Strategies for the Transformation of Waste Cooking Oils into High-Value Products: A Critical Review

Abstract

:1. Introduction

2. Methods

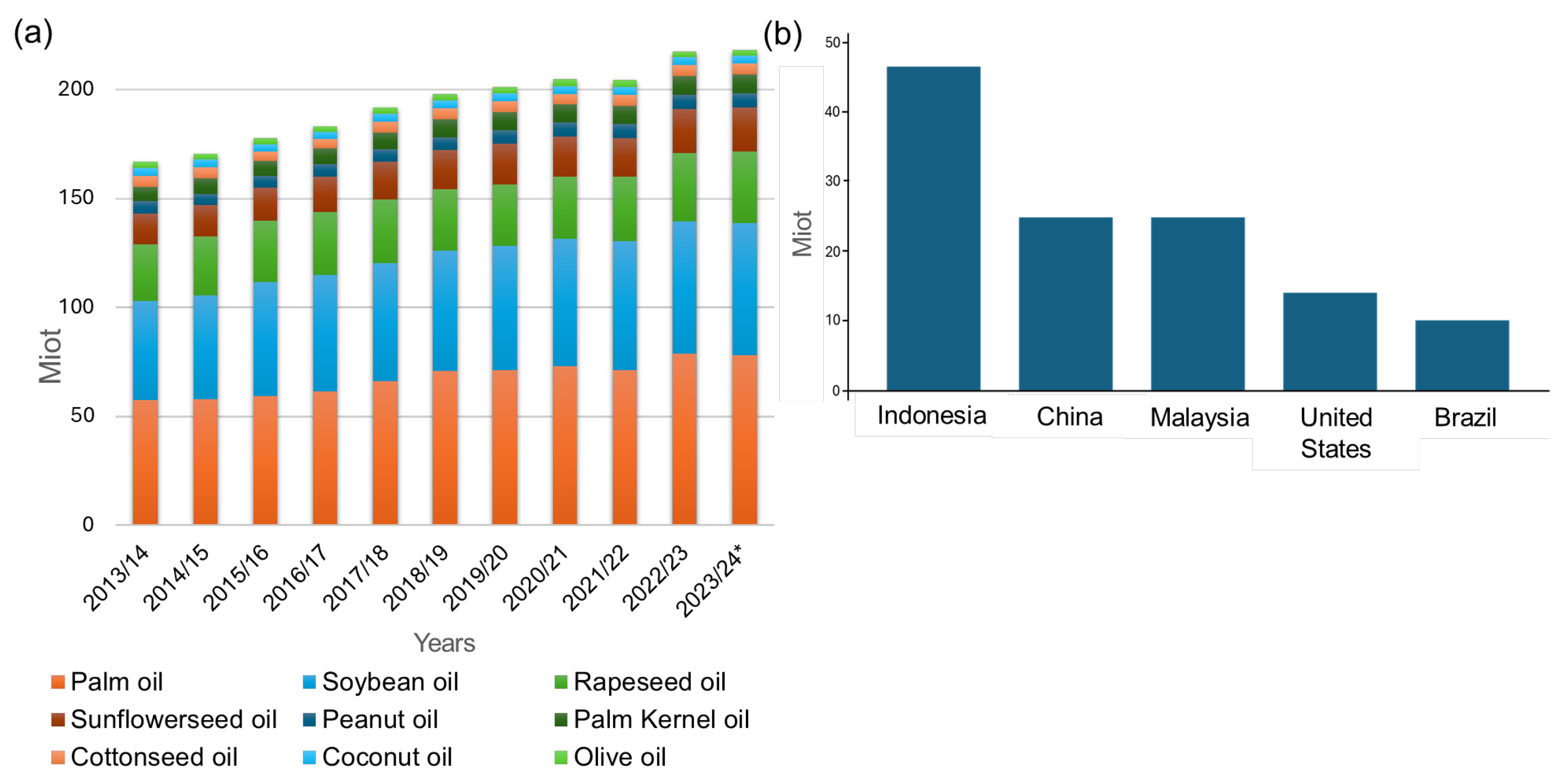

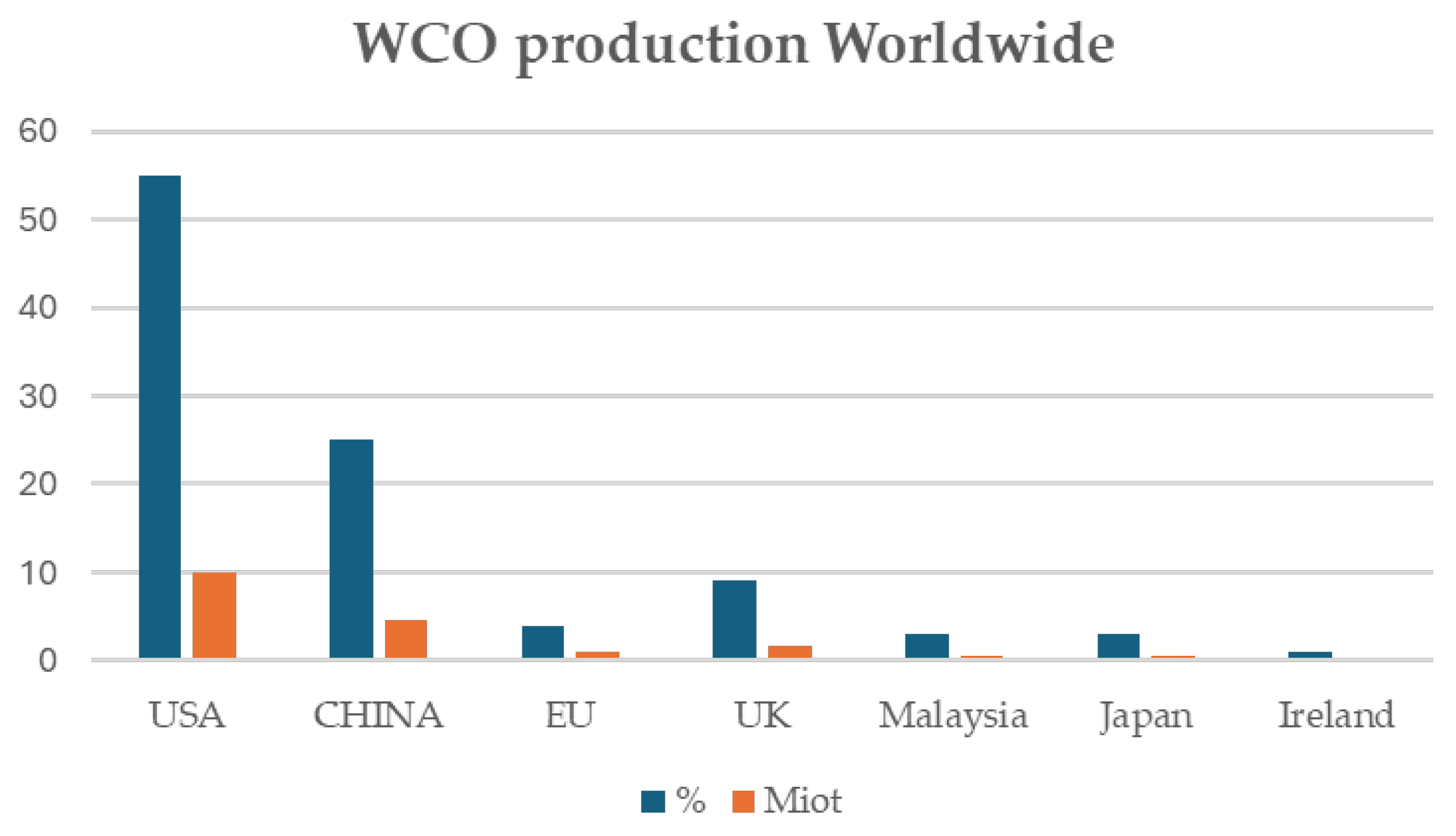

3. WCO Production and Market

4. Regulations and Restrictions Affecting WCOs

5. Environmental Impacts of WCOs

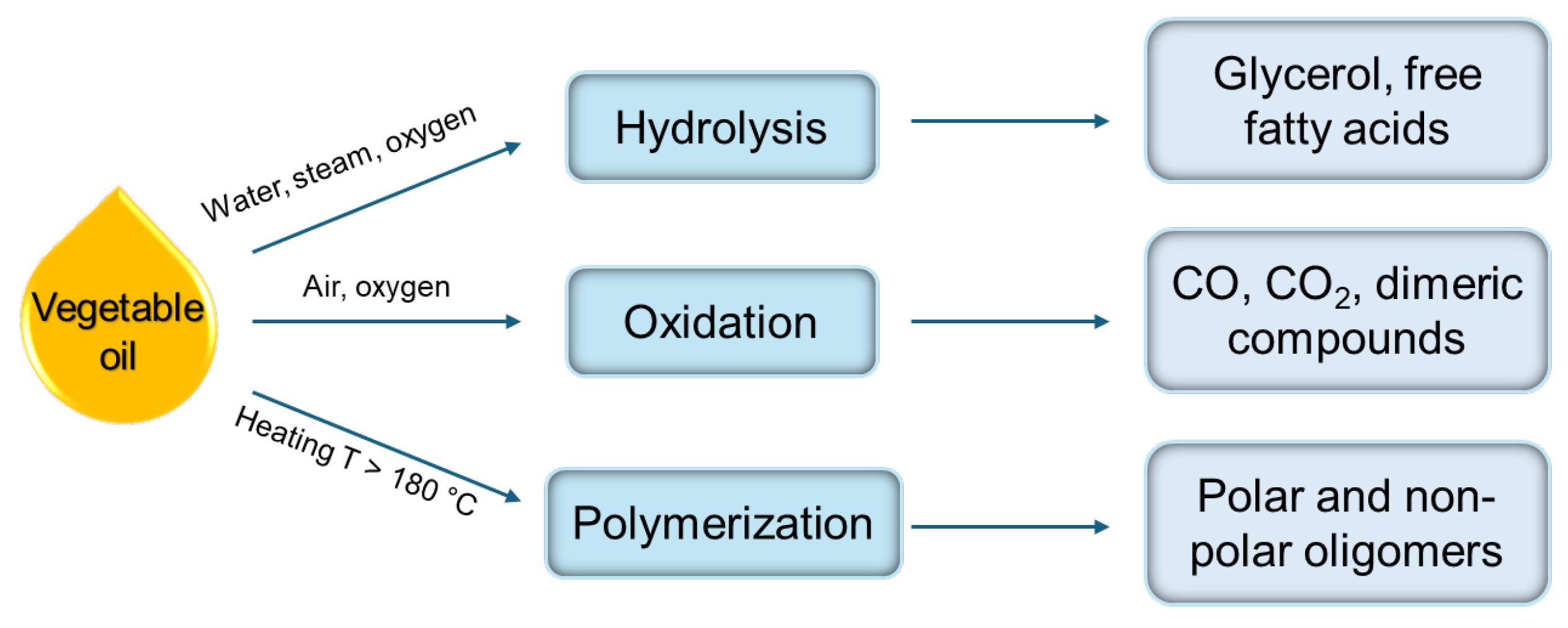

6. WCO Composition and Pretreatments

7. WCOs for Bio Lubricants and Bio Surfactants

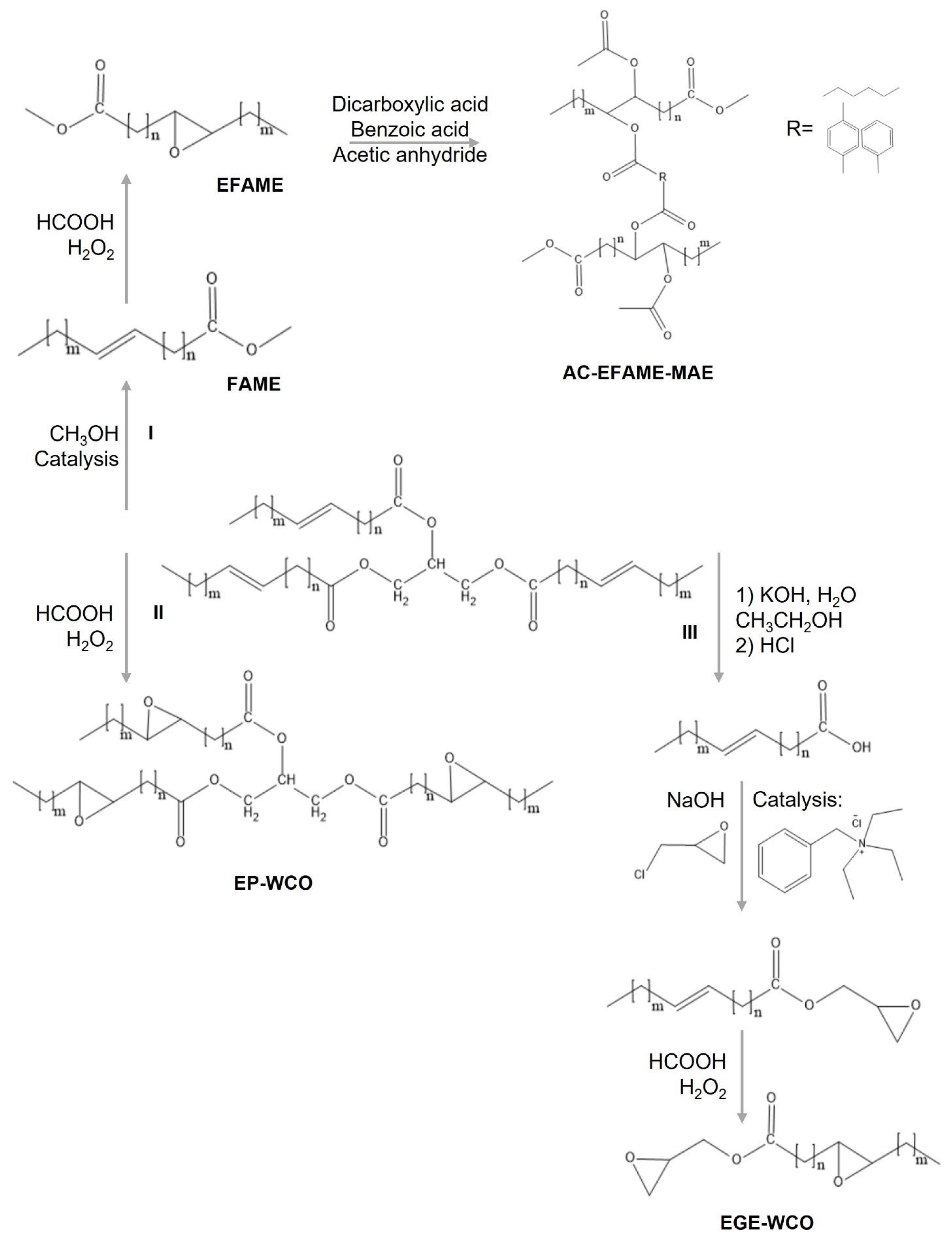

7.1. Bio Lubricants

7.2. Bio Surfactants

8. WCOs for Polymer Additives

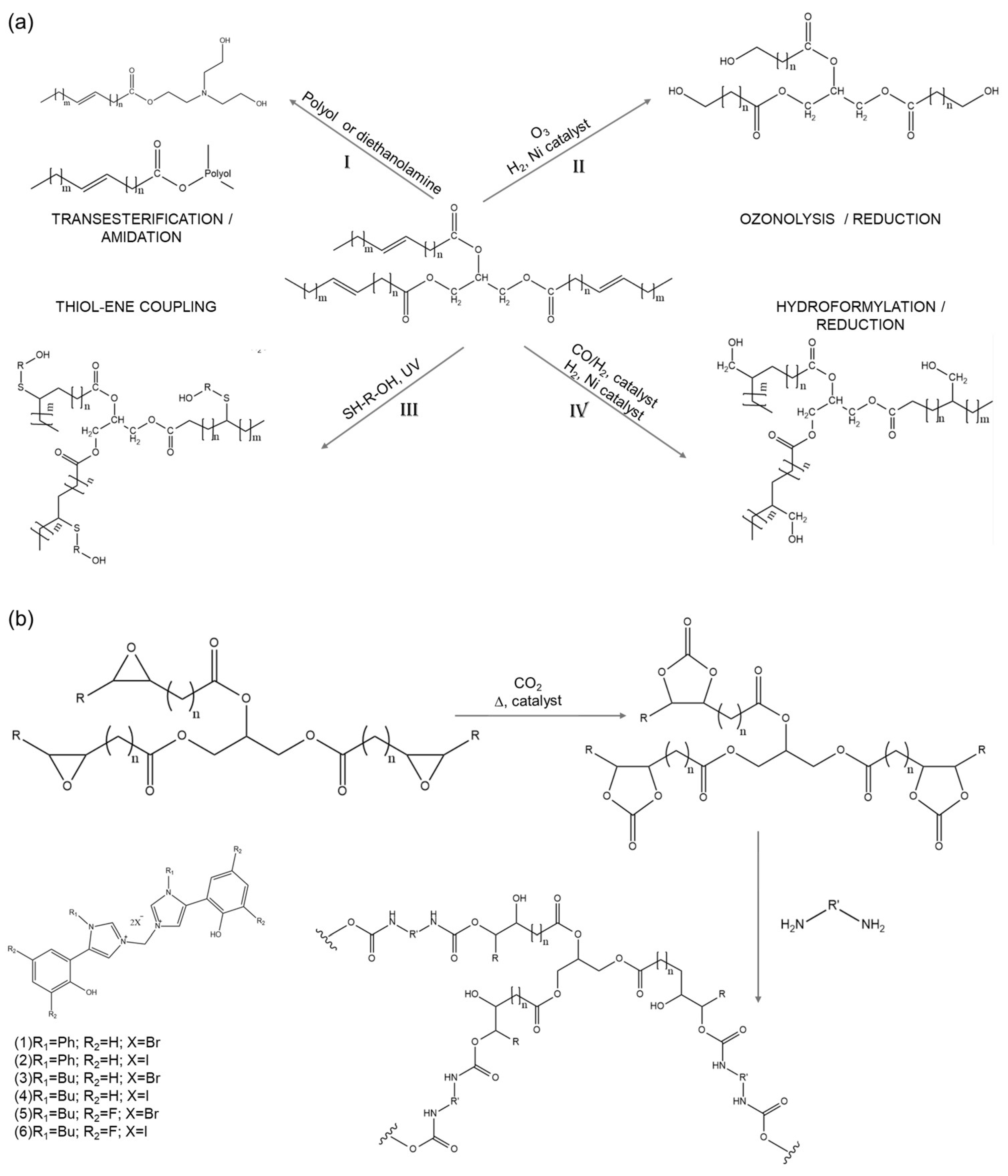

9. WCOs for Polymer Synthesis

9.1. Polyurethane

9.2. Acrylic Polymers

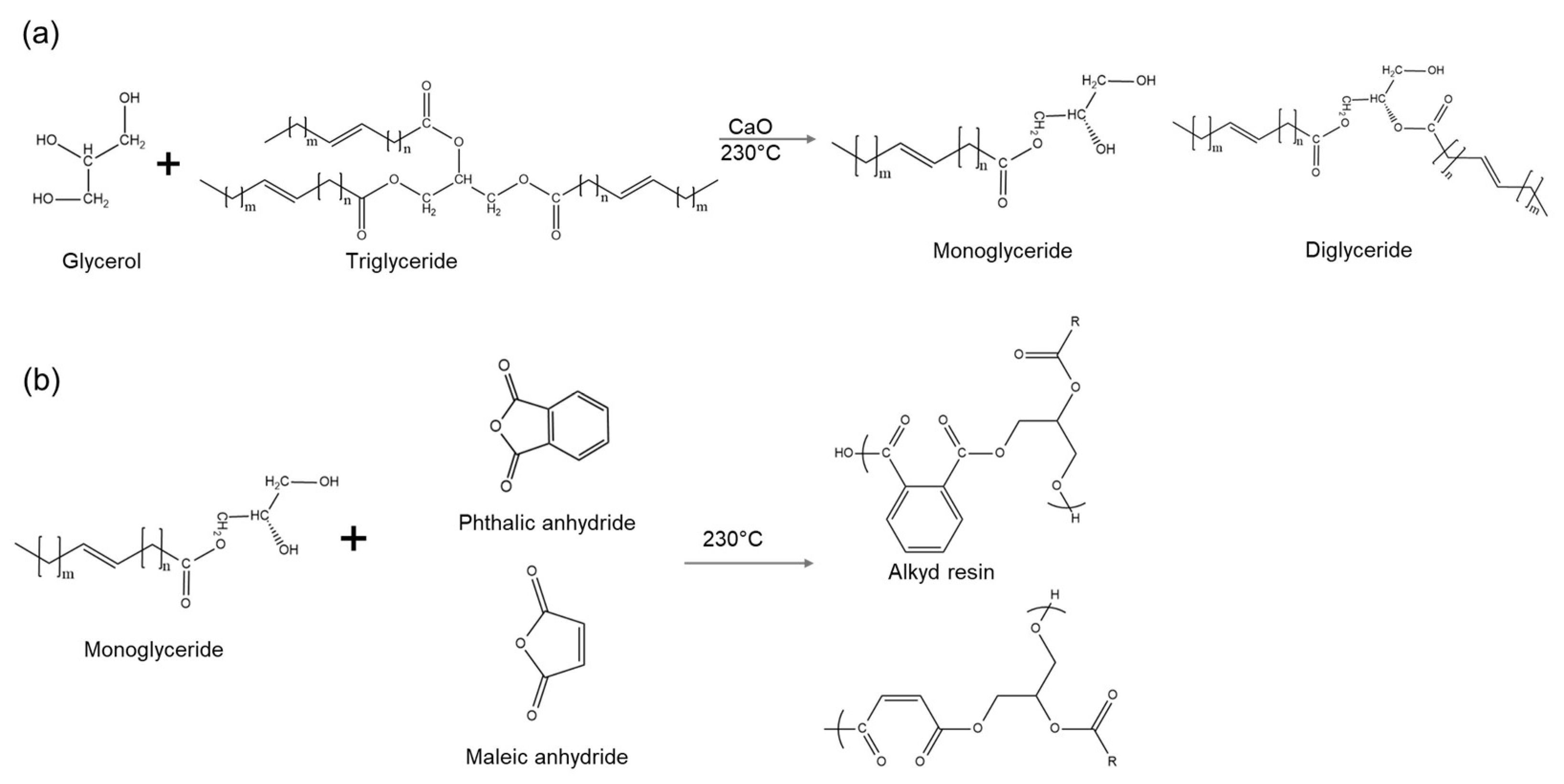

9.3. Alkyd Esters

9.4. Epoxy Resins

10. Waste Cooking Oils for Roads and Constructions

10.1. WCOs for Asphalt Production

10.2. WCOs for Concrete

11. WCOs as Bio Solvents

12. Other Applications

13. Conclusions

- Feedstock availability and cost variability: WCO supply is inconsistent due to regional and seasonal variations, high transportation costs, limited collection infrastructure, and competition from industries like biodiesel production, making it an expensive feedstock.

- High initial capital investment: scaling production requires costly infrastructure and advanced technologies.

- Processing costs and technological barriers: converting WCOs into polymers is more expensive than traditional methods, due to the need for impurity removal, quality control, and, often, complex processing technologies.

- Market competition and price sensitivity: competing with low-cost petrochemical polymers is difficult without incentives, especially in price-sensitive sectors.

- Regulatory and certification challenges: complying with varying regional regulations and obtaining the necessary certifications adds significant financial and administrative burdens.

- Consumer perception and demand uncertainty: limited awareness and misconceptions about waste-derived materials hinder market demand, requiring costly consumer education campaigns.

- Competition for alternative uses of WCOs: consolidated applications like biodiesel production, supported by mature markets and incentives, reduce the availability of WCOs for polymer production.

- Limited policy support and economic incentives make it difficult for WCO-based polymers to compete with conventional materials.

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferrusca, M.C.; Romero, R.; Martínez, S.L.; Ramírez-Serrano, A.; Natividad, R. Biodiesel Production from Waste Cooking Oil: A Perspective on Catalytic Processes. Processes 2023, 11, 1952. [Google Scholar] [CrossRef]

- Statista. Global Production of Vegetable Oils from 2000/01 to 2023/24. 2024. Available online: https://www.statista.com/statistics/263978/global-vegetable-oil-production-since-2000-200 (accessed on 10 January 2025).

- Azahar, W.N.A.W.; Bujang, M.; Jaya, R.P.; Hainin, M.R.; Mohamed, A.; Ngad, N.; Jayanti, D.S. The potential of waste cooking oil as bio-asphalt for alternative binder—An overview. J. Teknol. 2016, 78, 3722. [Google Scholar] [CrossRef]

- Iowa Farm Bureau. What’s Cooking with Vegetable Oils. 2022. Available online: https://www.iowafarmbureau.com/Article/Whats-Cooking-with-Vegetable-Oils (accessed on 12 January 2025).

- Markets and Markets. Biofuel Market. 2023. Available online: https://www.marketsandmarkets.com/Market-Reports/biofuels-market-297.html?gad_source=1&gclid=Cj0KCQjwwMqvBhCtARIsAIXsZpYveQ0-50boErhnWFXCgq_Z0oq8tQpxCUuu7vgZ44hackufMVylwJEaAmf-EALw_wcB (accessed on 12 January 2025).

- NationMaster. Vegetable Oils Production. 2023. Available online: https://www.nationmaster.com/nmx/ranking/vegetable-oils-production (accessed on 28 January 2025).

- Oils and Fats International. Global Vegetable Oil Production in 2021/22 Crop Year Set to Reach Record High. 2021. Available online: https://www.ofimagazine.com/news/global-vegetable-oil-production-in-2021-22-crop-year-set-to-reach-record-high (accessed on 12 January 2025).

- Statista. Forecast Volume of Vegetable Oil Consumed in the European Union (EU 27) from 2018 to 2032. 2024. Available online: https://www.statista.com/statistics/614522/vegetable-oil-consumption-volume-european-union-28/ (accessed on 12 January 2025).

- Statista. Consumption of Vegetable Oils Worldwide from 2013/14 to 2023/2024, by Oil Type. 2024. Available online: https://www.statista.com/statistics/263937/vegetable-oils-global-consumption/ (accessed on 12 January 2025).

- Isaksson, B. Demand for Edible Oils Increases as Biofuel Industry Grows. Biofuels Int. 2023. Available online: https://biofuels-news.com/news/demand-for-edible-oils-increases-as-biofuel-industry-grows/ (accessed on 7 October 2024).

- Waters, K.; Altiparmak, S.O.; Shutters, S.T.; Thies, C. The Green Mirage: The EU’s Complex Relationship with Palm Oil Biodiesel in the Context of Environmental Narratives and Global Trade Dynamics. Energies 2024, 17, 343. [Google Scholar] [CrossRef]

- Awogbemi, O.; Inambao, F.; Onuh, E.I. A review of the performance and emissions of compression ignition engine fuelled with waste cooking oil methyl ester. In Proceedings of the 2018 International Conference on the Domestic Use of Energy (DUE), Cape Town, South Africa, 3–5 April 2018; pp. 1–9. [Google Scholar] [CrossRef]

- Awogbemi, O.; Onuh, E.I.; Inambao, F.L. Comparative study of properties and fatty acid composition of some neat vegetable oils and waste cooking oils. Int. J. Low-Carbon. Technol. 2019, 14, 417–425. [Google Scholar] [CrossRef]

- Saba, T.; Estephane, J.; El Khoury, B.; El Khoury, M.; Khazma, M.; El Zakhem, H.; Aouad, S. Biodiesel production from refined sunflower vegetable oil over KOH/ZSM5 catalysts. Renew. Energy 2016, 90, 301–306. [Google Scholar] [CrossRef]

- Foo, W.H.; Chia, W.Y.; Tang, D.Y.Y.; Koay, S.S.N.; Lim, S.S.; Chew, K.W. The conundrum of waste cooking oil: Transforming hazard into energy. J. Hazard. Mater. 2021, 417, 126129. [Google Scholar] [CrossRef]

- Lombardi, L.; Mendecka, B.; Carnevale, E. Comparative life cycle assessment of alternative strategies for energy recovery from used cooking oil. J. Environ. Manag. 2018, 216, 235–245. [Google Scholar] [CrossRef]

- Aniołowska, M.; Zahran, H.; Kita, A. The effect of pan frying on thermooxidative stability of refined rapeseed oil and professional blend. J. Food Sci. Technol. 2016, 53, 712–720. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, M.R.; Nogueira, R.; Nunes, L.M. Quantitative assessment of the valorisation of used cooking oils in 23 countries. Waste Manag. 2018, 78, 611–620. [Google Scholar] [CrossRef] [PubMed]

- Olu-Arotiowa, O.A.; Odesanmi, A.A.; Adedotun, B.K.; Ajibade, O.A.; Olasesan, I.P.; Odofin, O.L.; Abass, A.O. Review on environmental impact and valourization of waste cooking oil. LAUTECH J. Eng. Technol. 2022, 16, 144–163. [Google Scholar]

- Fingas, M. Vegetable Oil Spills. In Handbook of Oil Spill Science and Technology; Wiley: Hoboken, NJ, USA, 2014; pp. 79–91. [Google Scholar] [CrossRef]

- Zahri, K.N.M.; Zulkharnain, A.; Sabri, S.; Gomez-Fuentes, C.; Ahmad, S.A. Research Trends of Biodegradation of Cooking Oil in Antarctica from 2001 to 2021: A Bibliometric Analysis Based on the Scopus Database. Int. J. Environ. Res. Public Health 2021, 18, 2050. [Google Scholar] [CrossRef]

- Foo, W.H.; Koay, S.S.N.; Chia, S.R.; Chia, W.Y.; Tang, D.Y.Y.; Nomanbhay, S.; Chew, K.W. Recent advances in the conversion of waste cooking oil into value-added products: A review. Fuel 2022, 324, 124539. [Google Scholar] [CrossRef]

- Cárdenas, J.; Orjuela, A.; Sánchez, D.L.; Narváez, P.C.; Katryniok, B.; Clark, J. Pre-treatment of used cooking oils for the production of green chemicals: A review. J. Clean. Prod. 2021, 289, 1215129. [Google Scholar] [CrossRef]

- Capuano, D.; Costa, M.; Di Fraia, S.; Massarotti, N.; Vanoli, L. Direct use of waste vegetable oil in internal combustion engines. Renew. Sustain. Energy Rev. 2017, 69, 759–770. [Google Scholar] [CrossRef]

- Carmona-Cabello, M.; Garcia, I.L.; Leiva-Candia, D.; Dorado, M.P. Valorization of food waste based on its composition through the concept of biorefinery. Curr. Opin. Green. Sustain. Chem. 2018, 14, 67–79. [Google Scholar] [CrossRef]

- Carmona-Cabello, M.; García, I.L.; Sáez-Bastante, J.; Pinzi, S.; Koutinas, A.A.; Dorado, M.P. Food waste from restaurant sector—Characterization for biorefinery approach. Bioresour. Technol. 2020, 301, 122779. [Google Scholar] [CrossRef]

- Carmona-Cabello, M.; Leiva-Candia, D.; Castro-Cantarero, J.L.; Pinzi, S.; Dorado, M.P. Valorization of food waste from restaurants by transesterification of the lipid fraction. Fuel 2018, 215, 492–498. [Google Scholar] [CrossRef]

- Chrysikou, L.P.; Dagonikou, V.; Dimitriadis, A.; Bezergianni, S. Waste cooking oils exploitation targeting EU 2020 diesel fuel production: Environmental and economic benefits. J. Clean. Prod. 2019, 219, 566–575. [Google Scholar] [CrossRef]

- D’Alessandro, B.; Bidini, G.; Zampilli, M.; Laranci, P.; Bartocci, P.; Fantozzi, F. Straight and waste vegetable oil in engines: Review and experimental measurement of emissions, fuel consumption and injector fouling on a turbocharged commercial engine. Fuel 2016, 182, 198–209. [Google Scholar] [CrossRef]

- Hasan, M.R.; Anzar, N.; Sharma, P.; Malode, S.J.; Shetti, N.P.; Narang, J.; Kakarla, R.R. Converting biowaste into sustainable bioenergy through various processes. Bioresour. Technol. Rep. 2023, 23, 101542. [Google Scholar] [CrossRef]

- Mannu, A.; Ferro, M.; Di Pietro, M.E.; Mele, A. Innovative applications of waste cooking oil as raw material. Sci. Prog. 2019, 102, 153–160. [Google Scholar] [CrossRef] [PubMed]

- Namoco, C.S.; Comaling, V.C.; Buna, C.C. Utilization of used cooking oil as an alternative cooking fuel resource. ARPN J. Eng. Appl. Sci. 2017, 12, 435–442. [Google Scholar]

- Ostadkalayeh, Z.H.; Babaeipour, V.; Pakdehi, S.G.; Sazandehchi, P. Optimization of Biodiesel Production Process from Household Waste Oil, Rapeseed, and Microalgae Oils as a Suitable Alternative for Jet Fuel. Bioenergy Res. 2023, 16, 1733–1745. [Google Scholar] [CrossRef]

- Sahar; Sadaf, S.; Iqbal, J.; Ullah, I.; Bhatti, H.N.; Nouren, S.; Habib-ur-Rehman; Nisar, J.; Iqbal, M. Biodiesel production from waste cooking oil: An efficient technique to convert waste into biodiesel. Sustain. Cities Soc. 2018, 41, 220–226. [Google Scholar] [CrossRef]

- Sudalai, S.; Prabakaran, S.; Varalakksmi, V.; Sai Kireeti, I.; Upasana, B.; Yuvasri, A.; Arumugam, A. A review on oilcake biomass waste into biofuels: Current conversion techniques, sustainable applications, and challenges: Waste to energy approach (WtE). Energy Convers. Manag. 2024, 314, 118724. [Google Scholar] [CrossRef]

- Beghetto, V.; Gatto, V.; Samiolo, R.; Scolaro, C.; Brahimi, S.; Facchin, M.; Visco, A. Plastics today: Key challenges and EU strategies towards carbon neutrality: A review. Environ. Pollut. 2023, 334, 122102. [Google Scholar] [CrossRef] [PubMed]

- Visco, A.; Scolaro, C.; Facchin, M.; Brahimi, S.; Belhamdi, H.; Gatto, V.; Beghetto, V. Agri-Food Wastes for Bioplastics: European Prospective on Possible Applications in Their Second Life for a Circular Economy. Polymers 2022, 14, 2752. [Google Scholar] [CrossRef]

- Facchin, M.; Gatto, V.; Samiolo, R.; Conca, S.; Santandrea, D.; Beghetto, V. May 1,3,5-Triazine derivatives be the future of leather tanning? A critical review. Environ. Pollut. 2024, 345, 123472. [Google Scholar] [CrossRef] [PubMed]

- Sole, R.; Gatto, V.; Conca, S.; Bardella, N.; Morandini, A.; Beghetto, V. Sustainable Triazine-Based Dehydro-Condensation Agents for Amide Synthesis. Molecules 2021, 26, 191. [Google Scholar] [CrossRef] [PubMed]

- Purohit, V.B.; Pięta, M.; Pietrasik, J.; Plummer, C.M. Towards sustainability and a circular Economy: ROMP for the goal of fully degradable and chemically recyclable polymers. Eur. Polym. J. 2024, 208, 112847. [Google Scholar] [CrossRef]

- Thushari, I.; Babel, S. Comparative study of the environmental impacts of used cooking oil valorization options in Thailand. J. Environ. Manag. 2020, 310, 114810. [Google Scholar] [CrossRef]

- Scott, A. Oil majors back out of biofuel in Europe. Cen. Acs. Org. 2024, 8, 15. [Google Scholar]

- Hamze, H.; Akia, M.; Yazdani, F. Optimization of biodiesel production from the waste cooking oil using response surface methodology. Process Saf. Environ. Prot. 2015, 94, 1–10. [Google Scholar] [CrossRef]

- Ibanez, J.; Martel Martín, S.; Baldino, S.; Prandi, C.; Mannu, A. European Union Legislation Overview about Used Vegetable Oils Recycling: The Spanish and Italian Case Studies. Processes 2020, 8, 798. [Google Scholar] [CrossRef]

- Mannu, A.; Garroni, S.; Ibanez Porras, J.; Mele, A. Available Technologies and Materials for Waste Cooking Oil Recycling. Processes 2020, 8, 366. [Google Scholar] [CrossRef]

- Mannu, A.; Ferro, M.; Dugoni, G.C.; Panzeri, W.; Petretto, G.L.; Urgeghe, P.; Mele, A. Improving the recycling technology of waste cooking oils: Chemical fingerprint as tool for non-biodiesel application. Waste Manag. 2019, 96, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Dou, Z.; Dierenfeld, E.S.; Wang, X.; Chen, X.; Shurson, G.C. A critical analysis of challenges and opportunities for upcycling food waste to animal feed to reduce climate and resource burdens. Resour. Conserv. Recycl. 2024, 203, 107418. [Google Scholar] [CrossRef]

- Panadare, D.C.; Rathod, V.K. Applications of Waste Cooking Oil Other Than Biodiesel: A Review. Iran. J. Chem. Eng. 2015, 12, 55–76. Available online: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://www.ijche.com/article_11253_54b41ee620eb7a8972ee3e37776dad5f.pdf&ved=2ahUKEwiMoK66rouIAxWPg_0HHbj0DNgQFnoECBsQAQ&usg=AOvVaw11QJ42AupQ5PiqrF-UlbHz (accessed on 10 January 2025).

- Salemdeeb, R.; zu Ermgassen, E.K.H.J.; Kim, M.H.; Balmford, A.; Al-Tabbaa, A. Environmental and health impacts of using food waste as animal feed: A comparative analysis of food waste management options. J. Clean. Prod. 2017, 140, 871–880. [Google Scholar] [CrossRef] [PubMed]

- Sarker, A.; Ahmmed, R.; Ahsan, S.M.; Rana, J.; Ghosh, M.K.; Nandi, R. A comprehensive review of food waste valorization for the sustainable management of global food waste. Sustain. Food Technol. 2024, 2, 48–69. [Google Scholar] [CrossRef]

- Bardella, N.; Facchin, M.; Fabris, E.; Baldan, M.; Beghetto, V. Waste Cooking Oil as Eco-Friendly Rejuvenator for Reclaimed Asphalt Pavement. Materials 2024, 17, 1477. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Xue, L.; Xie, W.; You, Z.; Yang, X. Laboratory investigation on chemical and rheological properties of bio-asphalt binders incorporating waste cooking oil. Constr. Build. Mater. 2018, 167, 348–358. [Google Scholar] [CrossRef]

- Staroń, A.; Chwastowski, J.; Kijania-Kontak, M.; Wiśniewski, M.; Staroń, P. Bio-enriched composite materials derived from waste cooking oil for selective reduction of odour intensity. Sci. Rep. 2024, 14, 16311. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, J.; Kang, H. Effect of waste cooking oil on the performance of EVA modified asphalt and its mechanism analysis. Sci. Rep. 2024, 14, 14072. [Google Scholar] [CrossRef]

- Onn, M.; Jalil, M.J.; Mohd Yusoff, N.I.S.; Edward, E.B.; Wahit, M.U. A comprehensive review on chemical route to convert waste cooking oils to renewable polymeric materials. Ind. Crops Prod. 2024, 211, 118194. [Google Scholar] [CrossRef]

- Singh, N.; Agarwal, P.; Porwal, J.; Porwal, S.K. Evaluation of multifunctional green copolymer additives–doped waste cooking oil–extracted natural antioxidant in biolubricant formulation. Biomass Convers. Biorefin. 2024, 14, 761–770. [Google Scholar] [CrossRef]

- Marriam, F.; Irshad, A.; Umer, I.; Asghar, M.A.; Atif, M. Vegetable oils as bio-based precursors for epoxies. Sustain. Chem. Pharm. 2023, 31, 100935. [Google Scholar] [CrossRef]

- Singh, N.; Agarwal, P.; Porwal, S.K. Natural Antioxidant Extracted Waste Cooking Oil as Sustainable Biolubricant Formulation in Tribological and Rheological Applications. Waste Biomass Valorization 2022, 13, 3127–3137. [Google Scholar] [CrossRef] [PubMed]

- Wierzchowska, K.; Derewiaka, D.; Zieniuk, B.; Nowak, D.; Fabiszewska, A. Whey and post-frying oil as substrates in the process of microbial lipids obtaining: A value-added product with nutritional benefits. Eur. Food Res. Technol. 2023, 249, 2675–2688. [Google Scholar] [CrossRef]

- Lhuissier, M.; Couvert, A.; Amrane, A.; Kane, A.; Audic, J.L. Characterization and selection of waste oils for the absorption and biodegradation of VOC of different hydrophobicities. Chem. Eng. Res. Des. 2018, 138, 482–489. [Google Scholar] [CrossRef]

- Worthington, M.J.H.; Kucera, R.L.; Albuquerque, I.S.; Gibson, C.T.; Sibley, A.; Slattery, A.D.; Campbell, J.A.; Alboaiji, S.F.K.; Muller, K.A.; Young, J.; et al. Laying Waste to Mercury: Inexpensive Sorbents Made from Sulfur and Recycled Cooking Oils. Chem. Eur. J. 2017, 23, 16219–16230. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Available online: https://commission.europa.eu/index_en (accessed on 15 December 2024).

- European Law Portal. Available online: https://eur-lex.europa.eu/homepage.html?locale=en (accessed on 18 December 2024).

- The European Alliance of News Agencies. Available online: https://www.newsalliance.org/ (accessed on 15 December 2024).

- European Environment Agency. Available online: https://www.eea.europa.eu/en (accessed on 15 December 2024).

- European Chemicals Agency. Available online: https://echa.europa.eu/it/home (accessed on 15 December 2024).

- Statista. Available online: https://www.statista.com/ (accessed on 15 December 2024).

- Eurostat Portal. Available online: https://ec.europa.eu/eurostat (accessed on 15 December 2024).

- Zhao, Y.; Zhu, K.; Li, J.; Zhao, Y.; Li, S.; Zhang, C.; Xiao, D.; Yu, A. High-efficiency production of bisabolene from waste cooking oil by metabolically engineered Yarrowia lipolytica. Microb. Biotechnol. 2021, 14, 2497–2513. [Google Scholar] [CrossRef] [PubMed]

- Khedaywi, T.; Melhem, M. Effect of Waste Vegetable Oil on Properties of Asphalt Cement and Asphalt Concrete Mixtures: An Overview. Int. J. Pavement Res. Technol. 2024, 17, 280–290. [Google Scholar] [CrossRef]

- Math, M.C.; Kumar, S.P.; Chetty, S.V. Technologies for biodiesel production from used cooking oil—A review. Sustain. Energy Dev. 2010, 14, 339–345. [Google Scholar] [CrossRef]

- Manikandan, G.; Kanna, P.R.; Taler, D.; Sobota, T. Review of Waste Cooking Oil (WCO) as a Feedstock for Biofuel—Indian Perspective. Energies 2023, 16, 1739. [Google Scholar] [CrossRef]

- Matušinec, J.; Hrabec, D.; Šomplák, R.; Nevrlý, V.; Pecha, J.; Smejkalová, V.; Redutskiy, Y. Cooking oil and fat waste management: A review of the current state. Chem. Eng. Trans. 2020, 81, 763–768. [Google Scholar] [CrossRef]

- Monika; Banga, S.; Pathak, V.V. Biodiesel production from waste cooking oil: A comprehensive review on the application of heterogenous catalysts. Energy Nexus 2023, 10, 100209. [Google Scholar] [CrossRef]

- Nanda, S.; Rana, R.; Hunter, H.N.; Fang, Z.; Dalai, A.K.; Kozinski, J.A. Hydrothermal catalytic processing of waste cooking oil for hydrogen-rich syngas production. Chem. Eng. Sci. 2019, 195, 935–945. [Google Scholar] [CrossRef]

- Nascimento, L.; Ribeiro, A.; Ferreira, A.; Valério, N.; Pinheiro, V.; Araújo, J.; Vilarinho, C.; Carvalho, J. Turning waste cooking oils into biofuels—Valorization technologies: A review. Energies 2022, 15, 116. [Google Scholar] [CrossRef]

- Ortner, M.E.; Müller, W.; Schneider, I.; Bockreis, A. Environmental assessment of three different utilization paths of waste cooking oil from households. Resour. Conserv. Recycl. 2016, 106, 59–67. [Google Scholar] [CrossRef]

- Rocha-Meneses, L.; Hari, A.; Inayat, A.; Yousef, L.A.; Alarab, S.; Abdallah, M.; Shanableh, A.; Ghenai, C.; Shanmugam, S.; Kikas, T. Recent advances on biodiesel production from waste cooking oil (WCO): A review of reactors, catalysts, and optimization techniques impacting the production. Fuel 2023, 348, 128514. [Google Scholar] [CrossRef]

- Tamošiūnas, A.; Gimžauskaitė, D.; Aikas, M.; Uscila, R.; Praspaliauskas, M.; Eimontas, J. Gasification of Waste Cooking Oil to Syngas by Thermal Arc Plasma. Energies 2019, 12, 2612. [Google Scholar] [CrossRef]

- Xu, L.; Li, Y.; Liao, M.; Song, Q.; Wang, C.; Weng, J.; Zhao, M.; Gao, N. Catalytic pyrolysis of waste cooking oil for hydrogen-rich syngas production over bimetallic Fe-Ru/ZSM-5 catalyst. Fuel Process. Technol. 2023, 247, 107812. [Google Scholar] [CrossRef]

- Sabino, J.; Liborio, D.O.; Arias, S.; Gonzalez, J.F.; Barbosa, C.M.B.M.; Carvalho, F.R.; Frety, R.; Barros, I.C.L.; Pacheco, J.G.A. Hydrogen-Free Deoxygenation of Oleic Acid and Industrial Vegetable Oil Waste on CuNiAl Catalysts for Biofuel Production. Energies 2023, 16, 6131. [Google Scholar] [CrossRef]

- Suzihaque, M.U.H.; Alwi, H.; Kalthum Ibrahim, U.; Abdullah, S.; Haron, N. Biodiesel production from waste cooking oil: A brief review. Mater. Today Proc. 2022, 63, S490–S495. [Google Scholar] [CrossRef]

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biomass Bioenergy 2014, 61, 276–297. [Google Scholar] [CrossRef]

- Tsoutsos, T.; Tournaki, S.; Gkouskos, Z.; Paraíba, O.; Giglio, F.; García, P.Q.; Braga, J.; Adrianos, H.; Filice, M. Quality Characteristics of Biodiesel Produced from Used Cooking Oil in Southern Europe. Chem. Eng. 2019, 3, 19. [Google Scholar] [CrossRef]

- Caldeira, C.; Freire, F.; Olivetti, E.A.; Kirchain, R.; Dias, L.C. Analysis of cost-environmental trade-offs in biodiesel production incorporating waste feedstocks: A multi-objective programming approach. J. Clean. Prod. 2019, 216, 64–73. [Google Scholar] [CrossRef]

- Cordero-Ravelo, V.; Schallenberg-Rodriguez, J. Biodiesel production as a solution to waste cooking oil (WCO) disposal. Will any type of WCO do for a transesterification process? A quality assessment. J. Environ. Manag. 2018, 228, 117–129. [Google Scholar] [CrossRef] [PubMed]

- Cadillo-Benalcazar, J.J.; Bukkens, S.G.F.; Ripa, M.; Giampietro, M. Why does the European Union produce biofuels? Examining consistency and plausibility in prevailing narratives with quantitative storytelling. Energy Res. Soc. Sci. 2021, 71, 101810. [Google Scholar] [CrossRef]

- Outili, N.; Kerras, H.; Meniai, A.H. Recent conventional and non-conventional WCO pretreatment methods: Implementation of green chemistry principles and metrics. Curr. Opin. Green. Sustain. Chem. 2023, 41, 100794. [Google Scholar] [CrossRef]

- Ripa, M.; Cadillo-Benalcazar, J.J.; Giampietro, M. Cutting through the biofuel confusion: A conceptual framework to check the feasibility, viability and desirability of biofuels. Energy Strategy Rev. 2021, 35, 100642. [Google Scholar] [CrossRef]

- Caldeira, C.; Queirós, J.; Freire, F. Biodiesel from Waste Cooking Oils in Portugal: Alternative Collection Systems. Waste Biomass Valorization 2015, 6, 771–779. [Google Scholar] [CrossRef]

- Directive (EU) 2023/2413, 2023. Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources, and Repealing Council Directive (EU) 2015/652, European Parliament and of the Council. Available online: http://data.europa.eu/eli/dir/2023/2413/oj (accessed on 3 August 2024).

- Directive 75/439/EEC, 1975. Disposal of Waste Oils, The Council of the European Communities. Available online: http://data.europa.eu/eli/dir/1975/439/oj (accessed on 20 September 2024).

- Directive 2014/955/EU, 2014. Commission Decision of 18 December 2014 amending Decision 2000/532/EC on the List of Waste Pursuant to Directive 2008/98/EC of the European Parliament and of the Council Text with EEA relevance, European Parliament and of the Council. Available online: http://data.europa.eu/eli/dec/2014/955/oj (accessed on 3 February 2024).

- Directive 75/442/EEC, 1975. Council Directive 75/442/EEC of 15 July 1975 on waste, The council of the European Communities. Available online: http://data.europa.eu/eli/dir/1975/442/oj (accessed on 15 October 2024).

- Directive 2008/98/EC, 2008. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance), European Parliament and of the Council. Available online: http://data.europa.eu/eli/dir/2008/98/oj (accessed on 25 December 2024).

- Directive (EU) 2018/851, 2018. Directive (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste (Text with EEA Relevance), European Parliament and of the Council. Available online: http://data.europa.eu/eli/dir/2018/851/oj (accessed on 3 December 2024).

- Borrello, M.; Caracciolo, F.; Lombardi, A.; Pascucci, S.; Cembalo, L. Consumers’ Perspective on Circular Economy Strategy for Reducing Food Waste. Sustainability 2017, 9, 141. [Google Scholar] [CrossRef]

- United States Environmental Agency. Available online: https://www.epa.gov/oil-spills-prevention-and-preparedness-regulations/facility-response-plan-frp-overview (accessed on 24 January 2025).

- US Congress Government. Available online: https://www.congress.gov/congressional-report/104th-congress/house-report/262/1 (accessed on 24 January 2025).

- Federal Regulations. Available online: https://www.ecfr.gov/current/title-40/chapter-I/subchapter-D/part-112?toc=1 (accessed on 24 January 2025).

- Beghetto, V.; Bardella, N.; Samiolo, R.; Gatto, V.; Conca, S.; Sole, R.; Molin, G.; Gattolin, A.; Ongaro, N. By-products from mechanical recycling of polyolefins improve hot mix asphalt performance. J. Clean. Prod. 2021, 318, 128627. [Google Scholar] [CrossRef]

- CONOE Annual Report 2018. Available online: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=http://www.conoe.it/wp-content/uploads/2018/11/ANNUAL-REPORT-2018.pdf&ved=2ahUKEwiB-v_3touIAxVJ8LsIHS8kAKAQFnoECBUQAQ&usg=AOvVaw0pNXsTRFSIaiWl9aUnWgPQ (accessed on 23 November 2024).

- De Feo, G.; Di Domenico, A.; Ferrara, C.; Abate, S.; Sesti Osseo, L. Evolution of Waste Cooking Oil Collection in an Area with Long-Standing Waste Management Problems. Sustainability 2020, 12, 8578. [Google Scholar] [CrossRef]

- De Feo, G.; Ferrara, C.; Giordano, L.; Ossèo, L.S. Assessment of Three Recycling Pathways for Waste Cooking Oil as Feedstock in the Production of Biodiesel, Biolubricant, and Biosurfactant: A Multi-Criteria Decision Analysis Approach. Recycling 2023, 8, 64. [Google Scholar] [CrossRef]

- Foo, W.H.; Koay, S.S.N.; Tang, D.Y.Y.; Chia, W.Y.; Chew, K.W.; Show, P.L. Safety control of waste cooking oil: Transforming hazard into multifarious products with available pre-treatment processes. Food Mater. Res. 2022, 2, 1–11. [Google Scholar] [CrossRef]

- Bazina, N.; He, J. Analysis of fatty acid profiles of free fatty acids generated in deep-frying process. J. Food Sci. Technol. 2018, 55, 3085–3092. [Google Scholar] [CrossRef] [PubMed]

- Park, J.-M.; Kim, J.-M. Monitoring of Used Frying Oils and Frying Times for Frying Chicken Nuggets Using Peroxide Value and Acid Value. Korean J. Food Sci. Anim. Resour. 2016, 36, 612–616. [Google Scholar] [CrossRef]

- Kulkarni, M.G.; Dalai, A.K. Waste Cooking OilAn Economical Source for Biodiesel: A Review. Ind. Eng. Chem. Res. 2006, 45, 2901–2913. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V.; Aigbodion, V.S.; Panda, S. Advances in biotechnological applications of waste cooking oil. CSCEE 2021, 4, 100158. [Google Scholar] [CrossRef]

- Fabiszewska, U.A.; Białecka-Florjańczyk, E. Factors influencing synthesis of extracellular lipases by yarrowia lipolytica in medium containing vegetable oils. J. Microbiol. Biotechnol. Food Sci. 2014, 4, 231–237. [Google Scholar] [CrossRef]

- Liepins, J.; Balina, K.; Soloha, R.; Berzina, I.; Lukasa, L.K.; Dace, E. Glycolipid biosurfactant production from waste cooking oils by yeast: Review of substrates, producers and products. Fermentation 2021, 7, 136. [Google Scholar] [CrossRef]

- Wadekar, S.; Kale, S.; Lali, A.; Bhowmick, D.; Pratap, A. Sophorolipid Production by Starmerella bombicola (ATCC 22214) from Virgin and Waste Frying Oils, and the Effects of Activated Earth Treatment of the Waste Oils. J. Am. Oil Chem. Soc. 2012, 89, 1029–1039. [Google Scholar] [CrossRef]

- Carmona-Cabello, M.; Sáez-Bastante, J.; Pinzi, S.; Dorado, M.P. Optimization of solid food waste oil biodiesel by ultrasound-assisted transesterification. Fuel 2019, 255, 115817. [Google Scholar] [CrossRef]

- EN 14214. International Standard that Describes the Minimum Requirements for Biodiesel Production from Vegetable Oils. Available online: https://www.chemeurope.com/en/encyclopedia/EN_14214.html (accessed on 23 August 2024).

- Hussein, R.Z.K.; Attia, N.K.; Fouad, M.K.; ElSheltawy, S.T. Experimental investigation and process simulation of biolubricant production from waste cooking oil. Biomass Bioenergy 2021, 144, 105850. [Google Scholar] [CrossRef]

- Liang, M.-Y.; Ma, C.; Qin, W.-Q.; Mtui, H.I.; Wang, W.; Liu, J.; Yang, S.-Z.; Mu, B.-Z. A synergetic binary system of waste cooking oil-derived bio-based surfactants and its interfacial performance for enhanced oil recovery. Colloids and Surfaces C: Environ. Asp. 2024, 2, 100039. [Google Scholar] [CrossRef]

- Jia, P.; Zhang, M.; Hu, L.; Song, F.; Feng, G.; Zhou, Y. A Strategy for Nonmigrating Plasticized PVC Modified with Mannich base of Waste Cooking Oil Methyl Ester. Sci. Rep. 2018, 8, 1589. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, A.H.; Botelho, B.G.; Oliveira, L.S.; Franca, A.S. Sustainable synthesis of epoxidized waste cooking oil and its application as a plasticizer for polyvinyl chloride films. Eur. Polym. J. 2018, 99, 142–149. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, Z.; Xie, Q.; Fang, J.; Hu, Y.; Lu, M.; Xia, F.; Nie, Y.; Ji, J. Structural modification of waste cooking oil methyl esters as cleaner plasticizer to substitute toxic dioctyl phthalate. J. Clean. Prod. 2018, 186, 1021–1030. [Google Scholar] [CrossRef]

- Moretti, C.; Junginger, M.; Shen, L. Environmental life cycle assessment of polypropylene made from used cooking oil. Resour. Conserv. Recycl. 2020, 157, 104750. [Google Scholar] [CrossRef]

- Tremblay-Parrado, K.K.; Astrain, C.G.; Avérous, L. Click chemistry for the synthesis of biobased polymers and networks derived from vegetable oils. Green Chem. 2021, 23, 4296–4327. [Google Scholar] [CrossRef]

- Huang, J.; Huo, Y.; Su, Q.; Lu, D.; Wu, Y.; Dong, X.; Gao, Y. Sustainable high-strength alkali-activated slag concrete is achieved by recycling emulsified waste cooking oil. Front. Mater. 2024, 11, 1–13. [Google Scholar] [CrossRef]

- Ingrassia, L.P.; Lu, X.; Ferrotti, G.; Canestrari, F. Renewable materials in bituminous binders and mixtures: Speculative pretext or reliable opportunity? Resour. Conserv. Recycl. 2019, 144, 209–222. [Google Scholar] [CrossRef]

- Ozdemir, K.D.; Dokandari, A.P.; Raufi, H.; Topal, A.; Sengoz, B. Feasibility and mixture performance assessment of waste oil based rejuvenators in high-RAP asphalt mixtures. Mater. Res. Express 2023, 10, 045306. [Google Scholar] [CrossRef]

- Sun, D.; Lu, T.; Xiao, F.; Zhu, X.; Sun, G. Formulation and aging resistance of modified bio-asphalt containing high percentage of waste cooking oil residues. J. Clean. Prod. 2017, 161, 1203–1214. [Google Scholar] [CrossRef]

- Straits Research. Bio-Lubricants Market Size, Share & Trends Analysis Report By Base Oil Type (Vegetable Oils, Animal Fats), By Application (Chainsaw Oils, Hydraulic Fluids), By End-User (Industrial, Commercial Transport, Passenger Vehicles) and By Region(North America, Europe, APAC, Middle East and Africa, LATAM) Forecasts, 2023-2031 [WWW Document]. 2024. Available online: https://straitsresearch.com/report/bio-lubricants-market#:~:text=The%20global%20bio%2Dlubricants%20market,the%20forecast%20period%202023%2D2031 (accessed on 19 August 2024).

- Joshi, J.R.; Bhanderi, K.K.; Patel, J.V. Waste cooking oil as a promising source for bio lubricants—A review. J. Indian Chem. Soc. 2023, 100, 100820. [Google Scholar] [CrossRef]

- Khodadadi, M.R.; Malpartida, I.; Tsang, C.-W.; Lin, C.S.K.; Len, C. Recent advances on the catalytic conversion of waste cooking oil. Mol. Catal. 2020, 494, 111128. [Google Scholar] [CrossRef]

- Kutluk, B.G.; Kutluk, T.; Kapucu, N. Enzymatic Synthesis of Trimethylolpropane-Bases Biolubricants from Waste Edible Oil Biodiesel Using Different Types of Biocatalysis. Iran. J. Chem. Chem. Eng. 2022, 41, 3234–3243. [Google Scholar] [CrossRef]

- Mukherjee, S.; Chandar, T.; Pradhan, S.; Prasad, L. Lubricant from Waste Cooking Oil. In Lubricants from Renewable Feedstocks; Wiley: Hoboken, NJ, USA, 2024; pp. 291–335. [Google Scholar] [CrossRef]

- Zhang, W.; Ji, H.; Song, Y.; Ma, S.; Xiong, W.; Chen, C.; Chen, B.; Zhang, X. Green preparation of branched biolubricant by chemically modifying waste cooking oil with lipase and ionic liquid. J. Clean. Prod. 2020, 274, 122918. [Google Scholar] [CrossRef]

- Borugadda, V.B.; Goud, V.V. Improved thermo-oxidative stability of structurally modified waste cooking oil methyl esters for bio-lubricant application. J. Clean. Prod. 2016, 112, 4515–4524. [Google Scholar] [CrossRef]

- Chowdhury, A.; Mitra, D.; Biswas, D. Biolubricant synthesis from waste cooking oil via enzymatic hydrolysis followed by chemical esterification. JCTB 2023, 88, 139–144. [Google Scholar] [CrossRef]

- Dabai, U.M.; Owuna, J.F.; Sokoto, A.M.; Abubakar, L.A. Assessment of Quality Parameters of Ecofriendly Biolubricant from Waste Cooking Palm Oil. Asian J. Appl. Chem. Res. 2018, 1, 1–11. [Google Scholar] [CrossRef]

- Bahadi, M.; Salimon, J.; Derawi, D. Synthesis of di-trimethylolpropane tetraester-based biolubricant from Elaeis guineensis kernel oil via homogeneous acid-catalyzed transesterification. Renew. Energy 2021, 171, 981–993. [Google Scholar] [CrossRef]

- Carvalho, W.C.A.; Luiz, J.H.H.; Fernandez-Lafuente, R.; Hirata, D.B.; Mendes, A.A. Eco-friendly production of trimethylolpropane triesters from refined and used soybean cooking oils using an immobilized low-cost lipase (Eversa>® Transform 2.0) as heterogeneous catalyst. Biomass Bioenergy 2021, 155, 106302. [Google Scholar] [CrossRef]

- Ivan-Tan, C.T.; Islam, A.; Yunus, R.; Taufiq-Yap, Y.H. Screening of solid base catalysts on palm oil based biolubricant synthesis. J. Clean. Prod. 2017, 148, 441–451. [Google Scholar] [CrossRef]

- Owuna, F.J.; Dabai, M.U.; Sokoto, M.A.; Dangoggo, S.M.; Bagudo, B.U.; Birnin-Yauri, U.A.; Hassan, L.G.; Sada, I.; Abubakar, A.L.; Jibrin, M.S. Chemical modification of vegetable oils for the production of biolubricants using trimethylolpropane: A review. Egypt. J. Pet. 2020, 29, 75–82. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, M.Y.; Fan, X.G.; Wang, L.; Liang, J.Y.; Jin, X.Y.; Che, R.J.; Ying, W.Y.; Chen, S.P. 4D printing of multifunctional photocurable resin based on waste cooking oil. ACS Sustain. Chem. Eng. 2022, 10, 16344–16358. [Google Scholar] [CrossRef]

- Wang, E.; Ma, X.; Tang, S.; Yan, R.; Wang, Y.; Riley, W.W.; Reaney, M.J.T. Synthesis and oxidative stability of trimethylolpropane fatty acid triester as a biolubricant base oil from waste cooking oil. Biomass Bioenergy 2014, 66, 371–378. [Google Scholar] [CrossRef]

- Lakkoju, B.; Vemulapalli, V. Synthesis and characterization of triol based bio-lubricant from waste cooking oil. AIP Conf. Proc. 2020, 2297, 020002. [Google Scholar] [CrossRef]

- Bashiri, S.; Ghobadian, B.; Dehghani Soufi, M.; Gorjian, S. Chemical modification of sunflower waste cooking oil for biolubricant production through epoxidation reaction. Mater. Sci. Energy Technol. 2021, 4, 119–127. [Google Scholar] [CrossRef]

- Li, W.; Wang, X. Bio-lubricants derived from waste cooking oil with improved oxidation stability and low-temperature properties. J. Oleo. Sci. 2015, 64, 367–374. [Google Scholar] [CrossRef]

- Jahromi, H.; Adhikari, S.; Roy, P.; Shelley, M.; Hassani, E.; Oh, T.-S. Synthesis of Novel Biolubricants from Waste Cooking Oil and Cyclic Oxygenates through an Integrated Catalytic Process. ACS Sustain. Chem. Eng. 2021, 9, 13424–13437. [Google Scholar] [CrossRef]

- Turco, R.; Tesser, R.; Vitiello, R.; Russo, V.; Andini, S.; Di Serio, M. Synthesis of Biolubricant Basestocks from Epoxidized Soybean Oil. Catalysts 2017, 7, 309. [Google Scholar] [CrossRef]

- Borah, M.J.; Das, A.; Das, V.; Bhuyan, N.; Deka, D. Transesterification of waste cooking oil for biodiesel production catalyzed by Zn substituted waste egg shell derived CaO nanocatalyst. Fuel 2019, 242, 345–354. [Google Scholar] [CrossRef]

- Ghafar, F.; Sapawe, N.; Dzazita Jemain, E.; Safwan Alikasturi, A.; Masripan, N. Study on The Potential of Waste Cockle Shell Derived Calcium Oxide for Biolubricant Production. Mater. Today Proc. 2019, 19, 1346–1353. [Google Scholar] [CrossRef]

- Guimarães, J.R.; Miranda, L.P.; Fernandez-Lafuente, R.; Tardioli, P.W. Immobilization of Eversa® Transform via CLEA Technology Converts It in a Suitable Biocatalyst for Biolubricant Production Using Waste Cooking Oil. Molecules 2021, 26, 193. [Google Scholar] [CrossRef]

- Sarno, M.; Iuliano, M.; Cirillo, C. Optimized procedure for the preparation of an enzymatic nanocatalyst to produce a bio-lubricant from waste cooking oil. Chem. Eng. J. 2019, 377, 120273. [Google Scholar] [CrossRef]

- Su, Y.; Lin, H.; Zhang, S.; Yang, Z.; Yuan, T. One-Step Synthesis of Novel Renewable Vegetable Oil-Based Acrylate Prepolymers and Their Application in UV-Curable Coatings. Polymers 2020, 12, 1165. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Kuching Sarawak, P.; Hafizah Naihi, M. Analysis of Produced Bio-Surfactants from Waste Cooking Oil and Pure Coconut. IJISRT 2019, 4, 682–685, ISSN 2456-2165. [Google Scholar]

- De, S.; Malik, S.; Ghosh, A.; Saha, R.; Saha, B. A review on natural surfactants. RSC Adv. 2015, 5, 65757–65767. [Google Scholar] [CrossRef]

- Inès, M.; Dhouha, G. Glycolipid biosurfactants: Potential related biomedical and biotechnological applications. Carbohydr. Res. 2015, 416, 59–69. [Google Scholar] [CrossRef] [PubMed]

- Miao, Y.; To, M.H.; Siddiqui, M.A.; Wang, H.; Lodens, S.; Chopra, S.S.; Kaur, G.; Roelants, S.L.K.W.; Lin, C.S.K. Sustainable biosurfactant production from secondary feedstock—Recent advances, process optimization and perspectives. Front. Chem. 2024, 12, 1327113. [Google Scholar] [CrossRef] [PubMed]

- Rawat, N.; Alam, P.; Bhonsle, A.K.; Ngomade, S.B.L.; Agarwal, T.; Singh, R.K.; Atray, N. Valorization of used cooking oil into bio-based surfactant: Modeling and optimization using response surface methodology. Biomass Convers. Biorefin. 2024, 5, 1–14. [Google Scholar] [CrossRef]

- Zhang, Q.Q.; Cai, B.X.; Xu, W.J.; Gang, H.Z.; Liu, J.F.; Yang, S.Z.; Mu, B.Z. The rebirth of waste cooking oil to novel bio-based surfactants. Sci. Rep. 2015, 5, 9971. [Google Scholar] [CrossRef]

- Market Research Engine. Biosurfactants Market Research. 2022. Available online: https://www.marketresearchengine.com/biosurfactants-market?srsltid=AfmBOopWbMrQRk5GEZTHLe-xSaQJk4fBT84YEX_zBlJ5Rqe64EyXE1tJ (accessed on 12 August 2024).

- Jahan, R.; Bodratti, A.M.; Tsianou, M.; Alexandridis, P. Biosurfactants, natural alternatives to synthetic surfactants: Physicochemical properties and applications. Adv. Colloid. Interface Sci. 2020, 275, 102061. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Peñalver, P.; Koh, A.; Gross, R.; Gea, T.; Font, X. Biosurfactants from Waste: Structures and Interfacial Properties of Sophorolipids Produced from a Residual Oil Cake. J. Surfactants Deterg. 2020, 23, 481–486. [Google Scholar] [CrossRef]

- Sharma, K.; Toor, S.S.; Brandão, J.; Pedersen, T.H.; Rosendahl, L.A. Optimized conversion of waste cooking oil into ecofriendly bio-based polymeric surfactant- A solution for enhanced oil recovery and green fuel compatibility. J. Clean. Prod. 2021, 294, 126214. [Google Scholar] [CrossRef]

- Cameotra, S.S.; Makkar, R.S. Biosurfactant-enhanced bioremediation of hydrophobic pollutants. Pure Appl. Chem. 2010, 82, 97–116. [Google Scholar] [CrossRef]

- Gaur, V.K.; Sharma, P.; Sirohi, R.; Varjani, S.; Taherzadeh, M.J.; Chang, J.-S.; Yong Ng, H.; Wong, J.W.C.; Kim, S.-H. Production of biosurfactants from agro-industrial waste and waste cooking oil in a circular bioeconomy: An overview. Bioresour. Technol. 2022, 343, 126059. [Google Scholar] [CrossRef]

- Gautam, K.; Sharma, P.; Gaur, V.K.; Gupta, P.; Pandey, U.; Varjani, S.; Pandey, A.; Wong, J.W.C.; Chang, J.S. Oily waste to biosurfactant: A path towards carbon neutrality and environmental sustainability. Environ. Technol. Innov. 2023, 30, 103095. [Google Scholar] [CrossRef]

- Nurdin, S.; Yunus, R.M.; Nour, A.H.; Gimbun, J.; Aisyah Azman, N.N.; Sivaguru, M.V. Restoration of waste cooking oil (WCO) using alkaline hydrolysis technique (ALHYT) for future biodetergent 11. ARPN J. Eng. Appl. Sci. 2016, 11, 6405–6410, ISSN 1819-6608. [Google Scholar]

- Yusuff, A.S.; Porwal, J.; Bhonsle, A.K.; Rawat, N.; Atray, N. Valorization of used cooking oil as a source of anionic surfactant fatty acid methyl ester sulfonate: Process optimization and characterization studies. Biomass Convers. Biorefin. 2023, 13, 8903–8914. [Google Scholar] [CrossRef]

- Permadani, R.L.; Ibadurrohman, M.; Slamet. Utilization of waste cooking oil as raw material for synthesis of Methyl Ester Sulfonates (MES) surfactant. In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristol, UK, 2018. [Google Scholar] [CrossRef]

- Jin, Y.; Tian, S.; Guo, J.; Ren, X.; Li, X.; Gao, S. Synthesis, Characterization and Exploratory Application of Anionic Surfactant Fatty Acid Methyl Ester Sulfonate from Waste Cooking Oil. J. Surfactants Deterg. 2016, 19, 467–475. [Google Scholar] [CrossRef]

- Lucchetti, M.G.; Paolotti, L.; Rocchi, L.; Boggia, A. The Role of Environmental Evaluation within Circular Economy: An Application of Life Cycle Assessment (LCA) Method in the Detergents Sector. Environ. Clim. Technol. 2019, 23, 238–257. [Google Scholar] [CrossRef]

- Dong, Q.; Li, X.; Dong, J. Synthesis of branched surfactant via ethoxylation of oleic acid derivative and its surface properties. Chem. Eng. Sci. 2022, 258, 117747. [Google Scholar] [CrossRef]

- Khalaf, M.M.; Tantawy, A.H.; Soliman, K.A.; Abd El-Lateef, H.M. Cationic gemini-surfactants based on waste cooking oil as new ‘green’ inhibitors for N80-steel corrosion in sulphuric acid: A combined empirical and theoretical approaches. J. Mol. Struct. 2020, 1203, 127442. [Google Scholar] [CrossRef]

- Guerrero-Hernández, L.; Meléndez-Ortiz, H.I.; Cortez-Mazatan, G.Y.; Vaillant-Sánchez, S.; Peralta-Rodríguez, R.D. Gemini and Bicephalous Surfactants: A Review on Their Synthesis, Micelle Formation, and Uses. Int. J. Mol. Sci. 2022, 23, 1798. [Google Scholar] [CrossRef] [PubMed]

- Bocqué, M.; Voirin, C.; Lapinte, V.; Caillol, S.; Robin, J.J. Petro-based and bio-based plasticizers: Chemical structures to plasticizing properties. J. Polym. Sci. A Polym. Chem. 2016, 54, 11–33. [Google Scholar] [CrossRef]

- Silviana; Anggoro, D.D.; Kumoro, A.C. Waste cooking oil utilisation as bio-plasticiser through epoxidation using inorganic acids as homogeneous catalysts. Chem. Eng. Trans. 2017, 56, 1861–1866. [Google Scholar] [CrossRef]

- Carlos, K.S.; de Jager, L.S.; Begley, T.H. Investigation of the primary plasticisers present in polyvinyl chloride (PVC) products currently authorised as food contact materials. Food Addit. 2018, 35, 1214–1222. [Google Scholar] [CrossRef]

- Friday Etuk, I.; Ekwere Inyang, U. Applications of Various Plasticizers in the Plastic Industry-Review. IJEMT 2024, 10, 38–55. [Google Scholar]

- Greco, A.; Ferrari, F.; Maffezzoli, A. UV and thermal stability of soft PVC plasticized with cardanol derivatives. J. Clean. Prod. 2017, 164, 757–764. [Google Scholar] [CrossRef]

- He, Z.; Lu, Y.; Lin, C.; Jia, H.; Wu, H.; Cao, F.; Ouyang, P. Designing anti-migration furan-based plasticizers and their plasticization properties in poly (vinyl chloride) blends. Polym. Test. 2020, 91, 106793. [Google Scholar] [CrossRef]

- Sahnoune Millot, M.; Devémy, J.; Chennell, P.; Pinguet, J.; Dequidt, A.; Sautou, V.; Malfreyt, P. Leaching of plasticizers from PVC medical devices: A molecular interpretation of experimental migration data. J. Mol. Liq. 2024, 396, 123965. [Google Scholar] [CrossRef]

- Cheng, Y.; Miao, D.; Kong, L.; Jiang, J.; Guo, Z. Preparation and Performance Test of the Super-Hydrophobic Polyurethane Coating Based on Waste Cooking Oil. Coatings 2019, 9, 861. [Google Scholar] [CrossRef]

- Feng, G.; Ma, Y.; Zhang, M.; Jia, P.; Liu, C.; Zhou, Y. Synthesis of Bio-base Plasticizer Using Waste Cooking Oil and Its Performance Testing in Soft Poly(vinyl chloride) Films. J. Bioresour. Bioprod. 2019, 4, 99–110. [Google Scholar] [CrossRef]

- Jia, P.; Ma, Y.; Kong, Q.; Xu, L.; Hu, Y.; Hu, L.; Zhou, Y. Graft modification of polyvinyl chloride with epoxidized biomass-based monomers for preparing flexible polyvinyl chloride materials without plasticizer migration. Mater. Today Chem. 2019, 13, 49–58. [Google Scholar] [CrossRef]

- Thirupathiah, G.; Satapathy, S.; Palanisamy, A. Studies on epoxidised castor oil as co-plasticizer with epoxidised soyabean oil for PVC processing. J. Renew. Mater. 2019, 7, 775–785. [Google Scholar] [CrossRef]

- Cai, D.-L.; Yue, X.; Hao, B.; Ma, P.-C. A sustainable poly(vinyl chloride) plasticizer derivated from waste cooking oil. J. Clean. Prod. 2020, 274, 122781. [Google Scholar] [CrossRef]

- Liu, D.; Jiang, P.; Nie, Z.; Wang, H.; Dai, Z.; Deng, J.; Cao, Z. Synthesis of an efficient bio-based plasticizer derived from waste cooking oil and its performance testing in PVC. Polym. Test. 2020, 90, 106625. [Google Scholar] [CrossRef]

- Ma, D.-X.; Yin, G.-Z.; Ye, W.; Jiang, Y.; Wang, N.; Wang, D.-Y. Exploiting Waste towards More Sustainable Flame-Retardant Solutions for Polymers: A Review. Materials 2024, 17, 2266. [Google Scholar] [CrossRef]

- Tan, J.; Zhang, S.; Lu, T.; Li, R.; Zhong, T.; Zhu, X. Design and synthesis of ethoxylated esters derived from waste frying oil as anti-ultraviolet and efficient primary plasticizers for poly(vinyl chloride). J. Clean. Prod. 2019, 229, 1274–1282. [Google Scholar] [CrossRef]

- Polaczek, K.; Kurańska, M.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell polyurethane foams of very low density modified with various palm oil-based bio-polyols in accordance with cleaner production. J. Clean. Prod. 2021, 290, 125875. [Google Scholar] [CrossRef]

- Gadhave, R.V.; Mahanwar, P.A.; Gadekar, P.T. Bio-Renewable Sources for Synthesis of Eco-Friendly Polyurethane Adhesives—Review. Open J. Polym. Chem. 2017, 7, 57–75. [Google Scholar] [CrossRef]

- Sarim, M.; Alavi Nikje, M.M.; Dargahi, M. Preparation and Characterization of Polyurethane Rigid Foam Nanocomposites from Used Cooking Oil and Perlite. Int. J. Polym. Sci. 2023, 1, 1–13. [Google Scholar] [CrossRef]

- Mangal, M.; Rao, C.V.; Banerjee, T. Bioplastic: An eco-friendly alternative to non-biodegradable plastic. Polym. Int. 2023, 72, 984–996. [Google Scholar] [CrossRef]

- Orjuela, A.; Clark, J. Green chemicals from used cooking oils: Trends, challenges, and opportunities. Curr. Opin. Green. Sustain. Chem. 2020, 26, 100369. [Google Scholar] [CrossRef]

- Salleh, W.N.F.W.; Tahir, S.M.; Mohamed, N.S. Synthesis of waste cooking oil-based polyurethane for solid polymer electrolyte. Polym. Bull. 2018, 75, 109–120. [Google Scholar] [CrossRef]

- Sawpan, M.A. Polyurethanes from vegetable oils and applications: A review. J. Polym. Res. 2018, 25, 184. [Google Scholar] [CrossRef]

- Delavarde, A.; Savin, G.; Derkenne, P.; Boursier, M.; Morales-Cerrada, R.; Nottelet, B.; Pinaud, J.; Caillol, S. Sustainable polyurethanes: Toward new cutting-edge opportunities. Prog. Polym. Sci. 2024, 151, 101805. [Google Scholar] [CrossRef]

- Maulana, S.; Wibowo, E.S.; Mardawati, E.; Iswanto, A.H.; Papadopoulos, A.; Lubis, M.A.R. Eco-Friendly and High-Performance Bio-Polyurethane Adhesives from Vegetable Oils: A Review. Polymers 2024, 16, 1613. [Google Scholar] [CrossRef] [PubMed]

- Paciorek-Sadowska, J.; Borowicz, M.; Isbrandt, M.; Czupryński, B.; Apiecionek, Ł. The Use of Waste from the Production of Rapeseed Oil for Obtaining of New Polyurethane Composites. Polymers 2019, 11, 1431. [Google Scholar] [CrossRef] [PubMed]

- Pu, M.; Fang, C.; Zhou, X.; Wang, D.; Lin, Y.; Lei, W.; Li, L. Recent Advances in Environment-Friendly Polyurethanes from Polyols Recovered from the Recycling and Renewable Resources: A Review. Polymers 2024, 16, 1889. [Google Scholar] [CrossRef]

- Asare, M.A.; de Souza, F.M.; Gupta, R.K. Waste to Resource: Synthesis of Polyurethanes from Waste Cooking Oil. Ind. Eng. Chem. Res. 2022, 61, 18400–18411. [Google Scholar] [CrossRef]

- Kurańska, M.; Banaś, J.; Polaczek, K.; Banaś, M.; Prociak, A.; Kuc, J.; Uram, K.; Lubera, T. Evaluation of application potential of used cooking oils in the synthesis of polyol compounds. J. Environ. Chem. Eng. 2019, 7, 103506. [Google Scholar] [CrossRef]

- Malewska, E.; Polaczek, K.; Kurańska, M. Impact of Various Catalysts on Transesterification of Used Cooking Oil and Foaming Processes of Polyurethane Systems. Materials 2022, 15, 7807. [Google Scholar] [CrossRef]

- Raofuddin, D.N.A.; Azmi, I.S.; Jalil, M.J. Catalytic Epoxidation of Oleic Acid Derived from Waste Cooking Oil by In Situ Peracids. J. Polym. Environ. 2024, 32, 803–814. [Google Scholar] [CrossRef]

- Sánchez, B.S.; Benitez, B.; Querini, C.A.; Mendow, G. Transesterification of sunflower oil with ethanol using sodium ethoxide as catalyst. Effect of the reaction conditions. Fuel Process. Technol. 2015, 131, 29–35. [Google Scholar] [CrossRef]

- Kurańska, M.; Malewska, E. Waste cooking oil as starting resource to produce bio-polyol—Analysis of transesteryfication process using gel permeation chromatography. Ind. Crops Prod. 2021, 162, 113294. [Google Scholar] [CrossRef]

- Kurańska, M.; Benes, H.; Polaczek, K.; Trhlikova, O.; Walterova, Z.; Prociak, A. Effect of homogeneous catalysts on ring opening reactions of epoxidized cooking oils. J. Clean. Prod. 2019, 230, 162–169. [Google Scholar] [CrossRef]

- Skleničková, K.; Abbrent, S.; Halecký, M.; Kočí, V.; Beneš, H. Biodegradability and ecotoxicity of polyurethane foams: A review. Crit. Rev. Environ. Sci. Technol. 2022, 52, 157–202. [Google Scholar] [CrossRef]

- Ul Haq, I.; Akram, A.; Nawaz, A.; Zohu, X.; Abbas, S.Z.; Xu, Y.; Rafatullah, M. Comparative analysis of various waste cooking oils for esterification and transesterification processes to produce biodiesel. Green. Chem. Lett. Rev. 2021, 14, 462–473. [Google Scholar] [CrossRef]

- Moreno, D.; Velasco, M.; Malagón-Romero, D. Production of polyurethanes from used vegetable oil-based polyols. Chem. Eng. Trans. 2020, 79, 337–342. [Google Scholar] [CrossRef]

- Lubis, M.; Prayogo, M.A.; Harahap, M.B.; Iriany; Ginting, M.H.S.; Lazuardi, I.N.; Akbar, R. The effect of fibre loading on characterization and mechanical properties of polyurethane foam composites derived waste cooking oil, polyol and toluene diisocyanate with adding filler sugar palm (Arenga pinnata) fibre. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1122, 012109. [Google Scholar] [CrossRef]

- Paraskar, P.M.; Prabhudesai, M.S.; Hatkar, V.M.; Kulkarni, R.D. Vegetable oil based polyurethane coatings—A sustainable approach: A review. Prog. Org. Coat. 2021, 156, 106267. [Google Scholar] [CrossRef]

- Silva, R.; Barros-Timmons, A.; Quinteiro, P. Life cycle assessment of fossil- and bio-based polyurethane foams: A review. J. Clean. Prod. 2023, 430, 139697. [Google Scholar] [CrossRef]

- Castro-Osma, J.A.; Martínez, J.; de la Cruz-Martínez, F.; Caballero, M.P.; Fernández-Baeza, J.; Rodríguez-López, J.; Otero, A.; Lara-Sánchez, A.; Tejeda, J. Development of hydroxy-containing imidazole organocatalysts for CO2 fixation into cyclic carbonates. Catal. Sci. Technol. 2018, 8, 1981–1987. [Google Scholar] [CrossRef]

- Werlinger, F.; Caballero, M.P.; Trofymchuk, O.S.; Flores, M.E.; Moreno-Villoslada, I.; de la Cruz-Martínez, F.; Castro-Osma, J.A.; Tejeda, J.; Martínez, J.; Lara-Sánchez, A. Turning waste into resources. Efficient synthesis of biopolyurethanes from used cooking oils and CO2. J. CO2 Util. 2024, 79, 102659. [Google Scholar] [CrossRef]

- Onn, M.; Mustafa, H.; Azman, H.A.; Ahmad, Z.; Wahit, M.U. Synthesis and Characterization of Photocrosslinkable Acrylic Prepolymers from Waste Palm Frying Oil. Chem. Eng. Trans. 2023, 106, 379–384. [Google Scholar] [CrossRef]

- Wu, B.; Sufi, A.; Ghosh Biswas, R.; Hisatsune, A.; Moxley-Paquette, V.; Ning, P.; Soong, R.; Dicks, A.P.; Simpson, A.J. Direct Conversion of McDonald’s Waste Cooking Oil into a Biodegradable High-Resolution 3D-Printing Resin. ACS Sustain. Chem. Eng. 2020, 8, 1171–1177. [Google Scholar] [CrossRef]

- Wu, W.; Deng, X.; Tian, S.; Wang, S.; He, Y.; Zheng, B.; Xin, K.; Zhou, Z.; Tang, L. Whole-Waste synthesis of Kilogram-Scale Macropores adsorbent materials for Wide-Range oil and heavy metal removal. Sep. Purif. Technol. 2025, 354, 128750. [Google Scholar] [CrossRef]

- Voet, V.S.D.; Guit, J.; Loos, K. Sustainable Photopolymers in 3D Printing: A Review on Biobased, Biodegradable, and Recyclable Alternatives. Macromol. Rapid Commun. 2021, 42, e2000475. [Google Scholar] [CrossRef]

- Heriyanto, H.; Suhendi, E.; Asyuni, N.F.; Shahila, I.K. Effect of Bayah natural zeolite for purification of waste cooking oil as feedstock of alkyd resin. Tek. J. Sains Dan Teknologi 2022, 18, 49. [Google Scholar] [CrossRef]

- Silvianti, F.; Wijayanti, W.; Sudjarwo, W.A.A.; Dewi, W.B. Synthesis of Alkyd Resin Modified with Waste Palm Cooking Oil as Precursor Using Pretreatment with Zeolite Adsorbent. Sci. Technol. Indones. 2018, 3, 119–122. [Google Scholar] [CrossRef]

- Markets and Markets. Epoxy Resin Market by Physical Form, Raw Materilas, Application, End-Use Industry and Region- Global Forecast to 2028. 2024. Available online: https://www.marketsandmarkets.com/Market-Reports/epoxy-resins-market-762.html (accessed on 10 January 2025).

- Jaengmee, T.; Pongmuksuwan, P.; Kitisatorn, W. Development of bio-based epoxy resin from palm oil. Mater. Today Proc. 2022, 52, 2357–2360. [Google Scholar] [CrossRef]

- Chong, K.L.; Lai, J.C.; Rahman, R.A.; Adrus, N.; Al-Saffar, Z.H.; Hassan, A.; Lim, T.H.; Wahit, M.U. A review on recent approaches to sustainable bio-based epoxy vitrimer from epoxidized vegetable oils. Ind. Crops Prod. 2022, 189, 115857. [Google Scholar] [CrossRef]

- Gonçalves, F.A.M.M.; Santos, M.; Cernadas, T.; Ferreira, P.; Alves, P. Advances in the development of biobased epoxy resins: Insight into more sustainable materials and future applications. Int. Mater. Rev. 2022, 67, 119–149. [Google Scholar] [CrossRef]

- Fernandes, F.C.; Kirwan, K.; Wilson, P.R.; Coles, S.R. Sustainable Alternative Composites Using Waste Vegetable Oil Based Resins. J. Polym. Environ. 2019, 27, 2464–2477. [Google Scholar] [CrossRef]

- Wang, Z.; Pei, Q.; Li, K.; Wang, Z.; Huo, X.; Wang, Y.; Zhang, X.; Kong, S. Molecular Dynamics Simulation of the Rejuvenation Performance of Waste Cooking Oil with High Acid Value on Aged Asphalt. Molecules 2024, 29, 2830. [Google Scholar] [CrossRef] [PubMed]

- Xu, N.; Wang, H.; Wang, H.; Kazemi, M.; Fini, E. Research progress on resource utilization of waste cooking oil in asphalt materials: A state-of-the-art review. J. Clean. Prod. 2023, 385, 135427. [Google Scholar] [CrossRef]

- Baranowska, W.; Rzepna, M.; Ostrowski, P.; Lewandowska, H. Radiation and Radical Grafting Compatibilization of Polymers for Improved Bituminous Binders—A Review. Materials 2024, 17, 1642. [Google Scholar] [CrossRef]

- Chamaa, A.; Khatib, J.; Elkordi, A. A review on the use of vegetable oil and its waste in construction applications. BAU J. Sci. Technol. 2020, 1, 1–10. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Kavitha Kathikeyan, S.; Snekha, G.; Vinothini, A. Experimental Investigation on Usage of Waste Cooking Oil (WCO) in Concrete Making and Adopting Innovative Curing Method. Int. J. Eng. Res. 2016, 5, 146–151. [Google Scholar] [CrossRef]

- Jain, S.; Chandrappa, A.K. Influence of Blended Waste Cooking Oils on the Sustainable Asphalt Rejuvenation Considering Secondary Aging. Int. J. Pavement Res. Technol. 2024, 1, 1–11. [Google Scholar] [CrossRef]

- Uz, V.E.; Gökalp, İ. Sustainable recovery of waste vegetable cooking oil and aged bitumen: Optimized modification for short and long term aging cases. Waste Manag. 2020, 110, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Su, J.; Liu, L.; Liu, Z.; Sun, G. Waste cooking oil based capsules for sustainable self-healing asphalt pavement: Encapsulation, characterization and fatigue-healing performance. Constr. Build. Mater. 2024, 425, 136032. [Google Scholar] [CrossRef]

- Ji, H.; Li, B.; Li, X.; Han, J.; Liu, D.; Dou, H.; Fu, M.; Yao, T. Waste cooking oil as a sustainable solution for UV-aged asphalt binder: Rheological, chemical and molecular structure. Constr. Build. Mater. 2024, 420, 135149. [Google Scholar] [CrossRef]

- Al Mamun, A.; Wahhab, H.I.A.-A.; Dalhat, M.A. Comparative laboratory evaluation of waste cooking oil rejuvenated asphalt concrete mixtures for high contents of reclaimed asphalt pavement. Int. J. Pavement Eng. 2020, 21, 1297–1308. [Google Scholar] [CrossRef]

- Taherkhani, H.; Noorian, F. Laboratory investigation on the properties of asphalt concrete containing reclaimed asphalt pavement and waste cooking oil as recycling agent. Int. J. Pavement Eng. 2021, 22, 539–549. [Google Scholar] [CrossRef]

- Al-Omari, A.A.; Khedaywi, T.S.; Khasawneh, M.A. Laboratory characterization of asphalt binders modified with waste vegetable oil using SuperPave specifications. Int. J. Pavement Res. Techn. 2018, 11, 68–76. [Google Scholar] [CrossRef]

- Jalkh, R.; El-Rassy, H.; Chehab, G.R.; Abiad, M.G. Assessment of the Physico-Chemical Properties of Waste Cooking Oil and Spent Coffee Grounds Oil for Potential Use as Asphalt Binder Rejuvenators. Waste Biomass Valorization 2018, 9, 2125–2132. [Google Scholar] [CrossRef]

- Ahmed, R.B.; Hossain, K. Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar] [CrossRef]

- Elahi, Z.; Mohd Jakarni, F.; Muniandy, R.; Hassim, S.; Ab Razak, M.S.; Ansari, A.H.; Ben Zair, M.M. Waste Cooking Oil as a Sustainable Bio Modifier for Asphalt Modification: A Review. Sustainability 2021, 13, 11506. [Google Scholar] [CrossRef]

- Elahi, Z.; Jakarni, F.M.; Muniandy, R.; Hassim, S.; Ab Razak, M.S.; Ansari, A.H. Influence of novel modified waste cooking oil beads on rheological characteristics of bitumen. Constr. Build. Mater. 2024, 414, 134829. [Google Scholar] [CrossRef]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review. J. Clean. Prod. 2021, 278, 123304. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E.; Alshraiedeh, K.A.; Bustanji, M.; Aleih, A.; Abukhamseh, F. Performance Assessment of Waste Cooking Oil-Modified Asphalt Mixtures. Appl. Sci. 2024, 14, 1228. [Google Scholar] [CrossRef]

- Chen, M.; Xiao, F.; Putman, B.; Leng, B.; Wu, S. High temperature properties of rejuvenating recovered binder with rejuvenator, waste cooking and cotton seed oils. Constr. Build. Mater. 2014, 59, 10–16. [Google Scholar] [CrossRef]

- Huo, Y.; Dong, X.; Gao, Y.; Xu, X.; Zeng, L.; Wu, Y.; Zhao, Y.; Yang, Y.; Su, Q.; Huang, J.; et al. Effects of cooking oil on the shrinkage-reducing of high-strength concrete. Results Mater. 2024, 23, 100602. [Google Scholar] [CrossRef]

- Joni, H.H.; Al-Rubaee, R.H.A.; Al-zerkani, M.A. Rejuvenation of aged asphalt binder extracted from reclaimed asphalt pavement using waste vegetable and engine oils. Case Stud. Constr. Mater. 2019, 11, e00279. [Google Scholar] [CrossRef]

- Xinxin, C.; Xuejuan, C.; Boming, T.; Yuanyuan, W.; Xiaolong, L. Investigation on Possibility of Waste Vegetable Oil Rejuvenating Aged Asphalt. Appl. Sci. 2018, 8, 765. [Google Scholar] [CrossRef]

- Azahar, W.N.A.W.; Jaya, R.P.; Hainin, M.R.; Bujang, M.; Ngadi, N. Mechanical performance of asphaltic concrete incorporating untreated and treated waste cooking oil. Constr. Build. Mater. 2017, 150, 653–663. [Google Scholar] [CrossRef]

- Oldham, D.; Rajib, A.; Dandamudi, K.P.R.; Liu, Y.; Deng, S.; Fini, E.H. Transesterification of Waste Cooking Oil to Produce A Sustainable Rejuvenator for Aged Asphalt. Resour. Conserv. Recy. 2021, 168, 105297. [Google Scholar] [CrossRef]

- Sun, Z.; Yi, J.; Huang, Y.; Feng, D.; Guo, C. Properties of asphalt binder modified by bio-oil derived from waste cooking oil. Constr. Build. Mater. 2016, 102, 496–504. [Google Scholar] [CrossRef]

- Enfrin, M.; Gowda, A.; Giustozzi, F. Low-cost chemical modification of refined used cooking oil to produce long-lasting bio-asphalt pavements. Resour. Conserv. Recycl. 2024, 204, 107493. [Google Scholar] [CrossRef]

- Yi, X.; Dong, R.; Shi, C.; Yang, J.; Leng, Z. The influence of the mass ratio of crumb rubber and waste cooking oil on the properties of rubberised bio-rejuvenator and rejuvenated asphalt. Road Mater. Pavement Des. 2023, 24, 578–591. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Z.; Lv, C.; Meng, F.; Yang, Y. Preparation of waste cooking oil emulsion as shrinkage reducing admixture and its potential use in high performance concrete: Effect on shrinkage and mechanical properties. J. Build. Eng. 2020, 32, 101488. [Google Scholar] [CrossRef]

- Tarnpradab, T.; Unyaphan, S.; Takahashi, F.; Yoshikawa, K. Tar removal capacity of waste cooking oil absorption and waste char adsorption for rice husk gasification. Biofuels 2016, 7, 401–412. [Google Scholar] [CrossRef]

- Cappello, M.; Brunazzi, E.; Rossi, D.; Seggiani, M. Absorption of n-butyl acetate from tannery air emissions by waste vegetable oil/water emulsions. J. Environ. Chem. Eng. 2024, 12, 112443. [Google Scholar] [CrossRef]

- Dong, R.; Zhao, M.; Tang, N. Characterization of crumb tire rubber lightly pyrolyzed in waste cooking oil and the properties of its modified bitumen. Constr. Build. Mater. 2019, 195, 10–18. [Google Scholar] [CrossRef]

- Aldagari, S.; Kabir, S.F.; Lamanna, A.; Fini, E.H. Functionalized Waste Plastic Granules to Enhance Sustainability of Bituminous Composites. Resour. Conserv. Recycl. 2022, 183, 106353. [Google Scholar] [CrossRef]

- Mousavi, M.; Fini, E.H. Preventing emissions of hazardous organic compounds from bituminous composites. J. Clean. Prod. 2022, 344, 131067. [Google Scholar] [CrossRef]

- Yi, X.; Dong, R.; Tang, N. Development of a novel binder rejuvenator composed by waste cooking oil and crumb tire rubber. Constr. Build. Mater. 2020, 236, 117621. [Google Scholar] [CrossRef]

- Gallart-Sirvent, P.; Martín, M.; Villorbina, G.; Balcells, M.; Solé, A.; Barrenche, C.; Cabeza, L.F.; Canela-Garayoa, R. Fatty acid eutectic mixtures and derivatives from non-edible animal fat as phase change materials. RSC Adv. 2017, 7, 24133–24139. [Google Scholar] [CrossRef]

- Kahwaji, S.; White, M.A. Edible Oils as Practical Phase Change Materials for Thermal Energy Storage. Appl. Sci. 2019, 9, 1627. [Google Scholar] [CrossRef]

- Afonso, I.S.; Nobrega, G.; Lima, R.; Gomes, J.R.; Ribeiro, J.E. Conventional and Recent Advances of Vegetable Oils as Metalworking Fluids (MWFs): A Review. Lubricants 2023, 11, 160. [Google Scholar] [CrossRef]

- Landi, F.A.F.; Fabiani, C.; Pisello, A.L. Palm oil for seasonal thermal energy storage applications in buildings: The potential of multiple melting ranges in blends of bio-based fatty acids. J. Energy Storage 2020, 29, 101431. [Google Scholar] [CrossRef]

- Chen, D.; Chen, M.; Zhao, Y.; Zhang, Y.; Wu, Y.; Zhang, J.; Yang, X. Waste cooking oil applicable phase change capsules to improve thermoregulation of foamed concrete. Constr. Build. Mater. 2024, 432, 136538. [Google Scholar] [CrossRef]

- Irsyad, M.; Amrizal; Harmen; Amrul; Susila Es, M.D.; Diva Putra, A.R. Experimental study of the thermal properties of waste cooking oil applied as thermal energy storage. Results Eng. 2023, 18, 101080. [Google Scholar] [CrossRef]

- Okogeri, O.; Stathopoulos, V.N. What about greener phase change materials? A review on biobased phase change materials for thermal energy storage applications. Int. J. Thermofluids 2021, 10, 100081. [Google Scholar] [CrossRef]

- Gatto, V.; Conca, S.; Bardella, N.; Beghetto, V. Efficient Triazine Derivatives for Collagenous Materials Stabilization. Materials 2021, 14, 3069. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.; Wu, S.; Xu, H.; Wan, P.; Zhang, J. Preparation and characterization of phase change capsules containing waste cooking oil for asphalt binder thermoregulation. Constr. Build. Mater. 2023, 395, 132311. [Google Scholar] [CrossRef]

| Component | Sunflower Oil a | Sunflower Oil WCO b | Rapeseed Oil a | Rapeseed Oil WCO a | Palm Oil a | Palm oil WCO a | Sun Foil a | Sun Foil WCO a |

|---|---|---|---|---|---|---|---|---|

| Saturated fatty acids | 71.5 | 32.0 | 80.0–93.0 | 74.4 | 73–15 | |||

| Monounsaturated fatty acids | - | 62.0 | 20.0–7.0 | 27–6 | ||||

| Polyunsaturated fatty acids | 28.5 | 6.0 | 25.6 | 0–79 | ||||

| Acidic value (mg KOH/g oil) | 0.30 | 2.29 | 0.06 | 1.06 | 0.66–1.13 | 0.72–1.44 | ||

| pH | 7.38 | 5.34 | 6.34 | 5.73–6.19 | 8.63 | 6.14–6.61 | ||

| Density at 20 °C (kg/m3) | 919.21 | 920.40 | 918.00 | 929.00 | 919.48 | 923.2–913.4 | 919.6 | 919.8–923.2 |

| Kinetic viscosity at 40 °C (mm2/s) | 28.744 | 31.381 | 63.286 | 68.568 | 27.962 | 44.254–38.407 | 28.224 | 43.521–35.236 |

| Molecular weight (g/mol) | 670.82 | 51.94 | 869.16 | 871.01 | 535.08 | 135.66–586.05 | 119.71 | 55.18–395.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beghetto, V. Strategies for the Transformation of Waste Cooking Oils into High-Value Products: A Critical Review. Polymers 2025, 17, 368. https://doi.org/10.3390/polym17030368

Beghetto V. Strategies for the Transformation of Waste Cooking Oils into High-Value Products: A Critical Review. Polymers. 2025; 17(3):368. https://doi.org/10.3390/polym17030368

Chicago/Turabian StyleBeghetto, Valentina. 2025. "Strategies for the Transformation of Waste Cooking Oils into High-Value Products: A Critical Review" Polymers 17, no. 3: 368. https://doi.org/10.3390/polym17030368

APA StyleBeghetto, V. (2025). Strategies for the Transformation of Waste Cooking Oils into High-Value Products: A Critical Review. Polymers, 17(3), 368. https://doi.org/10.3390/polym17030368