Development of Short Jute Fiber-Reinforced Thermoplastic Pre-Preg Tapes

Abstract

:1. Introduction

2. Materials and Methods

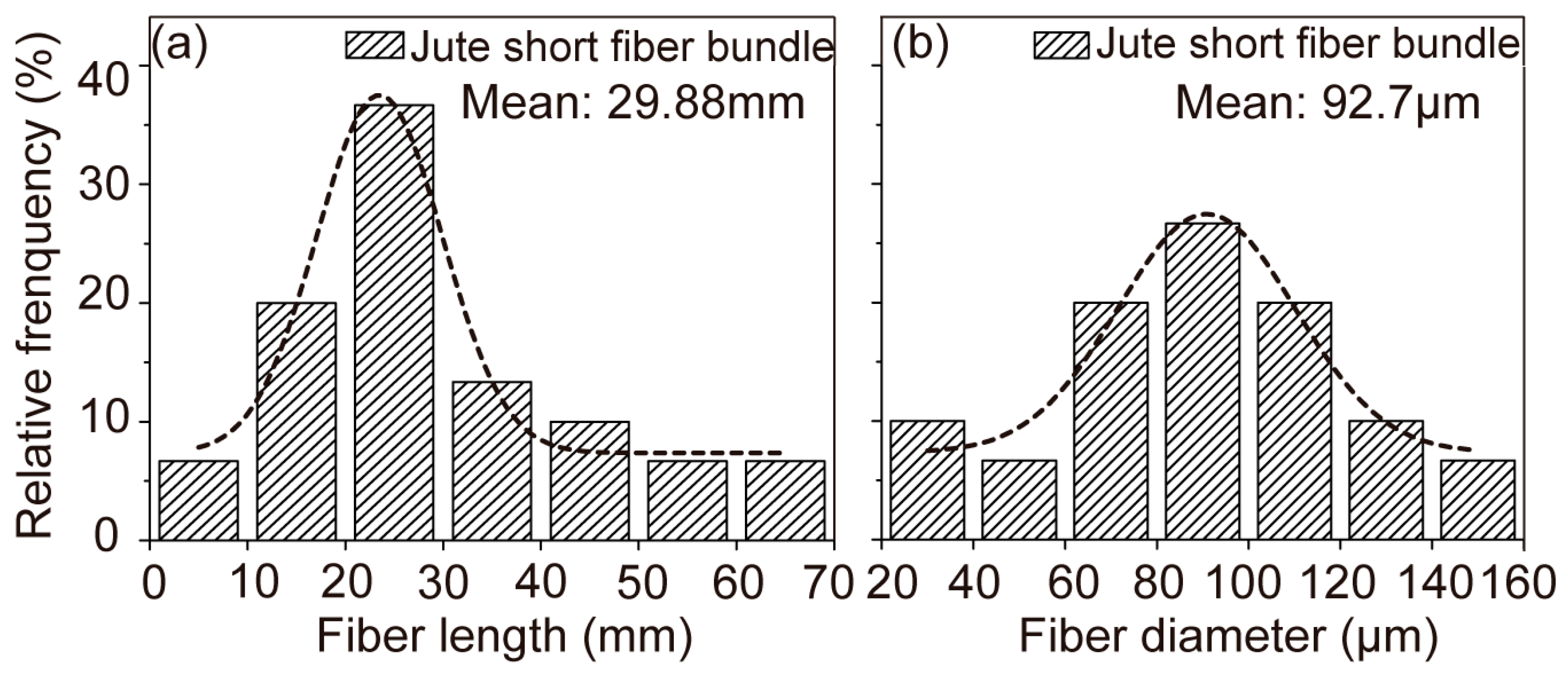

2.1. Materials

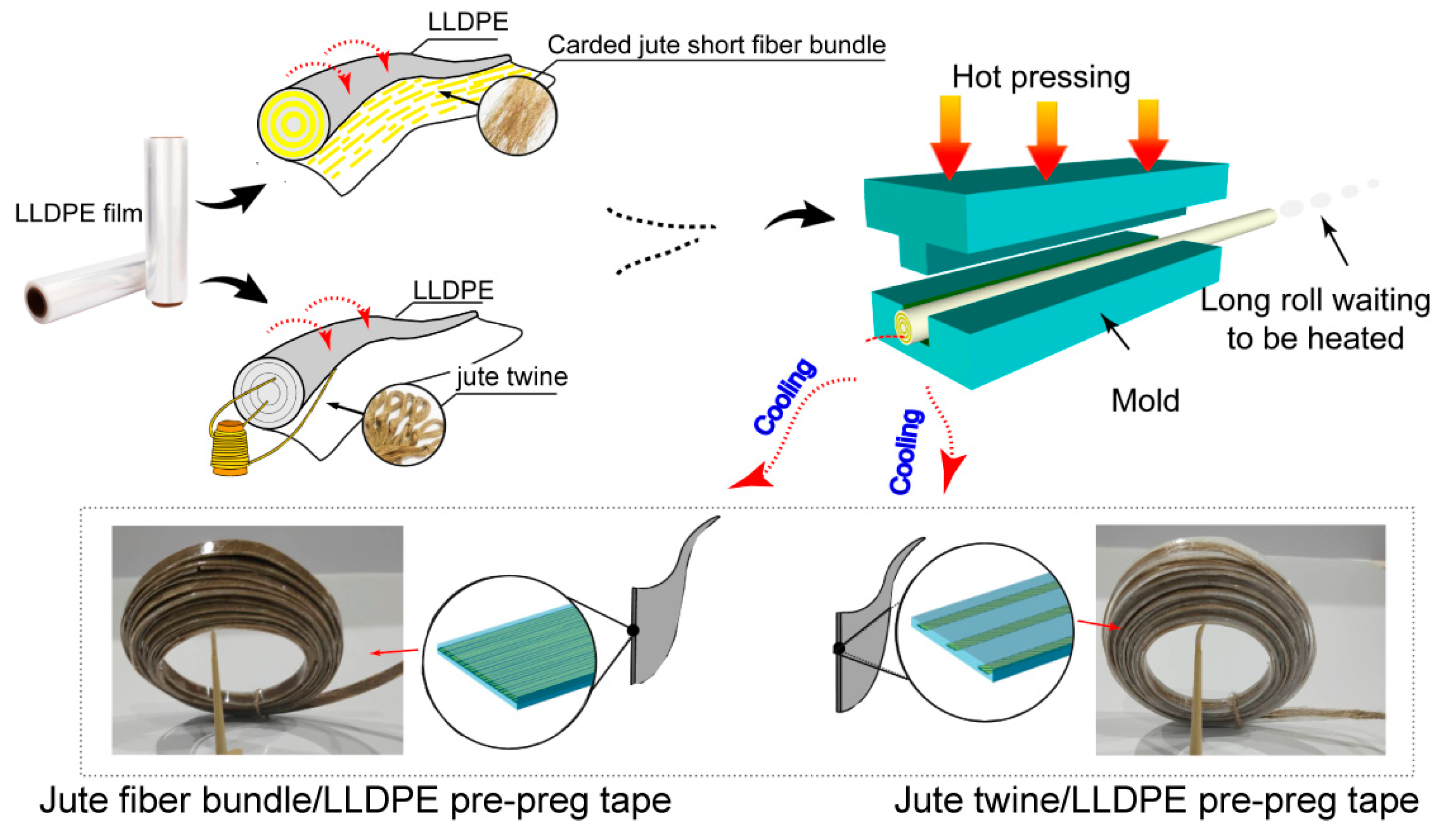

2.2. Fabrication of Jute Fiber Bundle/LLDPE and Jute Twine/LLDPE Pre-Pregs

3. Characterization

3.1. Void Content

3.2. Morphological Analysis

3.3. Mechanical Testing

3.3.1. Tensile Test for Jute Fiber Bundles and Twisted Jute Ropes

3.3.2. Tensile Testing on Pre-Pregs and Their Winding Specimens

3.3.3. Ring Stiffness Testing on Pre-Preg Winding Specimens

3.4. Statistical Analysis

4. Results and Discussion

4.1. Microstructure

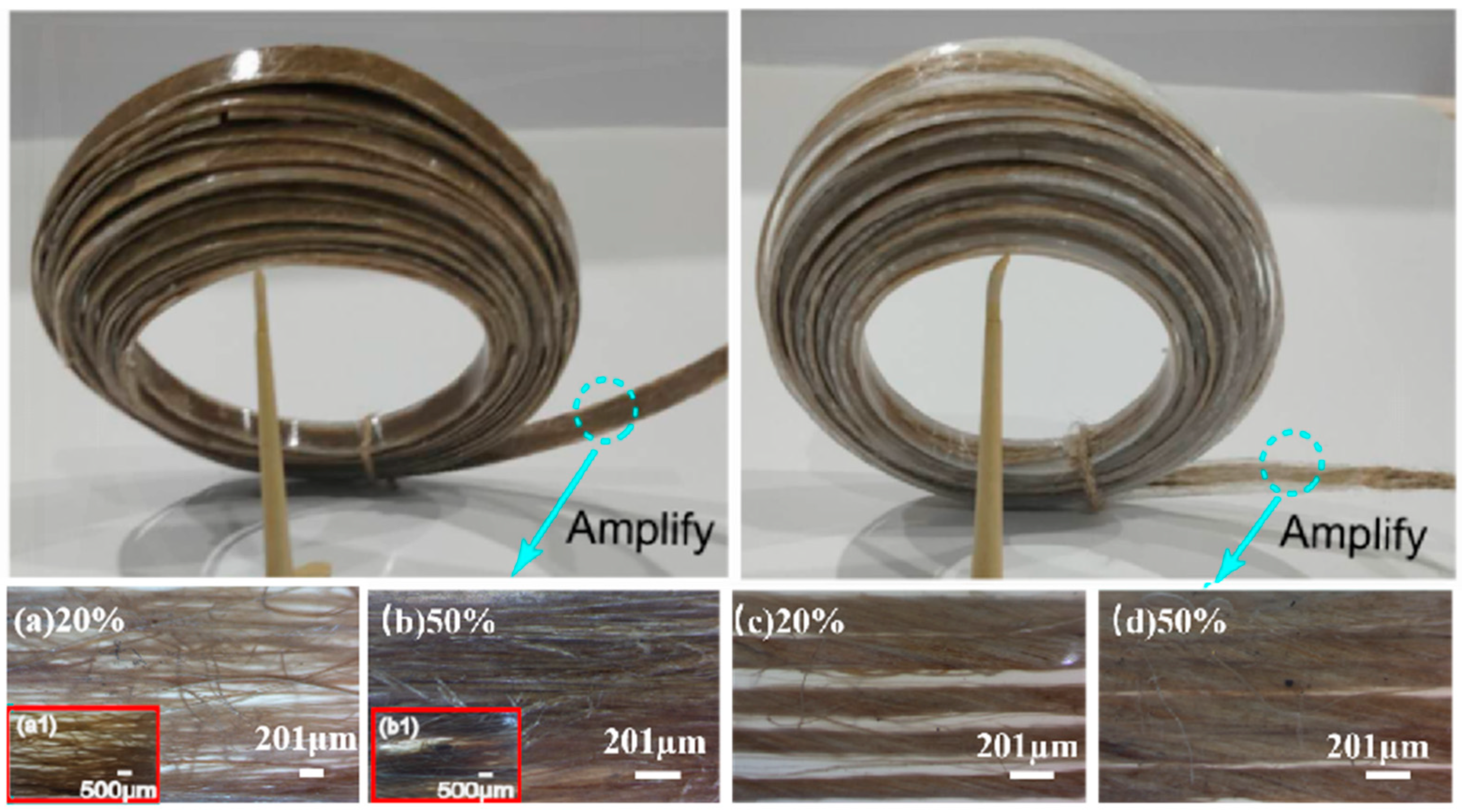

4.1.1. Planar Morphology of Jute Fiber Bundle/LLDPE and Twisted Jute Twine/LLDPE Pre-Pregs

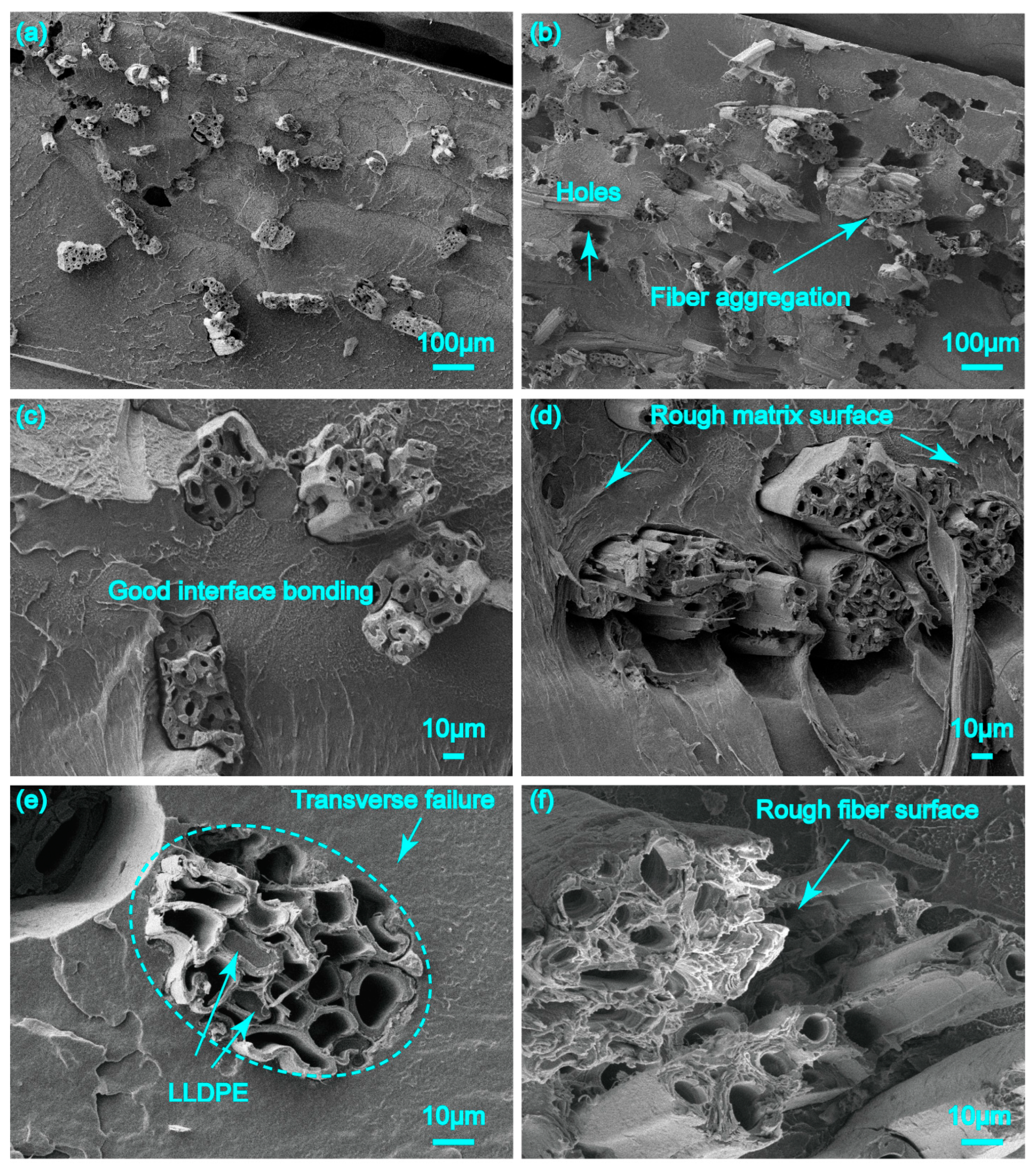

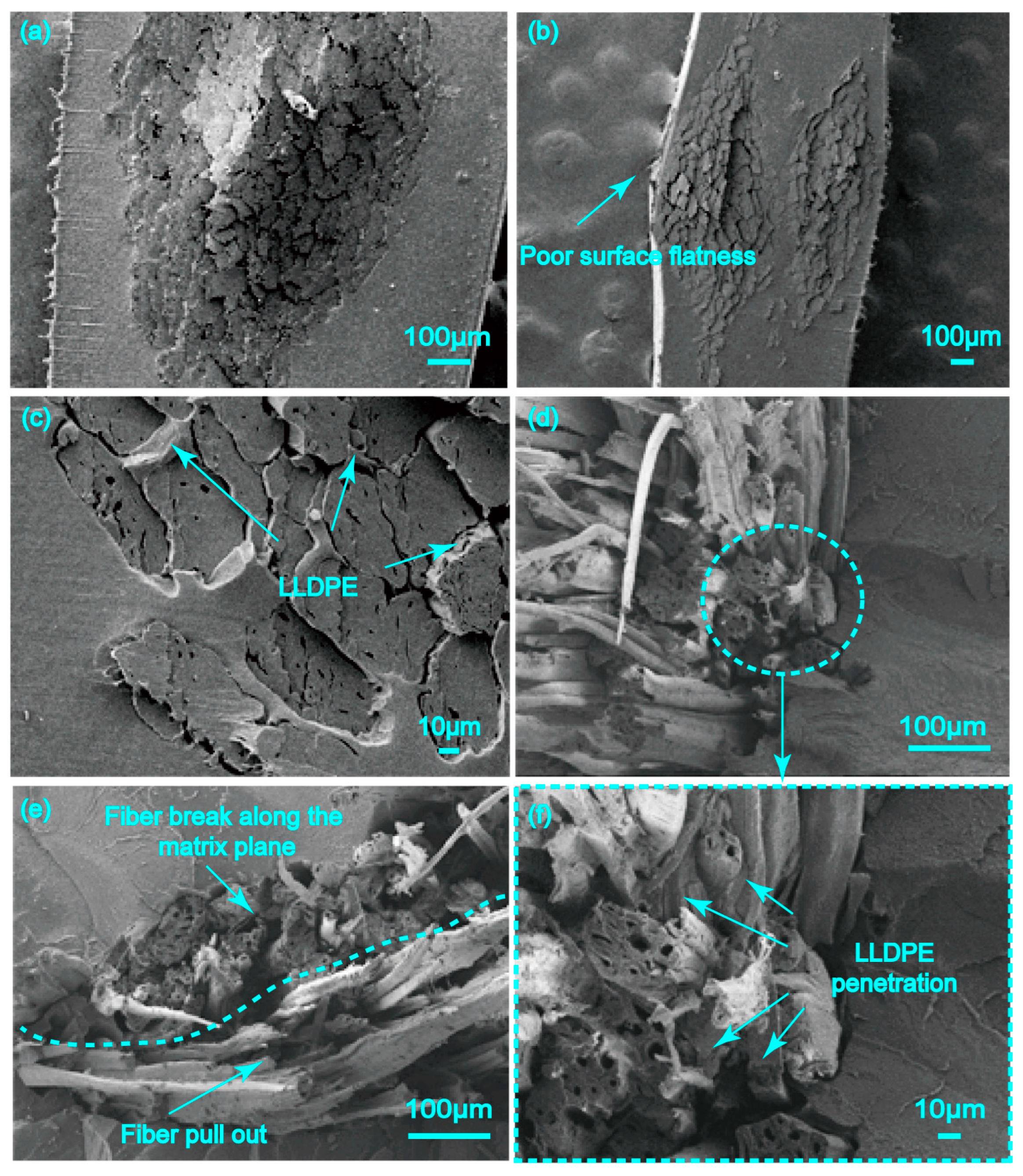

4.1.2. The Combination of Jute Fiber Bundle with LLDPE Matrix

4.1.3. The Combination of Twisted Jute Twine with LLDPE Matrix

4.2. Tensile Properties

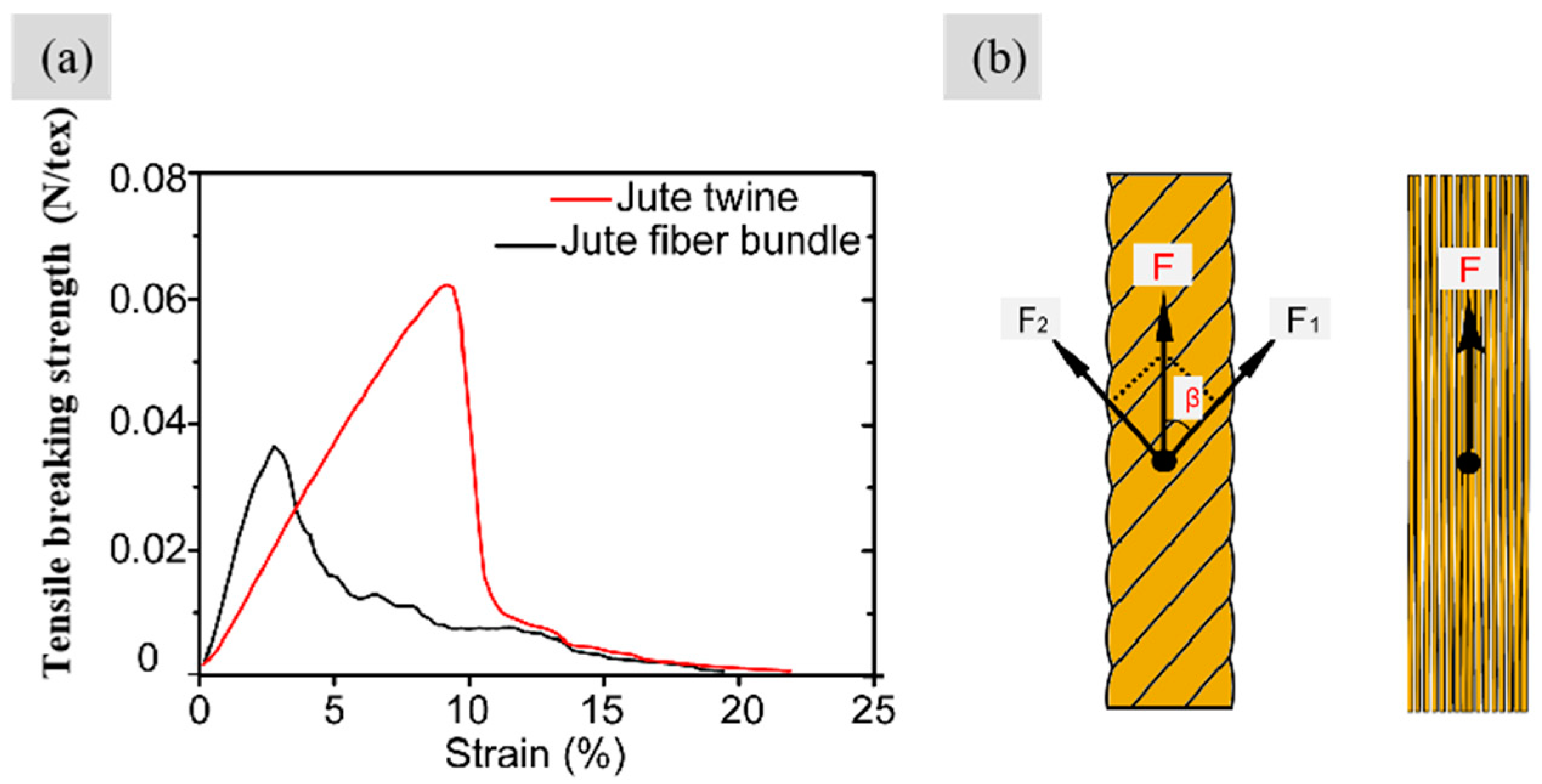

4.2.1. Tensile Breaking Strength of Jute Fiber Bundles and Twisted Jute Twines

4.2.2. Tensile Properties of the Pre-Pregs with Jute Fiber Bundle and Twisted Twine

4.2.3. Tensile Performance Evaluation of Developed Jute Pre-Pregs

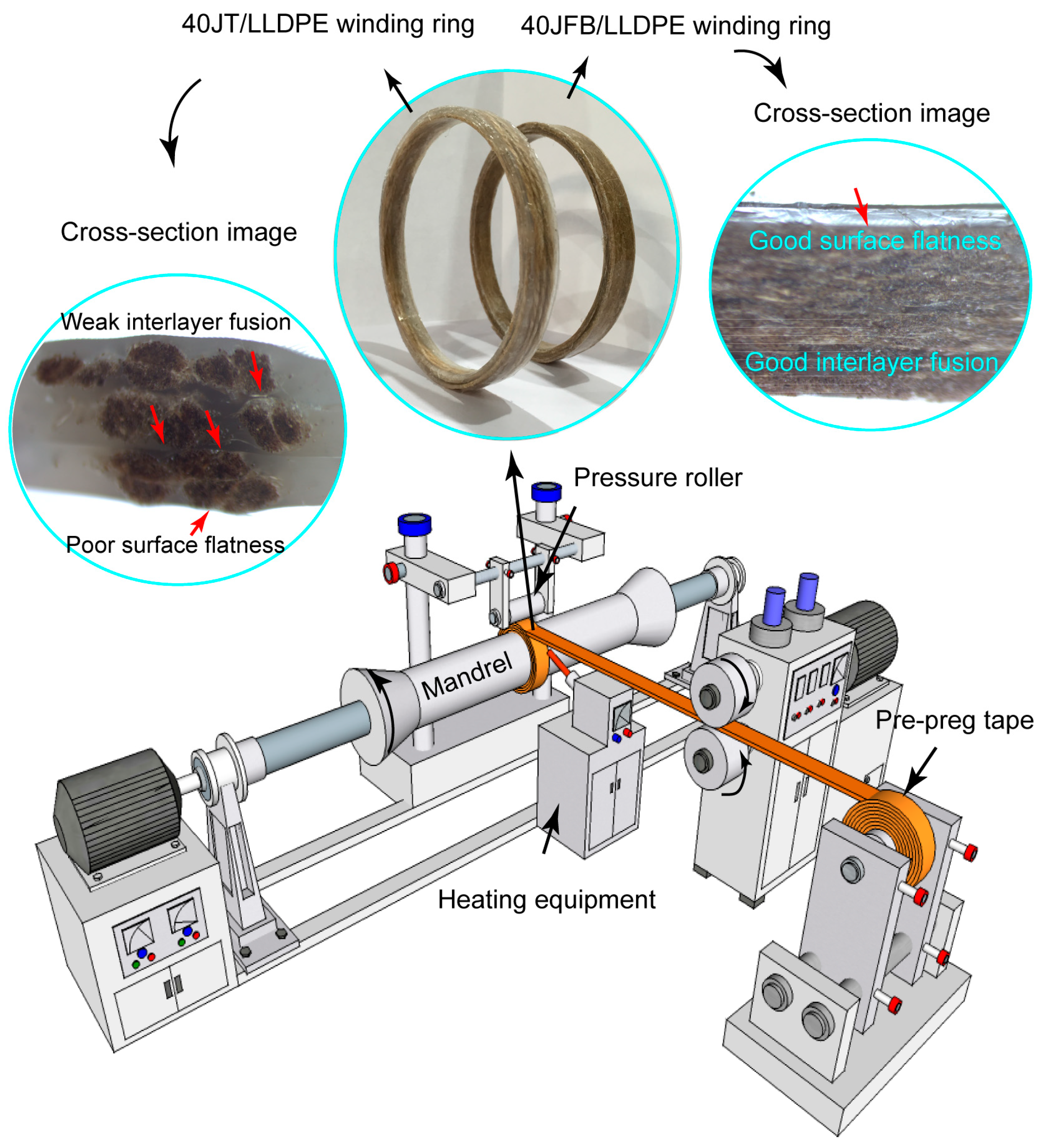

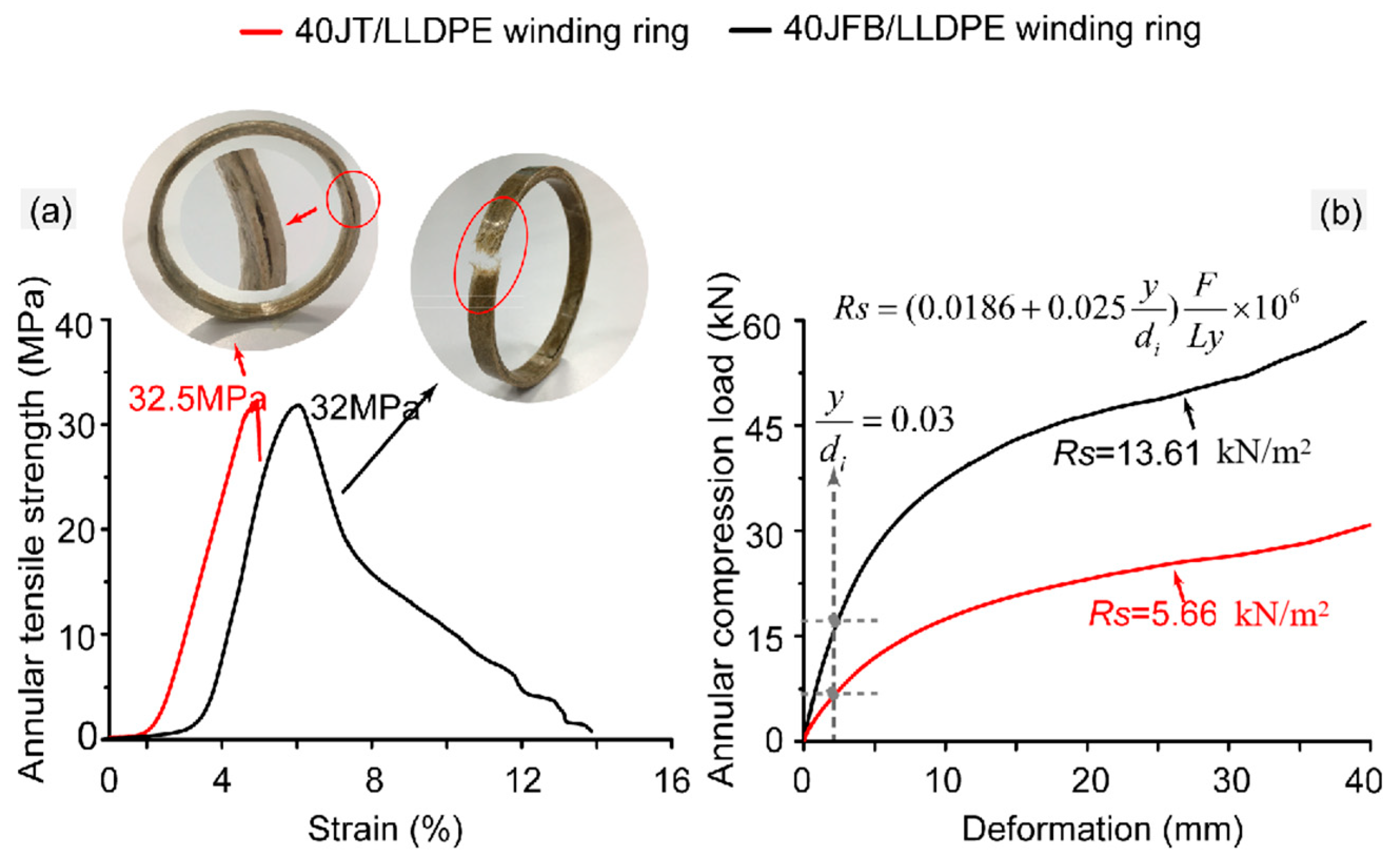

4.3. Filament Winding Demonstration of Developed Jute Pre-Preg Tapes

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Vashisth, A.; Healey, R.E.; Pospisil, M.J.; Oh, J.H.; Green, M.J. Continuous processing of pre-pregs using radio frequency heating. Compos. Sci. Technol. 2020, 195, 108211. [Google Scholar] [CrossRef]

- Clancy, G.; Peeters, D.; O’Higgins, D.; Weaver, P.M. In-line variable spreading of carbon fibre/thermoplastic pre-preg tapes for application in automatic tape placement. Mater. Des. 2020, 194, 108967. [Google Scholar] [CrossRef]

- Sava, L.A.; Tayfun, U.; Dogan, M. The use of polyethylene copolymers as compatibilizers in carbon fiber reinforced high density polyethylene composites. Compos. Part B Eng. 2016, 99, 188–195. [Google Scholar] [CrossRef]

- Dun, M.Y.; Hao, J.X.; Wang, W.H.; Wang, G.; Cheng, H.T. Sisal fiber reinforced high density polyethylene pre-preg for potential application in filament winding. Compos. Part B Eng. 2019, 159, 369–377. [Google Scholar] [CrossRef]

- Mohanty, A.; Misra, M.; Drzal, L.; Selke, S.; Harte, B.R.; Hinrichsen, G. Natural Fibers, Biopolymers, and Biocomposites: An Introduction; CRC Press: Boca Raton, FL, USA, 2005; pp. 1–36. [Google Scholar] [CrossRef]

- Haghighatnia, T.; Abbasian, A.; Morshedian, J. Hemp fiber reinforced thermoplastic polyurethane composite: An investigation in mechanical properties. Ind. Crops Prod. 2017, 108, 853–863. [Google Scholar] [CrossRef]

- Huang, J.K.; Young, W.B. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites. Compos. Part B Eng. 2019, 166, 272–283. [Google Scholar] [CrossRef]

- Goutianos, S.; Peijs, T. The optimisation of flax fibre yarns for the development of high-performance natural fibre composites. Adv. Compos. Lett. 2003, 12, 237–241. [Google Scholar] [CrossRef]

- George, G.; Jose, E.T.; Jayanarayanan, K.; Nagarajan, E.; Skrifvars, M.; Joseph, K. Novel bio-commingled composites based on jute/polypropylene yarns: Effect of chemical treatments on the mechanical properties. Compos. Part A Appl. Sci. Manuf. 2012, 43, 219–230. [Google Scholar] [CrossRef]

- Khondker, O.A.; Ishiaku, U.S.; Nakai, A.; Hamada, H. A novel processing technique for thermoplastic manufacturing of unidirectional composites reinforced with jute yarns. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2274–2284. [Google Scholar] [CrossRef]

- Zhang, L.; Miao, M. Commingled natural fibre/polypropylene wrap spun yarns for structured thermoplastic composites. Compos. Sci. Technol. 2010, 70, 130–135. [Google Scholar] [CrossRef]

- Shah, D.; Schubel, P.J.; Clifford, M.J.; Licence, P. Mechanical property characterization of aligned plant yarn reinforced thermoset matrix composites manufactured via vacuum infusion. J. Macromol. Sci. Part D Rev. Polym. Process. 2014, 53, 239–253. [Google Scholar] [CrossRef]

- Wongsriraksa, P.; Togashi, K.; Nakai, A.; Hamada, H. Continuous Natural Fiber Reinforced Thermoplastic Composites by Fiber Surface Modification. Adv. Mech. Eng. 2013, 1, 143–148. [Google Scholar] [CrossRef]

- Sambandamoorthy, S.; Narayanan, V.; Chinnapandi, L.B.M.; Aziz, A. Impact of fiber length and surface modification on the acoustic behaviour of jute fiber. Appl. Acoust. 2021, 173, 107677. [Google Scholar] [CrossRef]

- Ranganathan, N.; Oksman, K.; Nayak, S.K.; Sain, M. Regenerated cellulose fibers as impact modifier in long jute fiber reinforced polypropylene composites: Effect on mechanical properties, morphology, and fiber breakage. J. Appl. Polym. Sci. 2014. [Google Scholar] [CrossRef]

- Fujiura, T.; Nakamura, R.; Tanaka, T.; Arao, Y. Effect of Jute Fiber’s Thermal Degradation on the Fiber Strength and its Polymer Composites. Adv. Mater. Res. 2015, 1110, 7–12. [Google Scholar] [CrossRef]

- Wanner, P. Plastic in agricultural soils—A global risk for groundwater systems and drinking water supplies?—A review. Chemosphere 2020, 264, 128453. [Google Scholar] [CrossRef]

- Muise, I.; Adams, M.; Côté, R.; Price, G.W. Attitudes to the recovery and recycling of agricultural plastics waste: A case study of Nova Scotia, Canada, Resources. Conserv. Recycl. 2016, 109, 137–145. [Google Scholar] [CrossRef]

- Xian, G.; Zhou, P.; Li, C.; Dong, S.; Du, H.; Tian, J.; Guo, R.; Peng, Z.; Zhang, Z.; He, T. Mechanical properties evaluation of glass fiber reinforced thermoplastic composite plate under combined bending loading and water immersion. Constr. Build. Mater. 2024, 440, 137470. [Google Scholar] [CrossRef]

- Lancioni, N.; Parlapiano, M.; Sgroi, M.; Giorgi, L.; Fusi, V.; Darvini, G.; Soldini, L.; Szeląg, B.; Eusebi, A.L.; Fatone, F. Polyethylene pipes exposed to chlorine dioxide in drinking water supply system: A critical review of degradation mechanisms and accelerated aging methods. Water Res. 2023, 238, 120030. [Google Scholar] [CrossRef]

- He, Z. Deformation analysis of tube specimen during ring hoop tension test. Acta Metall. Sin. 2008, 44, 423–427. [Google Scholar] [CrossRef]

- Gager, V.; Legland, D.; Bourmaud, A.; Le Duigou, A.; Pierre, F.; Behlouli, K.; Baley, C. Oriented granulometry to quantify fibre orientation distributions in synthetic and plant fibre composite preforms. Ind. Crops Prod. 2020, 152, 112548. [Google Scholar] [CrossRef]

- Gao, J.; Lim, B.H.; Zhai, X.; Nie, Y.; Kedir, N.; Chen, W. Failure behaviors of single high-performance fibers under transverse dynamic cut. Int. J. Impact Eng. 2020, 144, 103660. [Google Scholar] [CrossRef]

- Madsen, B.; Hoffmeyer, P.; Thomsen, A.B.; Lilholt, H. Hemp yarn reinforced composites-I. Yarn characteristics. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2194–2203. [Google Scholar] [CrossRef]

- Sun, B.L.; Chen, P.; Li, W.; Lu, C. Prepreg Preparation and Filament Winding of Advanced Thermoplastic Composites. Fiber Compos. 2009, 26, 43–48. [Google Scholar] [CrossRef]

- Facca, G.A.; Kortschot, T.M.; Yan, N. Predicting the tensile strength of natural fibre reinforced thermoplastics. Compos. Sci. Technol. 2007, 67, 2454–2466. [Google Scholar] [CrossRef]

- Rahaman, N.; Hossain, S.; Razzak; Uddin, M.B.; Chowdhury, A.; Khan, R.A. Effect of dye and temperature on the physico-mechanical properties of jute/PP and jute/LLDPE based composites. Heliyon 2019, 5, e01753. [Google Scholar] [CrossRef]

- Choudhury, A.; Adhikari, B. Recycled milk pouch and virgin LDPE-LLDPE-based jute fiber composites. Polym. Compos. 2007, 28, 78–88. [Google Scholar] [CrossRef]

- Hidalgo-Salazar, A.M.; Juan, P.C. Mechanical and thermal properties of biocomposites from nonwoven industrial Fique fiber mats with Epoxy Resin and Linear Low Density Polyethylene. Results Phys. 2018, 8, 461–467. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, M. Injection Molded Sustainable Biocomposites From Poly(butylene succinate) Bioplastic and Perennial Grass. ACS Sustain. Chem. Eng. 2015, 3, 2767–2776. [Google Scholar] [CrossRef]

- Kabir, M.; Huque, M.; Islam, M.; Bledzki, A. Mechanical properties of jute fiber reinforced polypropylene composite; effect of chemical treatment by benzenediazonium salt in alkaline medium. J. Reinf. Plast. Compos. 2010, 29, 1618–1625. [Google Scholar] [CrossRef]

- Dick, C.P.; Korkolis, Y.P. Mechanics and full-field deformation study of the Ring Hoop Tension Test. Int. J. Solids Struct. 2014, 51, 3042–3057. [Google Scholar] [CrossRef]

| Pre-Preg | Ratio of Jute to LLDPE | Label | Void Content (%) |

|---|---|---|---|

| Jute fiber bundle/LLDPE | 20:80 | 20JFB/LLDPE | 3.80 |

| 30:70 | 30JFB/LLDPE | 4.31 | |

| 40:60 | 40JFB/LLDPE | 5.04 | |

| 50:50 | 50JFB/LLDPE | 6.22 | |

| Jute twine/LLDPE | 20:80 | 20JT/LLDPE | 5.80 |

| 30:70 | 30JT/LLDPE | 6.40 | |

| 40:60 | 40JT/LLDPE | 7.55 | |

| 50:50 | 50JT/LLDPE | 8.80 |

| Samples | Linear Density Bρ (tex) | Breaking Load BF (N) | Breaking Strength BS (N/tex) |

|---|---|---|---|

| Jute twine | 2.3 × 103 | 140.77 | 61.2 × 10−3 |

| Jute fiber bundle | 1.9 × 103 | 69.16 | 36.4 × 10−3 |

| Constituents of the Composites | Forming Method | Tensile Strength of Matrix (MPa) | Tensile Strength of Composites (MPa) | Tensile Modulus of Compisites (GPa) | Reference |

|---|---|---|---|---|---|

| 30 wt.% Jute fiber/LLDPE | compression molding | - | 32 | 0.82 | (Niloy Rahaman et al., 2019) [27] |

| 30 wt.% jute fiber/35 wt.%LDPE/35 wt.%LLDPE | melt mixing + compression molding | 20.3 ± 0.7 | 16 | 0.53 | (Choudhury and Adhikari, 2007) [28] |

| 20 wt.% fique fiber mats/LLDPE | compression molding | 15 | 17.6 | 1.37 | (Hidalgo-Salazar and Juan, 2018) [29] |

| 30 wt.%/hemp fiber/HDPE | melt mixing + compression molding | 22 | 33 | - | (Facca et al., 2007) [26] |

| 30 wt.% hemp fiber/Poly(ester amide) | Injection molding | 7 | 19 | 2 | (Muthuraj et al., 2015) [30] |

| 30 wt.% jute fiber/PP | Injection molding | 28.5 | 27.5 | 1.75 | (Kabir et al., 2010) [31] |

| 30 wt.% silane treated E-glass fiber/HDPE | melt mixing + compression molding | 22 | 34 | - | (Facca et al., 2007) [26] |

| Pre-Preg Wound Specimen | Ats (MPa) | Rs (kN/m2) |

|---|---|---|

| 40JFB/LLDPE | 32 ± 0.92 a | 13.61 ± 0.31 c |

| 40JT/LLDPE | 32.5 ± 1.43 a | 5.66 ± 0.13 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dun, M.; Fu, H.; Hao, J.; Wang, W. Development of Short Jute Fiber-Reinforced Thermoplastic Pre-Preg Tapes. Polymers 2025, 17, 388. https://doi.org/10.3390/polym17030388

Dun M, Fu H, Hao J, Wang W. Development of Short Jute Fiber-Reinforced Thermoplastic Pre-Preg Tapes. Polymers. 2025; 17(3):388. https://doi.org/10.3390/polym17030388

Chicago/Turabian StyleDun, Mengyuan, Haitao Fu, Jianxiu Hao, and Weihong Wang. 2025. "Development of Short Jute Fiber-Reinforced Thermoplastic Pre-Preg Tapes" Polymers 17, no. 3: 388. https://doi.org/10.3390/polym17030388

APA StyleDun, M., Fu, H., Hao, J., & Wang, W. (2025). Development of Short Jute Fiber-Reinforced Thermoplastic Pre-Preg Tapes. Polymers, 17(3), 388. https://doi.org/10.3390/polym17030388