Study on Deposition of Coaxial Electrospinning Fibers by Coaxial Auxiliary Flow Field

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

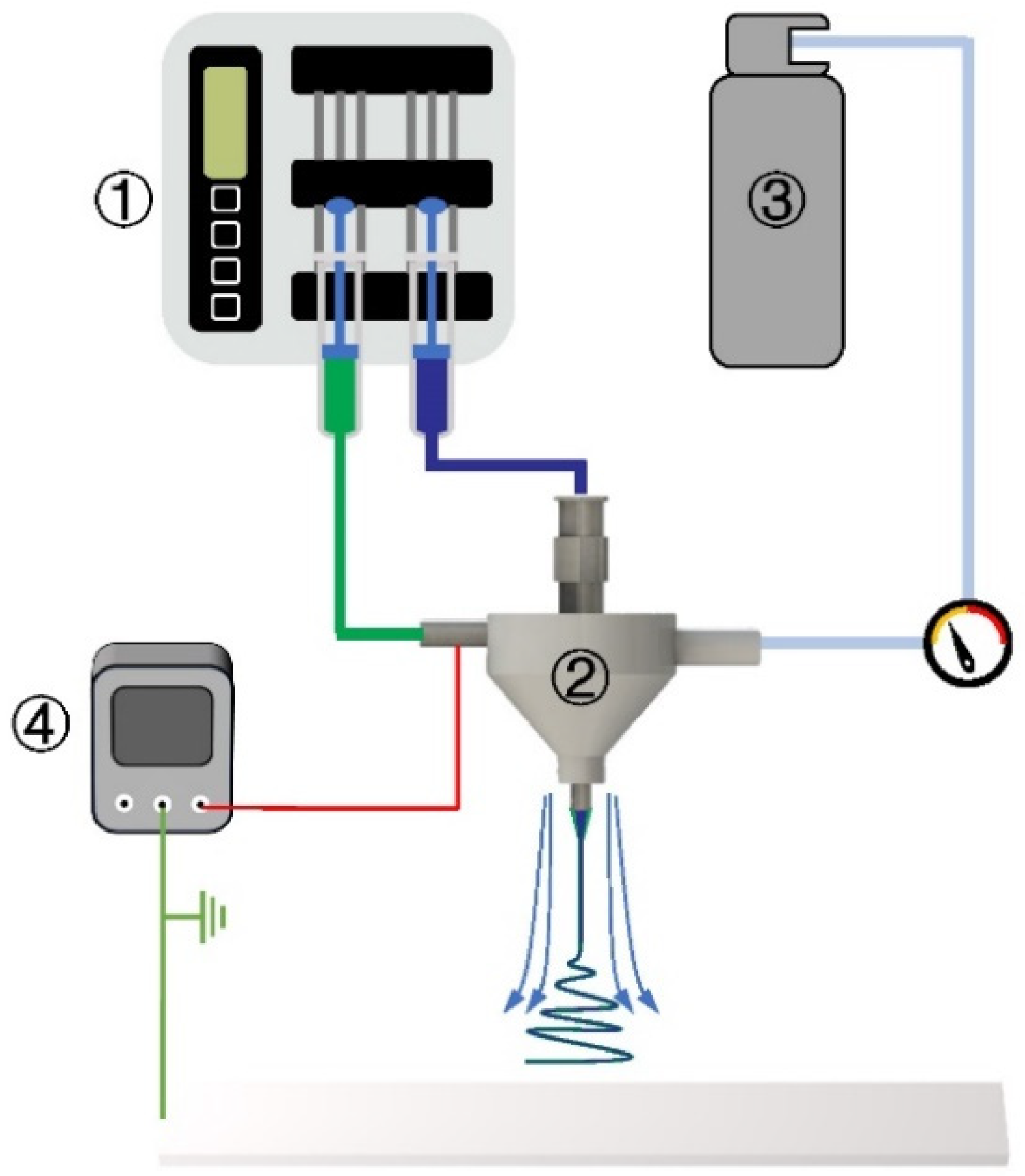

2.2. Fabrication of Nanofiber Membrane

2.3. Characterization and Deposition Evaluation of Nanofibers

2.4. Numerical Simulation of Flow Field

3. Results and Discussion

3.1. Theoretical Research of Electrospinning Instability by Introducing Coaxial Gas Flow

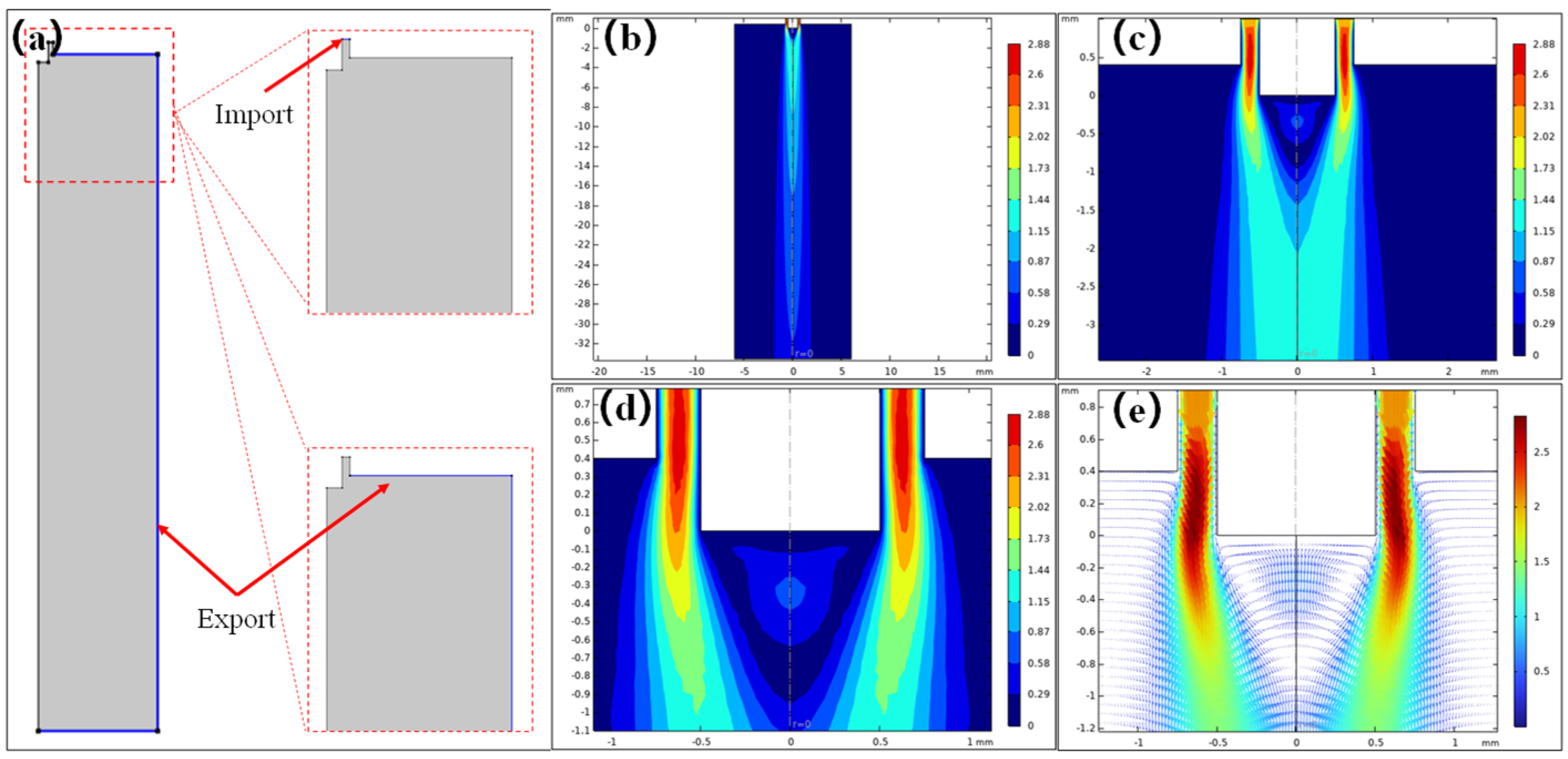

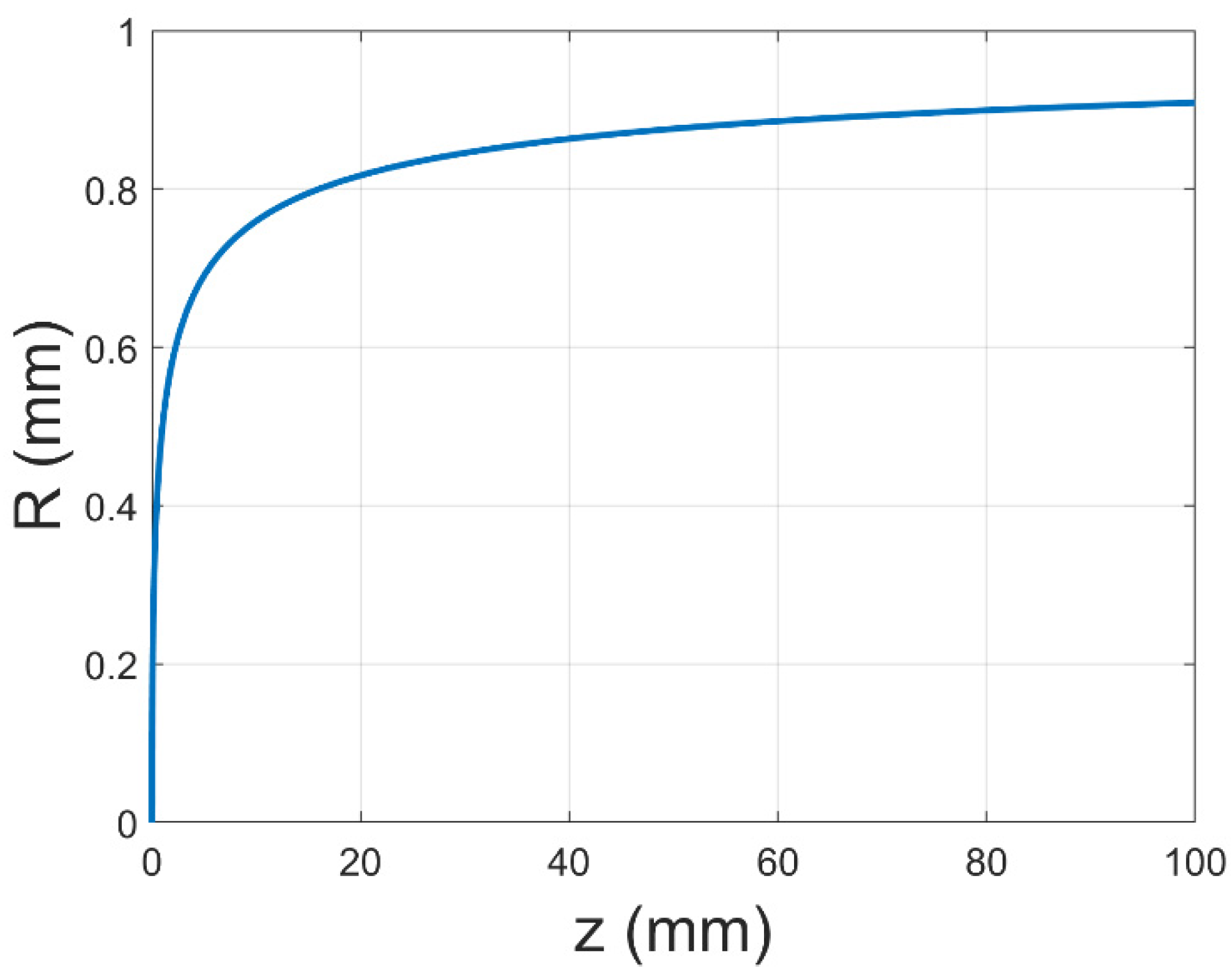

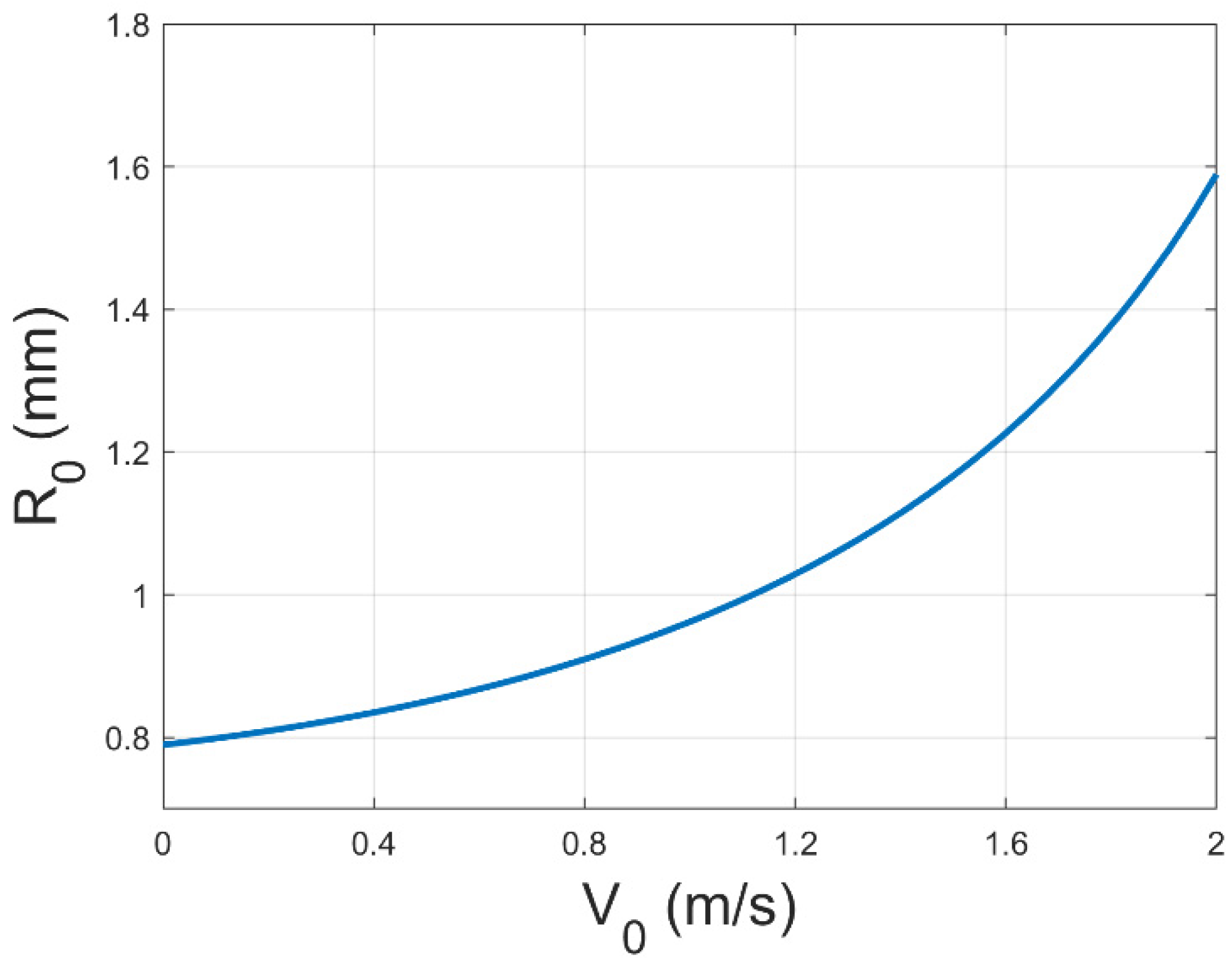

3.1.1. Simulation Analysis of Flow Field in Auxiliary Flow Coaxial Electrospinning

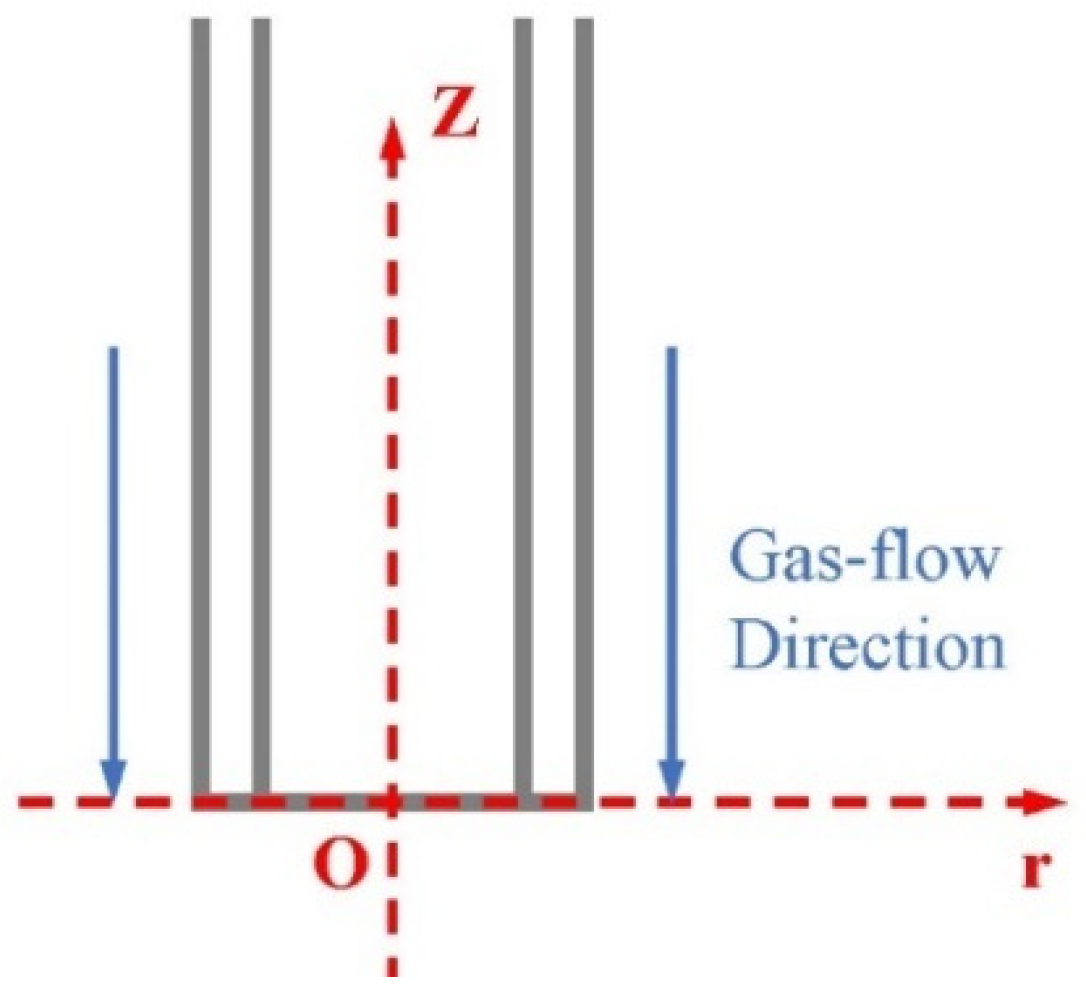

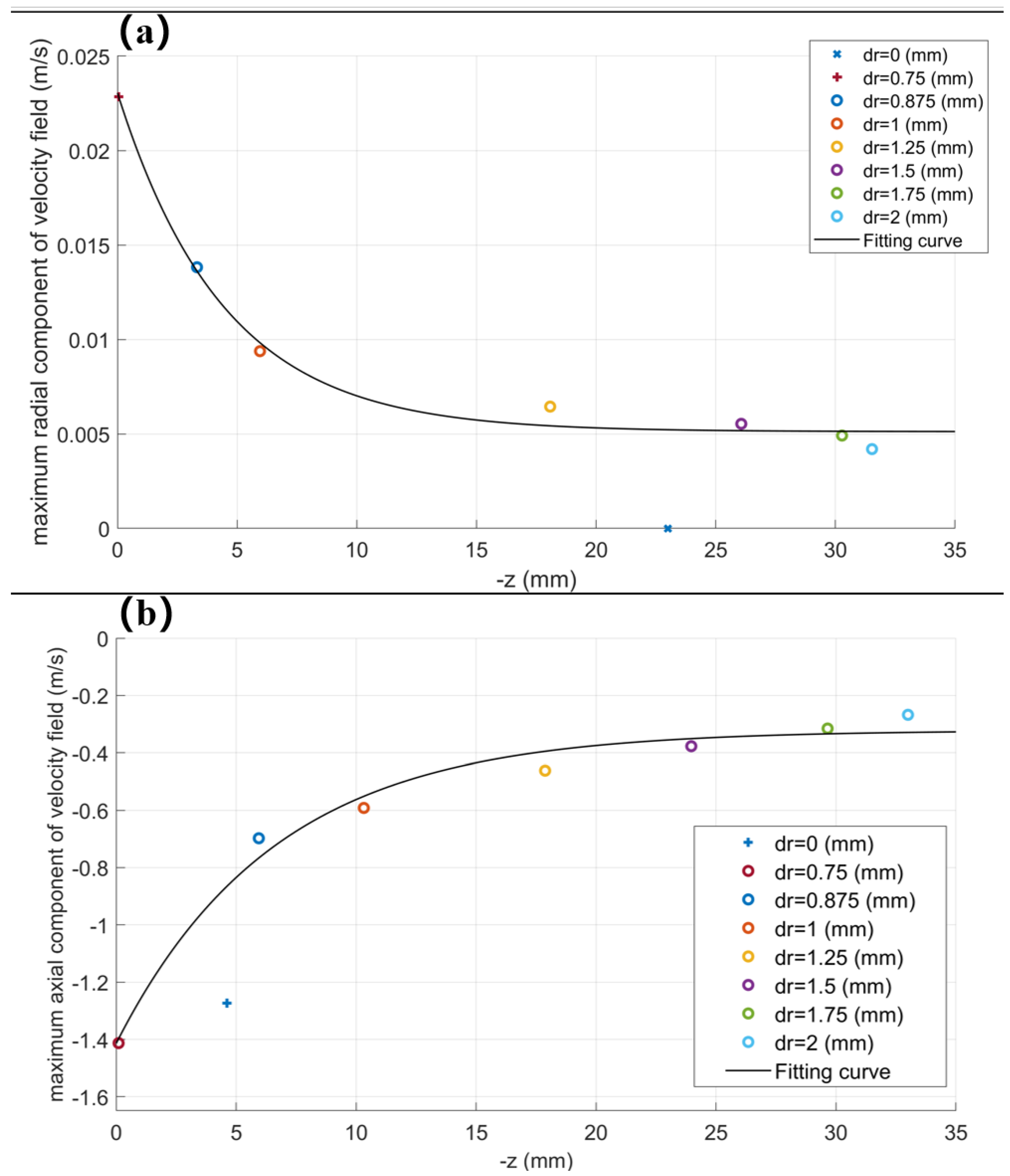

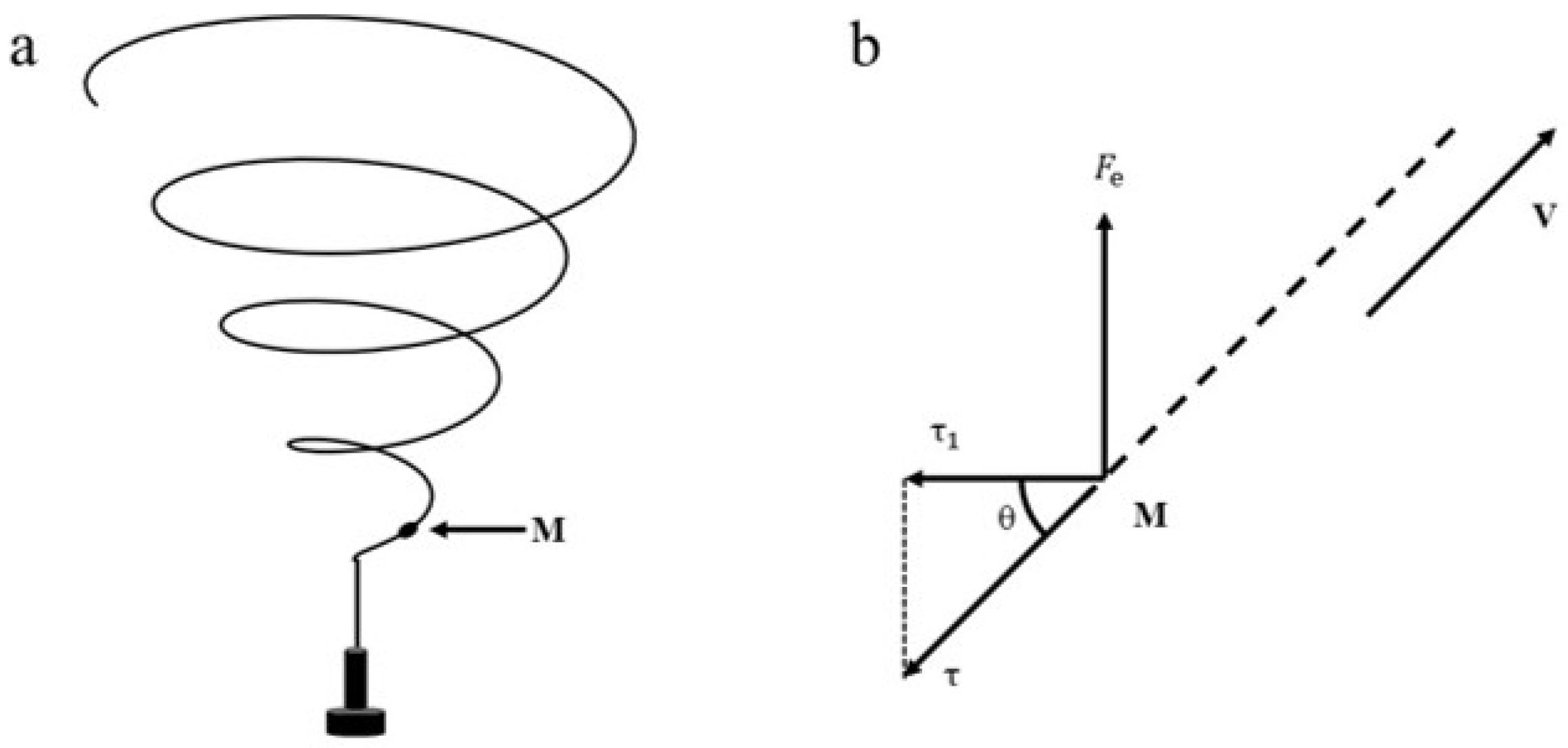

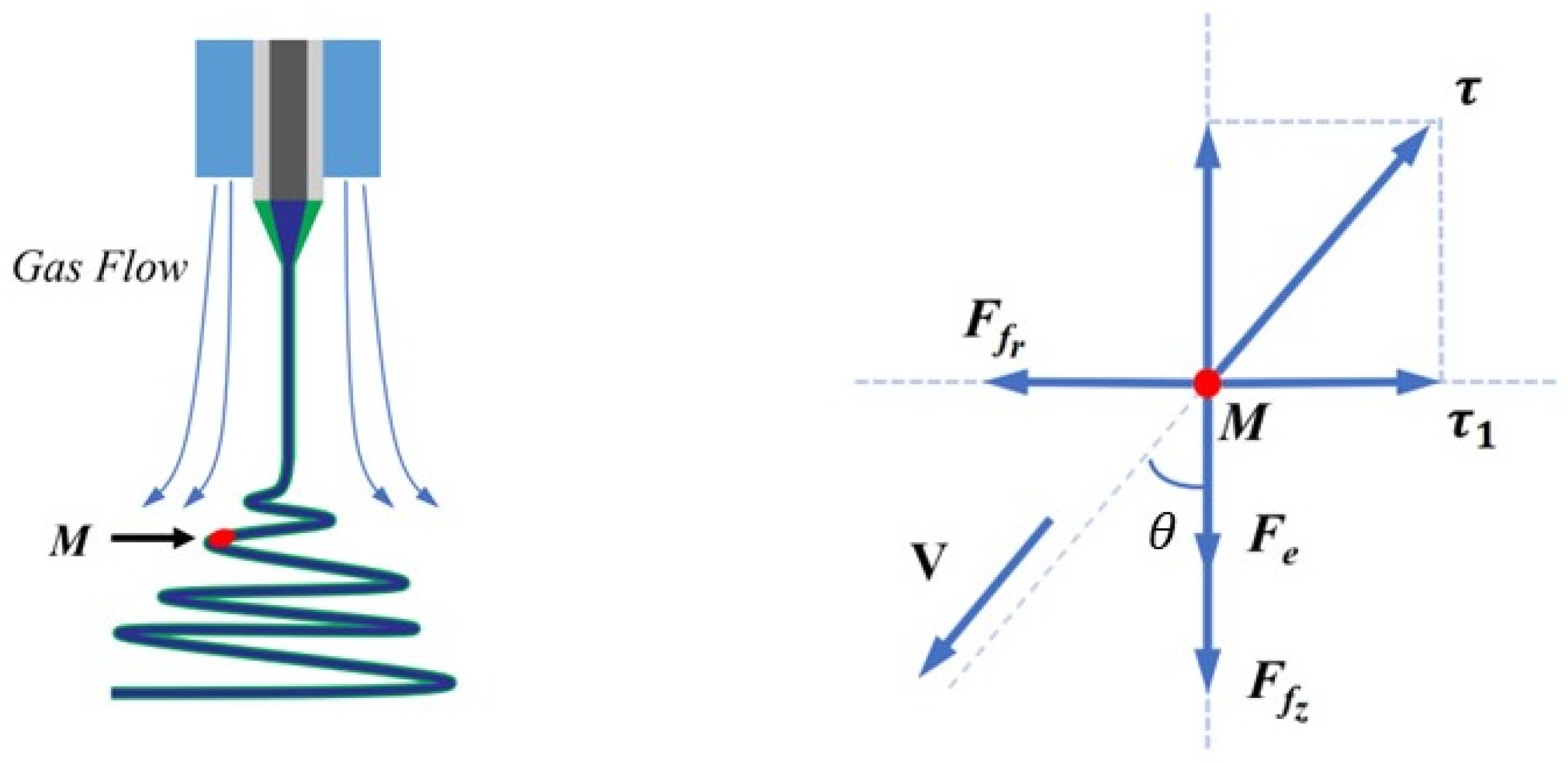

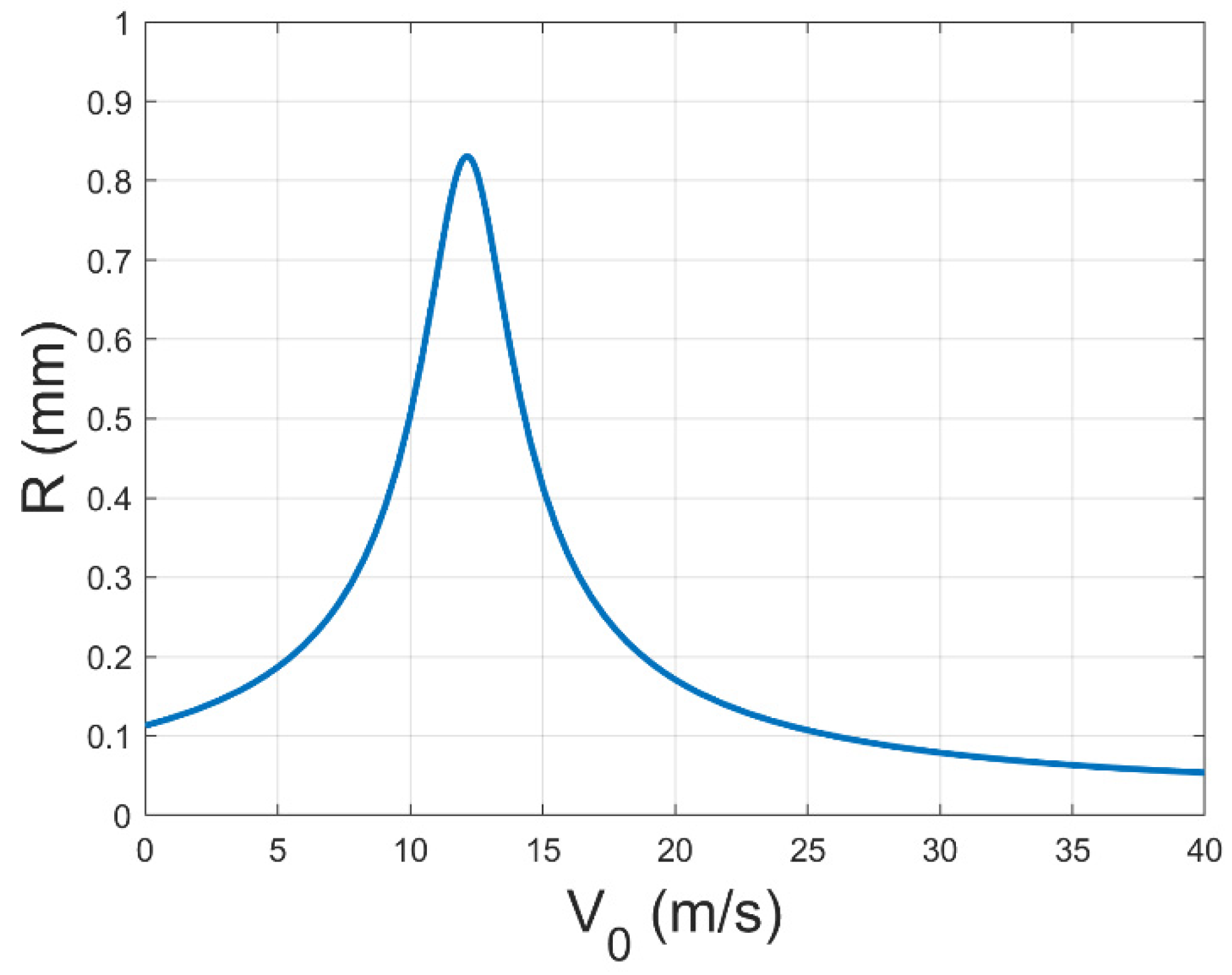

3.1.2. Mechanical Modeling and Analysis of Auxiliary Flow Coaxial Electrospinning Jet

3.2. Experimental Verification

3.2.1. Effect of Coaxial Gas Flow on Coaxial Fiber Deposition Area and Uniformity

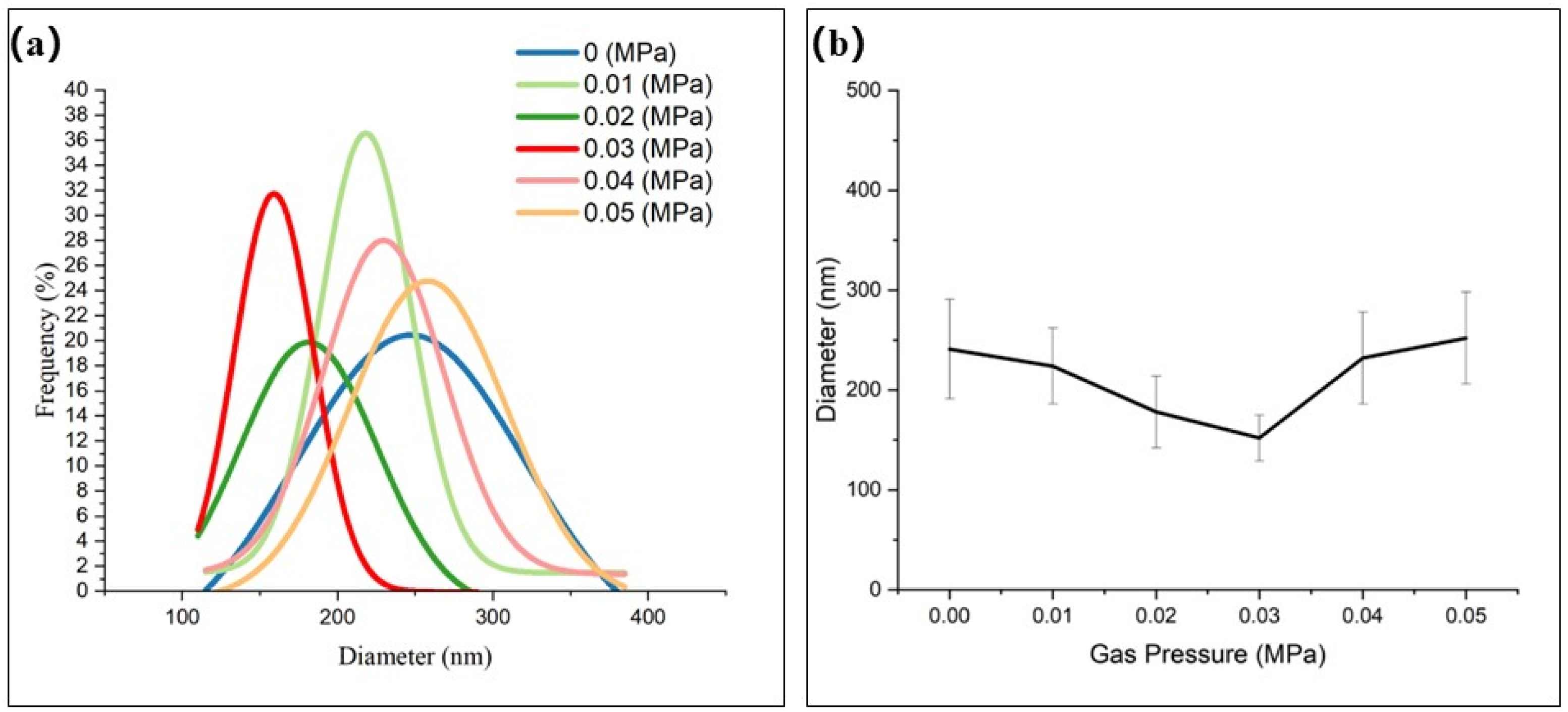

3.2.2. Effect of Coaxial Gas Flow on Coaxial Fiber Morphology and Diameter Distribution

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhi, D.; Li, T.; Qi, Z.; Li, J.; Tian, Y.; Deng, W.; Meng, F. Core-shell heterogeneous graphene-based aerogel microspheres for high-performance broadband microwave absorption via resonance loss and sequential attenuation. Chem. Eng. J. 2022, 433, 134496. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, L.; Zhu, Y.; Wang, L.; Yu, D.G.; Liu, L.Y. Tri-Layer Core–Shell Fibers from Coaxial Electrospinning for a Modified Release of Metronidazole. Pharmaceutics 2023, 15, 2561. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Xiao, X.; Fu, J.; Huan, C.; Qi, S.; Zhan, Y.; Zhu, Y.; Xu, G. Novel smart textile with phase change materials encapsulated core-sheath structure fabricated by coaxial electrospinning. Chem. Eng. J. 2019, 355, 532–539. [Google Scholar] [CrossRef]

- Pant, B.; Park, M.; Park, S.-J. Drug Delivery Applications of Core-Sheath Nanofibers Prepared by Coaxial Electrospinning, A Review. Pharmaceutics 2019, 11, 305. [Google Scholar] [CrossRef] [PubMed]

- Han, D.A.J. Coaxial Electrospinning Formation of Complex Polymer Fibers and their Applications. ChemPlusChem 2019, 84, 1453–1497. [Google Scholar] [CrossRef]

- Bognitzki, M.; Hou, H.; Ishaque, M.; Frese, T.; Hellwig, M.; Schwarte, C.; Schaper, A.; Wendorff, J.H.; Greiner, A. Polymer, metal, and hybrid nano and mesotubes by coating degradable polymer template fibers (TUFT process). Adv. Mater. 2000, 12, 637–640. [Google Scholar] [CrossRef]

- Liu, G.; Qiao, L.; Guo, A. Diblock copolymer nanofibers. Macromolecules 1996, 29, 5508–5510. [Google Scholar] [CrossRef]

- Jang, J.; Lim, B.; Lee, J.; Hyeon, T. Fabrication of a novel polypyrrole/poly (methyl methacrylate) coaxial nanocable using mesoporous silica as a nanoreactor. Chem. Commun. 2001, 1, 83–84. [Google Scholar] [CrossRef]

- Rashedi, S.; Afshar, S.; Rostamic, A.; Ghazalian, M.; Nazockdaste, H. Co-electrospinning poly (lactic acid)/gelati nanofibrous scaffold prepared by a new solvent system, morphological, mechanical and in vitro degradability properties. Int. J. Polym. Mater. Polym. Biomater. 2021, 70, 545–553. [Google Scholar] [CrossRef]

- Mahmood, K.; Kamilah, H.; Karim, A.A.; Ariffin, F. Enhancing the functional properties of fish gelatin mats by dual encapsulation of essential oils in β-cyclodextrins/fish gelatin matrix via coaxial electrospinning. Food Hydrocoll. 2023, 137, 108324. [Google Scholar] [CrossRef]

- Anaya Mancipe, J.M.; Boldrini Pereira, L.C.; de Miranda Borchio, P.G.; Dias, M.L.; da Silva Moreira Thiré, R.M. Novel polycaprolactone (PCL)-type I collagen core-shell electrospinning nanofibers for wound healing applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2023, 111, 366–381. [Google Scholar] [CrossRef] [PubMed]

- Ji, W.; Yang, F.; Beucken, J.J.v.D.; Bian, Z.; Fan, M.; Chen, Z.; Jansen, J.A. Fibrous scaffolds loaded with protein prepared by blend or coaxial electrospinning. Acta Biomater. 2010, 6, 4199–4207. [Google Scholar] [CrossRef] [PubMed]

- Movahedi, M.; Asefnejad, A.; Rafienia, M.; Khorasani, M.T. Potential of novel electrospinning core-shell structured polyurethane/starch (hyaluronic acid) nanofibers for skin tissue engineering, In vitro and in vivo evaluation. Int. J. Biol. Macromol. 2020, 146, 627–637. [Google Scholar] [CrossRef]

- Vysloužilová, L.; Valtera, J.; Pejchar, K.; Beran, J.; Lukáš, D. Design of coaxial needleless electrospinning electrode with respect to the distribution of electric field. Appl. Mech. Mater. 2014, 693, 394–399. [Google Scholar] [CrossRef]

- Vysloužilová, L.; Buzgo, M.; Pokorný, P.; Chvojka, J.; Míčková, A.; Rampichová, M.; Kula, J.; Pejchar, K.; Bílek, M.; Lukáš, D.; et al. Needleless coaxial electrospinning, A novel approach to mass production of coaxial nanofibers. Int. J. Pharm. 2017, 516, 293–300. [Google Scholar] [CrossRef]

- Buzgo, M.; Mickova, A.; Rampichova, M.; Doupnik, M. Blend electrospinning, coaxial electrospinning, and emulsion electrospinning techniques. In Core-shell Nanostructures for Drug Delivery and Theranostics; Woodhead Publishing Series in Biomaterials: Duxford, UK, 2018; pp. 325–347. [Google Scholar] [CrossRef]

- Batka, O.; Skrivanek, J.; Beran, J. Optimizing the Shape of the Spinning Electrode for Needleless Coaxial Electrospinning. Appl. Sci. 2024, 14, 4638. [Google Scholar] [CrossRef]

- Magaz, A.; Roberts, A.D.; Faraji, S.; Nascimento, T.R.L.; Medeiros, E.S.; Zhang, W.; Greenhalgh, R.D.; Mautner, A.; Li, X.; Blaker, J.J. Porous, Aligned and Biomimetic Fibers of Regenerated Silk Fibroin Produced by Solution Blow Spinning. Biomacromolecules 2018, 19, 4542–4553. [Google Scholar] [CrossRef]

- Tandon, B.; Kamble, P.; Olsson, R.T.; Blaker, J.J.; Cartmell, S.H. Fabrication and Characterisation of Stimuli Responsive Piezoelectric PVDF and Hydroxyapatite-Filled PVDF Fibrous Membranes. Molecules 2019, 24, 1903. [Google Scholar] [CrossRef]

- Hwang, S.H.; Song, J.Y.; Ryu, H.I.; Oh, J.H.; Lee, S.; Lee, D.; Park, D.Y.; Park, S.M. Correction to: Adaptive Electrospinning System Based on Reinforcement Learning for Uniform-Thickness Nanofiber Air Filters. Adv. Fiber Mater. 2023, 5, 695. [Google Scholar] [CrossRef]

- Zhang, R.; Chen, X.; Wang, H.; Zeng, J.; Zhang, X.; Chen, X. Study on uniformity of multi-needle electrostatic spinning by auxiliary flow field. Micro Nano Letters. 2024, 19, e12200. [Google Scholar] [CrossRef]

- Ryu, H.I.; Koo, M.S.; Kim, S.; Kim, S.; Park, Y.A.; Park, S.M. Uniform-thickness electrospinning nanofibers mat production system based on real-time thickness measurement. Sci. Rep. 2020, 10, 20847. [Google Scholar] [CrossRef] [PubMed]

- Shao, Z.; Wang, Q.; Gui, Z.; Shen, R.; Chen, R.; Liu, Y.; Zheng, G. Electrospun bimodal nanofibrous membranes for high-performance, multifunctional, and light-weight air filtration, A review. Sep. Purif. Technol. 2024, 358, 130417. [Google Scholar] [CrossRef]

- Atif, R.; Combrinck, M.; Khaliq, J.; Hassanin, A.H.; Shehata, N.; Elnabawy, E.; Shyha, I. Solution Blow Spinning of High-Performance Submicron Polyvinylidene Fluoride Fibres, Computational Fluid Mechanics Modelling and Experimental Results. Polymers 2020, 12, 1140. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Chen, M.; Gao, Y.; Chen, Y.; Luo, Z.; Wang, H.; Fan, J.; Luo, J.; Ou, W.; Zeng, J.; et al. Gas-assisted electrospinning of high-performance ceramic fibers, Optimal design modelling and experimental results of the gas channel of the nozzle. Front. Mater. 2023, 10, 1113168. [Google Scholar] [CrossRef]

- Wan, Y. Research on Electrospinning Process Behavior and Vibration Electrospinning Technology. Ph.D. Thesis, Donghua University, Shanghai, China, 2006. [Google Scholar]

- Wu, Y. Research on the Jet Instability of Magnetio-Electrospinning. Ph.D. Thesis, Donghua University, Shanghai, China, 2008. [Google Scholar]

- Zhao, Y.; Jiang, J.; Li, W.; Wang, X.; Zhang, K.; Zhu, P.; Zheng, G. Electrospinning jet behaviors under the constraints of a sheath gas. AIP Adv. 2016, 6, 115022. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L.; Fong, H.; Koombhongse, S. Bending Instability of Electrically Charged Liquid Jets of Polymer Solutions in Electrospinning. J. Appl. Phys. 2000, 87, 4531–4547. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Chen, X.; Wang, H.; Sun, J.; Huang, S.; Zhang, X.; Long, J. Study on Deposition of Coaxial Electrospinning Fibers by Coaxial Auxiliary Flow Field. Polymers 2025, 17, 396. https://doi.org/10.3390/polym17030396

Zhang R, Chen X, Wang H, Sun J, Huang S, Zhang X, Long J. Study on Deposition of Coaxial Electrospinning Fibers by Coaxial Auxiliary Flow Field. Polymers. 2025; 17(3):396. https://doi.org/10.3390/polym17030396

Chicago/Turabian StyleZhang, Rongguang, Xun Chen, Han Wang, Jianfeng Sun, Shize Huang, Xuanzhi Zhang, and Jiecai Long. 2025. "Study on Deposition of Coaxial Electrospinning Fibers by Coaxial Auxiliary Flow Field" Polymers 17, no. 3: 396. https://doi.org/10.3390/polym17030396

APA StyleZhang, R., Chen, X., Wang, H., Sun, J., Huang, S., Zhang, X., & Long, J. (2025). Study on Deposition of Coaxial Electrospinning Fibers by Coaxial Auxiliary Flow Field. Polymers, 17(3), 396. https://doi.org/10.3390/polym17030396