Characterization and Simulation of the Interface between a Continuous and Discontinuous Carbon Fiber Reinforced Thermoplastic by Using the Climbing Drum Peel Test Considering Humidity

Abstract

1. Introduction

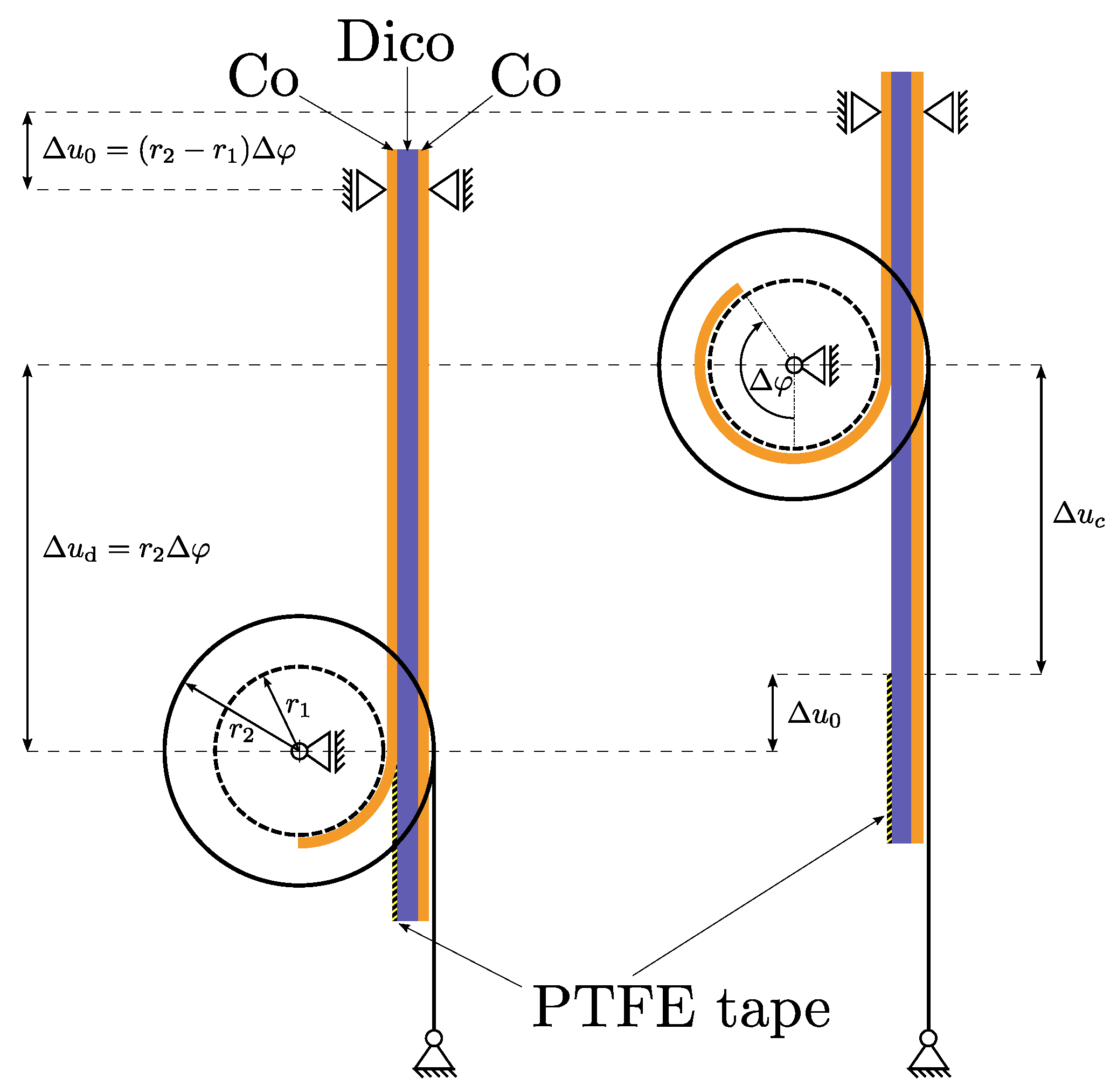

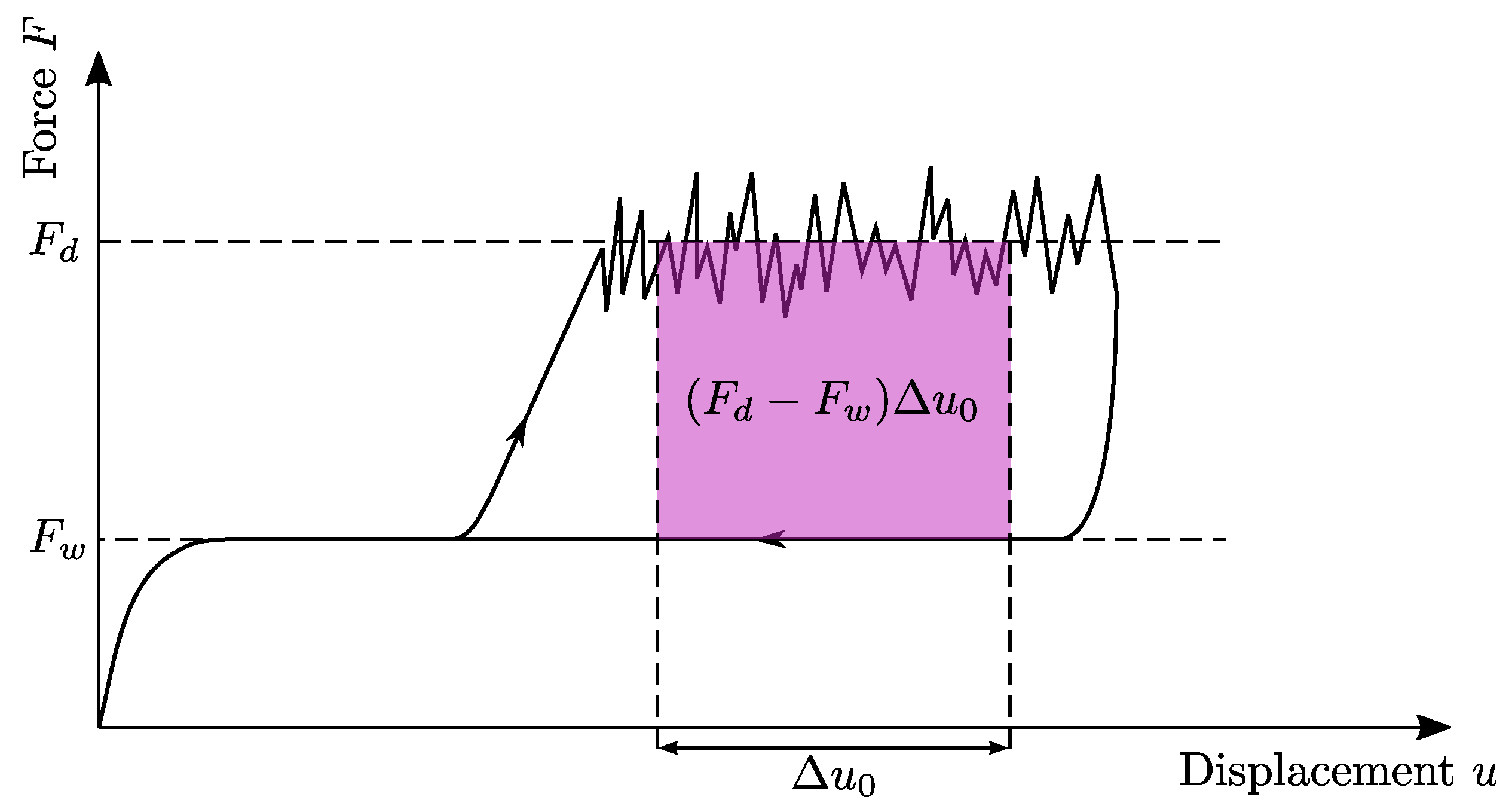

2. Climbing Drum Peel Test

- the radius of the drum needs to be large enough,

- the peel arm needs to be flexible,

- the winding forces need to be large,

3. Materials and Methods

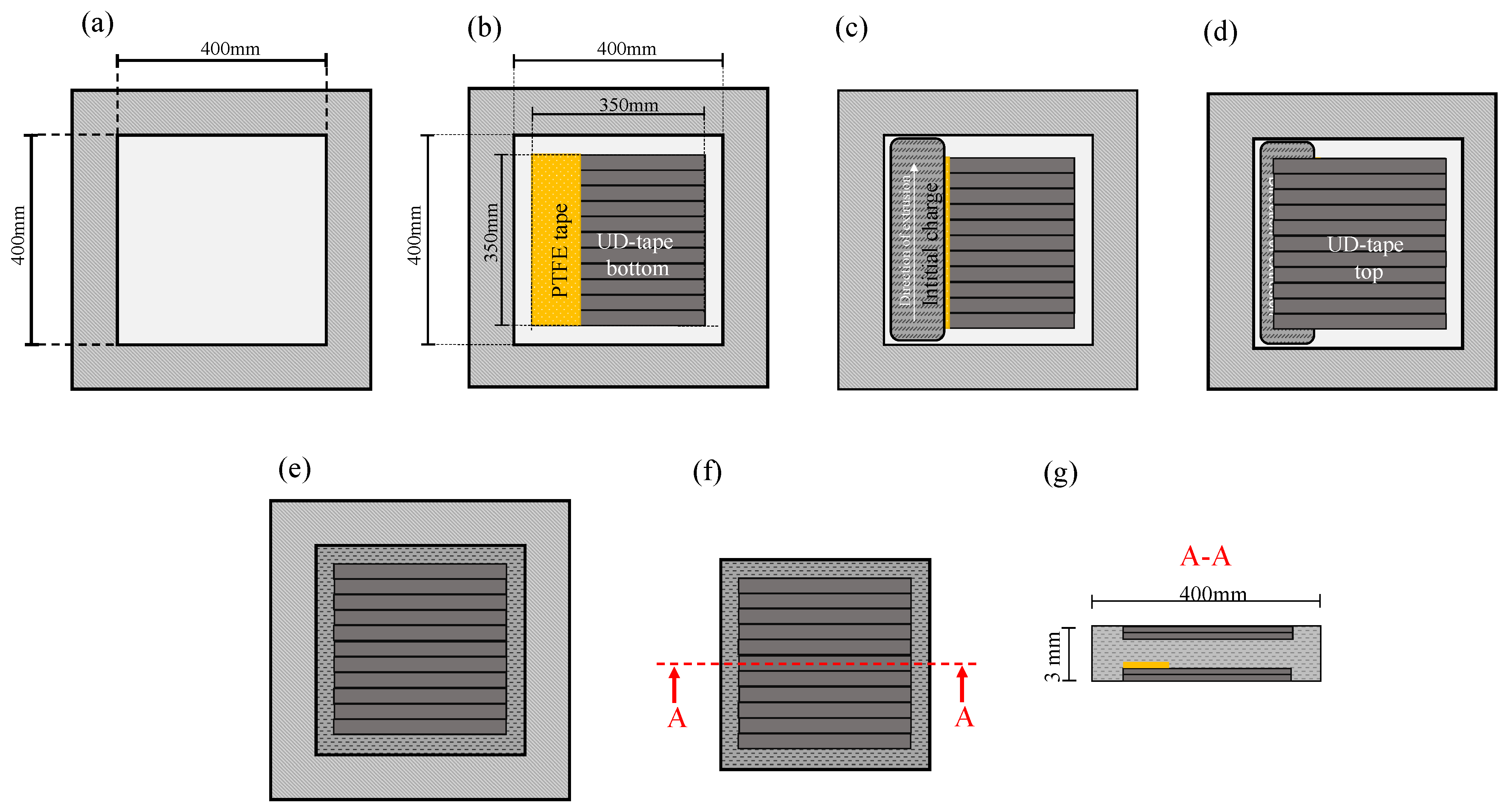

3.1. Production of Semi-Finished Materials and Plates

3.2. Specimen Preparation

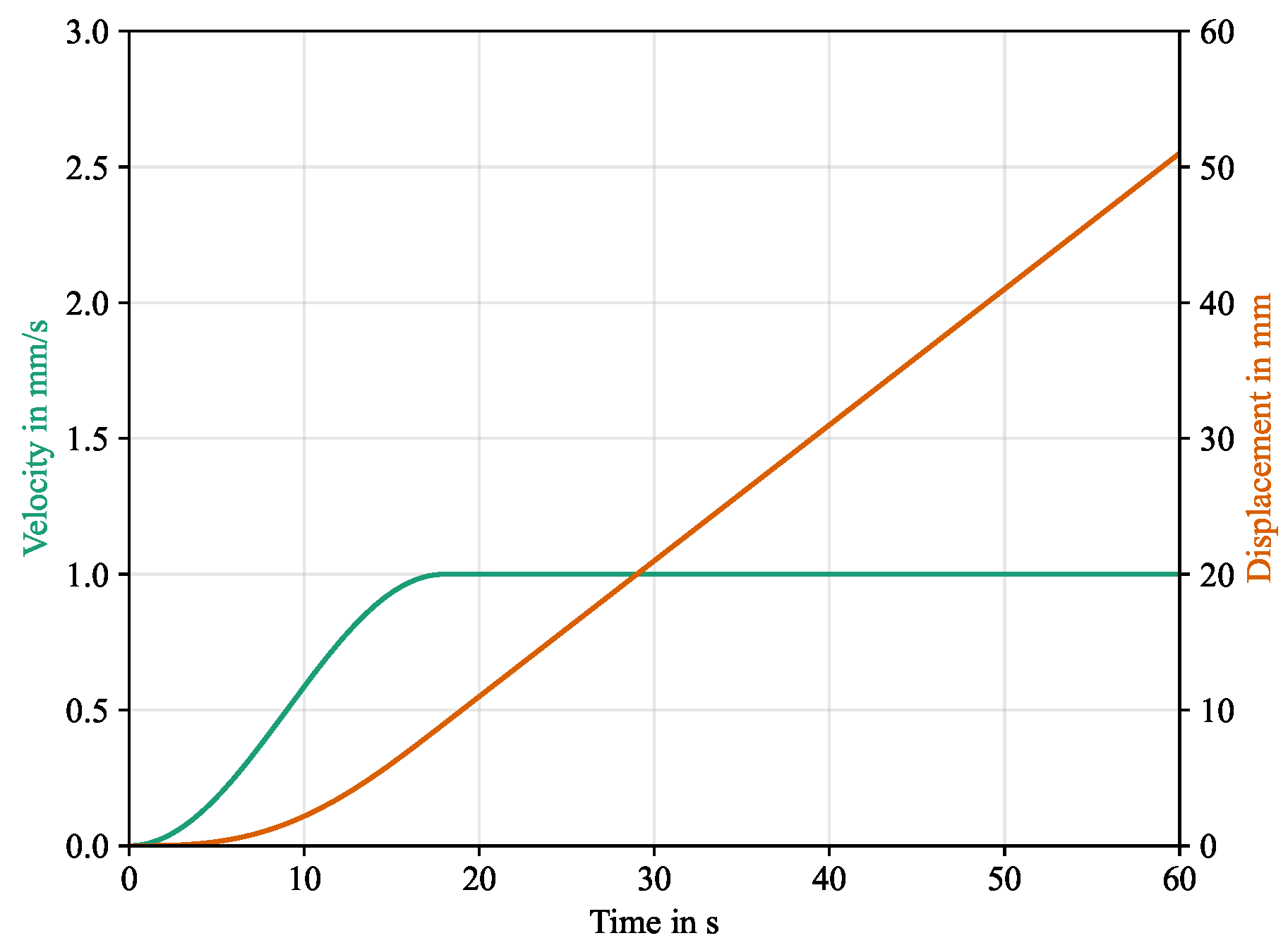

3.3. Parameters of Climbing Drum Peel Test

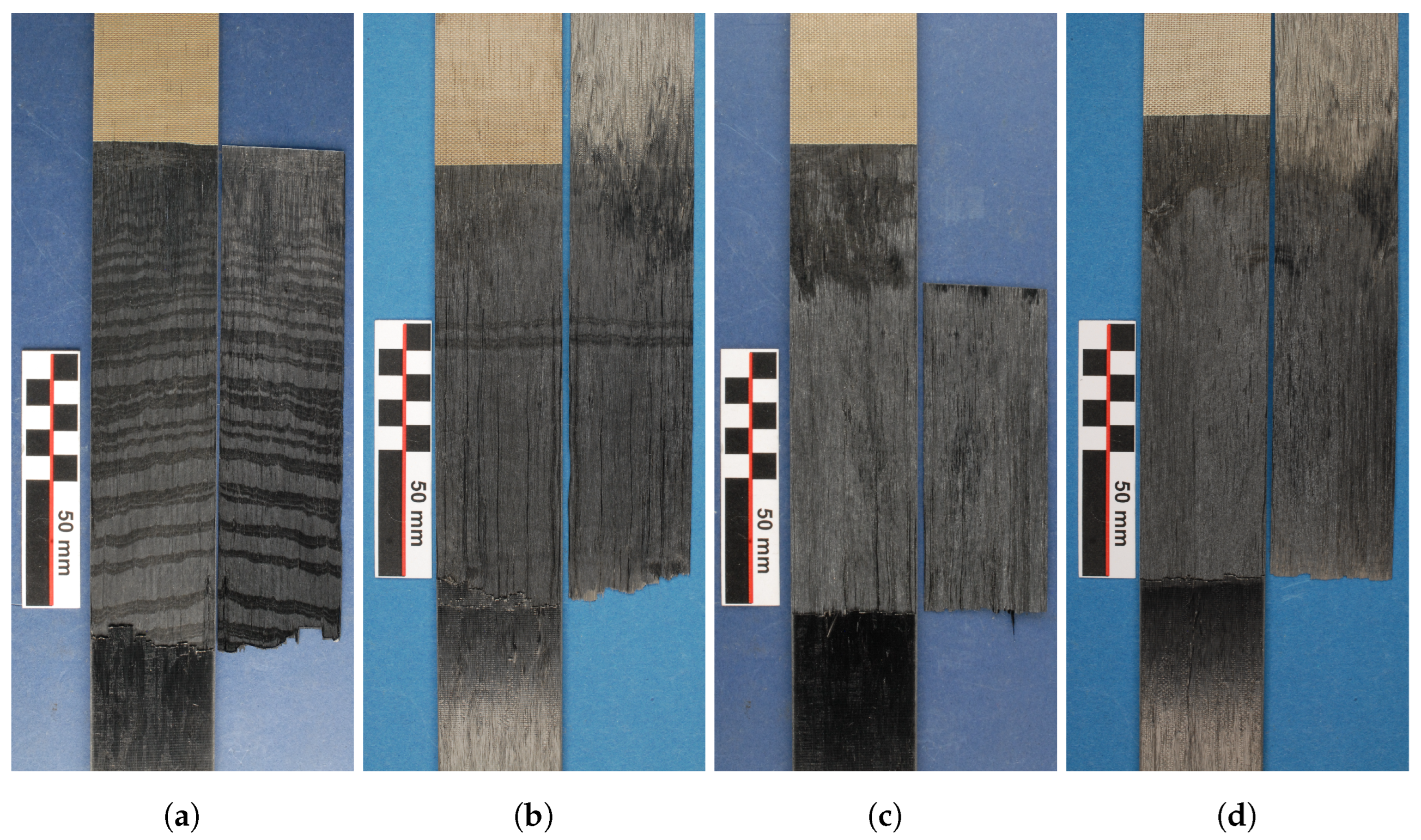

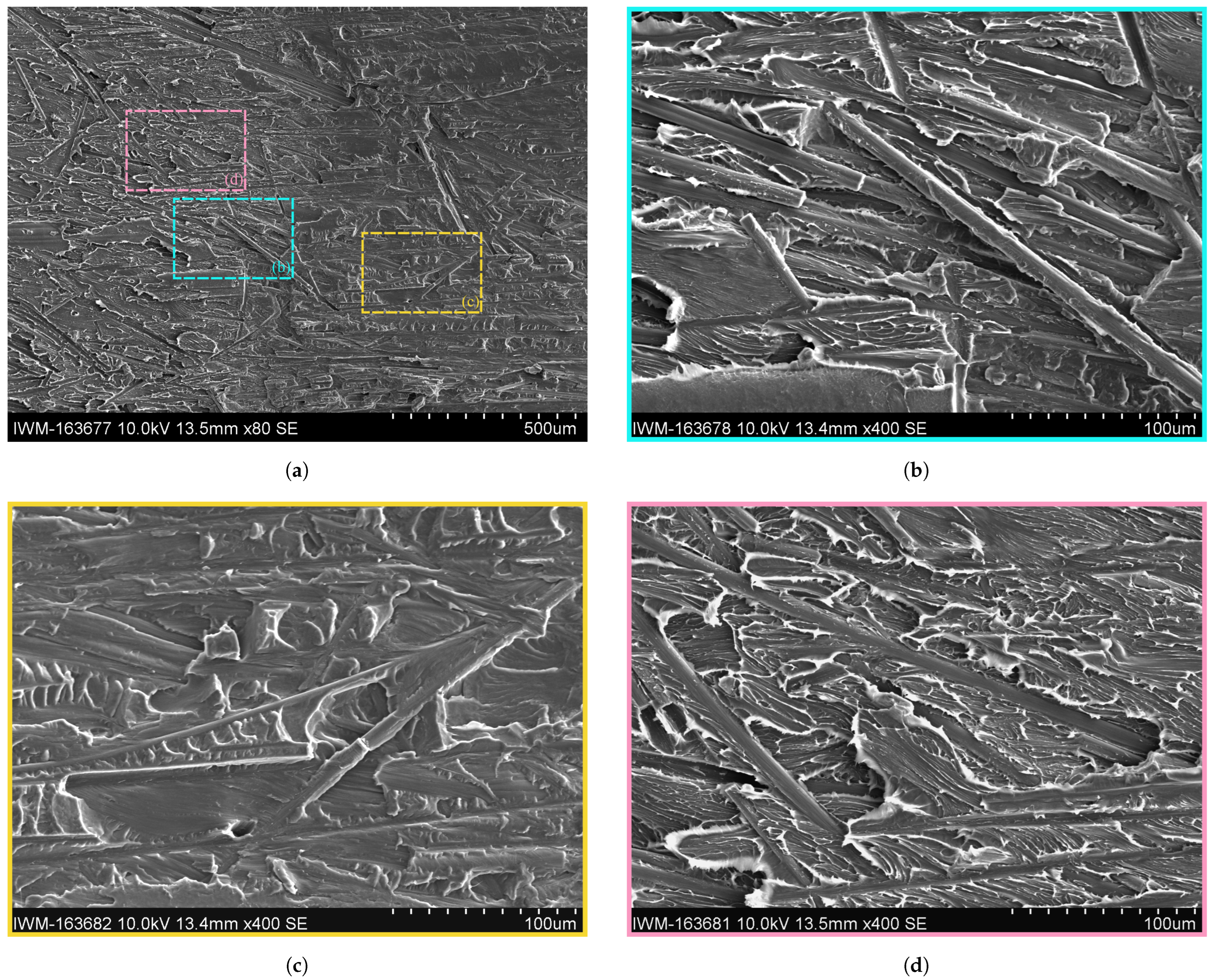

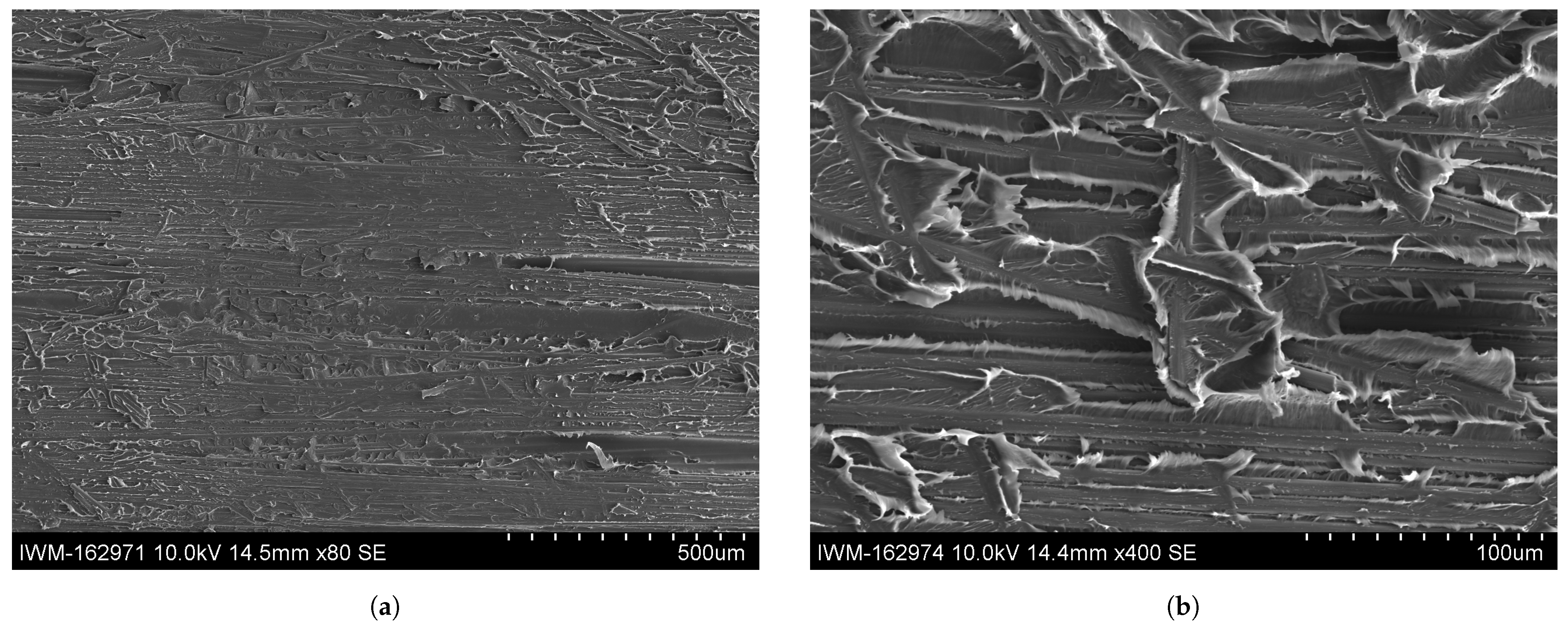

3.4. Fractography

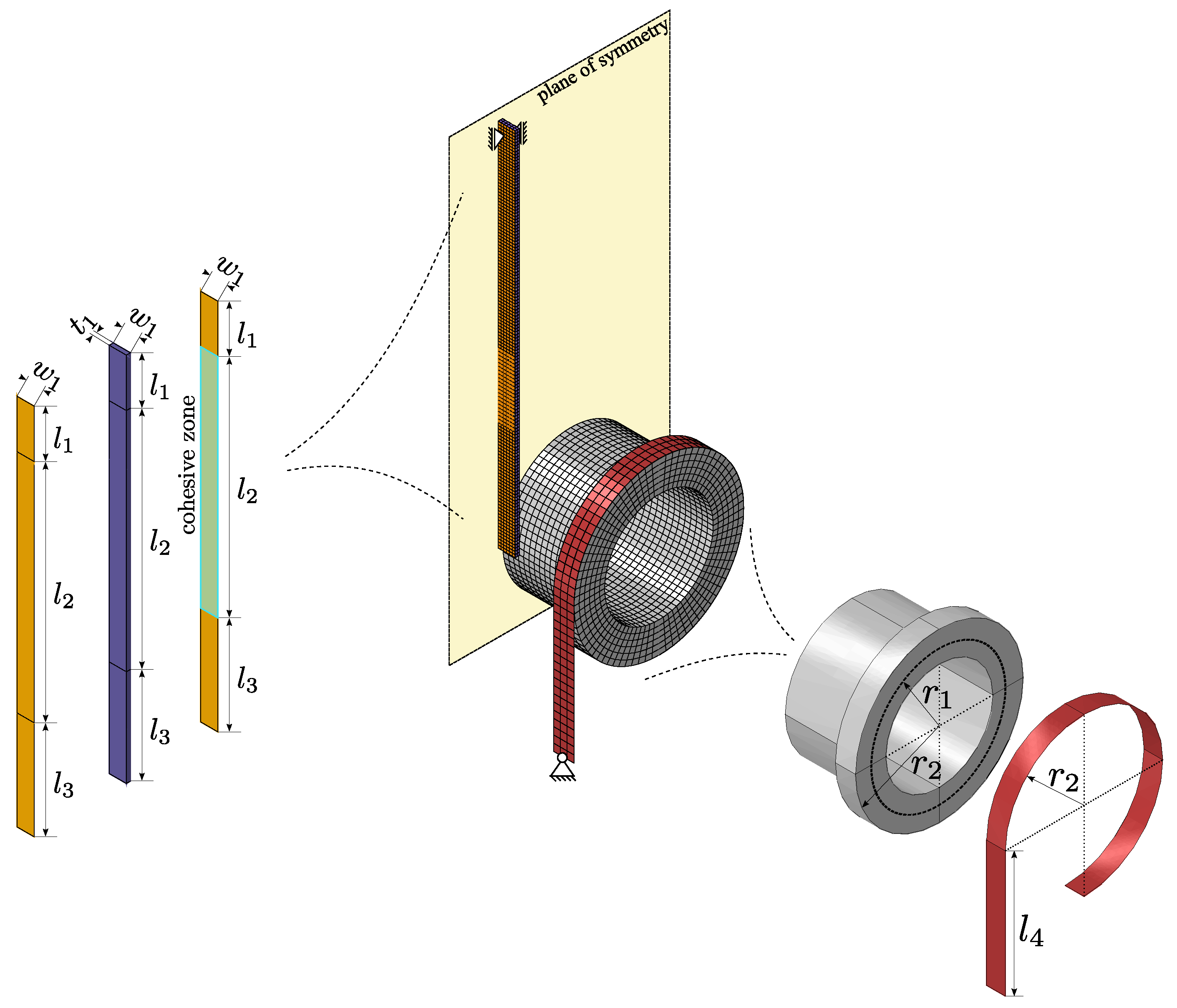

4. Numerical Model and Methods

4.1. Kinematics and Material Parameters

4.2. General Numerical Studies

- mesh sensitivity,

- mass scaling,

- material properties of Dico and Co,

- cohesive parameters.

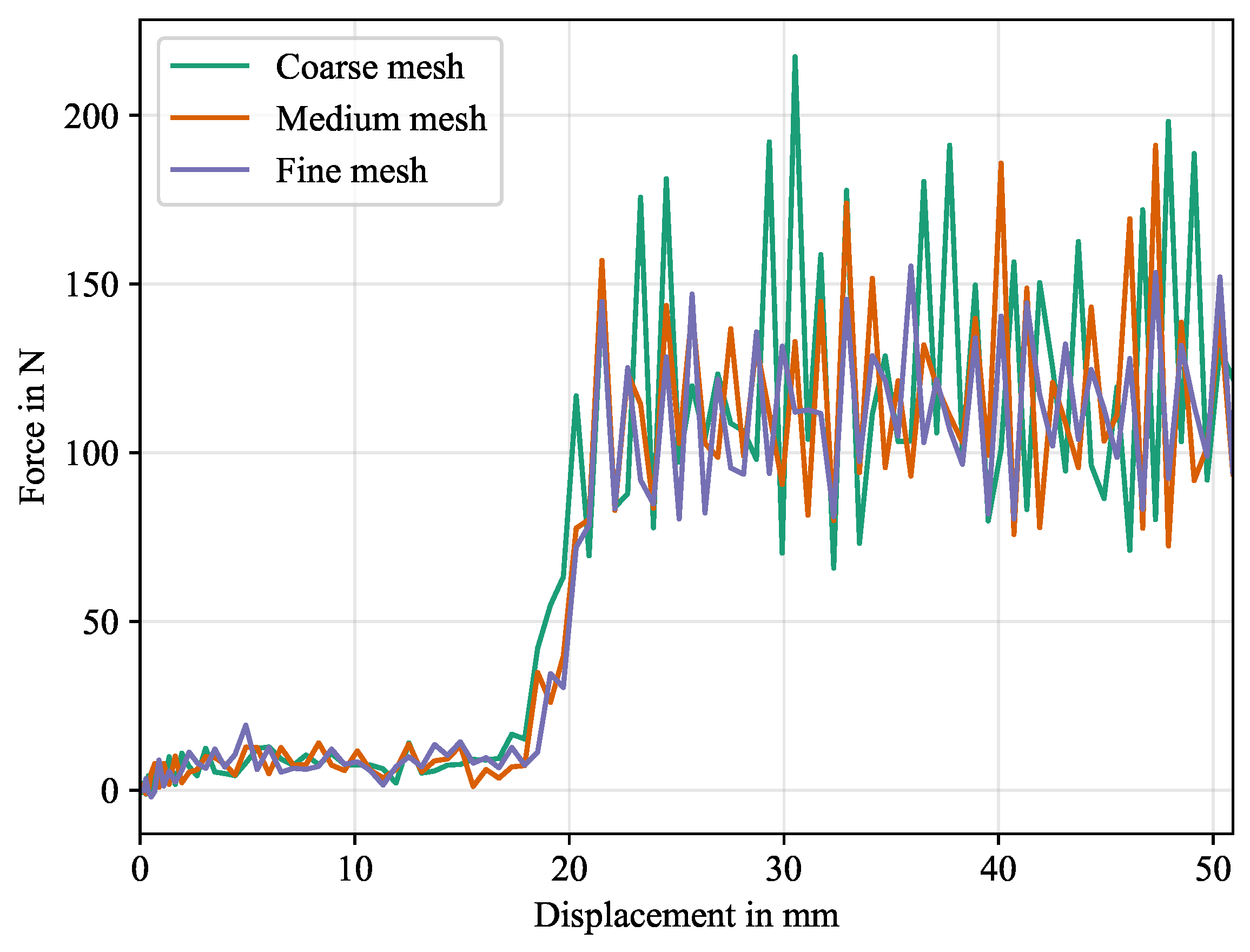

4.2.1. Mesh Sensitivity

4.2.2. Mass Scaling

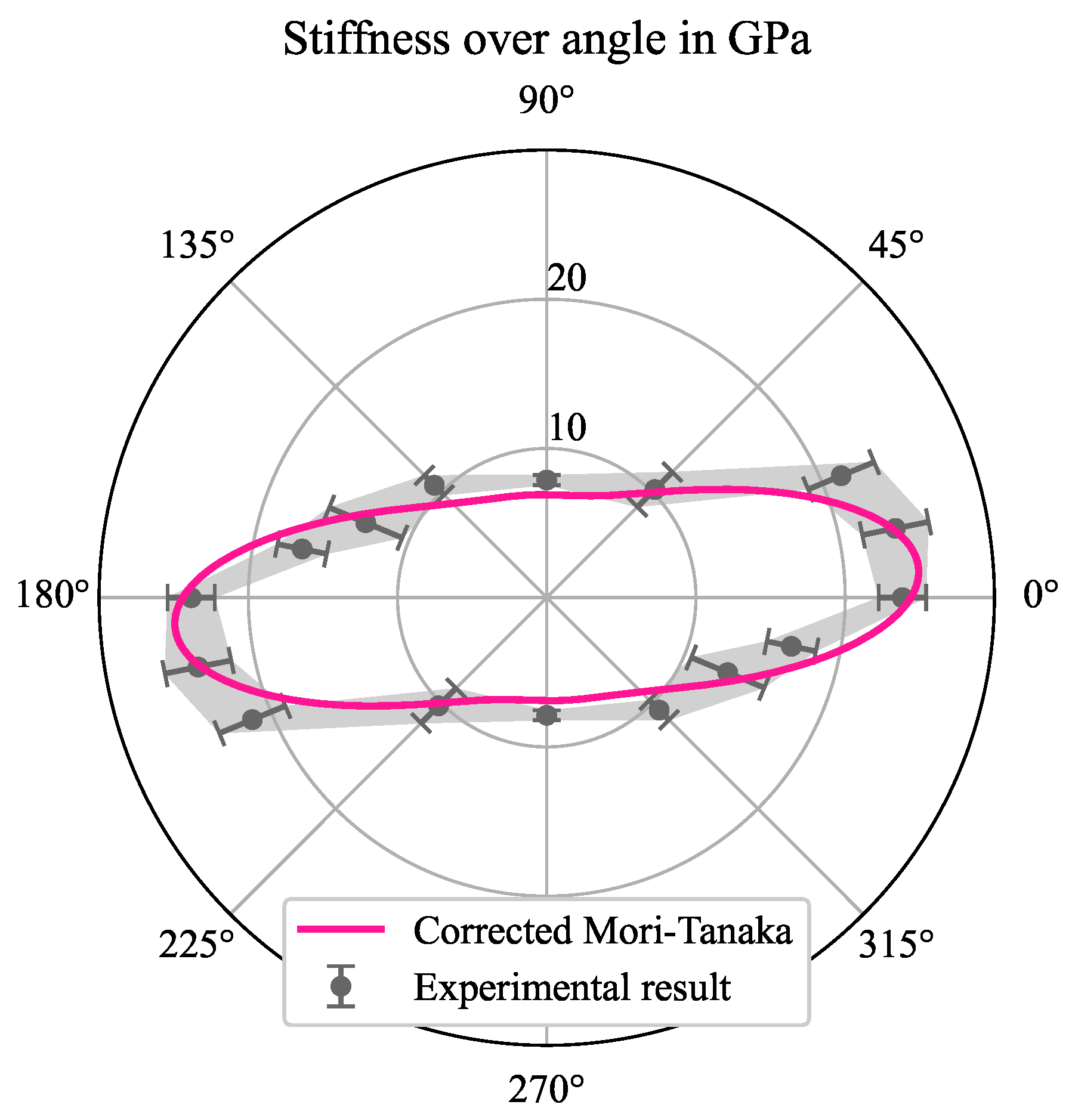

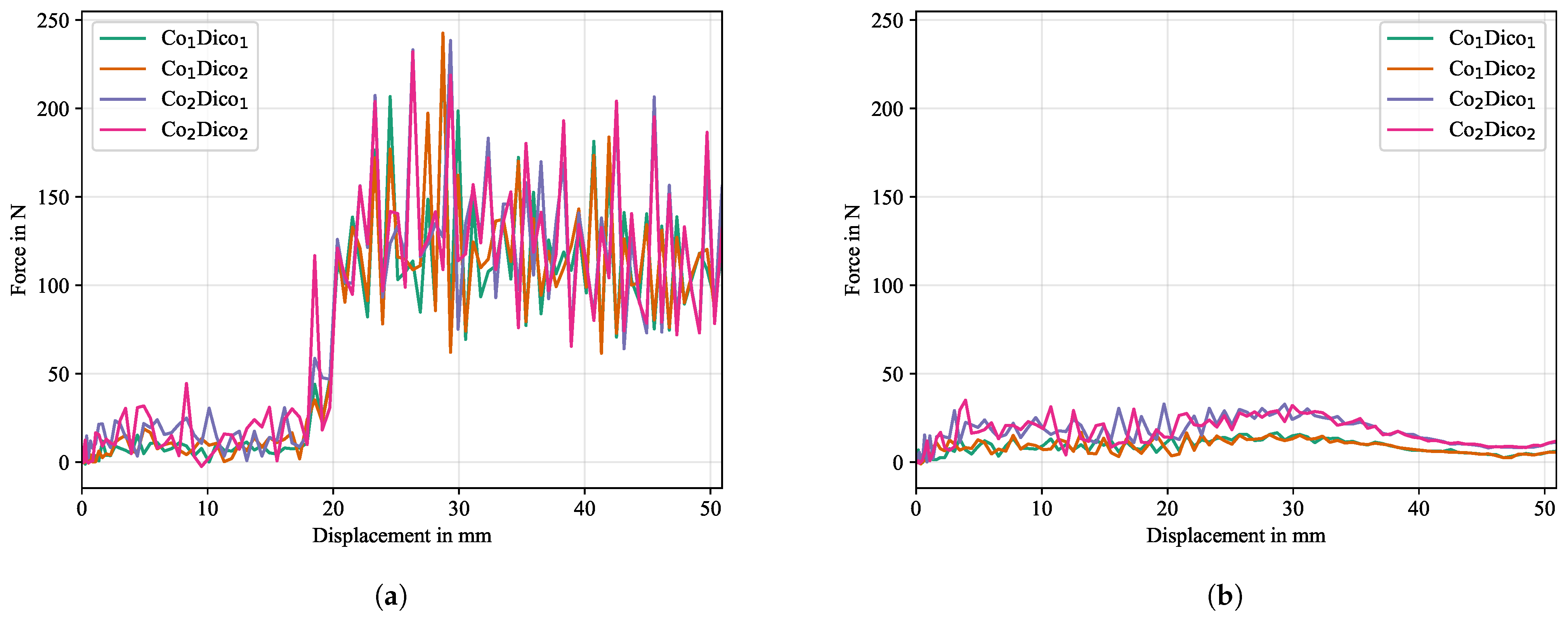

4.2.3. Material Properties of Dico and Co

4.2.4. Cohesive Parameters

4.2.5. Full Simulation of Experiment

5. Results and Discussion

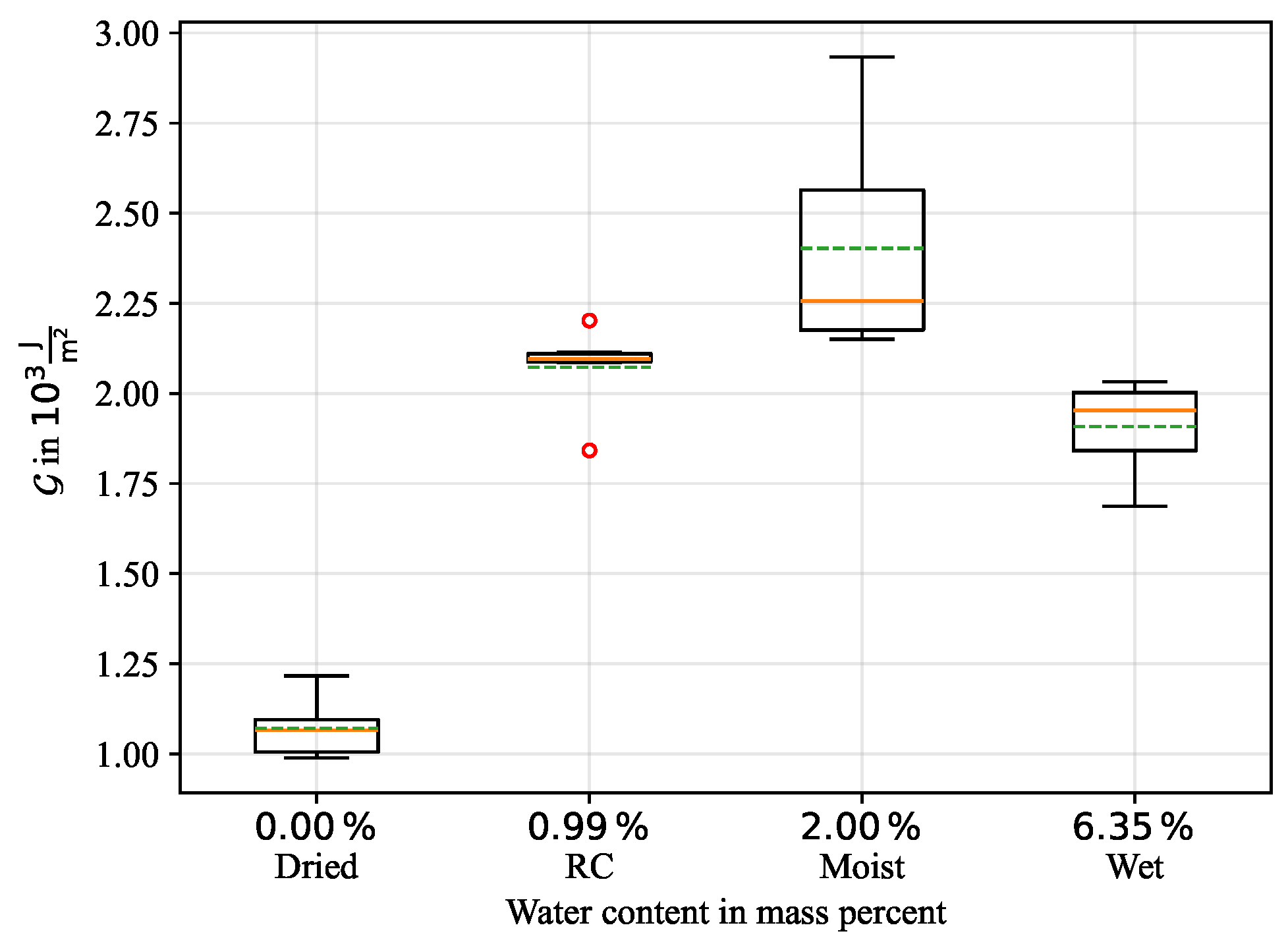

5.1. Experimental Results

5.1.1. Fractography

5.2. Numerical Results

5.2.1. General Numerical Studies

5.2.2. Mass Scaling

5.2.3. Material Properties of Co and Dico

5.2.4. Cohesive Parameters

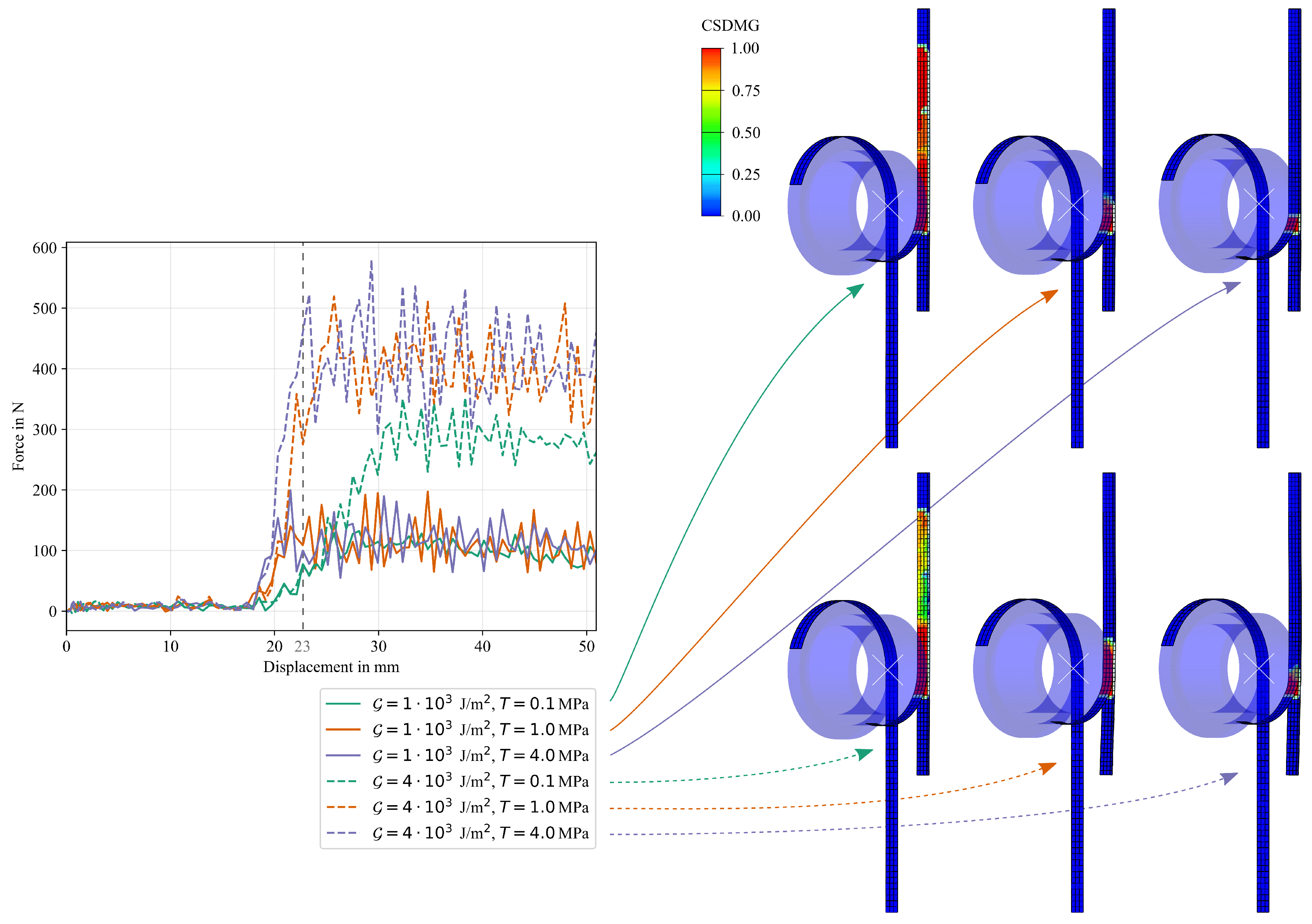

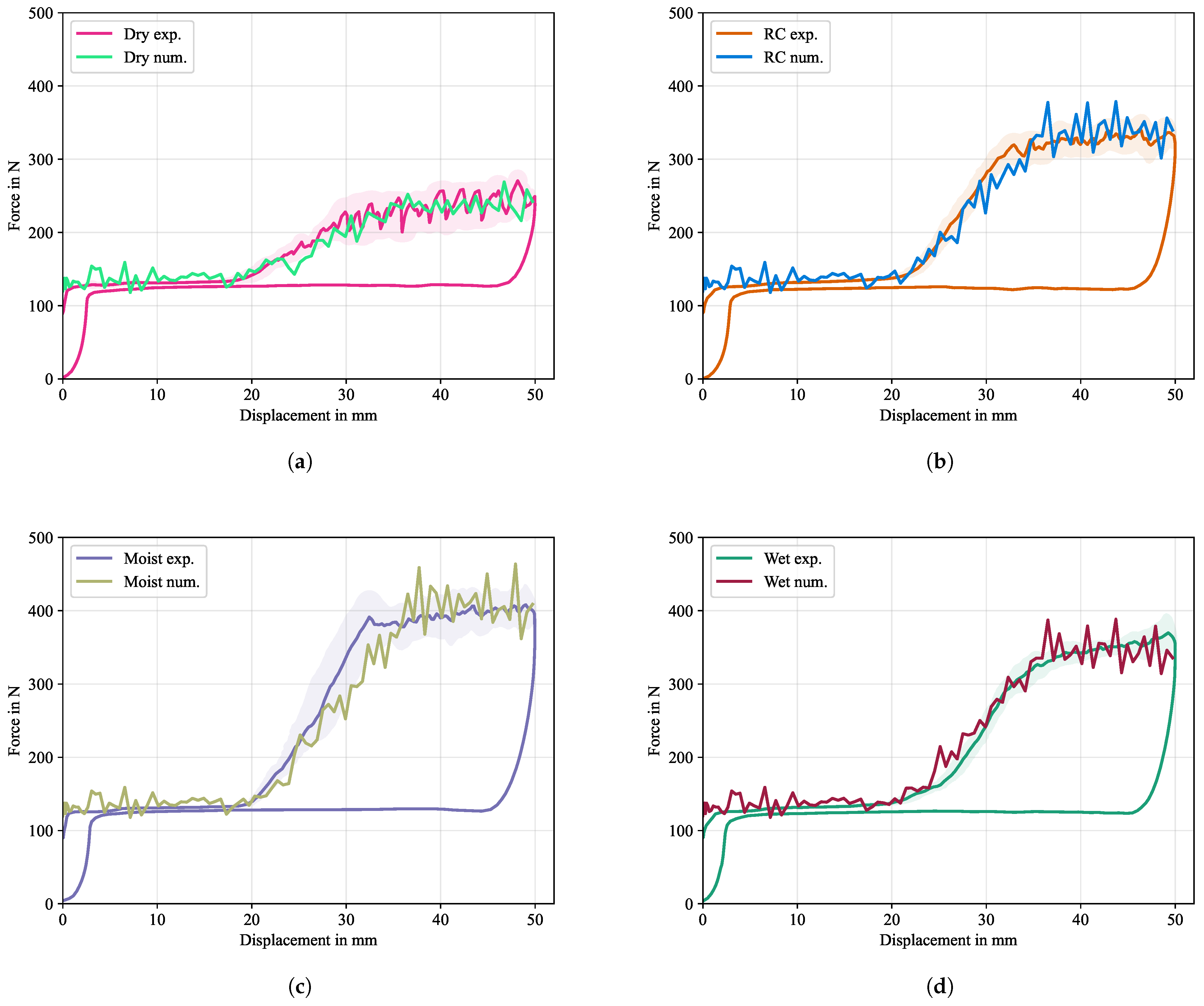

5.2.5. Final Simulation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| CDP | Climbing Drum Peel |

| CERR | Critical Energy Release Rate |

| CF | Carbon Fiber |

| Co | Continuous |

| CoDico | Conitnuous-Discontinuous |

| DCB | Double Cantilever Beam |

| Dico | Discontinuous |

| FRP | Fiber Reinforced Polymer |

| FRTP | Fiber Reinforced Thermoplastic |

| LFT | Long Fiber Thermoplastic |

| LFT-D | LFT Direct |

| MS | Mass Scaling |

| PA 6 | Polyamide 6 |

| PTFE | Polytetrafluoroethylene |

| RC | Room Climate |

| UD | Unidirectional |

References

- Ning, H.; Lu, N.; Hassen, A.A.; Chawla, K.; Selim, M.; Pillay, S. A review of Long fibre thermoplastic (LFT) composites. Int. Mater. Rev. 2020, 65, 164–188. [Google Scholar] [CrossRef]

- Gandhi, U.N.; Goris, S.; Osswald, T.A.; Song, Y.Y. Discontinuous Fiber-Reinforced Composites: Fundamentals and Applications; Hanser Publishers: Munich, Germany, 2020. [Google Scholar] [CrossRef]

- Wackernagel, M.; Schulz, N.B.; Deumling, D.; Linares, A.C.; Jenkins, M.; Kapos, V.; Monfreda, C.; Loh, J.; Myers, N.; Norgaard, R.; et al. Tracking the ecological overshoot of the human economy. Proc. Natl. Acad. Sci. USA 2002, 99, 9266–9271. [Google Scholar] [CrossRef]

- Rudolph, N.; Kiesel, R.; Aumnate, C. Understanding Plastics Recycling: Economic, Ecological, and Technical Aspects of Plastic Waste Handling, 2nd ed.; Hanser eLibrary, Hanser: Munich, Germany, 2020. [Google Scholar] [CrossRef]

- Favre, J.P.; Merienne, M.C. Characterization of fibre/resin bonding in composites using a pull-out test. Int. J. Adhes. Adhes. 1981, 1, 311–316. [Google Scholar] [CrossRef]

- Liu, L.; Jia, C.; He, J.; Zhao, F.; Fan, D.; Xing, L.; Wang, M.; Wang, F.; Jiang, Z.; Huang, Y. Interfacial characterization, control and modification of carbon fiber reinforced polymer composites. Compos. Sci. Technol. 2015, 121, 56–72. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Reverte, J.M. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Polym. Test. 2018, 68, 415–423. [Google Scholar] [CrossRef]

- Yavas, D.; Zhang, Z.; Liu, Q.; Wu, D. Interlaminar shear behavior of continuous and short carbon fiber reinforced polymer composites fabricated by additive manufacturing. Compos. Part Eng. 2021, 204, 108460. [Google Scholar] [CrossRef]

- Henning, F.; Moeller, E. Handbuch Leichtbau: Methoden, Werkstoffe, Fertigung; 2, Überarbeitete und Erweiterte Auflage, Ed.; Hanser: Munich, Germany, 2020. [Google Scholar]

- Böhlke, T.; Henning, F.; Hrymak, A.; Kärger, L.; Weidenmann, K.; Wood, J.T. (Eds.) Continuous–Discontinuous Fiber-Reinforced Polymers: An Integrated Engineering Approach; Carl Hanser Verlag: Munich, Germany, 2019. [Google Scholar]

- Bartkowiak, M.; Kizak, M.; Liebig, W.V.; Weidenmann, K.A. Fatigue behavior of hybrid continuous-discontinuous fiber-reinforced sheet molding compound composites under application-related loading conditions. Compos. Part Open Access 2022, 8, 100265. [Google Scholar] [CrossRef]

- Eyerer, P.; Krause, W.; Geiger, O.; Henning, F. Development of a Technology for the Large-Scale Production of Continuous Fiber Reinforced Composites. In Proceedings of the 63rd Annual Conference of the Society of Plastics Engineers (ANTEC 2005), Boston, MA, USA, 1–5 May 2005. [Google Scholar]

- Geiger, O.; Henning, F.; Eyerer, P.; Brüssel, R.; Ernst, H. LFT-D: Materials tailored for new applications. Reinf. Plast. 2006, 50, 30–35. [Google Scholar] [CrossRef]

- Witten, E.; Mathes, V. The European Market for Fibre-Reinforced Plastics and Composites 2022: Market Developments, Trends, Challenges and Outlook. 2023. Available online: https://www.avk-tv.de/files/publications/files/2023_avk_market_report_final.pdf (accessed on 10 January 2024).

- Schelleis, C.; Scheuring, B.M.; Liebig, W.V.; Hrymak, A.N.; Henning, F. Approaching Polycarbonate as an LFT-D Material: Processing and Mechanical Properties. Polymers 2023, 15, 2041. [Google Scholar] [CrossRef]

- Bondy, M.; Altenhof, W. Low velocity impact testing of direct/inline compounded carbon fibre/polyamide-6 long fibre thermoplastic. Int. J. Impact Eng. 2018, 111, 66–76. [Google Scholar] [CrossRef]

- Dahl, J.S.; Blanchard, P.J.; Rodgers, W.R. Direct compounding of a carbon fiber reinforced polyamide 66 composite. In Proceedings of the SAMPE Conference 2012, Baltimore, MD, USA, 23–25 May 2012. [Google Scholar]

- Deinzer, G.; Kothmann, M.; Rausch, J.; Baumgärtner, S.; Rosenberg, P.; Link, T.; Diebold, F.; Roquette, D.; Henning, F. Research Project SMiLE—Manufacturing Technologies for continuous fibre-reinforced lightweight automotive floor modules for cost-efficient high volume production. In Proceedings of the SAMPE Europe Conference, Stuttgart, Germany, 14–16 November 2017. [Google Scholar]

- Link, T.; Baumgärtner, S.; Dörr, D.; Henning, F. Hybrid thermoplastic composites for automotive applications—Development and manufacture of a lightweight rear floor structure in multi-material design. In Proceedings of the 18th European Conference on Composite Materials, Athens, Greece, 24–28 June 2018. [Google Scholar]

- Link, T.; Behnisch, F.; Rosenberg, P.; Seuffert, J.; Dörr, D.; Hohberg, M.; Joppich, T.; Henning, F. Hybrid Composites for Automotive Applications - Development and Manufacture of a System-integrated Lightweight floor Structure in multi-material Design. In Proceedings of the 19th Annual Automotive Composites Conference & Exhibition, Novi, MI, USA, 4–6 September 2019. [Google Scholar] [CrossRef]

- Kugele, D. Experimentelle und numerische Untersuchung des Abkühlverhaltens thermoplastischer Gelegelaminate in der Prozesskette. Ph.D. Thesis, Karlsruhe Institut für Technologie, Karlsruhe, Germany, 2020. [Google Scholar] [CrossRef]

- Nash, N.H.; Young, T.M.; Stanley, W.F. The influence of a thermoplastic toughening interlayer and hydrothermal conditioning on the Mode-II interlaminar fracture toughness of Carbon/Benzoxazine composites. Compos. Part Appl. Sci. Manuf. 2016, 81, 111–120. [Google Scholar] [CrossRef]

- Rathore, D.K.; Prusty, R.K.; Mohanty, S.C.; Singh, B.P.; Ray, B.C. In-situ elevated temperature flexural and creep response of inter-ply glass/carbon hybrid FRP composites. Mech. Mater. 2017, 105, 99–111. [Google Scholar] [CrossRef]

- Selzer, R.; Friedrich, K. Mechanical properties and failure behaviour of carbon fibre-reinforced polymer composites under the influence of moisture. Compos. Part Appl. Sci. Manuf. 1997, 28, 595–604. [Google Scholar] [CrossRef]

- Ray, B.C. Temperature effect during humid ageing on interfaces of glass and carbon fibers reinforced epoxy composites. J. Colloid Interface Sci. 2006, 298, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Pacheco, E.; Cauich-Cupul, J.I.; Valadez-González, A.; Herrera-Franco, P.J. Effect of moisture absorption on the mechanical behavior of carbon fiber/epoxy matrix composites. J. Mater. Sci. 2013, 48, 1873–1882. [Google Scholar] [CrossRef]

- Preda, F.M.; Alegría, A.; Bocahut, A.; Fillot, L.A.; Long, D.R.; Sotta, P. Investigation of water diffusion mechanisms in relation to polymer relaxations in polyamides. Macromolecules 2015, 48, 5730–5741. [Google Scholar] [CrossRef]

- Reuvers, N.; Huinink, H.; Adan, O. Water plasticizes only a small part of the amorphous phase in Nylon-6. Macromol. Rapid Commun. 2013, 34, 949–953. [Google Scholar] [CrossRef] [PubMed]

- Arhant, M.; Le Gac, P.Y.; Le Gall, M.; Burtin, C.; Briançon, C.; Davies, P. Modelling the non Fickian water absorption in polyamide 6. Polym. Degrad. Stab. 2016, 133, 404–412. [Google Scholar] [CrossRef]

- Moore, D.R. An Introduction to the Special Issue on Peel Testing. Int. J. Adhes. Adhes. 2008, 28, 153–157. [Google Scholar] [CrossRef]

- Keim, M.; Knappe, W.; Puck, A.; Schönewald, H. Zum Schälversuch mit der Kletterwalze/Analyse des Prüfverfahrens für Glasfaser Kunststoff-Laminate und -Sandwichplatten/On the climbing drum peel test Analysis of the test procedure for laminates of glassfibre reinforced plastics and sandwich panels/L’essai de délamination au cylindre a grimper Analyse de la methode à essayer des stratifies verre-resine et des stratifies sandwiches. Mater. Test. 1967, 9, 253–260. [Google Scholar] [CrossRef]

- Erartsin, O.; Zanjani, J.S.M.; Baran, I. Unravelling the interphase—Bond strength relationship in novel co-bonded thermoplastic—Thermoset hybrid composites for leading edge protection of wind turbine blades. Polym. Test. 2023, 117, 107856. [Google Scholar] [CrossRef]

- Michel, S.; Hauf, F.; Brunner, A.J. Evaluation of a climbing drum laminate peel test to determine the interlaminar mode I fracture toughness of thin CFRP laminates—Comparison with the standard mode I DCB test and a mandrel laminate peel test proposed by ESIS TC4. Front. Mater. 2023, 10, 981647. [Google Scholar] [CrossRef]

- Daghia, F.; Cluzel, C. The Climbing Drum Peel Test: An alternative to the Double Cantilever Beam for the determination of fracture toughness of monolithic laminates. Compos. Part Appl. Sci. Manuf. 2015, 78, 70–83. [Google Scholar] [CrossRef]

- Normenausschuss Luft- und Raumfahrt (NL) im DIN. Luft- und Raumfahrt—Nichtmetallische Werkstoffe—Strukturelle Klebstoffsysteme—Prüfverfahren—Teil 3: Trommelschälversuch für Wabenkernverbunde; Deutsche und Englische Fassung EN 2243-3:2006-10; Beuth Verlag: Berlin, Germany, 2006. [Google Scholar] [CrossRef]

- ASTM Committee D14. Standard Test Method for Climbing Drum Peel for Adhesives; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar] [CrossRef]

- Nettles, A.T.; Gregory, E.D.; Jackson, J.R. Using the Climbing Drum Peel (CDP) Test to Obtain a G IC Value for Core/Face Sheet Bonds. J. Compos. Mater. 2007, 41, 2863–2876. [Google Scholar] [CrossRef]

- Scheider, I. Cohesive Model for Crack Propagation Analyses of Structures with Elastic–Plastic Material Behavior Foundations and Implementation. 2001. Available online: https://www.climate-service.info/imperia/md/content/gkss/institut_fuer_werkstoffforschung/wms/czm-doku.pdf (accessed on 10 January 2024).

- Cornec, A.; Scheider, I.; Schwalbe, K.H. On the practical application of the cohesive model. Eng. Fract. Mech. 2003, 70, 1963–1987. [Google Scholar] [CrossRef]

- Salve, A.; Jalwadi, S. Implementation of Cohesive Zone in ABAQUS to Investigate Fracture Problems. In National Conference for Engineering Post Graduates RIT NConPG-15; 2015; pp. 60–66. Available online: https://www.researchgate.net/publication/310774819_Implementation_of_Cohesive_Zone_in_ABAQUS_to_Investigate_Fracture_Problems (accessed on 10 January 2024).

- Christ, N.; Scheuring, B.M.; Montesano, J.; Hohe, J. A Python package for homogenization procedures in fiber reinforced polymers. J. Open Source Softw. 2023, 8, 5295. [Google Scholar] [CrossRef]

- Scheuring, B.M.; Christ, N.; Blarr, J.; Liebig, W.V.; Hohe, J.; Montesano, J.; Weidenmann, K.A. Tensile properties of long fiber-reinforced thermoplastics with mixed fiber types: Experimental investigations and prediction by orientation-based homogenization approaches. Int. J. Mech. Sci. 2024. [Google Scholar]

- Suarez, S.A.; Gibson, R.F.; Sun, C.T.; Chaturvedi, S.K. The influence of fiber length and fiber orientation on damping and stiffness of polymer composite materials. Exp. Mech. 1986, 26, 175–184. [Google Scholar] [CrossRef]

- Hartlen, D.C.; Cronin, D.S. Arc-Length Re-Parametrization and Signal Registration to Determine a Characteristic Average and Statistical Response Corridors of Biomechanical Data. Front. Bioeng. Biotechnol. 2022, 10, 843148. [Google Scholar] [CrossRef]

| Label | Dried | RC | Moist | Wet |

|---|---|---|---|---|

| Conditioning | 50 °C 0% r.H. in vacuum | 23 °C 45% r.H. | 50 °C 80% r.H. | 50 °C submersed in distilled water |

| Duration | ≥240 h | 1500 h | 240 h | 240 h |

| E1 | E2 | ν12 | G12 | G13 | G23 | ||

|---|---|---|---|---|---|---|---|

| Drum | - | - | - | - | - | - | |

| Bands | 210,000.0 | - | - | - | - | ||

| Co | 108,700.0 | 11,039.2 | |||||

| Dico | see Table 3 | ||||||

| D1111 | D1122 | D2222 | D1133 | D2233 | D3333 | D1112 |

|---|---|---|---|---|---|---|

| D2212 | D3312 | D1212 | D1113 | D2213 | D3313 | D1213 |

| D1313 | D1123 | D2223 | D3323 | D1223 | D1323 | D2323 |

| Label | Co1Dico1 | Co2Dico1 | Co1Dico2 | Co2Dico2 |

|---|---|---|---|---|

| Young’s modulus Co | GPa | GPa | GPa | GPa |

| Young’s modulus Dico | GPa | GPa | GPa | GPa |

| Label | ||||||

|---|---|---|---|---|---|---|

| in | ||||||

| in MPa |

| Label | Dried | RC | Moist | Wet |

|---|---|---|---|---|

| Conditioning | 50 °C 0% r.H. | 23 °C 45% r.H. | 50 °C 80% r.H. | 50 °C submersed |

| Water uptake | 0.00% | 0.99% | 2.00% | 6.35% |

| Mesh Density | Coarse | Medium | Fine |

|---|---|---|---|

| Run time | s | 18,238 s | 78,203 s |

| Multiple of coarse run time | - |

| Mass Scaling Factor | 256 | 64 | 16 | 4 | 1 |

|---|---|---|---|---|---|

| Run time | 10,554 s | 16,243 s | 42,217 s | 83,807 s | 168,506 s |

| Run time factor to MS256 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Christ , N.; Scheuring , B.M.; Schelleis , C.; Liebig , W.V.; Montesano, J.; Weidenmann , K.A.; Hohe , J. Characterization and Simulation of the Interface between a Continuous and Discontinuous Carbon Fiber Reinforced Thermoplastic by Using the Climbing Drum Peel Test Considering Humidity. Polymers 2024, 16, 976. https://doi.org/10.3390/polym16070976

Christ N, Scheuring BM, Schelleis C, Liebig WV, Montesano J, Weidenmann KA, Hohe J. Characterization and Simulation of the Interface between a Continuous and Discontinuous Carbon Fiber Reinforced Thermoplastic by Using the Climbing Drum Peel Test Considering Humidity. Polymers. 2024; 16(7):976. https://doi.org/10.3390/polym16070976

Chicago/Turabian StyleChrist , Nicolas, Benedikt M. Scheuring , Christoph Schelleis , Wilfried V. Liebig , John Montesano, Kay A. Weidenmann , and Jörg Hohe . 2024. "Characterization and Simulation of the Interface between a Continuous and Discontinuous Carbon Fiber Reinforced Thermoplastic by Using the Climbing Drum Peel Test Considering Humidity" Polymers 16, no. 7: 976. https://doi.org/10.3390/polym16070976

APA StyleChrist , N., Scheuring , B. M., Schelleis , C., Liebig , W. V., Montesano, J., Weidenmann , K. A., & Hohe , J. (2024). Characterization and Simulation of the Interface between a Continuous and Discontinuous Carbon Fiber Reinforced Thermoplastic by Using the Climbing Drum Peel Test Considering Humidity. Polymers, 16(7), 976. https://doi.org/10.3390/polym16070976