Effect of Hydrocolloids on Penetration Tests, Sensory Evaluation, and Syneresis of Milk Pudding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Milk Pudding Preparation

2.3. Analysis of Textural Characteristics

2.4. Measurement % Syneresis

2.5. Sensory Evaluation

2.6. Statistical Analysis

3. Results

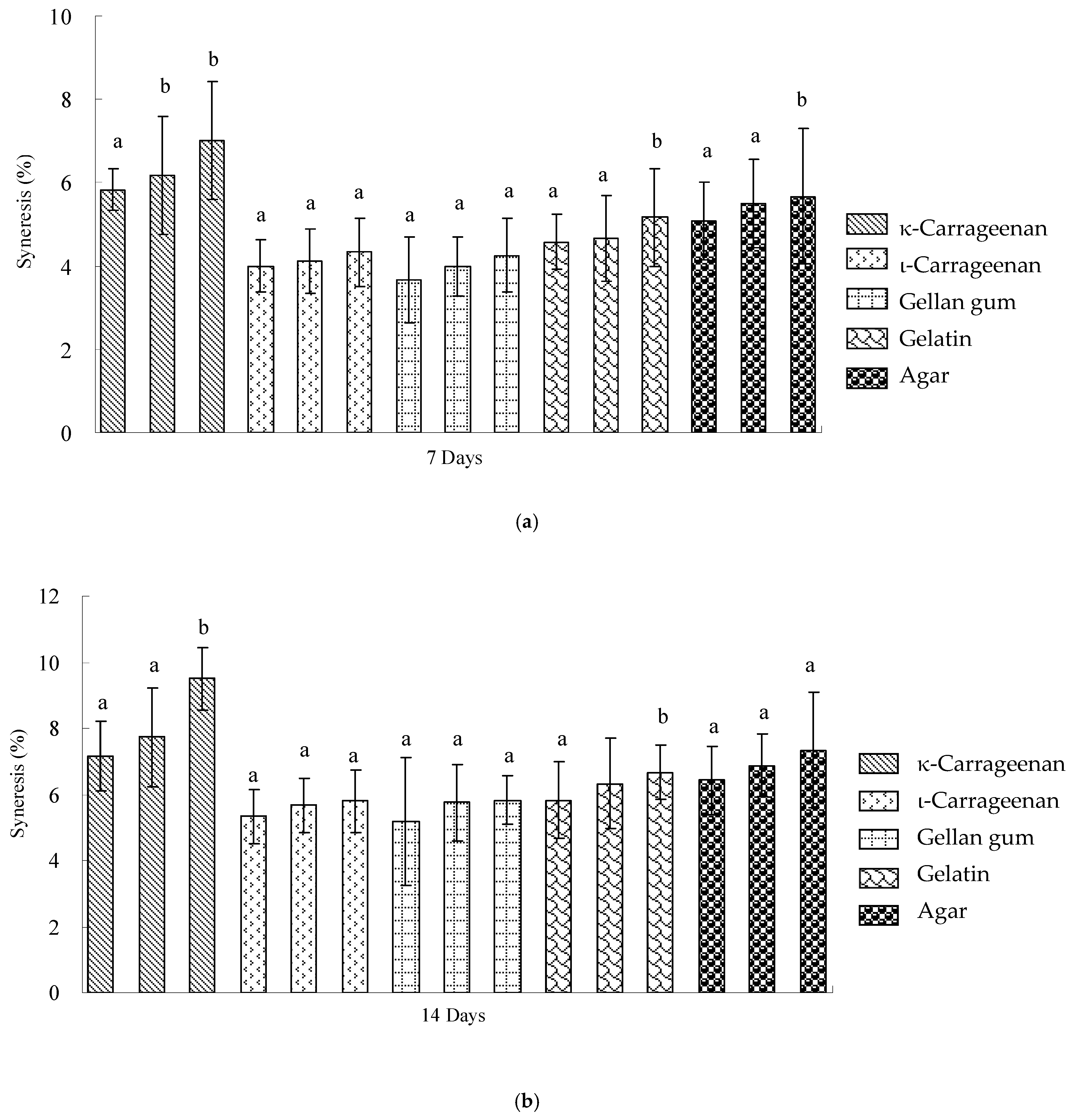

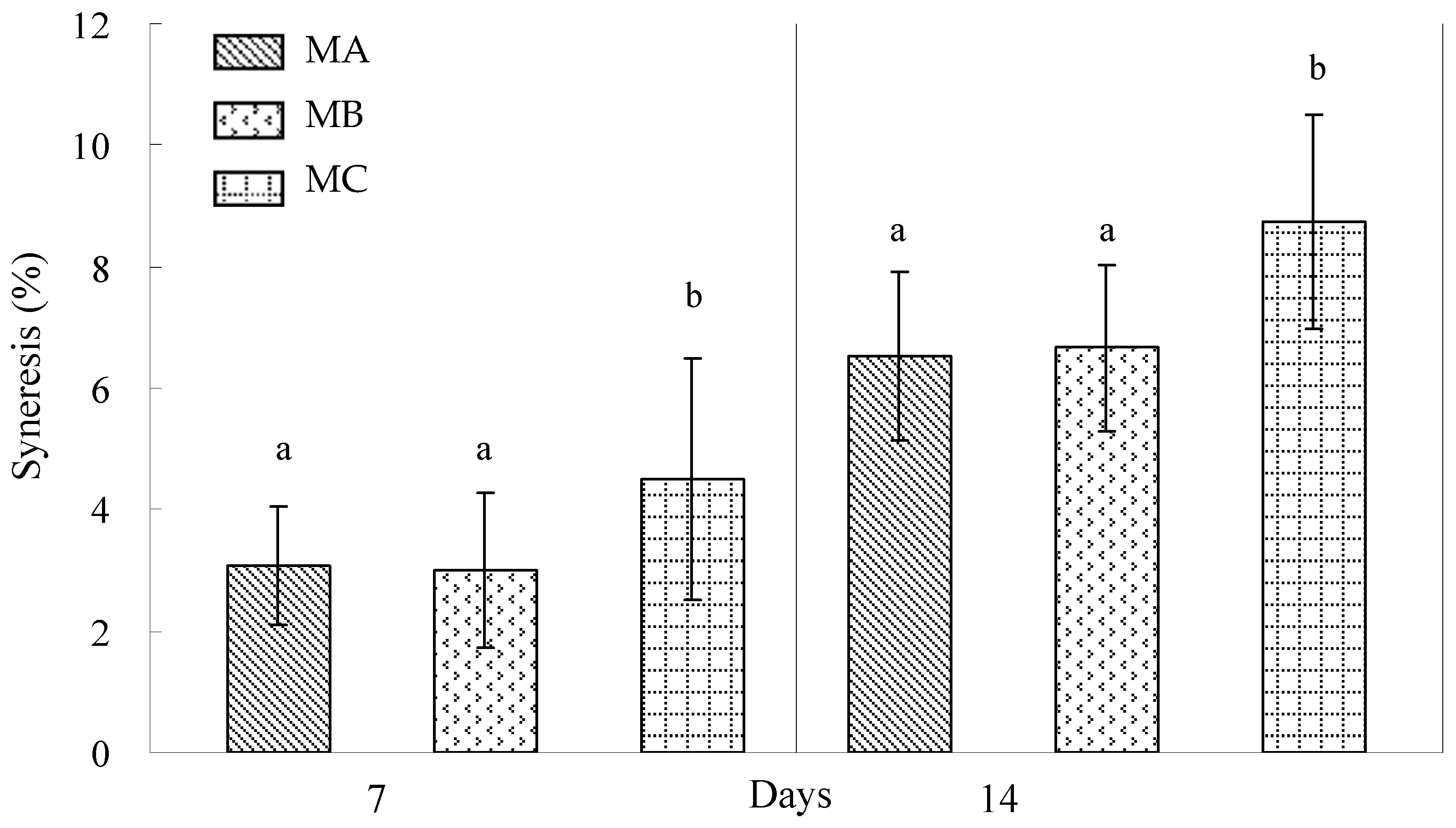

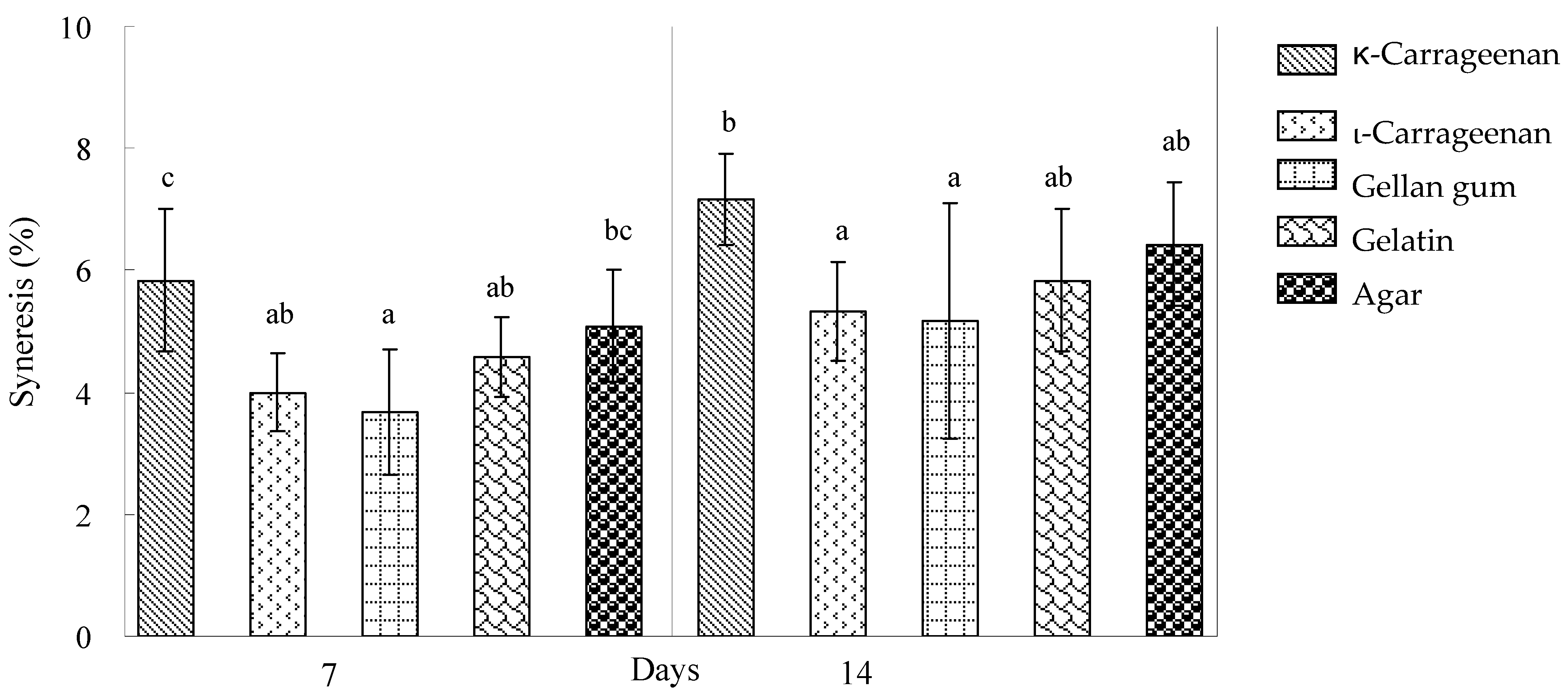

3.1. Analysis of Textural Characteristics and % Syneresis

| Type of Polysaccharide | Breaking Force (B.F.) | Breaking Point (B.P.) | Gel Strength (G.S.) | Rigidity (R.) |

|---|---|---|---|---|

| (g) | (mm) | (g × mm) | (g/mm) | |

| κ-carrageenan | 22.7 ± 0.3 d | 5.41 ± 0.14 c | 123 ± 4 d | 4.20 ± 0.10 d |

| ι-carrageenan | 11.7 ± 0.3 a | 6.34 ± 0.13 e | 74 ± 3 a | 1.84 ± 0.02 a |

| Gellan gum | 18.8 ± 0.5 c | 5.23 ± 0.10 a | 98 ± 3 c | 3.59 ± 0.12 c |

| Gelatin | 14.6 ± 0.5 b | 6.25 ± 0.14 d | 91 ± 3 b | 2.34 ± 0.08 b |

| Agar | 26.6 ± 0.4 e | 5.37 ± 0.03 b | 143 ± 2 e | 4.95 ± 0.06 e |

3.2. Sensory Evaluation of Milk Pudding

4. Discussion

4.1. Analysis of Textural Characteristics and % Syneresis

4.2. Sensory Evaluation of Milk Pudding

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Wijk, R.A.; Van Gemert, L.J.; Terpstra, M.E.J.; Wilkinson, C.L. Texture of semi-solids; sensory and instrumental measurements on vanilla custard desserts. Food Qual. Prefer. 2003, 14, 305–317. [Google Scholar] [CrossRef]

- Sheidae, Z.; Sarmadi, B.; Hosseini, S.M.; Javanmardi, F.; Kianoush, K.D.; Mortazavian, A.M. Influence of κ-carrageenan, modified starch and inulin addition on rheological and sensory properties of non-fat and non-added sugar dairy dessert. Curr. Nutr. Food Sci. 2020, 16, 462–469. [Google Scholar] [CrossRef]

- Imeson, A.P. Carrageenan. In Handbook of Hydrocolloids; Philips, G.O., Williams, P.A., Eds.; Wood-head Publishing Ltd.: Cambridge, UK, 2000; pp. 87–102. [Google Scholar]

- Lin, H.T.; Tsai, J.S.; Liao, H.H.; Sung, W.C. The effect of hydrocolloids on penetration tests and syneresis of binary gum gels and modified corn starch-gum gels. Gels 2023, 9, 605. [Google Scholar] [CrossRef]

- Langendorff, V.; Cuvelier, G.; Michon, C.; Launay, B.; Parker, A.; De Kruif, C.G. Effects of carrageenan type on the behaviour of carrageenan/milk mixtures. Food Hydrocoll. 2017, 14, 273–280. [Google Scholar] [CrossRef]

- Verbeken, D.; Bael, K.; Thas, O.; Dewettinck, K. Interactuions between κ-carrageenan, milk proteins and modified starch in sterilized dairy desserts. Int. Dairy J. 2006, 16, 482–488. [Google Scholar] [CrossRef]

- Agoda-Tandjawa, G.; Le Garnec, C.; Boulenguer, P.; Gilles, M.; Langendorff, V. Rheological behavior of starch/carrageenan/milk proteins mixed systems: Role of each biopolymer type and chemical characteristics. Food Hydrocoll. 2017, 73, 300–312. [Google Scholar] [CrossRef]

- Depypere, F.; Verbeken, D.; Thas, O.; Dewettinck, K. Mixture design approach on the dynamic rheological and uniaxial compression behaviour of milk desserts. Food Hydrocoll. 2003, 17, 311–320. [Google Scholar] [CrossRef]

- Verbeken, D.; Thas, O.; Dewettinck, K. Textural properties of gelled dairy desserts containing κ-carrageen and starch. Food Hydrocoll. 2004, 18, 817–823. [Google Scholar] [CrossRef]

- Mahmood, K.; Kamilah, H.; Shang, P.L.; Sulaiman, S.; Ariffin, F.; Alias, A.K. A review: Interaction of starch/non-starch hydrocolloid blending and the recent food applications. Food Biosci. 2017, 19, 110–120. [Google Scholar] [CrossRef]

- Sodini, I.; Remeuf, F.; Haddad, S.; Corrieu, G. The relative effect of milk base, starter, and process on yogurt texture: A review. Crit. Rev. Food Sci. Nutr. 2004, 44, 113–137. [Google Scholar] [CrossRef] [PubMed]

- Marta, H.; Cahyana, Y.; Djali, M. The effect of starch-hydrocolloid interaction on starch digestibility, pasting and physicochemical properties: A review. IOP Conf. Ser. Earth Environ. Sci. 2020, 443, 012084. [Google Scholar] [CrossRef]

- Christianson, D.D. Hydrocolloid interactions with starches. In Food Carbohydrates; Lineback, R.D., Inglett, G.E., Eds.; AVI Publishing Co.: Westport, CT, USA, 1982; pp. 399–419. [Google Scholar]

- Lethuant, L.; Brossard, C.; Rousseau, F.; Bousseau, B.; Genot, C. Sweetness-texture interactions in model dairy desserts: Effect of sucrose concentration and the carrageenan type. Int. Dairy J. 2003, 13, 631–641. [Google Scholar] [CrossRef]

- Nguyen, P.T.M.; Kravchuk, O.; Bhandari, B.; Prakash, S. Effect of different hydrocolloids on texture, rheology, tribology and sensory perception of texture and mouthfeel of low-fat pot-set yoghurt. Food Hydrycoll. 2017, 72, 90–104. [Google Scholar] [CrossRef]

- Supavititpatana, P.; Wirjantoro, T.I.; Apichartsrangkoon, A.; Raviyan, P. Addition of gelatin enhanced gelation of corn-milk yogurt. Food Chem. 2008, 106, 211–216. [Google Scholar] [CrossRef]

- Duboc, P.; Mollet, B. Application of exopolysaccharides in the dairy industry. Int. Dairy J. 2001, 11, 759–768. [Google Scholar] [CrossRef]

- Bagal-Kestwal, D.R.; Pan, M.H.; Chiang, B.H. Properties and applications of gelatin, Pectin, and carrageenan gels. In Bio Monomers for Green Polymeric Composite Materials; Visakh, P.M., Bayraktar, O., Menon, G., Eds.; John Wiley & Sons Ltd.: West Sussex, UK, 2019. [Google Scholar]

- Therkelsen, G.H. Carrageenan. In Industrial Gums; Whister, R.L., BeMiller, J.N., Eds.; Academic Press: San Diego, CA, USA, 1993; pp. 145–180. [Google Scholar]

- Richardson, R.K.; Goycoolea, F.M. Rheological measurement of κ-carrageenan during gelation. Carbohydr. Polym. 1994, 24, 233–235. [Google Scholar] [CrossRef]

- Chen, H.H.; Xu, S.Y.; Wang, Z. Gelation properties of flaxseed gum. J. Food Eng. 2006, 77, 295–303. [Google Scholar] [CrossRef]

- Karim, A.A.; Norziah, M.H.; Seow, C.C. Methods for the study of starch retrogradation. Food Chem. 2000, 7, 9–36. [Google Scholar] [CrossRef]

- Tang, Q.; Roos, Y.H.; Miao, S. Comparative studies of structural and thermal gelation behaviours of soy, lentil and whey protein: A pH-dependency evaluation. Food Hydrocoll. 2024, 146 Pt A, 109240. [Google Scholar] [CrossRef]

- Charoenrein, S.; Tatirat, O.; Muadklay, J. Use of centrifugation-filtration fordetermination of syneresis in freeze-thaw starch gels. Carbohydr. Polym. 2008, 73, 143–147. [Google Scholar] [CrossRef]

- Moskowitz, H.R. Sensory intensity versus hedonic functions: Classical psychophysical approaches. J. Food Qual. 1982, 5, 109–137. [Google Scholar] [CrossRef]

- Junaid, M.; Javed, I.; Abdullah, M.; Gulzar, M.; Younas, U.; Nasir, J.; Ahmad, N. Development and quality assessment of flavored probiotic acidophilus milk. J. Anim. Plant Sci. 2013, 23, 1342–1346. [Google Scholar]

- Morris, V.J. Starch gelation and retrogradation. Trends Food Sci. Technol. 1990, 1, 2–6. [Google Scholar] [CrossRef]

- Xu, X.; Ye, S.; Zuo, X.; Fang, S. Impact of guar gum and locust bean gum addition on the pasting, rheological properties, and freeze-thaw stability of rice starch gel. Foods 2022, 11, 2508. [Google Scholar] [CrossRef] [PubMed]

- Arunyanart, T.; Charoenrein, S. Effect of sucrose on the freeze-thaw stability of rice starch gels: Correlation with microstructure and freezeable water. Carbohydr. Polym. 2008, 74, 514–518. [Google Scholar] [CrossRef]

- Baker, L.A.; Rayas-Duarte, P. Freeze-thaw stability of amaranth starch and the effects of salt and sugars. Cereal Chem. 1998, 75, 301–307. [Google Scholar] [CrossRef]

- Zhang, C.; Lim, S.T.; Chung, H.J. Physical modification of potato starch using mild heating and freezing with minor addition of gums. Food Hydrocoll. 2019, 94, 294–303. [Google Scholar] [CrossRef]

- Mao, R.; Tang, J.; Swanson, B.G. Texture properties of high and low acyl mixed gellan gels. Carbohydr. Polym. 2000, 41, 331–338. [Google Scholar] [CrossRef]

- Lee, M.H.; Baek, M.H.; Cha, D.S.; Park, H.J.; Lim, S.T. Freeze-thaw stabilization of sweet potato starch gel by polysaccharide gums. Food Hydrocoll. 2002, 16, 345–352. [Google Scholar] [CrossRef]

- Dogsa, I.; Cerar, J.; Jamnik, A.; Tomsic, M. Supramolecular structure of methyl cellulose and lambda- and kappa- carrageenan in water: SAXS study using the string-of-beads model. Carbohydr. Polym. 2017, 172, 184–196. [Google Scholar] [CrossRef] [PubMed]

- de Vries, J.A. Interactions of starch and other hydrocolloids. Carbohydr. Neth. 2002, 8, 14–18. [Google Scholar]

- Lai, V.M.F.; Hung, A.L.; Lii, C.Y. Rheological properties and phase transition of red algal polysaccharide starch composites. Food Hydrocoll. 1999, 13, 409–418. [Google Scholar] [CrossRef]

- He, H.; Zhang, Y.; Hong, Y.; Gu, Z. Effects of hydrocolloids on corn starch retrogradation. Starch/Starke 2015, 67, 348–354. [Google Scholar] [CrossRef]

- Geonzon, L.C.; Kobayashi, M.; Tassieri, M.; Bacabac, R.G.; Adachi, Y.; Matsukawa, S. Microrheological properties and local structure of ι-carrageenan gels probed by using optical tweezers. Food Hydrocoll. 2023, 137, 108325. [Google Scholar] [CrossRef]

- Prokopowich, D.J.; Biliaderis, C.G. A comparative study of the effect of sugars on the thermal and mechanical properties of concentrated waxy maize, wheat, potato and pea starch gels. Food Chem. 1995, 52, 255–262. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, D.; Guo, Q.; Liu, C. Textural and structure properties of a κ-carrageenan-konjac gum mix gel: Effects of κ-carrageenan concentration, mixing ratio, sucrose and Ca2+ concentrations and its application in milk pudding. J. Sci. Food Agric. 2021, 101, 3021–3029. [Google Scholar] [CrossRef]

- Bayarri, S.; Costell, E.; Duran, L. Influence of low sucrose concentrations on the compression resistance of gellan gum gels. Food Hydrocoll. 2002, 16, 593–597. [Google Scholar] [CrossRef]

- Fiszman, S.M.; Duran, L. Mechanical properties of kappa carrageen-locust bean gum mixed gels with added sucrose. Food Hydrocoll. 1989, 3, 209–216. [Google Scholar] [CrossRef]

- Nishinari, K.; Fang, Y.; Rosenthal, A. Human oral processing and texture profile analysis parameters: Bridging the gap between the sensory evaluation and the instrumental measurements. J. Texture Stud. 2019, 50, 369–380. [Google Scholar] [CrossRef] [PubMed]

- Ekpong, A.; Ngarmsak, T.; Winger, R.J. Comparing sensory methods for the optimization of mango gel snacks. Food Qual. Prefer. 2006, 17, 622–628. [Google Scholar] [CrossRef]

| Commercial Milk Pudding | Breaking Force (B.F.) | Breaking Point (B.P.) | Gel Strength (G.S.) | Rigidity (R.) |

|---|---|---|---|---|

| (g) | (mm) | (g × mm) | (g/mm) | |

| MA | 15.0 ± 0.5 b | 8.75 ± 0.18 a | 131 ± 6 b | 1.72 ± 0.03 b |

| MB | 10.7 ± 0.4 a | 8.76 ± 0.25 a | 94 ± 5 a | 1.23 ± 0.04 a |

| MC | 17.4 ± 0.3 c | 9.82 ± 0.36 b | 171 ± 9 c | 1.77 ± 0.04 c |

| Type of Polysaccharide | Modified Corn Starch | Breaking Force (B.F.) | Breaking Point (B.P.) | Gel Strength (G.S.) | Rigidity (R.) |

|---|---|---|---|---|---|

| (%) | (g) | (mm) | (g × mm) | (g/mm) | |

| κ-carrageenan | 1.0 | 22.7 ± 0.3 c | 5.41 ± 0.14 c | 123 ± 4 c | 4.20 ± 0.10 b |

| 3.0 | 21.4 ± 0.8 b | 5.12 ± 0.13 b | 109 ± 3 b | 4.18 ± 0.24 b | |

| 5.0 | 17.9 ± 0.6 a | 4.85 ± 0.04 a | 86 ± 2 a | 3.69 ± 0.12 a | |

| ι-carrageenan | 1.0 | 11.7 ± 0.3 c | 6.34 ± 0.13 a | 74 ± 3 c | 1.84 ± 0.02 c |

| 3.0 | 10.5 ± 0.4 b | 6.27 ± 0.22 a | 65 ± 3 b | 1.68 ± 0.10 b | |

| 5.0 | 8.38 ± 0.4 a | 7.27 ± 0.25 b | 60 ± 2 a | 1.16 ± 0.07 a | |

| Gellan gum | 1.0 | 18.8 ± 0.5 c | 5.23 ± 0.10 a | 98 ± 3 c | 3.59 ± 0.12 c |

| 3.0 | 16.1 ± 0.4 b | 5.48 ± 0.17 b | 88 ± 3 b | 2.94 ± 0.11 b | |

| 5.0 | 13.6 ± 0.6 a | 5.43 ± 0.07 b | 73 ± 3 a | 2.51 ± 0.09 a | |

| Gelatin | 1.0 | 14.6 ± 0.5 c | 6.25 ± 0.14 b | 91 ± 4 c | 2.34 ± 0.08 a |

| 3.0 | 13.5 ± 0.5 b | 5.37 ± 0.34 a | 72 ± 4 b | 2.53 ± 0.21 a | |

| 5.0 | 12.5 ± 0.4 a | 5.25 ± 0.19 a | 65 ± 2 a | 2.38 ± 0.13 a | |

| Agar | 1.0 | 26.6 ± 0.4 c | 5.37 ± 0.02 a | 143 ± 2 c | 4.95 ± 0.06 c |

| 3.0 | 24.6 ± 0.5 b | 5.49 ± 0.12 ab | 135 ± 5 b | 4.48 ± 0.08 b | |

| 5.0 | 20.4 ± 0.5 a | 5.55 ± 0.16 b | 113 ± 3 a | 3.68 ± 0.15 a |

| Type of Polysaccharide | Sucrose | Breaking Force (B.F.) | Breaking Point (B.P.) | Gel Strength (G.S.) | Rigidity (R.) |

|---|---|---|---|---|---|

| (%) | (g) | (mm) | (g × mm) | (g/mm) | |

| κ-arrageenan | 2.5 | 20.4 ± 0.8 a | 5.03 ± 0.15 a | 103 ± 4 a | 4.05 ± 0.24 a |

| 5.0 | 21.4 ± 0.8 b | 5.12 ± 0.13 a | 109 ± 3 b | 4.18 ± 0.24 a | |

| 7.5 | 22.6 ± 0.4 c | 5.32 ± 0.15 b | 120 ± 5 c | 4.25 ± 0.08 a | |

| ι-carrageenan | 2.5 | 9.83 ± 0.7 a | 6.17 ± 0.16 a | 60.6 ± 4 a | 1.60 ± 0.14 a |

| 5.0 | 10.5 ± 0.4 a | 6.27 ± 0.22 a | 65.9 ± 3 b | 1.68 ± 0.10 a | |

| 7.5 | 11.1 ± 0.5 a | 6.30 ± 0.18 a | 70.2 ± 3 b | 1.77 ± 0.08 a | |

| Gellan gum | 2.5 | 15.5 ± 0.4 a | 5.38 ± 0.12 a | 83.4 ± 2 a | 2.88 ± 0.11 a |

| 5.0 | 16.1 ± 0.4 b | 5.48 ± 0.17 ab | 88.2 ± 3 b | 2.94 ± 0.11 a | |

| 7.5 | 16.8 ± 0.2 c | 5.62 ± 0.12 b | 94.4 ± 2 c | 2.29 ± 0.07 a | |

| Gelatin | 2.5 | 13.1 ± 0.8 a | 5.16 ± 0.13 a | 67.5 ± 3 a | 2.54 ± 0.14 a |

| 5.0 | 13.5 ± 0.5 ab | 5.37 ± 0.34 a | 72.6 ± 4 b | 2.53 ± 0.21 a | |

| 7.5 | 14.0 ± 0.6 b | 5.41 ± 0.16 a | 75.9 ± 4 b | 2.60 ± 0.12 a | |

| Agar | 2.5 | 22.8 ± 1.2 a | 5.27 ± 0.18 a | 120 ± 4 a | 4.34 ± 0.35 a |

| 5.0 | 24.6 ± 0.5 b | 5.49 ± 0.12 b | 135 ± 5 b | 4.48 ± 0.08 ab | |

| 7.5 | 27.3 ± 1.0 c | 5.75 ± 0.10 c | 157 ± 4 c | 4.76 ± 0.25 b |

| Milk Pudding | Color | Flavor | Sweetness | Springiness | Overall Acceptability |

|---|---|---|---|---|---|

| Commercial MA | 6.90 ± 0.99 a | 6.83 ± 1.15 a | 5.40 ± 1.07 a | 6.60 ± 1.19 a | 7.00 ± 1.01 a |

| Commercial MB | 5.77 ± 1.19 b | 5.97 ± 1.22 b | 5.17 ± 1.26 a | 5.53 ± 1.14 b | 5.73 ± 0.98 b |

| Commercial MC | 5.47 ± 1.31 b | 5.47 ± 1.41 b | 5.13 ± 1.22 a | 5.10 ± 1.06 b | 5.23 ± 1.19 b |

| κ-carrageenan | 5.10 ± 1.15 c | 5.67 ± 1.24 b | 5.25 ± 1.38 a | 4.20 ± 1.19 b | 4.53 ± 1.09 c |

| ι-carrageenan | 5.64 ± 0.89 b | 5.83 ± 1.14 b | 5.39 ± 1.11 a | 5.22 ± 1.05 b | 5.25 ± 1.14 b |

| Gellan gum | 5.75 ± 0.62 b | 5.51 ± 1.36 b | 5.41 ± 1.18 a | 5.55 ± 0.89 b | 5.72 ± 1.00 b |

| Gelatin | 5.27 ± 1.19 c | 5.47 ± 1.32 b | 5.16 ± 1.36 a | 5.31 ± 1.17 b | 5.13 ± 0.92 b |

| Agar | 5.12 ± 1.14 c | 5.58 ± 1.11 b | 4.87 ± 1.22 a | 4.07 ± 1.29 b | 4.22 ± 1.28 c |

| Type of Milk Pudding | Color | Flavor | Sweetness | Springiness | Overall Acceptability |

|---|---|---|---|---|---|

| Commercial milk pudding (MA) | 6.17 ± 1.18 b | 5.77 ± 1.25 b | 5.17 ± 1.49 ab | 6.07 ± 1.36 b | 7.03 ± 1.27 b |

| Milk pudding (B25) with 2.5% sucrose, 0.3% gellan, and 1% modified corn starch | 5.30 ± 1.64 a | 4.87 ± 1.59 a | 5.07 ± 1.44 ab | 5.17 ± 1.26 a | 5.07 ± 1.28 a |

| Milk pudding (B50) with 5.0% sucrose, 0.3% gellan, and 1% modified corn starch | 5.23 ± 1.65 a | 5.37 ± 1.56 ab | 5.70 ± 1.12 b | 5.73 ± 1.51 ab | 5.63 ± 1.22 a |

| Milk pudding (B75) with 7.5% sucrose, 0.3% gellan, and 1% modified corn starch | 5.47 ± 1.57 ab | 5.43 ± 1.43 ab | 4.80 ± 1.58 a | 5.40 ± 1.35 ab | 5.40 ± 1.45 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, H.-T.V.; Tsai, J.-S.; Liao, H.-H.; Sung, W.-C. Effect of Hydrocolloids on Penetration Tests, Sensory Evaluation, and Syneresis of Milk Pudding. Polymers 2025, 17, 300. https://doi.org/10.3390/polym17030300

Lin H-TV, Tsai J-S, Liao H-H, Sung W-C. Effect of Hydrocolloids on Penetration Tests, Sensory Evaluation, and Syneresis of Milk Pudding. Polymers. 2025; 17(3):300. https://doi.org/10.3390/polym17030300

Chicago/Turabian StyleLin, Hong-Ting Victor, Jenn-Shou Tsai, Hsiao-Hui Liao, and Wen-Chieh Sung. 2025. "Effect of Hydrocolloids on Penetration Tests, Sensory Evaluation, and Syneresis of Milk Pudding" Polymers 17, no. 3: 300. https://doi.org/10.3390/polym17030300

APA StyleLin, H.-T. V., Tsai, J.-S., Liao, H.-H., & Sung, W.-C. (2025). Effect of Hydrocolloids on Penetration Tests, Sensory Evaluation, and Syneresis of Milk Pudding. Polymers, 17(3), 300. https://doi.org/10.3390/polym17030300