Fatigue Behaviour of PA66 GF30 at Different Temperatures

Abstract

:1. Introduction

2. Materials and Methods

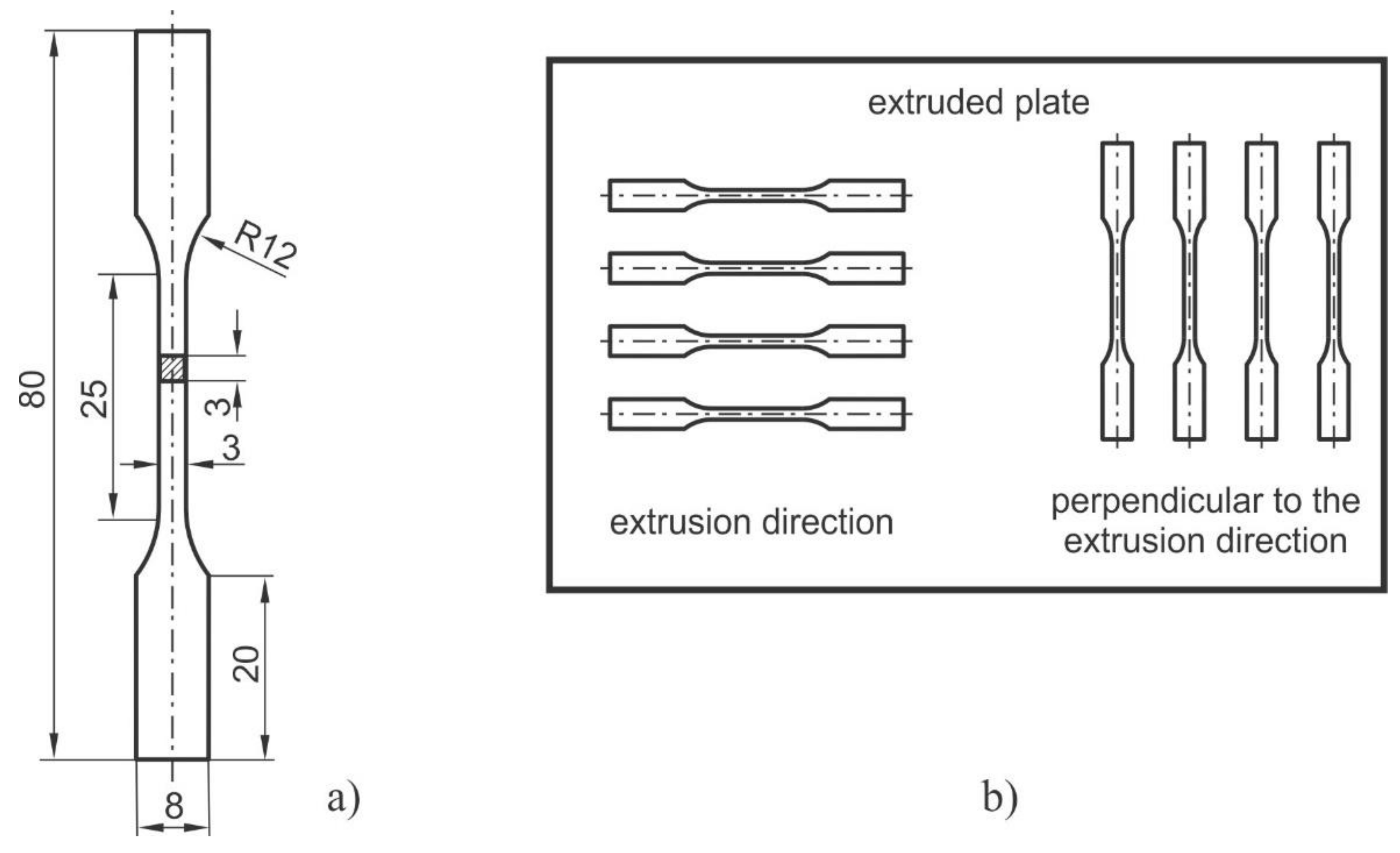

2.1. Material and Geometry of Specimens

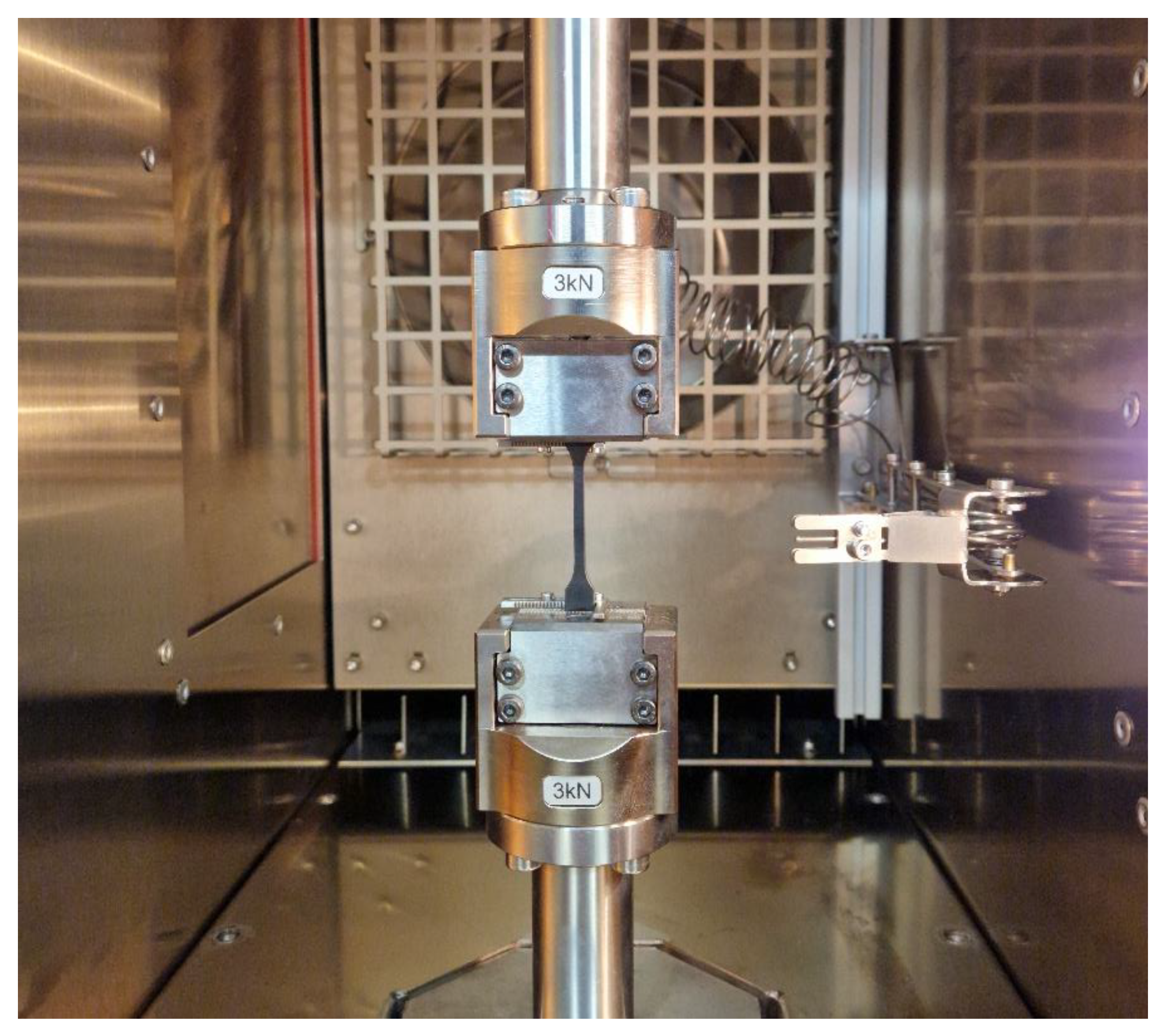

2.2. Experimental Testing

3. Results and Discussion

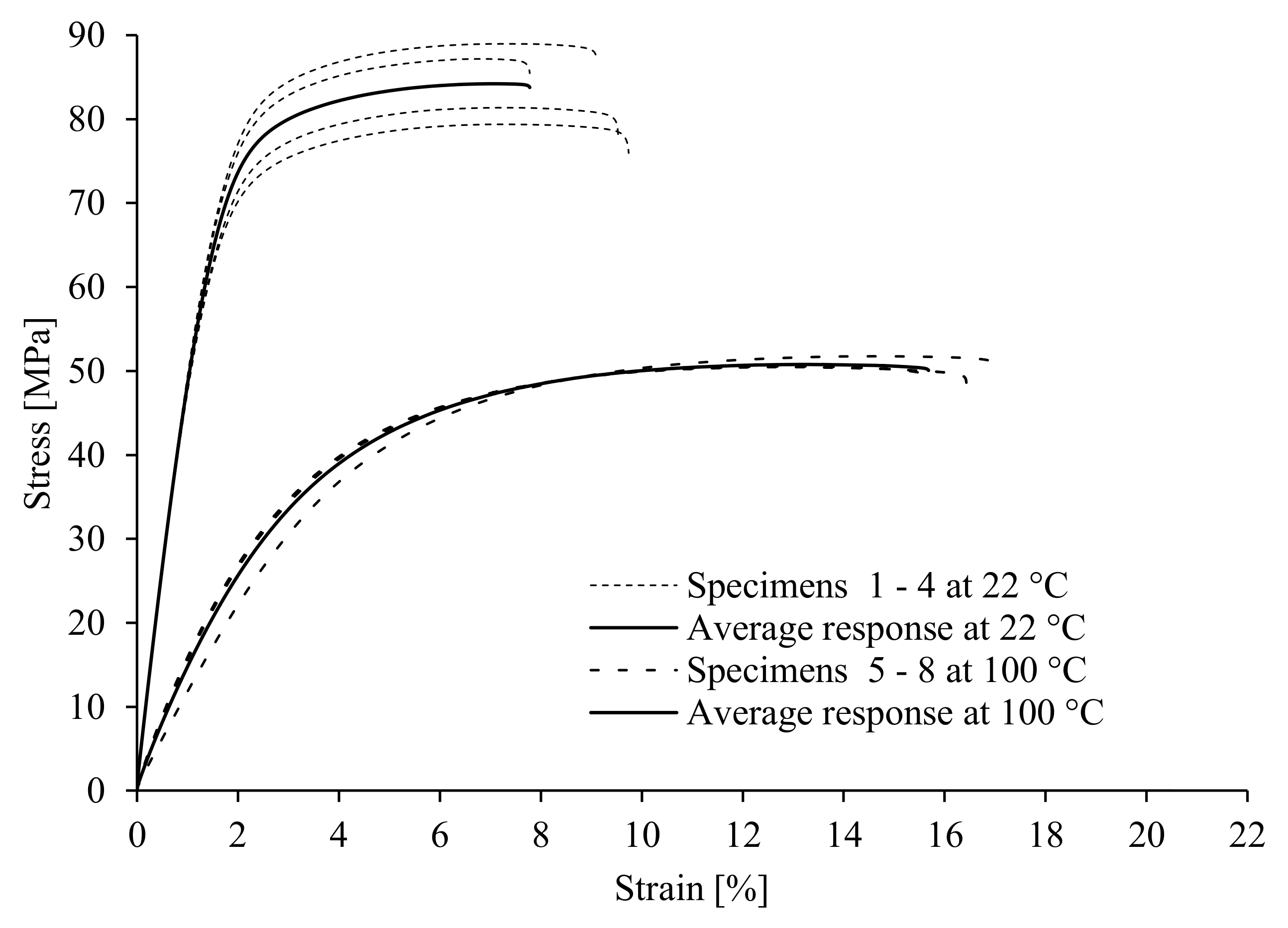

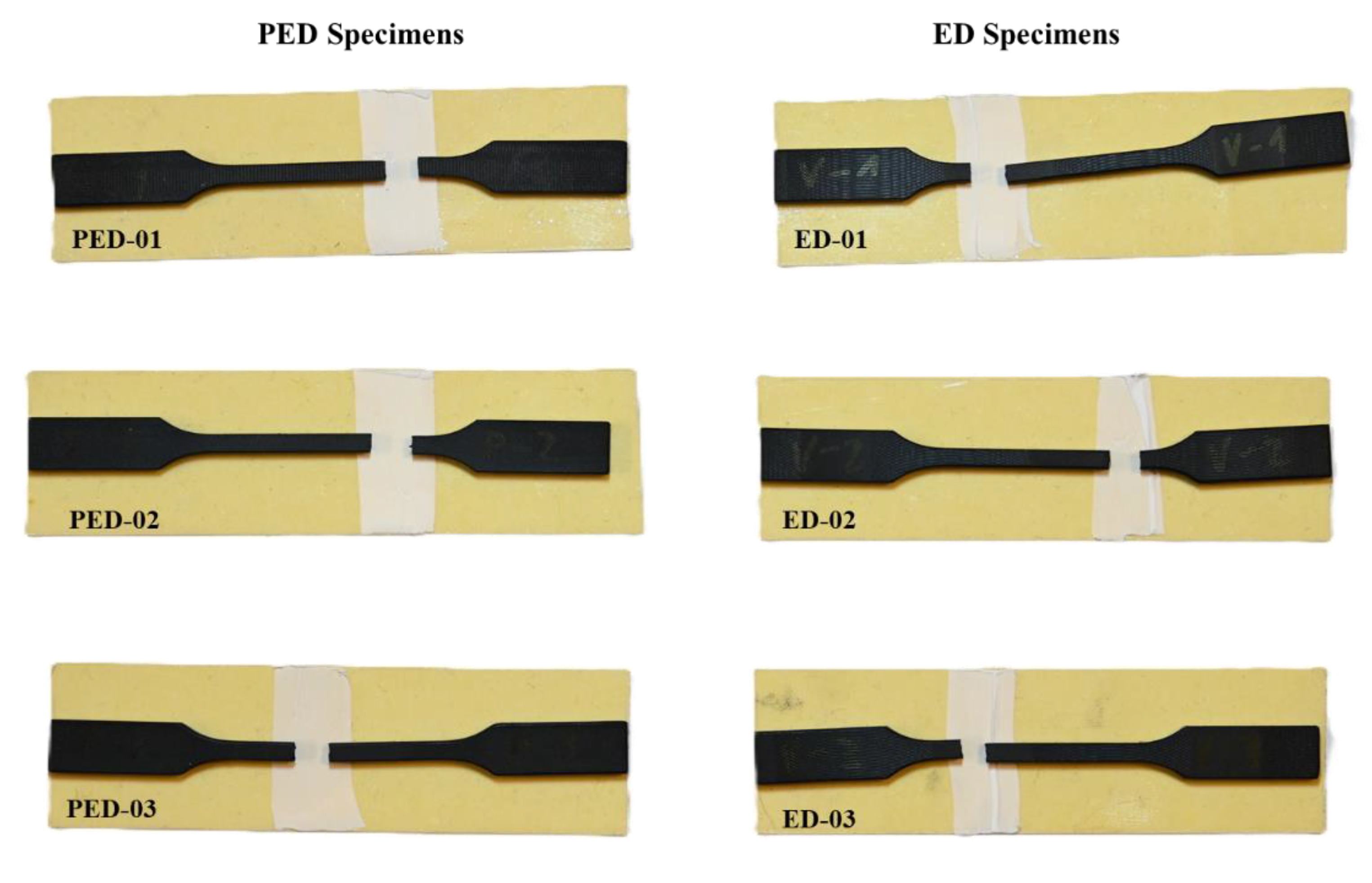

3.1. Quasi-Static Tests

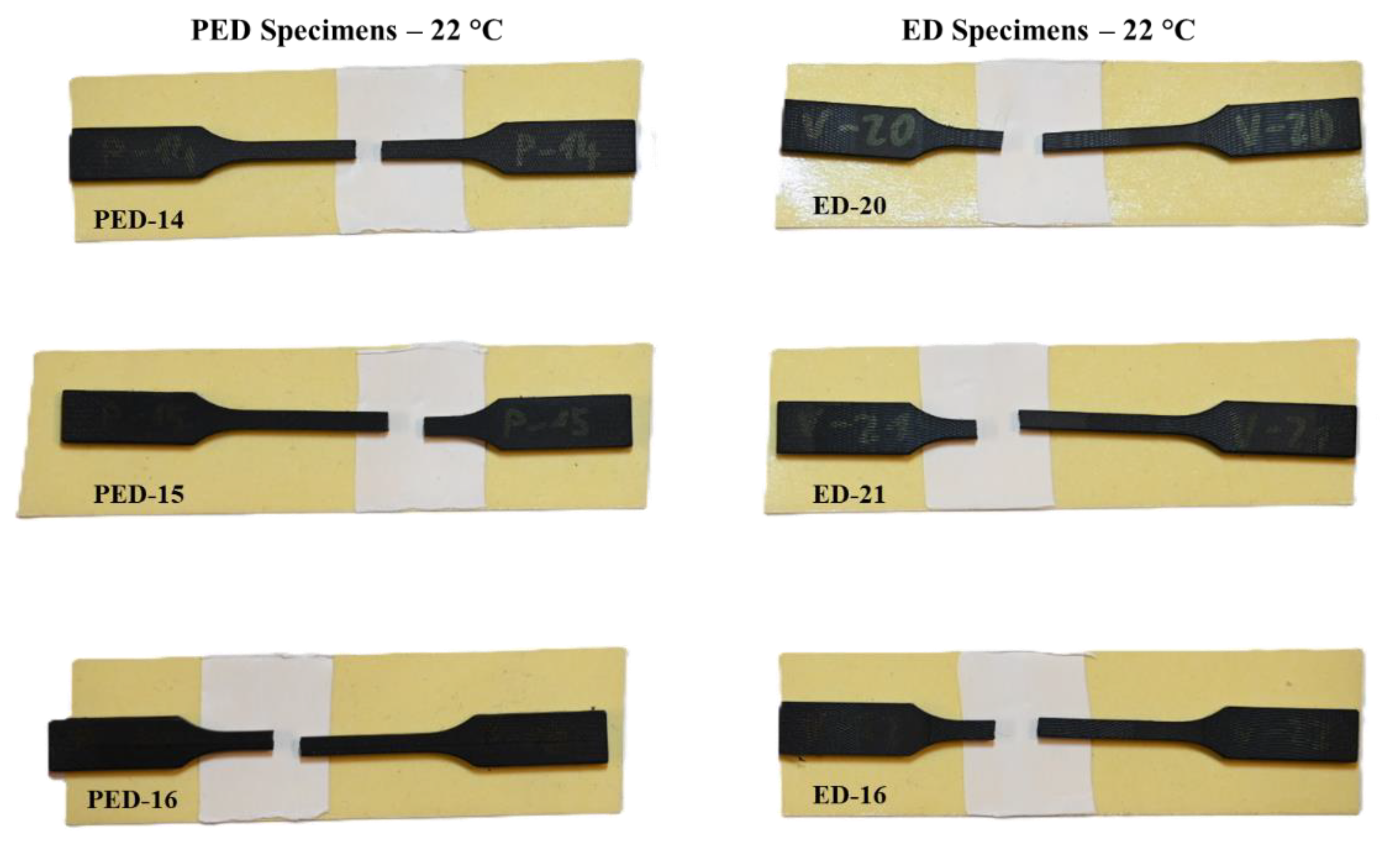

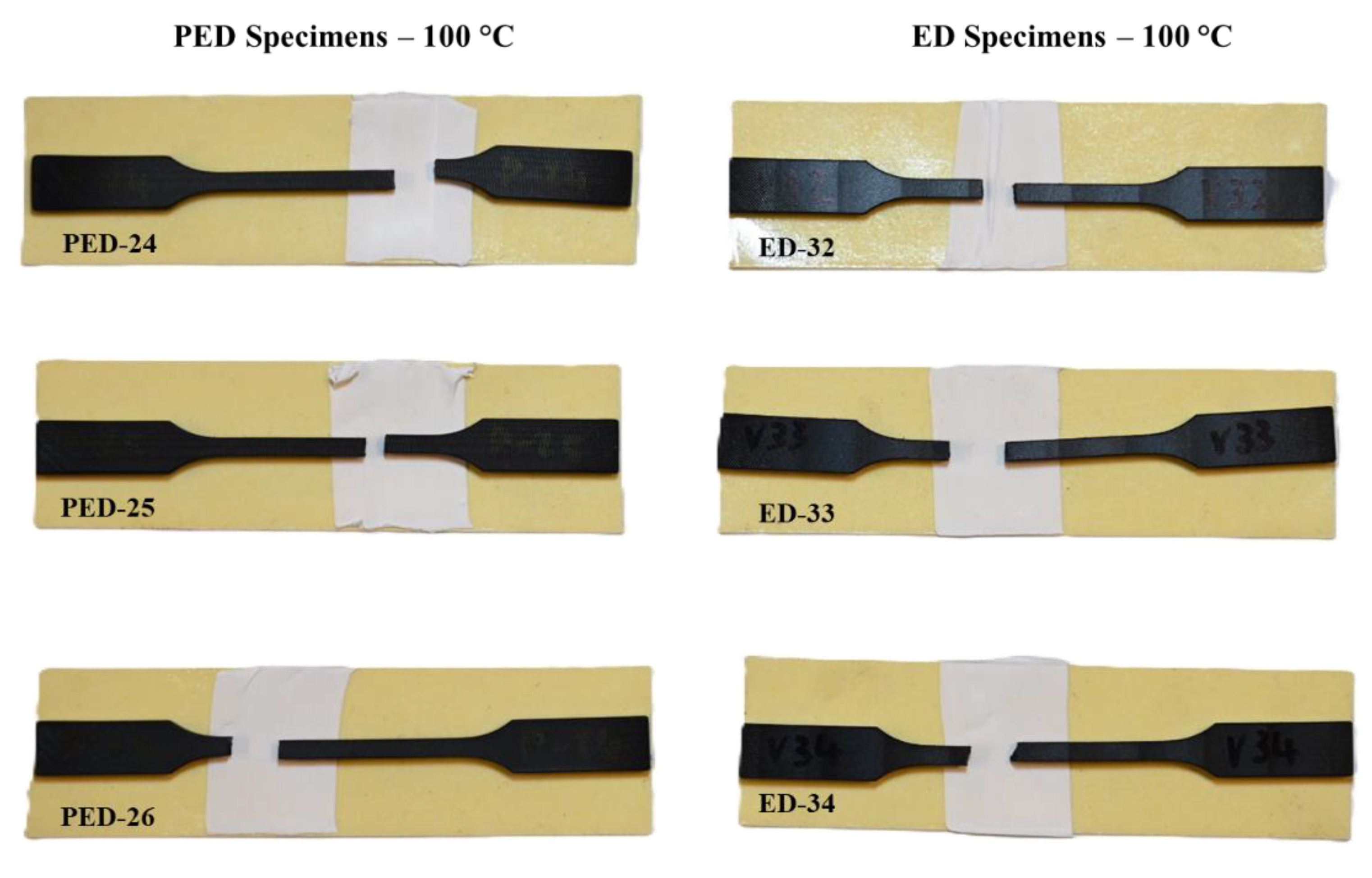

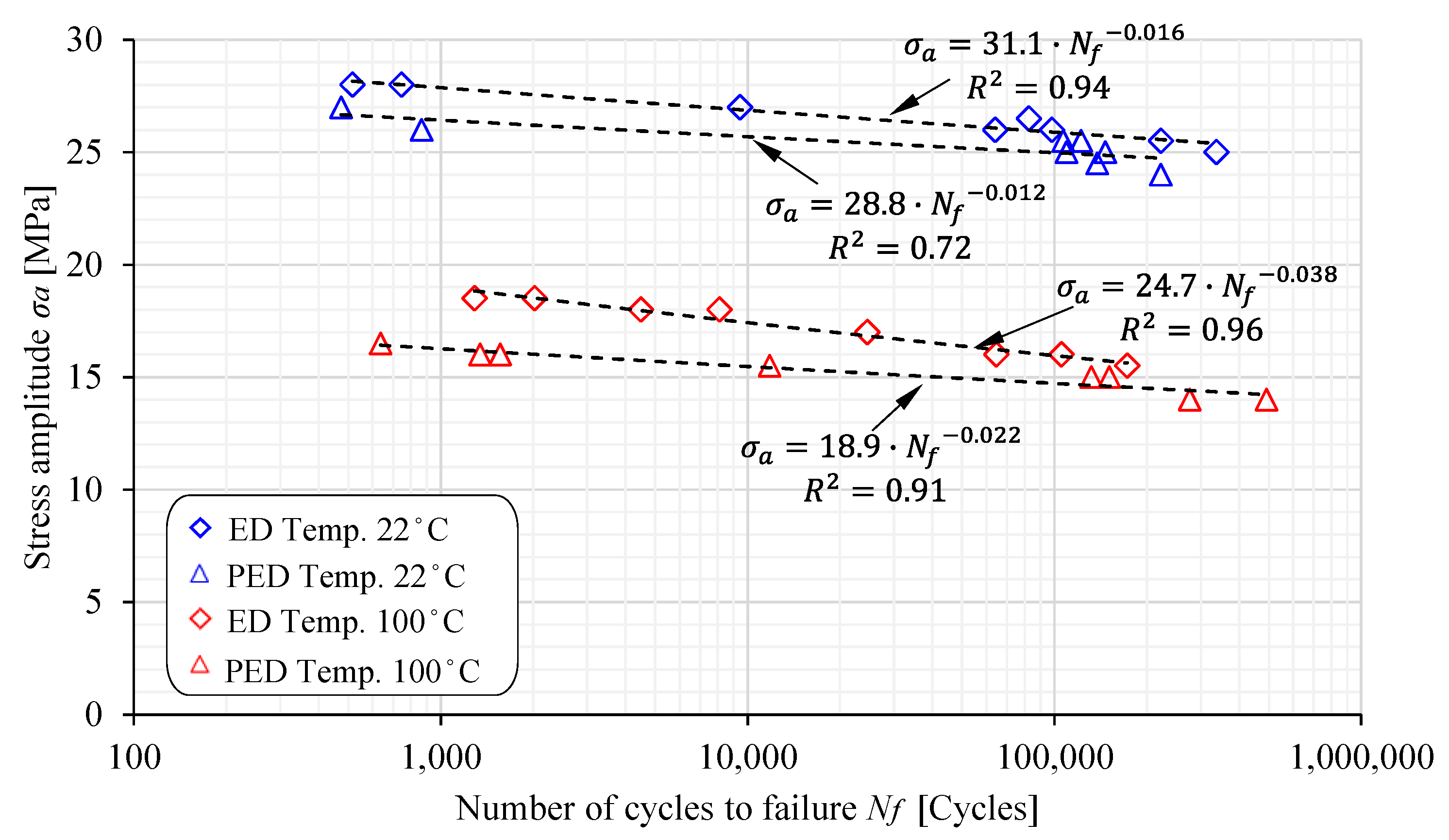

3.2. Fatigue Tests

4. Conclusions

- The results of quasi-static tests showed that mechanical properties (tensile strength, yield stress, and Young’s modulus) change significantly with temperature. As the temperature increases (from 22 °C to 100 °C), the strength parameters (tensile strength, yield stress, and Young’s modulus) decrease considerably. Furthermore, the experimental results of the quasi-static tests also showed that the test specimens manufactured in the extrusion direction (ED specimens) have better mechanical properties than those manufactured perpendicular to the extrusion direction (PED specimens). The greatest scatter in the results was found for the specimens produced in the extrusion direction at a room temperature of 22 °C. The most likely reason for widespread scattering is that the reinforcing glass fibres are unevenly distributed in the critical cross-section of the samples. However, the experimental results of the quasi-static tensile test at room conditions (tensile strength and modulus of elasticity) showed a relatively good agreement if compared to the available results in the literature and stated by the material manufacturers. The greatest difference was found in the elongation at break for the samples produced in the extrusion direction.

- The results of fatigue tests showed that for both the considered temperatures (22 °C and 100 °C), the test specimens manufactured in the extrusion direction (ED specimens) demonstrated better fatigue resistance than those manufactured perpendicular to the extrusion direction (PED specimens). For both the specimen’s orientations, fatigue resistance reduced significantly with temperature.

- The results obtained in this study provide a reasonable basis for the dimensioning of products and components made of PA66 GF30 at room or elevated temperatures.

- Further investigation should also focus on the microstructure of analysed material (i.e., length and diameter of glass fibres and their distribution in the base material), which may affect the mechanical and fatigue properties.

- According to the supplier of the extruded sheets used to manufacture the samples in this study, PA66 GF30 can withstand a short exposure time at elevated temperatures of 180 °C. Based on this assumption, future studies will focus on the short-life fatigue behaviour of PA66 GF30. Furthermore, it would also be essential to investigate the interaction between elevated temperatures and the presence of a medium, such as water or other fluids, on the fatigue life of the analysed component.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Puoci, F.; Iemma, F.; Spizzirri, U.G.; Cirillo, G.; Curcio, M.; Picci, N. Polymer in Agriculture: A Review. Am. J. Agric. Biol. Sci. 2008, 3, 299–314. [Google Scholar] [CrossRef]

- Nazeer, N.; Ahmed, M. Polymers in Medicine. In Polymer Science and Nanotechnology; Elsevier: Amsterdam, The Netherlands, 2020; pp. 281–323. [Google Scholar]

- Deb, P.K.; Kokaz, S.F.; Abed, S.N.; Paradkar, A.; Tekade, R.K. Pharmaceutical and Biomedical Applications of Polymers. In Basic Fundamentals of Drug Delivery; Elsevier: Amsterdam, The Netherlands, 2019; pp. 203–267. [Google Scholar]

- Kim, J.; Lee, J.; You, J.; Park, M.-S.; Al Hossain, M.S.; Yamauchi, Y.; Kim, J.H. Conductive Polymers for Next-Generation Energy Storage Systems: Recent Progress and New Functions. Mater. Horizons 2016, 3, 517–535. [Google Scholar] [CrossRef]

- EL-Ghoul, Y.; Alminderej, F.M.; Alsubaie, F.M.; Alrasheed, R.; Almousa, N.H. Recent Advances in Functional Polymer Materials for Energy, Water, and Biomedical Applications: A Review. Polymers 2021, 13, 4327. [Google Scholar] [CrossRef]

- Huda, M.K.; Widiastuti, I. Natural Fiber Reinforced Polymer in Automotive Application: A Systematic Literature Review. J. Phys. Conf. Ser. 2021, 1808, 012015. [Google Scholar] [CrossRef]

- Shah, V.; Bhaliya, J.; Patel, G.M.; Deshmukh, K. Advances in Polymeric Nanocomposites for Automotive Applications: A Review. Polym. Adv. Technol. 2022, 33, 3023–3048. [Google Scholar] [CrossRef]

- Volpe, V.; Lanzillo, S.; Affinita, G.; Villacci, B.; Macchiarolo, I.; Pantani, R. Lightweight High-Performance Polymer Composite for Automotive Applications. Polymers 2019, 11, 326. [Google Scholar] [CrossRef]

- Al-Lami, A.; Hilmer, P.; Sinapius, M. Eco-Efficiency Assessment of Manufacturing Carbon Fiber Reinforced Polymers (CFRP) in Aerospace Industry. Aerosp. Sci. Technol. 2018, 79, 669–678. [Google Scholar] [CrossRef]

- Dyer, W.E.; Kumru, B. Polymers as Aerospace Structural Components: How to Reach Sustainability? Macromol. Chem. Phys. 2023, 224, 2300186. [Google Scholar] [CrossRef]

- Muhammad, A.; Rahman, M.R.; Baini, R.; Bin Bakri, M.K. Applications of Sustainable Polymer Composites in Automobile and Aerospace Industry. In Advances in Sustainable Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 185–207. [Google Scholar]

- Zindani, D.; Kumar, K. Industrial Applications of Polymer Composite Materials. In Composites and Advanced Materials for Industrial Applications; IGI Global: Pennsylvania, PA, USA, 2018; pp. 1–15. [Google Scholar]

- Harussani, M.M.; Sapuan, S.M.; Nadeem, G.; Rafin, T.; Kirubaanand, W. Recent Applications of Carbon-Based Composites in Defence Industry: A Review. Def. Technol. 2022, 18, 1281–1300. [Google Scholar] [CrossRef]

- Siengchin, S. A Review on Lightweight Materials for Defence Applications: Present and Future Developments. Def. Technol. 2023, 24, 1–17. [Google Scholar] [CrossRef]

- Al-Ali AlMa’adeed, M.; Krupa, I. Erratum to: Chapters 2 and 9 of Polyolefin Compounds and Materials. In Polyolefin Compounds and Materials; Springer: Cham, Switzerland, 2016; p. E1. [Google Scholar]

- Chaudhry, A.U.; Mabrouk, A.N.; Abdala, A. Thermally Enhanced Polyolefin Composites: Fundamentals, Progress, Challenges, and Prospects. Sci. Technol. Adv. Mater. 2020, 21, 737–766. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.; Flanigan, C. Automotive Plastics and Composites. In Encyclopedia of Polymer Science and Technology; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Das, A.; Mahanwar, P. A Brief Discussion on Advances in Polyurethane Applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Alfath, S.A.; Ponte, F.; Sharma, P.; Ferreira, F.; Laranjeira, J.; Carvalho, S.; Figueiredo, N.M. PVD Decorative Coatings on Polycarbonate and Polyamide Substrates for the Automotive Industry. Surf. Interfaces 2024, 52, 104887. [Google Scholar] [CrossRef]

- Ortego, A.; Russo, S.; Iglesias-Émbil, M.; Valero, A.; Magdalena, R. Exergy Assessment of Plastic Car Parts. Vehicles 2023, 5, 1211–1226. [Google Scholar] [CrossRef]

- Zadravec, M.; Glodež, S.; Buzzi, C.; Brunnhofer, P.; Leitner, M.; Kramberger, J. Vibration Fatigue Analysis of Two Different Variants of Oil Suction Pipes. Materials 2024, 17, 1057. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, J.H.; Han, G.; Quagliato, L.; Kim, Y.; Choi, J.; Keum, T.; Kim, S.; Han, D.S.; Kim, N.; Lee, H. Design and Numerical Evaluation of Recycled-Carbon-Fiber-Reinforced Polymer/Metal Hybrid Engine Cradle Concepts. Int. J. Mech. Sci. 2019, 163, 105115. [Google Scholar] [CrossRef]

- Kondo, M.Y.; Montagna, L.S.; Morgado, G.F.d.M.; de Castilho, A.L.G.; Batista, L.A.P.d.S.; Botelho, E.C.; Costa, M.L.; Passador, F.R.; Rezende, M.C.; Ribeiro, M.V. Recent Advances in the Use of Polyamide-Based Materials for the Automotive Industry. Polímeros 2022, 32, 1–14. [Google Scholar] [CrossRef]

- Petraşcu, O.-L.; Pascu, A.-M. Comparative Study of Polyamide 6 (PA6) and Polyamide 6 Reinforced with 30% of Glass Fiber (PA6GF30). Mater. Today Proc. 2023, 93, 625–629. [Google Scholar] [CrossRef]

- Khan, R.M.; Mushtaq, A. Effect of Reinforced Glass Fibre on the Mechanical Properties of Polyamide. Pakistan J. Sci. Ind. Res. Ser. A Phys. Sci. 2021, 64, 10–18. [Google Scholar] [CrossRef]

- Autay, R.; Missaoui, S.; Mars, J.; Dammak, F. Mechanical and Tribological Study of Short Glass Fiber-Reinforced PA 66. Polym. Polym. Compos. 2019, 27, 587–596. [Google Scholar] [CrossRef]

- Thomason, J.L. Structure-Property Relationships in Glass-Reinforced Polyamide, Part 1: The Effects of Fiber Content. Polym. Compos. 2006, 27, 552–562. [Google Scholar] [CrossRef]

- Unal, H.; Mimaroglu, A. Evaluation of Morphological Characteristics and Mechanical Performance of Rockforce Mineral Fiber- and Glass Fiber-Reinforced Polyamide-6 Composites. Sci. Eng. Compos. Mater. 2014, 21, 323–328. [Google Scholar] [CrossRef]

- Nuruzzaman, D.M.; Iqbal, A.K.M.A.; Oumer, A.N.; Ismail, N.M.; Basri, S. Experimental Investigation on the Mechanical Properties of Glass Fiber Reinforced Nylon. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012118. [Google Scholar] [CrossRef]

- Ryu, J.B.; Lyu, M.-Y. A Study on the Mechanical Property and 3D Fiber Distribution in Injection Molded Glass Fiber Reinforced PA66. Int. Polym. Process. 2014, 29, 389–401. [Google Scholar] [CrossRef]

- da Costa Mattos, H.S.; Brandão, J.F.S.; Amorim, F.C.; Araújo, P.V.S.; Reis, J.M.L. A Unified Expression to Estimate the Stress-Strain Curve of Polyamides at Different Temperatures. Mater. Res. Express 2018, 6, 015304. [Google Scholar] [CrossRef]

- Chebbi, E.; Mars, J.; Wali, M.; Dammak, F. Fatigue Behavior of Short Glass Fiber Reinforced Polyamide 66: Experimental Study and Fatigue Damage Modelling. Period. Polytech. Mech. Eng. 2016, 60, 247–255. [Google Scholar] [CrossRef]

- Esmaeillou, B.; Ferreira, P.; Bellenger, V.; Tcharkhtchi, A. Fatigue Behavior of Polyamide 66/Glass Fiber under Various Kinds of Applied Load. Polym. Compos. 2012, 33, 540–547. [Google Scholar] [CrossRef]

- Brunbauer, J.; Mösenbacher, A.; Guster, C.; Pinter, G. Fundamental Influences on Quasistatic and Cyclic Material Behavior of Short Glass Fiber Reinforced Polyamide Illustrated on Microscopic Scale. J. Appl. Polym. Sci. 2014, 131, 40842. [Google Scholar] [CrossRef]

- Haddar, N.; Ksouri, I.; Kallel, T.; Mnif, N. Effect of Hygrothermal Ageing on the Monotonic and Cyclic Loading of Glass Fiber Reinforced Polyamide. Polym. Compos. 2014, 35, 501–508. [Google Scholar] [CrossRef]

- Will, F.; Boretti, A. A New Method to Warm Up Lubricating Oil to Improve the Fuel Efficiency During Cold Start. SAE Int. J. Engines 2011, 4, 175–187. [Google Scholar] [CrossRef]

- Ensiger. PA 66 Filled with 30% Glass Fibres. Available online: https://www.ensingerplastics.com/en/shapes/pa66-tecamid-66-gf30-black (accessed on 29 October 2024).

- ISO 527-2; Plastic—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ISO 179-1; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. ISO: Geneva, Switzerland, 2023.

- ISO 11357; Plastics—Differential Scanning Calorimetry (DSC). ISO: Geneva, Switzerland, 2016.

- ISO 62; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008.

- ISO 868; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). ISO: Geneva, Switzerland, 2003.

| Mechanical properties | ||

| Tensile strength | ISO 527-2 | 91 MPa |

| Elongation at break | ISO 527-2 | 14% |

| Tensile E-modulus | ISO 527-2 | 5500 MPa |

| Charpy impact strength | ISO 179-1 | 75 kJ/m2 |

| Thermal properties | ||

| Glass transition temperature | ISO 11357 | +48 °C |

| Melting temperature | ISO 11357 | +254 °C |

| max. Service temperature (long term) | +110 °C | |

| max. Service temperature (short term) | +180 °C | |

| Other properties | ||

| Density | 1.34 g/cm3 | |

| Moisture absorption at saturation (+23 °C) | ISO 62 | 2.0% |

| Shore hardness | ISO 868 | 86 |

| ED Specimens | PED Specimens | |||

|---|---|---|---|---|

| Width [mm] | 2.96 | 0.02 | 2.96 | 0.02 |

| Thickness | 3.08 | 0.01 | 3.06 | 0.01 |

| PED Specimens | ED Specimens | |||

|---|---|---|---|---|

| Testing temperature [°C] | 22 | 100 | 22 | 100 |

| Young’s modulus E [MPa] | 4000 | 1040 | 5705 | 1380 |

| Yield stress Re [MPa] | 67.7 * | 35.1 ** | 77.3 * | 40.9 ** |

| Tensile strength Rm [MPa] | 75.7 | 45.3 | 84.2 | 50.8 |

| Elongation at break [%] | 13.4 | 21 | 8.5 | 17 |

| PED Specimens | ED Specimens | |||

|---|---|---|---|---|

| Testing temperature [°C] | 22 | 100 | 22 | 100 |

| Constant C1 [MPa] | 28.8 | 18.9 | 31.1 | 24.7 |

| Constant C2 [/] | −0.012 | −0.022 | −0.016 | −0.038 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zadravec, M.; Kramberger, J.; Nečemer, B.; Glodež, S. Fatigue Behaviour of PA66 GF30 at Different Temperatures. Polymers 2025, 17, 42. https://doi.org/10.3390/polym17010042

Zadravec M, Kramberger J, Nečemer B, Glodež S. Fatigue Behaviour of PA66 GF30 at Different Temperatures. Polymers. 2025; 17(1):42. https://doi.org/10.3390/polym17010042

Chicago/Turabian StyleZadravec, Marko, Janez Kramberger, Branko Nečemer, and Srečko Glodež. 2025. "Fatigue Behaviour of PA66 GF30 at Different Temperatures" Polymers 17, no. 1: 42. https://doi.org/10.3390/polym17010042

APA StyleZadravec, M., Kramberger, J., Nečemer, B., & Glodež, S. (2025). Fatigue Behaviour of PA66 GF30 at Different Temperatures. Polymers, 17(1), 42. https://doi.org/10.3390/polym17010042