Prediction of the Bubble Growth Behavior by Means of the Time-, Temperature-, Pressure- and Blowing Agent Concentration-Dependent Transient Elongational Viscosity Function of Polymers

Abstract

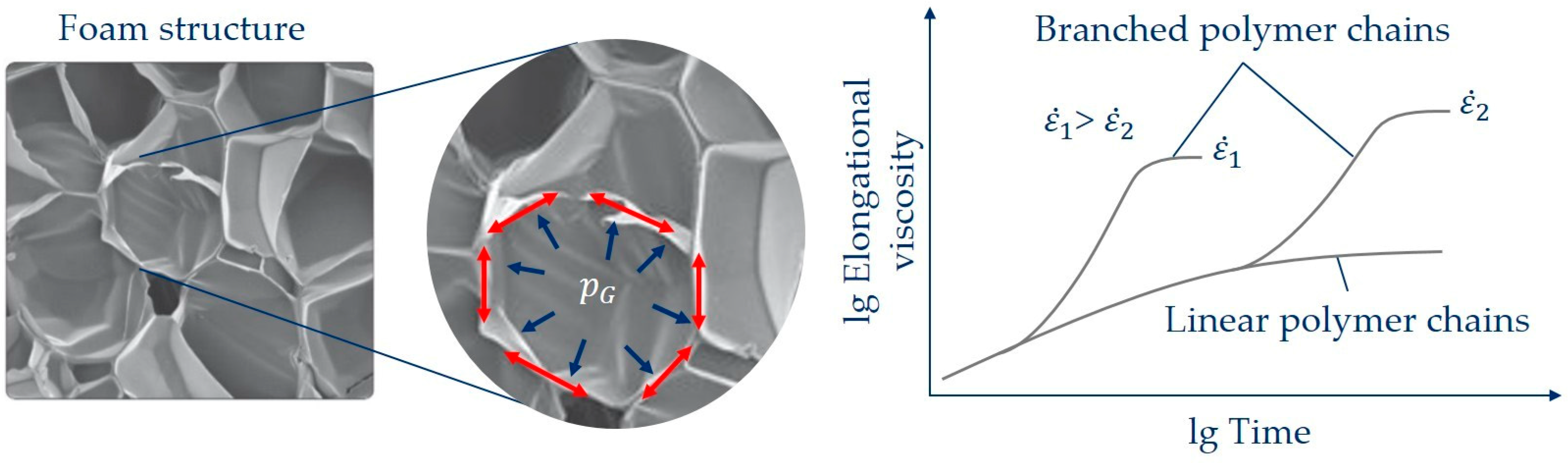

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Rheological Characterization and Superposition

2.3. In-Line Analysis of Bubble Growth and Transient Deformation Behavior over Time

3. Transient Elongational Viscosity Model and Bubble Growth Simulation

3.1. Molecular Stress Function Model Extension by Superposition

3.2. Bubble Growth Simulation Using the Single-Cell Model

4. Results and Discussion

4.1. Calibration of the Transient Uniaxial MSF Model for PS and PLA

4.2. Master Curve of the Transient Uniaxial Elongational Viscosity

4.3. Prediction of the Transient Equibiaxial Elongational Viscosity Function at the Bubble Wall during Bubble Growth

4.4. Prediction of the Viscosity-Driven and Diffusion-Controlled Bubble Growth Behavior over Time

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bonten, C. Plastics Technology. Introduction and Fundamentals; Hanser: Munich, Germany, 2019; ISBN 978-1-56990-768-9. [Google Scholar]

- Park, C.B.; Suh, N.P. Filamentary extrusion of microcellular polymers using a rapid decompressive element. Polym. Eng. Sci. 1996, 36, 34–48. [Google Scholar] [CrossRef]

- Park, C.B.; Baldwin, D.F.; Suh, N.P. Effect of the pressure drop rate on cell nucleation in continuous processing of microcellular polymers. Polym. Eng. Sci. 1995, 35, 432–440. [Google Scholar] [CrossRef]

- Braun, A. Verfahrensentwicklung von Physikalisch Geschäumten Polypropylenplatten für den Einsatz als Kernmaterial von Sandwichverbunden. Ph.D. Thesis, Montanuniversität Leoben, Leoben, Austria, 2011. [Google Scholar]

- Throne, J.L. Thermoplastic Foam Extrusion: An Introduction; Hanser: Munich, Germany, 2004; ISBN 3446228489. [Google Scholar]

- Ramesh, N.S.; Lee, S.T. Blowing Agent Effect on Extensional Viscosity Calculated from Fiber Spinning Method for Foam Processing. J. Cell. Plast. 2000, 36, 374–385. [Google Scholar] [CrossRef]

- Lee, C.H.; Lee, K.-J.; Jeong, H.G.; Kim, S.W. Growth of gas bubbles in the foam extrusion process. Adv. Polym. Technol. 2000, 19, 97–112. [Google Scholar]

- Murillo Castellón, S. In-Situ-Modifikation von Polylactiden Mittels Reaktiver Extrusion zur Herstellung von Bio-Schäumen. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2020. [Google Scholar]

- Wang, J. Rheology of Foaming Polymers and Its Influence on Microcellular Processing. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2009. [Google Scholar]

- Dealy, J.M.; Wang, J. Melt Rheology and Its Applications in the Plastics Industry, 2nd ed.; Springer: Dordrecht, The Netherlands, 2013; ISBN 9789400763951. [Google Scholar]

- Schaible, T.; Bonten, C. In-line measurement and modeling of temperature, pressure, and blowing agent dependent viscosity of polymer melts. Appl. Rheol. 2022, 32, 69–82. [Google Scholar] [CrossRef]

- Amon, M.; Denson, C.D. A study of the dynamics of foam growth: Analysis of the growth of closely spaced spherical bubbles. Polym. Eng. Sci. 1984, 24, 1026–1034. [Google Scholar] [CrossRef]

- Shafi, M.A.; Lee, J.G.; Flumerfelt, R.W. Prediction of cellular structure in free expansion polymer foam processing. Polym. Eng. Sci. 1996, 36, 1950–1959. [Google Scholar] [CrossRef]

- Arefmanesh, A.; Advani, S.G. Diffusion-induced growth of a gas bubble in a viscoelastic fluid. Rheol. Acta 1991, 30, 274–283. [Google Scholar] [CrossRef]

- Shafi, M.A.; Joshi, K.; Flumerfelt, R.W. Bubble size distributions in freely expanded polymer foams. Chem. Eng. Sci. 1997, 52, 635–644. [Google Scholar] [CrossRef]

- Prousevitch, A.A.; Sahagian, D.L.; Anderson, A.T. Dynamics of diffusive bubble growth in magmas: Isothermal case. J. Geophys. Res. Solid Earth 1993, 98, 22283–22307. [Google Scholar] [CrossRef]

- Shafi, M.A.; Flumerfelt, R.W. Initial bubble growth in polymer foam processes. Chem. Eng. Sci. 1997, 52, 627–633. [Google Scholar] [CrossRef]

- Schaible, T. Inline-Charakterisierung und Vorhersage der Viskosität Sowie des Initialen Blasenwachstumsverhaltens beim Schäumen von Treibmittelbeladenen Kunststoffschmelzen. Ph.D. Thesis, University of Stuttgart, Stuttgart, 2022. [Google Scholar]

- Tuladhar, T.R.; Mackley, M.R. Experimental observations and modelling relating to foaming and bubble growth from pentane loaded polystyrene melts. Chem. Eng. Sci. 2004, 59, 5997–6014. [Google Scholar] [CrossRef]

- Zhang, Y.; Xin, C.; Li, X.; Waqas, M.; He, Y. Bubble growth model and its influencing factors in a polymer melt under nonisothermal conditions. J. Appl. Polym. Sci. 2019, 136, 47210. [Google Scholar] [CrossRef]

- Ataei, M.; Shaayegan, V.; Wang, C.; Costa, F.; Han, S.; Park, C.B.; Bussmann, M. Numerical analysis of the effect of the local variation of viscosity on bubble growth and deformation in polymer foaming. J. Rheol. 2019, 63, 895–903. [Google Scholar] [CrossRef]

- Leung, S.N.; Park, C.B.; Xu, D.; Li, H.; Fenton, R.G. Computer Simulation of Bubble-Growth Phenomena in Foaming. Ind. Eng. Chem. Res. 2006, 45, 7823–7831. [Google Scholar] [CrossRef]

- Lee, M.; Park, C.B.; Tzoganakis, C. Measurements and modeling of PS/supercritical CO2 solution viscosities. Polym. Eng. Sci. 1999, 39, 99–109. [Google Scholar] [CrossRef]

- Ferasat, H.; Fasihi, M.; Ghoreishy, M.H.R.; Ajorloo, M. Development of a bubble growth model for natural rubber-based foams. Polym. Eng. Sci. 2021, 61, 477–488. [Google Scholar] [CrossRef]

- Han, C.D.; Yoo, H.J. Studies on structural foam processing. IV. Bubble growth during mold filling. Polym. Eng. Sci. 1981, 21, 518–533. [Google Scholar] [CrossRef]

- Kim, K.Y.; Kang, S.L.; Kwak, H.-Y. Bubble nucleation and growth in polymer solutions. Polym. Eng. Sci. 2004, 44, 1890–1899. [Google Scholar] [CrossRef]

- Ramesh, N.S.; Rasmussen, D.H.; Campbell, G.A. Numerical and experimental studies of bubble growth during the microcellular foaming process. Polym. Eng. Sci. 1991, 31, 1657–1664. [Google Scholar] [CrossRef]

- Shimoda, M.; Tsujimura, I.; Tanigaki, M.; Ohshima, M. Polymeric Foaming Simulation for Extrusion Processes. J. Cell. Plast. 2001, 37, 517–536. [Google Scholar] [CrossRef]

- Breuer, R.; Hendriks, S.; Reinhardt, N.; Facklam, M.; Hopmann, C. Modeling flow and cell formation in foam sheet extrusion of polystyrene with CO2 and co-blowing agents. Part II: Process model. Polym. Eng. Sci. 2021, 61, 2701–2715. [Google Scholar] [CrossRef]

- Chow, T.S. Molecular Interpretation of the Glass Transition Temperature of Polymer-Diluent Systems. Macromolecules 1980, 13, 362–364. [Google Scholar] [CrossRef]

- Raps, D.; Köppl, T.; Heymann, L.; Altstädt, V. Rheological behaviour of a high-melt-strength polypropylene at elevated pressure and gas loading for foaming purposes. Rheol. Acta 2017, 56, 95–111. [Google Scholar] [CrossRef]

- Yao, S.; Chen, Y.; Ling, Y.; Hu, D.; Xi, Z.; Zhao, L. Analysis of Bubble Growth in Supercritical CO2 Extrusion Foaming Polyethylene Terephthalate Process Based on Dynamic Flow Simulation. Polymers 2021, 13, 2799. [Google Scholar] [CrossRef]

- Rolón-Garrido, V.H.; Wagner, M.H. The damping function in rheology. Rheol. Acta 2009, 48, 245–284. [Google Scholar] [CrossRef]

- Rolón-Garrido, V.H. The molecular stress function (MSF) model in rheology. Rheol. Acta 2014, 53, 663–700. [Google Scholar] [CrossRef]

- Wagner, M.H.; Ehrecke, P.; Hachmann, P.; Meissner, J. A constitutive analysis of uniaxial, equibiaxial and planar extension of a commercial linear high-density polyethylene melt. J. Rheol. 1998, 42, 621–638. [Google Scholar] [CrossRef]

- Schaible, T.; Bonten, C. A Novel In-Line Measurement and Analysis Method of Bubble Growth-Dependent Strain and Deformation Rates during Foaming. Polymers 2024, 16, 277. [Google Scholar] [CrossRef]

- Schaible, T.; Bonten, C. Elongational viscosity analysis and modeling of a modified polylactide for foaming applications. AIP Conf. Proc. 2023, 2607, 80002. [Google Scholar] [CrossRef]

- Sentmanat, M.L. Miniature universal testing platform: From extensional melt rheology to solid-state deformation behavior. Rheol. Acta 2004, 43, 657–669. [Google Scholar] [CrossRef]

- Rólon Garrido, V.H. Molecular Structure and Constitutive Modelling of Polymer Melts. Ph.D. Thesis, TU Berlin, Berlin, Germany, 2007. [Google Scholar]

- Schaeffer, J. Entwicklung Einer Rheologischen Zustandsgleichung für Biaxiale Dehnungen und Scherung von Polymerschmelzen. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 1994. [Google Scholar]

- Bastian, H. Non-Linear Viscoelasticity of Linear and Long-Chain-Branched Polymer Melts in Shear and Extensional Flows. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2001. [Google Scholar]

- Wagner, M.H.; Schaeffer, J. Constitutive equations from Gaussian slip-link network theories in polymer melt rheology. Rheol. Acta 1992, 31, 22–31. [Google Scholar] [CrossRef]

- Wagner, M.H.; Schaeffer, J. Nonlinear strain measures for general biaxial extension of polymer melts. J. Rheol. 1992, 36, 1–26. [Google Scholar] [CrossRef]

- Wagner, M.H.; Rubio, P.; Bastian, H. The molecular stress function model for polydisperse polymer melts with dissipative convective constraint release. J. Rheol. 2001, 45, 1387–1412. [Google Scholar] [CrossRef]

- Wagner, M.H.; Rolón-Garrido, V.H. The interchain pressure effect in shear rheology. Rheol. Acta 2010, 49, 459–471. [Google Scholar] [CrossRef]

- Wagner, M.H.; Yamaguchi, M.; Takahashi, M. Quantitative assessment of strain hardening of low-density polyethylene melts by the molecular stress function model. J. Rheol. 2003, 47, 779–793. [Google Scholar] [CrossRef]

- Baumgaertel, M.; Winter, H.H. Determination of discrete relaxation and retardation time spectra from dynamic mechanical data. Rheol. Acta 1989, 28, 511–519. [Google Scholar] [CrossRef]

- Wagner, M.H.; Rolón-Garrido, V.H. Verification of branch point withdrawal in elongational flow of pom-pom polystyrene melt. J. Rheol. 2008, 52, 1049–1068. [Google Scholar] [CrossRef]

- Winter, H. Analysis of dynamic mechanical data: Inversion into a relaxation time spectrum and consistency check. J. Non-Newton. Fluid Mech. 1997, 68, 225–239. [Google Scholar] [CrossRef]

- Mours, M.; Winter, H.; Blackwell, R.J.; Wagner, M.H. IRIS Rheo-Hub Handbook: Part F: Predicitions from Non-Linear Viscoelastic Theory; IRIS Development LLC.: Amherst, MA, USA, 2011. [Google Scholar]

- Rolón-Garrido, V.H.; Wagner, M.H. Elongational viscosity of photo-oxidated LDPE. AIP Conf. Proc. 2015, 1593, 741–745. [Google Scholar] [CrossRef]

- Münstedt, H.; Laun, H.M. Elongational behaviour of a low density polyethylene melt. Rheol. Acta 1979, 18, 492–504. [Google Scholar] [CrossRef]

- Barlow, E.J.; Langlois, W.E. Diffusion of Gas from a Liquid into an Expanding Bubble. IBM J. Res. Dev. 1962, 6, 329–337. [Google Scholar] [CrossRef]

- Kiran, E.; Sarver, J.A.; Hassler, J.C. Solubility and Diffusivity of CO2 and N2 in Polymers and Polymer Swelling, Glass Transition, Melting, and Crystallization at High Pressure. A Critical Review and Perspectives on Experimental Methods, Data, and Modeling. J. Supercrit. Fluids 2021, 185, 105378. [Google Scholar] [CrossRef]

- Li, G.; Li, H.; Turng, L.S.; Gong, S.; Zhang, C. Measurement of gas solubility and diffusivity in polylactide. Fluid Phase Equilibria 2006, 246, 158–166. [Google Scholar] [CrossRef]

- Piszko, M.; Schaible, T.; Bonten, C.; Fröba, A.P. Mutual and Thermal Diffusivities in Polystyrene Melts with Dissolved Nitrogen by Dynamic Light Scattering. Macromolecules 2021, 54, 5662–5672. [Google Scholar] [CrossRef]

- Moreira, J.C.; Demarquette, N.R. Influence of temperature, molecular weight, and molecular weight dispersity on the surface tension of PS, PP, and PE. I. Experimental. J. Appl. Polym. Sci. 2001, 82, 1907–1920. [Google Scholar] [CrossRef]

- Mehrabi Mazidi, M.; Edalat, A.; Berahman, R.; Hosseini, F.S. Highly-Toughened Polylactide- (PLA-) Based Ternary Blends with Significantly Enhanced Glass Transition and Melt Strength: Tailoring the Interfacial Interactions, Phase Morphology, and Performance. Macromolecules 2018, 51, 4298–4314. [Google Scholar] [CrossRef]

- Sato, Y.; Yurugi, M.; Fujiwara, K.; Takishima, H.; Masuoka, H. Solubilities of carbon dioxide and nitrogen in polystyrene under high temperature and pressure. Fluid Phase Equilibria 1996, 125, 129–138. [Google Scholar] [CrossRef]

- Poh, L.; Narimissa, E.; Wagner, M.H.; Winter, H.H. Interactive Shear and Extensional Rheology—25 years of IRIS Software. Rheol. Acta 2022, 61, 259–269. [Google Scholar] [CrossRef]

- Winter, H.H.; Mours, M. The cyber infrastructure initiative for rheology. Rheol. Acta 2006, 45, 331–338. [Google Scholar] [CrossRef]

- Aho, J.; Rolón-Garrido, V.H.; Syrjälä, S.; Wagner, M.H. Measurement technique and data analysis of extensional viscosity for polymer melts by Sentmanat extensional rheometer (SER). Rheol. Acta 2010, 49, 359–370. [Google Scholar] [CrossRef]

- Wagner, M.H. Zur Netzwerktheorie von Polymer-Schmelzen. Rheol. Acta 1979, 18, 33–50. [Google Scholar] [CrossRef]

- Geiger, K.; Grünschloss, E. Analytische Betrachtung zum Granulatbildungsprozess bei der Unterwassergranulierung. In 20. Stuttgarter Kunststoff-Kolloquium 2007, 1st ed.; Fritz, H.G., Eisenbach, C.D., Eds.; Univeristy of Stuttgart: Stuttgart, Germany, 2007; ISBN 978-3-00-020846-1. [Google Scholar]

- Hu, D.; Gao, X.; Qiang, W.; Chen, Y.; Xu, Z.; Zhao, L. Effect of additives on the dynamic bubble growth behavior of polymer foam evaluated with in-situ visualizations and simulations. Polym. Test. 2022, 105, 107419. [Google Scholar] [CrossRef]

- Taki, K. Experimental and numerical studies on the effects of pressure release rate on number density of bubbles and bubble growth in a polymeric foaming process. Chem. Eng. Sci. 2008, 63, 3643–3653. [Google Scholar] [CrossRef]

| PS | PLA | |

|---|---|---|

| Temperature in °C | 220 | 220 |

| in wt.-% N2 | 0.33 | 0.34 |

| in mm | 0.05 | 0.04 |

| in mm | 0.078 | 0.116 |

| in bar | 110 | 146 |

| in Pa·s | 12.558 | 9.395 |

| kg/m3 | 926.7 | 1067 |

| in m2/s [54,55,56] | 2.36·10−9 | 4.60·10−9 |

| in N/m [57,58] | 0.0289 | 0.0251 |

| in Pa−1 [54,55,59] | 2.29·10−10 | 3.22·10−10 |

| DE | LMSF | MSF | ||||

|---|---|---|---|---|---|---|

| PS | 1 | 1 | 1 | 20 | - | - |

| PLA | 1 | 1 | 1 | 30 | 1.6 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schaible, T.; Bonten, C. Prediction of the Bubble Growth Behavior by Means of the Time-, Temperature-, Pressure- and Blowing Agent Concentration-Dependent Transient Elongational Viscosity Function of Polymers. Polymers 2024, 16, 1213. https://doi.org/10.3390/polym16091213

Schaible T, Bonten C. Prediction of the Bubble Growth Behavior by Means of the Time-, Temperature-, Pressure- and Blowing Agent Concentration-Dependent Transient Elongational Viscosity Function of Polymers. Polymers. 2024; 16(9):1213. https://doi.org/10.3390/polym16091213

Chicago/Turabian StyleSchaible, Tobias, and Christian Bonten. 2024. "Prediction of the Bubble Growth Behavior by Means of the Time-, Temperature-, Pressure- and Blowing Agent Concentration-Dependent Transient Elongational Viscosity Function of Polymers" Polymers 16, no. 9: 1213. https://doi.org/10.3390/polym16091213