Abrasive Water Jet Machining of Carbon Fiber-Reinforced PLA Composites: Optimization of Machinability and Surface Integrity for High-Precision Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

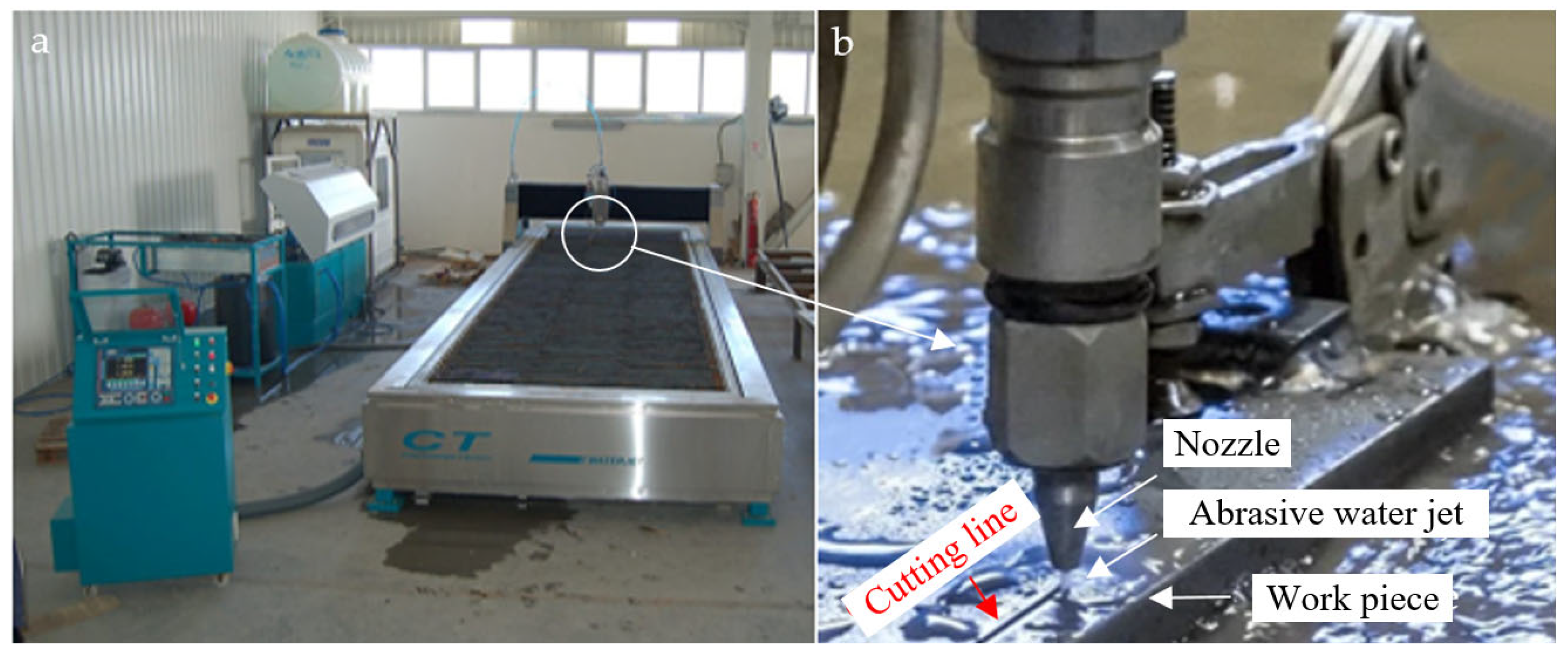

2.2. Machining Process

2.3. Experimental Design and Parameter Justification

2.4. Test Evaluation

3. Results and Discussions

3.1. Comparative Analysis with the Literature

3.2. Industrial Implications

3.3. Long-Term Performance Considerations

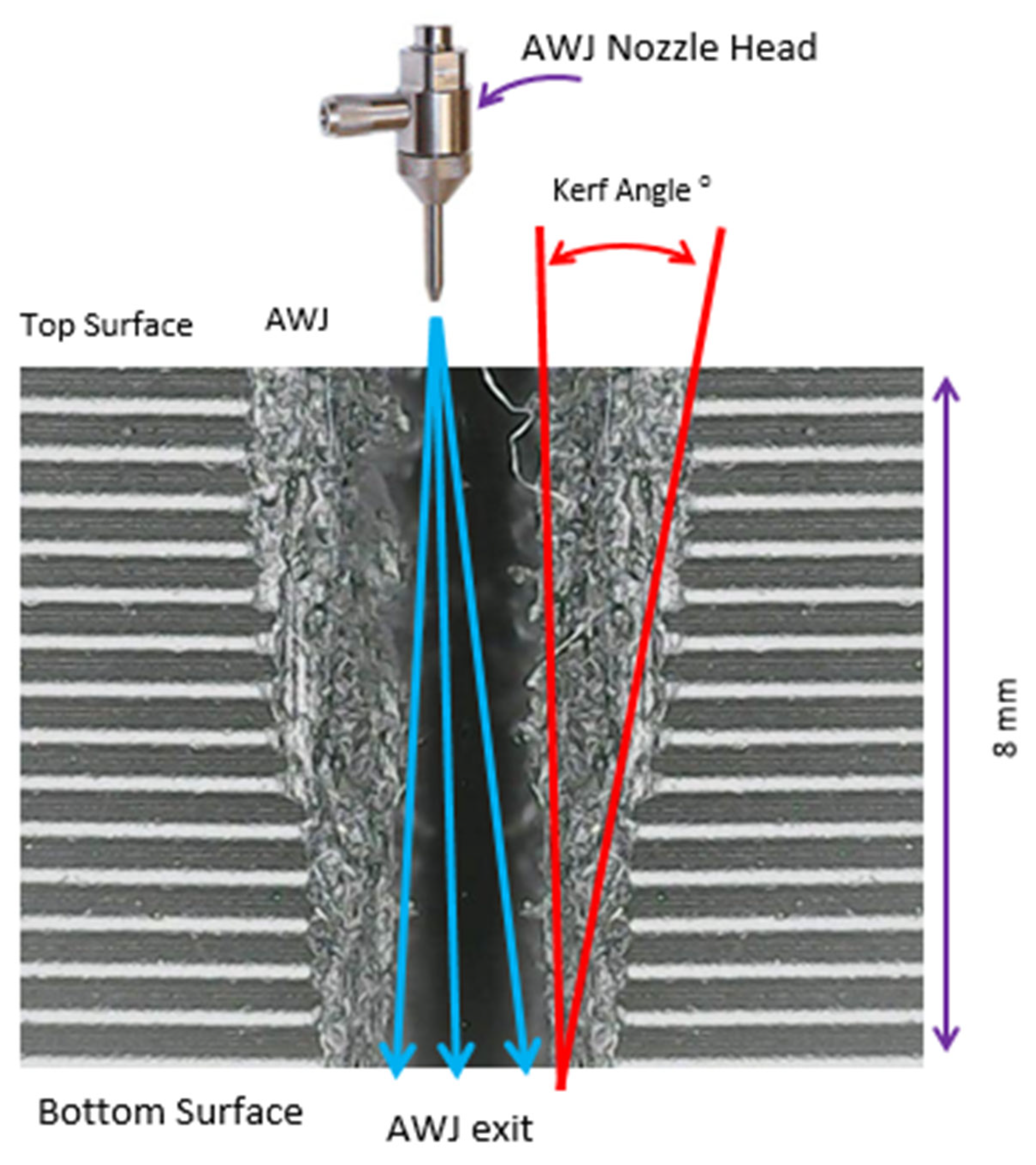

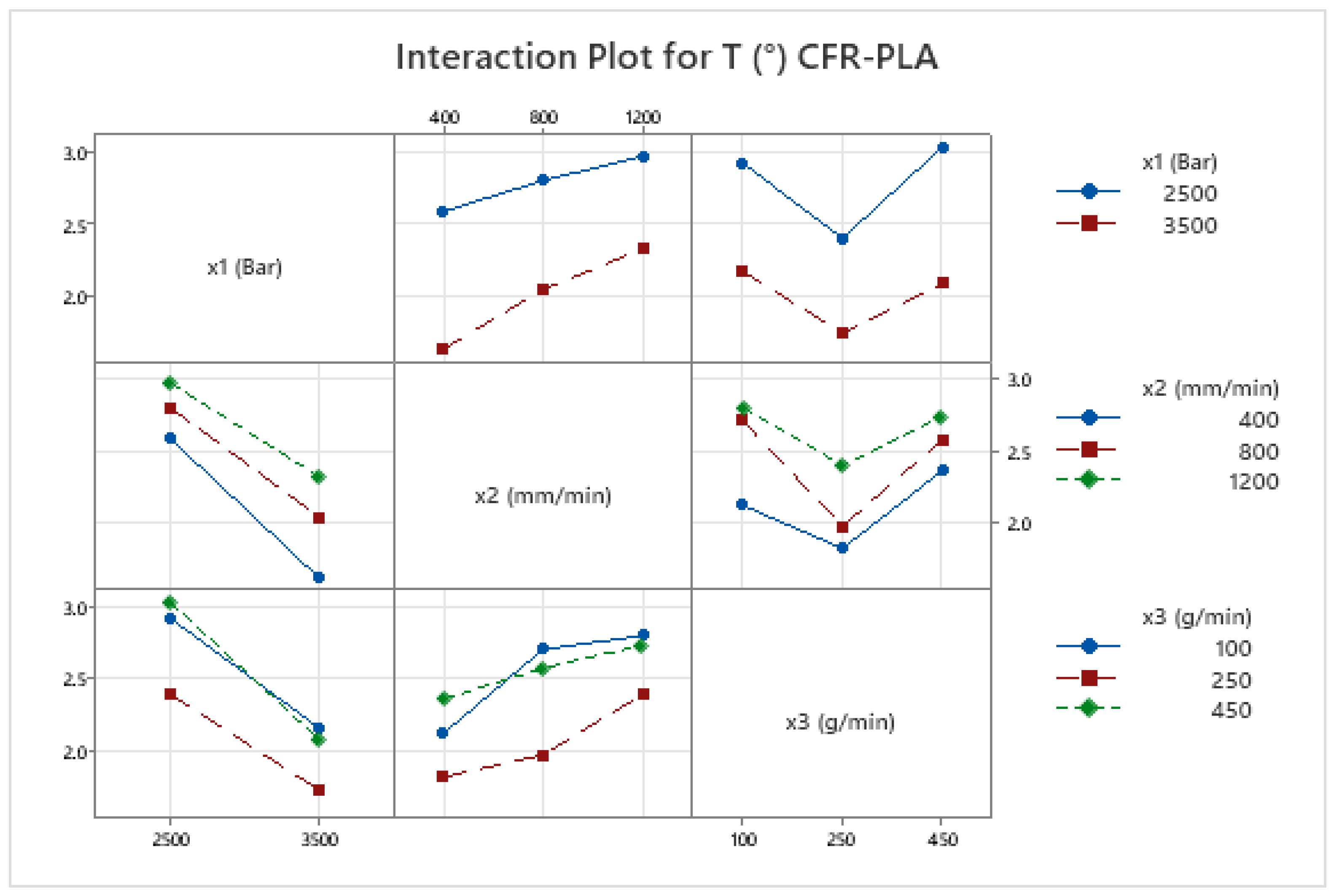

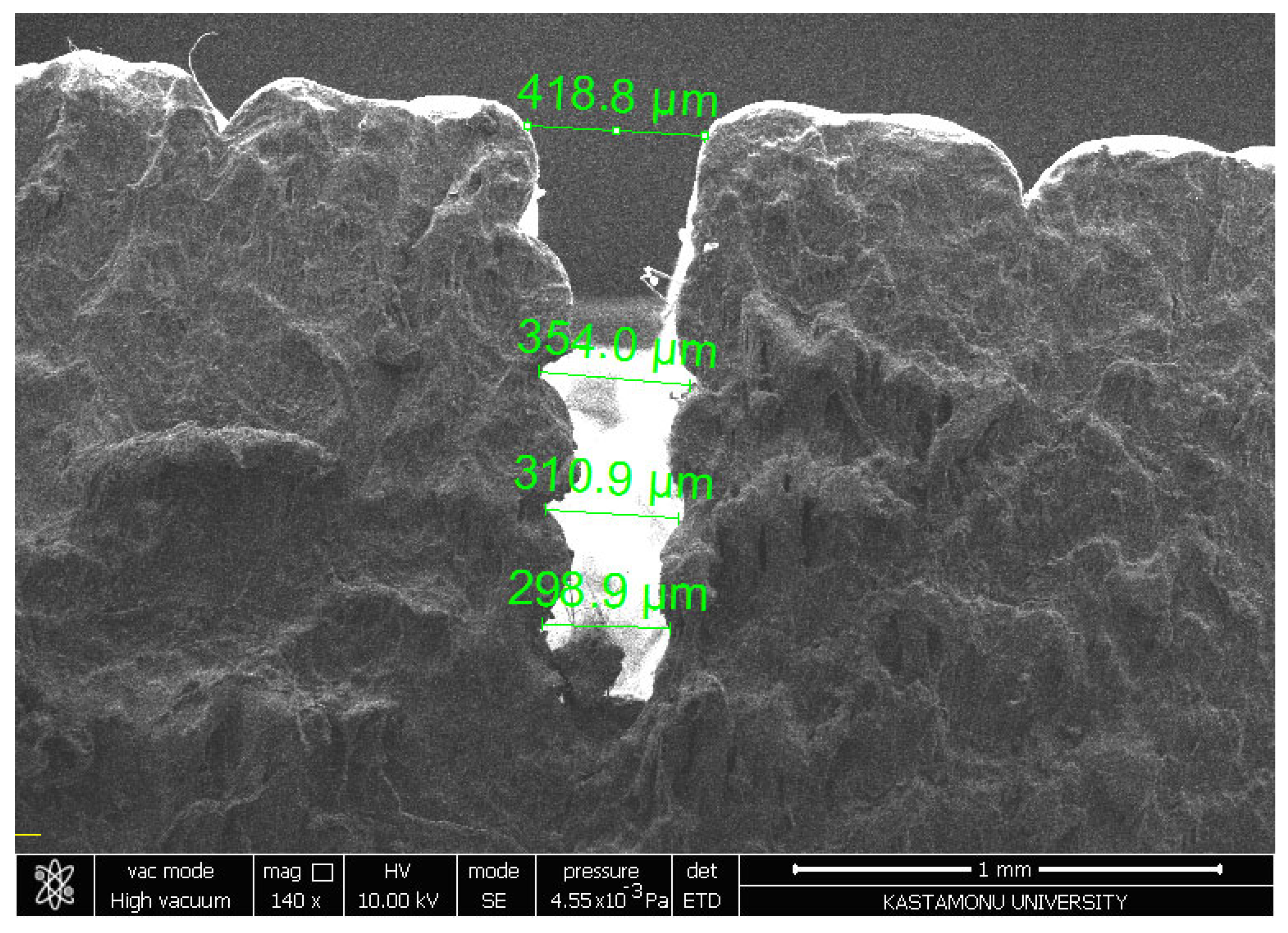

3.4. Kerf Taper Angle Analysis

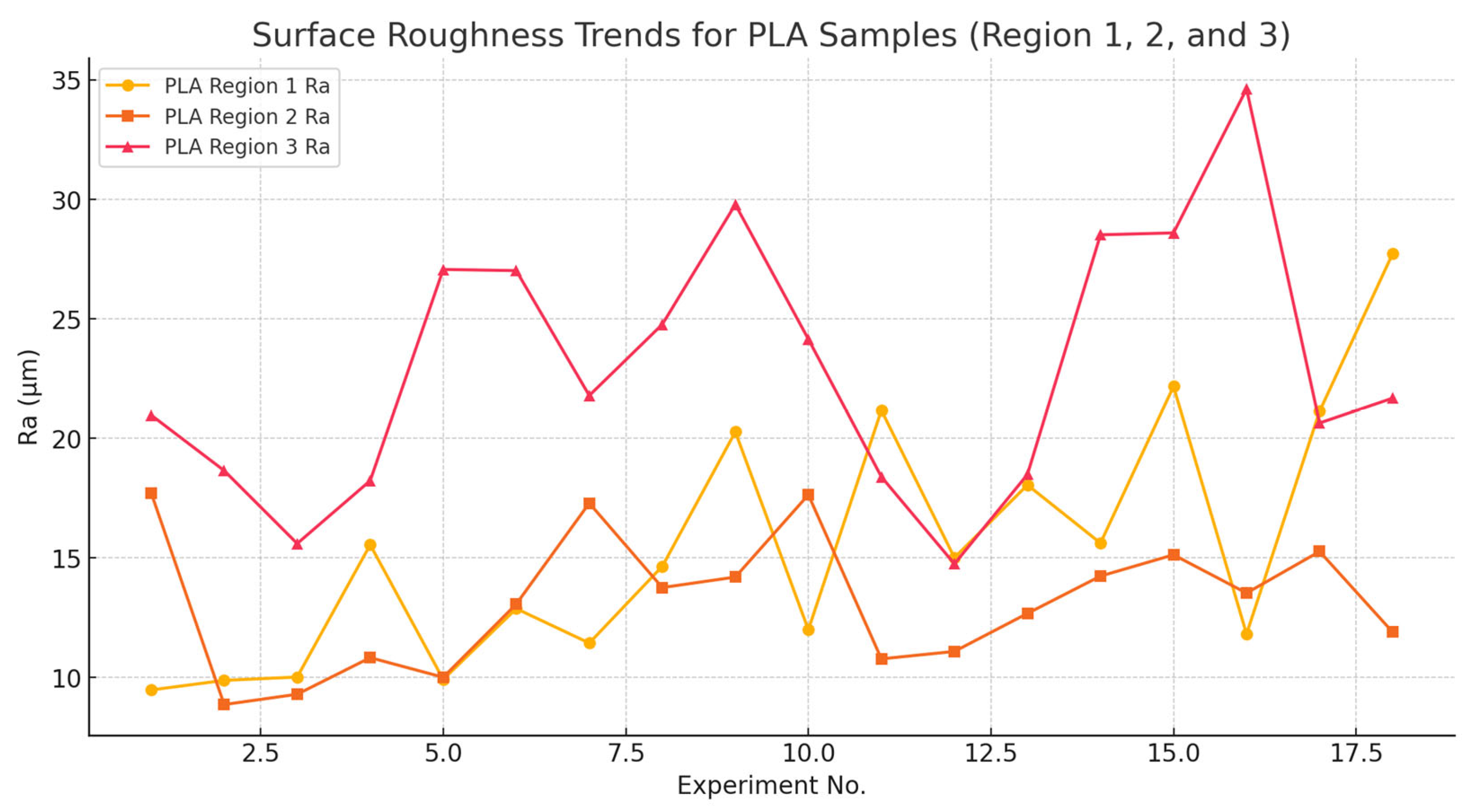

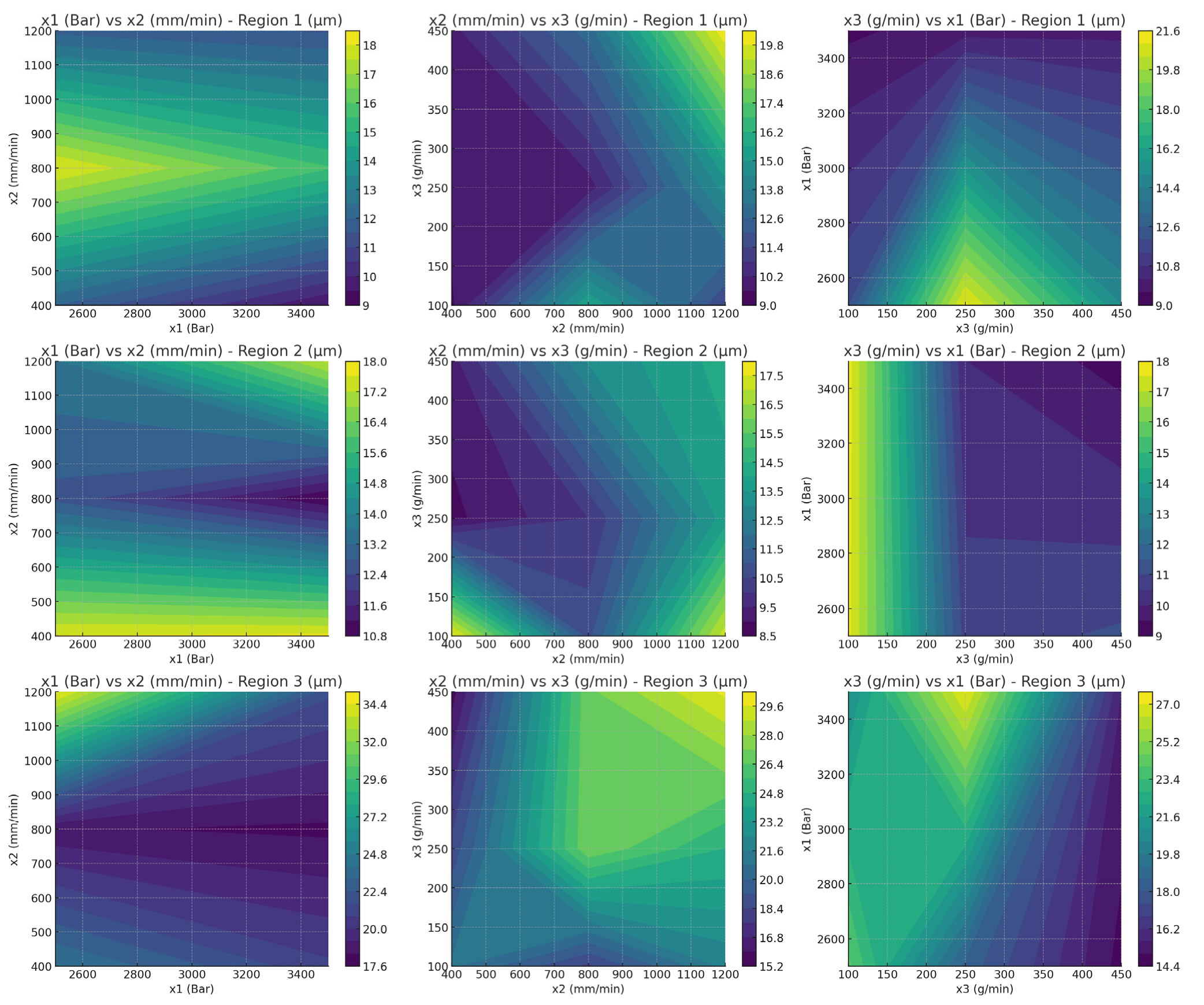

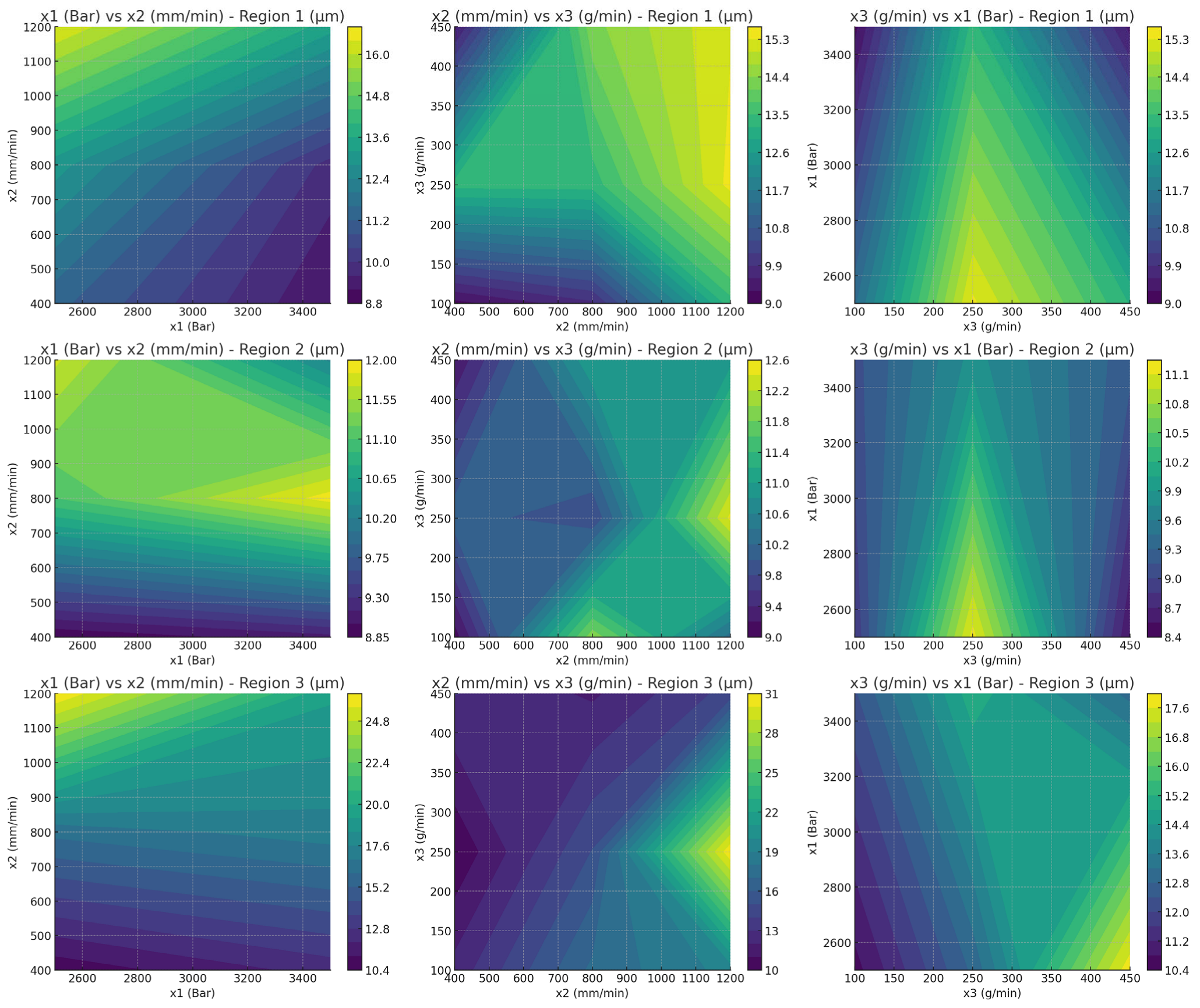

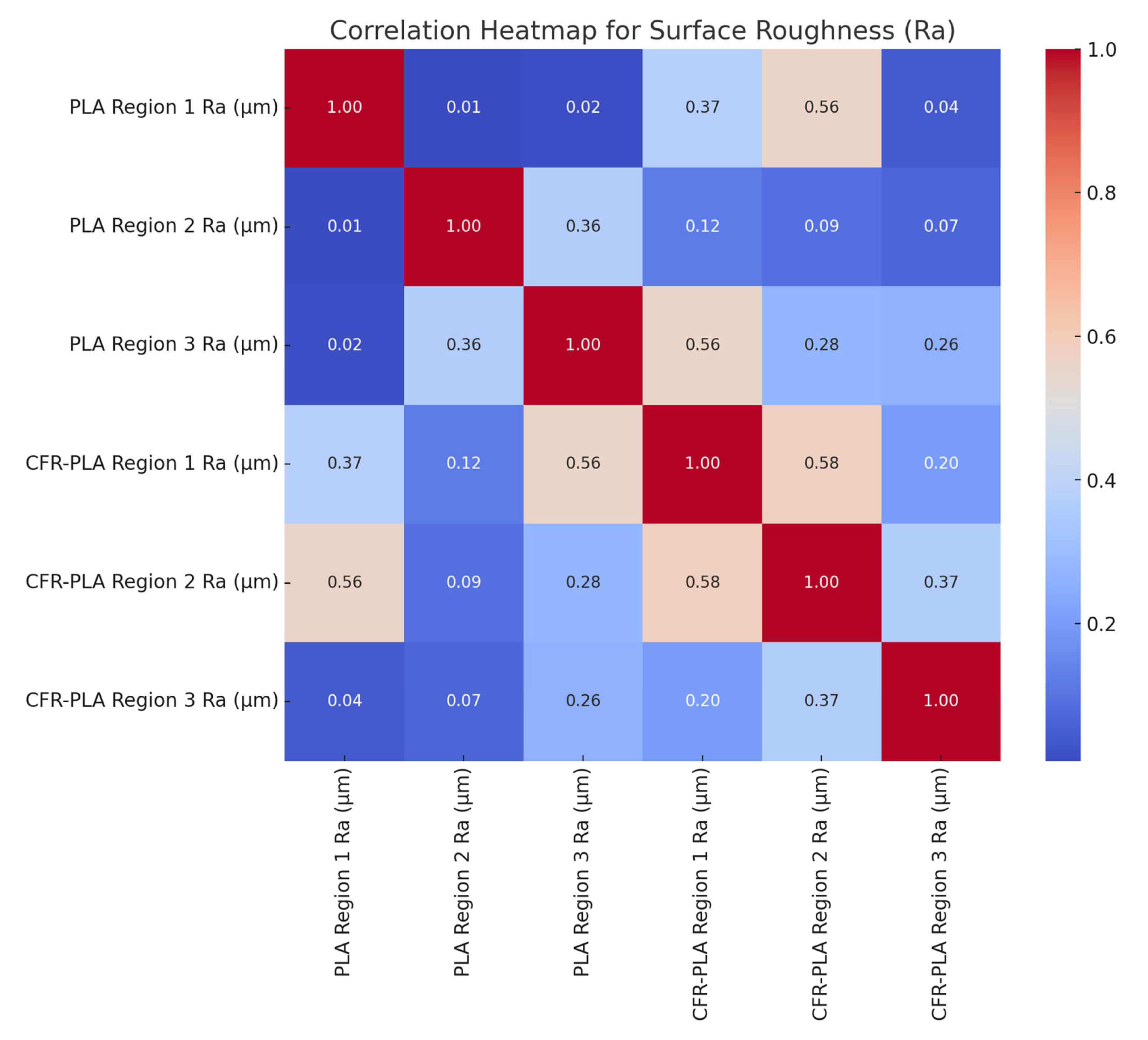

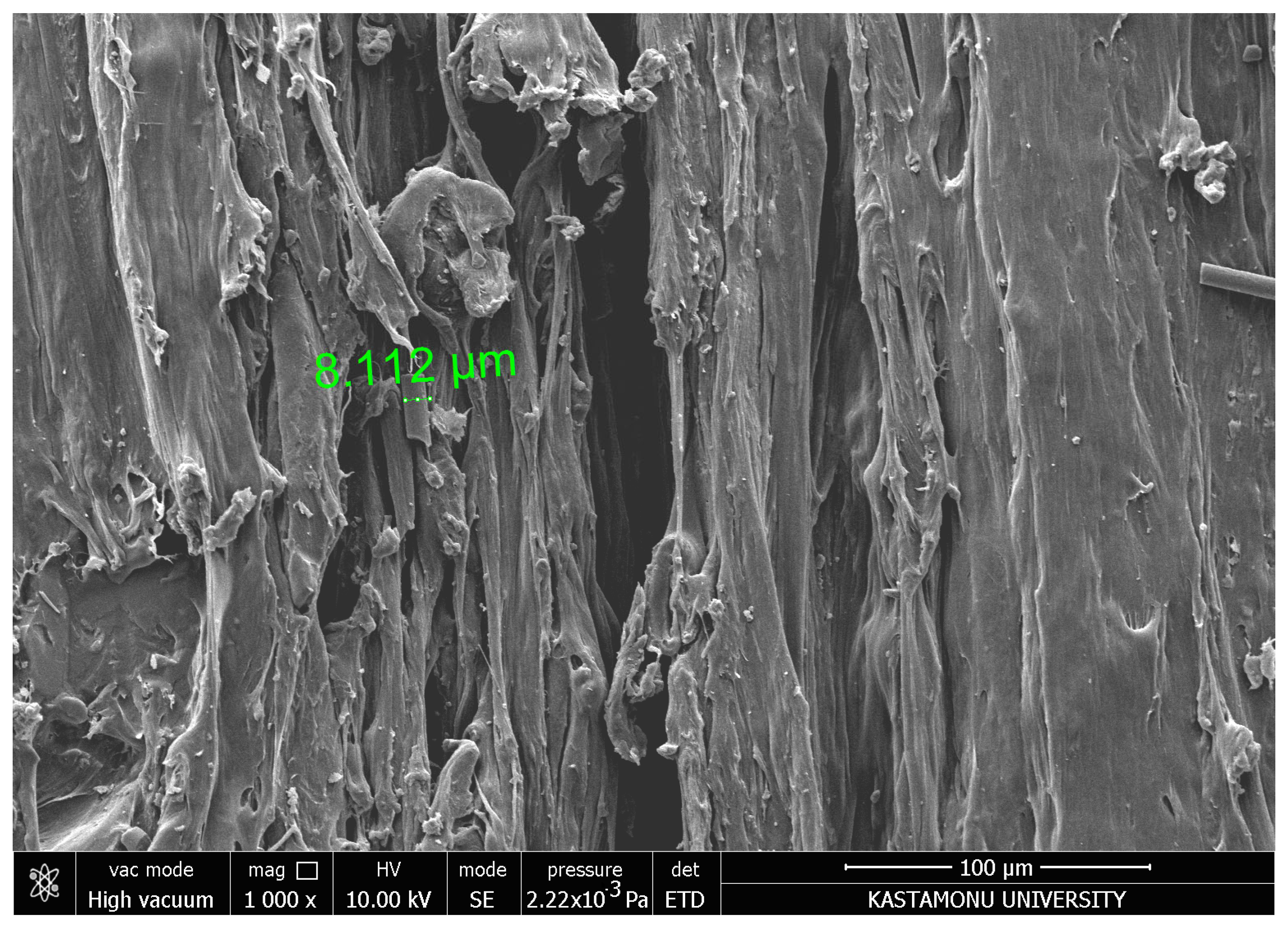

3.5. Surface Roughness Analysis

4. Conclusions

- Enhanced cutting quality with CFR-PLA: CFR-PLA demonstrated superior performance with reduced kerf taper angles and lower surface roughness compared to PLA, attributed to the stabilizing effect of carbon fibers that enhances dimensional accuracy and mechanical stability during machining.

- Significant influence of AWJM parameters: Water jet pressure and abrasive flow rate were identified as the most critical parameters. High water pressure (3500 bar) and moderate abrasive flow rates (250–450 g/min) consistently improved surface quality and minimized kerf taper angles.

- Impact of traverse speed: Higher traverse speeds (above 1200 mm/min) negatively affected surface roughness and kerf taper angles by reducing jet–material interaction time. Controlled traverse speeds (400–800 mm/min) yielded optimal results.

- Region-specific variability: Surface roughness varied across different regions, influenced by edge effects and fiber–matrix interactions, emphasizing the need for region-specific optimization of AWJM parameters.

- Statistical validation and optimization: ANOVA confirmed the significant impact of AWJM parameters on surface quality. Optimized conditions for both PLA and CFR-PLA were identified, providing a roadmap for achieving high cutting precision.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hlaváčová, I.M.; Sadílek, M.; Váňová, P.; Szumilo, Š.; Tyč, M. Influence of steel structure on machinability by abrasive water jet. Materials 2020, 13, 4424. [Google Scholar] [CrossRef]

- Chen, X.; Guan, J.; Deng, S.; Liu, Q.; Chen, M. Features and mechanism of abrasive water jet cutting of Q345 steel. Int. J. Heat Technol. 2018, 36, 81–87. [Google Scholar] [CrossRef]

- Bańkowski, D.; Spadło, S. The use of abrasive water jet cutting to remove flash from castings. Arch. Foundry Eng. 2019, 19, 94–98. [Google Scholar] [CrossRef]

- Hlaváč, L.M.; Bańkowski, D.; Krajcarz, D.; Štefek, A.; Tyč, M.; Młynarczyk, P. Abrasive waterjet (AWJ) forces—Indicator of cutting system malfunction. Materials 2021, 14, 1683. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Guo, C. Topography and microstructure of the cutting surface machined with abrasive waterjet. Int. J. Adv. Manuf. Technol. 2014, 73, 941–947. [Google Scholar] [CrossRef]

- Liu, X.C.; Liang, Z.W.; Wen, G.L.; Yuan, X.F. Water jet machining and research developments: A review. Int. J. Adv. Manuf. Technol. 2019, 102, 1257–1335. [Google Scholar] [CrossRef]

- Barsukov, G.; Zhuravleva, T.; Kozhus, O. Study of the effect of heat treatment of copper slag particles on abrasiveness for abrasive waterjet cutting. Int. J. Adv. Manuf. Technol. 2023, 129, 4293–4300. [Google Scholar] [CrossRef]

- Ishfaq, K.; Ahmed, N.; Rehman, A.U.; Hussain, A.; Umer, U.; Al-Zabidi, A. Minimizing the micro-edge damage at each constituent layer of the clad composite during AWJM. Materials 2020, 13, 2685. [Google Scholar] [CrossRef]

- Folkes, J. Water jet—An innovative tool for manufacturing. J. Mater. Process. Technol. 2009, 209, 6181–6189. [Google Scholar] [CrossRef]

- Kovacevic, R.; Hashish, M.; Mohan, R.; Ramulu, M.; Kim, T.J.; Geskin, S. State of the art of research and development in abrasive water jet machining. J. Manuf. Sci. Eng. 1997, 119, 776–785. [Google Scholar] [CrossRef]

- Spadło, S.; Bańkowski, D.; Młynarczyk, P.; Hlaváčová, I.M. Influence of local temperature changes on the material microstructure in abrasive water jet machining (AWJM). Materials 2021, 14, 5399. [Google Scholar] [CrossRef]

- Ohadi, M.M.; Cheng, K.L. Modeling of temperature distributions in the workpiece during abrasive water jet machining. J. Heat Transf. 1993, 115, 446–452. [Google Scholar] [CrossRef]

- Hlaváč, L.M.; Štefek, A.; Tyč, M.; Krajcarz, D. Influence of material structure on forces measured during abrasive water jet (AWJ) machining. Materials 2020, 13, 3878. [Google Scholar] [CrossRef]

- Perec, A. Research into the disintegration of abrasive materials in the abrasive water jet machining process. Materials 2021, 14, 3940. [Google Scholar] [CrossRef] [PubMed]

- Taiwo, E.M.; Yahya, K.; Haron, Z. Potential of using natural fiber for building acoustic absorber: A review. J. Phys. Conf. Ser. 2019, 1262, 012017. [Google Scholar] [CrossRef]

- Hernandes Diat, D.; Villar-Ribera, R.; Haron, Z.; Julián, F.; Hernández-Abad, V.; Delgado-Aguilar, M. Impact Properties and Water Uptake Behavior of Old Newspaper Recycled Fibers-Reinforced Polypropylene Composites. Materials 2020, 13, 1079. [Google Scholar] [CrossRef] [PubMed]

- Lu, N.; Swan, J.R.; Ferguson, I. Composition, structure, and mechanical properties of hemp fiber reinforced composite with recycled high-density polyethylene matrix. J. Compos. Mater. 2012, 46, 1915–1924. [Google Scholar] [CrossRef]

- Shahria, S. Fabrication and property evaluation of hemp-flax fiber reinforced hybrid composite. Cellulose 2019, 7, 17–23. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; Elayapemural, A. Mechanial and water absorption properties of woven jute/banana hybrid composites. Fibers Polym. 2012, 13, 907–914. [Google Scholar] [CrossRef]

- Bouafif, H.; Koubaa, A.; Perré, P.; Cloutier, A. Effects of fiber characteristics on the physical and mechanical properties of wood plastic composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1975–1981. [Google Scholar] [CrossRef]

- Murayama, K.; Ueno, T.; Kobori, H.; Kojima, Y.; Suzuki, S.; Aoki, K.; Ito, H.; Ogoe, S.; Okamoto, M. Mechanical properties of wood/plastic composites formed using wood flour produced by wet ball-milling under various milling times and drying methods. J. Wood Sci. 2019, 65, 5. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef] [PubMed]

- Niu, S.; Chang, Q.; He, W.; Zhao, D.; Xie, Y.; Deng, X. Mechanically Strong, Hydrostable, and Biodegradable Starch-Cellulose Composite Materials for Tableware. Starke 2022, 74, 2200019. [Google Scholar] [CrossRef]

- Chegdani, F.; El Mansori, M. New Multiscale Approach for Machining Analysis of Natural Fiber Reinforced Bio-Composites. J. Manuf. Sci. Eng. 2019, 141, 011004. [Google Scholar] [CrossRef]

- Zajac, J.; Hutyrova, Z.; Orlovsky, I. Investigation of surface roughness after turning of one kind of the bio-materials with thermoplastic matrix and natural fibers. Adv. Mater. Res. 2014, 941, 275–279. [Google Scholar] [CrossRef]

- Caggiano, A. Machining of fibre reinforced plastic composite materials. Materials 2018, 11, 442. [Google Scholar] [CrossRef] [PubMed]

- Babu, D.; Babu, K.S.; Gowd, B. Drilling uni-directional fiber-reinforced plastics manufactured by hand lay-up influence of fibers. Am. J. Mater. Sci. Technol. 2012, 1, 1–12. [Google Scholar] [CrossRef]

- Babu, D.; Babu, K.S.; Gowd, B. Determination of delamination and tensile strength of drilled natural fiber reinforced composites. Appl. Mech. Mater. 2014, 592, 134. [Google Scholar] [CrossRef]

- Goutham, E.R.S.; Hussain, S.S.; Muthukumar, C.; Krishnasamy, S.; Kumar, T.S.M.; Santulli, C.; Palanisamy, S.; Parameswaranpillai, J.; Jesuarockiam, N. Drilling parameters and post-drilling residual tensile properties of natural-fiber-reinforced composites: A review. J. Compos. Sci. 2023, 7, 136. [Google Scholar] [CrossRef]

- Abilash, N.; Sivapragash, M. Optimizing the delamination failure in bamboo fiber reinforced polyester composite. J. King Saud Univ.-Eng. Sci. 2016, 28, 92–102. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Uthayakumar, M.; Arumugaprabu, V. Abrasive water jet machining of fiber-reinforced composite materials. J. Reif. Plast Compos. 2018, 37, 230–237. [Google Scholar] [CrossRef]

- Masoud, F.; Sapuan, S.M.; Mohd Ariffin, M.K.A.; Nukman, Y.; Bayraktar, E. Cutting process of natural fiber-reinforced polymer composites. Polymers 2020, 12, 1332. [Google Scholar] [CrossRef] [PubMed]

- Boopathi, S.; Thillaivanan, A.; Azeem, M.A.; Shanmugam, P.; Pramod, V.R. Experimental investigation on abrasive water jet machining of neem wood plastic composite. Funct. Compos. Struct. 2022, 4, 025001. [Google Scholar] [CrossRef]

- Jagadish, S.B.; Amitava, R. Prediction of surface roughness quality of green abrasive water jet machining: A soft computing approach. J. Intell. Manuf. 2015, 30, 2965–2979. [Google Scholar] [CrossRef]

- Costa, R.D.F.S.; Sales-Contini, R.C.M.; Silva, F.J.G.; Sebbe, N.; Jesus, A.M.P. A Critical Review on Fiber Metal Laminates (FML): From Manufacturing to Sustainable Processing. Metals 2023, 13, 638. [Google Scholar] [CrossRef]

- Jamali, N.; Khosravi, H.; Rezvani, A.; Tohidlou, E. Mechanical properties of multiscale graphene oxide/basalt fiber/epoxy composites. Fibers Polym. 2019, 20, 138–146. [Google Scholar] [CrossRef]

- Saeimi Sadigh, M.A.; Marami, G. Investigating the effects of reduced graphene oxide additive on the tensile strength of adhesively bonded joints at different extension rates. Mater. Des. 2016, 92, 36–43. [Google Scholar] [CrossRef]

- Smolnicki, M.; Lesiuk, G.; Duda, S.; de Jesus, A.M.P. A Review on Finite-Element Simulation of Fibre Metal Laminates. Arch. Comput. Methods Eng. 2023, 30, 749–763. [Google Scholar] [CrossRef]

- Marques, F.; Silva, F.G.A.; Silva, T.E.F.; Rosa, P.A.R.; Marques, A.T.; de Jesus, A.M.P. Delamination of Fibre Metal Laminates Due to Drilling: Experimental Study and Fracture Mechanics-Based Modelling. Metals 2022, 12, 1262. [Google Scholar] [CrossRef]

- Pai, A.; Kini, C.R.; Shenoy, B.S. Scope of Non-Conventional Machining Techniques for Fibre Metal Laminates: A Review. Mater. Today 2022, 52, 787–795. [Google Scholar] [CrossRef]

- Siva Kumar, M.; Rajamani, D.; El-Sherbeeny, A.M.; Balasubramanian, E.; Karthik, K.; Hussein, H.M.A.; Astarita, A. Intelligent Modeling and Multi-Response Optimization of AWJC on Fiber Intermetallic Laminates through a Hybrid ANFIS-Salp Swarm Algorithm. Materials 2022, 15, 7216. [Google Scholar] [CrossRef] [PubMed]

- Doğankaya, E.; Kahya, M.; Özgür Ünver, H. Abrasive Water Jet Machining of UHMWPE and Trade-off Optimization. Mater. Manuf. Process. 2020, 35, 1339–1351. [Google Scholar] [CrossRef]

- Balamurugan, K.; Uthayakumar, M.; Sankar, S.; Hareesh, U.S.; Warrier, K.G.K. Predicting Correlations in Abrasive Waterjet Cutting Parameters of Lanthanum Phosphate/Yttria Composite by Response Surface Methodology. Measurement 2019, 131, 309–318. [Google Scholar] [CrossRef]

- Kalirasu, S.; Rajini, N.; Winowlin Jappes, J.T.; Uthayakumar, M.; Rajesh, S. Mechanical and Machining Performance of Glass and Coconut Sheath Fibre Polyester Composites Using AWJM. J. Reinf. Plast. Compos. 2015, 34, 564–580. [Google Scholar] [CrossRef]

- Alberdi, A.; Artaza, T.; Suárez, A.; Rivero, A.; Girot, F. An Experimental Study on Abrasive Waterjet Cutting of CFRP/Ti6Al4V Stacks for Drilling Operations. Int. J. Adv. Manuf. Technol. 2016, 86, 691–704. [Google Scholar] [CrossRef]

- Hutyrová, Z.; Ščučka, J.; Hloch, S.; Hlaváček, P.; Zeleňák, M. Turning of Wood Plastic Composites by Water Jet and Abrasive Water Jet. Int. J. Adv. Manuf. Technol. 2015, 84, 1615–1623. [Google Scholar] [CrossRef]

- Kalirasu, S.; Rajini, N.; Rajesh, S.; Jappes, J.T.W.; Karuppasamy, K. AWJM Performance of Jute/Polyester Composite Using MOORA and Analytical Models. Mater. Manuf. Process. 2017, 32, 1730–1739. [Google Scholar] [CrossRef]

- Pahuja, R.; Ramulu, M.; Hashish, M. Surface Quality and Kerf Width Prediction in Abrasive Water Jet Machining of Metal-Composite Stacks. Compos. B Eng. 2019, 175, 107134. [Google Scholar] [CrossRef]

- Pahuja, R.; Ramulu, M. Abrasive Water Jet Machining of Titanium (Ti6Al4V)–CFRP Stacks–A Semi-Analytical Modeling Approach in the Prediction of Kerf Geometry. J. Manuf. Process. 2019, 39, 327–337. [Google Scholar] [CrossRef]

- Hazir, E.; Ozcan, T. Response Surface Methodology Integrated with Desirability Function and Genetic Algorithm Approach for the Optimization of CNC Machining Parameters. Arab. J. Sci. Eng. 2019, 44, 2795–2809. [Google Scholar] [CrossRef]

- Palleda, M. A Study of Taper Angles and Material Removal Rates of Drilled Holes in the Abrasive Water Jet Machining Process. J. Mater. Process. Technol. 2007, 189, 292–295. [Google Scholar] [CrossRef]

- Mm, I.W.; Azmi, A.I.; Lee, C.C.; Mansor, A.F. Kerf Taper and Delamination Damage Minimization of FRP Hybrid Composites under Abrasive Water-Jet Machining. Int. J. Adv. Manuf. Technol. 2018, 94, 1727–1744. [Google Scholar] [CrossRef]

- Kumar, D.; Gururaja, S. Abrasive Waterjet Machining of Ti/CFRP/Ti Laminate and Multi-Objective Optimization of the Process Parameters Using Response Surface Methodology. J. Compos. Mater. 2020, 54, 1741–1759. [Google Scholar] [CrossRef]

- Rajamani, D.; Balasubramanian, E.; Murugan, A.; Tamilarasan, A. AWJC of NiTi Interleaved R-GO Embedded Carbon/Aramid Fibre Intermetallic Laminates: Experimental Investigations and Optimization through BMOA. Mater. Manuf. Process. 2023, 38, 1144–1158. [Google Scholar] [CrossRef]

- Khashaba, U.A.; El-Sonbaty, I.A.; Selmy, A.I.; Megahed, A.A. Machinability of Carbon Fiber Reinforced Polymers (CFRP). Compos. Part A Appl. Sci. Manuf. 2010, 41, 1368–1376. [Google Scholar] [CrossRef]

- Song, Y.; Cao, H.; Zheng, W.; Qu, D.; Liu, L.; Yan, C. Cutting force modeling of machining carbon fiber reinforced polymer (CFRP) composites: A review. Compos. Struct. 2022, 299, 116096. [Google Scholar] [CrossRef]

- Geier, N.; Xu, J.; Poor, D.I.; Dege, J.H.; Davim, J.P. A review on advanced cutting tools and technologies for edge trimming of carbon fibre reinforced polymer (CFRP) composites. Compos. Part B 2023, 266, 111037. [Google Scholar] [CrossRef]

- Chen, T.; Xiang, J.; Gao, F.; Liu, X.; Liu, G. Study on cutting performance of diamond-coated rhombic milling cutter in machining carbon fiber composites. Int. J. Adv. Manuf. Technol. 2019, 103, 4731–4737. [Google Scholar] [CrossRef]

- Rawal, S.; Sidpara, A.M.; Paul, J. A review on micro machining of polymer composites. J. Manuf. Process. 2022, 77, 87–113. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Shyha, I.S.; Soo, S.L.; Aspinwall, D.K.; Bradley, S. Effect of laminate configuration and feed rate on cutting performance when drilling holes in carbon fibre reinforced plastic composites. CIRP Ann. 2010, 59, 93–96. [Google Scholar] [CrossRef]

- Ozkan, D.; Panjan, P.; Gok, M.S.; Karaoglanli, A.C. Experimental study on tool wear and delamination in milling CFRPs with TiAlN-and TiN-coated tools. Coatings 2020, 10, 623. [Google Scholar] [CrossRef]

- Gara, S.; Tsoumarev, O. Prediction of surface roughness in slotting of CFRP. Measurement 2016, 91, 414–420. [Google Scholar] [CrossRef]

- Jiao, J.; Cheng, X.; Wang, J.; Sheng, L.; Zhang, Y.; Xu, J.; Jing, C.; Sun, S.; Xia, H.; Ru, H. A review of research progress on machining carbon fiber-reinforced composites with lasers. Micromachines 2022, 14, 24. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, T.M.; El Mesalamy, A.S.; Youssef, A.; El Midany, T.T. Improving surface roughness of abrasive waterjet cutting process by using statistical modeling. CIRP J. Manuf. Sci. Technol. 2018, 22, 30–36. [Google Scholar] [CrossRef]

- Dhanawade, A.; Kumar, S.; Kalmekar, R.V. Abrasive Water Jet Machining of Carbon Epoxy Composite. Def. Sci. J. 2016, 66, 522–528. [Google Scholar] [CrossRef][Green Version]

- Seo, J.; Kim, D.Y.; Kim, D.C.; Park, H.W. Recent developments and challenges on machining of carbon fiber reinforced polymer composite laminates. Int. J. Precis. Eng. Manuf. 2021, 22, 2027–2044. [Google Scholar] [CrossRef]

- Shanmugam, D.K.; Nguyen, T.; Wang, J. A study of delamination on graphite/epoxy composites in abrasive waterjet machining. Compos. Part A Appl. Sci. Manuf. 2008, 39, 923–929. [Google Scholar] [CrossRef]

- Gao, G.; Xu, F.; Xu, J. Parametric optimization of fdm process for improving mechanical strengths using taguchi method and response surface method: A comparative investigation. Machines 2022, 10, 750. [Google Scholar] [CrossRef]

- Chalgham, A.; Ehrmann, A.; Wickenkamp, I. Mechanical properties of FDM printed PLA parts before and after thermal treatment. Polymers 2021, 13, 1239. [Google Scholar] [CrossRef] [PubMed]

- Rowe, A.; Pramanik, A.; Basak, A.K.; Prakash, C.; Subramaniam, S.; Dixit, A.R.; Radhika, N. Effects of abrasive waterjet machining on the quality of the surface generated on a carbon fibre reinforced polymer composite. Machines 2023, 11, 749. [Google Scholar] [CrossRef]

- Płodzień, M.; Żyłka, Ł.; Żak, K.; Wojciechowski, S. Modelling the kerf angle, roughness and waviness of the surface of inconel 718 in an abrasive water jet cutting process. Materials 2023, 16, 5288. [Google Scholar] [CrossRef] [PubMed]

- Sambruno, A.; Bañon, F.; Salguero, J.; Simonet, B.; Batista, M. Kerf taper defect minimization based on abrasive waterjet machining of low thickness thermoplastic carbon fiber composites C/TPU. Materials 2019, 12, 4192. [Google Scholar] [CrossRef] [PubMed]

- Murthy, B.R.N.; Makki, E.; Potti, S.R.; Hiremath, A.; Bolar, G.; Giri, J.; Sathish, T. Optimization of process parameters to minimize the surface roughness of abrasive water jet machined jute/epoxy composites for different fiber inclinations. J. Compos. Sci. 2023, 7, 498. [Google Scholar] [CrossRef]

- Sambruno, A.; Gómez-Parra, Á.; Márquez, P.; Tellaeche-Herrera, I.; Batista, M. Evaluation of Peripheral Milling and Abrasive Water Jet Cutting in CFRP Manufacturing: Analysis of Defects and Surface Quality. Fibers 2024, 12, 78. [Google Scholar] [CrossRef]

- De la Rosa, S.; Rodríguez-Parada, L.; Ponce, M.B.; Mayuet Ares, P.F. The Abrasive Water Jet Cutting Process of Carbon-Fiber-Reinforced Polylactic Acid Samples Obtained by Additive Manufacturing: A Comparative Analysis. J. Compos. Sci. 2024, 8, 437. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Layer height | 0.2 mm |

| Layer width | 0.4 mm |

| Wall thickness | 0.8 mm |

| Printing temperature | 220 °C |

| Bed temperature | 60 °C |

| Printing speed | 60 mm/s |

| Displacement speed | 100 mm/s |

| Flow | 100% |

| Raster angle | −45°/45° |

| Infill density | 100% |

| Device | Accuracy Limit | Error Margin |

|---|---|---|

| Mitutoyo SJ-210 Surface Roughness Tester | ±0.003 mm | ±1% |

| Siemens CNC-Controlled AWJM System | ±0.03 mm | ±2% |

| OPTIKA B-510MET Microscope | ±1 μm | ±5% |

| KMT Pressure Sensor | ±1 bar | ±0.5% |

| Abrasive Flow Rate Control Unit | ±5 g/min | ±1% |

| Parameters | Codes | Level 1 | Level 2 | Level 3 | Units |

|---|---|---|---|---|---|

| Water pressure | x1 | 2500 | - | 3500 | Bar |

| Nozzle feed rate | x2 | 400 | 800 | 1200 | mm/min |

| Abrasive flow rate | x3 | 100 | 250 | 450 | g/min |

| Exp. No. | Water Pressure (bar) | Nozzle Feed Rate (mm/min) | Abrasive Flow Rate (g/min) |

|---|---|---|---|

| 1 | 3500 | 400 | 100 |

| 2 | 3500 | 400 | 250 |

| 3 | 3500 | 400 | 450 |

| 4 | 3500 | 800 | 100 |

| 5 | 3500 | 800 | 250 |

| 6 | 3500 | 800 | 450 |

| 7 | 3500 | 1200 | 100 |

| 8 | 3500 | 1200 | 250 |

| 9 | 3500 | 1200 | 450 |

| 10 | 2500 | 400 | 100 |

| 11 | 2500 | 400 | 250 |

| 12 | 2500 | 400 | 450 |

| 13 | 2500 | 800 | 100 |

| 14 | 2500 | 800 | 250 |

| 15 | 2500 | 800 | 450 |

| 16 | 2500 | 1200 | 100 |

| 17 | 2500 | 1200 | 250 |

| 18 | 2500 | 1200 | 450 |

| No. | x1 (bar) | x2 (mm/min) | x3 (g/min) | T (°) | Region 1 (μm) | Region 2 (μm) | Region 3 (μm) |

|---|---|---|---|---|---|---|---|

| 1 | 3500 | 400 | 100 | 1.608 | 9.186 | 9.096 | 12.336 |

| 2 | 3500 | 400 | 250 | 1.338 | 13.326 | 10.126 | 10.136 |

| 3 | 3500 | 400 | 450 | 1.918 | 9.486 | 9.216 | 13.046 |

| 4 | 3500 | 800 | 100 | 2.368 | 9.826 | 11.926 | 17.246 |

| 5 | 3500 | 800 | 250 | 1.778 | 13.336 | 9.806 | 15.056 |

| 6 | 3500 | 800 | 450 | 1.978 | 14.306 | 10.986 | 11.816 |

| 7 | 3500 | 1200 | 100 | 2.518 | 13.366 | 10.316 | 19.376 |

| 8 | 3500 | 1200 | 250 | 2.088 | 15.406 | 12.446 | 30.766 |

| 9 | 3500 | 1200 | 450 | 2.358 | 15.266 | 10.926 | 14.376 |

| 10 | 2500 | 400 | 100 | 2.638 | 11.336 | 8.866 | 10.636 |

| 11 | 2500 | 400 | 250 | 2.308 | 15.366 | 11.156 | 12.886 |

| 12 | 2500 | 400 | 450 | 2.808 | 13.176 | 8.546 | 17.876 |

| 13 | 2500 | 800 | 100 | 3.048 | 12.996 | 11.096 | 16.256 |

| 14 | 2500 | 800 | 250 | 2.178 | 22.426 | 12.016 | 13.986 |

| 15 | 2500 | 800 | 450 | 3.178 | 16.516 | 11.776 | 13.986 |

| 16 | 2500 | 1200 | 100 | 3.088 | 16.416 | 11.736 | 26.336 |

| 17 | 2500 | 1200 | 250 | 2.708 | 16.796 | 14.806 | 16.016 |

| 18 | 2500 | 1200 | 450 | 3.118 | 13.796 | 11.736 | 17.366 |

| No. | x1 (bar) | x2 (mm/min) | x3 (g/min) | T (°) | Region 1 (μm) | Region 2 (μm) | Region 3 (μm) |

| 1 | 3500 | 400 | 100 | 3.65 | 9.476 | 17.716 | 20.966 |

| 2 | 3500 | 400 | 250 | 1.54 | 9.876 | 8.866 | 18.646 |

| 3 | 3500 | 400 | 450 | 2.19 | 10.016 | 9.296 | 15.596 |

| 4 | 3500 | 800 | 100 | 2.25 | 15.546 | 10.826 | 18.226 |

| 5 | 3500 | 800 | 250 | 1.77 | 9.916 | 10.006 | 27.066 |

| 6 | 3500 | 800 | 450 | 2.16 | 12.876 | 13.066 | 27.016 |

| 7 | 3500 | 1200 | 100 | 2.35 | 11.436 | 17.286 | 21.786 |

| 8 | 3500 | 1200 | 250 | 1.83 | 14.646 | 13.756 | 24.766 |

| 9 | 3500 | 1200 | 450 | 2.55 | 20.266 | 14.196 | 29.786 |

| 10 | 2500 | 400 | 100 | 2.91 | 11.996 | 17.636 | 24.146 |

| 11 | 2500 | 400 | 250 | 2.21 | 21.166 | 10.776 | 18.386 |

| 12 | 2500 | 400 | 450 | 2.72 | 15.006 | 11.086 | 14.746 |

| 13 | 2500 | 800 | 100 | 3.07 | 18.046 | 12.676 | 18.486 |

| 14 | 2500 | 800 | 250 | 3.18 | 15.616 | 14.236 | 28.516 |

| 15 | 2500 | 800 | 450 | 3.11 | 22.166 | 15.126 | 28.596 |

| 16 | 2500 | 1200 | 100 | 3.06 | 11.816 | 13.526 | 34.626 |

| 17 | 2500 | 1200 | 250 | 2.69 | 21.126 | 15.266 | 20.636 |

| 18 | 2500 | 1200 | 450 | 3.46 | 27.726 | 11.896 | 21.676 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| x1 (bar) | 1 | 1.973 | 1.9734 | 0.07 | 0.794 |

| x2 (mm/min) | 2 | 163.735 | 81.8677 | 2.95 | 0.091 |

| x3 (g/min) | 2 | 0.06 | 0.03 | 0 | 0.999 |

| Error | 12 | 333.587 | 27.7989 | ||

| Total | 17 | 499.355 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| x1 (bar) | 1 | 0.079 | 0.079 | 0 | 0.952 |

| x2 (mm/min) | 2 | 203.218 | 101.609 | 4.94 | 0.027 |

| x3 (g/min) | 2 | 17.063 | 8.532 | 0.41 | 0.67 |

| Error | 12 | 246.38 | 20.578 | ||

| Total | 17 | 467.298 |

| Region | Optimal x1 (bar) | Optimal x2 (mm/min) | Optimal x3 (g/min) | Lowest Ra (μm) |

|---|---|---|---|---|

| PLA Region 1 | 2500 | 600 | 200 | 9.0 |

| PLA Region 2 | 2500 | 700 | 250 | 9.1 |

| PLA Region 3 | 2500 | 800 | 300 | 15.2 |

| CFR-PLA Region 1 | 2500 | 600 | 200 | 9.0 |

| CFR-PLA Region 2 | 2500 | 700 | 250 | 9.1 |

| CFR-PLA Region 3 | 2500 | 800 | 300 | 12.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kartal, F. Abrasive Water Jet Machining of Carbon Fiber-Reinforced PLA Composites: Optimization of Machinability and Surface Integrity for High-Precision Applications. Polymers 2025, 17, 445. https://doi.org/10.3390/polym17040445

Kartal F. Abrasive Water Jet Machining of Carbon Fiber-Reinforced PLA Composites: Optimization of Machinability and Surface Integrity for High-Precision Applications. Polymers. 2025; 17(4):445. https://doi.org/10.3390/polym17040445

Chicago/Turabian StyleKartal, Fuat. 2025. "Abrasive Water Jet Machining of Carbon Fiber-Reinforced PLA Composites: Optimization of Machinability and Surface Integrity for High-Precision Applications" Polymers 17, no. 4: 445. https://doi.org/10.3390/polym17040445

APA StyleKartal, F. (2025). Abrasive Water Jet Machining of Carbon Fiber-Reinforced PLA Composites: Optimization of Machinability and Surface Integrity for High-Precision Applications. Polymers, 17(4), 445. https://doi.org/10.3390/polym17040445