The Impact of High-Speed Crushing Process of Fibrous Polytetrafluoroethylene on Pyrolyzed Carbon Black/Natural Rubber Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Equipment

2.3. Experimental Program

2.4. Sample Preparation

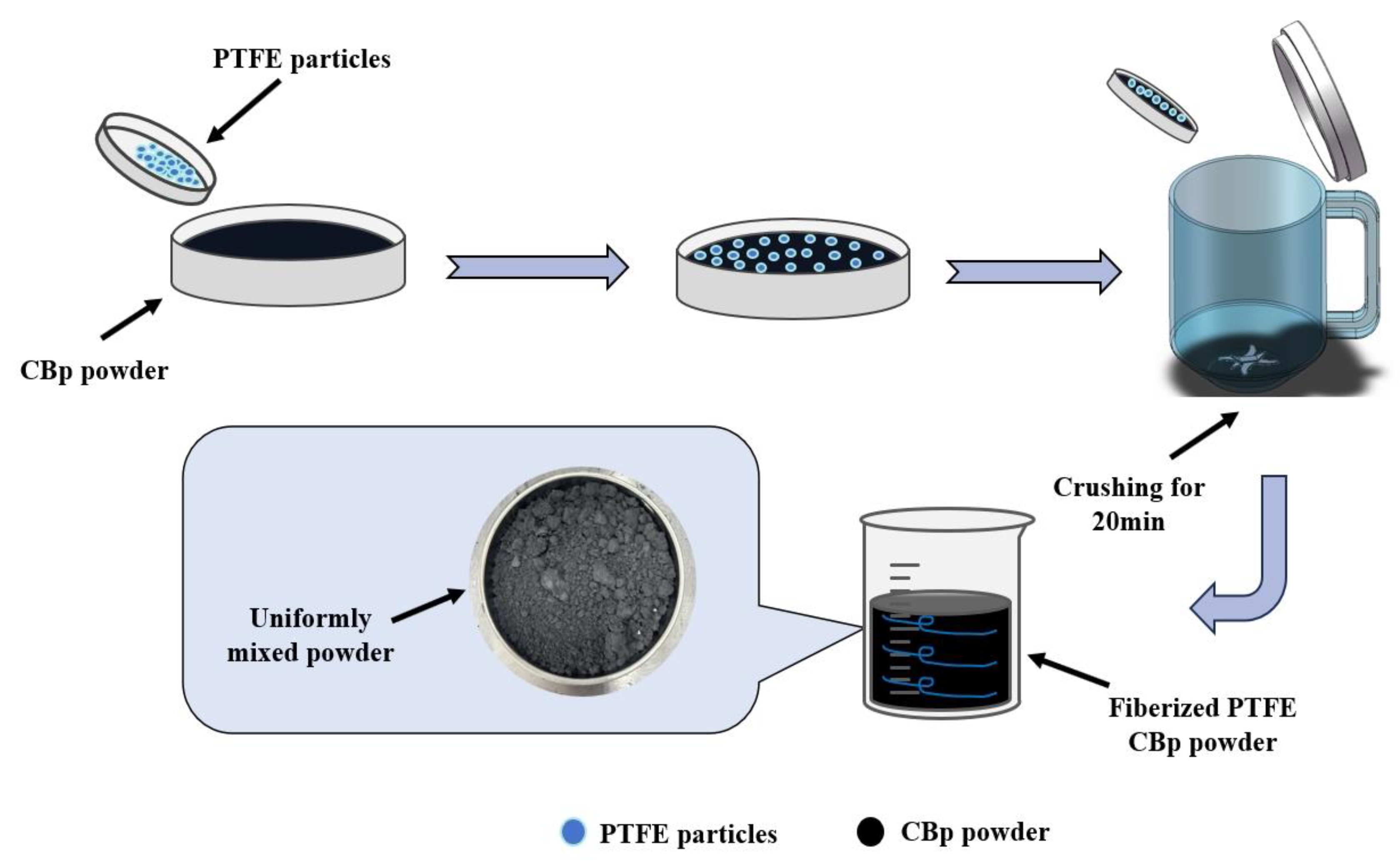

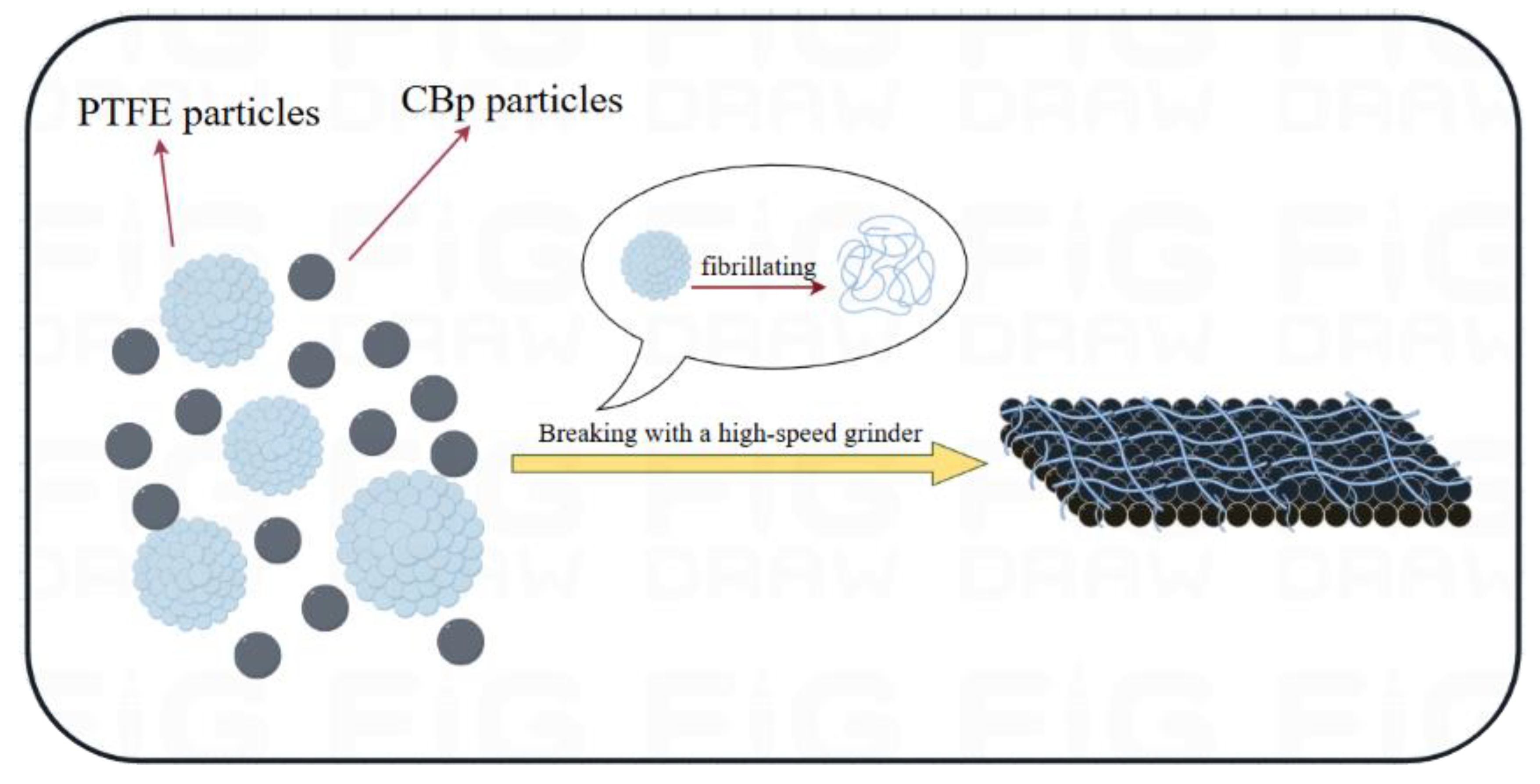

2.4.1. Preparation of PTFE-Modified CBp

2.4.2. Mixing and Vulcanization

2.5. Characterization

2.5.1. Characterization of Properties

2.5.2. Characterization of Structure and Morphology

3. Results and Discussion

3.1. SEM Images

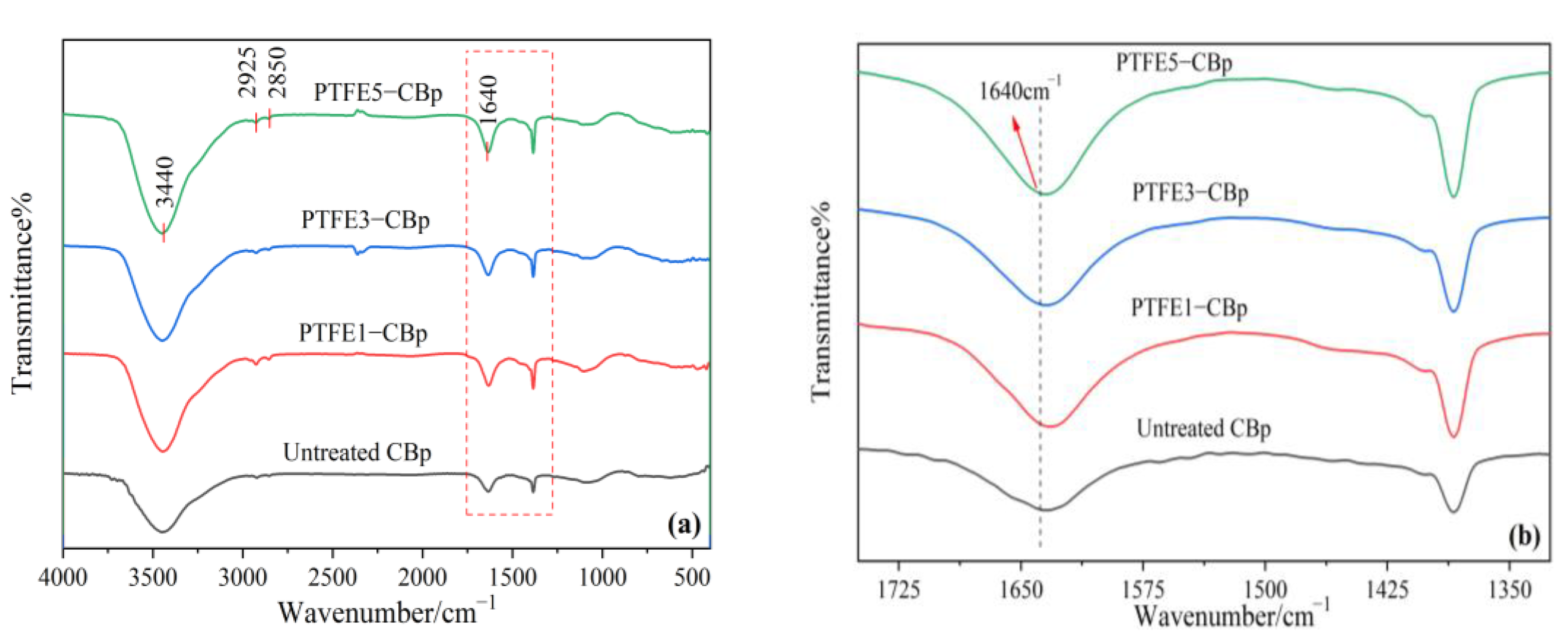

3.2. Fourier Transform Infrared Spectroscopy

3.3. Filler Dispersion

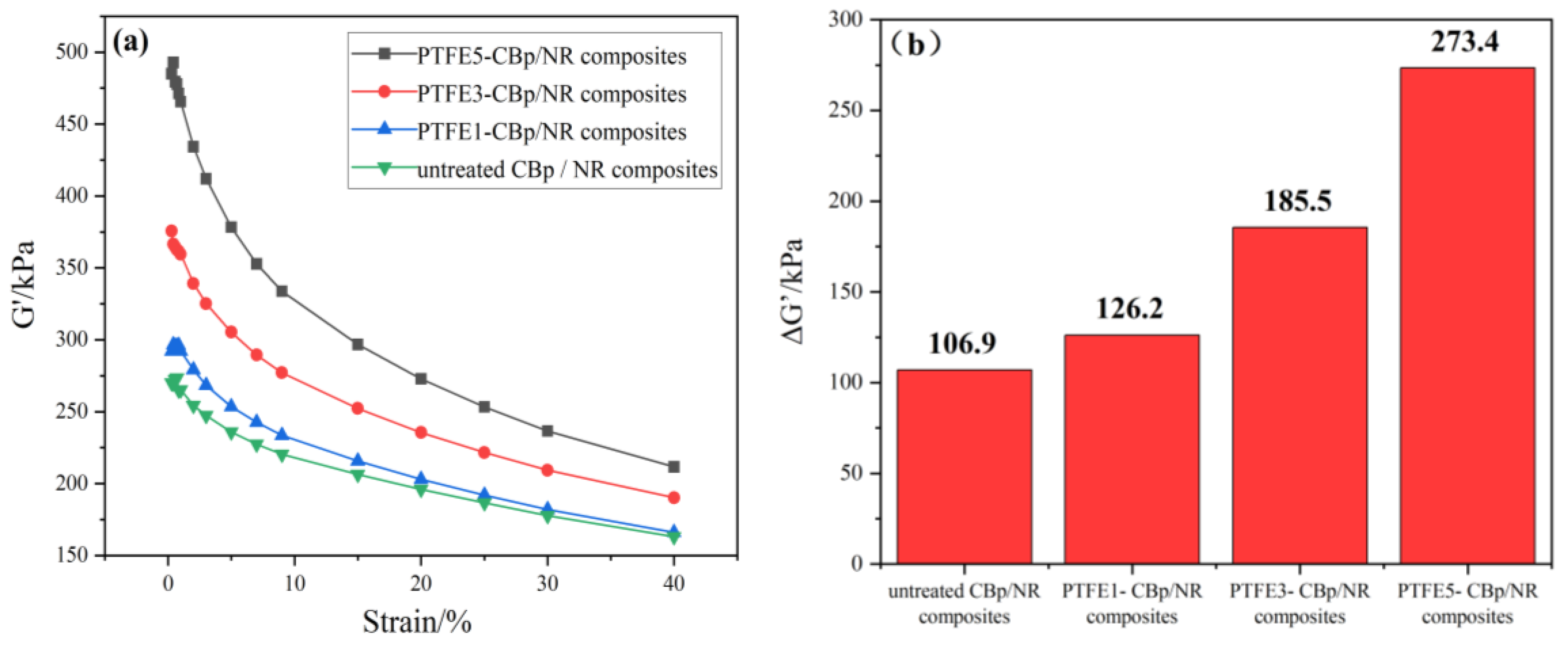

3.4. Payne Effect

3.5. Mooney Viscosity and Vulcanization Characteristics

3.6. Mechanical Properties

3.7. Density and Wear Resistance

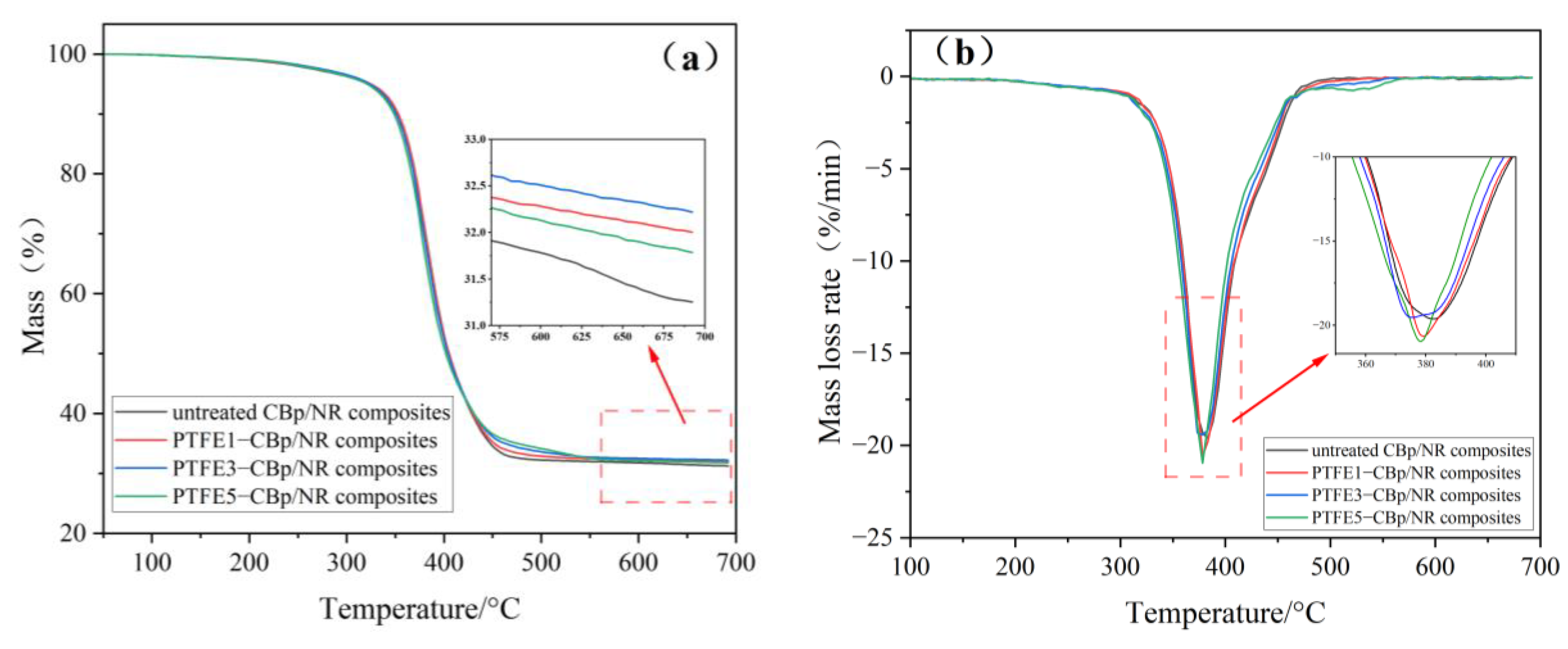

3.8. Thermal Stability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, G.H.; Zhang, Y.F.; Zhang, L.Q. Progress of waste rubber in the application of pyrolysis. Polym. Bull. 2017, 12, 1–13. [Google Scholar]

- Qiu, J. Activation mechanism and experimental study on the utilization of cracked carbon black from waste tires. Qingdao Univ. Sci. Technol. 2023, 6, 1–80. [Google Scholar]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Xu, J.; Yu, J.; Xu, J. High-value utilization of waste tires: A review with focus on modified carbon black from pyrolysis. Sci. Total Environ. 2020, 742, 140235. [Google Scholar] [CrossRef]

- Roy, C.; Labrecque, B.; Caumia, B. Recycling of scrap tires to oil and carbon black by vacuum pyrolysis. Resour. Conserv. Recycl. 1990, 4, 203–213. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, T.; Ma, L. Vacuum pyrolysis of waste tires with basic additives. Waste Manag. 2008, 28, 2301–2310. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T. Fuel production from pyrolysis of natural and synthetic rubbers. Fuel 2017, 191, 403–410. [Google Scholar] [CrossRef]

- Liu, J.Z. The Golden key to unlocking the resource utilization of waste rubber. Environ. Prot. 2012, 10, 67–90. [Google Scholar] [CrossRef]

- Dhanumalayan, E.; Joshi, G.M. Performance properties and applications of polytetrafluoroethylene (PTFE)—A review. Adv. Compos. Hybrid Mater. 2018, 1, 247–268. [Google Scholar] [CrossRef]

- Dyment, J.; Ziebland, H. The tensile properties of some plastics at low temperatures. J. Appl. Chem. 1958, 8, 203–206. [Google Scholar] [CrossRef]

- Ayanleye, O.; Hammed, V.; Akinrotimi, O. Utilization of polytetrafluoroethylene (PTFE) for insulating aerospace cables. Int. J. Adv. Res. Eng. Technol. 2024, 15, 57–64. [Google Scholar] [CrossRef]

- Teng, H. Overview of the development of the fluoropolymer industry. Appl. Sci. 2012, 2, 496–512. [Google Scholar] [CrossRef]

- Yuan, X.D.; Yang, X.J. A study on friction and wear properties of PTFE coatings under vacuum conditions. Wear 2010, 26, 291–297. [Google Scholar] [CrossRef]

- Park, E.S. Processibility and mechanical properties of micronized polytetrafluoroethylene reinforced silicone rubber composites. J. Appl. Polym. Sci. 2008, 107, 372–381. [Google Scholar] [CrossRef]

- Khan, M.S.; Franke, R.; Lehmann, D. Physical and tribological properties of PTFE micropowder-filled EPDM rubber. Tribol. Int. 2009, 42, 890–896. [Google Scholar] [CrossRef]

- Bai, Y.Y.; Du, J.H. Effect of PTFE on properties of nitrile rubber. China Elastomerics 2024, 34, 72–76. [Google Scholar]

- Wang, R.; Xu, G. Structure and properties of polytetrafluoroethylene (PTFE) fibers. e-Polymers 2017, 17, 215–220. [Google Scholar] [CrossRef]

- O’leary, K.; Geil, P.H. Polytetrafluoroethylene fibril structure. J. Appl. Phys. 1967, 38, 4169–4181. [Google Scholar] [CrossRef]

- ISO 6502-3:2018; Rubber—Measurement of Vulcanization Characteristics Using Curemeters—Part 3: Rotorless Curemeter. ISO: Geneva, Switzerland, 2018.

- ISO 37:2005; Rubber—Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. ISO: Geneva, Switzerland, 2005.

- ISO 289-1:2014; Rubber, Unvulcanized—Determinations Using a Shearing-Disc Viscometer—Part 1: Determination of Mooney Viscosity. ISO: Geneva, Switzerland, 2014.

- ISO 4649:1985; Rubber—Determination of Abrasion Resistance Using a Rotating Cylindrical Drum Device. ISO: Geneva, Switzerland, 1985.

- ISO 11345; Rubber—Assessment of Carbon Black Dispersion—Rapid Comparative Methods. ISO: Geneva, Switzerland, 2006.

- ASTM D7723; Standard Test Method for Rubber Property—Macro-Dispersion of Fillers in Compounds. ASTM: West Conshohocken, PA, USA, 2024.

- Frick, A.; Sich, D.; Heinrich, G. Relationship between structure and mechanical properties of melt processable PTFE: Influence of molecular weight and comonomer content. Macromol. Mater. Eng. 2013, 298, 954–966. [Google Scholar] [CrossRef]

- Svatoš, A.; Attygalle, A.B. Characterization of vinyl-substituted, carbon−carbon double bonds by GC/FT-IR analysi. Anal. Chem. 1997, 69, 1827–1836. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of infrared spectra, a practical approach. Encycl. Anal. Chem. 2000, 12, 10815–10837. [Google Scholar]

- Yalamanchili, M.R.; Atia, A.A.; Miller, J.D. Analysis of interfacial water at a hydrophilic silicon surface by in-situ FTIR/internal reflection spectroscopy. Langmuir 1996, 12, 4176–4184. [Google Scholar] [CrossRef]

- Boonstra, B.B.; Medalia, A.I. Effect of carbon black dispersion on the mechanical properties of rubber vulcanizates. Rubber Chem. Technol. 1963, 36, 115–142. [Google Scholar] [CrossRef]

- Zhang, L.Q. Rubber nanocomposites: Basics and applications. Chem. Ind. Press 2018, 1, 12. [Google Scholar]

- Payne, A.R. The dynamic properties of carbon black-loaded natural rubber vulcanizates. J. Appl. Polym. Sci. 1962, 6, 57–63. [Google Scholar] [CrossRef]

- Xiao, Y.; Xu, Z.; Gong, Z. An animal glycerol potassium salt without volatile organic compounds emission combined with plasma-atomization technology and its application in green tires. Polym. Compos. 2023, 44, 3856–3873. [Google Scholar] [CrossRef]

- Khan, M.S.; Heinrich, G. PTFE-based rubber composites for tribological applications. Adv. Rubber Compos. 2011, 01, 249–310. [Google Scholar]

- Shan, C.; Li, P.; Clayfield, T. Development of high mooney viscosity, homogeneous long-chain branched EPDM. Rubber World 2014, 250, 34–40. [Google Scholar]

- Wang, C.; Lai, Q.; Hong, Y. Research on full formula wet continuous mixing process. China Rubber Ind. 2023, 70, 667–674. [Google Scholar]

- Watanabe, T.; Suwa, T.; Okamoto, J. Emulsifier-free emulsion polymerization of tetrafluoroethylene by radiation. IV. Effects of additives on polymer molecular weight. J. Appl. Polym. Sci. 1979, 23, 967–983. [Google Scholar] [CrossRef]

- Blumm, J.; Lindemann, A.; Meyer, M. Characterization of PTFE using advanced thermal analysis techniques. Int. J. Thermophys. 2010, 31, 1919–1927. [Google Scholar] [CrossRef]

- Martínez, J.D.; Cardona, U.N.; Murillo, R. Carbon black recovery from waste tire pyrolysis by demineralization: Production and application in rubber compounding. Waste Manag. 2019, 85, 574–584. [Google Scholar] [CrossRef] [PubMed]

- Blanchet, T.A. Wear of polytetrafluoroethylene and PTFE composites. Polym. Tribol. 2009, 01, 347–370. [Google Scholar]

- Xu, Y.; Huang, C.; Jin, X. A comparative study of characteristics of polytetrafluoroethylene fibers manufactured by various processes. J. Appl. Polym. Sci. 2016, 133, 26–50. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, B.; Huang, Y.G. High-value application of kaolin by wet mixing method in low heat generation and high wear-resistant natural rubber composites. Appl. Clay Sci. 2024, 261, 107–574. [Google Scholar] [CrossRef]

- Puts, G.J.; Crouse, P.; Ameduri, B. Polytetrafluoroethylene: Synthesis and characterization of the original extreme polymer. Chem. Rev. 2019, 119, 1763–1805. [Google Scholar] [CrossRef]

- Khanna, Y.P.; Chomyn, G.; Kumar, R. Observation of a new high-temperature transition in polytetrafluoroethylene. Macromolecules 1990, 23, 2488–2494. [Google Scholar] [CrossRef]

| Material | Amount (phr 1) | Material | Amount (phr) |

|---|---|---|---|

| NR | 100 | Sulfur | 2.5 |

| CBp | 50 | DM | 0.6 |

| ZnO | 5 | SAD | 3 |

| PTFE | 0/1/3/5 |

| Equipment | Model | Manufacturer |

|---|---|---|

| High-speed grinder | WPB12J30 | Meiyu, Fuzhou, Fujian, China |

| Fourier transform infrared spectrometer | IS50 | Thermo-Scientific, Waltham, MA, USA |

| Rotorless rheometer | MDR-C | Alpha Technologies, Wilmington, DE, USA |

| Mooney viscometer | PREMIER MV | Alpha Technologies, Wilmington, DE, USA |

| Rubber process analyzer | RPA-2000 | Alpha Technologies, Wilmington, DE, USA |

| Universal testing machine | Instron-3365 | U-CAN, Norwood, MA, USA |

| Carbon black dispersibility tester | Disper GRADER | Alpha Technologies, Wilmington, DE, USA |

| Shore A hardness tester | H17A | Wallace instruments, Dorking, Surrey, UK |

| Thermogravimetric analyzer | 209F3 | NETZSCH, Selb, Bavaria, Germany |

| Rotary roller abrasion tester | SS-5643-D | Songshu, Dongguan, Guangzhou, China |

| Untreated CBp | PTFE1-CBp | PTFE3-CBp | PTFE5-CBp | |

|---|---|---|---|---|

| PTFE(phr 1) | 0 | 1 | 3 | 5 |

| CBp(phr 1) | 50 | 50 | 50 | 50 |

| Pre-treatment process | Add PTFE and CBp simultaneously into the high-speed grinder, with a rotational speed of 25,000 rpm and a processing time of 20 min. | |||

| Untreated CBp/NR Composites | PTFE1-CBp/NR Composites | PTFE3-CBp/NR Composites | PTFE5-CBp/NR Composites | |

|---|---|---|---|---|

| Dispersion level | 5.0 | 4.5 | 5.5 | 5.2 |

| Average particle size of agglomerates/um | 3.4 | 3.5 | 3.2 | 3.2 |

| White area/% | 13.6 | 14.3 | 12.2 | 9.6 |

| Test Project | Untreated CBp/NR Composites | PTFE1-CBp/NR Composites | PTFE3-CBp/NR Composites | PTFE5-CBp/NR Composites |

|---|---|---|---|---|

| ML1+4 (100 °C) | 36.0 | 40.9 | 55.1 | 58.3 |

| ML/(dN·m) | 1.1 | 1.3 | 1.7 | 2.0 |

| MH/(dN·m) | 10.6 | 10.7 | 11.4 | 11.3 |

| MH − ML/(dN·m) | 9.5 | 9.4 | 9.7 | 9.3 |

| t10/(min) | 1.8 | 1.7 | 1.7 | 1.6 |

| t90/(min) | 11.5 | 11.4 | 9.9 | 10.7 |

| Untreated CBp-CBp/NR Composites | PTFE1-CBp/NR Composites | PTFE3-CBp/NR Composites | PTFE5-CBp/NR Composites | |

|---|---|---|---|---|

| Onset decomposition temperature/(°C) | 365.9 | 371.6 | 366.6 | 371.2 |

| Residual mass at 700 °C/(%) | 31.3 | 32.0 | 32.2 | 31.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, Z.; Xiao, Y.; Zhou, Y.; Zhu, D.; Dai, B.; Wang, Z.; Wang, C.; Bian, H. The Impact of High-Speed Crushing Process of Fibrous Polytetrafluoroethylene on Pyrolyzed Carbon Black/Natural Rubber Composites. Polymers 2025, 17, 222. https://doi.org/10.3390/polym17020222

Gong Z, Xiao Y, Zhou Y, Zhu D, Dai B, Wang Z, Wang C, Bian H. The Impact of High-Speed Crushing Process of Fibrous Polytetrafluoroethylene on Pyrolyzed Carbon Black/Natural Rubber Composites. Polymers. 2025; 17(2):222. https://doi.org/10.3390/polym17020222

Chicago/Turabian StyleGong, Zheng, Yao Xiao, Yukun Zhou, Donglin Zhu, Baochang Dai, Ziyang Wang, Chuansheng Wang, and Huiguang Bian. 2025. "The Impact of High-Speed Crushing Process of Fibrous Polytetrafluoroethylene on Pyrolyzed Carbon Black/Natural Rubber Composites" Polymers 17, no. 2: 222. https://doi.org/10.3390/polym17020222

APA StyleGong, Z., Xiao, Y., Zhou, Y., Zhu, D., Dai, B., Wang, Z., Wang, C., & Bian, H. (2025). The Impact of High-Speed Crushing Process of Fibrous Polytetrafluoroethylene on Pyrolyzed Carbon Black/Natural Rubber Composites. Polymers, 17(2), 222. https://doi.org/10.3390/polym17020222