Facile Preparation of Lightweight Natural Rubber Nanocomposite Foams with High Wear Resistance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Organic Modification of Nano-Montmorillonite

2.3. Preparation of Natural-Rubber-Based Foams

2.4. Characterization

2.4.1. Fourier Infrared Test

2.4.2. X-ray Diffraction (XRD)

2.4.3. Vulcanization Characteristics

2.4.4. Physical and Mechanical Properties

2.4.5. Differential Scanning Calorimeter

2.4.6. Thermogravimetric Analyzer

2.4.7. Akron Abrasion Resistance Test

- ρ—sample density; unit: grams/cubic centimeter (g/cm3).

- m0—initial mass; unit: grams (g).

- m1—final mass; unit: grams (g).

- ∆V—abrasion volume; unit: cubic centimeter/1.61 Km (cm3/1.61 Km).

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, Z.; Cai, Y.; Zhan, Y.; Meng, Y.; Li, Y.; Xie, Q.; Xia, H. Thermal insulating rubber foams embedded with segregated carbon nanotube networks for electromagnetic shielding applications. Chem. Eng. J. 2022, 435, 135118. [Google Scholar] [CrossRef]

- Hu, J.; Ma, T.; Yin, T.; Zhou, Y. Foamed warm mix asphalt mixture containing crumb rubber: Foaming optimization and performance evaluation. J. Clean Prod. 2022, 333, 130085. [Google Scholar] [CrossRef]

- Shui, Y.; Huang, L.; Wei, C.; Sun, G.; Chen, J.; Lu, A.; Sun, L.; Liu, D. How the silica determines properties of filled silicone rubber by the formation of filler networking and bound rubber. Compos. Sci. Technol. 2021, 215, 109024. [Google Scholar] [CrossRef]

- Phiri, M.M.; Sibeko, M.A.; Phiri, M.J.; Hlangothi, S.P. Effect of free foaming and pre-curing on the thermal, morphological and physical properties of reclaimed tyre rubber foam composites. J. Clean Prod. 2019, 218, 665–672. [Google Scholar] [CrossRef]

- Dogan, M.; Dogan, S.D.; Savas, L.A.; Ozcelik, G.; Tayfun, U. Flame retardant effect of boron compounds in polymeric materials. Compos. Part B Eng. 2021, 222, 109088. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, W.; Gong, W.; Ma, W.; Hou, C.; Li, Y.; Zhang, Q.; Wang, H. Abrasion resistant/waterproof stretchable triboelectric yarns based on fermat spirals. Adv. Mater. 2021, 33, 2100782. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Tan, C.; Qiu, Z.; Ma, W.; Kuang, M.; Zeng, D. Additively manufactured SiC-reinforced stainless steel with excellent strength and wear resistance. Addit. Manuf. 2021, 41, 101971. [Google Scholar] [CrossRef]

- Luo, J.; Sun, W.; Duan, R.; Yang, W.; Chan, K.C.; Ren, F.; Yang, X. Laser surface treatment-introduced gradient nanostructured TiZrHfTaNb refractory high-entropy alloy with significantly enhanced wear resistance. J. Mater. Sci. Technol. 2022, 110, 43–56. [Google Scholar] [CrossRef]

- Fan, S.; Gao, C.; Duan, C.; Zhang, S.; Zhang, P.; Yu, L.; Zhang, Z. Geometry effect of copper nanoparticles and nanowires on polyetheretherketone-matrix nanocomposites: Thermal conductivity, dynamic mechanical properties and wear resistance. Compos. Sci. Technol. 2022, 219, 109224. [Google Scholar] [CrossRef]

- Liu, G.; Du, D.; Wang, K.; Pu, Z.; Zhang, D.; Chang, B. Microstructure and wear behavior of IC10 directionally solidified superalloy repaired by directed energy deposition. J. Mater. Sci. Technol. 2021, 93, 71–78. [Google Scholar] [CrossRef]

- Gashti, M.P.; Moradian, S.; Rashidi, A.; Yazdanshenas, M.E. Various nano-silica particles affecting dyeability of poly (ethylene terephthalate)/silica nanocomposite films. Fiber. Polym. 2013, 14, 743–751. [Google Scholar] [CrossRef]

- Kong, X.; Liu, Y.; Chen, M.; Zhang, T.; Wang, Q.; Wang, F. Heterostructured NiCr matrix composites with high strength and wear resistance. J. Mater. Sci. Technol. 2022, 105, 142–152. [Google Scholar] [CrossRef]

- Tong, Y.; Li, W.; Shi, Q.; Chen, L.; Yang, G. Self-lubricating epoxy-based composite abradable seal coating eliminating adhesive transfer via hierarchical design. J. Mater. Sci. Technol. 2022, 104, 145–154. [Google Scholar] [CrossRef]

- Tinkler, J.D.; Scacchi, A.; Kothari, H.R.; Tulliver, H.; Argaiz, M.; Archer, A.J.; Martín-Fabiani, I. Evaporation-driven self-assembly of binary and ternary colloidal polymer nanocomposites for abrasion resistant applications. J. Colloid Interface Sci. 2021, 581, 729–740. [Google Scholar] [CrossRef]

- Jeon, H.; Kim, Y.; Yu, W.; Lee, J.U. Exfoliated graphene/thermoplastic elastomer nanocomposites with improved wear properties for 3D printing. Compos. Part B Eng. 2020, 189, 107912. [Google Scholar] [CrossRef]

- Yin, Y.; Zhao, Y.; En Koey, K.; Tan, Q.; Zhang, M.; Huang, H. In-situ synthesized age-hardenable high-entropy composites with superior wear resistance. Compos. Part B Eng. 2022, 235, 109795. [Google Scholar] [CrossRef]

- Li, Y.; Liu, G.; Wang, L.; Zhang, J.; Xu, M.; Shi, S.Q. Multifunctional conductive graphite/cellulosic microfiber-natural rubber composite sponge with ultrasensitive collision-warning and fire-waring. Chem. Eng. J. 2022, 431, 134046. [Google Scholar] [CrossRef]

- Yin, J.; Hu, J.; Han, Y.; Chen, Y.; Hu, J.; Zhang, Z.; Huang, S.; Duan, Y.; Wu, H.; Zhang, J. Facile fabrication of high nanofiller-content natural rubber nanocomposites for reversible plasticity shape memory polymers. Compos. Sci. Technol. 2022, 221, 109349. [Google Scholar] [CrossRef]

- Zeng, S.; Ren, Y.; Liu, P.; Wang, Q.; He, L.; Wang, Q. Facile fabrication of chrome-tanned leather wastes/natural rubber composite: Mechanochemical de-crosslinking effect on collagen fibers and chrome complexation enabled in-situ compatibilization. Compos. Sci. Technol. 2021, 214, 108998. [Google Scholar] [CrossRef]

- Zhang, G.; Zhou, X.; Liang, K.; Guo, B.; Li, X.; Wang, Z.; Zhang, L. Mechanically Robust and Recyclable EPDM Rubber Composites by a Green Cross-Linking Strategy. ACS Sustain. Chem. Eng. 2019, 7, 11712–11720. [Google Scholar] [CrossRef]

- Wang, H.; Xue, C.; Guo, X.; Liu, B.; Ji, Z.; Huang, M.; Jia, S. Superhydrophobic porous film for daytime radiative cooling. Appl. Mater. Today 2021, 24, 101100. [Google Scholar] [CrossRef]

- Wang, G.; Li, A.; Li, K.; Zhao, Y.; Ma, Y.; He, Q. A fluorine-free superhydrophobic silicone rubber surface has excellent self-cleaning and bouncing properties. J. Colloid Interface Sci. 2021, 588, 175–183. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Fan, J.; Cao, L.; Xu, C.; Chen, Y. A novel strategy to construct co-continuous PLA/NBR thermoplastic vulcanizates: Metal-ligand coordination-induced dynamic vulcanization, balanced stiffness-toughness and shape memory effect. Chem. Eng. J. 2020, 385, 123828. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, H.; Shi, C.; Chen, Z. A novel warm-mix additive for SBR modified asphalt binder: Effects of Sasobit/epoxidized soybean oil compound on binder rheological and long-term aging performance. J. Clean Prod. 2021, 326, 129405. [Google Scholar] [CrossRef]

- Yang, Q.; Yu, S.; Zhong, H.; Liu, T.; Yao, E.; Zhang, Y.; Zou, H.; Du, W. Gas products generation mechanism during co-pyrolysis of styrene-butadiene rubber and natural rubber. J. Hazard. Mater. 2021, 401, 123302. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, Z.; Wemyss, A.M.; Wan, C.; Liu, Y.; Song, P.; Wang, S. Effective thermal-oxidative reclamation of waste tire rubbers for producing high-performance rubber composites. ACS Sustain. Chem. Eng. 2020, 8, 9079–9087. [Google Scholar] [CrossRef]

- Guerra, N.B.; Sant’Ana Pegorin, G.; Boratto, M.H.; de Barros, N.R.; de Oliveira Graeff, C.F.; Herculano, R.D. Biomedical applications of natural rubber latex from the rubber tree Hevea brasiliensis. Mater. Sci. Eng. C 2021, 126, 112126. [Google Scholar] [CrossRef] [PubMed]

- Si, Y.; Luo, H.; Zhou, F.; Bai, X.; Han, L.; Sun, H.; Cha, R. Advances in polysaccharide nanocrystals as pharmaceutical excipients. Carbohydr. Polym. 2021, 262, 117922. [Google Scholar] [CrossRef]

- Goh, Y.; Lauro, S.; Barber, S.T.; Williams, S.A.; Trabold, T.A. Cleaner production of flexographic ink by substituting carbon black with biochar. J. Clean Prod. 2021, 324, 129262. [Google Scholar] [CrossRef]

- Tian, Q.; Zhang, C.; Tang, Y.; Liu, Y.; Niu, L.; Ding, T.; Li, X.; Zhang, Z. Preparation of hexamethyl disilazane-surface functionalized nano-silica by controlling surface chemistry and its “agglomeration-collapse” behavior in solution polymerized styrene butadiene rubber/butadiene rubber composites. Compos. Sci. Technol. 2021, 201, 108482. [Google Scholar] [CrossRef]

- Jiang, Y.; Tian, C.; Yao, J.; Wu, W.; Ning, N.; Tian, M.; Zhang, L. Nano-Silica/Polydimethyl(methylvinyl)siloxane dielectric elastomer generator with high generating energy density, high efficiency and long fatigue life. Chem. Eng. J. 2022, 439, 135339. [Google Scholar] [CrossRef]

- He, R.; Yang, Z.; Gan, V.J.L.; Chen, H.; Cao, D. Mechanism of nano-silica to enhance the robustness and durability of concrete in low air pressure for sustainable civil infrastructures. J. Clean Prod. 2021, 321, 128783. [Google Scholar] [CrossRef]

- Intapun, J.; Rungruang, T.; Suchat, S.; Cherdchim, B.; Hiziroglu, S. The Characteristics of natural rubber composites with Klason lignin as a green reinforcing filler: Thermal stability, mechanical and dynamical Properties. Polymers 2021, 13, 1109. [Google Scholar] [CrossRef] [PubMed]

- Wantat, A.; Seraypheap, K.; Rojsitthisak, P. Effect of chitosan coatings supplemented with chitosan-montmorillonite nanocomposites on postharvest quality of ‘Hom Thong’banana fruit. Food Chem. 2022, 374, 131731. [Google Scholar] [CrossRef] [PubMed]

- Archibong, F.N.; Orakwe, L.C.; Ogah, O.A.; Mbam, S.O.; Ajah, S.A.; Okechukwu, M.E.; Igberi, C.O.; Okafor, K.J.; Chima, M.O.; Ikelle, I.I. Emerging progress in montmorillonite rubber/polymer nanocomposites: A review. J. Mater. Sci. 2023, 58, 2396–2429. [Google Scholar] [CrossRef]

- Hu, W.; Yu, K.; Zheng, Q.; Hu, Q.; Cao, C.; Cao, K.; Sun, W.; Gao, J.; Shi, Y.; Song, P. Intelligent cyclic fire warning sensor based on hybrid PBO nanofiber and montmorillonite nanocomposite papers decorated with phenyltriethoxysilane. J. Colloid Interface Sci. 2023, 647, 467–477. [Google Scholar] [CrossRef]

- Mallick, B. X-ray diffraction analysis of polymeric solid using Bragg-Brentano geometry. Int. J. Mater. Chem. Phys. 2015, 1, 265–270. [Google Scholar]

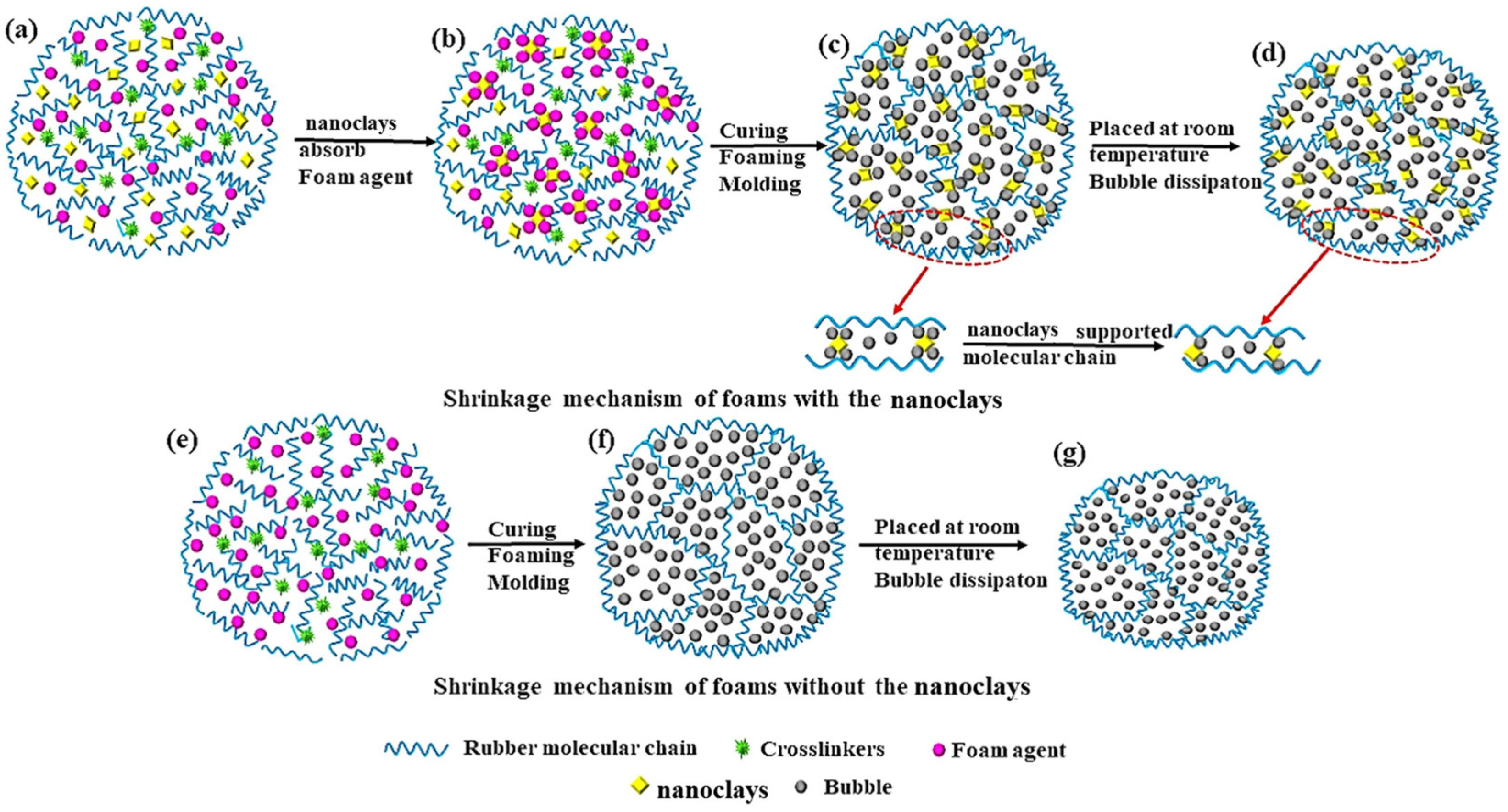

- Ji, Z.; Ma, J.; Fei, G.; Wang, H.; Yang, Y.; Ma, Z.; Zhang, G.; Shao, L. Enhanced dimensional stability of lightweight SBR/EVA foam by an inorganic scaffold structure constructed in the cell wall. Polymer 2022, 253, 125002. [Google Scholar] [CrossRef]

- Barghamadi, M.; Karrabi, M.; Ghoreishy, M.H.R.; Naderi, G. Effect of TESPT on viscoelastic and mechanical properties with the morphology of SSBR/BR hybrid nanocomposites. J. Appl. Polym. Sci. 2023, 140, e53863. [Google Scholar] [CrossRef]

- Shi, H.; Zhou, W.; Wen, Z.; Wang, W.; Zeng, X.; Sun, R.; Ren, L. Thermally conductive and compliant polyurethane elastomer composites by constructing a tri-branched polymer network. Mater. Horizons 2023, 10, 928–937. [Google Scholar] [CrossRef]

- Hao, Z.; Cheng, G.; Fan, Y.; Li, L.; Kong, L. Research on tool stick-slip erosion wear mechanism in cutting nickel-based alloy GH4169. Tribol. Int. 2023, 188, 108803. [Google Scholar] [CrossRef]

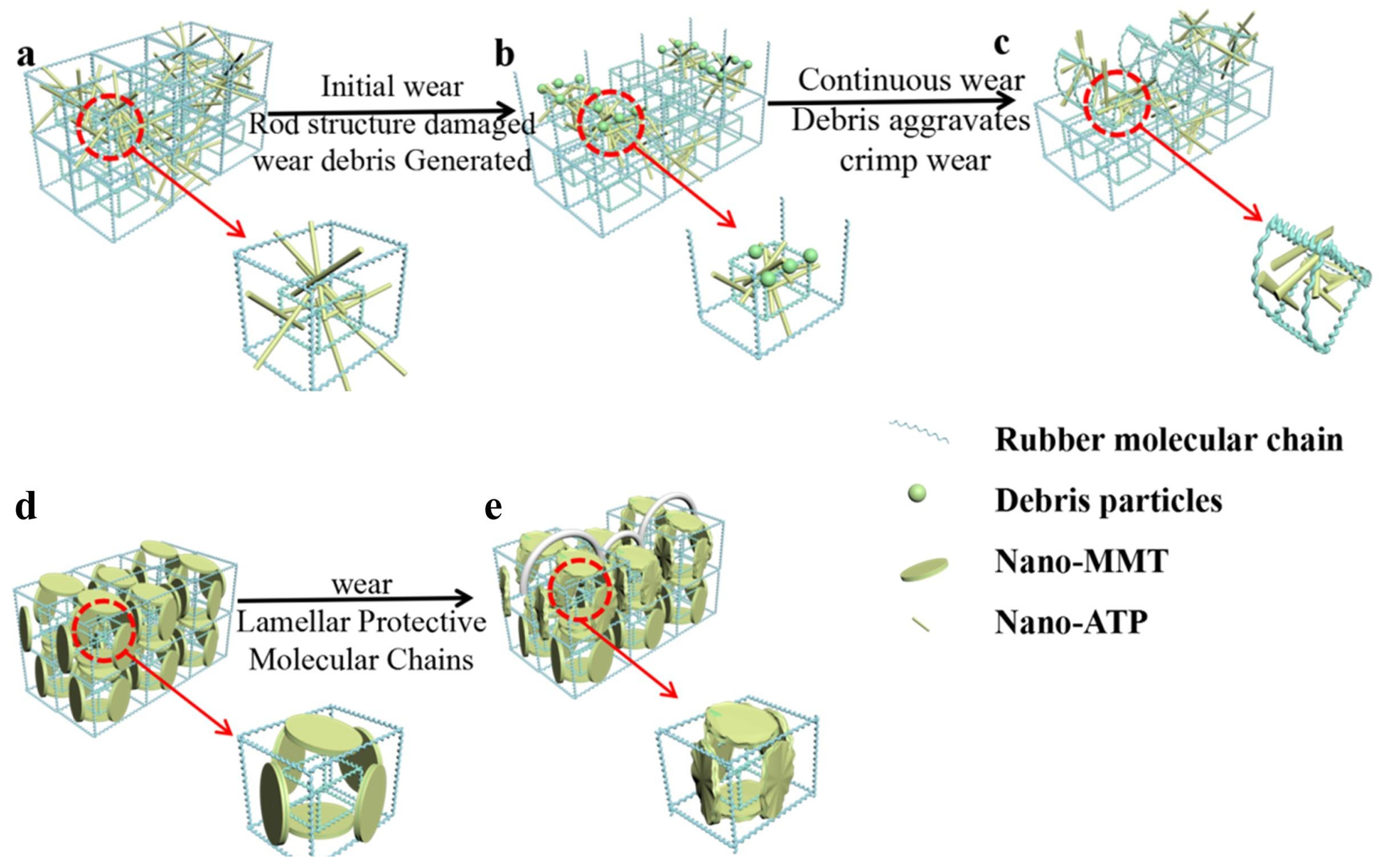

- Dasari, A.; Yu, Z.; Mai, Y. Fundamental aspects and recent progress on wear/scratch damage in polymer nanocomposites. Mater. Sci. Eng. R Rep. 2009, 63, 31–80. [Google Scholar] [CrossRef]

| Sample | FOAM | F–ATP | F–LDH | F–MMT | F–OMMT |

|---|---|---|---|---|---|

| ATP | 0 | 3 | 0 | 0 | 0 |

| LDH | 0 | 0 | 3 | 0 | 0 |

| MMT | 0 | 0 | 0 | 3 | 0 |

| OMMT | 0 | 0 | 0 | 0 | 3 |

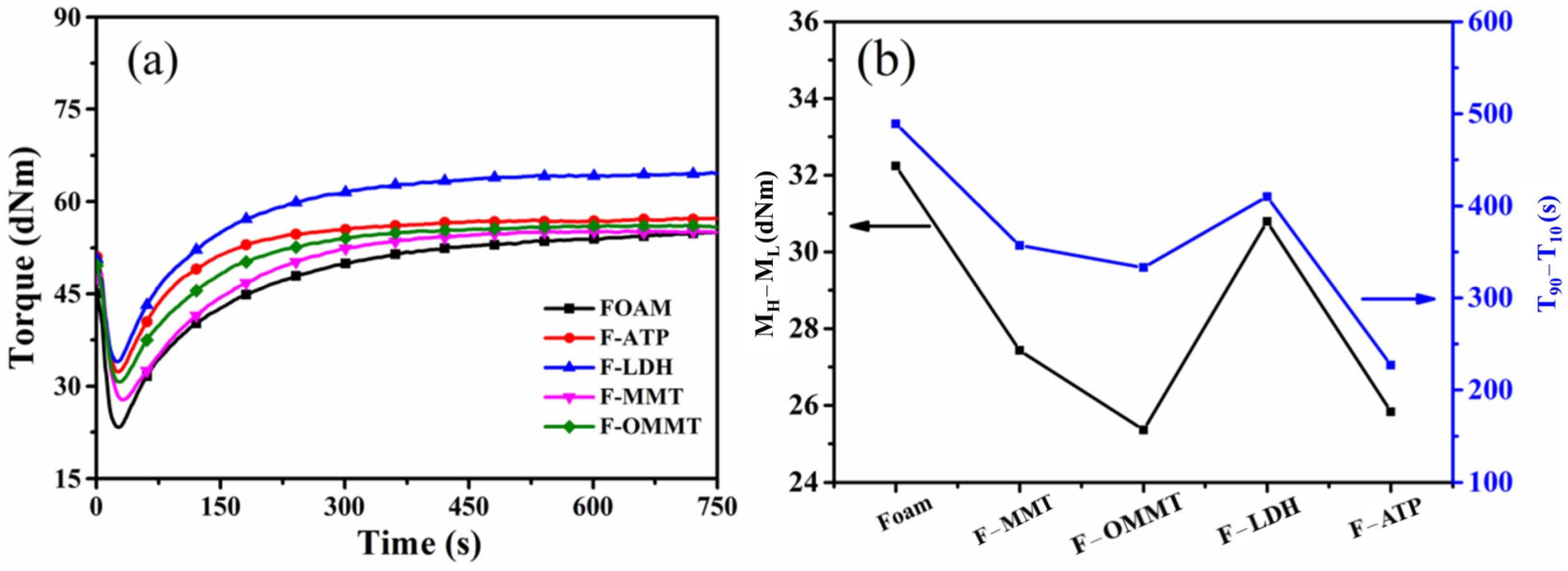

| Sample | Mi (dNm) | ML (dNm) | MH (dNm) | ∆M (dNm) | t10 (s) | t90 (s) | CRI |

|---|---|---|---|---|---|---|---|

| FOAM | 45.05 | 23.31 | 55.55 | 32.24 | 28 | 517 | 0.2045 |

| F–MMT | 47.73 | 27.73 | 55.16 | 27.43 | 28 | 385 | 0.2833 |

| F–OMMT | 49.63 | 30.64 | 56 | 25.36 | 27 | 360 | 0.3003 |

| F–LDH | 50.62 | 33.97 | 64.76 | 30.79 | 25 | 435 | 0.2439 |

| F–ATP | 51 | 32.33 | 58.16 | 25.83 | 26 | 253 | 0.4405 |

| Samples | Temperature/°C | Residual Rate/% | ||

|---|---|---|---|---|

| TiD | T5 | T30 | ||

| FOAM | 243.5 | 286.2 | 382.7 | 17.3 |

| F–ATP | 248.3 | 305.5 | 385.0 | 19 |

| F–LDH | 250.4 | 308.2 | 384.6 | 19 |

| F–MMT | 253.6 | 318.7 | 385.2 | 19 |

| F–OMMT | 260.4 | 321.4 | 388.1 | 18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, H.; Deng, F. Facile Preparation of Lightweight Natural Rubber Nanocomposite Foams with High Wear Resistance. Polymers 2024, 16, 1226. https://doi.org/10.3390/polym16091226

Jin H, Deng F. Facile Preparation of Lightweight Natural Rubber Nanocomposite Foams with High Wear Resistance. Polymers. 2024; 16(9):1226. https://doi.org/10.3390/polym16091226

Chicago/Turabian StyleJin, Hua, and Fuquan Deng. 2024. "Facile Preparation of Lightweight Natural Rubber Nanocomposite Foams with High Wear Resistance" Polymers 16, no. 9: 1226. https://doi.org/10.3390/polym16091226

APA StyleJin, H., & Deng, F. (2024). Facile Preparation of Lightweight Natural Rubber Nanocomposite Foams with High Wear Resistance. Polymers, 16(9), 1226. https://doi.org/10.3390/polym16091226