Optimization of Bio-Based Polyurethane Elastic Nanofibrous Membrane via Electrospinning for Waterproof and Breathable Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

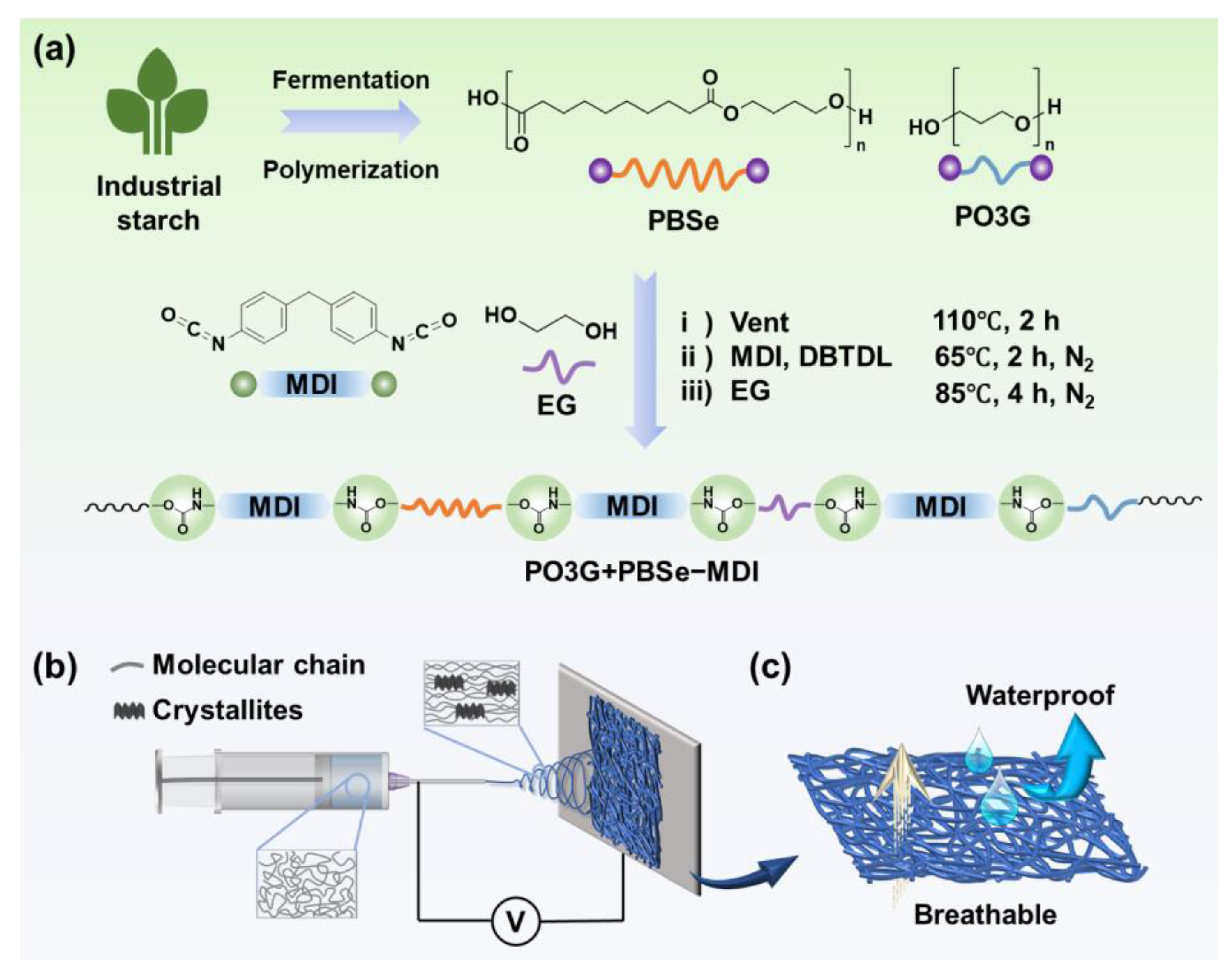

2.2. Synthesis of PBSe/PO3G-BPU

2.3. Preparation of PBSe/PO3G-BPU Nanofibrous Membranes

2.4. Characterizations

3. Results and Discussion

3.1. Chemical Structure of PBSe/PO3G-BPU

3.2. Microstructure of PBSe/PO3G-BPU Nanofibrous Membranes

3.3. Properties of PBSe/PO3G-BPU Nanofibrous Membranes

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dong, J.; Peng, Y.; Nie, X.; Li, L.; Zhang, C.; Lai, F.; He, G.; Ma, P.; Wei, Q.; Huang, Y.; et al. Hierarchically Designed Super-Elastic Metafabric for Thermal-Wet Comfortable and Antibacterial Epidermal Electrode. Adv. Funct. Mater. 2022, 32, 2209762. [Google Scholar] [CrossRef]

- Gong, X.; Ding, M.; Gao, P.; Ji, Y.; Wang, X.; Liu, X.-Y.; Yu, J.; Zhang, S.; Ding, B. High-Performance Waterproof, Breathable, and Radiative Cooling Membranes Based on Nanoarchitectured Fiber/Meshworks. Nano Lett. 2023, 23, 11337–11344. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Ji, Y.; Liu, X.; Yu, J.; Zhang, S.; Ding, B. Biomimetic and Durably Superhydrophobic Nanofibrous Membranes for High-Performance Waterproof and Breathable Textiles. Adv. Funct. Mater. 2024, 34, 2316030. [Google Scholar] [CrossRef]

- Arik, N.; Horzum, N.; Truong, Y.B. Development and Characterizations of Engineered Electrospun Bio-Based Polyurethane Containing Essential Oils. Membranes 2022, 12, 209. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Zhou, Y.; Zhao, L.; Liu, F.; Yan, X.; Sun, P.; Lu, G. Waterproof Breathable Multifunctional Flexible Sensor for Underwater Tactile Sensing and Ammonia Gas Monitoring. Nano Energy 2023, 117, 108881. [Google Scholar] [CrossRef]

- Yin, A.; Wang, J.; Hu, S.; Sun, M.; Sun, B.; Dong, M.; Zhang, T.; Feng, Z.; Zhang, H.; Shi, B.; et al. High Performance Waterproof-Breathable Fully Flexible Tactile Sensor Based on Piezotronics Coupled OFET. Nano Energy 2023, 106, 108034. [Google Scholar] [CrossRef]

- Sheng, J.; Zhang, M.; Xu, Y.; Yu, J.; Ding, B. Tailoring Water-Resistant and Breathable Performance of Polyacrylonitrile Nanofibrous Membranes Modified by Polydimethylsiloxane. ACS Appl. Mater. Interfaces 2016, 8, 27218–27226. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.; Zhi, C.; Zhang, S.; Yang, J.; Si, Y.; Jiang, Y.; Ming, Y.; Lau, K.; Fei, B.; Hu, J. Lotus Leaf-Inspired Breathable Membrane with Structured Microbeads and Nanofibers. ACS Appl. Mater. Interfaces 2022, 14, 39610–39621. [Google Scholar] [CrossRef]

- Cui, H.; Li, Y.; Zhao, X.; Yin, X.; Yu, J.; Ding, B. Multilevel Porous Structured Polyvinylidene Fluoride/Polyurethane Fibrous Membranes for Ultrahigh Waterproof and Breathable Application. Compos. Commun. 2017, 6, 63–67. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(Ethylene Terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef]

- Cywar, R.M.; Rorrer, N.A.; Hoyt, C.B.; Beckham, G.T.; Chen, E.Y.-X. Bio-Based Polymers with Performance-Advantaged Properties. Nat. Rev. Mater. 2022, 7, 83–103. [Google Scholar] [CrossRef]

- Frone, A.N.; Popa, M.S.; Uşurelu, C.D.; Panaitescu, D.M.; Gabor, A.R.; Nicolae, C.A.; Raduly, M.F.; Zaharia, A.; Alexandrescu, E. Bio-Based Poly(Lactic Acid)/Poly(Butylene Sebacate) Blends with Improved Toughness. Polymers 2022, 14, 3998. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Dun, C.; Jariwala, H.; Wang, R.; Cui, P.; Zhang, H.; Dai, Q.; Yang, S.; Zhang, H. Improvement of Bio-Based Polyurethane and Its Optimal Application in Controlled Release Fertilizer. J. Control. Release 2022, 350, 748–760. [Google Scholar] [CrossRef]

- Kaur, R.; Singh, P.; Tanwar, S.; Varshney, G.; Yadav, S. Assessment of Bio-Based Polyurethanes: Perspective on Applications and Bio-Degradation. Macromol 2022, 2, 284–314. [Google Scholar] [CrossRef]

- Guo, R.; Zhang, Q.; Wu, Y.; Chen, H.; Liu, Y.; Wang, J.; Duan, X.; Chen, Q.; Ge, Z.; Zhang, Y. Extremely Strong and Tough Biodegradable Poly(Urethane) Elastomers with Unprecedented Crack Tolerance via Hierarchical Hydrogen-Bonding Interactions. Adv. Mater. 2023, 35, 2212130. [Google Scholar] [CrossRef]

- Lligadas, G.; Ronda, J.C.; Galià, M.; Cádiz, V. Poly(Ether Urethane) Networks from Renewable Resources as Candidate Biomaterials: Synthesis and Characterization. Biomacromolecules 2007, 8, 686–692. [Google Scholar] [CrossRef]

- Ding, M.; Zeng, X.; He, X.; Li, J.; Tan, H.; Fu, Q. Cell Internalizable and Intracellularly Degradable Cationic Polyurethane Micelles as a Potential Platform for Efficient Imaging and Drug Delivery. Biomacromolecules 2014, 15, 2896–2906. [Google Scholar] [CrossRef]

- Kucinska-Lipka, J.; Gubanska, I.; Janik, H.; Sienkiewicz, M. Fabrication of Polyurethane and Polyurethane Based Composite Fibres by the Electrospinning Technique for Soft Tissue Engineering of Cardiovascular System. Mater. Sci. Eng. C 2015, 46, 166–176. [Google Scholar] [CrossRef]

- Saisangtham, S.; Okhawilai, M.; Potiyaraj, P. Preparation of Novel Partially Bio-Based Thermoplastic Polyurethane / Polyacrylonitrile Electrospun Fiber Mats. J. Phys. Conf. Ser. 2022, 2175, 012005. [Google Scholar] [CrossRef]

- Shan, X.; Liu, L.; Wu, Y.; Yuan, D.; Wang, J.; Zhang, C.; Wang, J. Aerogel-Functionalized Thermoplastic Polyurethane as Waterproof, Breathable Freestanding Films and Coatings for Passive Daytime Radiative Cooling. Adv. Sci. 2022, 9, 2201190. [Google Scholar] [CrossRef] [PubMed]

- Sheng, J.; Xu, Y.; Yu, J.; Ding, B. Robust Fluorine-Free Superhydrophobic Amino-Silicone Oil/SiO2 Modification of Electrospun Polyacrylonitrile Membranes for Waterproof-Breathable Application. ACS Appl. Mater. Interfaces 2017, 9, 15139–15147. [Google Scholar] [CrossRef]

- Yu, X.; Wu, X.; Si, Y.; Wang, X.; Yu, J.; Ding, B. Waterproof and Breathable Electrospun Nanofibrous Membranes. Macromol. Rapid Commun. 2019, 40, 1800931. [Google Scholar] [CrossRef]

- Azimi, B.; Maleki, H.; Zavagna, L.; De la Ossa, J.G.; Linari, S.; Lazzeri, A.; Danti, S. Bio-Based Electrospun Fibers for Wound Healing. J. Funct. Biomater. 2020, 11, 67. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Si, Y.; Yu, J.; Ding, B. Super-Elastic Fluorinated Polyurethane Nanofibrous Membranes with Simultaneously Waterproof and Breathable Performance. ACS Appl. Polym. Mater. 2022, 4, 5557–5565. [Google Scholar] [CrossRef]

- Gu, X.; Li, N.; Gu, H.; Xia, X.; Xiong, J. Polydimethylsiloxane-Modified Polyurethane–Poly(ɛ-Caprolactone) Nanofibrous Membranes for Waterproof, Breathable Applications. J. Appl. Polym. Sci. 2018, 135, 46360. [Google Scholar] [CrossRef]

- Yu, Y.; Xu, G.; Zhao, P.; Zhang, J. Biocompatible, Robust, Waterproof and Breathable PDMS-Based PU Fibrous Membranes for Potential Application in Wound Dressing. Mater. Today Commun. 2024, 38, 107870. [Google Scholar] [CrossRef]

- Kim, E.-Y.; Lee, J.-H.; Lee, D.-J.; Lee, Y.-H.; Lee, J.-H.; Kim, H.-D. Synthesis and Properties of Highly Hydrophilic Waterborne Polyurethane-Ureas Containing Various Hardener Content for Waterproof Breathable Fabrics. J. Appl. Polym. Sci. 2013, 129, 1745–1751. [Google Scholar] [CrossRef]

- Banikazemi, S.; Rezaei, M.; Rezaei, P.; Babaie, A.; Eyvazzadeh-Kalajahi, A. Preparation of Electrospun Shape Memory Polyurethane Fibers in Optimized Electrospinning Conditions via Response Surface Methodology. Polym. Adv. Technol. 2020, 31, 2199–2208. [Google Scholar] [CrossRef]

- Cengiz, F.; Jirsak, O. The Effect of Salt on the Roller Electrospinning of Polyurethane Nanofibers. Fibers Polym. 2009, 10, 177–184. [Google Scholar] [CrossRef]

- Park, S.H.; Ryu, Y.S.; Kim, S.H. Effect of Modified Silica Nanoparticle on the Properties of Bio-Based Polyurethane Ultrafine Fibers. J. Mater. Sci. 2015, 50, 1760–1769. [Google Scholar] [CrossRef]

- Gu, J.; Gu, H.; Cao, J.; Chen, S.; Li, N.; Xiong, J. Robust Hydrophobic Polyurethane Fibrous Membranes with Tunable Porous Structure for Waterproof and Breathable Application. Appl. Surf. Sci. 2018, 439, 589–597. [Google Scholar] [CrossRef]

- Gradinaru, L.M.; Bercea, M.; Vlad, S.; Barbalata Mandru, M.; Drobota, M.; Aflori, M.; Ciobanu, R.C. Preparation and Characterization of Electrospun Magnetic Poly(Ether Urethane) Nanocomposite Mats: Relationships between the Viscosity of the Polymer Solutions and the Electrospinning Ability. Polymer 2022, 256, 125186. [Google Scholar] [CrossRef]

- Li, X.; Lin, Y.; Zhao, C.; Meng, N.; Bai, Y.; Wang, X.; Yu, J.; Ding, B. Biodegradable Polyurethane Derived from Hydroxylated Polylactide with Superior Mechanical Properties. Polymers 2024, 16, 1809. [Google Scholar] [CrossRef] [PubMed]

- ASTM E96/E96M-24; Standard Test Methods for Water Vapor Transmission of Materials. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Park, H.; Seo, J.; Lee, H.-Y.; Kim, H.-W.; Wall, I.B.; Gong, M.-S.; Knowles, J.C. Synthesis of Elastic Biodegradable Polyesters of Ethylene Glycol and Butylene Glycol from Sebacic Acid. Acta Biomater. 2012, 8, 2911–2918. [Google Scholar] [CrossRef]

- Karthika, V.K.; Gorakh, G.; Sonali, S.N.; Joseph, R.; Kiran, S. Synthesis and Characterization of Non-Invasively Traceable Poly(Ether Urethane)s for Biomedical Applications. Biomed. Phys. Eng. Express 2023, 9, 045001. [Google Scholar] [CrossRef]

- Yao, Y.; Xu, D.; Liu, C.; Guan, Y.; Zhang, J.; Su, Y.; Zhao, L.; Meng, F.; Luo, J. Biodegradable pH-Sensitive Polyurethane Micelles with Different Polyethylene Glycol (PEG) Locations for Anti-Cancer Drug Carrier Applications. RSC Adv. 2016, 6, 97684–97693. [Google Scholar] [CrossRef]

- Patil, C.K.; Rajput, S.D.; Marathe, R.J.; Kulkarni, R.D.; Phadnis, H.; Sohn, D.; Mahulikar, P.P.; Gite, V.V. Synthesis of Bio-Based Polyurethane Coatings from Vegetable Oil and Dicarboxylic Acids. Prog. Org. Coat. 2017, 106, 87–95. [Google Scholar] [CrossRef]

- Park, S.H.; Oh, K.W.; Kim, S.H. Reinforcement Effect of Cellulose Nanowhisker on Bio-Based Polyurethane. Compos. Sci. Technol. 2013, 86, 82–88. [Google Scholar] [CrossRef]

- Hsieh, C.-C.; Chen, Y.-C. Synthesis of Bio-Based Polyurethane Foam Modified with Rosin Using an Environmentally-Friendly Process. J. Clean. Prod. 2020, 276, 124203. [Google Scholar] [CrossRef]

- Mani, M.; Jaganathan, S.; Faudzi, A.; Sunar, M. Engineered Electrospun Polyurethane Composite Patch Combined with Bi-Functional Components Rendering High Strength for Cardiac Tissue Engineering. Polymers 2019, 11, 705. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-Chilito, J.; Lara-Ramos, J.A.; Marín, L.; Machuca-Martínez, F.; Correa-Aguirre, J.P.; Hidalgo-Salazar, M.A.; García-Navarro, S.; Roca-Blay, L.; Rodríguez, L.A.; Mosquera-Vargas, E.; et al. Morphological Electrical and Hardness Characterization of Carbon Nanotube-Reinforced Thermoplastic Polyurethane (TPU) Nanocomposite Plates. Molecules 2023, 28, 3598. [Google Scholar] [CrossRef]

- Isik, M.; Sardon, H.; Mecerreyes, D. Ionic Liquids and Cellulose: Dissolution, Chemical Modification and Preparation of New Cellulosic Materials. Int. J. Mol. Sci. 2014, 15, 11922–11940. [Google Scholar] [CrossRef] [PubMed]

- McKee, M.G.; Wilkes, G.L.; Colby, R.H.; Long, T.E. Correlations of Solution Rheology with Electrospun Fiber Formation of Linear and Branched Polyesters. Macromolecules 2004, 37, 1760–1767. [Google Scholar] [CrossRef]

- Veleirinho, B.; Rei, M.F.; Lopes-DA-Silva, J.A. Solvent and Concentration Effects on the Properties of Electrospun Poly(Ethylene Terephthalate) Nanofiber Mats. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 460–471. [Google Scholar] [CrossRef]

- Shao, H.; Fang, J.; Wang, H.; Lin, T. Effect of Electrospinning Parameters and Polymer Concentrations on Mechanical-to-Electrical Energy Conversion of Randomly-Oriented Electrospun Poly(Vinylidene Fluoride) Nanofiber Mats. RSC Adv. 2015, 5, 14345–14350. [Google Scholar] [CrossRef]

- Hyung Lee, J.; Ho Park, S.; Hun Kim, S. Fabrication of Bio-Based Polyurethane Nanofibers Incorporated with a Triclosan/Cyclodextrin Complex for Antibacterial Applications. RSC Adv. 2020, 10, 3450–3458. [Google Scholar] [CrossRef]

- Cantournet, S.; Desmorat, R.; Besson, J. Mullins Effect and Cyclic Stress Softening of Filled Elastomers by Internal Sliding and Friction Thermodynamics Model. Int. J. Solids Struct. 2009, 46, 2255–2264. [Google Scholar] [CrossRef]

- Wan, H.; Gao, K.; Li, S.; Zhang, L.; Wu, X.; Wang, X.; Liu, J. Chemical Bond Scission and Physical Slippage in the Mullins Effect and Fatigue Behavior of Elastomers. Macromolecules 2019, 52, 4209–4221. [Google Scholar] [CrossRef]

- Ding, C.; Lin, Y.; Cheng, N.; Meng, N.; Wang, X.; Yin, X.; Yu, J.; Ding, B. Dual-Cooling Textile Enables Vertical Heat Dissipation and Sweat Evaporation for Thermal and Moisture Regulation. Adv. Funct. Mater. 2024, 34, 2400987. [Google Scholar] [CrossRef]

- Zhu, W.; Zhao, J.; Wang, X.; Liu, X.; Yu, J.; Ding, B. Facile Fabrication of Fluorine-Free Breathable Poly(Methylhydrosiloxane)/Polyurethane Fibrous Membranes with Enhanced Water-Resistant Capability. J. Colloid Interface Sci. 2019, 556, 541–548. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, Y.; Zhang, F.; Jin, S.; Xiao, Y.; Xin, B.; Zheng, Y. Preparation of Waterproof and Breathable Polyurethane Fiber Membrane Modified by Fluorosilane-Modified Silica. Fibers Polym. 2020, 21, 954–964. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Li, X.; Lin, Y.; Cheng, N.; Jiao, W.; Wang, X.; Yu, J.; Ding, B. Optimization of Bio-Based Polyurethane Elastic Nanofibrous Membrane via Electrospinning for Waterproof and Breathable Applications. Polymers 2025, 17, 486. https://doi.org/10.3390/polym17040486

Zhang B, Li X, Lin Y, Cheng N, Jiao W, Wang X, Yu J, Ding B. Optimization of Bio-Based Polyurethane Elastic Nanofibrous Membrane via Electrospinning for Waterproof and Breathable Applications. Polymers. 2025; 17(4):486. https://doi.org/10.3390/polym17040486

Chicago/Turabian StyleZhang, Bin, Xueqin Li, Yanyan Lin, Ningbo Cheng, Wenling Jiao, Xianfeng Wang, Jianyong Yu, and Bin Ding. 2025. "Optimization of Bio-Based Polyurethane Elastic Nanofibrous Membrane via Electrospinning for Waterproof and Breathable Applications" Polymers 17, no. 4: 486. https://doi.org/10.3390/polym17040486

APA StyleZhang, B., Li, X., Lin, Y., Cheng, N., Jiao, W., Wang, X., Yu, J., & Ding, B. (2025). Optimization of Bio-Based Polyurethane Elastic Nanofibrous Membrane via Electrospinning for Waterproof and Breathable Applications. Polymers, 17(4), 486. https://doi.org/10.3390/polym17040486