The Behaviour of Stratified Fabrics of Aramid Fibres under Stabbing Conditions

Abstract

1. Introduction

- Tests on usually smaller samples, which point out and rank the stabbing, puncture, or ballistic responses of the panels, without too closely mimicking the conditions of real attacks, such as tests on drop-test machines, where impact energy, velocity, and time can be accurately measured but do not realistically mimic the grip or support (materials are not close to body response) of panels;

- Tests according to the accepted standards for assessing stab resistance under conditions closer to reality;

- Tests required by the beneficiaries with different weapons or projectiles.

2. Materials and Methods

2.1. Materials

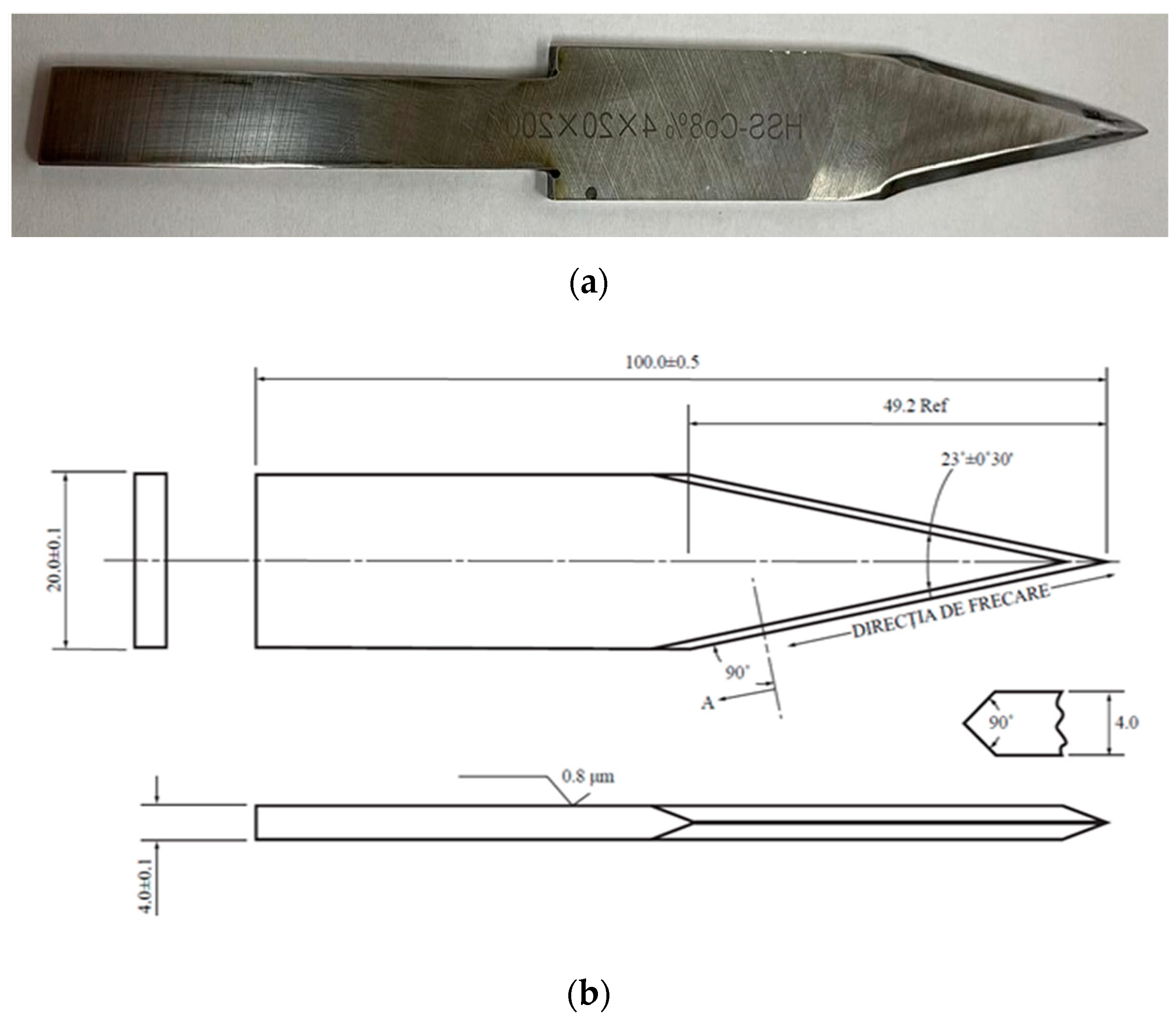

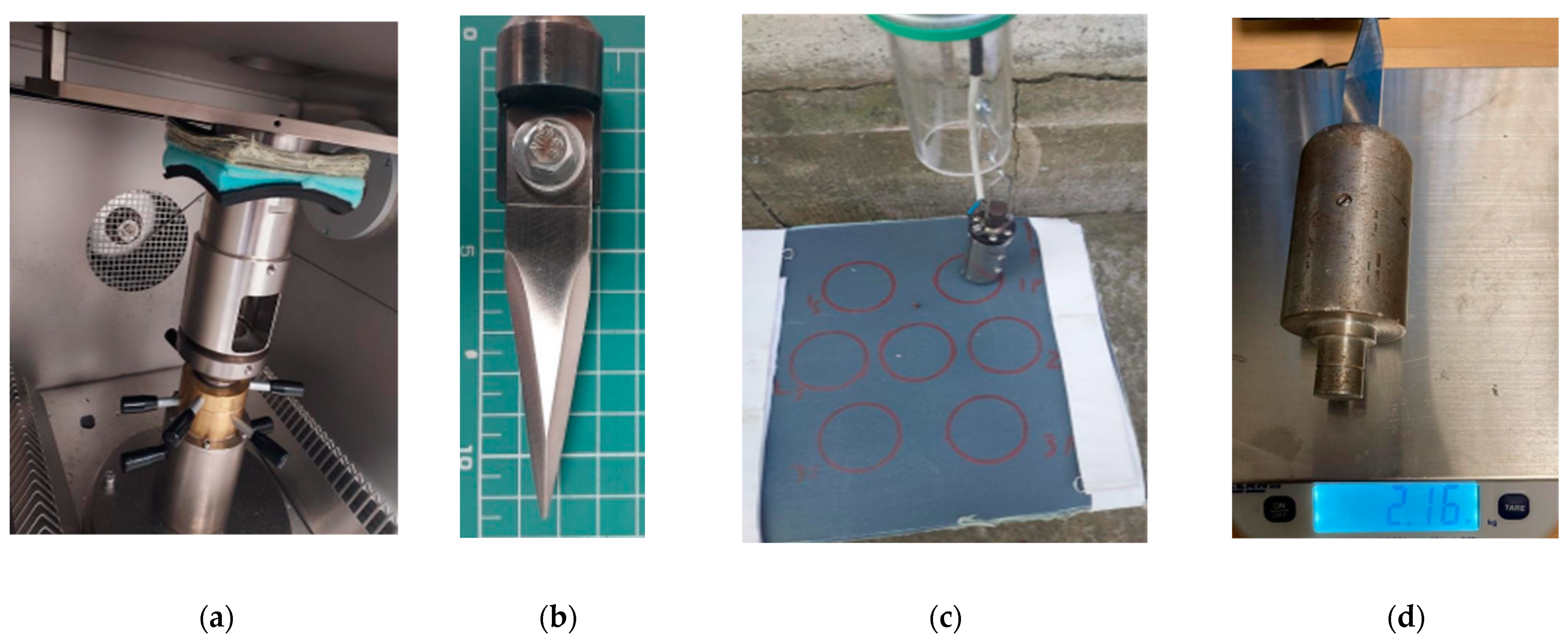

2.2. Methods

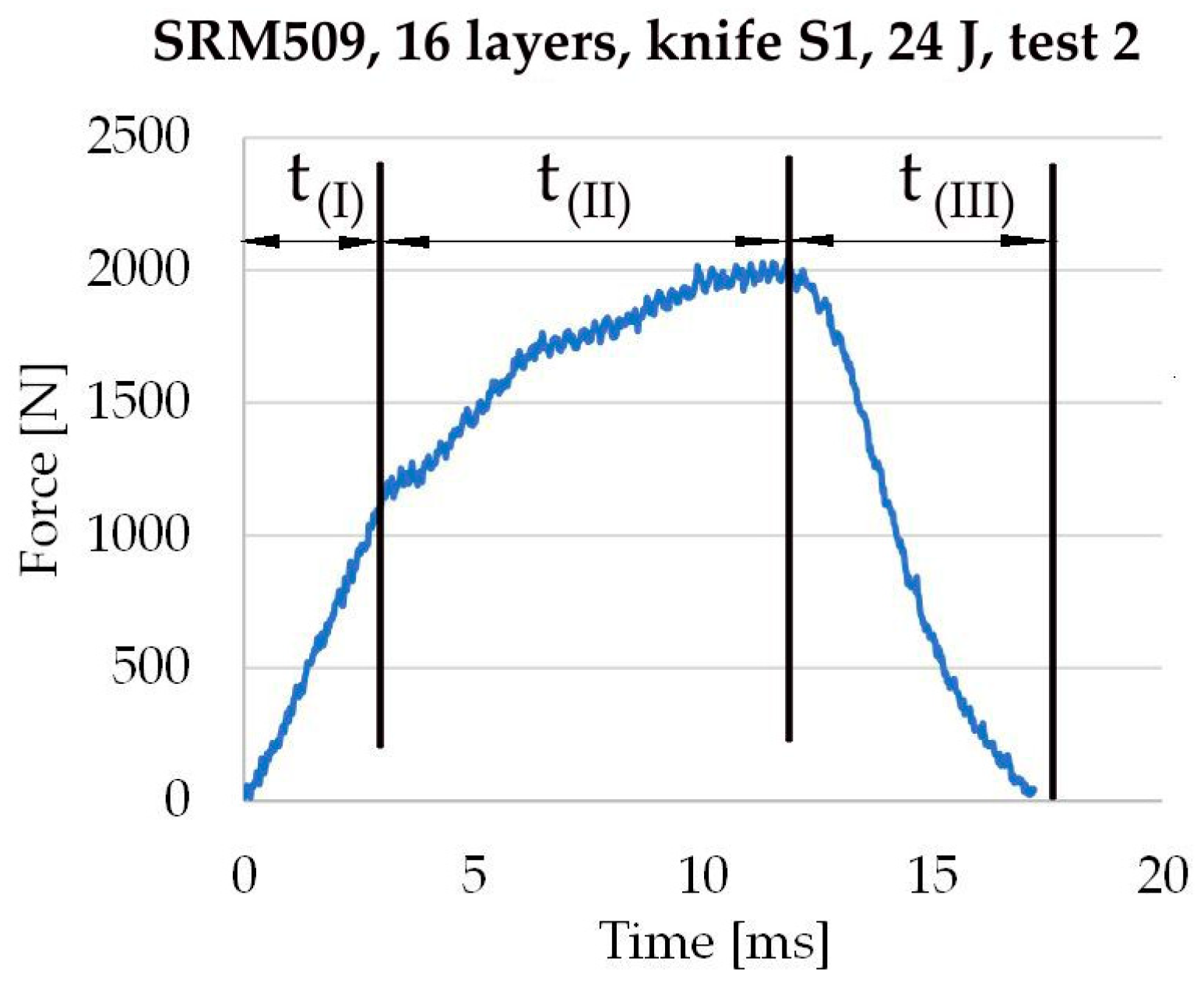

2.3. Data Analysis

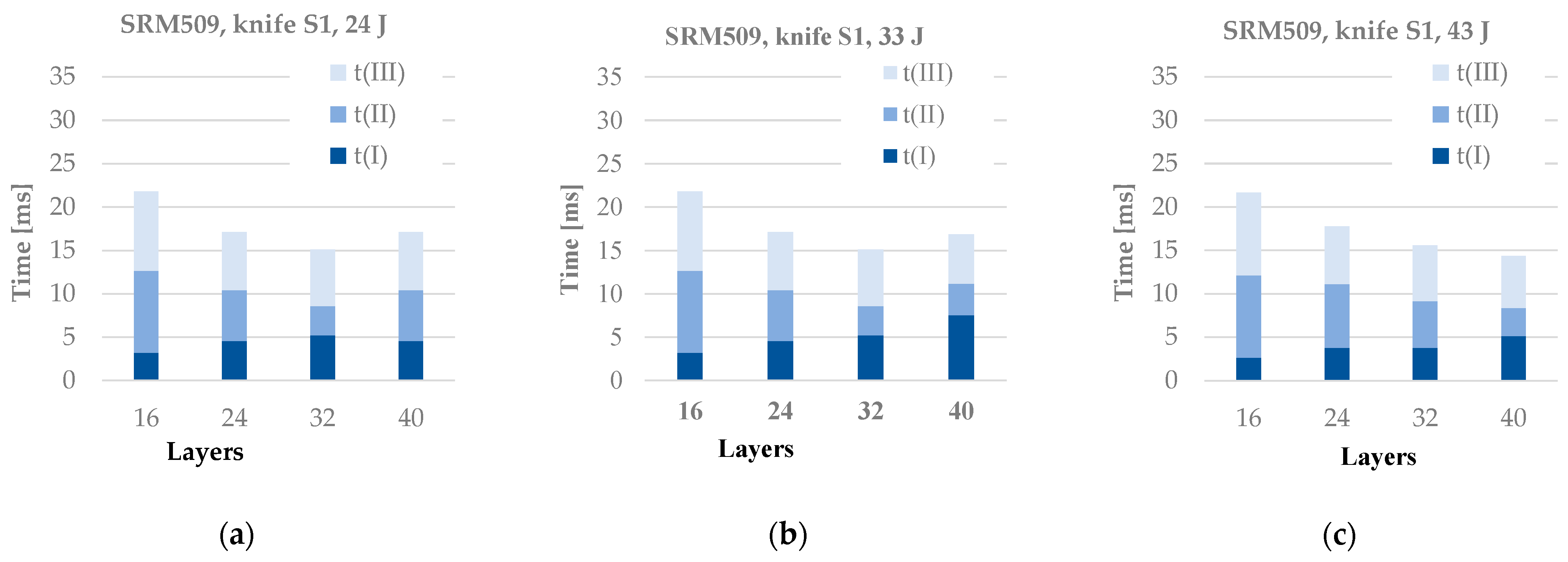

- Stage I: The force increases rapidly, apparently after a straight line;

- Stage II: A slope linking the first and last stage, usually with increasing force;

- Stage III: The force is decreasing to 0 (zero); the curve has the shape of a very narrow and high S.

- The initial point of the stabbing process, when t0 = 0 and F0 = 0, both values are considered null but are the last null value of the force in the string of (t, F) pairs. After this null value, the force is increasing (the force F oscillates around zero during the distance travelled until the blade tip hits the panel, so it is the moment of the last zero value of the force before it starts to increase).

- tf is the moment when the force F reaches the first zero value after the blade strike, so F(tf) = 0; thus, the stabbing process ends at this moment.

- Commercial threats:

- ○

- 7 mm at primary energy levels E1 (with values of 24 J, 33 J, and 43 J, respectively) for fair hits at incidence angles of 0° and 45°;

- ○

- 20 mm at overtest energy levels E2 for fair hits at angles of incidence of 0°.

- Improvised threats:

- ○

- 0 mm at E1 for fair hits at angles of incidence of 0° and 45°;

- ○

- 20 mm at E2 for fair hits at angles of incidence of 0°.

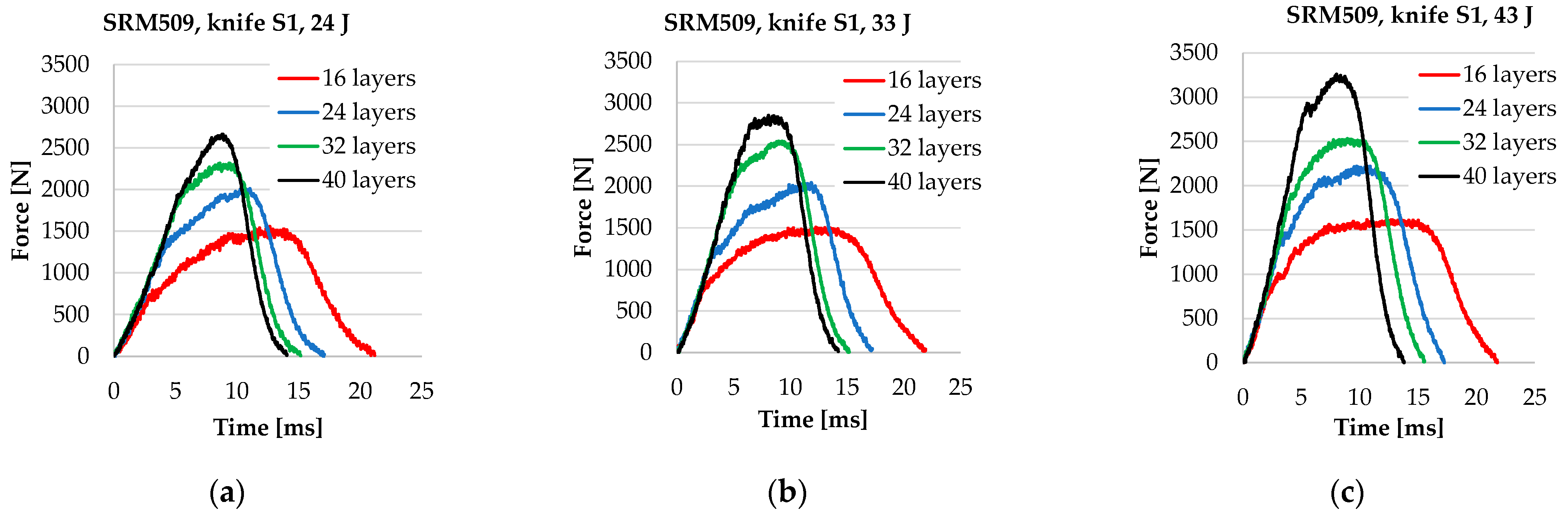

3. Discussion of the Test Results

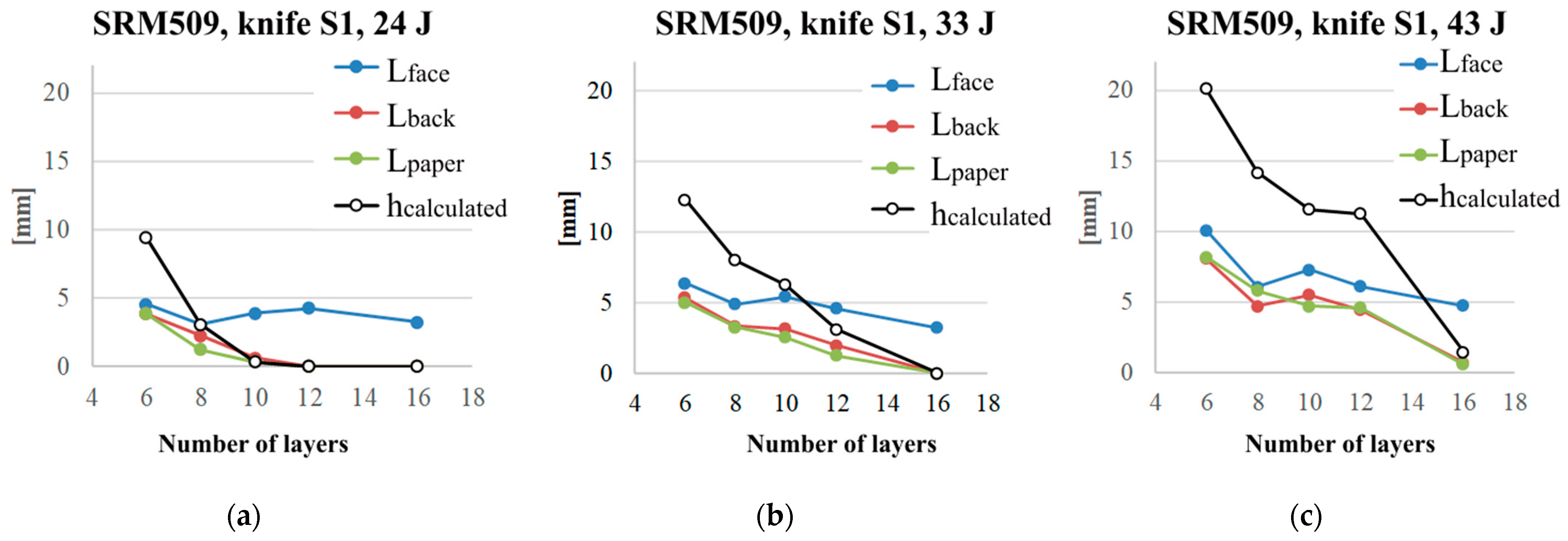

3.1. Data from Tests on Instron CEAST 9340 Machine

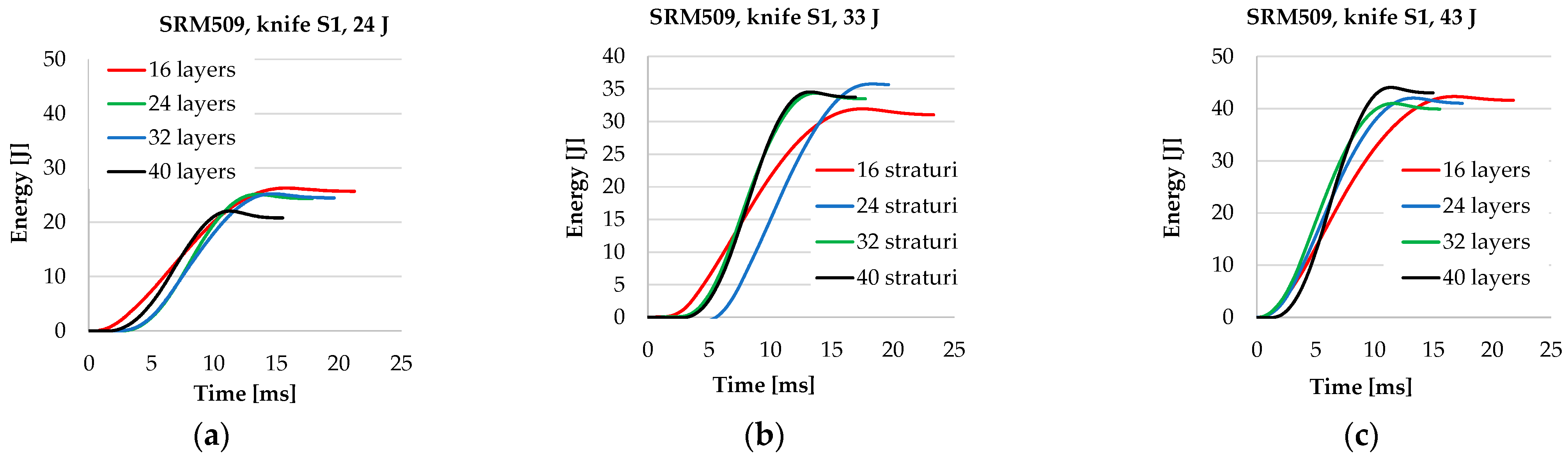

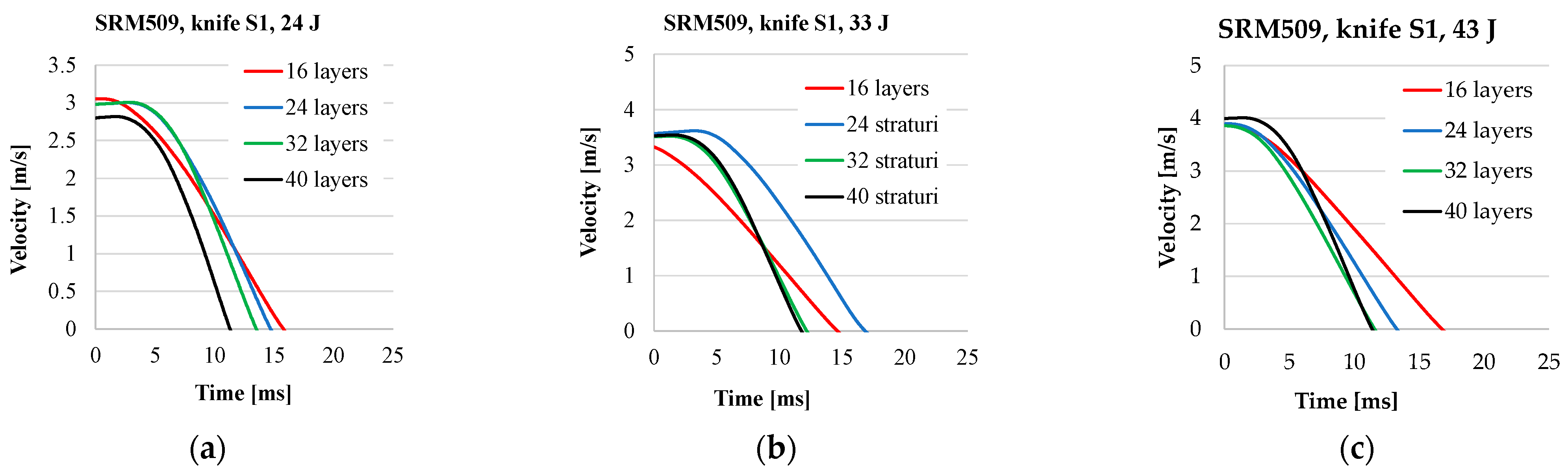

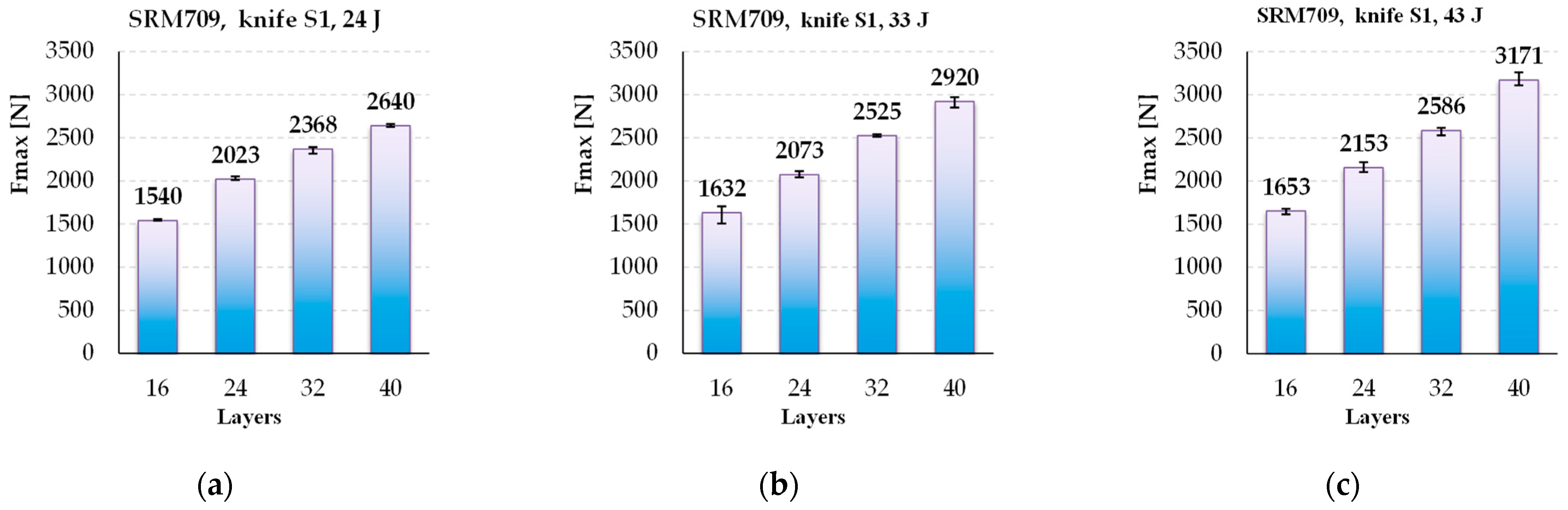

- The values for Fmax increase with the number of layers for the same striking energy;

- The first part of the curves is almost linear and overlap;

- Time of the stabbing process is decreasing when the number of layers increases;

- The stabbing time is less sensitive to the striking energy;

- The plateau characterising the second stage of the stabbing process becomes narrower when the number of layers increases because, for the thinner panels (16 layers), the failure of the layers unravels one by one, or at least in a larger time interval, with the panel being more flexible; for thicker panels, as they have a higher non-deflecting behaviour, the knife destroys them quicker.

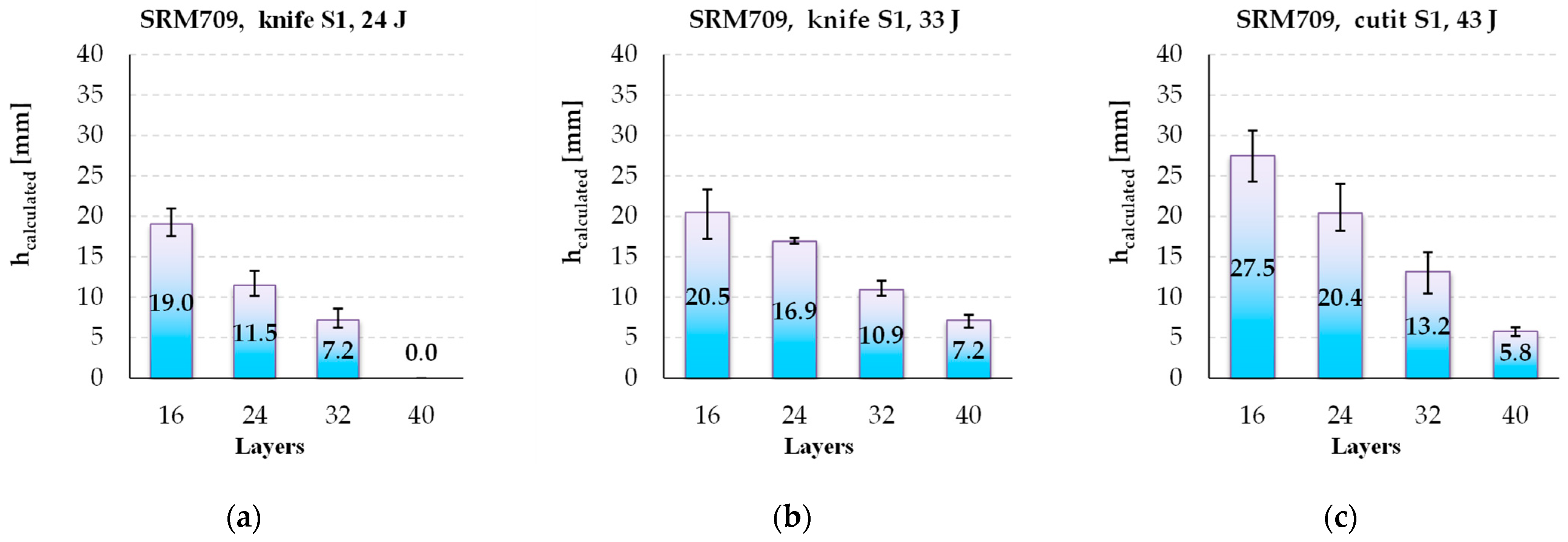

3.2. Data from Tests on Facility from the Center for Research and Innovation for CBRN Defense and Ecology (CRICBRNDE)

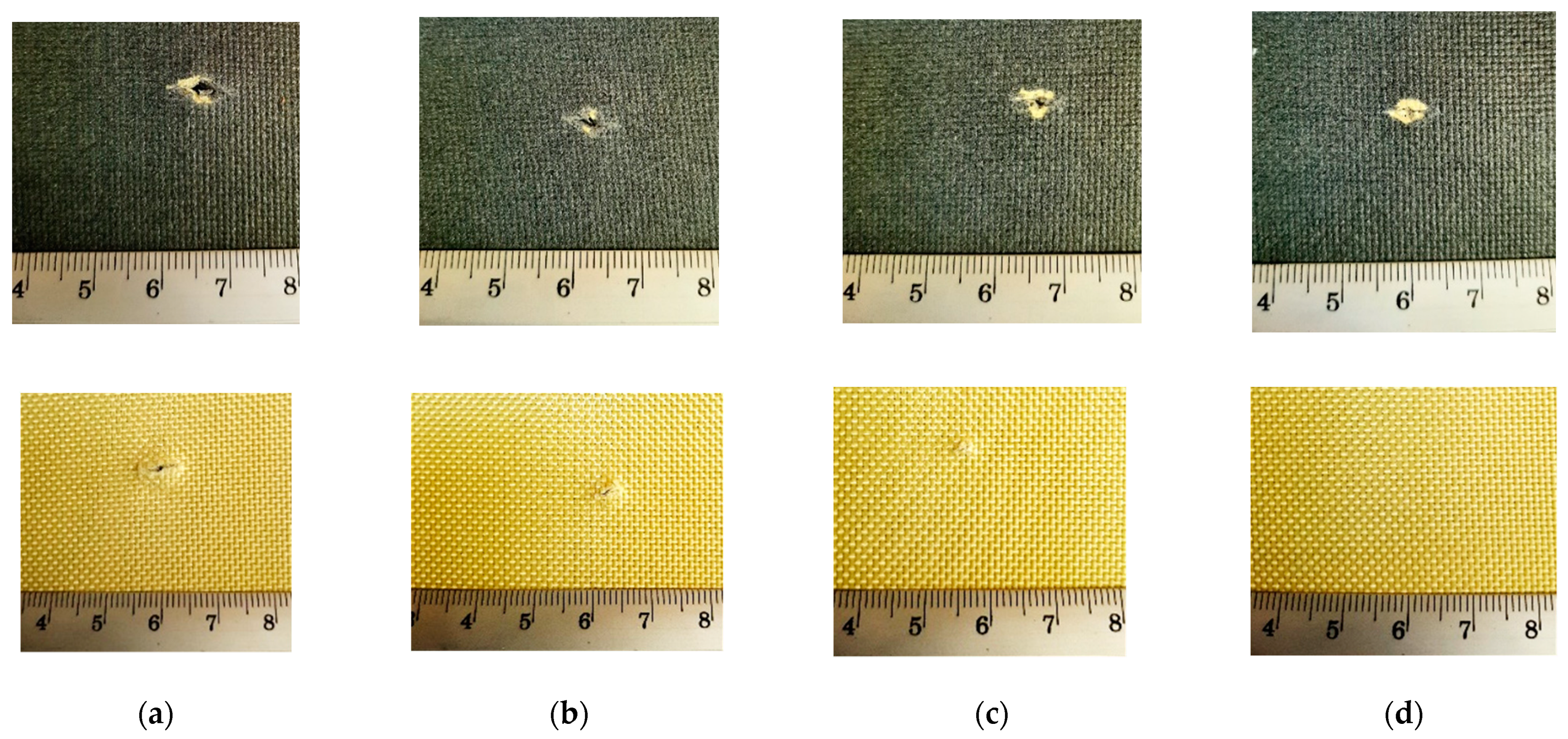

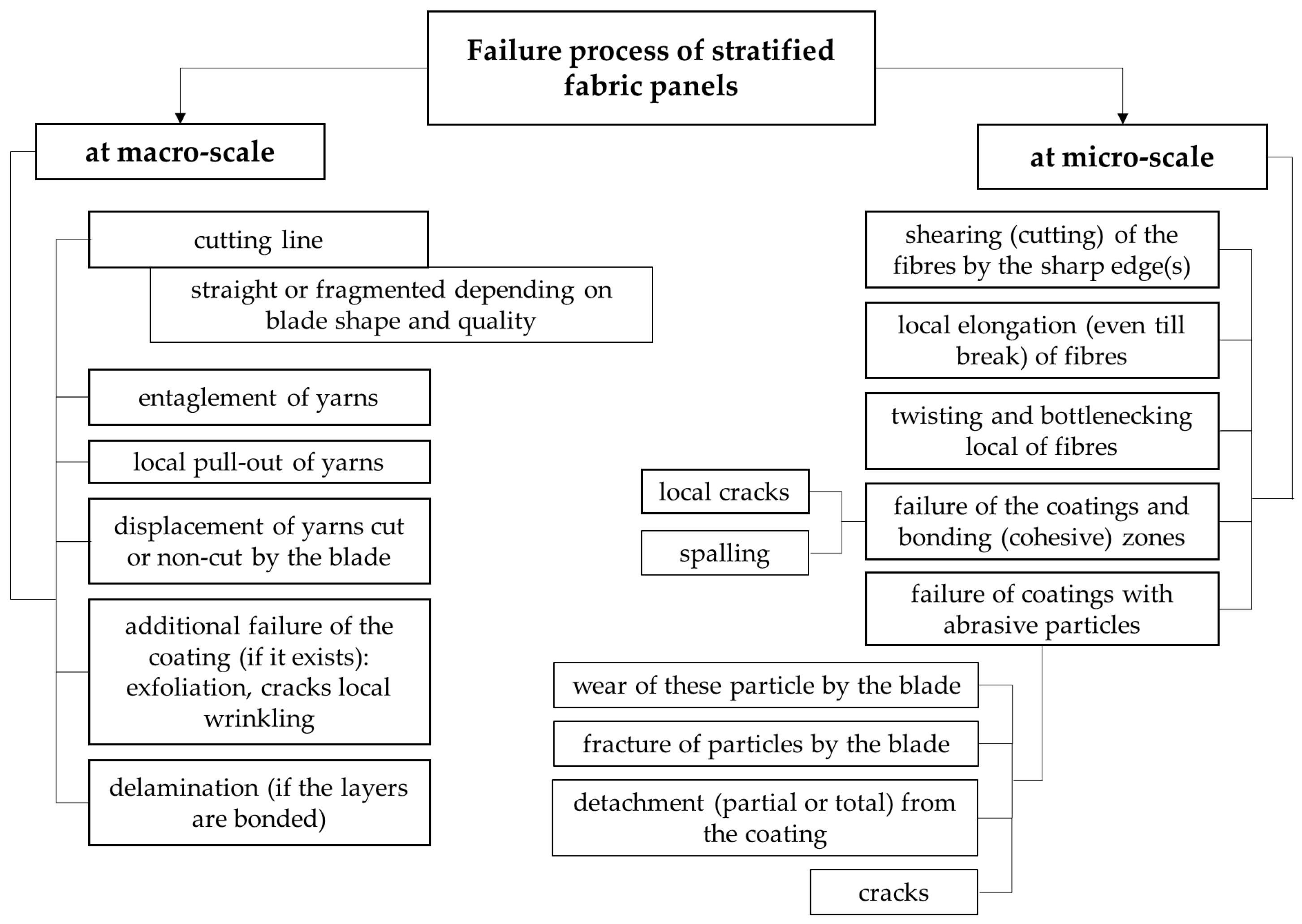

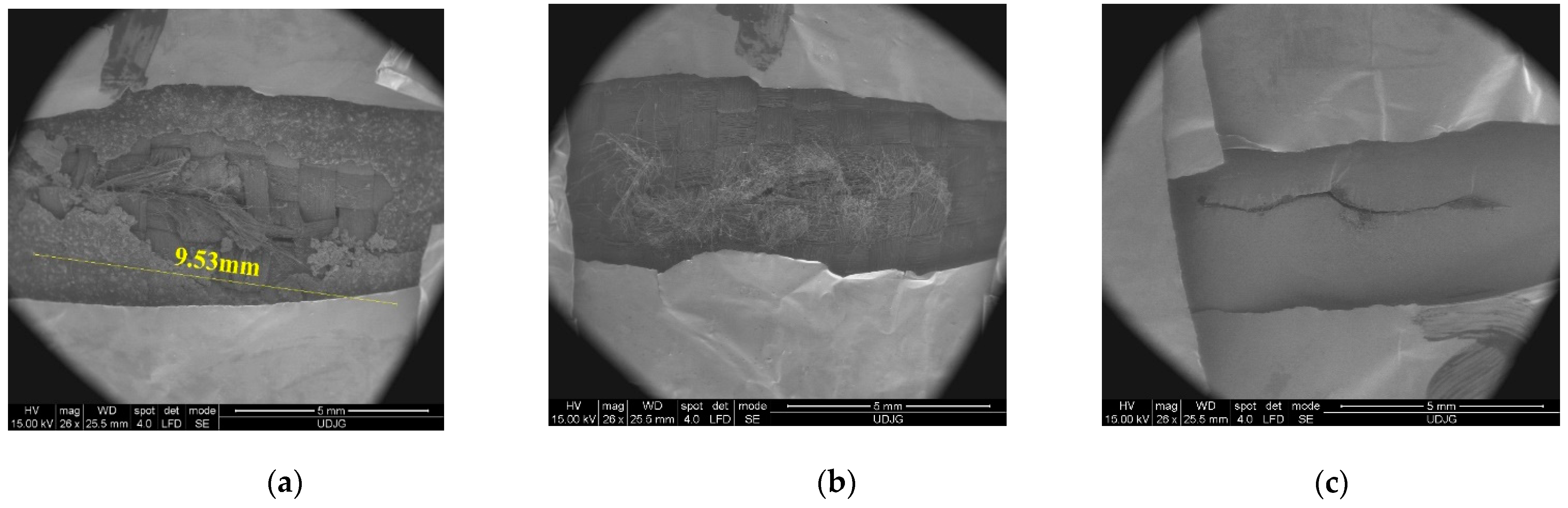

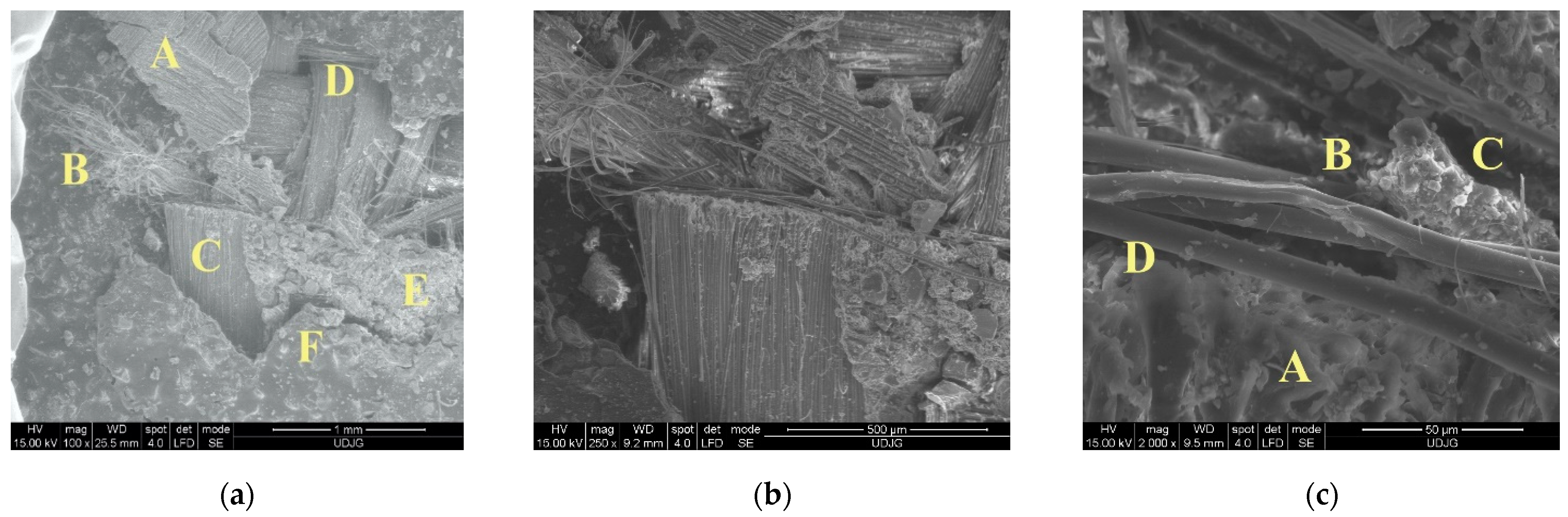

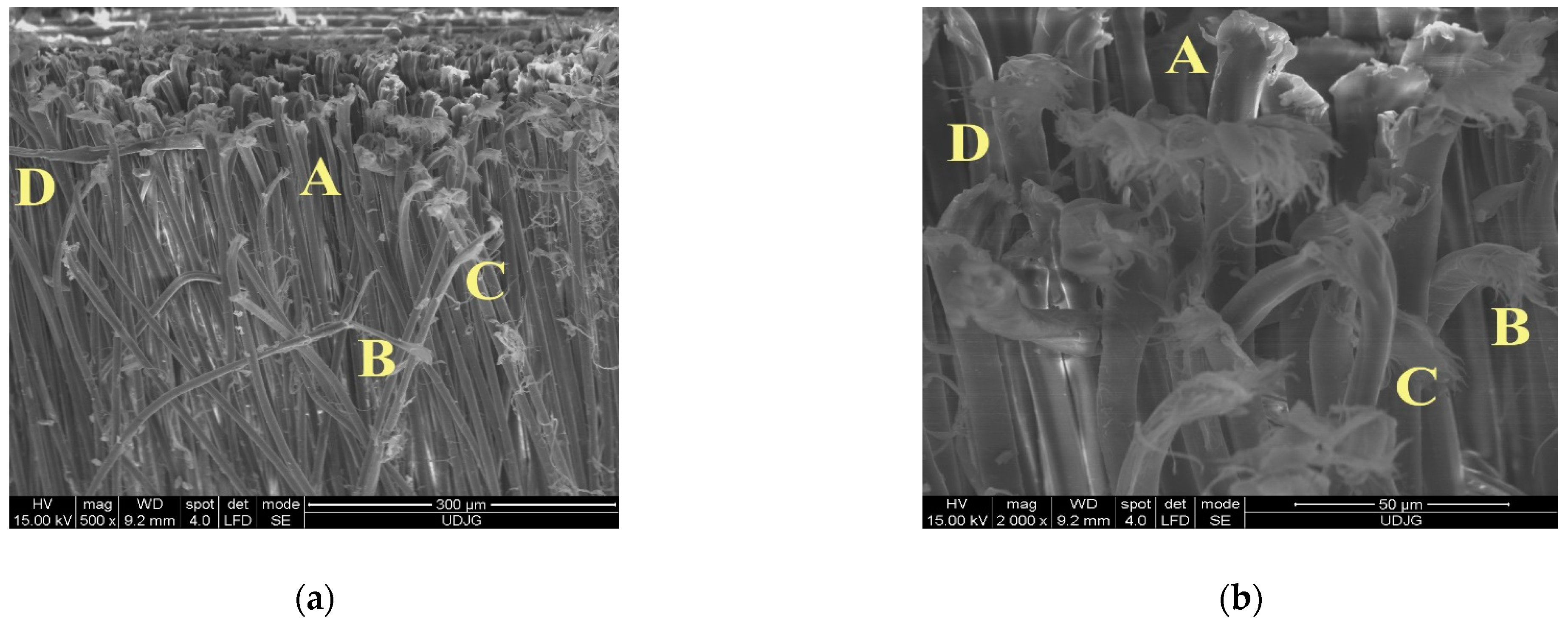

3.3. Stabbing Failure Mechanisms

- (a)

- Image of the left end of the cut: A—a rotated fragment of the abrasive coating because of the blade action, in which one may notice the shape of the fabric yarns; B—a bunch of fibre, cut at different lengths, in which their positions suggest a small rebound of the knife; C—a yarn perpendicular to the blade width, with fibres cut at the same length (like a guillotine); D—the yarn next to that in C is also cut, but the fibres are a little disordered, possibly because of the friction with the blade and because the blade tip displaces the yarn in its direction of movement: E—small fragments from the coating, with fibres still bonded to them, in which they could increase friction when the blade continues its displacement; F—fracture line of the abrasive coating;

- (b)

- A detail (×250) of yarn C from the previous image;

- (c)

- Failures: A—micro-fragments of the coating; B—a locally stretched (strangled) fibre because it was tensioned in traction, and its position is along the blade surface; C—another fragment from the coating; D—a fibre without visible damage but with very small fragments from fabric coating.

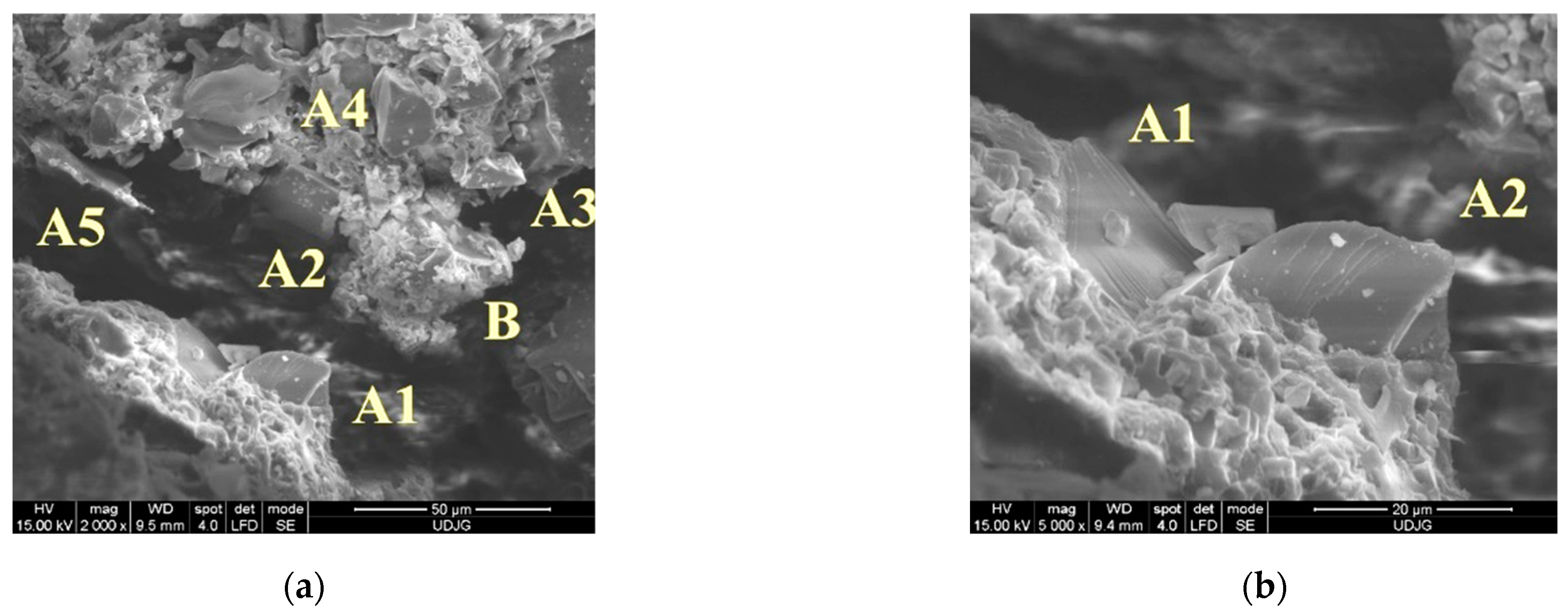

- (a)

- A—typically cut aramid fibres (the cut end of the fibre is like a nail head), B—a fibre that was broken after fibrillation meaning that it was also stretched and bent before breakage, C—fibre twisted with a thinner local section, and D—very rare failure for an aramid fibre consisting of flattening, meaning the main load was of a compressive nature;

- (b)

- Detail of the cut fibres: A—a neat sheared fibre, B—the end of this fibre is sheared but also bent, probably after being cut because of the friction with the steel body, C—fibre broken by stretching and shearing, with throttled areas and distinct fibrils indicating differences in the degree of crystallinity and/or micro defects in the fibrils, and D—sheared but blade driven fibre with a flattened area, revealing that the cutting edge attacks fibrils one by one but in a very short time.

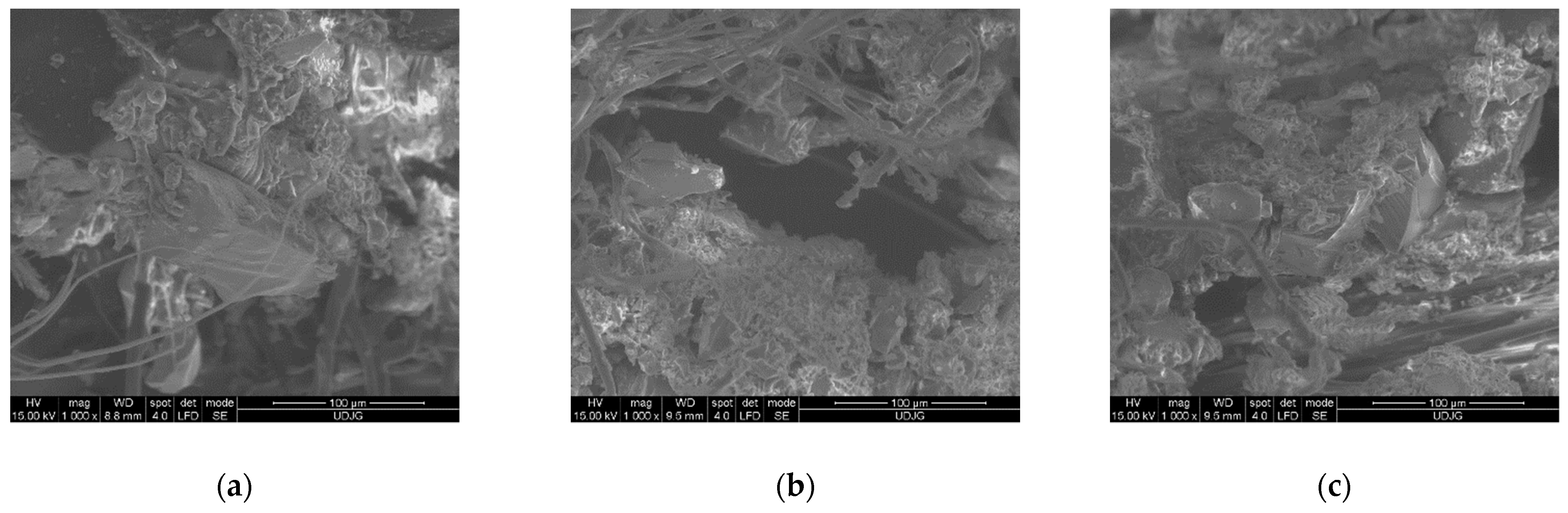

- (a)

- For the hard particle, partially detached from the matrix as its upper face still have traces of matrix it was embedded in, visible fibres are locally stretched, and their sharp ends suggest break by traction because they were tensioned before being cutting, when the last layers were pushed in the direction of knife movement;

- (b)

- Left end of the cut;

- (c)

- At a magnification of ×1000, with two hard particles at the right end of the cut, the bigger particle has marks of abrasion and a visible fracture line.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- El Messiry, M. Protective Armor Engineering Design; Apple Academic Press Inc.: Burlington, ON, Canada, 2020; p. 328. [Google Scholar]

- Bilisik, K. Impact-resistant fabrics (ballistic/stabbing/slashing/spike). In Engineering of High-Performance Textiles; Miao, M., Xin, J.H., Eds.; Woodhead Publishing, Elsevier: Cambridge, MA, USA, 2018; p. 377. [Google Scholar]

- Arciszewski, T.; Cornell, J. Bio-inspiration: Learning creative design principia. In Intelligent Computing in Engineering and Architecture; Cornell, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 32–53. [Google Scholar]

- Chen, I.H.; Yang, W.; Meyers, M.A. Alligator osteoderms: Mechanical behavior and hierarchical structure. Mater. Sci. Eng. C 2014, 35, 441–448. [Google Scholar] [CrossRef]

- Chen, I.H.; Kiang, J.H.; Correa, V.; Lopez, M.I.; Chen, P.Y.; Mckittrick, J.; Meyers, M.A. Armadillo armor: Mechanical testing and micro-structural evaluation. J. Mech. Behav. Biomed. Mater. 2011, 4, 713–722. [Google Scholar] [CrossRef] [PubMed]

- Ghazlan, A.; Ngo, T.; Tan, P.; Xie, Y.M.; Tran, P.; Donough, M. Inspiration from Nature’s body armours—A review of biological and bioinspired composites. Compos. Part B Eng. 2021, 205, 108513. [Google Scholar] [CrossRef]

- Liu, Q.; Mao, H.; Niu, L.; Chen, F.; Ma, P. Excellent flexibility and stab-resistance on pangolin-inspired scale-like structure composite for versatile protection. Compos. Commun. 2022, 35, 101266. [Google Scholar] [CrossRef]

- Martini, R.; Barthelat, F. Stability of hard plates on soft substrates and application to the design of bioinspired segmented armor. J. Mech. Phys. Solids 2016, 92, 195–209. [Google Scholar] [CrossRef]

- Yang, W.; Gludovatz, B.; Zimmermann, E.A.; Bale, H.A.; Ritchie, R.O.; Meyers, M.A. Structure and fracture resistance of alligator gar (Atractosteus spatula) armored fish scales. Acta Biomater. 2013, 9, 5876. [Google Scholar] [CrossRef]

- Panneke, N.; Ehrmann, A. Stab-Resistant Polymers—Recent Developments in Materials and Structures. Polymers 2023, 15, 983. [Google Scholar] [CrossRef] [PubMed]

- Chintapalli, R.K.; Mirkhalaf, M.; Dastjerdi, A.K.; Barthelat, F. Fabrication, testing and modeling of a new flexible armor inspired from natural fish scales and osteoderms. Bioinspiration Biomim. 2014, 9, 036005. [Google Scholar] [CrossRef]

- Connors, M.; Yang, T.; Hosny, A.; Deng, Z.; Yazdandoost, F.; Massaadi, H.; Eernisse, D.; Mirzaeifar, R.; Dean, M.N.; Weaver, J.C.; et al. Bioinspired design of flexible armor based on chiton scales. Nat. Commun. 2019, 10, 5413. [Google Scholar] [CrossRef]

- Martini, R.; Balit, Y.; Barthelat, F. A comparative study of bio-inspired protective scales using 3D printing and mechanical testing. Acta Biomater. 2017, 55, 360–372. [Google Scholar] [CrossRef]

- He, Q.; Cao, S.; Wang, Y.; Xuan, S.; Wang, P.; Gong, X. Impact resistance of shear thickening fluid/Kevlar composite treated with shear-stiffening gel. Compos. Part A Appl. Sci. Manuf. 2018, 106, 82–90. [Google Scholar] [CrossRef]

- Dong, J.; Liu, X.; Yu, W. Determination about geometry of stab-resistant resin flakes on surface of fabric. J. Text. Res. 2017, 38, 60–64. [Google Scholar]

- Guo, Y.X.; Yuan, M.Q.; Qian, X.M. Bionic stab-resistant body armor based on triangular pyramid structure. Def. Technol. 2021, 17, 792–799. [Google Scholar] [CrossRef]

- Guo, Y.; Yuan, M.; Qian, X.; Wei, Y.; Liu, Y. Rapid prediction of polymer stab resistance performance. Mater. Des. 2020, 192, 108721. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B.; Khorasani, M.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Maidin, S.; Chong, S.Y.; Heing, T.K.; Abdullah, Z.; Alkahari, R. Stab resistant analysis of body armour design features manufactured via fused deposition modelling process. In Textile Manufacturing Processes; Uddin, F., Ed.; IntechOpen: London, UK, 2019; pp. 69–83. [Google Scholar]

- Islam, M.K.; Hazell, P.J.; Escobedo, J.P.; Wang, H. Biomimetic armour design strategies for additive manufacturing: A review. Mater. Des. 2021, 205, 109730. [Google Scholar] [CrossRef]

- Zhang, X.; Li, T.T.; Wang, Y.; Shiu, B.C.; Peng, H.K.; Lou, C.W.; Lin, J.H. Hydrogel with high toughness and strength for fabricating high-performance stab-resistant aramid composite fabric. J. Mater. Res. Technol. 2021, 15, 1630–1641. [Google Scholar] [CrossRef]

- Zhang, X.; Li, T.T.; Wang, Z.; Peng, H.K.; Lou, C.W.; Lin, J.H. Facile fabrication and mass production of TPU/Silica/STF coated aramid fabric with excellent flexibility and quasi-static stab resistance for versatile protection. Prog. Org. Coat. 2021, 151, 106088. [Google Scholar] [CrossRef]

- Li, D.; Wang, R.; Guan, F.; Zhu, Y.; You, F. Enhancement of the quasi-static stab resistance of Kevlar fabrics impregnated with shear thickening fluid. J. Mater. Res. Technol. 2022, 18, 3673–3683. [Google Scholar] [CrossRef]

- Dong, J. Structure Design and Protective Performance of the Stab-Resistant Fabric. Ph.D. Thesis, Donghua University, Shanghai, China, 2018. [Google Scholar]

- Bingham, G.A. Revolving Investment Fund for Research: Stab-Resistant RM Textile Structures; De Montfort University: Leicester, UK, 2010. [Google Scholar]

- Deora, P.S.; Khurana, M.; Muhal, R.A.; Upadhyay, D.; Goswami, C. A review on fibrous materials for body armor application. Mater. Today Proc. 2022, 60, 2230–2235. [Google Scholar] [CrossRef]

- Govarthanam, K.K.; Anand, S.; Rajendran, S. Development of advanced personal protective equipment fabrics for protection against slashes and pathogenic bacteria part 1: Development and evaluation of slash-resistant garments. J. Ind. Text. 2010, 40, 23–26. [Google Scholar] [CrossRef]

- Khuyen, N.Q.; Han, P.V.D.; Nguyen, N.T.; Le, Q.B.; Harjo, M.; Anbarjafari, G.; Kiefer, R.; Tamm, T. The Use of Laminates of Commercially Available Fabrics for Anti-Stab Body-Armor. Polymers 2021, 13, 1077. [Google Scholar] [CrossRef]

- Kim, H.; Nam, I. (). Stab resisting behavior of polymeric resin reinforced p-aramid fabrics. J. Appl. Polym. Sci. 2012, 123, 2733–2742. [Google Scholar] [CrossRef]

- Häsä, R.; Pinho, S.T. Bio-inspired armour: CFRP with scales for perforation resistance. Mater. Lett. 2020, 273, 127966. [Google Scholar] [CrossRef]

- Amirshirzad, F.; Ezazshahabi, N.; Mousazadegan, F. Assessment of the knife penetration resistance of single and double-layer metal reinforced fabrics. Forensic Sci. Int. 2021, 318, 110629. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Zhang, S.; Liu, S.; Cao, S.; Wang, S.; Bai, L.; Sang, M.; Xuan, S.; Jiamg, W.; Gong, X. CNT/STF/Kevlar-based wearable electronic textile with excellent anti-impact and sensing performance. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105612. [Google Scholar] [CrossRef]

- Wu, R.; Mudzi, P.; Firouzi, D.; Ching, C.Y.; Selvaganapathy, P.R. Development of high-performance hypodermic needle penetration resistance flexible cotton fabric using patterned thermoplastic adhesive film. Mater. Today Commun. 2022, 33, 104444. [Google Scholar] [CrossRef]

- Cai, F.; Gao, S.; Bao, Y.; Sun, J.; Si, Y.; Fu, Y. Robust 3D-trapezoid composite fabric withstanding repeat impact/compression for personal protection. Compos. Struct. 2021, 273, 114333. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, X.; Yu, W. Preparation and stab-resistant mechanism of coated stab-resistant fabric. J. Text. Res. 2018, 39, 108–113. [Google Scholar] [CrossRef]

- Manaee, P.; Valefi, Z.; Goodarz, M. The effect of bond coat type on the stab resistance of Al2O3–13 wt% TiO2 plasma sprayed ceramic coating on aramid fabrics. Surf. Interfaces 2020, 18, 100432. [Google Scholar] [CrossRef]

- Rodríguez-Millán, M.; Díaz-Álvarez, A.; Aranda-Ruiz, J.; Díaz-Álvarez, J.; Loya, J.A. Experimental analysis for stabbing resistance of different aramid composite architectures. Compos. Struct. 2019, 208, 525–534. [Google Scholar] [CrossRef]

- Moure, M.M.; Feito, N.; Aranda-Ruiz, J.; Loya, J.A.; Rodriguez-Millan, M. On the characterization and modelling of high-performance para-aramid Fabrics. Compos. Struct. 2019, 212, 326–337. [Google Scholar] [CrossRef]

- Şahin, K.; Clawson, J.K.; Singletary, J.; Chasiotis, I. Shear strength of homopolymer and copolymer aramid fibers. Polymer 2020, 186, 122034. [Google Scholar] [CrossRef]

- Crouch, I.G. Introduction to armour materials. In The Science of Armour Materials; Woodhead Publishing, Elsevier: Cambridge, MA, USA, 2017; pp. 1–54. [Google Scholar]

- Crouch, I.G.; Sandlin, J.; Thomas, S. Polymers and fibre-reinforced plastics. In The Science of Armour Materials; Woodhead Publishing, Elsevier: Cambridge, MA, USA, 2017; pp. 203–268. [Google Scholar]

- Abtew, M.A.; Boussu, F.; Bruniaux, P. Dynamic impact protective body armour: A comprehensive appraisal on panel engineering design and its prospective materials. Def. Technol. 2021, 17, 2027–2049. [Google Scholar] [CrossRef]

- Li, D.X. Cut Protective Textiles; Woodhead Publishing, Elsevier: Cambridge, MA, USA, 2020. [Google Scholar]

- Moure, M.M.; Rubio, I.; Aranda-Ruiz, J.; Loya, J.A.; Rodríguez-Millán, M. Analysis of impact energy absorption by lightweight aramid structures. Compos. Struct. 2018, 203, 917–926. [Google Scholar] [CrossRef]

- Chen, X. Introduction. In Advanced Fibrous Composite Materials for Ballistic Protection; Chen, X., Ed.; Woodhead Publishing, Elsevier: Cambridge, MA USA, 2016; pp. 1–9. [Google Scholar]

- Pîrvu, C.; Deleanu, L. Failure Investigation of Layered LFT SB1plus Package after Ballistic Tests for Level IIA. Polymers 2021, 13, 2912. [Google Scholar] [CrossRef]

- Rebouillat, S. ARAMIDS: ‘Disruptive’, open and continuous innovation 2. In Advanced Fibrous Composite Materials for Ballistic Protection; Chen, X., Ed.; Woodhead Publishing, Elsevier: Cambridge, MA, USA, 2016; pp. 11–70. [Google Scholar]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Ballistic impact mechanisms–a review on textiles and fibre-reinforced composites impact responses. Compos. Struct. 2019, 223, 110966. [Google Scholar] [CrossRef]

- Croft, J.; Longhurst, D. HOSDB Body Armour Standards for UK Police. Part 3: Knife and Spike Resistance—39/07/C; Home Office: London, UK, 2007. [Google Scholar]

- El Messiry, M.; Eltahan, E. Stab resistance of triaxial woven fabrics for soft body armor. J. Ind. Text. 2016, 45, 1062–1082. [Google Scholar] [CrossRef]

- Cronin, J.; Kinsler, R.; Allen, J. Testing of armor systems. In Lightweight Ballistic Composites. Military and Law-Enforcement Applications, 2nd ed.; Bhatnagar, A., Ed.; Woodhead Publishing, Elsevier: Cambridge, MA, USA, 2016; pp. 311–326. [Google Scholar]

- National Research Council. 2011 Opportunities in Protection Materials Science and Technology for Future Army Applications; The National Academies Press: Washington, DC, USA, 2011. [Google Scholar] [CrossRef]

- Ojoc, G.G.; Pirvu, C.; Sandu, S.; Deleanu, L. Standardization in testing ballistic protection systems. In Proceedings of the International Conference on Tribology (ROTRIB’19), IOP Conference Series: Materials Science and Engineering, Cluj-Napoca, Romania, 19–21 September 2019; Volume 724. [Google Scholar] [CrossRef]

- National Institute of Justice. NIJ Standard 0115.00 Stab Resistance of Body Armor. Available online: https://www.ojp.gov/pdffiles1/nij/183652.pdf (accessed on 1 March 2022).

- National Institute of Justice. NIJ Standard 0115.01. Stab Resistance of Personal Body Armor (Draft for Public Comment). 2000. Available online: https://nij.ojp.gov/sites/g/files/xyckuh171/files/media/document/nij-standard-0115-01-stab-resistance-of-body-armor-draft-for-public-comment.pdf (accessed on 22 August 2023).

- Catalog Teijin Ballistics Material Handbook, QMB1.1-20181001EN. Available online: https://www.scribd.com/document/680870996/Teijin-Aramid-Ballistic-Handbook (accessed on 12 January 2024).

- Catalog Teijin Ballistics Material Handbook; Twaron®. The Power of Aramid, 38-14-05/2012. Available online: https://pdf.directindustry.com/pdf/teijin-aramid/ballistics-material-handbook1/18087-309131.html (accessed on 12 January 2024).

- BO1 (BS4659) Product Datasheet. Available online: https://www.smithmetal.com/bo1-tool-steel.htm (accessed on 10 February 2024).

- Tien, D.T.; Kim, J.S.; Huh, Y. Stab-resistant Property of the Fabrics Woven with the Aramid/Cotton Core-spun Yarns. Fibers Polym. 2010, 11, 500–506. [Google Scholar] [CrossRef]

- Termonia, Y. Puncture resistance of fibrous structures. Int. J. Impact Eng. 2006, 32, 1512–1520. [Google Scholar] [CrossRef]

- Nolan, G.; Hainsworth, S.V.; Rutty, G.N. Forces generated in stabbing attacks: An evaluation of the utility of the mild, moderate and severe scale. Int. J. Legal Med. 2018, 132, 229–236. [Google Scholar] [CrossRef]

- Carr, D.J.; Wainwright, A. Variability of simulants used in recreating stab events. Forensic Sci. Int. 2011, 210, 42–46. [Google Scholar] [CrossRef] [PubMed]

- Kantor, M.; Lewinski, W.J.; Reiner, S.; Pettitt, R. The performance during four stationary knife attacks: Implications for tactical training. Forensic Sci. Int. 2022, 337, 111371. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Gu, C.; Liu, N.; He, Y.; Du, Z. Cut resistant characteristic of weft plain-knitted structure for protective clothing. Int. J. Clothing Sci. Technol. 2021, 33, 35–46. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | W | V | Cr |

|---|---|---|---|---|---|---|

| Wt% | 0.85–1.0 | 1.10–1.35 | 0.40 | 0.40–0.60 | Max 0.25 | 0.40–0.60 |

| Component | Characteristics | Supplier from Romania |

|---|---|---|

| Sponge plate | 25 kg/m3, type HR, pressure strength 2000 kPa, 8 mm thickness | Intex Conect SRL Giurgiu |

| Soft polymeric foam | 35 kg/m3 density, type HR, pressure strength 2500 kPa, 30 mm | Intex Conect SRL, Giurgiu, Romania |

| SBR rubber technical board—general purpose rubber, without textile insert, working temperature: −30 °C to +70 °C | 6 mm thickness, smooth, black, 1400 mm width, hardness 65 ± 5° Shore A, 6 mm thickness | SC Arte Rubber Distribution SRL, Târgu Jiu, Romania |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deleanu, L.; Totolici Rusu, V.; Ojoc, G.G.; Cristea, G.C.; Boțan, M.; Vasiliu, A.V.; Popescu, C. The Behaviour of Stratified Fabrics of Aramid Fibres under Stabbing Conditions. Polymers 2024, 16, 882. https://doi.org/10.3390/polym16070882

Deleanu L, Totolici Rusu V, Ojoc GG, Cristea GC, Boțan M, Vasiliu AV, Popescu C. The Behaviour of Stratified Fabrics of Aramid Fibres under Stabbing Conditions. Polymers. 2024; 16(7):882. https://doi.org/10.3390/polym16070882

Chicago/Turabian StyleDeleanu, Lorena, Viorel Totolici Rusu, George Ghiocel Ojoc, George Catalin Cristea, Mihail Boțan, Alexandru Viorel Vasiliu, and Christian Popescu. 2024. "The Behaviour of Stratified Fabrics of Aramid Fibres under Stabbing Conditions" Polymers 16, no. 7: 882. https://doi.org/10.3390/polym16070882

APA StyleDeleanu, L., Totolici Rusu, V., Ojoc, G. G., Cristea, G. C., Boțan, M., Vasiliu, A. V., & Popescu, C. (2024). The Behaviour of Stratified Fabrics of Aramid Fibres under Stabbing Conditions. Polymers, 16(7), 882. https://doi.org/10.3390/polym16070882