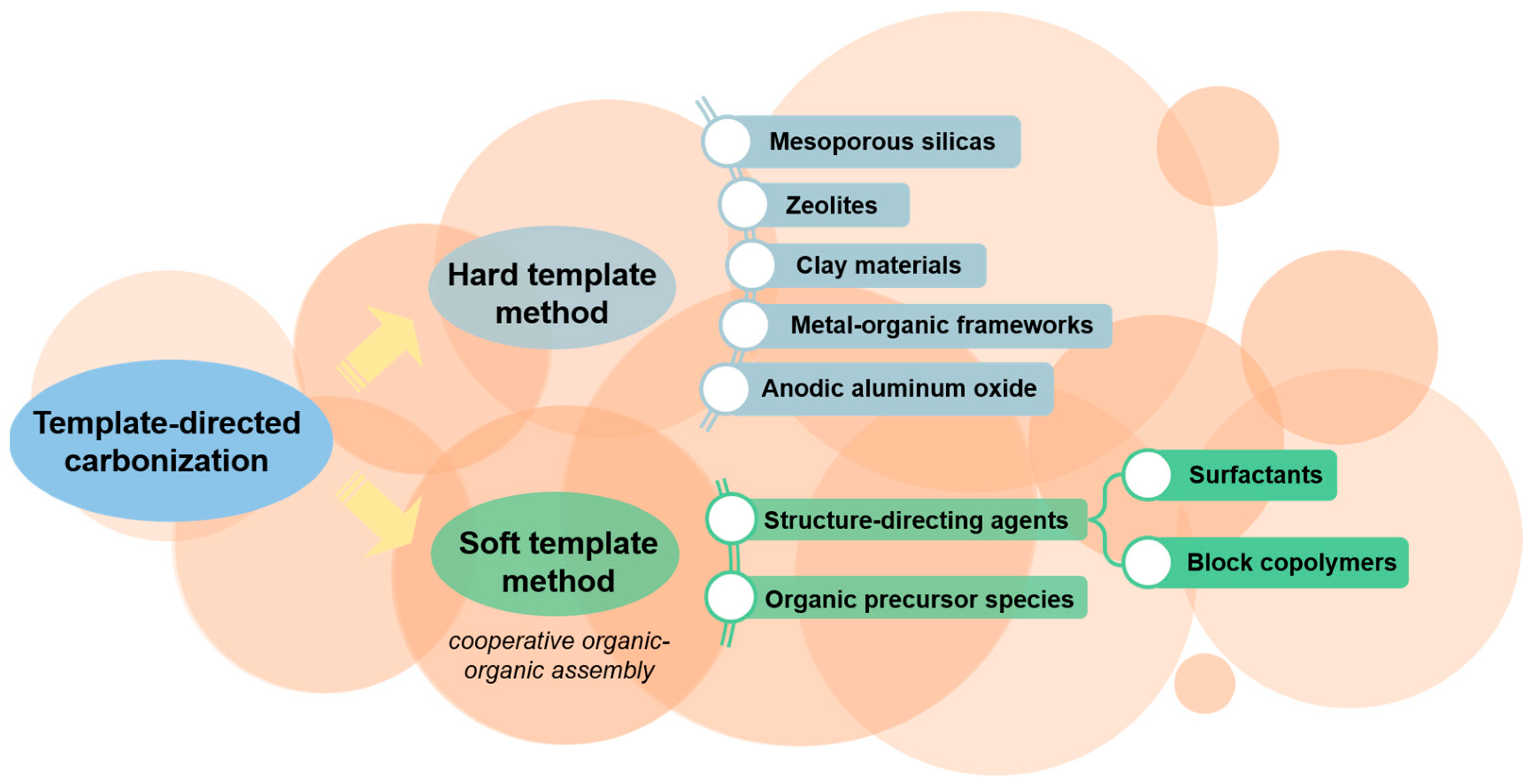

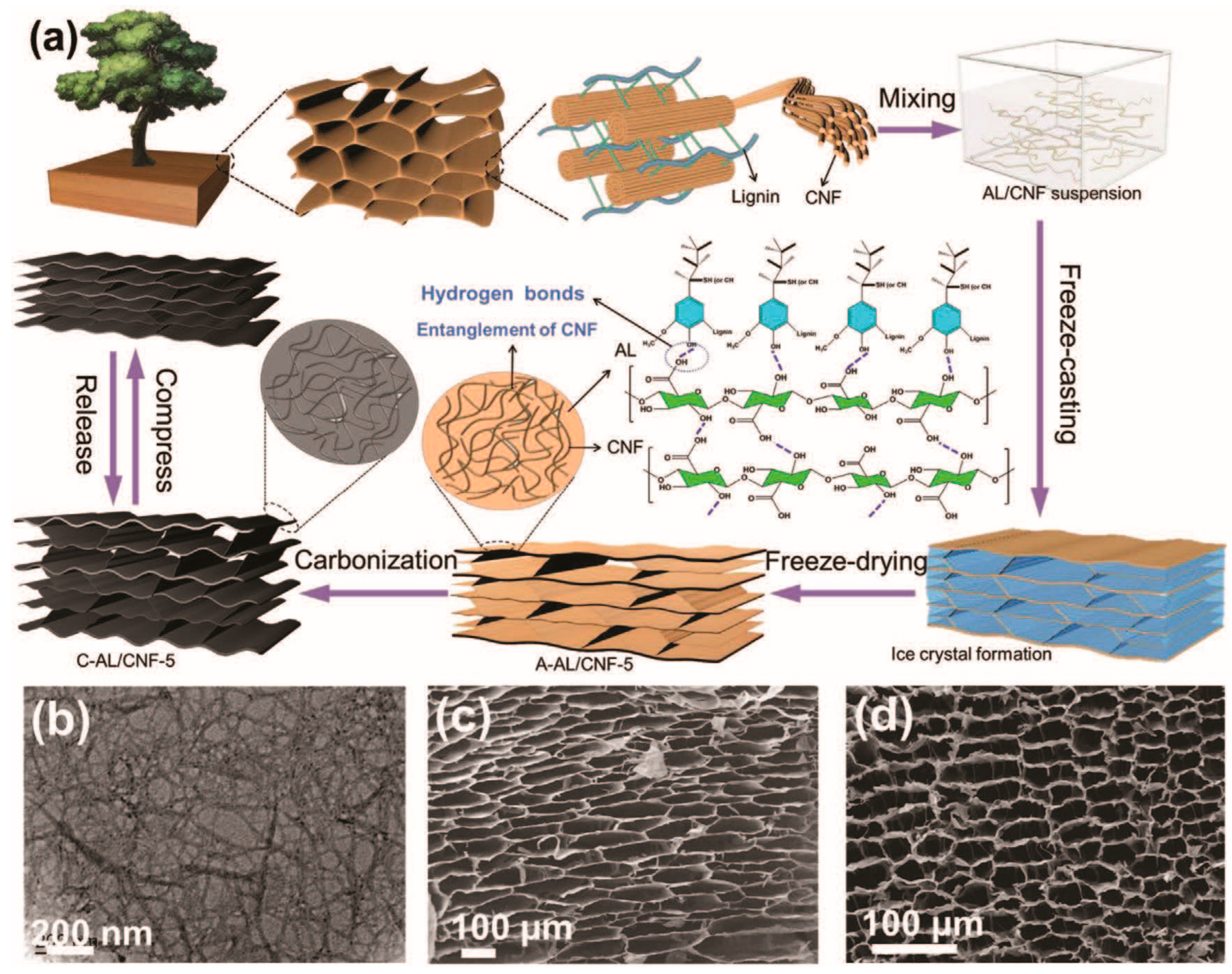

2.1.3. Template-Directed Carbonization

2.1.4. Microwave-Assisted Carbonization

2.2. Activation Methods

2.2.1. Physical Activation

2.2.2. Chemical Activation

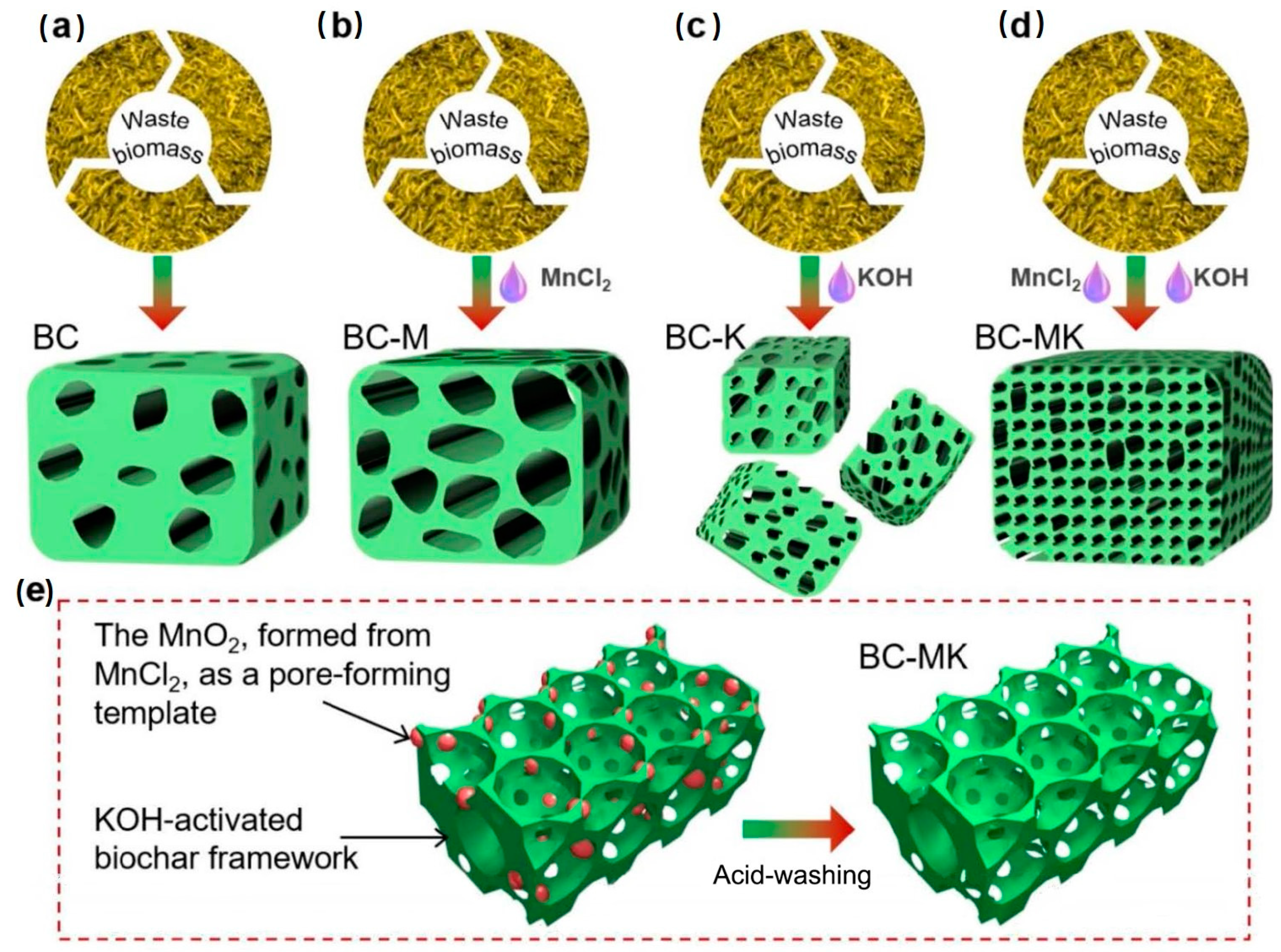

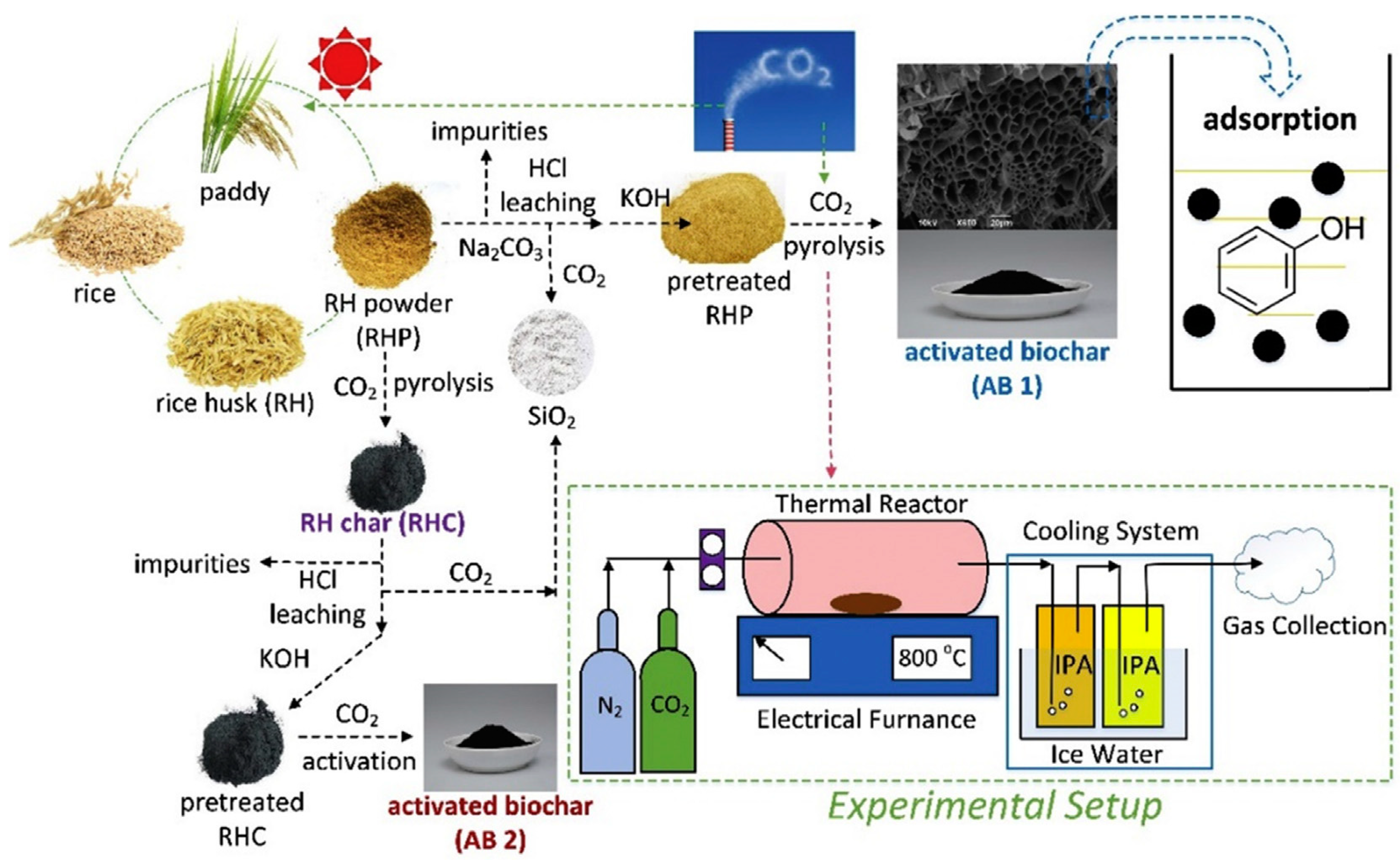

2.2.3. Physicochemical Activation

3. Applications of Lignocellulosic Biomass-Derived Biochar

3.1. Adsorption

3.2. Catalysis

3.3. Energy Storage

3.4. Other Applications

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sheng, P.; He, Y.; Guo, X. The Impact of Urbanization on Energy Consumption and Efficiency. Energy Environ. 2017, 28, 673–686. [Google Scholar] [CrossRef]

- Ebhota, W.S.; Jen, T.-C. Fossil Fuels Environmental Challenges and the Role of Solar Photovoltaic Technology Advances in Fast Tracking Hybrid Renewable Energy System. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 97–117. [Google Scholar] [CrossRef]

- Destek, M.A.; Pata, U.K. Carbon Efficiency and Sustainable Environment in India: Impacts of Structural Change, Renewable Energy Consumption, Fossil Fuel Efficiency, Urbanization, and Technological Innovation. Environ. Sci. Pollut. Res. 2023, 30, 92224–92237. [Google Scholar] [CrossRef]

- Töbelmann, D.; Wendler, T. The Impact of Environmental Innovation on Carbon Dioxide Emissions. J. Clean. Prod. 2020, 244, 118787. [Google Scholar] [CrossRef]

- Antar, M.; Lyu, D.; Nazari, M.; Shah, A.; Zhou, X.; Smith, D.L. Biomass for a Sustainable Bioeconomy: An Overview of World Biomass Production and Utilization. Renew. Sustain. Energy Rev. 2021, 139, 110691. [Google Scholar] [CrossRef]

- Sharma, G.; Kaur, M.; Punj, S.; Singh, K. Biomass as a Sustainable Resource for Value-Added Modern Materials: A Review. Biofuels Bioprod. Biorefining 2020, 14, 673–695. [Google Scholar] [CrossRef]

- Allen, L.H.; Boote, K.J.; Jones, J.W.; Jones, P.H.; Valle, R.R.; Acock, B.; Rogers, H.H.; Dahlman, R.C. Response of Vegetation to Rising Carbon Dioxide: Photosynthesis, Biomass, and Seed Yield of Soybean. Glob. Biogeochem. Cycles 1987, 1, 1–14. [Google Scholar] [CrossRef]

- Lesmana, S.O.; Febriana, N.; Soetaredjo, F.E.; Sunarso, J.; Ismadji, S. Studies on Potential Applications of Biomass for the Separation of Heavy Metals from Water and Wastewater. Biochem. Eng. J. 2009, 44, 19–41. [Google Scholar] [CrossRef]

- Abuadala, A.; Dincer, I. A Review on Biomass-Based Hydrogen Production and Potential Applications: A Review on Biomass-Based Hydrogen Production and Applications. Int. J. Energy Res. 2012, 36, 415–455. [Google Scholar] [CrossRef]

- Maurya, R.K.; Patel, A.R.; Sarkar, P.; Singh, H.; Tyagi, H. Biomass, Its Potential and Applications. In Biorefining of Biomass to Biofuels; Biofuel and Biorefinery, Technologies; Kumar, S., Sani, R.K., Eds.; Springer International Publishing: Cham, Switzerland, 2018; Volume 4, pp. 25–52. ISBN 978-3-319-67677-7. [Google Scholar]

- Kwapinski, W.; Byrne, C.M.P.; Kryachko, E.; Wolfram, P.; Adley, C.; Leahy, J.J.; Novotny, E.H.; Hayes, M.H.B. Biochar from Biomass and Waste. Waste Biomass Valorization 2010, 1, 177–189. [Google Scholar] [CrossRef]

- Tripathi, M.; Sahu, J.N.; Ganesan, P. Effect of Process Parameters on Production of Biochar from Biomass Waste through Pyrolysis: A Review. Renew. Sustain. Energy Rev. 2016, 55, 467–481. [Google Scholar] [CrossRef]

- Omoriyekomwan, J.E.; Tahmasebi, A.; Dou, J.; Wang, R.; Yu, J. A Review on the Recent Advances in the Production of Carbon Nanotubes and Carbon Nanofibers via Microwave-Assisted Pyrolysis of Biomass. Fuel Process. Technol. 2021, 214, 106686. [Google Scholar] [CrossRef]

- Hoang, A.T.; Nižetić, S.; Cheng, C.K.; Luque, R.; Thomas, S.; Banh, T.L.; Nguyen, X.P. Heavy Metal Removal by Biomass-Derived Carbon Nanotubes as a Greener Environmental Remediation: A Comprehensive Review. Chemosphere 2022, 287, 131959. [Google Scholar] [CrossRef] [PubMed]

- Samal, C.; Mishra, P.C.; Mukherjee, S.; Das, D. Evolution of High Performance and Low Emission Biomass Cookstoves-an Overview. AIP Conf. Proc. 2019, 2200, 020021. [Google Scholar] [CrossRef]

- Knauf, M.; Moniruzzaman, M. Lignocellulosic Biomass Processing: A Perspective. Int. Sugar J. 2004, 106, 147–150. [Google Scholar]

- Tandon, G. Bioproducts from Residual Lignocellulosic Biomass. In Advances in Biotechnolgy; I.K.Internal Publishing House Pvt.Ltd.: New Delhi, India, 2015; pp. 52–75. [Google Scholar]

- Mujtaba, M.; Fraceto, L.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; de Medeiros, G.A.; Santo Pereira, A.d.E.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic Biomass from Agricultural Waste to the Circular Economy: A Review with Focus on Biofuels, Biocomposites and Bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Ayeni, A.O.; Adeeyo, O.A.; Oresegun, O.M.; Oladimeji, T.E. Compositional Analysis of Lignocellulosic Materials: Evaluation of an Economically Viable Method Suitable for Woody and Non-Woody Biomass. Am. J. Eng. Res. 2015, 4, 14–19. [Google Scholar]

- Yuan, R.; Yu, S.; Shen, Y. Pyrolysis and Combustion Kinetics of Lignocellulosic Biomass Pellets with Calcium-Rich Wastes from Agro-Forestry Residues. Waste Manag. 2019, 87, 86–96. [Google Scholar] [CrossRef]

- Singh, D.; Chavan, D.; Pandey, A.K.; Periyaswami, L.; Kumar, S. Determination of Landfill Gas Generation Potential from Lignocellulose Biomass Contents of Municipal Solid Waste. Sci. Total Environ. 2021, 785, 147243. [Google Scholar] [CrossRef] [PubMed]

- Akar, S.T.; Yilmazer, D.; Celik, S.; Balk, Y.Y.; Akar, T. Effective Biodecolorization Potential of Surface Modified Lignocellulosic Industrial Waste Biomass. Chem. Eng. J. 2015, 259, 286–292. [Google Scholar] [CrossRef]

- Liu, C.; Wang, H.; Karim, A.M.; Sun, J.; Wang, Y. Catalytic Fast Pyrolysis of Lignocellulosic Biomass. Chem. Soc. Rev. 2014, 43, 7594–7623. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Yang, X.; Li, Q.; Zhang, Y.; Zhou, H. Breaking the Temperature Limit of Hydrothermal Carbonization of Lignocellulosic Biomass by Decoupling Temperature and Pressure. Green Energy Environ. 2023, 8, 1216–1227. [Google Scholar] [CrossRef]

- Siddiqa, A.; Yhobu, Z.; Nagaraju, D.H.; Padaki, M.; Budagumpi, S.; Pasupuleti, V.R.; Lim, J.-W. Review and Perspectives of Sustainable Lignin, Cellulose, and Lignocellulosic Carbon Special Structures for Energy Storage. Energy Fuels 2023, 37, 2498–2519. [Google Scholar] [CrossRef]

- Gęca, M.; Wiśniewska, M.; Nowicki, P. Modified Method of Lignocellulose Content Determination and Its Use for the Analysis of Selected Herbs—Precursors of Biochars and Activated Carbons. Measurement 2023, 212, 112672. [Google Scholar] [CrossRef]

- Panwar, N.L.; Pawar, A.; Salvi, B.L. Comprehensive Review on Production and Utilization of Biochar. SN Appl. Sci. 2019, 1, 168. [Google Scholar] [CrossRef]

- Bong, H.K.; Selvarajoo, A.; Arumugasamy, S.K. Stability of Biochar Derived from Banana Peel through Pyrolysis as Alternative Source of Nutrient in Soil: Feedforward Neural Network Modelling Study. Environ. Monit. Assess. 2022, 194, 70. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, S.S.; Vijay, V.K.; Chandra, R.; Kumar, H. Production and Characterization of Biochar Produced from Slow Pyrolysis of Pigeon Pea Stalk and Bamboo. Clean. Eng. Technol. 2021, 3, 100101. [Google Scholar] [CrossRef]

- Hong, Z.; Zhong, F.; Niu, W.; Zhang, K.; Su, J.; Liu, J.; Li, L.; Wu, F. Effects of Temperature and Particle Size on the Compositions, Energy Conversions and Structural Characteristics of Pyrolysis Products from Different Crop Residues. Energy 2020, 190, 116413. [Google Scholar] [CrossRef]

- Qin, F.; Zhang, C.; Zeng, G.; Huang, D.; Tan, X.; Duan, A. Lignocellulosic Biomass Carbonization for Biochar Production and Characterization of Biochar Reactivity. Renew. Sustain. Energy Rev. 2022, 157, 112056. [Google Scholar] [CrossRef]

- Adekanye, T.; Dada, O.; Kolapo, J. Pyrolysis of Maize Cob at Different Temperatures for Biochar Production: Proximate, Ultimate and Spectroscopic Characterisation. Res. Agric. Eng. 2022, 68, 27–34. [Google Scholar] [CrossRef]

- Farobie, O.; Amrullah, A.; Bayu, A.; Syaftika, N.; Anis, L.A.; Hartulistiyoso, E. In-Depth Study of Bio-Oil and Biochar Production from Macroalgae Sargassum sp. via Slow Pyrolysis. RSC Adv. 2022, 12, 9567–9578. [Google Scholar] [CrossRef]

- Ojha, D.K.; Viju, D.; Vinu, R. Fast Pyrolysis Kinetics of Lignocellulosic Biomass of Varying Compositions. Energy Convers. Manag. X 2021, 10, 100071. [Google Scholar] [CrossRef]

- Makepa, D.C.; Chihobo, C.H.; Musademba, D. Advances in Sustainable Biofuel Production from Fast Pyrolysis of Lignocellulosic Biomass. Biofuels 2023, 14, 529–550. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Baloch, H.A.; Griffin, G.J.; Mubarak, N.M.; Bhutto, A.W.; Abro, R.; Mazari, S.A.; Ali, B.S. An Overview of Effect of Process Parameters on Hydrothermal Carbonization of Biomass. Renew. Sustain. Energy Rev. 2017, 73, 1289–1299. [Google Scholar] [CrossRef]

- Regmi, P.; Garcia Moscoso, J.L.; Kumar, S.; Cao, X.; Mao, J.; Schafran, G. Removal of Copper and Cadmium from Aqueous Solution Using Switchgrass Biochar Produced via Hydrothermal Carbonization Process. J. Environ. Manag. 2012, 109, 61–69. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hu, L.; Shen, B.; Dai, C.; Xu, Q.; Liu, D.; Jiang, J.; Li, Y.; Xu, M. Rib-like Hierarchical Porous Carbon as Reservoir for Long-Life and High-Rate Li-Te Batteries. Electrochim. Acta 2017, 250, 10–15. [Google Scholar] [CrossRef]

- Cheng, C.; Guo, Q.; Ding, L.; Raheem, A.; He, Q.; Shiung Lam, S.; Yu, G. Upgradation of Coconut Waste Shell to Value-Added Hydrochar via Hydrothermal Carbonization: Parametric Optimization Using Response Surface Methodology. Appl. Energy 2022, 327, 120136. [Google Scholar] [CrossRef]

- Wang, Z.; Wen, S.; Wang, J.; Li, Z.; Ma, J.; Jiang, Z. Enhanced Performance of Porous Carbon Microspheres from Bamboo Fiber for Supercapacitors through Acid-Assisted Hydrothermal Carbonization. Mater. Lett. 2024, 355, 135404. [Google Scholar] [CrossRef]

- Ercan, B.; Alper, K.; Ucar, S.; Karagoz, S. Comparative Studies of Hydrochars and Biochars Produced from Lignocellulosic Biomass via Hydrothermal Carbonization, Torrefaction and Pyrolysis. J. Energy Inst. 2023, 109, 101298. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, K.; Bhaskar, T. Hydochar and Biochar: Production, Physicochemical Properties and Techno-Economic Analysis. Bioresour. Technol. 2020, 310, 123442. [Google Scholar] [CrossRef]

- Huff, M.D.; Kumar, S.; Lee, J.W. Comparative Analysis of Pinewood, Peanut Shell, and Bamboo Biomass Derived Biochars Produced via Hydrothermal Conversion and Pyrolysis. J. Environ. Manag. 2014, 146, 303–308. [Google Scholar] [CrossRef]

- Falco, C.; Baccile, N.; Titirici, M.-M. Morphological and Structural Differences between Glucose, Cellulose and Lignocellulosic Biomass Derived Hydrothermal Carbons. Green Chem. 2011, 13, 3273. [Google Scholar] [CrossRef]

- Yue, Q.; Wang, M.; Wei, J.; Deng, Y.; Liu, T.; Che, R.; Tu, B.; Zhao, D. A Template Carbonization Strategy to Synthesize Ordered Mesoporous Silica Microspheres with Trapped Sulfonated Carbon Nanoparticles for Efficient Catalysis. Angew. Chem. 2012, 124, 10514–10518. [Google Scholar] [CrossRef]

- De, S.; Balu, A.M.; van der Waal, J.C.; Luque, R. Biomass-Derived Porous Carbon Materials: Synthesis and Catalytic Applications. ChemCatChem 2015, 7, 1608–1629. [Google Scholar] [CrossRef]

- Yin, Y.; Liu, Q.; Zhao, Y.; Chen, T.; Wang, J.; Gui, L.; Lu, C. Recent Progress and Future Directions of Biomass-Derived Hierarchical Porous Carbon: Designing, Preparation, and Supercapacitor Applications. Energy Fuels 2023, 37, 3523–3554. [Google Scholar] [CrossRef]

- Liu, R.-L.; Liu, Y.; Zhou, X.-Y.; Zhang, Z.-Q.; Zhang, J.; Dang, F.-Q. Biomass-Derived Highly Porous Functional Carbon Fabricated by Using a Free-Standing Template for Efficient Removal of Methylene Blue. Bioresour. Technol. 2014, 154, 138–147. [Google Scholar] [CrossRef]

- Chen, Z.; Zhuo, H.; Hu, Y.; Lai, H.; Liu, L.; Zhong, L.; Peng, X. Wood-Derived Lightweight and Elastic Carbon Aerogel for Pressure Sensing and Energy Storage. Adv. Funct. Mater. 2020, 30, 1910292. [Google Scholar] [CrossRef]

- Ge, S.; Yek, P.N.Y.; Cheng, Y.W.; Xia, C.; Wan Mahari, W.A.; Liew, R.K.; Peng, W.; Yuan, T.-Q.; Tabatabaei, M.; Aghbashlo, M.; et al. Progress in Microwave Pyrolysis Conversion of Agricultural Waste to Value-Added Biofuels: A Batch to Continuous Approach. Renew. Sustain. Energy Rev. 2021, 135, 110148. [Google Scholar] [CrossRef]

- Li, Y.; Xing, B.; Ding, Y.; Han, X.; Wang, S. A Critical Review of the Production and Advanced Utilization of Biochar via Selective Pyrolysis of Lignocellulosic Biomass. Bioresour. Technol. 2020, 312, 123614. [Google Scholar] [CrossRef]

- Luque, R.; Menendez, J.A.; Arenillas, A.; Cot, J. Microwave-Assisted Pyrolysis of Biomass Feedstocks: The Way Forward? Energy Environ. Sci. 2012, 5, 5481–5488. [Google Scholar] [CrossRef]

- Haeldermans, T.; Campion, L.; Kuppens, T.; Vanreppelen, K.; Cuypers, A.; Schreurs, S. A Comparative Techno-Economic Assessment of Biochar Production from Different Residue Streams Using Conventional and Microwave Pyrolysis. Bioresour. Technol. 2020, 318, 124083. [Google Scholar] [CrossRef] [PubMed]

- Beneroso, D.; Monti, T.; Kostas, E.T.; Robinson, J. Microwave Pyrolysis of Biomass for Bio-Oil Production: Scalable Processing Concepts. Chem. Eng. J. 2017, 316, 481–498. [Google Scholar] [CrossRef]

- Li, J.; Dai, J.; Liu, G.; Zhang, H.; Gao, Z.; Fu, J.; He, Y.; Huang, Y. Biochar from Microwave Pyrolysis of Biomass: A Review. Biomass Bioenergy 2016, 94, 228–244. [Google Scholar] [CrossRef]

- Khelfa, A.; Rodrigues, F.A.; Koubaa, M.; Vorobiev, E. Microwave-Assisted Pyrolysis of Pine Wood Sawdust Mixed with Activated Carbon for Bio-Oil and Bio-Char Production. Processes 2020, 8, 1437. [Google Scholar] [CrossRef]

- Yek, P.N.Y.; Liew, R.K.; Mahari, W.A.W.; Peng, W.; Sonne, C.; Kong, S.H.; Tabatabaei, M.; Aghbashlo, M.; Park, Y.-K.; Lam, S.S. Production of Value-Added Hydrochar from Single-Mode Microwave Hydrothermal Carbonization of Oil Palm Waste for de-Chlorination of Domestic Water. Sci. Total Environ. 2022, 833, 154968. [Google Scholar] [CrossRef]

- Nair, V.; Vinu, R. Peroxide-Assisted Microwave Activation of Pyrolysis Char for Adsorption of Dyes from Wastewater. Bioresour. Technol. 2016, 216, 511–519. [Google Scholar] [CrossRef]

- Luo, X.; Liu, G.; Xia, Y.; Chen, L.; Jiang, Z.; Zheng, H.; Wang, Z. Use of Biochar-Compost to Improve Properties and Productivity of the Degraded Coastal Soil in the Yellow River Delta, China. J. Soils Sediments 2017, 17, 780–789. [Google Scholar] [CrossRef]

- Selvam, S.M.; Paramasivan, B. Microwave Assisted Carbonization and Activation of Biochar for Energy-Environment Nexus: A Review. Chemosphere 2022, 286, 131631. [Google Scholar] [CrossRef]

- Hessien, M. Microwave-Assisted Hydrothermal Carbonization of Pomegranate Peels into Hydrochar for Environmental Applications. Energies 2022, 15, 3629. [Google Scholar] [CrossRef]

- Hidalgo, P.; Navia, R.; Hunter, R.; Coronado, G.; Gonzalez, M. Synthesis of Carbon Nanotubes Using Biochar as Precursor Material under Microwave Irradiation. J. Environ. Manag. 2019, 244, 83–91. [Google Scholar] [CrossRef]

- Zhang, T.; Kang, K.; Nanda, S.; Dalai, A.K.; Xie, T.; Zhao, Y. Comparative Study on Fuel Characteristics and Pyrolysis Kinetics of Corn Residue-Based Hydrochar Produced via Microwave Hydrothermal Carbonization. Chemosphere 2022, 291, 132787. [Google Scholar] [CrossRef] [PubMed]

- Jones, D.A.; Lelyveld, T.P.; Mavrofidis, S.D.; Kingman, S.W.; Miles, N.J. Microwave Heating Applications in Environmental Engineering—A Review. Resour. Conserv. Recycl. 2002, 34, 75–90. [Google Scholar] [CrossRef]

- Lawas, K.I.; Doliente, S.; Carpio, R.; Migo, V.; Alfafara, C. Parametric Study of Corn Cob Biochar (CCBc) Yield via Microwave Pyrolysis. MATEC Web Conf. 2019, 268, 04005. [Google Scholar] [CrossRef]

- Morgan, H.M.; Bu, Q.; Liang, J.; Liu, Y.; Mao, H.; Shi, A.; Lei, H.; Ruan, R. A Review of Catalytic Microwave Pyrolysis of Lignocellulosic Biomass for Value-Added Fuel and Chemicals. Bioresour. Technol. 2017, 230, 112–121. [Google Scholar] [CrossRef] [PubMed]

- Nishu; Liu, R.; Rahman, M.M.; Sarker, M.; Chai, M.; Li, C.; Cai, J. A Review on the Catalytic Pyrolysis of Biomass for the Bio-Oil Production with ZSM-5: Focus on Structure. Fuel Process. Technol. 2020, 199, 106301. [Google Scholar] [CrossRef]

- Zhang, X.; Rajagopalan, K.; Lei, H.; Ruan, R.; Sharma, B.K. An Overview of a Novel Concept in Biomass Pyrolysis: Microwave Irradiation. Sustain. Energy Fuels 2017, 1, 1664–1699. [Google Scholar] [CrossRef]

- Zhang, C.; Qin, D.; Zhou, Y.; Qin, F.; Wang, H.; Wang, W.; Yang, Y.; Zeng, G. Dual Optimization Approach to Mo Single Atom Dispersed G-C3N4 Photocatalyst: Morphology and Defect Evolution. Appl. Catal. B Environ. 2022, 303, 120904. [Google Scholar] [CrossRef]

- Ahmed, M.J. Preparation of Activated Carbons from Date (Phoenix dactylifera L.) Palm Stones and Application for Wastewater Treatments: Review. Process Saf. Environ. Prot. 2016, 102, 168–182. [Google Scholar] [CrossRef]

- do Nascimento, C.T.; Vieira, M.G.A.; Scheufele, F.B.; Palu, F.; da Silva, E.A.; Borba, C.E. Adsorption of Atrazine from Aqueous Systems on Chemically Activated Biochar Produced from Corn Straw. J. Environ. Chem. Eng. 2022, 10, 107039. [Google Scholar] [CrossRef]

- Hsiao, C.H.; Gupta, S.; Lee, C.Y.; Tai, N.H. Effects of Physical and Chemical Activations on the Performance of Biochar Applied in Supercapacitors. Appl. Surf. Sci. 2023, 610, 155560. [Google Scholar] [CrossRef]

- Wen, C.; Liu, T.; Wang, D.; Wang, Y.; Chen, H.; Luo, G.; Zhou, Z.; Li, C.; Xu, M. Biochar as the Effective Adsorbent to Combustion Gaseous Pollutants: Preparation, Activation, Functionalization and the Adsorption Mechanisms. Prog. Energy Combust. Sci. 2023, 99, 101098. [Google Scholar] [CrossRef]

- Sharmila, V.G.; Tyagi, V.K.; Varjani, S.; Banu, J.R. A Review on the Lignocellulosic Derived Biochar-Based Catalyst in Wastewater Remediation: Advanced Treatment Technologies and Machine Learning Tools. Bioresour. Technol. 2023, 387, 129587. [Google Scholar]

- Heidarinejad, Z.; Dehghani, M.H.; Heidari, M.; Javedan, G.; Ali, I.; Sillanpää, M. Methods for Preparation and Activation of Activated Carbon: A Review. Environ. Chem. Lett. 2020, 18, 393–415. [Google Scholar] [CrossRef]

- Cao, X.; Sun, S.; Sun, R. Application of Biochar-Based Catalysts in Biomass Upgrading: A Review. RSC Adv. 2017, 7, 48793–48805. [Google Scholar] [CrossRef]

- Sumathi, S.; Bhatia, S.; Lee, K.T.; Mohamed, A.R. Optimization of Microporous Palm Shell Activated Carbon Production for Flue Gas Desulphurization: Experimental and Statistical Studies. Bioresour. Technol. 2009, 100, 1614–1621. [Google Scholar] [CrossRef]

- Zhao, H.; Yu, Q.; Li, M.; Sun, S. Preparation and Water Vapor Adsorption of “Green” Walnut-Shell Activated Carbon by CO2 Physical Activation. Adsorpt. Sci. Technol. 2020, 38, 60–76. [Google Scholar] [CrossRef]

- Sakanishi, K.; Wu, Z.; Matsumura, A.; Saito, I.; Hanaoka, T.; Minowa, T.; Tada, M.; Iwasaki, T. Simultaneous Removal of H2S and COS Using Activated Carbons and Their Supported Catalysts. Catal. Today 2005, 104, 94–100. [Google Scholar] [CrossRef]

- Hoang, A.T.; Kumar, S.; Lichtfouse, E.; Cheng, C.K.; Varma, R.S.; Senthilkumar, N.; Nguyen, P.Q.P.; Nguyen, X.P. Remediation of Heavy Metal Polluted Waters Using Activated Carbon from Lignocellulosic Biomass: An Update of Recent Trends. Chemosphere 2022, 302, 134825. [Google Scholar] [CrossRef] [PubMed]

- Isinkaralar, K. Experimental Evaluation of Benzene Adsorption in the Gas Phase Using Activated Carbon from Waste Biomass. Biomass Convers. Biorefinery 2023, 1–10. [Google Scholar] [CrossRef]

- Tsai, W.-T.; Bai, Y.-C.; Lin, Y.-Q.; Lai, Y.-C.; Tsai, C.-H. Porous and Adsorption Properties of Activated Carbon Prepared from Cocoa Pod Husk by Chemical Activation. Biomass Convers. Biorefinery 2020, 10, 35–43. [Google Scholar] [CrossRef]

- Davarnejad, R.; Afshar, S.; Etehadfar, P. Activated Carbon Blended with Grape Stalks Powder: Properties Modification and Its Application in a Dye Adsorption. Arab. J. Chem. 2020, 13, 5463–5473. [Google Scholar] [CrossRef]

- Taheripak, O.; Fathi, S. Removal of Heavy Crude Oil from Wastewater Using Activated Carbon Obtained from Oak Seed Husk Biodegradable Lignocellulosic Biomass. Water. Air. Soil Pollut. 2023, 234, 295. [Google Scholar] [CrossRef]

- Chen, H.; Xia, P.; Lei, W.; Pan, Y.; Zou, Y.; Ma, Z. Preparation of Activated Carbon Derived from Biomass and Its Application in Lithium–Sulfur Batteries. J. Porous Mater. 2019, 26, 1325–1333. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Chen, K.; Shen, S.; Hu, H.; Chang, M.; Chen, D.; Wu, Y.; Yuan, H.; Wang, Y. Engineering Banana-Peel-Derived Biochar for the Rapid Adsorption of Tetracycline Based on Double Chemical Activation. Resour. Conserv. Recycl. 2023, 190, 106821. [Google Scholar] [CrossRef]

- Seow, Y.X.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Ibrahim, M.L.; Ghasemi, M. A Review on Biochar Production from Different Biomass Wastes by Recent Carbonization Technologies and Its Sustainable Applications. J. Environ. Chem. Eng. 2022, 10, 107017. [Google Scholar] [CrossRef]

- Patel, H.; Weldekidan, H.; Mohanty, A.; Misra, M. Effect of Physicochemical Activation on CO2 Adsorption of Activated Porous Carbon Derived from Pine Sawdust. Carbon Capture Sci. Technol. 2023, 8, 100128. [Google Scholar] [CrossRef]

- Shen, Y.; Fu, Y. KOH-Activated Rice Husk Char via CO2 Pyrolysis for Phenol Adsorption. Mater. Today Energy 2018, 9, 397–405. [Google Scholar] [CrossRef]

- Krishnamoorthy, R.; Govindan, B.; Banat, F.; Sagadevan, V.; Purushothaman, M.; Show, P.L. Date Pits Activated Carbon for Divalent Lead Ions Removal. J. Biosci. Bioeng. 2019, 128, 88–97. [Google Scholar] [CrossRef]

- Musthapa, S.M.B.H.; Shams, S.; Prasad, D.R. Removal of Pollutants from Wastewater Using Activated Carbon from Durian Peel. IOP Conf. Ser. Earth Environ. Sci. 2023, 1135, 012001. [Google Scholar] [CrossRef]

- Igbmno, M.J.; Khalid, M.; Raju, G.; Mubarak, N.M.; Walvekar, R.; Ratnam, C.T.; Chaudhary, V.; Rani, G.M. Effect of Electron Beam Irradiation on Durian-Peel-Based Activated Carbon for Phenol Removal. Carbon Lett. 2023, 33, 1161–1170. [Google Scholar] [CrossRef]

- Bai, J.; Huang, J.; Yu, Q.; Demir, M.; Akgul, E.; Altay, B.N.; Hu, X.; Wang, L. Fabrication of Coconut Shell-Derived Porous Carbons for CO2 Adsorption Application. Front. Chem. Sci. Eng. 2023, 17, 1122–1130. [Google Scholar] [CrossRef]

- Lawal, I.M.; Soja, U.B.; Mambo, A.D.; Kutty, S.R.M.; Jagaba, A.H.; Hayder, G.; Abubakar, S.; Umaru, I. Adsorption of Abattoir Wastewater Contaminants by Coconut Shell-Activated Carbon. In Sustainability Challenges and Delivering Practical Engineering Solutions; Advances in Science, Technology & Innovation; Salih, G.H.A., Saeed, R.A., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 145–150. ISBN 978-3-031-26579-2. [Google Scholar]

- Packialakshmi, S.; Anuradha, B.; Nagamani, K.; Devi, J.S.; Sujatha, S. Treatment of Industrial Wastewater Using Coconut Shell Based Activated Carbon. Mater. Today Proc. 2023, 81, 1167–1171. [Google Scholar] [CrossRef]

- Kosheleva, R.I.; Mitropoulos, A.C.; Kyzas, G.Z. Synthesis of Activated Carbon from Food Waste. Environ. Chem. Lett. 2019, 17, 429–438. [Google Scholar] [CrossRef]

- Nindjio, G.F.K.; Tagne, R.F.T.; Jiokeng, S.L.Z.; Fotsop, C.G.; Bopda, A.; Doungmo, G.; Temgoua, R.C.T.; Doench, I.; Njoyim, E.T.; Tamo, A.K. Lignocellulosic-Based Materials from Bean and Pistachio Pod Wastes for Dye-Contaminated Water Treatment: Optimization and Modeling of Indigo Carmine Sorption. Polymers 2022, 14, 3776. [Google Scholar] [CrossRef]

- Mergbi, M.; Galloni, M.G.; Aboagye, D.; Elimian, E.; Su, P.; Ikram, B.M.; Nabgan, W.; Bedia, J.; Amor, H.B.; Contreras, S.; et al. Valorization of Lignocellulosic Biomass into Sustainable Materials for Adsorption and Photocatalytic Applications in Water and Air Remediation. Environ. Sci. Pollut. Res. 2023, 30, 74544–74574. [Google Scholar] [CrossRef]

- Sani, J.E.; Moses, G.; Musa, S. Physicochemical Evaluation of Coconut Shell Biochar Remediation Effect on Crude Oil Contaminated Soil. Cogent Eng. 2023, 10, 2269659. [Google Scholar] [CrossRef]

- Shah, K.; Chauhan, L.I.; Galgale, A.D. Treatability Study of Pesticide-Based Industrial Wastewater. J. Environ. Sci. Eng. 2012, 54, 570–576. [Google Scholar] [PubMed]

- Liu, Z.; Sun, Y.; Xu, X.; Meng, X.; Qu, J.; Wang, Z.; Liu, C.; Qu, B. Preparation, Characterization and Application of Activated Carbon from Corn Cob by KOH Activation for Removal of Hg(II) from Aqueous Solution. Bioresour. Technol. 2020, 306, 123154. [Google Scholar] [CrossRef]

- Zhao, J.; Shen, X.-J.; Domene, X.; Alcañiz, J.-M.; Liao, X.; Palet, C. Comparison of Biochars Derived from Different Types of Feedstock and Their Potential for Heavy Metal Removal in Multiple-Metal Solutions. Sci. Rep. 2019, 9, 9869. [Google Scholar] [CrossRef]

- Zamani, S.A.; Yunus, R.; Samsuri, A.W.; Salleh, M.A.M.; Asady, B. Removal of Zinc from Aqueous Solution by Optimized Oil Palm Empty Fruit Bunches Biochar as Low Cost Adsorbent. Bioinorg. Chem. Appl. 2017, 2017, e7914714. [Google Scholar] [CrossRef]

- Chiang, C.-H.; Chen, J.; Lin, J.-H. Preparation of Pore-Size Tunable Activated Carbon Derived from Waste Coffee Grounds for High Adsorption Capacities of Organic Dyes. J. Environ. Chem. Eng. 2020, 8, 103929. [Google Scholar] [CrossRef]

- Wang, Y.; Srinivasakannan, C.; Wang, H.; Xue, G.; Wang, L.; Wang, X.; Duan, X. Preparation of Novel Biochar Containing Graphene from Waste Bamboo with High Methylene Blue Adsorption Capacity. Diam. Relat. Mater. 2022, 125, 109034. [Google Scholar] [CrossRef]

- Essandoh, M.; Kunwar, B.; Pittman, C.U.; Mohan, D.; Mlsna, T. Sorptive Removal of Salicylic Acid and Ibuprofen from Aqueous Solutions Using Pine Wood Fast Pyrolysis Biochar. Chem. Eng. J. 2015, 265, 219–227. [Google Scholar] [CrossRef]

- Rashidi, N.A.; Yusup, S. Production of Palm Kernel Shell-Based Activated Carbon by Direct Physical Activation for Carbon Dioxide Adsorption. Environ. Sci. Pollut. Res. 2019, 26, 33732–33746. [Google Scholar] [CrossRef]

- Mukherjee, A.; Borugadda, V.B.; Dynes, J.J.; Niu, C.; Dalai, A.K. Carbon Dioxide Capture from Flue Gas in Biochar Produced from Spent Coffee Grounds: Effect of Surface Chemistry and Porous Structure. J. Environ. Chem. Eng. 2021, 9, 106049. [Google Scholar] [CrossRef]

- Igalavithana, A.D.; Choi, S.W.; Shang, J.; Hanif, A.; Dissanayake, P.D.; Tsang, D.C.W.; Kwon, J.-H.; Lee, K.B.; Ok, Y.S. Carbon Dioxide Capture in Biochar Produced from Pine Sawdust and Paper Mill Sludge: Effect of Porous Structure and Surface Chemistry. Sci. Total Environ. 2020, 739, 139845. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, Y.; Ding, N.; Liang, L.; Zhao, S.; Yin, D.; Cheng, Y.; Wang, C.; Wang, L. Preparation and Hydrogen Storage Performance of Poplar Sawdust Biochar with High Specific Surface Area. Ind. Crops Prod. 2023, 200, 116788. [Google Scholar] [CrossRef]

- Niju, S.; Ajieth Kanna, S.K.; Ramalingam, V.; Satheesh Kumar, M.; Balajii, M. Sugarcane Bagasse Derived Biochar—A Potential Heterogeneous Catalyst for Transesterification Process. Energy Sources Part Recovery Util. Environ. Eff. 2023, 45, 9815–9826. [Google Scholar] [CrossRef]

- Saeed, M.; Mohammad, A.; Singh, P.; Lal, B.; Suliman, M.; Alshahrani, M.Y.; Sharma, M. Coconut Waste Valorization to Produce Biochar Catalyst and Its Application in Cellulose-Degrading Enzymes Production via SSF. Int. J. Biol. Macromol. 2023, 240, 124382. [Google Scholar] [CrossRef]

- Jiang, C.; Yakaboylu, G.A.; Yumak, T.; Zondlo, J.W.; Sabolsky, E.M.; Wang, J. Activated Carbons Prepared by Indirect and Direct CO2 Activation of Lignocellulosic Biomass for Supercapacitor Electrodes. Renew. Energy 2020, 155, 38–52. [Google Scholar] [CrossRef]

- Li, J.; Liu, Z.; Tian, Y.; Zhu, Y.; Qin, S.; Qiao, Y. Catalytic Conversion of Gaseous Tars Using Land, Coastal and Marine Biomass-Derived Char Catalysts in a Bench-Scale Downstream Combined Fixed Bed System. Bioresour. Technol. 2020, 304, 122735. [Google Scholar] [CrossRef]

- Lee, J.; Kim, K.-H.; Kwon, E.E. Biochar as a Catalyst. Renew. Sustain. Energy Rev. 2017, 77, 70–79. [Google Scholar] [CrossRef]

- Yuan, X.; Cao, Y.; Li, J.; Patel, A.K.; Dong, C.-D.; Jin, X.; Gu, C.; Yip, A.C.K.; Tsang, D.C.W.; Ok, Y.S. Recent Advancements and Challenges in Emerging Applications of Biochar-Based Catalysts. Biotechnol. Adv. 2023, 67, 108181. [Google Scholar] [CrossRef]

- Zhang, M.; Duan, Y.; Chen, T.; Qi, J.; Xu, T.; Du, H.; Si, C. Lignocellulosic Materials for Energy Storage Devices. Ind. Crops Prod. 2023, 203, 117174. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Y.; Liu, H.; Xu, Y.; Wu, J.; Li, P. Effect of Pyrolysis Temperature on Carbon Materials Derived from Reed Residue Waste Biomass for Use in Supercapacitor Electrodes. J. Phys. Chem. Solids 2023, 178, 111318. [Google Scholar] [CrossRef]

- Liao, Y.; Shang, Z.; Ju, G.; Wang, D.; Yang, Q.; Wang, Y.; Yuan, S. Biomass Derived N-Doped Porous Carbon Made from Reed Straw for an Enhanced Supercapacitor. Molecules 2023, 28, 4633. [Google Scholar] [CrossRef] [PubMed]

- Numee, P.; Sangtawesin, T.; Yilmaz, M.; Kanjana, K. Activated Carbon Derived from Radiation-Processed Durian Shell for Energy Storage Application. Carbon Resour. Convers. 2024, 7, 100192. [Google Scholar] [CrossRef]

- Aboughaly, M.; Babaei-Ghazvini, A.; Dhar, P.; Patel, R.; Acharya, B. Enhancing the Potential of Polymer Composites Using Biochar as a Filler: A Review. Polymers 2023, 15, 3981. [Google Scholar] [CrossRef]

- Cappello, M.; Rossi, D.; Filippi, S.; Cinelli, P.; Seggiani, M. Wood Residue-Derived Biochar as a Low-Cost, Lubricating Filler in Poly(Butylene Succinate-Co-Adipate) Biocomposites. Materials 2023, 16, 570. [Google Scholar] [CrossRef] [PubMed]

- Kalderis, D.; Tsuchiya, S.; Phillipou, K.; Paschalidou, P.; Pashalidis, I.; Tashima, D.; Tsubota, T. Utilization of Pine Tree Biochar Produced by Flame-Curtain Pyrolysis in Two Non-Agricultural Applications. Bioresour. Technol. Rep. 2020, 9, 100384. [Google Scholar] [CrossRef]

- Nikolopoulos, C.D.; Baklezos, A.T.; Kapetanakis, T.N.; Vardiambasis, I.O.; Tsubota, T.; Kalderis, D. Characterization of the Electromagnetic Shielding Effectiveness of Biochar-Based Materials. IEEE Access 2023, 11, 6413–6420. [Google Scholar] [CrossRef]

- Nguyen, T.-B.; Sherpa, K.; Bui, X.-T.; Nguyen, V.-T.; Vo, T.-D.-H.; Ho, H.-T.-T.; Chen, C.-W.; Dong, C.-D. Biochar for Soil Remediation: A Comprehensive Review of Current Research on Pollutant Removal. Environ. Pollut. 2023, 337, 122571. [Google Scholar] [CrossRef]

- Singh, P.; Rawat, S.; Jain, N.; Bhatnagar, A.; Bhattacharya, P.; Maiti, A. A Review on Biochar Composites for Soil Remediation Applications: Comprehensive Solution to Contemporary Challenges. J. Environ. Chem. Eng. 2023, 11, 110635. [Google Scholar] [CrossRef]

- Lv, Y.; Bao, J.; Liu, D.; Gao, X.; Yu, Y.; Zhu, L. Synergistic Effects of Rice Husk Biochar and Aerobic Composting for Heavy Oil-Contaminated Soil Remediation and Microbial Community Succession Evaluation. J. Hazard. Mater. 2023, 448, 130929. [Google Scholar] [CrossRef] [PubMed]

- Rasul, M.; Cho, J.; Shin, H.-S.; Hur, J. Biochar-Induced Priming Effects in Soil via Modifying the Status of Soil Organic Matter and Microflora: A Review. Sci. Total Environ. 2022, 805, 150304. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, E.A.; El-Sherbini, M.A.A.; Selim, E.-M.M. Effects of Biochar on Soil Properties, Heavy Metal Availability and Uptake, and Growth of Summer Squash Grown in Metal-Contaminated Soil. Sci. Hortic. 2022, 301, 111097. [Google Scholar] [CrossRef]

| Direct Carbonization | Hydrothermal Carbonization | Template-Directed Carbonization | Microwave-Assisted Carbonization | |

|---|---|---|---|---|

| Slow Pyrolysis | Fast Pyrolysis | |||

|

|

|

|

|

| Physical Activation | Chemical Activation | Physicochemical Activation |

|---|---|---|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, K.; Remón, J.; Jiang, Z.; Ding, W. Recent Advances in the Preparation and Application of Biochar Derived from Lignocellulosic Biomass: A Mini Review. Polymers 2024, 16, 851. https://doi.org/10.3390/polym16060851

Wang K, Remón J, Jiang Z, Ding W. Recent Advances in the Preparation and Application of Biochar Derived from Lignocellulosic Biomass: A Mini Review. Polymers. 2024; 16(6):851. https://doi.org/10.3390/polym16060851

Chicago/Turabian StyleWang, Kanglei, Javier Remón, Zhicheng Jiang, and Wei Ding. 2024. "Recent Advances in the Preparation and Application of Biochar Derived from Lignocellulosic Biomass: A Mini Review" Polymers 16, no. 6: 851. https://doi.org/10.3390/polym16060851

APA StyleWang, K., Remón, J., Jiang, Z., & Ding, W. (2024). Recent Advances in the Preparation and Application of Biochar Derived from Lignocellulosic Biomass: A Mini Review. Polymers, 16(6), 851. https://doi.org/10.3390/polym16060851