Evaluation of Workability and Crack Resistance of Recycled Plastic Asphalt Mixtures

Abstract

1. Introduction

2. Scope and Objectives

3. Raw Materials and Methods

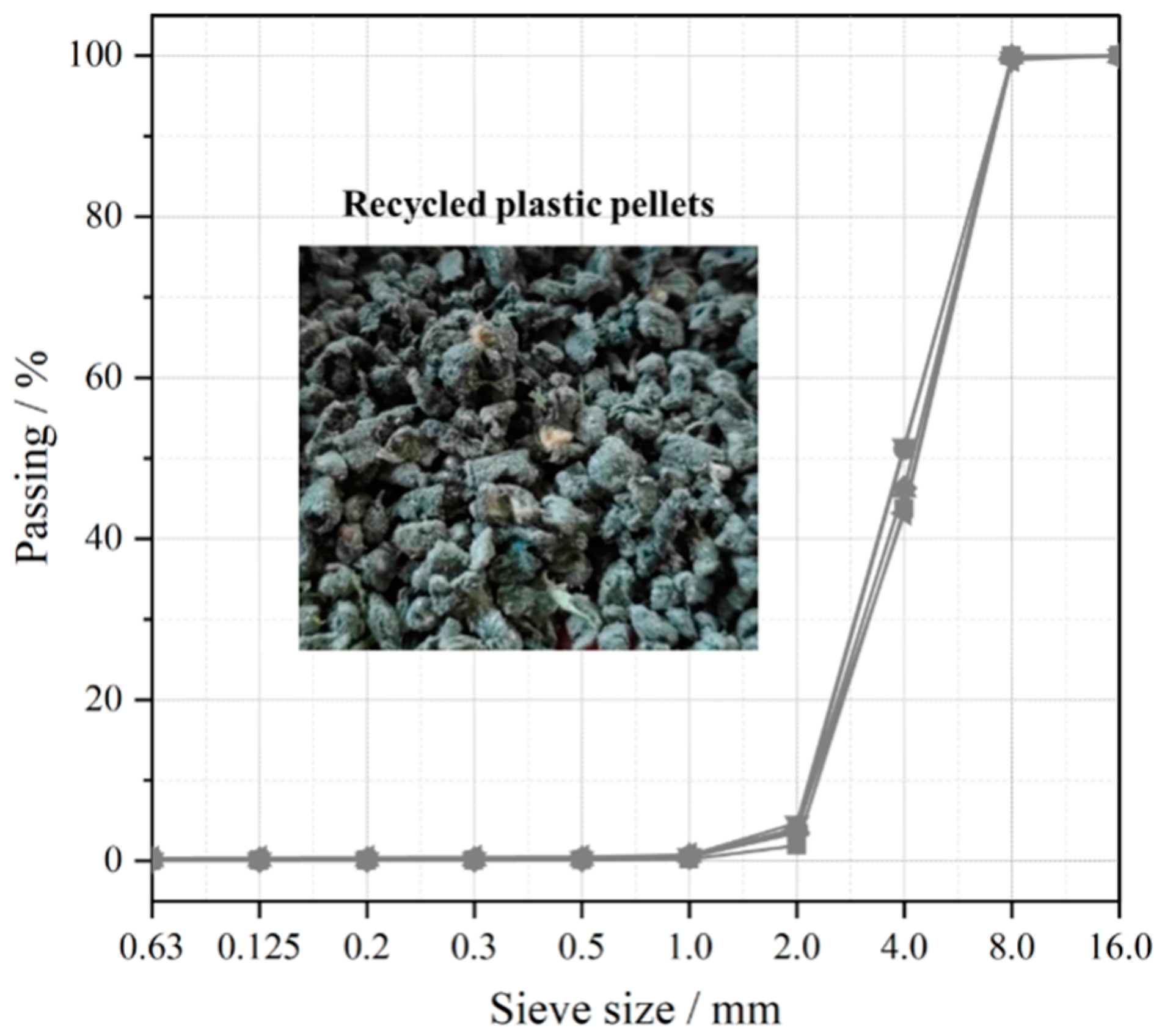

3.1. Raw Materials

3.2. Methods

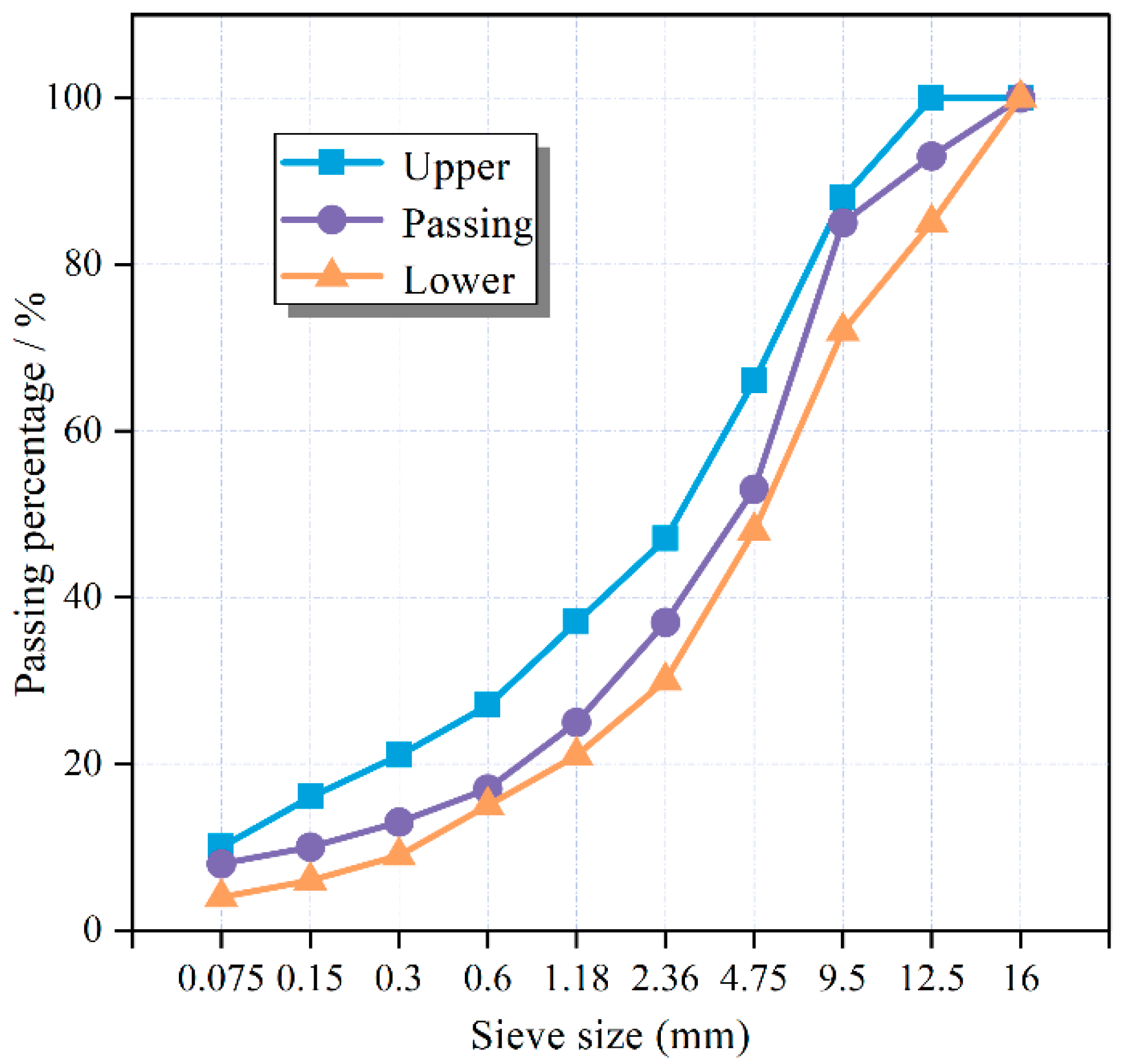

3.2.1. Plastic-Modified Asphalt Mixture Preparation

3.2.2. FTIR Test

3.2.3. Thermal Stability Evaluation

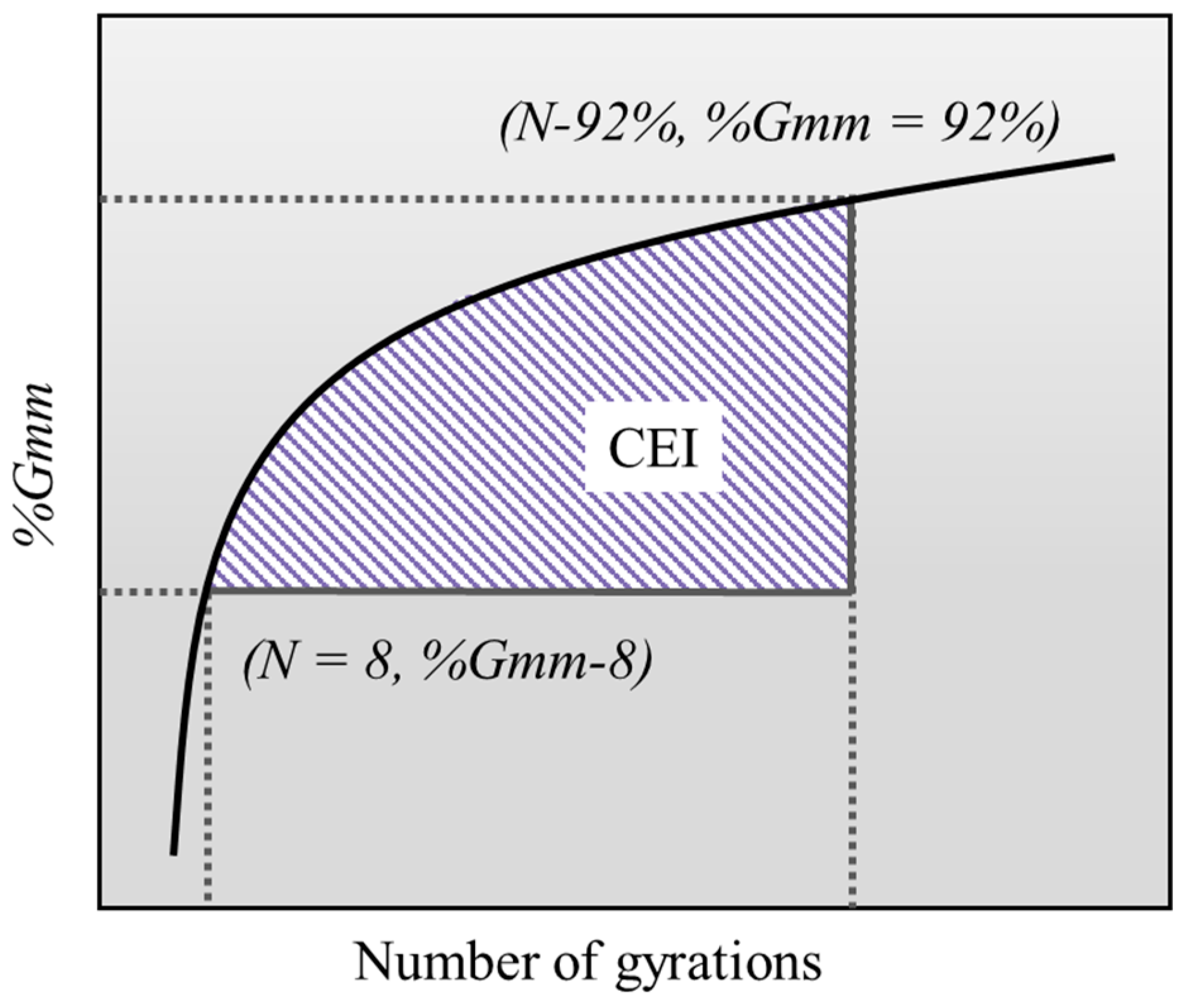

3.2.4. Workability Evaluation

3.2.5. Optical Microscope

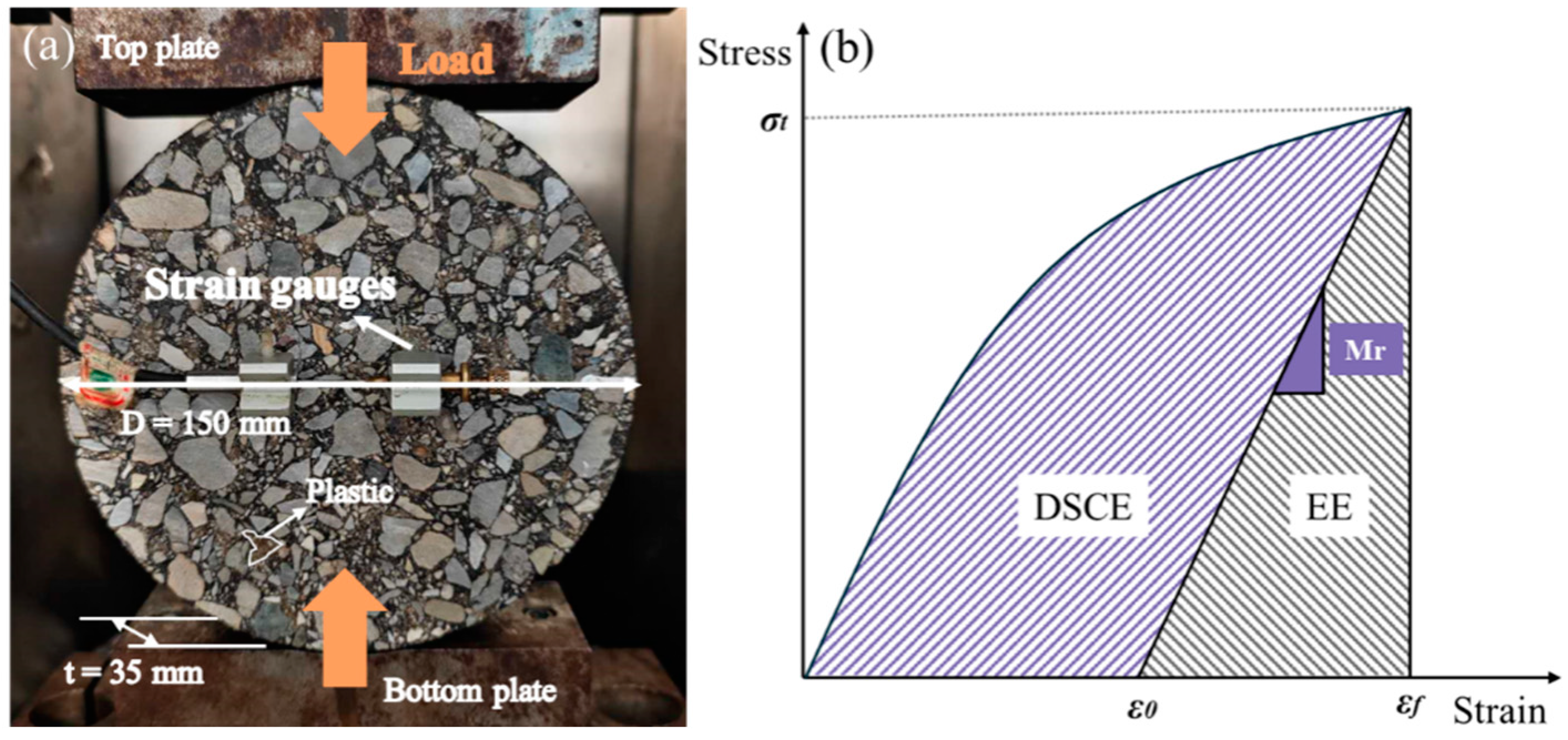

3.2.6. Superpave IDT Test

4. Results and Discussion

4.1. FTIR Analysis

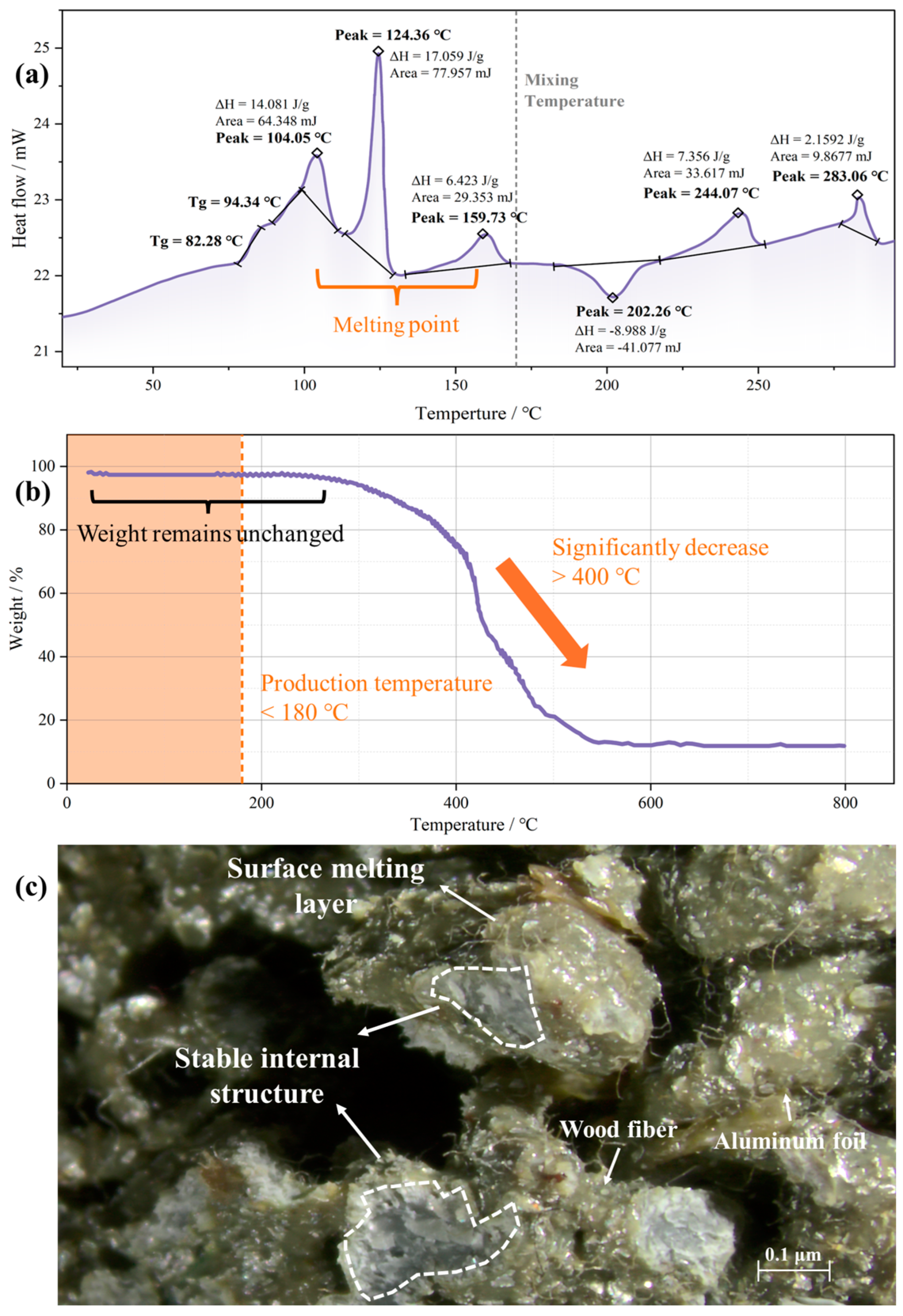

4.2. Thermal Stability

4.3. Workability

4.4. Superpave IDT Evaluation

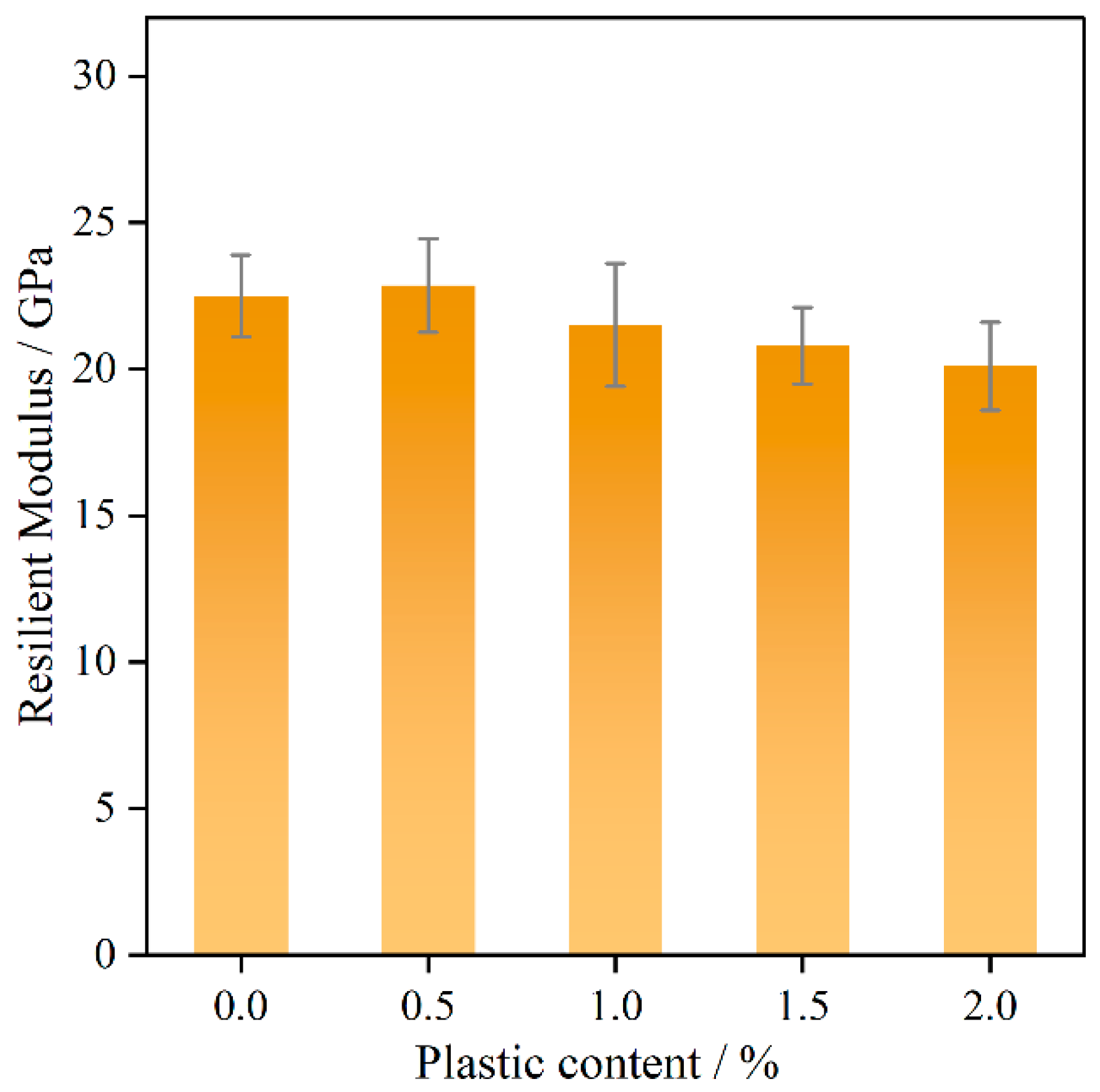

4.4.1. Resilient Modulus

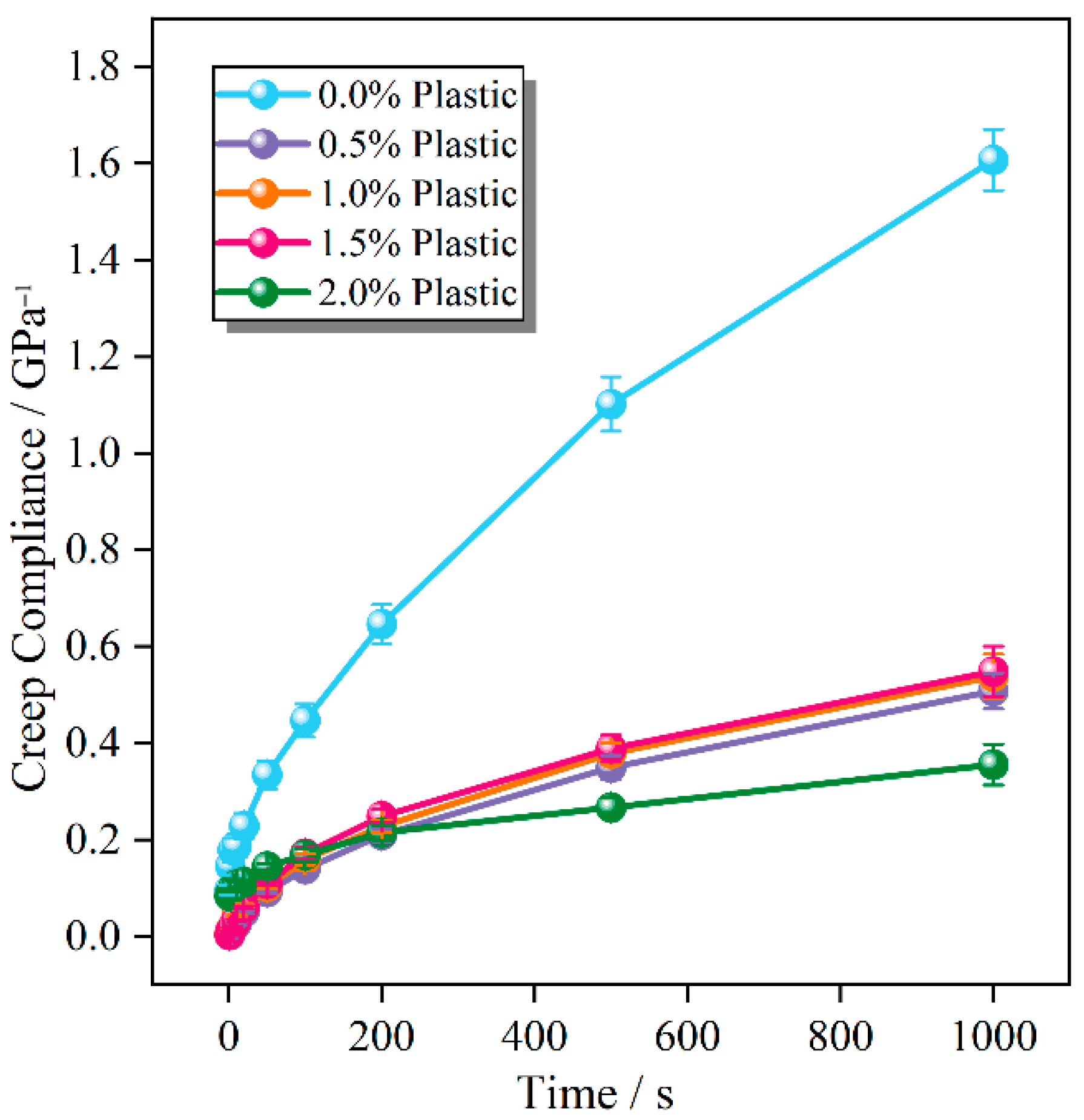

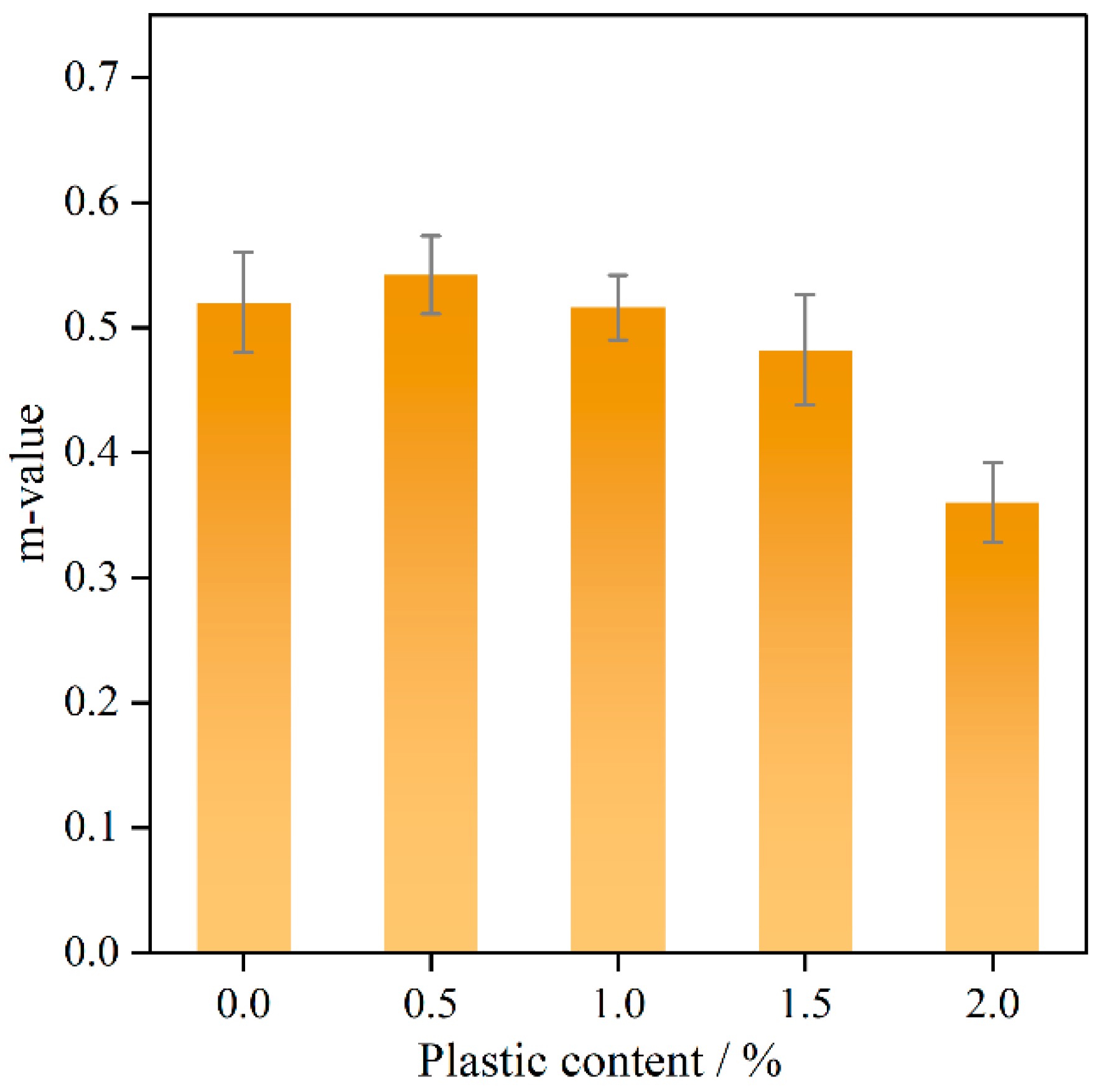

4.4.2. Creep Properties

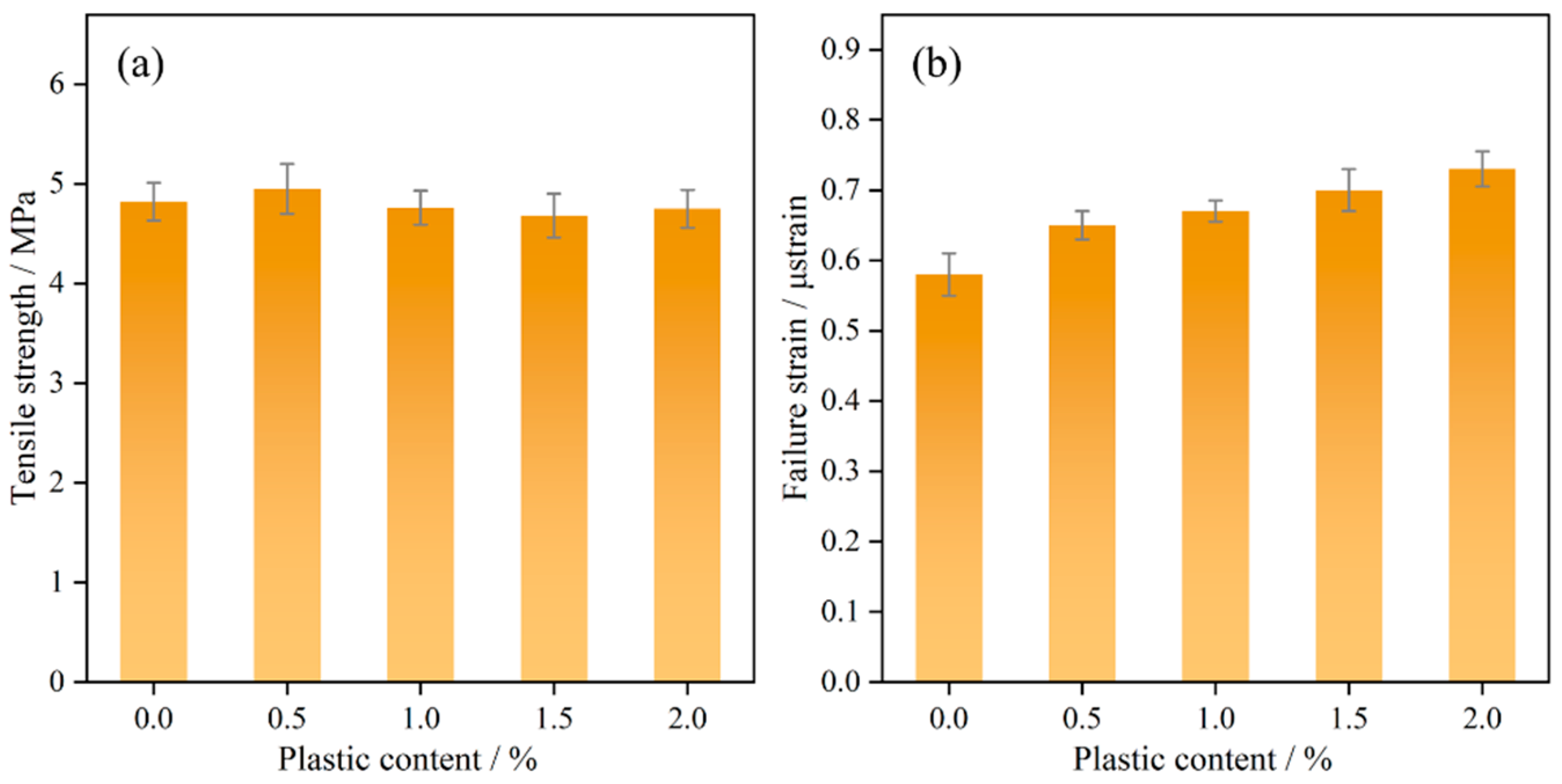

4.4.3. Tensile Properties

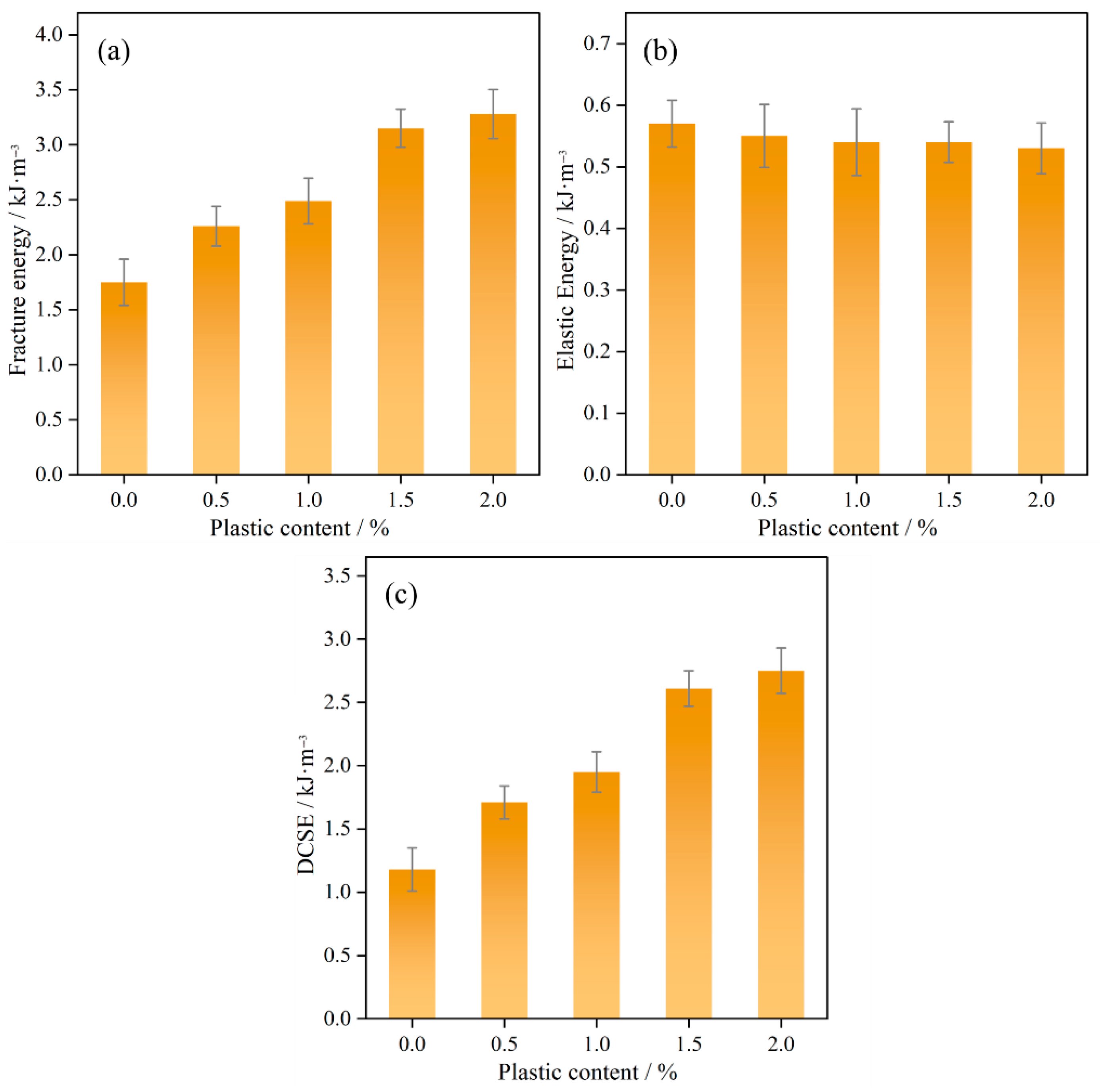

4.4.4. Fracture Energy

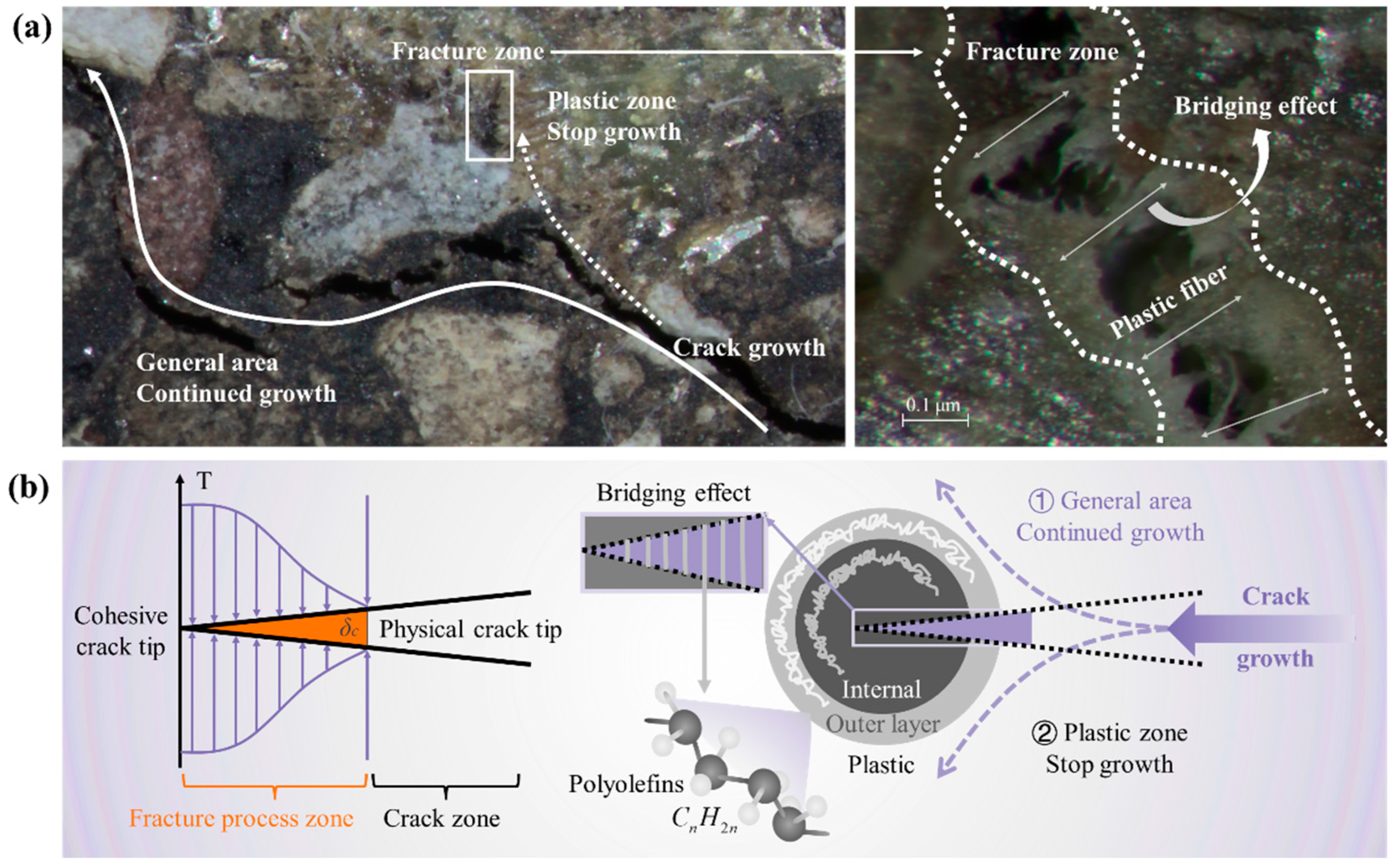

4.5. Fracture Mechanism of Plastic Asphalt Mixture

5. Conclusions

- The recycled plastic used for food packaging is a polyolefin composite plastic primarily composed of LDPE, LLDPE, HDPE, and PP. The wood cellulose and aluminum foil contained in the material improve its thermal stability, enabling the plastic to withstand actual production temperatures.

- When less than 2% plastic (by aggregate weight) is added, the asphalt mixture exhibits good workability. As the plastic content increases, the plastics begin to occupy spaces within the asphalt and voids, and their role gradually shifts from aggregate replacement to void filling. Meanwhile, the shape of the plastic changes from regular to irregular.

- When the plastic content increased from 0.5% to 2.0%, creep compliance decreased from 68.4% to 77.87%, while the m-value, tensile strength, and maximum elastic energy decreased by 30.77%, 5.6%, and 7%, respectively. The ability of the recycled plastic–asphalt mixture to resist permanent deformation is improved.

- In contrast, the failure strain, fracture energy, and maximum DSCE increased by 25.86%, 87.43%, and 133.05%, respectively. Adding up to 2% plastic (by aggregate weight) improves toughness and cracking resistance, increasing dissipated energy during crack propagation.

- When cracks propagate into the plastic zone, the polyolefin molecular chains rearrange and slip, forming plastic fibers that hinder crack extension through a bridging effect. As a result, cracks tend to bypass the plastic zone, and the plastic zone exhibits fewer cracks than the surrounding regions.

6. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lopes, L.; Dauari, H.; Mendonça, P.; Almeida, M. Marine Plastic Waste in Construction: A Systematic Review of Applications in the Built Environment. Polymers 2025, 17, 1729. [Google Scholar] [CrossRef]

- Plastics—The Fast Facts. 2024. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2024/ (accessed on 4 September 2025).

- Naderi Kalali, E.; Lotfian, S.; Entezar Shabestari, M.; Khayatzadeh, S.; Zhao, C.; Nezhad, H.Y. A Critical Review of the Current Progress of Plastic Waste Recycling Technology in Structural Materials. Curr. Opin. Green Sustain. Chem. 2023, 40, 100763. [Google Scholar] [CrossRef]

- CORNAGO Elisabetta, ENV/EEI. Global Plastics Outlook: Resource Efficiency Policies in the G20 Policy Commons. Available online: https://policycommons.net/artifacts/3860763/outlook-for-material-resources-and-implications-for-resource-efficiency-policies-in-the-g20/4666718/ (accessed on 4 September 2025).

- Stoett, P.; Scrich, V.M.; Elliff, C.I.; Andrade, M.M.; de M.Grilli, N.; Turra, A. Global Plastic Pollution, Sustainable Development, and Plastic Justice. World Dev. 2024, 184, 106756. [Google Scholar] [CrossRef]

- MacLeod, M.; Arp, H.P.H.; Tekman, M.B.; Jahnke, A. The Global Threat from Plastic Pollution. Science 2021, 373, 61–65. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Enfrin, M.; Giustozzi, F. Recent Advances in the Construction of Sustainable Asphalt Roads with Recycled Plastic. Polym. Int. 2022, 71, 1376–1383. [Google Scholar] [CrossRef]

- Wang, D.; Baliello, A.; Poulikakos, L.; Vasconcelos, K.; Kakar, M.R.; Giancontieri, G.; Pasquini, E.; Porot, L.; Tušar, M.; Riccardi, C.; et al. Rheological Properties of Asphalt Binder Modified with Waste Polyethylene: An Interlaboratory Research from the RILEM TC WMR. Resour. Conserv. Recycl. 2022, 186, 106564. [Google Scholar] [CrossRef]

- Khatun, R.; Xiang, H.; Yang, Y.; Wang, J.; Yildiz, G. Bibliometric Analysis of Research Trends on the Thermochemical Conversion of Plastics during 1990–2020. J. Clean. Prod. 2021, 317, 128373. [Google Scholar] [CrossRef]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a Sustainable Paving Material through Chemical Recycling of Waste PET into Crumb Rubber Modified Asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Singh, A.; Gupta, A. Upcycling of Plastic Waste in Bituminous Mixes Using Dry Process: Review of Laboratory to Field Performance. Constr. Build. Mater. 2024, 425, 136005. [Google Scholar] [CrossRef]

- Lugeiyamu, L.; Kunlin, M.; Mensahn, E.S.K.; Faraz, A. Utilization of Waste Polyethylene Terephthalate (PET) as Partial Replacement of Bitumen in Stone Mastic Asphalt. Constr. Build. Mater. 2021, 309, 125176. [Google Scholar] [CrossRef]

- Vasudevan, R.; Ramalinga Chandra Sekar, A.; Sundarakannan, B.; Velkennedy, R. A Technique to Dispose Waste Plastics in an Ecofriendly Way—Application in Construction of Flexible Pavements. Constr. Build. Mater. 2012, 28, 311–320. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, S.; Zhou, H.; Hu, W.; Polaczyk, P.; Zhang, M.; Huang, B. Compatibility and Rheological Characterization of Asphalt Modified with Recycled Rubber-Plastic Blends. Constr. Build. Mater. 2021, 270, 121416. [Google Scholar] [CrossRef]

- Oberoi, G.; Garg, A. Single-Use Plastics: A Roadmap for Sustainability? Supremo Amic. 2021, 24, 585–595. [Google Scholar]

- Tušar, M.; Kakar, M.R.; Poulikakos, L.D.; Pasquini, E.; Baliello, A.; Pasetto, M.; Porot, L.; Wang, D.; Falchetto, A.C.; Dalmazzo, D.; et al. RILEM TC 279 WMR Round Robin Study on Waste Polyethylene Modified Bituminous Binders: Advantages and Challenges. Road Mater. Pavement Des. 2022, 24, 311–339. [Google Scholar] [CrossRef]

- Elnaml, I.; Liu, J.; Mohammad, L.N.; Wasiuddin, N.; Cooper, S.B. Developing Sustainable Asphalt Mixtures Using High-Density Polyethylene Plastic Waste Material. Sustainability 2023, 15, 9897. [Google Scholar] [CrossRef]

- Pasetto, M.; Baliello, A.; Pasquini, E.; Poulikakos, L. Dry Addition of Recycled Waste Polyethylene in Asphalt Mixtures: A Laboratory Study. Materials 2022, 15, 4739. [Google Scholar] [CrossRef] [PubMed]

- Poulikakos, L.D.; Pasquini, E.; Tusar, M.; Hernando, D.; Wang, D.; Mikhailenko, P.; Pasetto, M.; Baliello, A.; Cannone Falchetto, A.; Miljković, M.; et al. RILEM Interlaboratory Study on the Mechanical Properties of Asphalt Mixtures Modified with Polyethylene Waste. J. Clean. Prod. 2022, 375, 134124. [Google Scholar] [CrossRef]

- Yu, D.; Jing, H.; Liu, J. Effects of Freeze–Thaw Cycles on the Internal Voids Structure of Asphalt Mixtures. Materials 2022, 15, 3560. [Google Scholar] [CrossRef]

- Du, Z.; Jiang, C.; Yuan, J.; Xiao, F.; Wang, J. Low Temperature Performance Characteristics of Polyethylene Modified Asphalts—A Review. Constr. Build. Mater. 2020, 264, 120704. [Google Scholar] [CrossRef]

- Liu, J.; Jing, H.; Wang, Z.; Wang, X.; Zhang, L. Recycling of Steel Slag in Sustainable Bituminous Mixtures: Self-Healing Performance, Mechanism, Environmental and Economic Analyses. J. Clean. Prod. 2023, 429, 139496. [Google Scholar] [CrossRef]

- Yu, R.; Fang, C.; Liu, P.; Liu, X.; Li, Y. Storage Stability and Rheological Properties of Asphalt Modified with Waste Packaging Polyethylene and Organic Montmorillonite. Appl. Clay Sci. 2015, 104, 1–7. [Google Scholar] [CrossRef]

- Fang, C.; Li, T.; Zhang, Z.; Wang, X. Combined Modification of Asphalt by Waste PE and Rubber. Polym. Compos. 2008, 29, 1183–1187. [Google Scholar] [CrossRef]

- Yousefi, A.A.; Ait-Kadi, A.; Roy, C. Composite Asphalt Binders: Effect of Modified RPE on Asphalt. J. Mater. Civ. Eng. 2000, 12, 2. [Google Scholar] [CrossRef]

- Sui, Y.; Chen, Z. Application and Performance of Polyethylene Modifying Additive in Asphalt Mixture. In Proceedings of the ICTE 2011: International Conference on Transportation Engineering, Chengdu, China, 23–25 July 2011. [Google Scholar] [CrossRef]

- Hao, G.; He, M.; Lim, S.M.; Ong, G.P.; Zulkati, A.; Kapilan, S. Recycling of Plastic Waste in Porous Asphalt Pavement: Engineering, Environmental, and Economic Implications. J. Clean. Prod. 2024, 440, 140865. [Google Scholar] [CrossRef]

- Goli, A.; Rout, B.; Cyril, T.; Govindaraj, V. Evaluation of Mechanical Characteristics and Plastic Coating Efficiency in Plastic-Modified Asphalt Mixes. Int. J. Pavement Res. Technol. 2023, 16, 693–704. [Google Scholar] [CrossRef]

- Carullo, D.; Casson, A.; Rovera, C.; Ghaani, M.; Bellesia, T.; Guidetti, R.; Farris, S. Testing a Coated PE-Based Mono-Material for Food Packaging Applications: An in-Depth Performance Comparison with Conventional Multi-Layer Configurations. Food Packag. Shelf Life 2023, 39, 101143. [Google Scholar] [CrossRef]

- Naskar, M.; Chaki, T.K.; Reddy, K.S. Effect of Waste Plastic as Modifier on Thermal Stability and Degradation Kinetics of Bitumen/Waste Plastics Blend. Thermochim. Acta 2010, 509, 128–134. [Google Scholar] [CrossRef]

- Heydari, S.; Hajimohammadi, A.; Haji Seyed Javadi, N.; Khalili, N. The Use of Plastic Waste in Asphalt: A Critical Review on Asphalt Mix Design and Marshall Properties. Constr. Build. Mater. 2021, 309, 125185. [Google Scholar] [CrossRef]

- Bhattacharya, B.B.; Jayant, S.; Carter, T.; Curren, P.; Hailemichael, A.; Sebaaly, P.E.; Colbert, B. Impact of Laboratory Air Voids Using AASHTO T 166 versus AASHTO T 275 for HMA Specimens Compacted under AASHTO T 312. In Proceedings of the International Conference on Transportation and Development 2024, Atlanta, GA, USA, 15–18 June 2024. [Google Scholar] [CrossRef]

- Leiva, F.; West, R.C. Analysis of Hot-Mix Asphalt Lab Compactability Using Lab Compaction Parameters and Mix Characteristics. Transp. Res. Rec. J. Transp. Res. Board 2008, 2057, 89–98. [Google Scholar] [CrossRef]

- Reynaldo, R.; Björn, B.; Boonchais, S.; Zhang, Z. Hot Mix Asphalt Fracture Mechanics: A Fundamental Crack Growth Law for Asphalt Mixtures. J. Assoc. Asph. Paving Technol. 2002, 71, 816–827. [Google Scholar]

- Evaluation of the Low Temperature Cracking Performance of Asphalt Mixtures Utilizing HMA Fracture Mechanics. Constr. Build. Mater. 2013, 47, 594–600. [CrossRef]

- Zhang, Z.; Roque, R.; Birgisson, B. Evaluation of Laboratory-Measured Crack Growth Rate for Asphalt Mixtures. Transp. Res. Rec. J. Transp. Res. Board 2001, 1767, 1–6. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B.; Vukosavljevic, D. Laboratory Evaluation of Fatigue Characteristics of Recycled Asphalt Mixture. Constr. Build. Mater. 2008, 22, 1323–1330. [Google Scholar] [CrossRef]

- Monticelli, R.; Roberto, A.; Romeo, E.; Tebaldi, G. Mixed Design Optimization of Polymer-Modified Asphalt Mixtures (PMAs) Containing Carton Plastic Packaging Wastes. Sustainability 2023, 15, 10574. [Google Scholar] [CrossRef]

- Lynch, J.M.; Corniuk, R.N.; Brignac, K.C.; Jung, M.R.; Sellona, K.; Marchiani, J.; Weatherford, W. Differential Scanning Calorimetry (DSC): An Important Tool for Polymer Identification and Characterization of Plastic Marine Debris. Environ. Pollut. 2024, 346, 123607. [Google Scholar] [CrossRef]

- Amjad, H.; Ahmad, F.; Irshad Qureshi, M. Enhanced Mechanical and Durability Resilience of Plastic Aggregate Concrete Modified with Nano-Iron Oxide and Sisal Fiber Reinforcement. Constr. Build. Mater. 2023, 401, 132911. [Google Scholar] [CrossRef]

- Park, B.; Zou, J.; Yan, Y.; Roque, R.; Lopp, G.; Moseley, H. Effect of Reclaimed Asphalt Pavement on Cracking Performance of Asphalt Mixtures with Regular and High Polymer Modified Binders. Road Mater. Pavement Des. 2022, 23, 1492–1504. [Google Scholar] [CrossRef]

- Monticelli, R.; Roberto, A.; Bisanti, F.; Romeo, E.; Tebaldi, G. Effects of a Bio-Oil Additive on the Fracture Behavior of Heavy Polymer–Modified Asphalt Mixtures with High RAP Contents and Steel Slags. J. Test. Eval. 2025, 53, 338–348. [Google Scholar] [CrossRef]

- Yan, Y.; Hernando, D.; Park, B.; Tebaldi, G.; Roque, R. Effect of Aged Binder Distribution on the Fracture Tolerance of Asphalt Mixtures with Reclaimed Asphalt Pavement. J. Test. Eval. 2022, 50, 836–847. [Google Scholar] [CrossRef]

- Park, K.; Paulino, G.H.; Roesler, J.R. A Unified Potential-Based Cohesive Model of Mixed-Mode Fracture. J. Mech. Phys. Solids 2009, 57, 891–908. [Google Scholar] [CrossRef]

- Sun, Y.G.; Wang, S.Y.; Ren, Z.Y.; Wang, C. Identifying the Fatigue Crack Initiation Behavior of Asphalt Binder under Dynamic Shear Load. In Proceedings of the International Conference on Road and Airfield Pavement Technology 2023, Beijing, China, 6–8 July 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, H.; Monticelli, R.; Graiff, C.; Bergamonti, L.; Romeo, E.; Tebaldi, G. Evaluation of Workability and Crack Resistance of Recycled Plastic Asphalt Mixtures. Polymers 2025, 17, 2840. https://doi.org/10.3390/polym17212840

Jing H, Monticelli R, Graiff C, Bergamonti L, Romeo E, Tebaldi G. Evaluation of Workability and Crack Resistance of Recycled Plastic Asphalt Mixtures. Polymers. 2025; 17(21):2840. https://doi.org/10.3390/polym17212840

Chicago/Turabian StyleJing, Haosen, Riccardo Monticelli, Claudia Graiff, Laura Bergamonti, Elena Romeo, and Gabriele Tebaldi. 2025. "Evaluation of Workability and Crack Resistance of Recycled Plastic Asphalt Mixtures" Polymers 17, no. 21: 2840. https://doi.org/10.3390/polym17212840

APA StyleJing, H., Monticelli, R., Graiff, C., Bergamonti, L., Romeo, E., & Tebaldi, G. (2025). Evaluation of Workability and Crack Resistance of Recycled Plastic Asphalt Mixtures. Polymers, 17(21), 2840. https://doi.org/10.3390/polym17212840