Recent Progress of Carrageenan-Based Composite Films in Active and Intelligent Food Packaging Applications

Abstract

1. Introduction

2. Physicochemical and Structural Properties of Carrageenan

3. Food Packaging Materials Based on Carrageenan

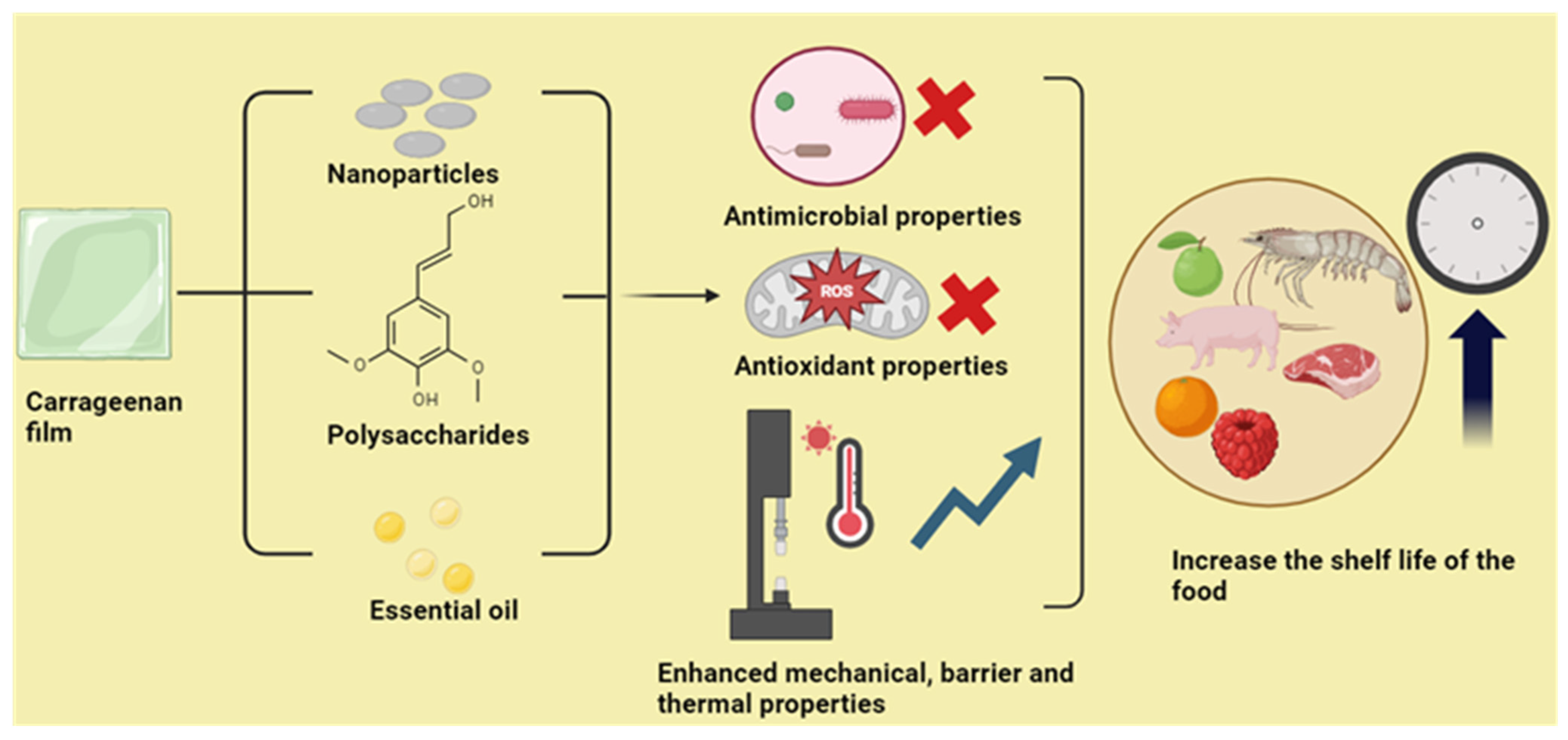

4. Properties of Carrageenan-Based Packaging Film

4.1. Mechanical Properties

4.2. Barrier Properties

4.3. Thermal Properties

4.4. UV-Light Barrier and Transparency

4.5. Antioxidant Properties

4.6. Antimicrobial Properties

5. Application of Carrageenan-Based Film in Food System

5.1. Active Packaging Applications

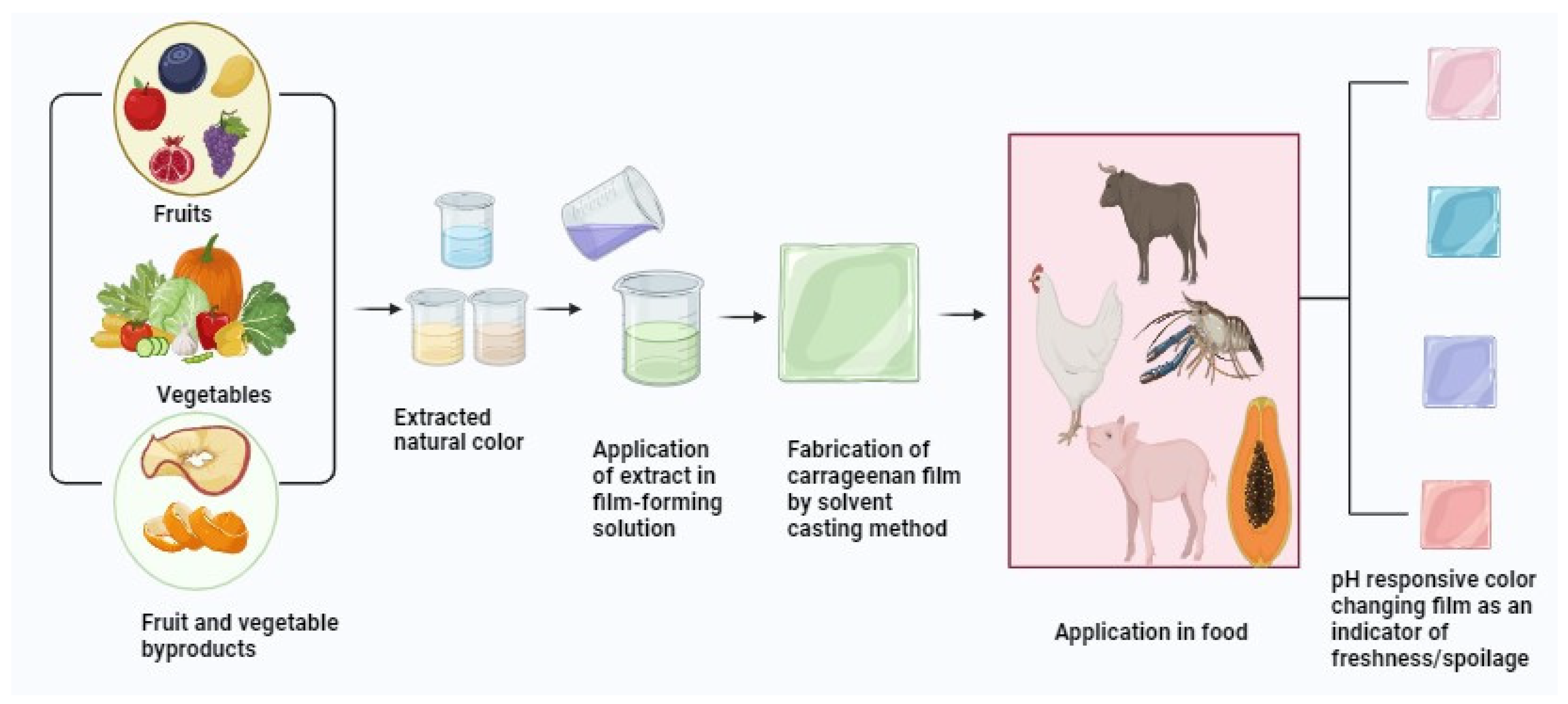

5.2. Intelligent Packaging Applications

6. Potential Challenges and Future Perspectives

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef] [PubMed]

- Puscaselu, R.G.; Besliu, I.; Gutt, G. Edible Biopolymers-Based Materials for Food Applications—The Eco Alternative to Conventional Synthetic Packaging. Polymers 2021, 13, 3779. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Sani, M.A.; Zhang, Z.; McClements, D.J.; Jafari, S.M. High-Performance Biopolymeric Packaging Films Containing Zinc Oxide Nanoparticles for Fresh Food Preservation: A Review. Int. J. Biol. Macromol. 2023, 230, 123188. [Google Scholar] [CrossRef] [PubMed]

- Reddy, M.S.B.; Ponnamma, D.; Choudhary, R.; Sadasivuni, K.K. A Comparative Review of Natural and Synthetic Biopolymer Composite Scaffolds. Polymers 2021, 13, 1105. [Google Scholar] [CrossRef]

- Swetha, T.A.; Bora, A.; Mohanrasu, K.; Balaji, P.; Raja, R.; Ponnuchamy, K.; Muthusamy, G.; Arun, A. A Comprehensive Review on Polylactic Acid (PLA)—Synthesis, Processing and Application in Food Packaging. Int. J. Biol. Macromol. 2023, 234, 123715. [Google Scholar] [CrossRef] [PubMed]

- Chudasama, N.A.; Sequeira, R.A.; Moradiya, K.; Prasad, K. Seaweed Polysaccharide Based Products and Materials: An Assessment on Their Production from a Sustainability Point of View. Molecules 2021, 26, 2608. [Google Scholar] [CrossRef] [PubMed]

- Lomartire, S.; Marques, J.C.; Gonçalves, A.M.M. An Overview of the Alternative Use of Seaweeds to Produce Safe and Sustainable Bio-Packaging. Appl. Sci. 2022, 12, 3123. [Google Scholar] [CrossRef]

- Yegappan, R.; Selvaprithiviraj, V.; Amirthalingam, S.; Jayakumar, R. Carrageenan Based Hydrogels for Drug Delivery, Tissue Engineering and Wound Healing. Carbohydr. Polym. 2018, 198, 385–400. [Google Scholar] [CrossRef]

- Rammak, T.; Boonsuk, P.; Kaewtatip, K. Mechanical and Barrier Properties of Starch Blend Films Enhanced with Kaolin for Application in Food Packaging. Int. J. Biol. Macromol. 2021, 192, 1013–1020. [Google Scholar] [CrossRef]

- Ahmad, N.A.; Heng, L.Y.; Salam, F.; Zaid, M.H.M.; Hanifah, S.A. A Colorimetric PH Sensor Based on Clitoria sp. and Brassica sp. for Monitoring of Food Spoilage Using Chromametry. Sensors 2019, 19, 4813. [Google Scholar] [CrossRef]

- Ahmed, M.; Bose, I.; Roy, S. Development of Intelligent Indicators Based on Cellulose and Prunus domestica Extracted Anthocyanins for Monitoring the Freshness of Packaged Chicken. Int. J. Biomater. 2024, 2024, 7949258. [Google Scholar] [CrossRef] [PubMed]

- Das, P.; Ganguly, S.; Ahmed, S.R.; Sherazee, M.; Margel, S.; Gedanken, A.; Srinivasan, S.; Rajabzadeh, A.R. Carbon Dot Biopolymer-Based Flexible Functional Films for Antioxidant and Food Monitoring Applications. ACS Appl. Polym. Mater. 2022, 4, 9323–9340. [Google Scholar] [CrossRef]

- Matche, R.S.; Anup, G.J.; Mrudula, G. Development of Biodegradable Films from Marine Ingredients Incorporated with Natural Antimicrobial Agents for Food Packaging. J. Packag. Technol. Res. 2020, 4, 45–55. [Google Scholar] [CrossRef]

- Sedayu, B.B.; Cran, M.J.; Bigger, S.W. A Review of Property Enhancement Techniques for Carrageenan-Based Films and Coatings. Carbohydr. Polym. 2019, 216, 287–302. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, S.; Su, J.; Zhu, M.; Zhou, M.; Chen, T.; Han, Y. Recent Advances in Carrageenan-Based Films for Food Packaging Applications. Front. Nutr. 2022, 9, 1004588. [Google Scholar] [CrossRef] [PubMed]

- Aga, M.B.; Dar, A.H.; Nayik, G.A.; Panesar, P.S.; Allai, F.; Khan, S.A.; Shams, R.; Kennedy, J.F.; Altaf, A. Recent Insights into Carrageenan-Based Bio-Nanocomposite Polymers in Food Applications: A Review. Int. J. Biol. Macromol. 2021, 192, 197–209. [Google Scholar] [CrossRef] [PubMed]

- Pacheco-Quito, E.M.; Ruiz-Caro, R.; Veiga, M.D. Carrageenan: Drug Delivery Systems and Other Biomedical Applications. Mar. Drugs 2020, 18, 583. [Google Scholar] [CrossRef]

- Zakaria, Z.; Kamarudin, S.K.; Osman, S.H.; Mohamad, A.A.; Razali, H. A Review of Carrageenan as a Polymer Electrolyte in Energy Resource Applications. J. Polym. Environ. 2023, 31, 4127–4142. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Saurabh, C.K.; Tye, Y.Y.; Lai, T.K.; Easa, A.M.; Rosamah, E.; Fazita, M.R.N.; Syakir, M.I.; Adnan, A.S.; Fizree, H.M.; et al. Seaweed Based Sustainable Films and Composites for Food and Pharmaceutical Applications: A Review. Renew. Sustain. Energy Rev. 2017, 77, 353–362. [Google Scholar] [CrossRef]

- Dirpan, A.; Ainani, A.F.; Djalal, M. A Review on Biopolymer-Based Biodegradable Film for Food Packaging: Trends over the Last Decade and Future Research. Polymers 2023, 15, 2781. [Google Scholar] [CrossRef]

- Versino, F.; Ortega, F.; Monroy, Y.; Rivero, S.; López, O.V.; García, M.A. Sustainable and Bio-Based Food Packaging: A Review on Past and Current Design Innovations. Foods 2023, 12, 1057. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Zhu, S.; Chen, P.; Liu, Z.; Lin, L.; Zhang, J. Effect of Physiological PH on the Molecular Characteristics, Rheological Behavior, and Molecular Dynamics of κ-Carrageenan/Casein. Front. Nutr. 2023, 10, 1174888. [Google Scholar] [CrossRef] [PubMed]

- Humayun, S.; Premarathna, A.D.; Rjabovs, V.; Howlader, M.M.; Darko, C.N.S.; Mok, I.K.; Tuvikene, R. Biochemical Characteristics and Potential Biomedical Applications of Hydrolyzed Carrageenans. Mar. Drugs 2023, 21, 269. [Google Scholar] [CrossRef] [PubMed]

- Levy-Ontman, O.; Abu-Galiyun, E.; Huleihel, M. Studying the Relationship between the Antiviral Activity and the Structure of Ἰ-Carrageenan Using Ultrasonication. Int. J. Mol. Sci. 2023, 24, 14200. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Liu, T.; Wang, S.; Zou, Y.; Cao, J.; Wang, C.; Hang, C.; Jin, L. Antioxidant and Ammonia-Sensitive Films Based on Starch, κ-Carrageenan and Oxalis triangularis Extract as Visual Indicator of Beef Meat Spoilage. Int. J. Biol. Macromol. 2023, 235, 123698. [Google Scholar] [CrossRef] [PubMed]

- Souza, H.K.S.; Kraiem, W.; Ben Yahia, A.; Aschi, A.; Hilliou, L. From Seaweeds to Hydrogels: Recent Progress in Kappa-2 Carrageenans. Materials 2023, 16, 5387. [Google Scholar] [CrossRef] [PubMed]

- Chi, W.; Liu, W.; Li, J.; Wang, L. Simultaneously Realizing Intelligent Color Change and High Haze of κ-Carrageenan Film by Incorporating Black Corn Seed Powder for Visually Monitoring Pork Freshness. Food Chem. 2023, 402, 134257. [Google Scholar] [CrossRef] [PubMed]

- Cunha, L.; Grenha, A. Sulfated Seaweed Polysaccharides as Multifunctional Materials in Drug Delivery Applications. Mar. Drugs 2016, 14, 42. [Google Scholar] [CrossRef]

- Udo, T.; Mummaleti, G.; Mohan, A.; Singh, R.K.; Kong, F. Current and Emerging Applications of Carrageenan in the Food Industry. Food Res. Int. 2023, 173, 113369. [Google Scholar] [CrossRef]

- Santos, L.G.; Alves-Silva, G.F.; Martins, V.G. Active-Intelligent and Biodegradable Sodium Alginate Films Loaded with Clitoria ternatea Anthocyanin-Rich Extract to Preserve and Monitor Food Freshness. Int. J. Biol. Macromol. 2022, 220, 866–877. [Google Scholar] [CrossRef]

- Wang, B.; Li, J.; Li, Y.; Mavelil-Sam, R.; Ouseph, E.M.; Morreale, M.; Scaffaro, R.; Thomas, S. Recent Developments and Formulations for Hydrophobic Modification of Carrageenan Bionanocomposites. Polymers 2023, 15, 1650. [Google Scholar] [CrossRef] [PubMed]

- Ferdiansyah, R.; Abdassah, M.; Zainuddin, A.; Rachmaniar, R.; Chaerunisaa, A.Y. Effects of Alkaline Solvent Type and PH on Solid Physical Properties of Carrageenan from Eucheuma Cottonii. Gels 2023, 9, 397. [Google Scholar] [CrossRef] [PubMed]

- Hanani, Z.A.N.; Husna, A.B.A. Effect of Different Types and Concentrations of Emulsifier on the Characteristics of Kappa-Carrageenan Films. Int. J. Biol. Macromol. 2018, 114, 710–716. [Google Scholar] [CrossRef] [PubMed]

- Nouri, A.; Yaraki, M.T.; Ghorbanpour, M.; Wang, S. Biodegradable κ-Carrageenan/Nanoclay Nanocomposite Films Containing Rosmarinus Officinalis L. Extract for Improved Strength and Antibacterial Performance. Int. J. Biol. Macromol. 2018, 115, 227–235. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Roy, S.; Naskar, J.; Kole, R.K. Plant-mediated synthesis of mono-and bimetallic (Au–Ag) nanoparticles: Future prospects for food quality and safety. J. Nanomater. 2023, 2023, 2781667. [Google Scholar] [CrossRef]

- Fadiji, T.; Rashvand, M.; Daramola, M.O.; Iwarere, S.A. A Review on Antimicrobial Packaging for Extending the Shelf Life of Food. Processes 2023, 11, 590. [Google Scholar] [CrossRef]

- Kishore, A.; Aravind, S.M.; Singh, A. Bionanocomposites for Active and Smart Food Packaging: A Review on Its Application, Safety, and Health Aspects. J. Food Process Eng. 2023, 46, e14320. [Google Scholar] [CrossRef]

- Tran, T.T.B.; Roach, P.; Nguyen, M.H.; Pristijono, P.; Vuong, Q.V. Development of Biodegradable Films Based on Seaweed Polysaccharides and Gac Pulp (Momordica cochinchinensis), the Waste Generated from Gac Oil Production. Food Hydrocoll. 2020, 99, 105322. [Google Scholar] [CrossRef]

- Madruga, L.Y.C.; Sabino, R.M.; Santos, E.C.G.; Popat, K.C.; Balaban, R.d.C.; Kipper, M.J. Carboxymethyl-Kappa-Carrageenan: A Study of Biocompatibility, Antioxidant and Antibacterial Activities. Int. J. Biol. Macromol. 2020, 152, 483–491. [Google Scholar] [CrossRef]

- Zhang, Y.; Man, J.; Li, J.; Xing, Z.; Zhao, B.; Ji, M.; Xia, H.; Li, J. Preparation of the Alginate/Carrageenan/Shellac Films Reinforced with Cellulose Nanocrystals Obtained from Enteromorpha for Food Packaging. Int. J. Biol. Macromol. 2022, 218, 519–532. [Google Scholar] [CrossRef]

- Firouz, M.S.; Mohi-Alden, K.; Omid, M. A Critical Review on Intelligent and Active Packaging in the Food Industry: Research and Development. Food Res. Int. 2021, 141, 110113. [Google Scholar] [CrossRef] [PubMed]

- Kuswandi, B. Jumina. Active and Intelligent Packaging, Safety, and Quality Controls. In Fresh-Cut Fruits and Vegetables: Technologies and Mechanisms for Safety Control; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 243–294. ISBN 9780128161845. [Google Scholar]

- Kanatt, S.R. Development of Active/Intelligent Food Packaging Film Containing Amaranthus Leaf Extract for Shelf Life Extension of Chicken/Fish during Chilled Storage. Food Packag. Shelf Life 2020, 24, 100506. [Google Scholar] [CrossRef]

- Roy, S.; Ezati, P.; Rhim, J.-W. Gelatin/carrageenan-based functional films with carbon dots from enoki mushroom for active food packaging applications. ACS Appl. Polym. Mater. 2021, 3, 6437–6445. [Google Scholar] [CrossRef]

- Khojah, S.M. Bio-Based Coating from Fish Gelatin, K-Carrageenan and Extract of Pomegranate Peels for Maintaining the Overall Qualities of Fish Fillet. J. Aquat. Food Prod. Technol. 2020, 29, 810–822. [Google Scholar] [CrossRef]

- Janseerat; Kolekar, M.; Reddy, C.S.; Sharma, S.; Roy, S. Anthocyanin-Based Natural Color Induced Intelligent Food Packaging Sensor: A Review. Current Food Sci. Technol. Rep. 2024, in press. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, X.; Huang, Y.; Li, H.; Chen, L.; Liu, X. Two Colorimetric Films Based on Chitin Whiskers and Sodium Alginate/Gelatin Incorporated with Anthocyanins for Monitoring Food Freshness. Food Hydrocoll. 2022, 127, 107517. [Google Scholar] [CrossRef]

- Kim, Y.T.; Min, B.; Kim, K.W. General Characteristics of Packaging Materials for Food System. In Innovations in Food Packaging: Second Edition; Elsevier Ltd.: Amsterdam, The Netherlands, 2013; pp. 13–35. ISBN 9780123946010. [Google Scholar]

- Zia, K.M.; Tabasum, S.; Nasif, M.; Sultan, N.; Aslam, N.; Noreen, A.; Zuber, M. A Review on Synthesis, Properties and Applications of Natural Polymer Based Carrageenan Blends and Composites. Int. J. Biol. Macromol. 2017, 96, 282–301. [Google Scholar] [CrossRef]

- Bakar, M.H.A.; Azeman, N.H.; Mobarak, N.N.; Mokhtar, M.H.H.; Bakar, A.A.A. Effect of Active Site Modification towards Performance Enhancement in Biopolymer κ-Carrageenan Derivatives. Polymers 2020, 12, 2040. [Google Scholar] [CrossRef]

- Genecya, G.; Adhika, D.R.; Sutrisno, W.; Wungu, T.D.K. Characteristic Improvement of a Carrageenan-Based Bionanocomposite Polymer Film Containing Montmorillonite as Food Packaging through the Addition of Silver and Cerium Oxide Nanoparticles. ACS Omega 2023, 8, 39194–39202. [Google Scholar] [CrossRef]

- Adam, F.; Othman, N.A.; Yasin, N.H.M.; Cheng, C.K.; Azman, N.A.M. Evaluation of Reinforced and Green Bioplastic from Carrageenan Seaweed with Nanocellulose. Fibers Polym. 2022, 23, 2885–2896. [Google Scholar] [CrossRef]

- Kang, J.; Yun, S.I. Double-Network Hydrogel Films Based on Cellulose Derivatives and κ-Carrageenan with Enhanced Mechanical Strength and Superabsorbent Properties. Gels 2023, 9, 20. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Chen, F.Q.; Chen, S.; Xiao, Q.; Weng, H.F.; Yang, Q.M.; Xiao, A.F. Preparation and Characterization of κ-Carrageenan Modified with Maleic Anhydride and Its Application in Films. Mar. Drugs 2021, 19, 486. [Google Scholar] [CrossRef] [PubMed]

- Islamiyah, H.S.; Alamsjah, M.A.; Pujiastuti, D.Y. Application of Modified Starch in the Carragenan-Based Biodegradable Packaging from Eucheuma cottonii on Biodegradablility and Mechanical Properties. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: London, UK, 2022; Volume 1036. [Google Scholar]

- Wang, R.; Zhang, S.; Liu, S.; Sun, Y.; Xu, H. A Contribution to Improve Barrier Properties and Reduce Swelling Ratio of κ-Carrageenan Film from the Incorporation of Guar Gum or Locust Bean Gum. Polymers 2023, 15, 1751. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Rhim, J.W. Fabrication of Copper Sulfide Nanoparticles and Limonene Incorporated Pullulan/Carrageenan-Based Film with Improved Mechanical and Antibacterial Properties. Polymers 2020, 12, 2665. [Google Scholar] [CrossRef] [PubMed]

- Ezati, P.; Riahi, Z.; Rhim, J.-W. Carrageenan-Based Functional Films Integrated with CuO-Doped Titanium Nanotubes for Active Food-Packaging Applications. ACS Sustain. Chem. Eng. 2021, 9, 9300–9307. [Google Scholar] [CrossRef]

- Fathiraja, P.; Gopalrajan, S.; Karunanithi, M.; Nagarajan, M.; Obaiah, M.C.; Durairaj, S.; Neethirajan, N. Response Surface Methodology Model to Optimize Concentration of Agar, Alginate and Carrageenan for the Improved Properties of Biopolymer Film. Polym. Bull. 2022, 79, 6211–6237. [Google Scholar] [CrossRef]

- Tyuftin, A.A.; Kerry, J.P. Gelatin Films: Study Review of Barrier Properties and Implications for Future Studies Employing Biopolymer Films. Food Packag. Shelf Life 2021, 29, 100688. [Google Scholar] [CrossRef]

- Roy, S.; Ghosh, T.; Zhang, W.; Rhim, J.-W. Recent progress in PBAT-based films and food packaging applications: A mini-review. Food Chem. 2024, 437, 137822. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.C.; Chang, C.C.; Nagarajan, D.; Chen, C.Y.; Chang, J.S. Algae-Derived Hydrocolloids in Foods: Applications and Health-Related Issues. Bioengineered 2021, 12, 3787–3801. [Google Scholar] [CrossRef]

- Dong, Y.; Wei, Z.; Xue, C. Recent Advances in Carrageenan-Based Delivery Systems for Bioactive Ingredients: A Review. Trends Food Sci. Technol. 2021, 112, 348–361. [Google Scholar] [CrossRef]

- Bharti, S.K.; Pathak, V.; Arya, A.; Alam, T.; Rajkumar, V.; Verma, A.K. Packaging Potential of Ipomoea batatas and κ-Carrageenan Biobased Composite Edible Film: Its Rheological, Physicomechanical, Barrier and Optical Characterization. J. Food Process Preserv. 2021, 45, e15153. [Google Scholar] [CrossRef]

- Nouri, A.; Yaraki, M.T.; Lajevardi, A.; Rahimi, T.; Tanzifi, M.; Ghorbanpour, M. An Investigation of the Role of Fabrication Process in the Physicochemical Properties of κ-Carrageenan-Based Films Incorporated with Zataria multiflora Extract and Nanoclay. Food Packag. Shelf Life 2020, 23, 100435. [Google Scholar] [CrossRef]

- Guo, J.; Dong, S.; Ye, M.; Wu, X.; Lv, X.; Xu, H.; Li, M. Effects of Hydroxypropyl Methylcellulose on Physicochemical Properties and Microstructure of κ-Carrageenan Film. Foods 2022, 11, 3023. [Google Scholar] [CrossRef] [PubMed]

- Sandhu, K.S.; Sharma, L.; Kaur, M.; Kaur, R. Physical, Structural and Thermal Properties of Composite Edible Films Prepared from Pearl Millet Starch and Carrageenan Gum: Process Optimization Using Response Surface Methodology. Int. J. Biol. Macromol. 2020, 143, 704–713. [Google Scholar] [CrossRef]

- Meng, F.; Zhang, Y.; Xiong, Z.; Wang, G.; Li, F.; Zhang, L. Mechanical, Hydrophobic and Thermal Properties of an Organic-Inorganic Hybrid Carrageenan-Polyvinyl Alcohol Composite Film. Compos. B Eng. 2018, 143, 1–8. [Google Scholar] [CrossRef]

- Bhatia, S.; Shah, Y.A.; Al-Harrasi, A.; Jawad, M.; Koca, E.; Aydemir, L.Y. Enhancing Tensile Strength, Thermal Stability, and Antioxidant Characteristics of Transparent Kappa Carrageenan Films Using Grapefruit Essential Oil for Food Packaging Applications. ACS Omega 2024, 9, 9003–9012. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.; Yadav, R.; Tanwar, R.; Gaikwad, K.K. κ-Carrageenan-Based Bio-Nanocomposite Film Reinforced with Cellulose Nanocrystals Derived from Amla Pomace for Food Packaging. Biomass Convers. Biorefinery 2023, 13, 16899–16908. [Google Scholar] [CrossRef]

- Rapa, M.; Nicoleta, R.; Nita, D.; Vasile, C. Influence of Plasticizers Over Some Physico-Chemical Properties of PLA. Mater. Plast. 2017, 54, 73–78. [Google Scholar] [CrossRef]

- Yadav, M.; Chiu, F.C. Cellulose Nanocrystals Reinforced κ-Carrageenan Based UV Resistant Transparent Bionanocomposite Films for Sustainable Packaging Applications. Carbohydr. Polym. 2019, 211, 181–194. [Google Scholar] [CrossRef]

- Khan, A.; Priyadarshi, R.; Bhattacharya, T.; Rhim, J.-W. Carrageenan/Alginate-Based Functional Films Incorporated with Allium sativum Carbon Dots for UV-Barrier Food Packaging. Food Bioproc. Technol. 2023, 16, 2001–2015. [Google Scholar] [CrossRef]

- Rukmanikrishnan, B.; Rajasekharan, S.K.; Lee, J.; Ramalingam, S.; Lee, J. K-Carrageenan/Lignin Composite Films: Biofilm Inhibition, Antioxidant Activity, Cytocompatibility, UV and Water Barrier Properties. Mater. Today Commun. 2020, 24, 101346. [Google Scholar] [CrossRef]

- Arifin, M.A.Z.; Adzahan, N.M.; Abedin, N.H.Z.; Lasik-Kurdyś, M. Utilization of Food Waste and By-Products in the Fabrication of Active and Intelligent Packaging for Seafood and Meat Products. Foods 2023, 12, 456. [Google Scholar] [CrossRef]

- Sanches, M.A.R.; Camelo-Silva, C.; Carvalho, C.d.S.; de Mello, J.R.; Barroso, N.G.; Barros, E.d.S.; Silva, P.P.; Pertuzatti, P.B. Active Packaging with Starch, Red Cabbage Extract and Sweet Whey: Characterization and Application in Meat. LWT 2021, 135, 110275. [Google Scholar] [CrossRef]

- da Rosa, G.S.; Vanga, S.K.; Gariepy, Y.; Raghavan, V. Development of Biodegradable Films with Improved Antioxidant Properties Based on the Addition of Carrageenan Containing Olive Leaf Extract for Food Packaging Applications. J. Polym. Environ. 2020, 28, 123–130. [Google Scholar] [CrossRef]

- Balasubramaniam, S.P.L.; Patel, A.S.; Nayak, B. Fabrication of Antioxidative Food Packaging Films Using Cellulose Nanofibers, Kappa-Carrageenan, and Gallic Acid. J. Food Process Preserv. 2021, 45, e15480. [Google Scholar] [CrossRef]

- Farhan, A.; Hani, N.M. Active Edible Films Based on Semi-Refined κ-Carrageenan: Antioxidant and Color Properties and Application in Chicken Breast Packaging. Food Packag. Shelf Life 2020, 24, 100476. [Google Scholar] [CrossRef]

- Avila, L.B.; Barreto, E.R.C.; Moraes, C.C.; Morais, M.M.; da Rosa, G.S. Promising New Material for Food Packaging: An Active and Intelligent Carrageenan Film with Natural Jaboticaba Additive. Foods 2022, 11, 792. [Google Scholar] [CrossRef] [PubMed]

- Dordevic, D.; Dordevic, S.; Abdullah, F.A.A.; Mader, T.; Medimorec, N.; Tremlova, B.; Kushkevych, I. Edible/Biodegradable Packaging with the Addition of Spent Coffee Grounds Oil. Foods 2023, 12, 2626. [Google Scholar] [CrossRef] [PubMed]

- Valdés, A.; Ramos, M.; Beltrán, A.; Jiménez, A.; Garrigós, M.C. State of the Art of Antimicrobial Edible Coatings for Food Packaging Applications. Coatings 2017, 7, 56. [Google Scholar] [CrossRef]

- Young, E.; Mirosa, M.; Bremer, P. A Systematic Review of Consumer Perceptions of Smart Packaging Technologies for Food. Front. Sustain. Food Syst. 2020, 4, 63. [Google Scholar] [CrossRef]

- Simona, J.; Dani, D.; Petr, S.; Marcela, N.; Jakub, T.; Bohuslava, T. Edible Films from Carrageenan/Orange Essential Oil/Trehalose—Structure, Optical Properties, and Antimicrobial Activity. Polymers 2021, 13, 332. [Google Scholar] [CrossRef] [PubMed]

- Prasetyaningrum, A.; Utomo, D.P.; Raemas, A.F.A.; Kusworo, T.D.; Jos, B.; Djaeni, M. Alginate/κ-Carrageenan-Based Edible Films Incorporated with Clove Essential Oil: Physico-Chemical Characterization and Antioxidant-Antimicrobial Activity. Polymers 2021, 13, 354. [Google Scholar] [CrossRef] [PubMed]

- Martiny, T.R.; Raghavan, V.; de Moraes, C.C.; da Rosa, G.S.; Dotto, G.L. Bio-Based Active Packaging: Carrageenan Film with Olive Leaf Extract for Lamb Meat Preservation. Foods 2020, 9, 1759. [Google Scholar] [CrossRef] [PubMed]

- Yildirim, S.; Röcker, B.; Pettersen, M.K.; Nilsen-Nygaard, J.; Ayhan, Z.; Rutkaite, R.; Radusin, T.; Suminska, P.; Marcos, B.; Coma, V. Active Packaging Applications for Food. Compr. Rev. Food Sci. Food Saf. 2018, 17, 165–199. [Google Scholar] [CrossRef] [PubMed]

- Wyrwa, J.; Barska, A. Innovations in the Food Packaging Market: Active Packaging. Eur. Food Res. Technol. 2017, 243, 1681–1692. [Google Scholar] [CrossRef]

- Khan, A.; Riahi, Z.; Kim, J.T.; Rhim, J.-W. Gelatin/Carrageenan-Based Smart Packaging Film Integrated with Cu-Metal Organic Framework for Freshness Monitoring and Shelf-Life Extension of Shrimp. Food Hydrocoll. 2023, 145, 109180. [Google Scholar] [CrossRef]

- Brito, T.B.N.; Ferreira, M.S.L.; Fai, A.E.C. Utilization of Agricultural By-Products: Bioactive Properties and Technological Applications. Food Rev. Int. 2022, 38, 1305–1329. [Google Scholar] [CrossRef]

- Avila, L.B.; Barreto, E.R.C.; de Souza, P.K.; Silva, B.D.Z.; Martiny, T.R.; Moraes, C.C.; Morais, M.M.; Raghavan, V.; da Rosa, G.S. Carrageenan-Based Films Incorporated with Jaboticaba Peel Extract: An Innovative Material for Active Food Packaging. Molecules 2020, 25, 5563. [Google Scholar] [CrossRef]

- Wani, S.M.; Gull, A.; Ahad, T.; Malik, A.R.; Ganaie, T.A.; Masoodi, F.A.; Gani, A. Effect of Gum Arabic, Xanthan and Carrageenan Coatings Containing Antimicrobial Agent on Postharvest Quality of Strawberry: Assessing the Physicochemical, Enzyme Activity and Bioactive Properties. Int. J. Biol. Macromol. 2021, 183, 2100–2108. [Google Scholar] [CrossRef]

- Khan, A.; Riahi, Z.; Kim, J.T.; Rhim, J.-W. Carrageenan-Based Multifunctional Packaging Films Containing Zn-Carbon Dots/Anthocyanin Derived from Kohlrabi Peel for Monitoring Quality and Extending the Shelf Life of Shrimps. Food Chem. 2023, 432, 137215. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Carrageenan/agar-based functional film integrated with zinc sulfide nanoparticles and Pickering emulsion of tea tree essential oil for active packaging applications. Int. J. Biol. Macromol. 2021, 193, 2038–2046. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Rhim, J.-W. Preparation of Carrageenan-Based Functional Nanocomposite Films Incorporated with Melanin Nanoparticles. Colloids Surf. B Biointerfaces 2019, 176, 317–324. [Google Scholar] [CrossRef] [PubMed]

- de Jesus, G.A.M.; Berton, S.B.R.; Simões, B.M.; Zola, R.S.; Monteiro, J.P.; Martins, A.F.; Bonafé, E.G. κ-Carrageenan/Poly(Vinyl Alcohol) Functionalized Films with Gallic Acid and Stabilized with Metallic Ions. Int. J. Biol. Macromol. 2023, 253, 127087. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Rhim, J.-W. Carrageenan-Based Antimicrobial Bionanocomposite Films Incorporated with ZnO Nanoparticles Stabilized by Melanin. Food Hydrocoll. 2019, 90, 500–507. [Google Scholar] [CrossRef]

- Amanda, P.; Ismadi, I.; Ningrum, R.S.; Nabila, S.; Prasetyo, K.W. Carrageenan Functional Film Integrated with Pickering Emulsion of Oregano Oil Stabilized by Cationic Nanocellulose for Active Packaging. Food Sci. Technol. Int. 2022, 30, 61–72. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Shankar, S.; Rhim, J.-W. Melanin-Mediated Synthesis of Silver Nanoparticle and Its Use for the Preparation of Carrageenan-Based Antibacterial Films. Food Hydrocoll. 2019, 88, 237–246. [Google Scholar] [CrossRef]

- Saedi, S.; Shokri, M.; Roy, S.; Rhim, J.-W. Silver Loaded Aminosilane Modified Halloysite for the Preparation of Carrageenan-Based Functional Films. Appl. Clay Sci. 2021, 211, 106170. [Google Scholar] [CrossRef]

- Wang, X.; Guo, C.; Guo, H. Progress of Carrageenan-Based Films and Coatings for Food Packaging Applications. Packag. Technol. Sci. 2024, in press. [Google Scholar] [CrossRef]

- Han, Y.; Zhou, M.; McClements, D.J.; Liu, F.; Cheng, C.; Xiong, J.; Zhu, M.; Chen, S. Investigation of a Novel Smart and Active Packaging Materials: Nanoparticle-Filled Carrageenan-Based Composite Films. Carbohydr. Polym. 2023, 301, 120331. [Google Scholar] [CrossRef]

- Zhou, M.; Han, Y.; McClements, D.J.; Cheng, C.; Chen, S. Co-Encapsulation of Anthocyanin and Cinnamaldehyde in Nanoparticle-Filled Carrageenan Films: Fabrication, Characterization, and Active Packaging Applications. Food Hydrocoll. 2024, 149, 109609. [Google Scholar] [CrossRef]

- Khan, A.; Ezati, P.; Rhim, J.-W. Chitosan/Starch-Based Active Packaging Film with N, P-Doped Carbon Dots for Meat Packaging. ACS Appl. Bio Mater. 2023, 6, 1294–1305. [Google Scholar] [CrossRef]

- Riahi, Z.; Khan, A.; Rhim, J.-W.; Shin, G.H.; Kim, J.T. Carrageenan-Based Active and Intelligent Packaging Films Integrated with Anthocyanin and TiO2-Doped Carbon Dots Derived from Sweet Potato Peels. Int. J. Biol. Macromol. 2024, 259, 129371. [Google Scholar] [CrossRef]

- Roy, S.; Deshmukh, R.K.; Tripathi, S.; Gaikwad, K.K.; Das, S.S.; Sharma, D. Recent Advances in the Carotenoids Added to Food Packaging Films: A Review. Foods 2023, 12, 4011. [Google Scholar] [CrossRef] [PubMed]

- Balbinot-Alfaro, E.; Craveiro, D.V.; Lima, K.O.; Costa, H.L.G.; Lopes, D.R.; Prentice, C. Intelligent Packaging with pH Indicator Potential. Food Eng. Rev. 2019, 11, 235–244. [Google Scholar] [CrossRef]

- Fang, Z.; Zhao, Y.; Warner, R.D.; Johnson, S.K. Active and Intelligent Packaging in Meat Industry. Trends Food Sci. Technol. 2017, 61, 60–71. [Google Scholar] [CrossRef]

- Kalpana, S.; Priyadarshini, S.R.; Leena, M.M.; Moses, J.A.; Anandharamakrishnan, C. Intelligent Packaging: Trends and Applications in Food Systems. Trends Food Sci. Technol. 2019, 93, 145–157. [Google Scholar] [CrossRef]

- Liu, J.; Wang, H.; Wang, P.; Guo, M.; Jiang, S.; Li, X.; Jiang, S. Films Based on κ-Carrageenan Incorporated with Curcumin for Freshness Monitoring. Food Hydrocoll. 2018, 83, 134–142. [Google Scholar] [CrossRef]

- Wang, C.; Cao, J.; Liu, T.; Jin, L.; Hang, C.; Zhang, C.; Qian, X.; Jiang, D.; Jiang, C. Preparation and Characterization of Antioxidant and pH-Sensitive Films Based on Arrowhead (Sagittaria sagittifolia) Starch, κ-Carrageenan and Black Chokeberry (Aronia melanocarpa) Extract for Monitoring Spoilage of Chicken Wings. Int. J. Biol. Macromol. 2023, 224, 544–555. [Google Scholar] [CrossRef]

- Zhang, C.; Sun, G.; Cao, L.; Wang, L. Accurately Intelligent Film Made from Sodium Carboxymethyl Starch/κ-Carrageenan Reinforced by Mulberry Anthocyanins as an Indicator. Food Hydrocoll. 2020, 108, 106012. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, Y.; Bai, R.; Zhang, X.; Yuan, L.; Liu, J. Preparation of pH-Sensitive and Antioxidant Packaging Films Based on κ-Carrageenan and Mulberry Polyphenolic Extract. Int. J. Biol. Macromol. 2019, 134, 993–1001. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Preparation of Gelatin/Carrageenan-Based Color-Indicator Film Integrated with Shikonin and Propolis for Smart Food Packaging Applications. ACS Appl. Bio Mater. 2021, 4, 770–779. [Google Scholar] [CrossRef]

- Sangeetha, U.K.; Sudhakaran, N.; Parvathy, P.A.; Abraham, M.; Das, S.; De, S.; Sahoo, S.K. Coconut husk-lignin derived carbon dots incorporated carrageenan based functional film for intelligent food packaging. Int. J. Biol. Macromol. 2024, 266, 131005. [Google Scholar] [CrossRef] [PubMed]

- Chi, W.; Cao, L.; Sun, G.; Meng, F.; Zhang, C.; Li, J.; Wang, L. Developing a Highly pH-Sensitive ĸ-Carrageenan-Based Intelligent Film Incorporating Grape Skin Powder via a Cleaner Process. J. Clean. Prod. 2019, 244, 118862. [Google Scholar] [CrossRef]

- Yong, H.; Liu, J.; Kan, J.; Liu, J. Active/Intelligent Packaging Films Developed by Immobilizing Anthocyanins from Purple Sweet potato and Purple Cabbage in Locust Bean Gum, Chitosan and κ-Carrageenan-Based Matrices. Int. J. Biol. Macromol. 2022, 211, 238–248. [Google Scholar] [CrossRef]

- Rong, L.; Zhang, T.; Ma, Y.; Wang, T.; Liu, Y.; Wu, Z. An Intelligent Label Using Sodium Carboxymethyl Cellulose and Carrageenan for Monitoring the Freshness of Fresh-Cut Papaya. Food Control 2023, 145, 109420. [Google Scholar] [CrossRef]

| Polymers | Fillers | Key Properties/Effects of Active Agent | Application | References |

|---|---|---|---|---|

| Carrageenan | Zinc oxide doped carbon dots and anthocyanin | The anthocyanin was extracted from the kohlrabi peel extract. The anthocyanin-nanocomposite incorporated into the carrageenan film improved barrier properties, antioxidant properties, and antimicrobial properties. The UV-A blocking property of the film improved by 85.2% and UV-B about 99.4%. The film also exhibited excellent antioxidant properties of about 99% which was confirmed by an ABTS assay, and 58% antioxidant activity confirmed by a DPPH assay. The antimicrobial property against L. monocytogenes was about 100%, and there was about 8.1 log CFU/mL after 12 h of incubation. | Shrimp packaging applications | [93] |

| Carrageenan/agar | Zinc sulfide nano and tea tree essential oil | The presence of nanofillers and Pickering emulsion of essential oils showed a positive impact on the physical and functional properties of the film. The mechanical strength increased by 30% in the presence of nanofillers but decreased by 8% in the presence of oil emulsion, while the barrier properties improved by about 10%. The hydrophobicity of the film was also enhanced by 10%. Moreover, the film showed good antioxidant properties and antimicrobial action. | Active food packaging | [94] |

| Carrageenan | Melanin nanoparticles | The addition of organic nanofillers showed significant enhancement in the mechanical strength (10%) but reduced the water vapor barrier properties. The melanin-added film almost completely blocked the UV light. The functional film also exhibited potent antioxidant activity. | Active food packaging | [95] |

| Carrageenan/polyvinyl alcohol | Gallic acid and metallic ions (Na, K, and Ca) | The gallic-acid-added film showed a higher water vapor permeability and lower mechanical properties. The antioxidant activity of the film was enhanced due to the presence of gallic acid. The functional packaging film showed good antibacterial activity against E. coli and S. aureus. | Active food packaging | [96] |

| Carrageenan | Zinc oxide nanoparticles | The incorporation of metallic oxide nanofillers did not much alter the mechanical properties, while the water vapor barrier improved by 10%, the UV-light barrier properties of the film were enhanced 6-fold, and the hydrophobicity increased by 15%. The presence of nanofillers showed strong antibacterial activity towards E. coli and L. monocytogenes. | Active food packaging | [97] |

| Carrageenan | Oregano essential oil | The addition of nanocellulose stabilized the Pickering emulsion of oregano essential oils, reduced the mechanical strength, and increased the flexibility of the carrageenan-based film. The functional film showed strong antibacterial action against E. coli and S. aureus. | Active food packaging | [98] |

| Carrageenan | Silver nanoparticles | The inclusion of the metallic nanofillers in carrageenan enhanced the mechanical strength by 30% and increased the thermal stability of the film. There was strong antibacterial action towards the foodborne pathogens E. coli and L. monocytogenes. | Active food packaging | [99] |

| Carrageenan | Silver-loaded amino silane modified halloysite | The nanofiller-included film showed 20% higher mechanical strength, superior hydrophobicity, water vapor barrier properties, and UV-light barrier properties compared to the carrageenan-only film. The film exhibited potent antibacterial action towards E. coli and L. monocytogenes. | Active food packaging | [100] |

| Carrageenan | Copper oxide-modified titanium nanotube | The addition of nanofillers improved the mechanical strength, hydrophobicity, UV-light barrier properties, and water vapor barrier properties of the film. The functional film was used for banana packaging, and the film-packed banana had a longer shelf life (~12 days) with retained organoleptic properties. | Banana packaging application | [58,101] |

| Carrageenan | Curcumin, zein, epigallocatechin gallate | The antioxidant activity of the film was monitored by the DPPH and ABTS assay. The DPPH activity was found to be 79% antioxidant activity, and ABTS activity was found to be 73.34%. This could possibly extend the shelf life of fish. | Fish packaging application | [102] |

| Carrageenan | Anthocyanin and cinnamaldehyde added in zein nanoparticles | The film reduced the TVB-N content of the mandarin fish by 13.3% which could enhance the shelf life of the fish. This was attributed to its antioxidant activity (92.77% activity by ABTS and 48% DPPH activity). | Mandarin fish packaging application | [103] |

| k-carrageenan, xanthan gum, and gellan gum | Titanium dioxide | The film with 5 and 7% titanium dioxide showed partial antimicrobial activity against S. aureus when applied in a concentration of about 100–1000 µg and formed an inhibition zone around the colony of the foodborne pathogen. | Active food packaging | [74] |

| k-carrageenan | Lignin | The lignin incorporated into the carrageenan film enhanced the mechanical as well as the functional properties of the film. The lignin elevates the antioxidant property of the neat carrageenan film, which previously showed reduced or zero antioxidant activity. The film incorporated with 15% lignin showed 43% antioxidant activity when assayed with DPPH reagent. The addition of 30% lignin could reduce the antioxidant activity, possibly due to the agglomeration of lignin particles. The film also successfully inhibited the biofilm formation by S. aureus and S. epidermis. The combination of these two activities rendered this film an excellent candidate for food packaging application. | Food packaging | [61] |

| Carrageenan/alginate | Allium sativum-derived nitrogen, phosphorous carbon dots | The nanoparticle-included film showed a high antimicrobial and antioxidant capacity as compared to the control film. The active film showed higher antimicrobial effects against L. monocytogenes, E. coli, and S. aureus (about less than 2.5 Log CFU/g after 48 h). The film also showed about 98% antioxidant activity while being assessed with an ABTS assay and 71.4% while being assayed with DPPH activity. It can be used to monitor the freshness of the shrimp. | Meat packaging application | [104] |

| Carrageenan | Sweet potato anthocyanin and titanium dioxide doped carbon dots | The film showed 100% antimicrobial activity against microorganisms such as L. monocytogenes and E. coli within 3 h of incubation. The film also showed high antioxidant activity during ABTS and DPPH assays (both of about 100% activity). | Shrimp packaging applications | [105] |

| Base Polymer Material | Natural Source of Color Indicator | Indicator | Applied Food System | Remarks | References |

|---|---|---|---|---|---|

| κ-carrageenan | Mulberry phenolic extract | Anthocyanin | Milk | The fabricated film with carrageenan was originally blue upon the application of mulberry polyphenolic extract. Upon the application of milk, it turned a purple color. After keeping the milk for 6 h at 40 °C, the milk became acidic, i.e., the pH of the milk changed. This resulted in changing the color of the film from purple to pink. | [113] |

| κ-carrageenan | Curcumin powder | Curcumin | Pork and shrimp | During the spoilage of pork and shrimp, increased microbial activity leads to the accumulation of nitrogenous compounds such as ammonia and trimethylamine, which increases alkalinity. This makes it alkaline in nature, which can be an indicator of spoilage. The color of the curcumin film changes from yellow to red on the third day of storage, which is an indicator of pH changes and spoilage. | [110] |

| κ-carrageenan/Gelatin | Shikonin and propolis | Flavonoids and anthocyanins | Packaging milk | The color of the packaging film changes from purple to reddish pink as time passes by due to the change in pH of the milk upon storage at room temperature. | [114] |

| κ-carrageenan/Sodium carboxymethyl starch (CMS) | Mulberry anthocyanin extract | Anthocyanin | Mirror carp fish (Cyprinus carpio var. specularis) | The pH of the fish changes from slightly acidic to neutral upon storage due to the accumulation of various nitrogenous compounds in the body of the fish that renders their meat alkaline. This pH change could be reflected owing to the addition of mulberry anthocyanin extract to the carrageenan/CMS film, in which the anthocyanin changes its color from red to dark blue. | [112] |

| κ-carrageenan | Jaboticaba peels extract (JPE) | Anthocyanin | Food packaging applications | When the pH conditions outside the food change, the carrageenan film incorporated with the jaboticaba peel extract could change its color from purple to brown. The film could be a potential colorimetric indicator in the packaging of fish to monitor the spoilage of the fish. | [80] |

| κ-carrageenan/Hydroxypropyl methylcellulose | Grape skin powder | Anthocyanin | Pork | As pork decomposes, the nitrogen compounds in the pork increase, making the pork more basic. This change in the pH of the pork is indicated by the change in the film color from purple to green, which in turn indicates the spoilage of meat. | [116] |

| κ-carrageenan/Polyvinyl alcohol | Purple sweet potato anthocyanins (PSA) and purple cabbage anthocyanins (PCA) | Anthocyanin | Shrimp | In this study, polyvinyl alcohol, purple cabbage anthocyanins, and purple sweet potato anthocyanins are combined to form films with chitosan, locust bean gum, and κ-carrageenan. Even though the κ-carrageenan/polyvinyl alcohol does not show strong color changes as compared to the chitosan composite film, it still changes its color. The cabbage anthocyanin changes its color from dark blue to pale blue as the pH of the shrimp increases from 6.2 to 8.3. The potato anthocyanin changes its color from purple to brown as the pH of the shrimp changes from 6.2 to 8.3. | [117] |

| κ-carrageenan/Arrowhead starch | Black chokeberry | Anthocyanins | Chicken wings | Protein-rich chicken wings release a lot of volatile amines during decomposition that can increase the chicken’s alkalinity. After storage for 36 h, the TVB value exceeds the maximum permissible limit. Simultaneously, the color of the film also changes from pink to dark pink. The intensity of the color change strengthens as the concentration of the extract is increased. | [111] |

| κ-carrageenan/Sodium carboxymethyl cellulose (Na-CMC) | Bromothymol blue | 3,3′,5,5′-tetrabromophenolsulfonphthalein (a synthetic compound) | Fresh cut papaya | The color of the indicator changes from dark blue to various colors as the concentration of CO2 in the package increases. This testing is performed by placing a CO2-releasing tablet inside the package, which could increase the CO2 concentration inside the package from 0 to 10%. The shelf life of the papaya was studied for 7 days. During these 7 days, the color of the label changed from blue to green, indicating that the papaya was still edible. After a few days, it changed from green to yellow-green, which indicated that the papaya was still edible. After 7 days, the indicator changed from yellow-green to yellow-brown, indicating that the papaya should be discarded. | [118] |

| κ-carrageenan/TiO2 doped carbon dots | Sweet potato peel anthocyanin extract | Anthocyanin | Shrimp | The pH of the shrimp changes due to the accumulation of volatile amines inside the shrimp. At low pH, the film appears red, and the color gradually changes as the pH increases. As shrimp decompose, they develop an alkaline pH, causing the indicators to turn dark brown. | [105] |

| κ-carrageenan/Gelatin/Copper metal | Red cabbage anthocyanin extract | Anthocyanin | Shrimp | The indicator film changes its color from gray to reddish yellow as the pH changes to alkaline conditions. It also depends upon the anthocyanin content that is incorporated into the film that act as an indicator of freshness/spoilage of shrimp. | [89] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kokkuvayil Ramadas, B.; Rhim, J.-W.; Roy, S. Recent Progress of Carrageenan-Based Composite Films in Active and Intelligent Food Packaging Applications. Polymers 2024, 16, 1001. https://doi.org/10.3390/polym16071001

Kokkuvayil Ramadas B, Rhim J-W, Roy S. Recent Progress of Carrageenan-Based Composite Films in Active and Intelligent Food Packaging Applications. Polymers. 2024; 16(7):1001. https://doi.org/10.3390/polym16071001

Chicago/Turabian StyleKokkuvayil Ramadas, Bharath, Jong-Whan Rhim, and Swarup Roy. 2024. "Recent Progress of Carrageenan-Based Composite Films in Active and Intelligent Food Packaging Applications" Polymers 16, no. 7: 1001. https://doi.org/10.3390/polym16071001

APA StyleKokkuvayil Ramadas, B., Rhim, J.-W., & Roy, S. (2024). Recent Progress of Carrageenan-Based Composite Films in Active and Intelligent Food Packaging Applications. Polymers, 16(7), 1001. https://doi.org/10.3390/polym16071001