Unveiling the Future of Meat Packaging: Functional Biodegradable Packaging Preserving Meat Quality and Safety

Abstract

1. Introduction

2. Major Challenges for Meat Products

2.1. Meat Composition

2.2. Quality and Safety of Meat Products

2.2.1. Discoloration

2.2.2. Texture

2.2.3. Flavor and Odor

2.2.4. Microorganisms

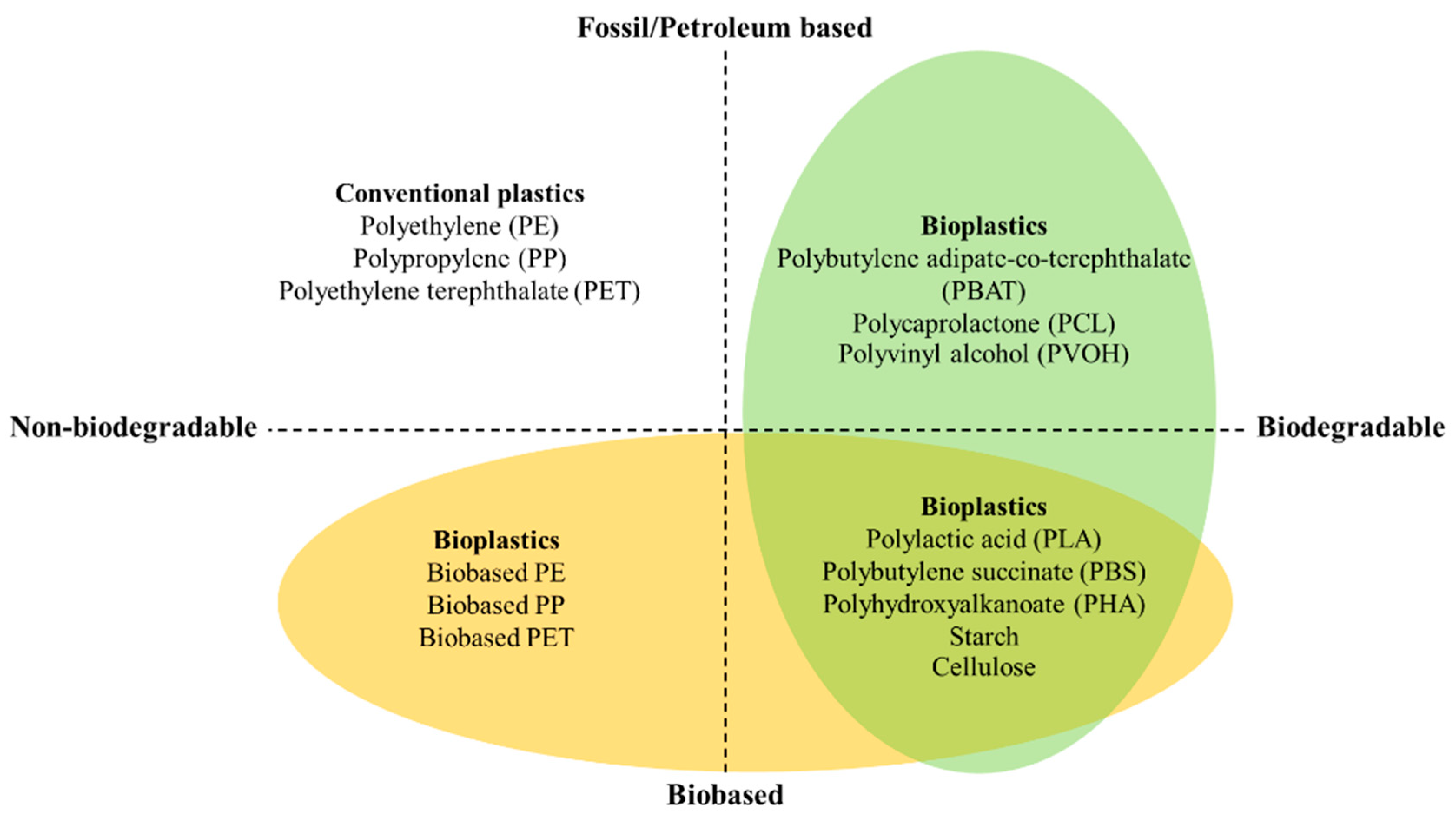

3. Bioplastic Materials

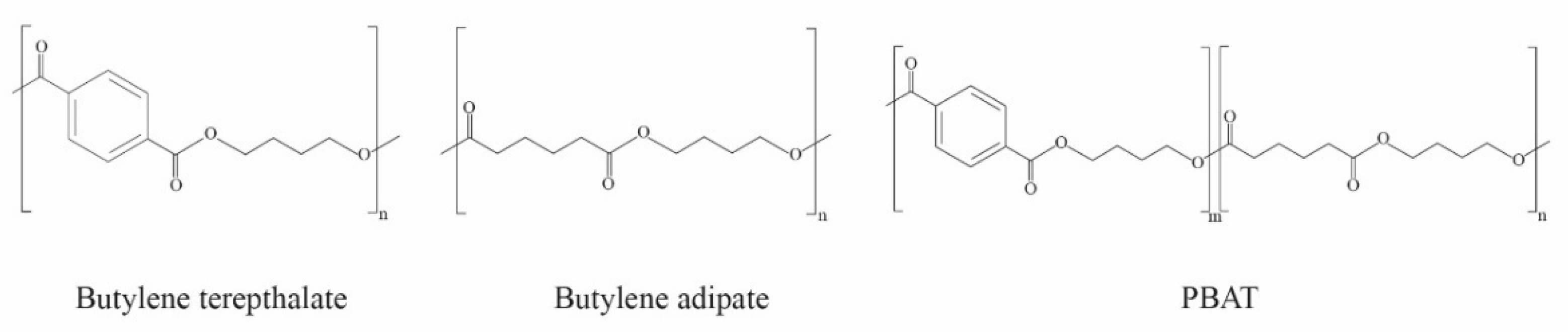

3.1. Polybutylene Adipate-Co-Terephthalate (PBAT)

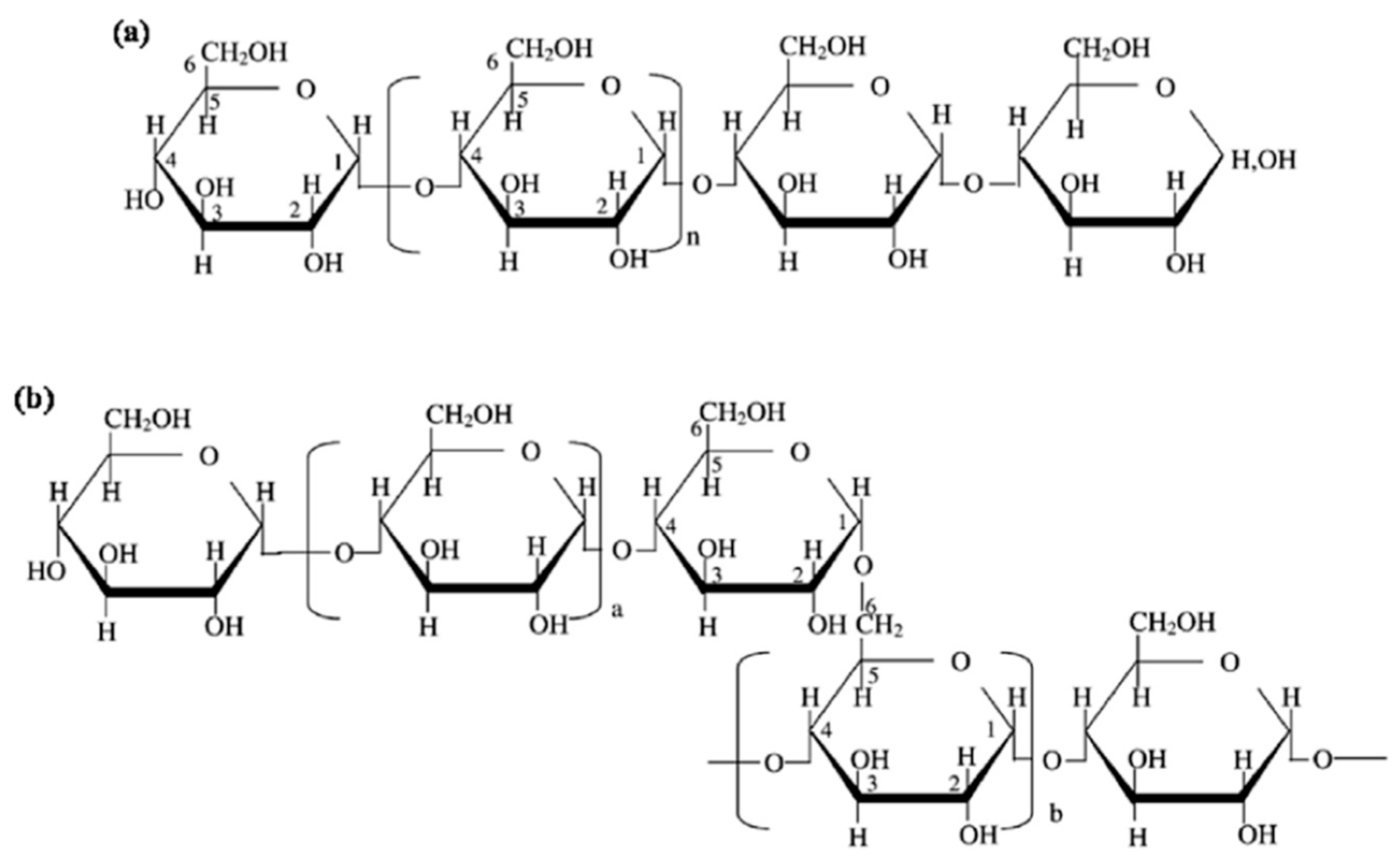

3.2. Starch

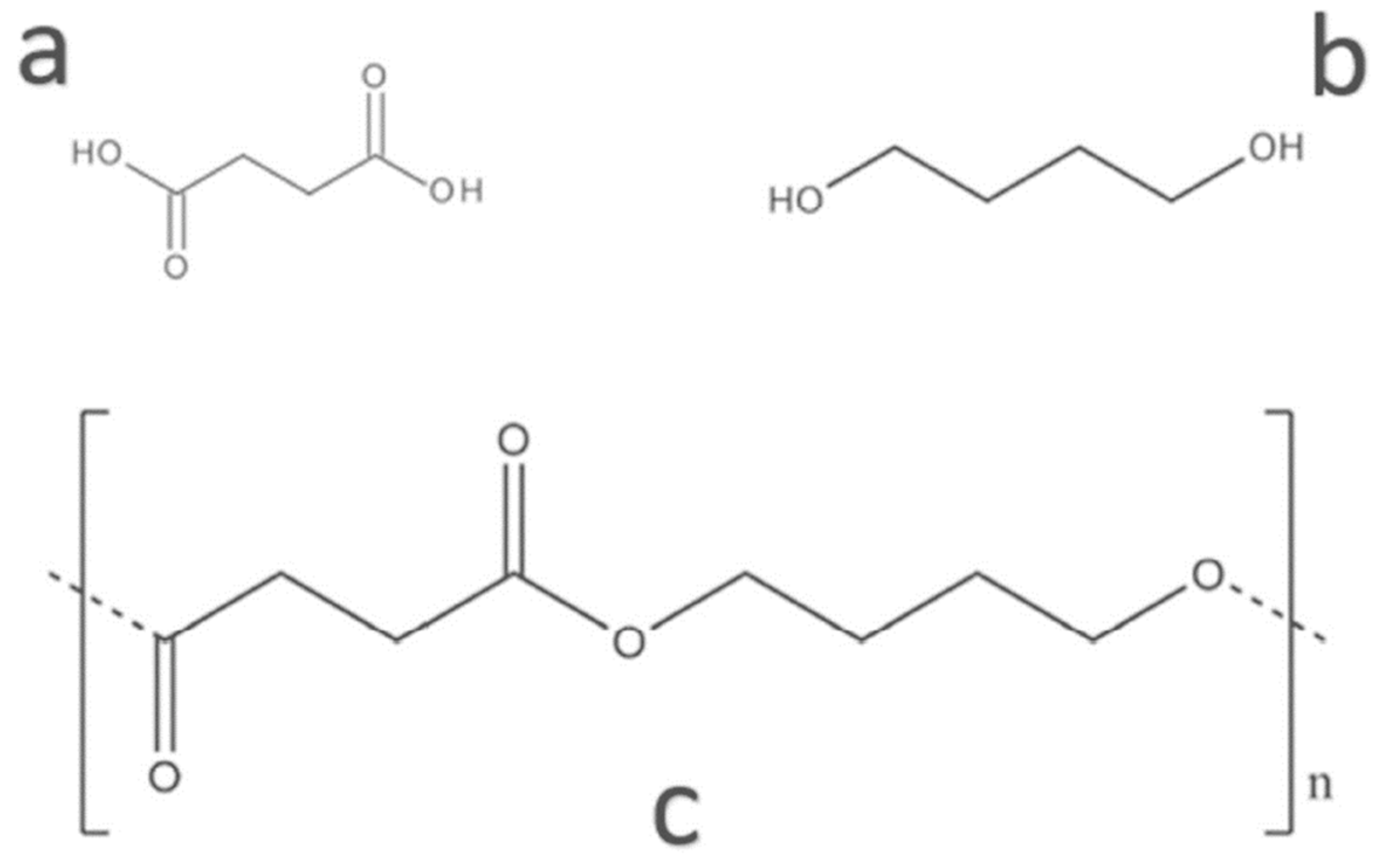

3.3. Polybutylene Succinate (PBS)

3.4. Polylactic Acid (PLA)

3.5. Bioplastic Blends

| Bioplastic | Properties | Advantages | Disadvantages | Packaging Applications | References |

|---|---|---|---|---|---|

| PBAT | Tm~110–125 °C EB > 500% TS~15–20 MPa WVP~3 g·mm/m2·d·kPa OP~60 cm2·mm/m2·d·atm | High flexibility Good biodegradability Thermal stability Good processing stability | Low transparency High production costs | Blowing film application Mulch film Cutlery Bags | [2,3,46] |

| TPS | EB < 100% TS < 5 MPa WVP~7–11 10−10·g/s·m·Pa Water solubility > 20% | Abundant renewable resources Biodegradable Cheap biopolymer | Poor thermal processability Low water vapor barrier Moisture sensitivity Retrogradation processes | Compost bags Food packaging Edible film Coating | [6,52,53,63] |

| PBS | EB~100–200%. TS~25 MPa. WVP~1.5 g·mm/m2·d·kPa OP~30 cm2·mm/m2·d·atm | High flexibility Excellent thermal stability | High stiffness High melt viscosity for processing Low transparency | Film (polymer blends) Film coating | [2,57,63] |

| PLA | Tm~130–210 °C EB < 15% TS~20–60 MPa WVP~3 g·mm/m2·d·kPa OP~60 cm2·mm/m2·d·atm | High strength High transparency High processability | High brittleness Low heat distortion temperature Slow crystallization rate | Tray Bag Metallized and shrink films | [3,57,58] |

4. Bio-Functional Packaging

5. Functional Packaging for Meat Products

5.1. Antioxidant Packaging

5.2. Antimicrobial Packaging

| Packaging Material | Antimicrobial Agent | Product | Findings | Reference |

|---|---|---|---|---|

| PLA/PBAT | Cinnamaldehyde and tea polyphenols | Meat analogue | Films protective against E. coli and S. aureus during 10 days of storage. | [96] |

| PBAT/TPS | Nisin and ethylenediaminetetraacetic acid | Pork | Ethylenediaminetetraacetic acid and nisin protective against L. monocytogenes, C. perfringens, S. aureus, and L. innocua. | [29] |

| TPS/whey protein isolate | Rambutan peel extract and cinnamon oil | Salami | Rambutan peel extract and cinnamon oil displayed antibacterial activity against B. cereus, E. coli, and S. aureus. | [86] |

| PLA | Carvacrol | Ground beef | Carvacrol-loaded PLA film reduced TVC and extended shelf life at 1.1 ± 1.5 days. | [97] |

| PLA | Lauric arginate ester, sodium lactate, and sorbic acid | Meat | - Lauric arginate ester reduced L. innocua, L. monocytogenes, and S. typhimurium growth for 3–5 weeks - Sorbic acid reduced the growth of L. innocua but not Salmonella. | [98] |

| TPS | Gallic acid, chitosan, and carvacrol | Ham | - Chitosan and carvacrol acted synergistically in L. monocytogenes inhibition. | [99] |

| TPS/PBAT | Sodium nitrite | Pork | - Nitrite reduced TVC up to 1.5 log CFU/g. - Nitrite against Pseudomonas aeruginosa. | [74] |

| Chitosan | Thyme essential oil | Meat | - Thyme essential oil reduced yeast populations but did not affect aerobic mesophilic bacteria, lactic acid bacteria, and enterobacteria. | [100] |

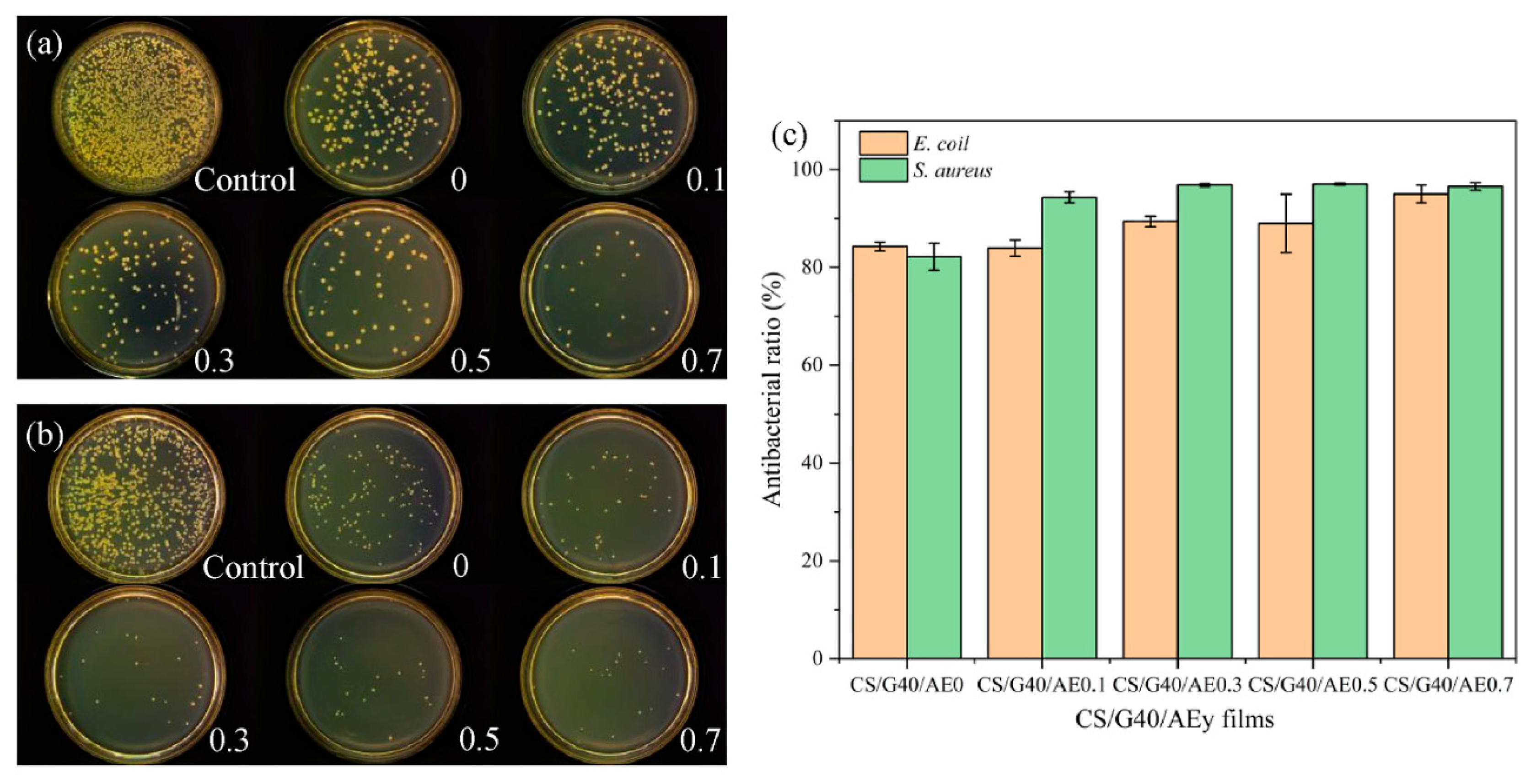

| Chitosan | Aloe emodin | Pork | - Chitosan is a natural antibacterial agent with positively charged amino groups that interacted with microbial cell membranes. - Aloe emodin inhibited bacterial formation, bringing about bacterial metabolism disorder and death and protecting against E. coli and S. aureus as shown in Figure 7. | [101] |

| Sodium caseinate | Pomegranate peel extract | Ground beef | - Pomegranate peel extract protecting against S. aureus and E. coli enhanced the germicidal activity of sodium caseinate. | [102] |

| Carboxymethyl cellulose (CMC) | Encapsulated pomegranate extract | Fresh beef and chicken meat | - CMC film and encapsulated pomegranate extract interacted via hydrogen bonding at 3320 cm−1, which shifted to a lower wavenumber. - The film system was more effective in inhibiting L. monocytogenes than C. jejuni, S. typhimurium, and S. aureus. - The classical CMC could not retard the growth of bacteria until the end of storage, while CMC with encapsulated pomegranate extract could delay microbial growth in beef and chicken meat. | [103] |

| Cassava starch and sodium carboxymethyl cellulose | Caffeic acid and silica nanoparticles (C@SNPs) | Fresh beef and chicken meat | - Reduction in hydrogen bonds and hydroxyl groups of the film formed by the nanoparticles, reduced the hydrophilicity of the film matrix. - Film containing C@SNPs 5:1 could inhibit E. coli and S. aureus with percent reductions up to 65.43% and 61.90%, respectively. - The active packaging delayed the microbial growth and TBARS in the fresh meat. The TBARS in the meat packed in film were 0.130 mg MDA/kg, while in the control group, they were 0.611 mg MDA/kg. | [104] |

| PBAT/TPS | Zinc oxide (ZnO) nanoparticles | Pork | - ZnO delayed microbial growth and extended shelf life to more than 12 days. - ZnO against S. aureus, E. coli, Enterobacteriaceae, and Pseudomonas spp. | [105] |

| Bacterial nanocellulose (BNC) | Postbiotics of Lactobacillus sakei | Buffalo patty | - A slight shift in the stretching vibration of the carboxylic groups of the BNC (1627 cm−1) indicates the successful incorporation of postbiotics into the BNC matrix. - The growth of L. monocytogenes in the buffalo patty was significantly reduced by the BNC film containing postbiotics of Lactobacillus sakei. | [106] |

5.3. Other Functional Packaging

6. Food Preservatives as Alternative Functional Compounds

7. Flavor/Odor Contamination

8. The Prospective Future of Functional Packaging Technology for Meat Products

9. Conclusions and Challenges

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Nachod, B.; Keller, E.; Hassanein, A.; Lansing, S. Assessment of petroleum-based plastic and bioplastics degradation using anaerobic digestion. Sustainability 2021, 13, 13295. [Google Scholar] [CrossRef]

- Bumbudsanpharoke, N.; Wongphan, P.; Promhuad, K.; Leelaphiwat, P.; Harnkarnsujarit, N. Morphology and permeability of bio-based poly(butylene adipate-co-terephthalate) (PBAT), poly(butylene succinate) (PBS) and linear low-density polyethylene (LLDPE) blend films control shelf-life of packaged bread. Food Control 2022, 132, 108541. [Google Scholar] [CrossRef]

- Jariyasakoolroj, P.; Leelaphiwat, P.; Harnkarnsujarit, N. Advances in research and development of bioplastic for food packaging. J. Sci. Food Agric. 2020, 100, 5032–5045. [Google Scholar] [CrossRef] [PubMed]

- European, B. Global Production Capacities of Biodegradable Plastic 2023 (by Material Type). Available online: https://www.european-bioplastics.org/bioplastics/materials/biodegradable/ (accessed on 23 January 2024).

- Harnkarnsujarit, N.; Wongphan, P.; Chatkitanan, T.; Laorenza, Y.; Srisa, A. Bioplastic for Sustainable Food Packaging. In Sustainable Food Processing and Engineering Challenges; Academic Press: Amsterdam, The Netherlands, 2021; pp. 203–277. [Google Scholar]

- Narancic, T.; Cerrone, F.; Beagan, N.; O’Connor, K.E. Recent Advances in Bioplastics: Application and Biodegradation. Polymers 2020, 12, 920. [Google Scholar] [CrossRef] [PubMed]

- Dammak, M.; Fourati, Y.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P.; Boufi, S. Blends of PBAT with plasticized starch for packaging applications: Mechanical properties, rheological behaviour and biodegradability. Ind. Crops Prod. 2020, 144, 112061. [Google Scholar] [CrossRef]

- de Castro, L.; Silva, L.G.L.; Abreu, I.R.; Braz, C.J.F.; Rodrigues, S.C.S.; Moreira-Araujo, R.; Folkersma, R.; de Carvalho, L.H.; Barbosa, R.; Alves, T.S. Biodegradable PBAT/PLA blend films incorporated with turmeric and cinnamomum powder: A potential alternative for active food packaging. Food Chem. 2024, 439, 138146. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Ghosh, T.; Zhang, W.; Rhim, J.-W. Recent progress in PBAT-based films and food packaging applications: A mini-review. Food Chem. 2024, 437, 137822. [Google Scholar] [CrossRef]

- RameshKumar, S.; Shaiju, P.; O’Connor, K.E. Bio-based and biodegradable polymers-State-of-the-art, challenges and emerging trends. Curr. Opin. Green Sustain. Chem. 2020, 21, 75–81. [Google Scholar] [CrossRef]

- Zhang, D.; Ivane, N.M.A.; Haruna, S.A.; Zekrumah, M.; Elyse, F.K.R.; Tahir, H.E.; Wang, G.; Wang, C.; Zou, X. Recent trends in the micro-encapsulation of plant-derived compounds and their specific application in meat as antioxidants and antimicrobials. Meat Sci. 2022, 191, 108842. [Google Scholar] [CrossRef]

- Wongphan, P.; Nerin, C.; Harnkarnsujarit, N. Enhanced compatibility and functionality of thermoplastic cassava starch blended PBAT blown films with erythorbate and nitrite. Food Chem. 2023, 420, 136107. [Google Scholar] [CrossRef]

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Nethra, P.V.; Sunooj, K.V.; Aaliya, B.; Navaf, M.; Akhila, P.P.; Sudheesh, C.; Mir, S.A.; Shijin, A.; George, J. Critical factors affecting the shelf life of packaged fresh red meat–A review. Meas. Food 2023, 10, 100086. [Google Scholar] [CrossRef]

- Li, X.L.; Shen, Y.; Hu, F.; Zhang, X.X.; Thakur, K.; Rengasamy, K.R.; Khan, M.R.; Busquets, R.; Wei, Z.J. Fortification of polysaccharide-based packaging films and coatings with essential oils: A review of their preparation and use in meat preservation. Int. J. Biol. Macromol. 2023, 242, 124767. [Google Scholar] [CrossRef] [PubMed]

- Smaoui, S.; Chérif, I.; Hlima, H.B.; Khan, M.U.; Rebezov, M.; Thiruvengadam, M.; Sarkar, T.; Shariati, M.A.; Lorenzo, J.M. Zinc oxide nanoparticles in meat packaging: A systematic review of recent literature. Food Packag. Shelf Life 2023, 36, 101045. [Google Scholar] [CrossRef]

- Domínguez, R.; Barba, F.J.; Gómez, B.; Putnik, P.; Kovačević, D.B.; Pateiro, M.; Santos, E.M.; Lorenzo, J.M. Active packaging films with natural antioxidants to be used in meat industry: A review. Food Res. Int. 2018, 113, 93–101. [Google Scholar] [CrossRef] [PubMed]

- Nair, M.S.; Nair, D.V.; Johny, A.K.; Venkitanarayanan, K. Use of food preservatives and additives in meat and their detection techniques. In Meat Quality Analysis; Elsevier: Amsterdam, The Netherlands, 2020; pp. 187–213. [Google Scholar]

- Toldrá, F. Handbook of Meat Processing; John Wiley & Sons: Ames, IA, USA, 2010. [Google Scholar]

- Kerry, J.P. Advances in Meat, Poultry and Seafood Packaging; Woodhead Publishing: Sawston, UK, 2012. [Google Scholar]

- Robertson, G.L. Food Packaging—Principles and Practice, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Holman, B.W.; Kerry, J.P.; Hopkins, D.L. Meat packaging solutions to current industry challenges: A review. Meat Sci. 2018, 144, 159–168. [Google Scholar] [CrossRef] [PubMed]

- Mancini, R.A.; Hunt, M.C. Current research in meat color. Meat Sci. 2005, 71, 100–121. [Google Scholar] [CrossRef]

- Brewer, S. Irradiation effects on meat color—A review. Meat Sci. 2004, 68, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Luo, X.; Zhang, Y.; Hopkins, D.L.; Liang, R.; Dong, P.; Zhu, L. Effects of microbiota dynamics on the color stability of chilled beef steaks stored in high oxygen and carbon monoxide packaging. Food Res. Int. 2020, 134, 109215. [Google Scholar] [CrossRef]

- Sánchez-Escalante, A.; Djenane, D.; Torrescano, G.; Beltrán, J.A.; Roncalés, P. The effects of ascorbic acid, taurine, carnosine and rosemary powder on colour and lipid stability of beef patties packaged in modified atmosphere. Meat Sci. 2001, 58, 421–429. [Google Scholar] [CrossRef]

- Seydim, A.C.; Guzel-Seydim, Z.B.; Acton, J.C.; Dawson, P.L. Effects of Rosemary extract and sodium lactate on quality of vacuum-packaged ground ostrich meat. J. Food Sci. 2006, 71, S71–S76. [Google Scholar] [CrossRef]

- Chatkitanan, T.; Harnkarnsujarit, N. Effects of nitrite incorporated active films on quality of pork. Meat Sci. 2021, 172, 108367. [Google Scholar] [CrossRef] [PubMed]

- Leelaphiwat, P.; Pechprankan, C.; Siripho, P.; Bumbudsanpharoke, N.; Harnkarnsujarit, N. Effects of nisin and EDTA on morphology and properties of thermoplastic starch and PBAT biodegradable films for meat packaging. Food Chem. 2022, 369, 130956. [Google Scholar] [CrossRef]

- Guerrero-Legarreta, I. Handbook of Poultry Science and Technology, Volume 2: Secondary Processing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Juárez, M.; Aldai, N.; López-Campos, Ó.; Dugan, M.; Uttaro, B.; Aalhus, J. Beef texture and juiciness. Handb. Meat Meat Process. 2012, 9, 177–206. [Google Scholar]

- Seyfert, M.; Hunt, M.; Mancini, R.; Hachmeister, K.; Kropf, D.; Unruh, J.; Loughin, T. Beef quadriceps hot boning and modified-atmosphere packaging influence properties of injection-enhanced beef round muscles. J. Anim. Sci. 2005, 83, 686–693. [Google Scholar] [CrossRef][Green Version]

- Kim, Y.H.; Huff-Lonergan, E.; Sebranek, J.G.; Lonergan, S.M. High-oxygen modified atmosphere packaging system induces lipid and myoglobin oxidation and protein polymerization. Meat Sci. 2010, 85, 759–767. [Google Scholar] [CrossRef]

- Shahidi, F. Flavor of meat and meat products—An overview. In Flavor of Meat and Meat Products; Springer: New York, NY, USA, 1994; pp. 1–3. [Google Scholar]

- Rhee, K.S. Chemistry of meat flavor. In Flavor Chemistry of Lipid Foods; The American Oil Chemists Society: Urbana, IL, USA, 1989; pp. 166–189. [Google Scholar]

- Dominguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J.M. A Comprehensive Review on Lipid Oxidation in Meat and Meat Products. Antioxidants 2019, 8, 429. [Google Scholar] [CrossRef] [PubMed]

- Gray, J.; Pearson, A. Lipid-derived off-flavours in meat—Formation and inhibition. In Flavor of Meat and Meat Products; Springer: New York, NY, USA, 1994; pp. 116–143. [Google Scholar]

- de W Blackburn, C. Food Spoilage Microorganisms; Woodhead Publishing: Boca Raton, FL, USA, 2006. [Google Scholar]

- Pellissery, A.J.; Vinayamohan, P.G.; Amalaradjou, M.A.R.; Venkitanarayanan, K. Spoilage bacteria and meat quality. In Meat Quality Analysis; Elsevier: Amsterdam, The Netherlands, 2020; pp. 307–334. [Google Scholar]

- Jay, J.M.; Loessner, M.J.; Golden, D.A. Fresh meats and poultry. In Modern Food Microbiology; Springer Science & Business Media: New York, NY, USA, 2005; pp. 63–99. [Google Scholar]

- Doyle, M.P. Compendium of the Microbiological Spoilage of Foods and Beverages; Springer: New York, NY, USA, 2009. [Google Scholar]

- Barros-Velazquez, J. Antimicrobial Food Packaging; Academic Press: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Rahmadiawan, D.; Shi, S.C.; Abral, H.; Ilham, M.K.; Sugiarti, E.; Muslimin, A.N.; Putra, N.S.D. Comparative Analysis of the Influence of Different Preparation Methods on the Properties of TEMPO-Oxidized Bacterial Cellulose Powder Films. J. Nat. Fibers 2024, 21, 2301386. [Google Scholar] [CrossRef]

- Bioplastics, E. Global Production Capacities of Bioplastics 2021 (by Material Type). Available online: https://www.european-bioplastics.org/bioplastics/materials/ (accessed on 20 May 2021).

- Herrera, R.; Franco, L.; Rodríguez-Galán, A.; Puiggalí, J. Characterization and degradation behavior of poly(butylene adipate-co-terephthalate)s. J. Polym. Sci. Part A Polym. Chem. 2002, 40, 4141–4157. [Google Scholar] [CrossRef]

- Jiao, J.; Zeng, X.; Huang, X. An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv. Ind. Eng. Polym. Res. 2020, 3, 19–26. [Google Scholar] [CrossRef]

- Dominici, F.; Gigli, M.; Armentano, I.; Genovese, L.; Luzi, F.; Torre, L.; Munari, A.; Lotti, N. Improving the flexibility and compostability of starch/poly(butylene cyclohexanedicarboxylate)-based blends. Carbohydr. Polym. 2020, 246, 116631. [Google Scholar] [CrossRef] [PubMed]

- Menzel, C. Improvement of starch films for food packaging through a three-principle approach: Antioxidants, cross-linking and reinforcement. Carbohydr. Polym. 2020, 250, 116828. [Google Scholar] [CrossRef] [PubMed]

- Zhu, F. Composition, structure, physicochemical properties, and modifications of cassava starch. Carbohydr. Polym. 2015, 122, 456–480. [Google Scholar] [CrossRef] [PubMed]

- Amagliani, L.; O’Regan, J.; Kelly, A.L.; O’Mahony, J.A. Chemistry, structure, functionality and applications of rice starch. J. Cereal Sci. 2016, 70, 291–300. [Google Scholar] [CrossRef]

- Colivet, J.; Carvalho, R.A. Hydrophilicity and physicochemical properties of chemically modified cassava starch films. Ind. Crops Prod. 2017, 95, 599–607. [Google Scholar] [CrossRef]

- Zhang, Y.; Rempel, C.; Liu, Q. Thermoplastic starch processing and characteristics-a review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1353–1370. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi Nafchi, A.; Moradpour, M.; Saeidi, M.; Alias, A.K. Thermoplastic starches: Properties, challenges, and prospects. Starch-Stärke 2013, 65, 61–72. [Google Scholar] [CrossRef]

- Khan, B.; Bilal Khan Niazi, M.; Samin, G.; Jahan, Z. Thermoplastic Starch: A Possible Biodegradable Food Packaging Material-A Review. J. Food Process. Eng. 2017, 40, e12447. [Google Scholar] [CrossRef]

- Aliotta, L.; Seggiani, M.; Lazzeri, A.; Gigante, V.; Cinelli, P. A Brief Review of Poly (Butylene Succinate) (PBS) and Its Main Copolymers: Synthesis, Blends, Composites, Biodegradability, and Applications. Polymers 2022, 14, 844. [Google Scholar] [CrossRef]

- Mochane, M.J.; Magagula, S.I.; Sefadi, J.S.; Mokhena, T.C. A Review on Green Composites Based on Natural Fiber-Reinforced Polybutylene Succinate (PBS). Polymers 2021, 13, 1200. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and Its Blends with Poly(butylene succinate) (PBS): A Brief Review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [PubMed]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Deng, S.; Chen, P.; Ruan, R. Polylactic acid (PLA) synthesis and modifications: A review. Front. Chem. China 2009, 4, 259–264. [Google Scholar] [CrossRef]

- Zhai, X.; Wang, W.; Zhang, H.; Dai, Y.; Dong, H.; Hou, H. Effects of high starch content on the physicochemical properties of starch/PBAT nanocomposite films prepared by extrusion blowing. Carbohydr. Polym. 2020, 239, 116231. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Liu, Q.; Shi, J.; Ye, H.; Zhou, Q. Distinctive Tensile Properties of the Blends of Poly(l-lactic acid) (PLLA) and Poly(butylene succinate) (PBS). J. Polym. Environ. 2017, 26, 1737–1744. [Google Scholar] [CrossRef]

- Garalde, R.A.; Thipmanee, R.; Jariyasakoolroj, P.; Sane, A. The effects of blend ratio and storage time on thermoplastic starch/poly(butylene adipate-co-terephthalate) films. Heliyon 2019, 5, e01251. [Google Scholar] [CrossRef] [PubMed]

- Bartolucci, L.; Cordiner, S.; De Maina, E.; Kumar, G.; Mele, P.; Mulone, V.; Igliński, B.; Piechota, G. Sustainable valorization of bioplastic waste: A review on effective recycling routes for the most widely used biopolymers. Int. J. Mol. Sci. 2023, 24, 7696. [Google Scholar] [CrossRef]

- Qiu, S.; Zhou, Y.; Waterhouse, G.I.N.; Gong, R.; Xie, J.; Zhang, K.; Xu, J. Optimizing interfacial adhesion in PBAT/PLA nanocomposite for biodegradable packaging films. Food Chem. 2021, 334, 127487. [Google Scholar] [CrossRef] [PubMed]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Studies on mechanical, thermal, and morphological characteristics of biocomposites from biodegradable polymer blends and natural fibers. In Biocomposites; Woodhead Publishing: Cambridge, UK, 2015; pp. 93–140. [Google Scholar]

- Garcia, P.S.; Grossmann, M.V.E.; Shirai, M.A.; Lazaretti, M.M.; Yamashita, F.; Muller, C.M.O.; Mali, S. Improving action of citric acid as compatibiliser in starch/polyester blown films. Ind. Crops Prod. 2014, 52, 305–312. [Google Scholar] [CrossRef]

- Olivato, J.B.; Grossmann, M.V.; Bilck, A.P.; Yamashita, F. Effect of organic acids as additives on the performance of thermoplastic starch/polyester blown films. Carbohydr. Polym. 2012, 90, 159–164. [Google Scholar] [CrossRef]

- Olivato, J.B.; Grossmann, M.V.E.; Yamashita, F.; Nobrega, M.M.; Scapin, M.R.S.; Eiras, D.; Pessan, L.A. Compatibilisation of starch/poly(butylene adipate co-terephthalate) blends in blown films. Int. J. Food Sci. Technol. 2011, 46, 1934–1939. [Google Scholar] [CrossRef]

- Laorenza, Y.; Harnkarnsujarit, N. Carvacrol, citral and alpha-terpineol essential oil incorporated biodegradable films for functional active packaging of Pacific white shrimp. Food Chem. 2021, 363, 130252. [Google Scholar] [CrossRef] [PubMed]

- Klinmalai, P.; Srisa, A.; Laorenza, Y.; Katekhong, W.; Harnkarnsujarit, N. Antifungal and plasticization effects of carvacrol in biodegradable poly(lactic acid) and poly(butylene adipate terephthalate) blend films for bakery packaging. LWT 2021, 152, 112356. [Google Scholar] [CrossRef]

- Basavegowda, N.; Baek, K.H. Advances in Functional Biopolymer-Based Nanocomposites for Active Food Packaging Applications. Polymers 2021, 13, 4198. [Google Scholar] [CrossRef]

- European, C. Commission Regulation (EC) No 450/2009 of 29 May 2009 on Active and Intelligent Materials and Articles Intended to Come into Contact with Food. Available online: https://eur-lex.europa.eu/eli/reg/2009/450/oj (accessed on 5 July 2022).

- Suppakul, P.; Miltz, J.; Sonneveld, K.; Bigger, S.W. Active packaging technologies with an emphasis on antimicrobial packaging and its applications. J. Food Sci. 2003, 68, 408–420. [Google Scholar] [CrossRef]

- Katekhong, W.; Wongphan, P.; Klinmalai, P.; Harnkarnsujarit, N. Thermoplastic starch blown films functionalized by plasticized nitrite blended with PBAT for superior oxygen barrier and active biodegradable meat packaging. Food Chem. 2022, 374, 131709. [Google Scholar] [CrossRef] [PubMed]

- Jha, P. Effect of plasticizer and antimicrobial agents on functional properties of bionanocomposite films based on corn starch-chitosan for food packaging applications. Int. J. Biol. Macromol. 2020, 160, 571–582. [Google Scholar] [CrossRef] [PubMed]

- Vilarinho, F.; Andrade, M.; Buonocore, G.G.; Stanzione, M.; Vaz, M.F.; Sanches Silva, A. Monitoring lipid oxidation in a processed meat product packaged with nanocomposite poly(lactic acid) film. Eur. Polym. J. 2018, 98, 362–367. [Google Scholar] [CrossRef]

- Tsironi, M.; Kosma, I.S.; Badeka, A.V. The Effect of Whey Protein Films with Ginger and Rosemary Essential Oils on Microbiological Quality and Physicochemical Properties of Minced Lamb Meat. Sustainability 2022, 14, 3434. [Google Scholar] [CrossRef]

- Kongkaoroptham, P.; Piroonpan, T.; Pasanphan, W. Chitosan nanoparticles based on their derivatives as antioxidant and antibacterial additives for active bioplastic packaging. Carbohydr. Polym. 2021, 257, 117610. [Google Scholar] [CrossRef]

- Leal, I.L.; Silva Rosa, Y.C.; Silva Penha, J.; Cruz Correia, P.R.; Silva Melo, P.; Guimarães, D.H.; Barbosa, J.D.V.; Druzian, J.I.; Machado, B.A.S. Development and application starch films: PBAT with additives for evaluating the shelf life of Tommy Atkins mango in the fresh-cut state. J. Appl. Polym. Sci. 2019, 136, 48150. [Google Scholar] [CrossRef]

- Balaguer, M.P.; Fajardo, P.; Gartner, H.; Gomez-Estaca, J.; Gavara, R.; Almenar, E.; Hernandez-Munoz, P. Functional properties and antifungal activity of films based on gliadins containing cinnamaldehyde and natamycin. Int. J. Food Microbiol. 2014, 173, 62–71. [Google Scholar] [CrossRef]

- Pires, J.R.A.; de Souza, V.G.L.; Fernando, A.L. Chitosan/montmorillonite bionanocomposites incorporated with rosemary and ginger essential oil as packaging for fresh poultry meat. Food Packag. Shelf Life 2018, 17, 142–149. [Google Scholar] [CrossRef]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K.; Promsorn, J.; Harnkarnsujarit, N. Biodegradable Poly(Butylene Adipate-Co-Terephthalate) and Thermoplastic Starch-Blended TiO2 Nanocomposite Blown Films as Functional Active Packaging of Fresh Fruit. Polymers 2021, 13, 4192. [Google Scholar] [CrossRef]

- Wangprasertkul, J.; Siriwattanapong, R.; Harnkarnsujarit, N. Antifungal packaging of sorbate and benzoate incorporated biodegradable films for fresh noodles. Food Control 2021, 123, 107763. [Google Scholar] [CrossRef]

- Sebranek, J.; Sewalt, V.; Robbins, K.; Houser, T. Comparison of a natural rosemary extract and BHA/BHT for relative antioxidant effectiveness in pork sausage. Meat Sci. 2005, 69, 289–296. [Google Scholar] [CrossRef] [PubMed]

- Moore, M.; Han, I.; Acton, J.; Ogale, A.; Barmore, C.; Dawson, P. Effects of antioxidants in polyethylene film on fresh beef color. J. Food Sci. 2003, 68, 99–104. [Google Scholar] [CrossRef]

- Chollakup, R.; Pongburoos, S.; Boonsong, W.; Khanoonkon, N.; Kongsin, K.; Sothornvit, R.; Sukyai, P.; Sukatta, U.; Harnkarnsujarit, N. Antioxidant and antibacterial activities of cassava starch and whey protein blend films containing rambutan peel extract and cinnamon oil for active packaging. LWT 2020, 130, 109573. [Google Scholar] [CrossRef]

- Moreno, O.; Atares, L.; Chiralt, A. Effect of the incorporation of antimicrobial/antioxidant proteins on the properties of potato starch films. Carbohydr. Polym. 2015, 133, 353–364. [Google Scholar] [CrossRef]

- Fiore, A.; Park, S.; Volpe, S.; Torrieri, E.; Masi, P. Active packaging based on PLA and chitosan-caseinate enriched rosemary essential oil coating for fresh minced chicken breast application. Food Packag. Shelf Life 2021, 29, 100708. [Google Scholar] [CrossRef]

- Panrong, T.; Karbowiak, T.; Harnkarnsujarit, N. Thermoplastic starch and green tea blends with LLDPE films for active packaging of meat and oil-based products. Food Packag. Shelf Life 2019, 21, 100331. [Google Scholar] [CrossRef]

- Ribeiro Sanches, M.A.; Camelo-Silva, C.; da Silva Carvalho, C.; Rafael de Mello, J.; Barroso, N.G.; Lopes da Silva Barros, E.; Silva, P.P.; Pertuzatti, P.B. Active packaging with starch, red cabbage extract and sweet whey: Characterization and application in meat. LWT 2021, 135, 110275. [Google Scholar] [CrossRef]

- Li, T.; Xia, N.; Xu, L.; Zhang, H.; Zhang, H.; Chi, Y.; Zhang, Y.; Li, L.; Li, H. Preparation, characterization and application of SPI-based blend film with antioxidant activity. Food Packag. Shelf Life 2021, 27, 100614. [Google Scholar] [CrossRef]

- Mohammadi, H.; Kamkar, A.; Misaghi, A.; Zunabovic-Pichler, M.; Fatehi, S. Nanocomposite films with CMC, okra mucilage, and ZnO nanoparticles: Extending the shelf-life of chicken breast meat. Food Packag. Shelf Life 2019, 21, 100330. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Kim, S.-M.; Rhim, J.-W. Carboxymethyl cellulose-based multifunctional film combined with zinc oxide nanoparticles and grape seed extract for the preservation of high-fat meat products. Sustain. Mater. Technol. 2021, 29, e00325. [Google Scholar] [CrossRef]

- Promsorn, J.; Harnkarnsujarit, N. Pyrogallol loaded thermoplastic cassava starch based films as bio-based oxygen scavengers. Ind. Crops Prod. 2022, 186, 115226. [Google Scholar] [CrossRef]

- Promsorn, J.; Harnkarnsujarit, N. Oxygen absorbing food packaging made by extrusion compounding of thermoplastic cassava starch with gallic acid. Food Control 2022, 142, 109273. [Google Scholar] [CrossRef]

- Wang, L.; Xu, J.; Zhang, M.; Zheng, H.; Li, L. Preservation of soy protein-based meat analogues by using PLA/PBAT antimicrobial packaging film. Food Chem. 2022, 380, 132022. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Heising, J.; Fogliano, V.; Dekker, M. Fat content and storage conditions are key factors on the partitioning and activity of carvacrol in antimicrobial packaging. Food Packag. Shelf Life 2020, 24, 100500. [Google Scholar] [CrossRef]

- Guo, M.; Jin, T.Z.; Yang, R. Antimicrobial Polylactic Acid Packaging Films against Listeria and Salmonella in Culture Medium and on Ready-to-Eat Meat. Food Bioprocess. Technol. 2014, 7, 3293–3307. [Google Scholar] [CrossRef]

- Zhao, Y.; Teixeira, J.S.; Saldana, M.D.A.; Ganzle, M.G. Antimicrobial activity of bioactive starch packaging films against Listeria monocytogenes and reconstituted meat microbiota on ham. Int. J. Food Microbiol. 2019, 305, 108253. [Google Scholar] [CrossRef] [PubMed]

- Quesada, J.; Sendra, E.; Navarro, C.; Sayas-Barbera, E. Antimicrobial Active Packaging including Chitosan Films with Thymus vulgaris L. Essential Oil for Ready-to-Eat Meat. Foods 2016, 5, 57. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Ning, Y.; Ren, Z.; Xu, S.; Li, J.; Wang, L. Fabricating anti-ultraviolet and antibacterial films with lower water solubility from chitosan, glycerol and aloe emodin for pork preservation. Food Hydrocoll. 2024, 153, 110030. [Google Scholar] [CrossRef]

- Emam-Djomeh, Z.; Moghaddam, A.; Yasini Ardakani, S.A. Antimicrobial Activity of Pomegranate (Punica granatum L.) Peel Extract, Physical, Mechanical, Barrier and Antimicrobial Properties of Pomegranate Peel Extract-incorporated Sodium Caseinate Film and Application in Packaging for Ground Beef. Packag. Technol. Sci. 2015, 28, 869–881. [Google Scholar] [CrossRef]

- Khalid, S.A.; Ghanem, A.F.; Abd-El-Malek, A.; Ammar, M.A.; El-Khateib, T.; El-Sherbiny, I.M. Free-standing carboxymethyl cellulose film incorporating nanoformulated pomegranate extract for meat packaging. Carbohydr. Polym. 2024, 332, 121915. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Peng, S.; Chen, X.; Li, C.; Cui, H. Silica nanoparticles loaded with caffeic acid to optimize the performance of cassava starch/sodium carboxymethyl cellulose film for meat packaging. Int. J. Biol. Macromol. 2023, 241, 124591. [Google Scholar] [CrossRef] [PubMed]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K.; Promsorn, J.; Harnkarnsujarit, N. Blown film extrusion of PBAT/TPS/ZnO nanocomposites for shelf-life extension of meat packaging. Colloids Surf. B Biointerfaces 2022, 214, 112472. [Google Scholar] [CrossRef]

- Rasouli, Y.; Moradi, M.; Tajik, H.; Molaei, R. Fabrication of anti-Listeria film based on bacterial cellulose and Lactobacillus sakei-derived bioactive metabolites; application in meat packaging. Food Biosci. 2021, 42, 101218. [Google Scholar] [CrossRef]

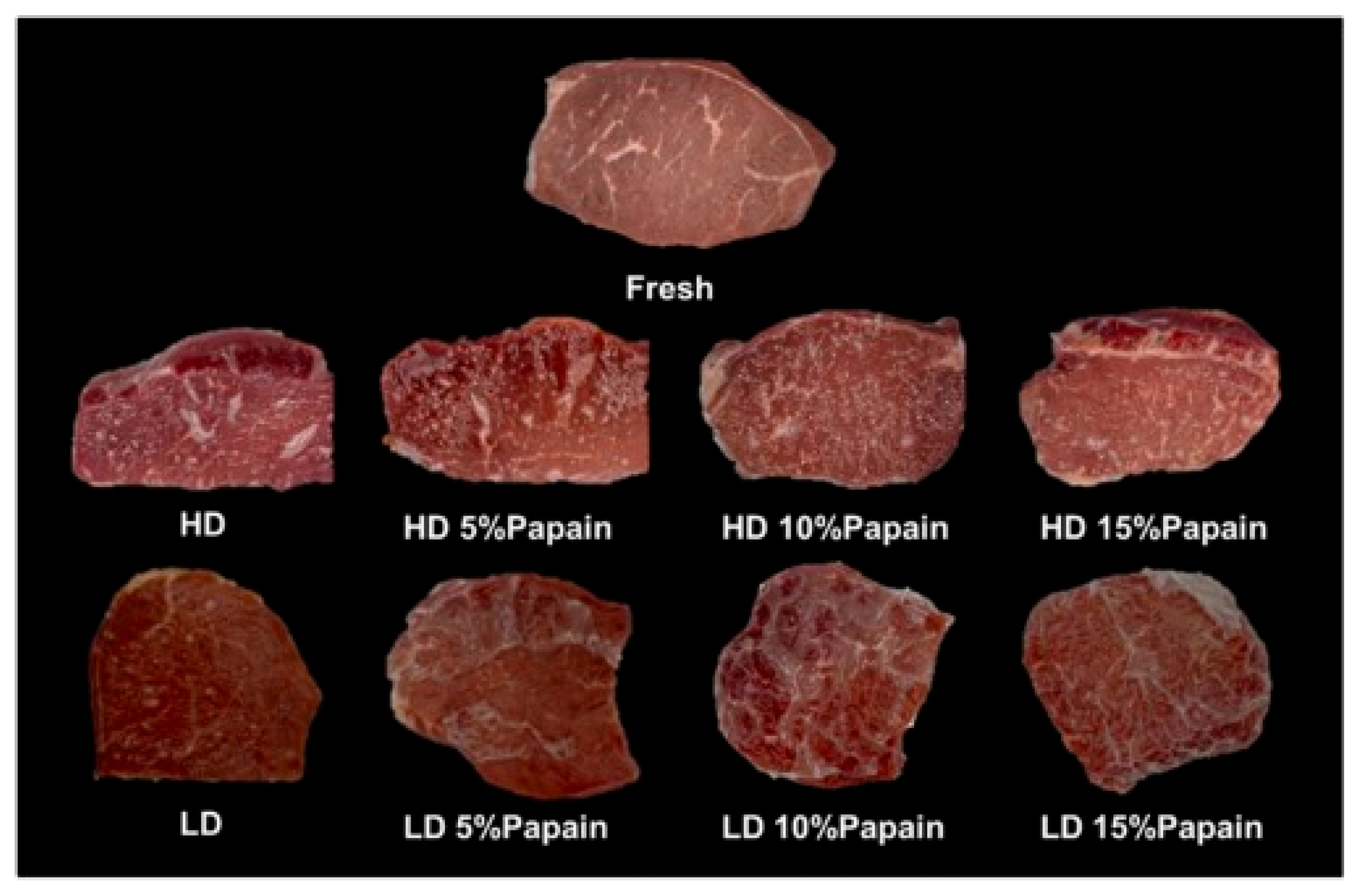

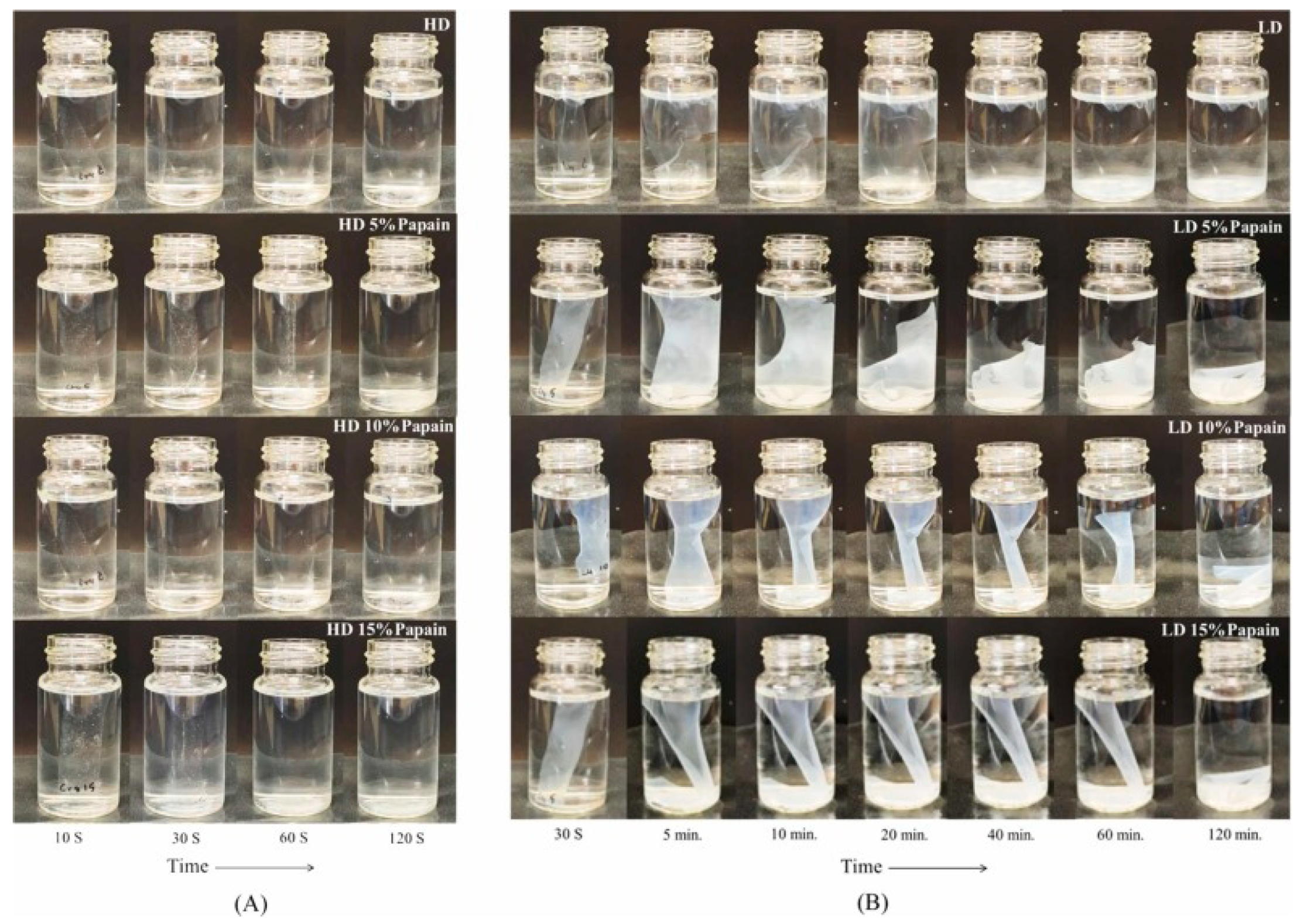

- Wongphan, P.; Khowthong, M.; Supatrawiporn, T.; Harnkarnsujarit, N. Novel edible starch films incorporating papain for meat tenderization. Food Packag. Shelf Life 2022, 31, 100787. [Google Scholar] [CrossRef]

- FDA. Overview of Food Ingredients, Additives & Colors. Available online: https://www.fda.gov/food/food-ingredients-packaging/overview-food-ingredients-additives-colors (accessed on 14 July 2022).

- Kumari, P.; Akhila, S.; Rao, Y.S.; Devi, B.R. Alternative to artificial preservatives. Syst. Rev. Pharm. 2019, 10, 99–102. [Google Scholar]

- Martí-Quijal, F.J.; Khubber, S.; Remize, F.; Tomasevic, I.; Roselló-Soto, E.; Barba, F.J. Obtaining Antioxidants and Natural Preservatives from Food By-Products through Fermentation: A Review. Fermentation 2021, 7, 106. [Google Scholar] [CrossRef]

- Falleh, H.; Ben Jemaa, M.; Saada, M.; Ksouri, R. Essential oils: A promising eco-friendly food preservative. Food Chem. 2020, 330, 127268. [Google Scholar] [CrossRef] [PubMed]

- Al-Maqtari, Q.A.; Rehman, A.; Mahdi, A.A.; Al-Ansi, W.; Wei, M.; Yanyu, Z.; Phyo, H.M.; Galeboe, O.; Yao, W. Application of essential oils as preservatives in food systems: Challenges and future prospectives—A review. Phytochem. Rev. 2021, 21, 1209–1246. [Google Scholar] [CrossRef]

- Yu, H.H.; Chin, Y.W.; Paik, H.D. Application of Natural Preservatives for Meat and Meat Products against Food-Borne Pathogens and Spoilage Bacteria: A Review. Foods 2021, 10, 2418. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations; World Health Organization. FOOD ADDITIVE INDEX, GSFA Online. Available online: https://www.fao.org/gsfaonline/additives/index.html (accessed on 14 July 2022).

- Ben Braïek, O.; Smaoui, S.; Wan, C. Chemistry, Safety, and Challenges of the Use of Organic Acids and Their Derivative Salts in Meat Preservation. J. Food Qual. 2021, 2021, 6653190. [Google Scholar] [CrossRef]

- Theron, M.M.; Lues, J.F.R. Organic Acids and Meat Preservation: A Review. Food Rev. Int. 2007, 23, 141–158. [Google Scholar] [CrossRef]

- Pirnia, M.; Shirani, K.; Tabatabaee Yazdi, F.; Moratazavi, S.A.; Mohebbi, M. Characterization of antioxidant active biopolymer bilayer film based on gelatin-frankincense incorporated with ascorbic acid and Hyssopus officinalis essential oil. Food Chem. X 2022, 14, 100300. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, G.M.; Sibaja, J.C.; Espitia, P.J.; Otoni, C.G. Antioxidant active packaging based on papaya edible films incorporated with Moringa oleifera and ascorbic acid for food preservation. Food Hydrocoll. 2020, 103, 105630. [Google Scholar] [CrossRef]

- Almasi, L.; Radi, M.; Amiri, S.; McClements, D.J. Fabrication and characterization of antimicrobial biopolymer films containing essential oil-loaded microemulsions or nanoemulsions. Food Hydrocoll. 2021, 117, 106733. [Google Scholar] [CrossRef]

- Sayanjali, S.; Ghanbarzadeh, B.; Ghiassifar, S. Evaluation of antimicrobial and physical properties of edible film based on carboxymethyl cellulose containing potassium sorbate on some mycotoxigenic Aspergillus species in fresh pistachios. LWT—Food Sci. Technol. 2011, 44, 1133–1138. [Google Scholar] [CrossRef]

- Brink, I.; Šipailienė, A.; Leskauskaitė, D. Antimicrobial properties of chitosan and whey protein films applied on fresh cut turkey pieces. Int. J. Biol. Macromol. 2019, 130, 810–817. [Google Scholar] [CrossRef] [PubMed]

- da Rocha, M.; Loiko, M.R.; Tondo, E.C.; Prentice, C. Physical, mechanical and antimicrobial properties of Argentine anchovy (Engraulis anchoita) protein films incorporated with organic acids. Food Hydrocoll. 2014, 37, 213–220. [Google Scholar] [CrossRef]

- Flores, S.; Haedo, A.S.; Campos, C.; Gerschenson, L. Antimicrobial performance of potassium sorbate supported in tapioca starch edible films. Eur. Food Res. Technol. 2006, 225, 375–384. [Google Scholar] [CrossRef]

- Mondal, D.; Bhowmick, B.; Maity, D.; Mollick, M.M.; Rana, D.; Rangarajan, V.; Sen, R.; Chattopadhyay, D. Investigation on sodium benzoate release from poly(butylene adipate-co-terephthalate)/organoclay/sodium benzoate based nanocomposite film and their antimicrobial activity. J. Food Sci. 2015, 80, E602–E609. [Google Scholar] [CrossRef] [PubMed]

- San, H.; Harnkarnsujarit, N. Sulfite incorporated thermoplastic cassava starch blended PBAT blown films as antimicrobial and antibrowning packaging. Ind. Crops Prod. 2023, 206, 117610. [Google Scholar] [CrossRef]

- Aznar, M.; Domeno, C.; Osorio, J.; Nerin, C. Release of volatile compounds from cooking plastic bags under different heating sources. Food Packag. Shelf Life 2020, 26, 100552. [Google Scholar] [CrossRef]

- Khan, M.I.; Jo, C.; Tariq, M.R. Meat flavor precursors and factors influencing flavor precursors—A systematic review. Meat Sci. 2015, 110, 278–284. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Canellas, E.; Nerin, C. Screening of volatile decay markers of minced pork by headspace-solid phase microextraction-gas chromatography-mass spectrometry and chemometrics. Food Chem. 2021, 342, 128341. [Google Scholar] [CrossRef] [PubMed]

- Kerry, J.P.; Kerry, J.F.; Ledward, D.A. Meat Processing: Improving Quality; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Argyri, A.A.; Mallouchos, A.; Panagou, E.Z.; Nychas, G.J. The dynamics of the HS/SPME-GC/MS as a tool to assess the spoilage of minced beef stored under different packaging and temperature conditions. Int. J. Food Microbiol. 2015, 193, 51–58. [Google Scholar] [CrossRef]

- Rivas-Canedo, A.; Fernandez-Garcia, E.; Nunez, M. Volatile compounds in fresh meats subjected to high pressure processing: Effect of the packaging material. Meat Sci. 2009, 81, 321–328. [Google Scholar] [CrossRef]

- Rivas-Canedo, A.; Nunez, M.; Fernandez-Garcia, E. Volatile compounds in Spanish dry-fermented sausage s‘alchichon’ subjected to high pressure processing. Effect of the packaging material. Meat Sci. 2009, 83, 620–626. [Google Scholar] [CrossRef] [PubMed]

- Wrona, M.; Nerín, C.; Alfonso, M.J.; Caballero, M.Á. Antioxidant packaging with encapsulated green tea for fresh minced meat. Innov. Food Sci. Emerg. Technol. 2017, 41, 307–313. [Google Scholar] [CrossRef]

- Calkins, C.R.; Hodgen, J.M. A fresh look at meat flavor. Meat Sci. 2007, 77, 63–80. [Google Scholar] [CrossRef] [PubMed]

| Material | Additive or Condition | Food Product | Quality | References |

|---|---|---|---|---|

| Polypropylene trays | Modified atmosphere packaging: (i) HiOx MAP (80% O2/20% CO2) and (ii) CO MAP (0.4%CO/30%CO2/69.6% N2) | Beef steaks | Both MAP steaks developed bioprotective strategies to improve their color stability | [25] |

| Styrofoam trays | Modified atmosphere (70%O2 + 20%CO2 + 10% N2) and ascorbic acid, taurine, carnosine, and rosemary powder | Beef patties | - Rosemary powder and rosemary–ascorbic acid were effective in inhibiting the oxidation of both lipids and myoglobin - Ascorbic acid, taurine + ascorbic acid, and carnosine + ascorbic acid showed a small inhibitory effect on myoglobin oxidation | [26] |

| Multilayer polyolefin bag | Rosemary extract and sodium lactate with vacuum packaging | Ground ostrich meat | Rosemary extract retarded the formation of TBARS and showed the highest protection against discoloration | [27] |

| TPS/linear low-density polyethylene (LLDPE) | Incorporated sodium nitrite into film | Pork | Films containing nitrite effectively improved redness | [28] |

| PBAT/TPS | Incorporated nisin and nisin-ethylenediaminetetraacetic acid into film | Pork | PBAT/TPS films containing EDTA and nisin effectively inhibited lipid degradation, stabilized redness, and delayed meat discoloration | [29] |

| Bioplastic Material | Functional Compound | Food Product | Packaging Properties | Food Quality | References |

|---|---|---|---|---|---|

| Corn starch/chitosan | Potassium sorbate and grapefruit seed extract | Bread | - Grapefruit seed extract films have high crystallinity, low hydrophilicity, low water vapor permeability, and high mechanical properties. - Potassium sorbate films showed high mechanical properties, high water vapor permeability than grapefruit seed extract films. | - Grapefruit seed extract showed the maximum zone of inhibition against A. niger. - Grapefruit seed extract extended the shelf life of bread after storage for 6 days. | [75] |

| PLA | Na+-montmorillonite | Salami | - Montmorillonite enhanced its water barrier properties. | - Montmorillonite reduced the lipid oxidation of processed meat products. | [76] |

| Whey protein | Ginger and rosemary essential oils | Minced lamb meat | - Increased essential oil content gave statistically high % of elongation and slightly decreased tensile strength. | - Incorporation of 1% essential oil significantly delayed microbiological deterioration of minced lamb meat. | [77] |

| PBAT/PLA | Carvacrol, citral, and α-terpineol essential oils | Pacific white shrimp | - Microstructures and water vapor and oxygen barrier properties were modified depending on the types and concentrations of the essential oils. - Citral conferred smoothness due to plasticization effects and improved compatibility. | - Citral and carvacrol effectively stabilized protein conformation in muscle tissues, delayed drip loss, and retained the adhesion between the shrimp cephalothorax and abdomen. - Essential-oil-compounded films prevented melanosis. | [69] |

| PLA/chitosan | Polyethylene glycol methyl ether methacrylate, stearyl methacrylate, and deoxycholic acid | Bread | - Functional compounds improved the compatibility of chitosan with PLA. - Deoxycholic acid was used as an antioxidant and antibacterial additive in PLA bioplastics. | - Deoxycholic acid was most efficient in inhibiting the growth of natural microorganisms on the bread slices stored in the packaging. | [78] |

| PBAT/TPS | Coconut nanocellulose, annatto, and citric acid | Freshly cut mango | - Nanocrystals reduced the water vapor permeability and influenced the increased stiffness of the films. - Tensile strength was dependent on the percentage of nanocrystals. | - The film maintained the characteristics of packaged Tommy Atkins mango for 14 days. | [79] |

| Gliadins (protein) | Cinnamaldehyde and natamycin | Cheese slices | - Incorporation of natamycin gave rise to films with a greater water uptake, weight loss, and diameter gain and higher water vapor and oxygen permeabilities. - Cinnamaldehyde enhanced the barrier properties of gliadin films due to the formation of a cross-linked matrix that restricted chain mobility and produced a more compact structure. | - Both compounds acted synergistically to prevent the growth of A. niger. The combination of cinnamaldehyde and natamycin gave rise to antifungal bioplastic films against common food spoilage microorganisms both in vitro and in cheese slices. | [80] |

| Chitosan | Montmorillonites and rosemary and ginger essential oils | Fresh poultry meat | - Reinforcement with montmorillonites improved chitosan barrier properties. | - Essential oil reduced oxidative processes in poultry meat. - Reinforcement with nanoclays reduced lipid oxidation and microbiological contamination, but the incorporation of essential oils only improved the barrier to oxidation. | [81] |

| PBAT/TPS | Titanium dioxide (TiO2) | Banana | - TiO2 nanoparticles increased mechanical strength and reduced oxygen, carbon dioxide, and water vapor permeability. - Films containing TiO2 also showed efficient oxygen-scavenging activity that removed residual oxygen from the package headspace. | - Banana fruit packaged in films containing TiO2 recorded a slower darkening color change and an enhanced shelf life with an increasing TiO2 content. | [82] |

| PBAT/TPS | Sodium benzoate and potassium sorbate | Noodle | - Sodium benzoate and potassium sorbate gave more homogeneous microstructures. | - Sodium benzoate and potassium sorbate effectively delayed A. niger and Rhizopus spp. and reduced the total viable count, yeast, and mold in fresh noodles. - Sodium benzoate and potassium sorbate improved the polymer compatibility but reduced the tensile strength and elongation. | [83] |

| TPS/PBAT | Nisin and ethylenediaminetetraacetic acid (EDTA) | Pork | - Nisin and EDTA improved the compatibility and adhesion networks, giving homo-structures. | - Nisin and EDTA showed efficiency in inhibiting microbial growth, stabilized the color of the packaged pork. - EDTA efficiently stabilized the lipid structures in wrapped meat muscles and retained the quality of the meat. | [29] |

| Preservative | Functionality |

|---|---|

| Ascorbic acid | Oxygen scavenger |

| Citric acid | Enzyme inhibitor/metal chelator |

| Sulfites | Enzyme inhibitor/oxygen scavenger |

| Tocopherols | Free radical scavenger |

| Acetic acid | Disrupts cell membrane function (bacteria, yeasts, some molds) |

| Benzoic acid | Disrupts cell membrane function/inhibits enzymes (molds, yeasts, some bacteria) |

| Natamycin | Binds sterol groups in fungal cell membranes (molds, yeasts) |

| Nisin | Disrupts cell membrane function (Gram-positive bacteria, lactic-acid-producing bacteria) |

| Nitrates, nitrites | Inhibits enzymes/disrupts cell membrane function (bacteria, primarily Clostridium botulinum) |

| Propionic acid | Disrupts cell membrane function (molds, some bacteria) |

| Sorbic acid | Disrupts cell membrane function/inhibits enzymes/inhibits bacterial spore germination (yeasts, molds, some bacteria) |

| Sulfites and sulfur dioxide | Inhibits enzymes/forms additional compounds (bacteria, yeasts, molds) |

| Phosphate | Maintain juiciness and shelf life, emulsifying and stabilizing |

| Material | Preservative | Method of Preparation | Findings | Reference |

|---|---|---|---|---|

| Gelatin | Ascorbic acid | Solution casting | - Ascorbic acid acted as an antioxidant and increased DPPH radical scavenging activity and total phenolic content. - Ascorbic acid had hydrogen donation capabilities and could scavenge free radicals by transferring electrons. - Ascorbic acid improved the flexibility related to a complex and dense microstructure. | [117] |

| Pectin (papaya) | Ascorbic acid | Solution casting | - Ascorbic acid acted as an antioxidant and prolonged the shelf life of pears. - Ascorbic acid provided weak films (low mechanical properties) and increased the aw values of papaya films due to its hydrophilic nature. | [118] |

| Calcium alginate | Acetic and propionic acid | Solution casting | - Organic acid acted as an antimicrobial against total coliform, S. aureus, lactic acid bacteria, and mold and yeast viable counts. - Alginate and organic acids showed H bonding between free water molecules and hydroxyl groups. - Films had strong mechanical properties but were more stretchable than the control films. | [119] |

| PBAT/TPS | Nisin and EDTA | Blown film extrusion | - EDTA and nisin acted as antimicrobials and inhibited Listeria, C. perfringens, S. aureus, and L. innocua. - The interaction between PBAT/TPS, EDTA, and nisin was alkylation. - EDTA and nisin improved the compatibility, as also shown by a smoother microstructure. | [29] |

| TPS/PBAT | Sodium nitrite and sodium erythorbate | Blown film extrusion | - Sodium nitrite and sodium erythorbate modified starch granule and increased compatibility. - Sodium nitrite and sodium erythorbate preserved ham quality via delay antioxidation. | [12] |

| Carboxymethyl cellulose | Potassium sorbate | Solution casting | - Potassium sorbate acted as an antimicrobial and inhibited A. parasiticus, A. parasiticus, and A. flavus. - The incorporation of potassium sorbate into carboxymethyl cellulose films increased the WVP values via blockage of the polymer matrix pores. | [120] |

| Chitosan/whey protein | Ascorbic acid, benzoic acid, and potassium sorbate | Solution casting | - Organic acid acted as an antimicrobial and delayed S. Typhimurium, E. coli, and C. jejuni in fresh-cut turkey for 6 days. | [121] |

| Protein | Sorbic or benzoic acids | Solution casting | - Organic acid acted as an antimicrobial and inhibited the growth of E. coli O157:H7, L. monocytogenes, and S. aureus. - Sorbic acid penetrated into protein more easily than benzoic acid, forming hydrogen bonds with amide groups of proteins. - Sorbic and benzoic acid gave high solubility. | [122] |

| TPS/PBAT | Sodium nitrite | Blown film extrusion | - Sodium nitrite acted as an antimicrobial and reduced total viable count, lactic acid bacteria and yeast and molds. - Interaction between the pork and TPS/PBAT film released nitrite from the film matrices and interacted with the myoglobin in the pork to form nitrosyl myoglobin, increased redness. - Sodium nitrite modified the C=O bonding of PBAT and improved its compatibility with TPS networks. | [74] |

| Starch | Potassium sorbate | Solution casting | - Potassium sorbate acted as an antimicrobial and delayed yeast growth. - Potassium sorbate formed complexes that modified the solubility, diffusivity and partition coefficients. | [123] |

| PBAT/TPS | Sodium benzoate and potassium sorbate | Blown film extrusion | - Organic acid acted as an antimicrobial and delayed A. niger and Rhizopus sp. growth. - Sodium benzoate and potassium sorbate modified the starch network and compatibility between PBAT and TPS. | [83] |

| PBAT | Sodium benzoate | Solution casting | - Sodium benzoate acted as an antimicrobial against B. subtilis and S. aureus. - Sodium benzoate gave higher barrier properties against water and methanol vapor to the PBAT film. | [124] |

| TPS/PBAT | Sodium metabisulfite | Blown film extrusion | - Sodium metabisulfite prevented mold growth and darkening in packaged salami. - Sodium metabisulfite prevented recrystallization. - Sodium metabisulfite formed S-O bonds with starch molecules. | [125] |

| Compound Name | Characteristic Flavors/Aromas |

|---|---|

| Benzaldehyde | Volatile almond oil, bitter almond, burning aromatic taste |

| Benzene | Pleasant, distinct |

| sec-Butanamine | Seafood, green, onion |

| Butenal | Malty, green, roasted |

| n-Caproic acid | Goaty |

| 3-Carene | Sweet and pungent odor but more agreeable than turpentine, orange peel, lemon, resin |

| Cyclobutanol | Roasted |

| 2,2,6-Trimethylcyclohexanone | Mint, acetone |

| 2,4-Decadiena | Deep fatty flavor, chicken flavor at 10 ppm, citrus/orange/grapefruit flavor at lower dilutions |

| Decanal | Powerful, waxy, aldehydic, orange, citrus peel |

| 2-Decenal | Tallow, orange |

| 1,3-Bis(1,1-dimethylethyl) benzene | Cooked beef |

| N,N 0-Dimethyl 1,2-ethanediamine | Ammonia |

| 5-Ethylcyclopent-1-enecarboxaldehyde | Fragrant, perfume |

| 2-Pentylfuran | Green bean, butter |

| 2,4-Heptadienal | Nut, fat |

| Heptanal | Oily, fatty, rancid, unpleasant, penetrating fruity odor in liquid |

| 1-Heptanol | Fragrant, woody, oily, green, fatty, winey, sap, herb |

| 2-Heptanone | Fruity, spicy, cinnamon, penetrating fruity odor in liquid |

| 6-Methyl 2-heptanone | Cloves, menthol, eugenol |

| 2-Heptenal | Soapy, fatty, almond, fishy, unpleasant |

| Hexanal | Fatty, green, grassy, strong green, tallow, fat, unripe fruit when dilute |

| Hexane | Faint peculiar odor |

| Hexanol | Woody, cut grass, chemical/winey, fatty, fruity, weakly metallic, green |

| 2-Ethyl 1-hexanol | Resin, flower, green |

| 2-Hexen-1-ol | Green, sharp, leafy, fruity, unripe banana |

| 3-Methylbutanal | Pungent apple-like odor, malt |

| Limonene | Pleasant, lemon-like, turpentine, citrus, fruity, fresh, light |

| Methyl salicylate | Cooling sensation, wintergreen, gaultheria |

| 2,4-Nonadienal | Fat, wax, green, watermelon, geranium, pungent |

| Nonanal | Floral, citrus, fatty, grassy, waxy, green |

| 2-Nonanone | Hot milk, soap, green, fruity, floral |

| 2-Nonenal | Cardboardy, orris, fat, cucumber |

| Octadecanal | Oil |

| Octanal | Harsh, fatty, orange peel, soapy, lemon, green, honey |

| 1-Octanol | Penetrating aromatic odor, fatty, waxy, citrus, oily, walnut, moss, chemical, metal, burnt |

| 2-Methyl 3-octanone | Herb, butter, resin, gasoline |

| 2-Octenal | Green, nut, fat |

| (Z)-3-Octene | Fruity, old apples |

| 1-Octen-3-ol | Mushrooms, compound excreted by many insects |

| 2-Octen-1-ol | Green citrus |

| 3-Octen-2-one | Nuts, crushed bugs, earthy, spicy, herbal, sweet, mushroom, hay, blueberry |

| Pentanal | Almond, malt, pungent, acrid, fermented, fruity |

| Pentane | Very slight warm flavor, oxidized |

| 1-Pentanol | Mild odor, fuel oil, sweet, fruity |

| 5-Amino 1-pentanol | Mild |

| α-Pinene | Piney, fruity, citrus, turpentine |

| β-Pinene | Pine, citrus, fruity, resin, turpentine |

| Piperazine | Salty |

| Propanol | Alcoholic |

| Styrene | Penetrating odor, sweet smell |

| Tetradecane | Alkane |

| Tridecane | Alkane |

| 2-Tridecenal | Sweet, strong, spicy |

| Ethanol | Sweet, alcoholic |

| 2,3-butanedione | Butter, pungent |

| Acetic acid | Sour, vinegar |

| 3-Hydroxy-2-butanone | Sweet, fatty |

| 3-Methyl-1-butanol | Alcoholic, fruity |

| 4-Methyl-2-pentanone | Green, herbal, fruity |

| Toluene | Paint |

| 2,3-Butanediol | Buttery |

| Ethylbenzene | Paint |

| m-Xylene | Plastic |

| 1-Hexanol | Sweet, alcoholic |

| 5-Methyl-4-hepten-3-one | Fruity |

| Decane | Gasoline |

| p-Cymene | Citrus, woody |

| 2-Ethyl-1-hexanol | Floral, sweet |

| Benzeneacetaldehyde | Floral, sweet |

| 1-Octanol | Green, orange |

| Tridecane | Gasoline |

| Dodecane | Gasoline |

| (Z)-2-Octen-1-ol | Sweet |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wongphan, P.; Promhuad, K.; Srisa, A.; Laorenza, Y.; Oushapjalaunchai, C.; Harnkarnsujarit, N. Unveiling the Future of Meat Packaging: Functional Biodegradable Packaging Preserving Meat Quality and Safety. Polymers 2024, 16, 1232. https://doi.org/10.3390/polym16091232

Wongphan P, Promhuad K, Srisa A, Laorenza Y, Oushapjalaunchai C, Harnkarnsujarit N. Unveiling the Future of Meat Packaging: Functional Biodegradable Packaging Preserving Meat Quality and Safety. Polymers. 2024; 16(9):1232. https://doi.org/10.3390/polym16091232

Chicago/Turabian StyleWongphan, Phanwipa, Khwanchat Promhuad, Atcharawan Srisa, Yeyen Laorenza, Chayut Oushapjalaunchai, and Nathdanai Harnkarnsujarit. 2024. "Unveiling the Future of Meat Packaging: Functional Biodegradable Packaging Preserving Meat Quality and Safety" Polymers 16, no. 9: 1232. https://doi.org/10.3390/polym16091232

APA StyleWongphan, P., Promhuad, K., Srisa, A., Laorenza, Y., Oushapjalaunchai, C., & Harnkarnsujarit, N. (2024). Unveiling the Future of Meat Packaging: Functional Biodegradable Packaging Preserving Meat Quality and Safety. Polymers, 16(9), 1232. https://doi.org/10.3390/polym16091232