Polypropylene Modified with Carbon Nanomaterials: Structure, Properties and Application (A Review)

Abstract

1. Introduction

2. Polypropylene

2.1. Composites of PP with Various Nanoparticles

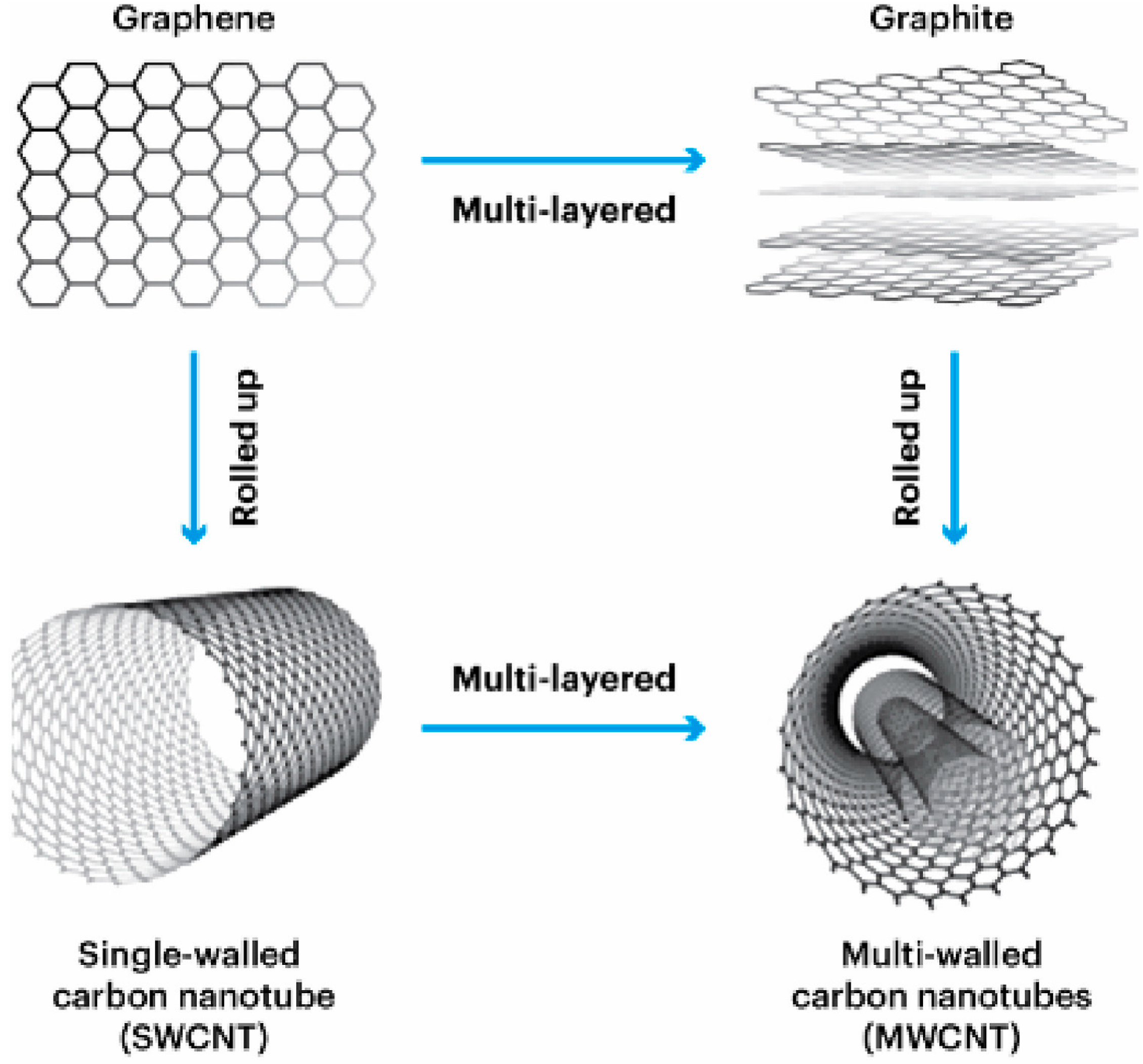

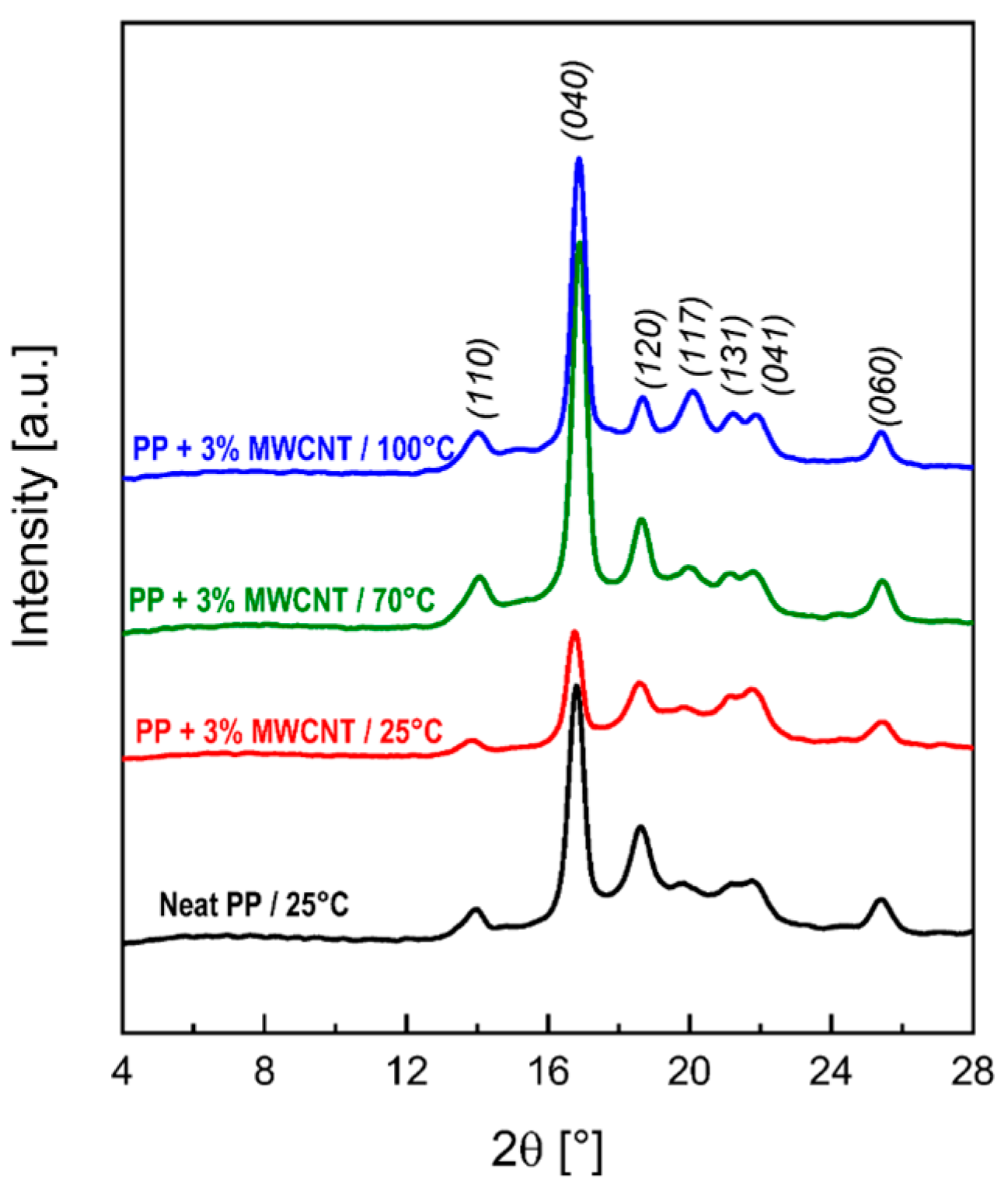

2.2. Composites of PP with Single- and Multi-Walled Carbon Nanotubes

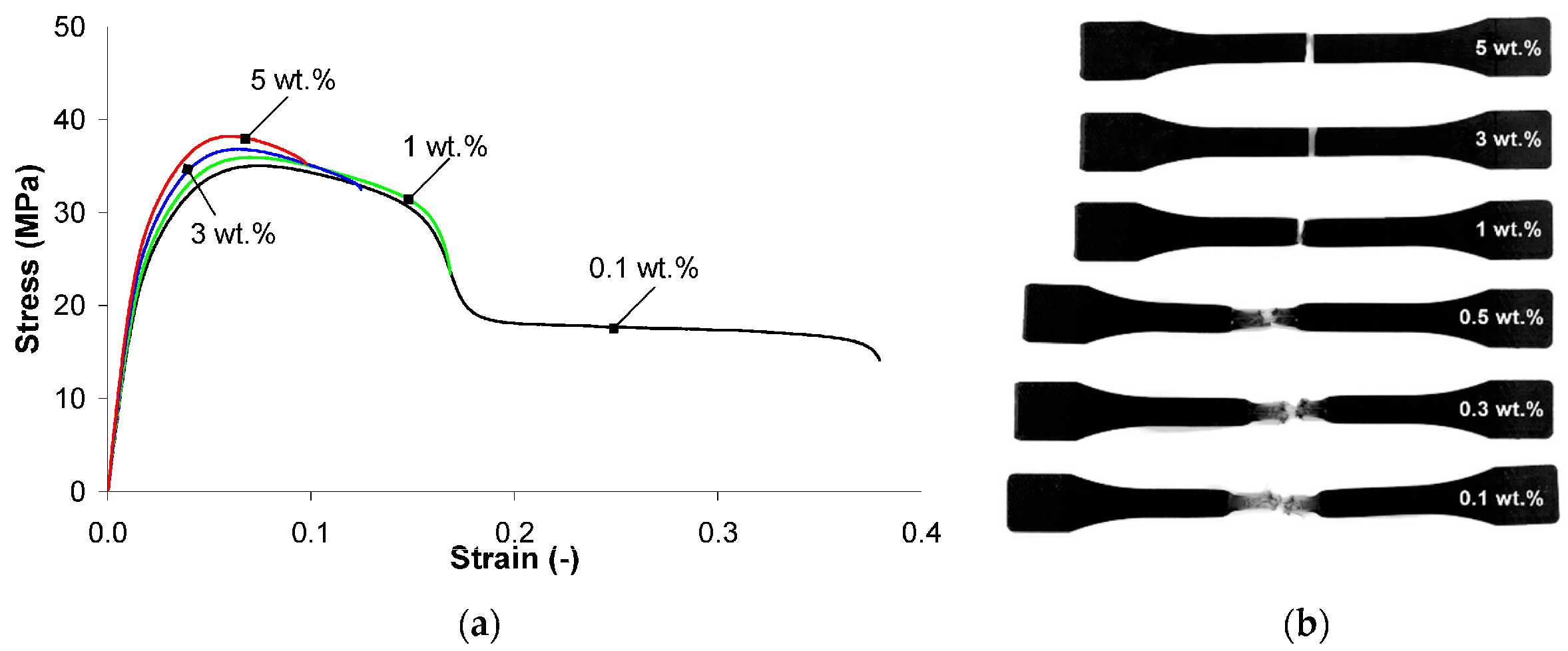

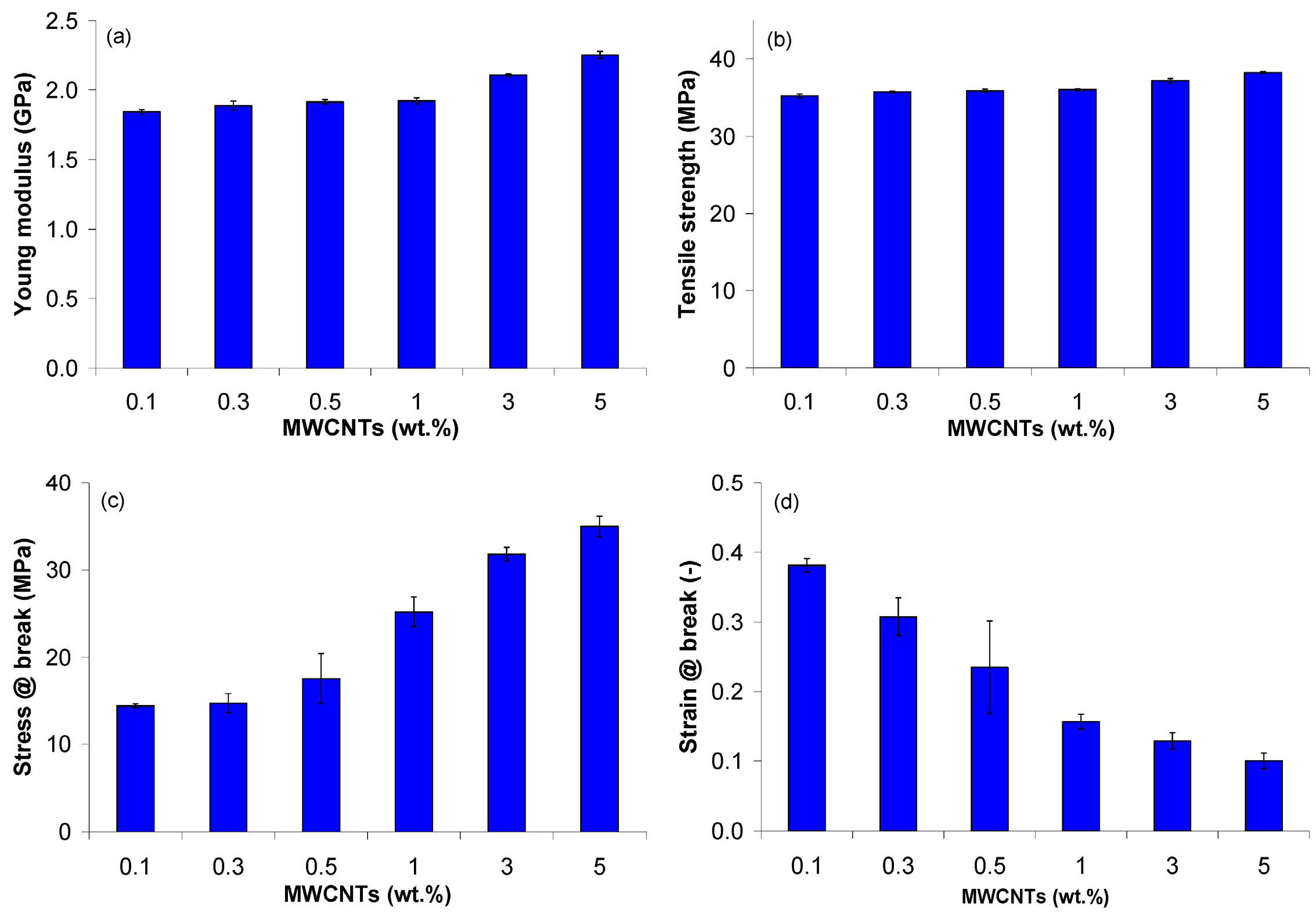

2.3. The Use of CNTs in a PP Matrix to Improve the Mechanical and Thermal Characteristics of a Polymer Material

2.4. The Use of CNTs in a PP Matrix to Create Conductive Polymers

| Methods for Obtaining Composite PP/CNT Materials | Investigated Properties | References |

|---|---|---|

| Ultrasonic irradiation method after extrusion of composite material | Slight oxidation of the polypropylene structure, decrease in molecular weight, increase in crystallinity, increase in modulus of elasticity, increase in thermal decomposition temperature, increase in volumetric resistivity, increase in thermal conductivity | [51] |

| The melting method using a twin-screw extruder followed by injection molding | Thermal conductivity, tensile modulus of elasticity, tensile strength and the stress at break are gradually increased, while the elongation at break is significantly reduced | [52] |

| The method of mixing a melt with a controlled time of CNT dispersion in a PP matrix. | Mechanical properties (increase in tensile strength and Young’s modulus) | [53] |

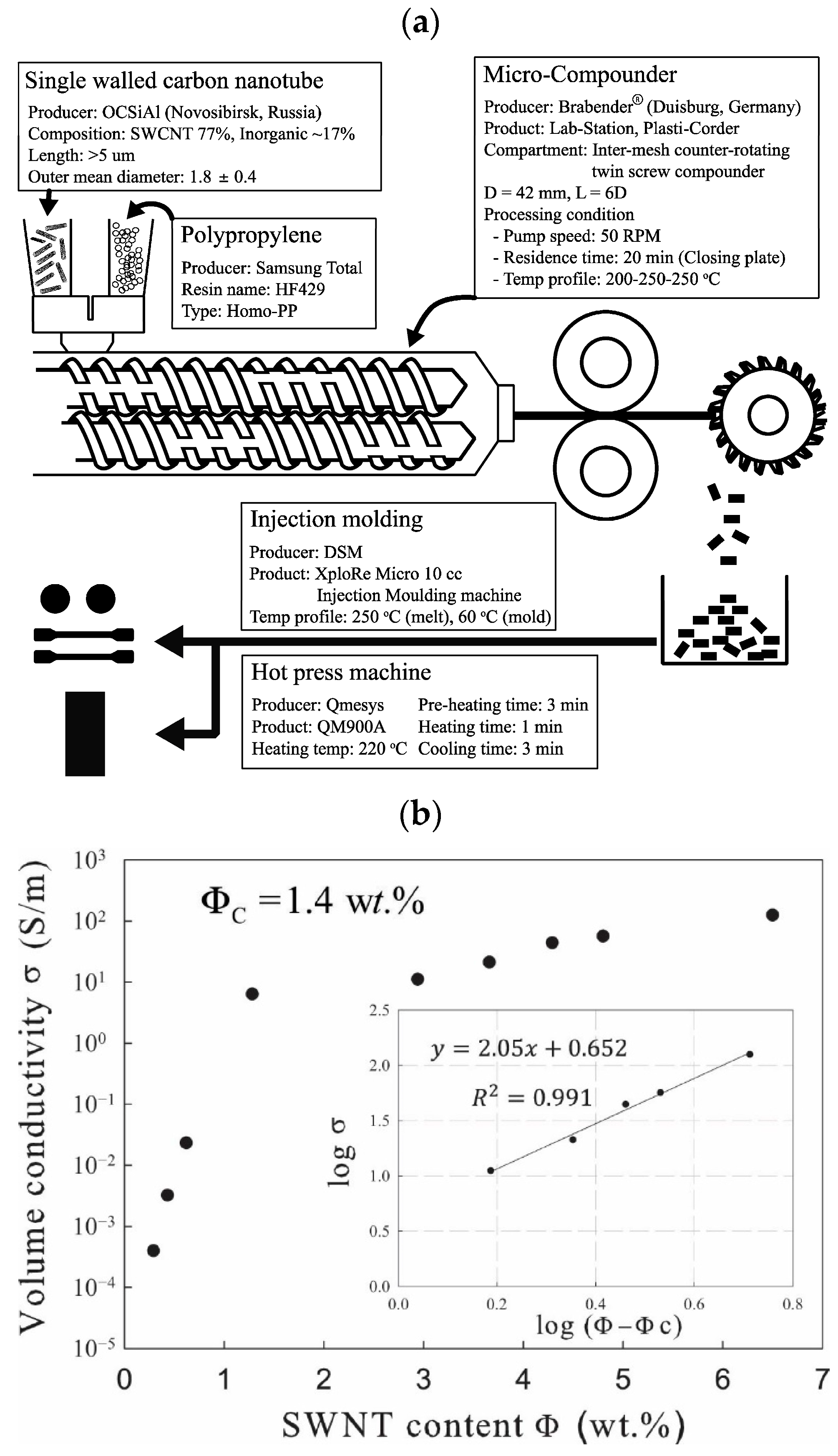

| The melting method using a twin-screw extruder followed by injection molding | Improvement in physical properties, conductive properties (the “percolation threshold” has been identified) | [56] |

| The method of additional treatment by microwaves after extrusion of composite material | Mechanical properties (an increase in mechanical strength and ultimate strength, while the nanocomposite exhibits elastoplastic properties) | [59] |

| Addition of an external nucleating agent (NA) based on sorbitol and control of the cooling rate. | Conductive properties (significant reduction in the percolation threshold) | [72] |

| Melt mixing technique with controlled residence time for CNT dispersion in a PP matrix using a twin-screw extruder | Rheological properties (lowest average molecular weight and lowest average molecular weight), electrical properties, mechanical properties (tensile strength and Young’s modulus increased linearly) | [74] |

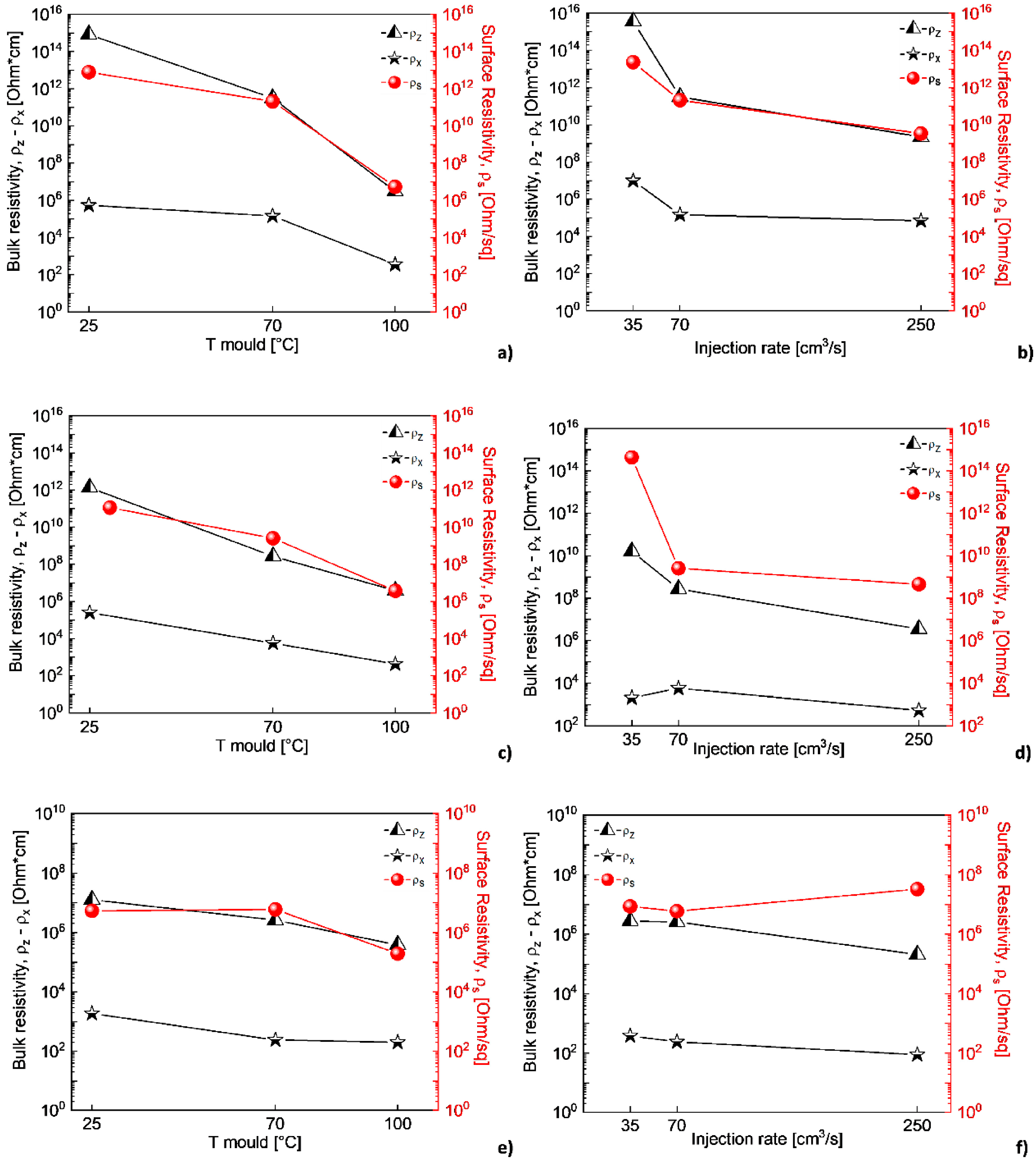

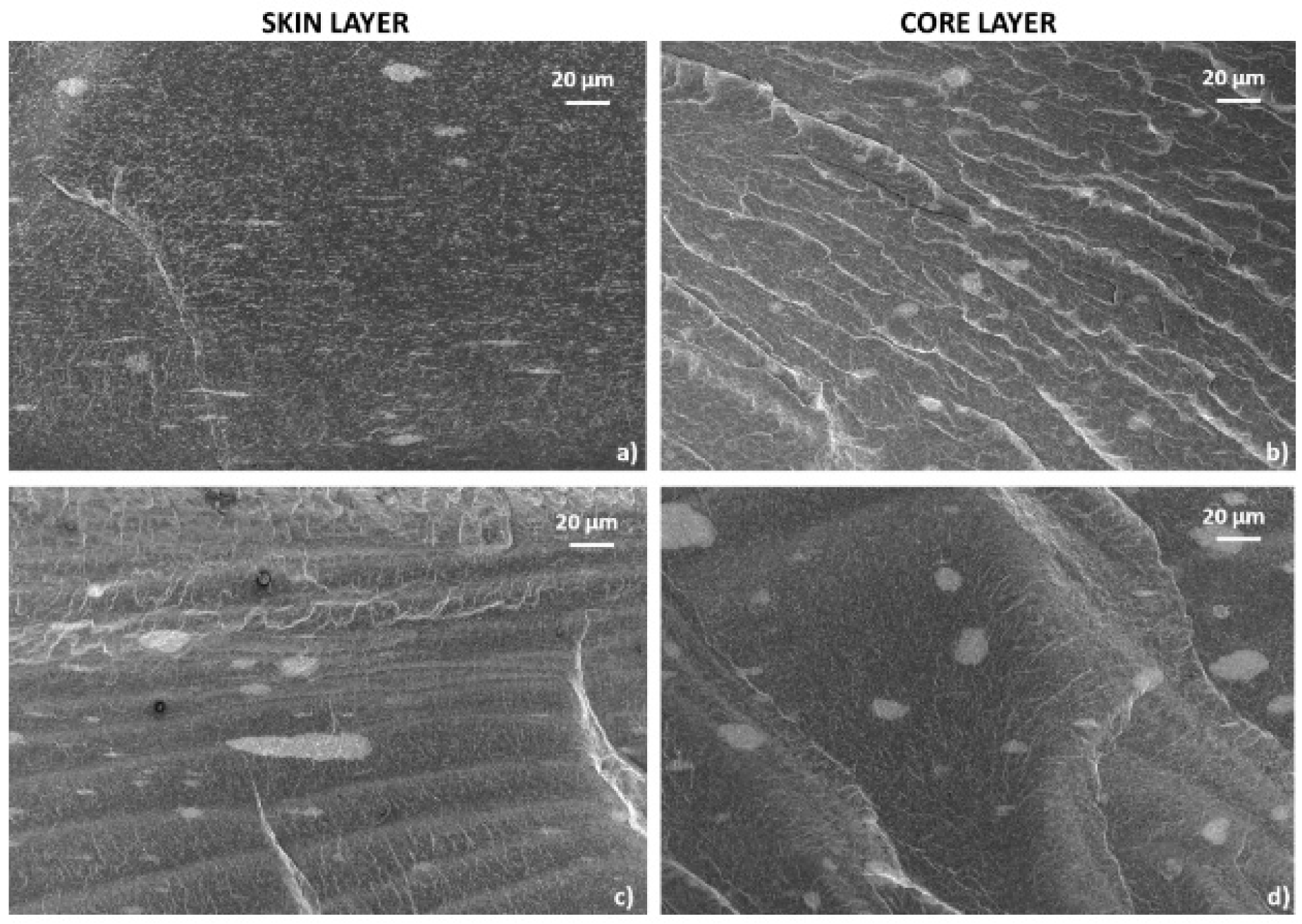

| The melting method using a twin-screw extruder and the injection molding method; samples with the same MNT content, but with different mold temperatures and injection rates, were studied. | Electrical properties (an increase in mold temperature and injection rate leads to a decrease in electrical resistivity) | [76] |

| The method of shear impact | Mechanical properties (increase in hardness), electrical properties (dependence of electrical conductivity on shear and CNT content) | [77] |

| Preparation of a nanocomposite by compounding a melt using a twin-screw extruder | Detection of sensory properties, increase in impedance | [78] |

| The melting method using a twin-screw extruder followed by injection molding | Mechanical properties (improvement in tensile strength and modulus of elasticity), increased electrical conductivity, shielding efficiency | [80] |

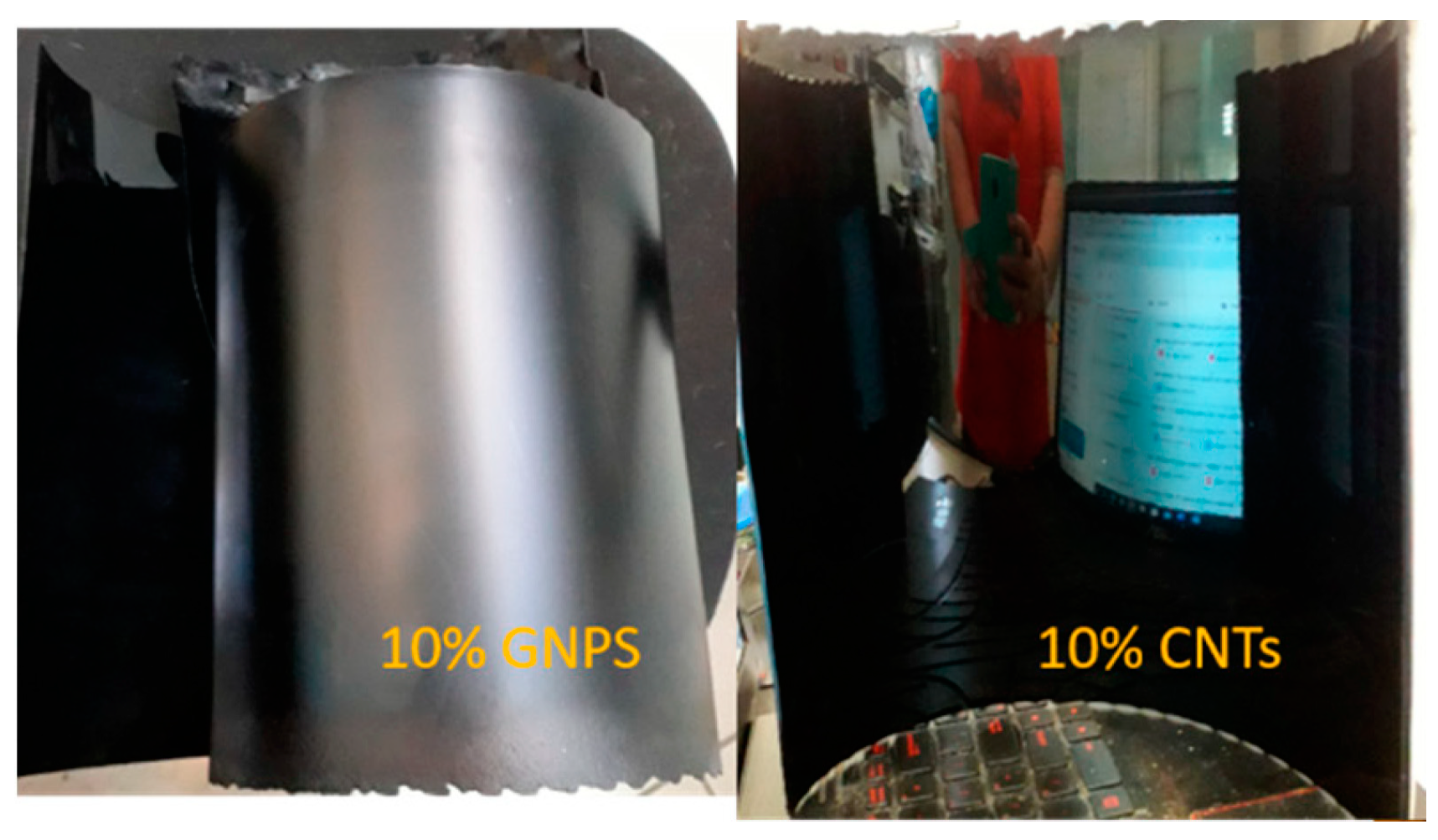

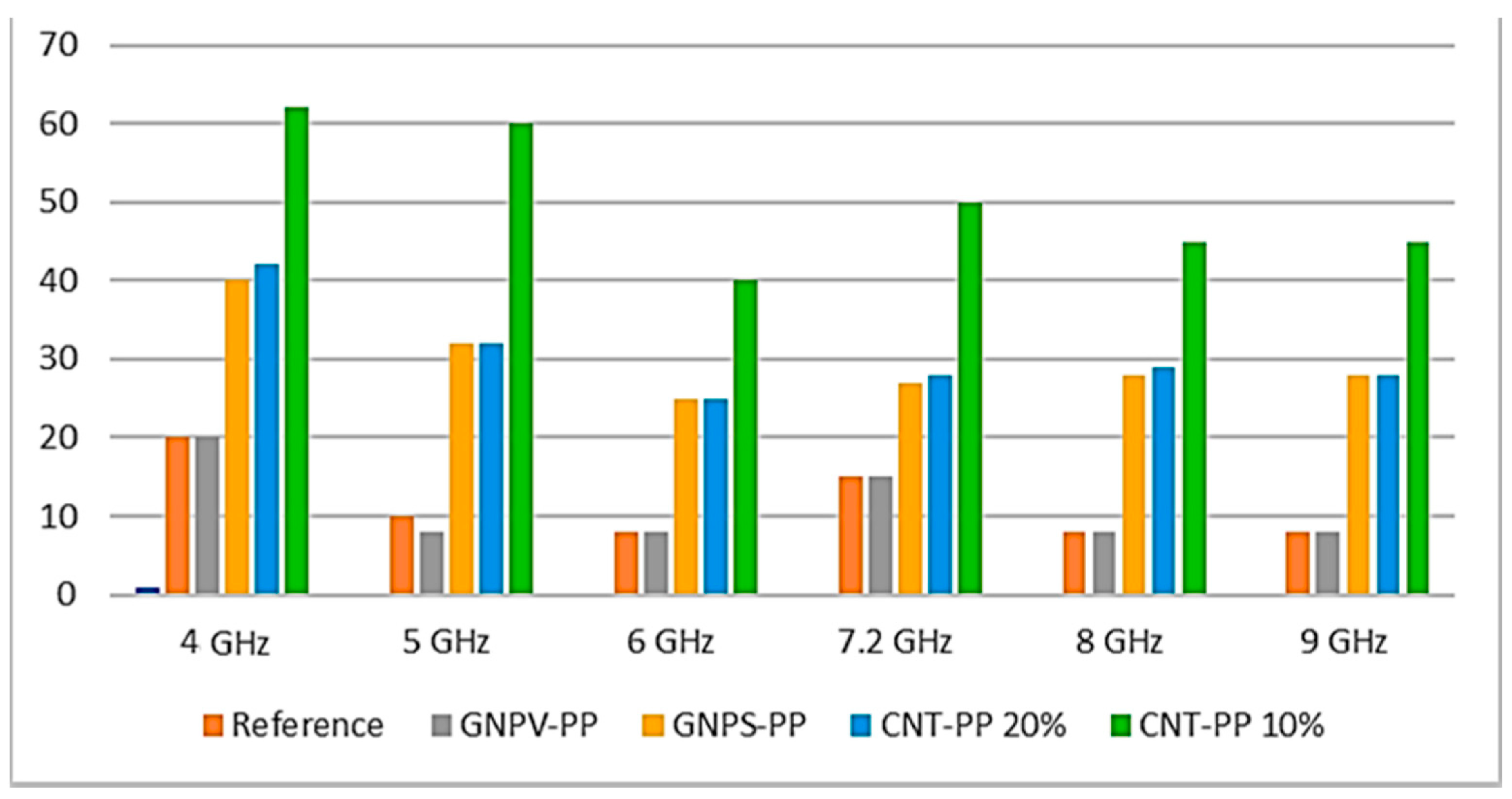

2.5. The Use of CNTs in a PP Matrix to Create Composite Materials for Electromagnetic Shielding

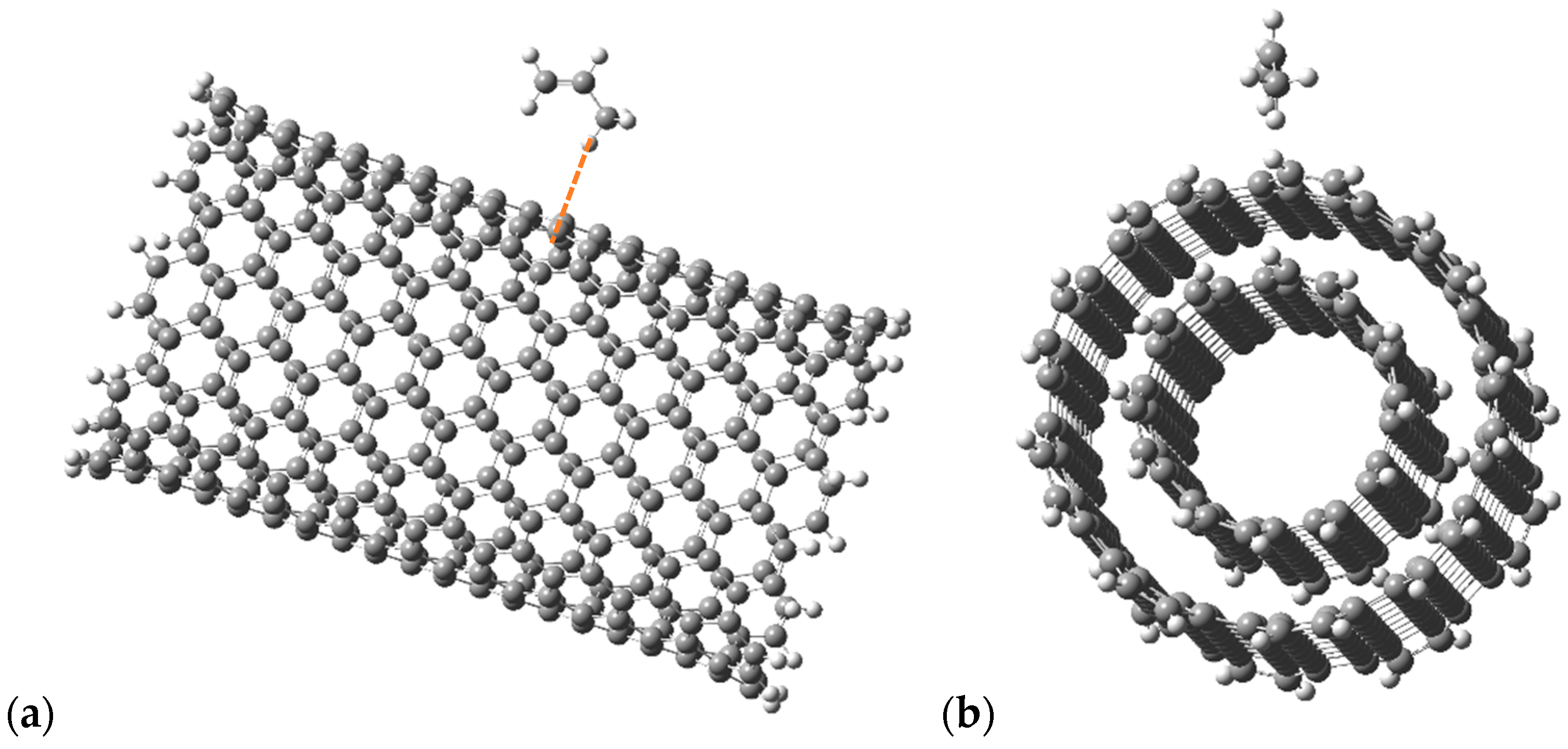

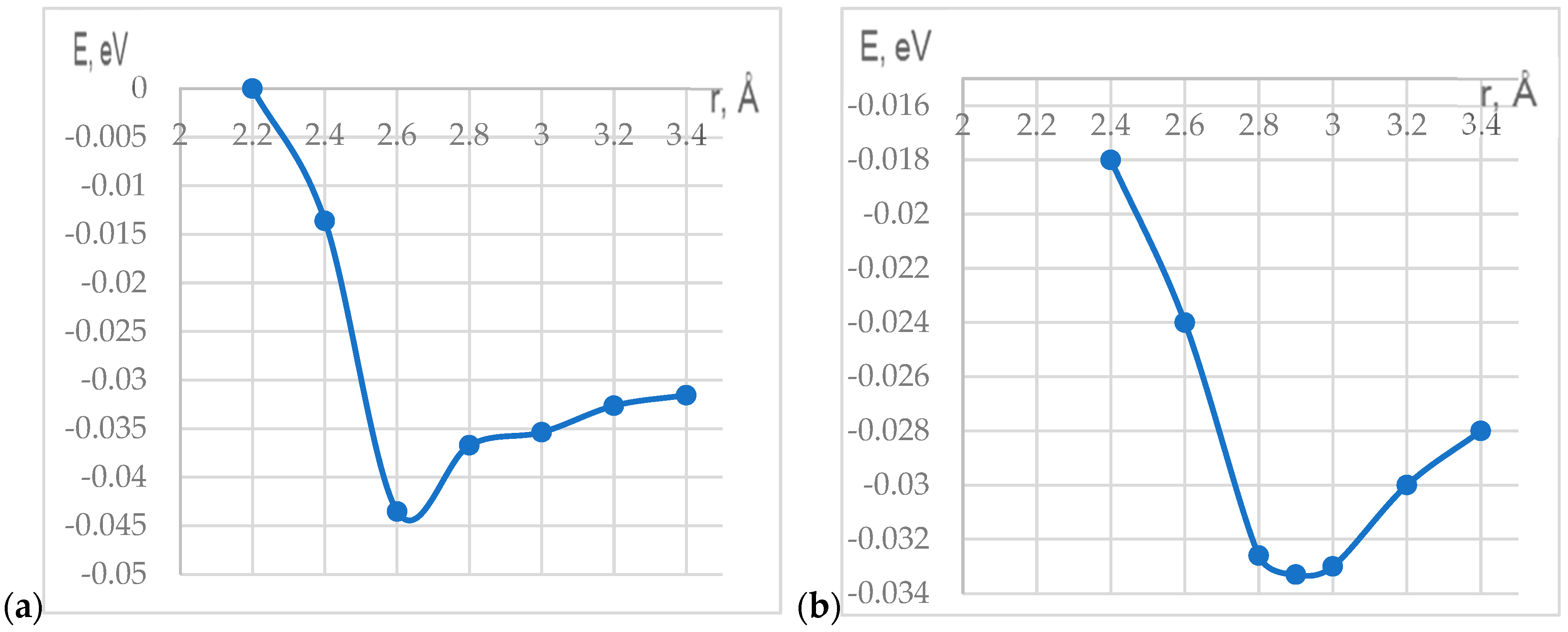

3. Theoretical Studies on Polymer Composite Materials Based on Polypropylene and Carbon Nanotubes

4. Conclusions

Funding

Conflicts of Interest

References

- Choudhary, V.; Gupta, A. Polymer/Carbon Nanotube Nanocomposites. Carbon Nanotub. Polym. Nanocompos. 2011, 2011, 65–90. [Google Scholar] [CrossRef]

- de Oliveira, A.D.; Beatrice, C.A.G. Polymer Nanocomposites with Different Types of Nanofiller. Nanocompos. Recent Evol. 2018, 103–104. [Google Scholar] [CrossRef]

- Xia, X.; Zhao, S.; Zhang, J.; Fang, C.; Weng, G.J. Revealing the time-dependent electromechanically coupled performances of viscoelastic MWCNT/polyethylene nanocomposite stress sensors. Compos. Sci. Technol. 2024, 247, 110417. [Google Scholar] [CrossRef]

- Akhtar, M.S.; Li, Z.Y.; Park, D.M.; Oh, D.W.; Kwak, D.-H.; Yang, O.-B. A new carbon nanotubes (CNTs)–poly acrylonitrile (PAN) composite electrolyte for solid state dye sensitized solar cells. Electrochim. Acta 2011, 56, 9973–9979. [Google Scholar] [CrossRef]

- Efimov, M.N.; Vasilev, A.A.; Muratov, D.G.; Dzidziguri, E.L.; Sheverdiyev, K.A.; Karpacheva, G.P. Conversion of polyethylene terephthalate waste in the presence of cobalt compound into highly-porous metal-carbon nanocomposite (c-PET-Co). Compos. Commun. 2022, 33, 101200. [Google Scholar] [CrossRef]

- Lu, M.; Xu, J.; Arias-Monje, P.J.; Gulgunje, P.V.; Gupta, K.; Shirolkar, N.; Maffe, A.; DiLoreto, E.; Ramachandran, J.; Sahoo, Y.; et al. Continuous stabilization of polyacrylonitrile (PAN)—Carbon nanotube (CNT) fibers by Joule heating. Chem. Eng. Sci. 2021, 236, 116495. [Google Scholar] [CrossRef]

- Saito, R.; Dresselhaus, M.S.; Dresselhaus, G. Physical Properties of Carbon Nanotubes; Imperial College Press: London, UK, 1999; p. 251. [Google Scholar]

- Ali, S.A.; Konwar, A.N.; Thakur, D.; Kundu, S. Metal (Ag)/metal oxide (CuO, ZnO)@polyvinyl alcohol (PVA) nanocomposite free-standing films: Physical and antimicrobial properties. Surf. Interfaces 2025, 56, 105587. [Google Scholar] [CrossRef]

- Ghanbari, A.; Heuzey, M.-C.; Carreau, P.J. Polyethylene terephthalate/organoclay nanocomposites: Improvement of morphology and viscoelastic properties by using a chain-extender. Appl. Clay Sci. 2022, 225, 106551. [Google Scholar] [CrossRef]

- Meng, Z.; Lu, S.; Zhang, D.; Liu, Q.; Chen, X.; Liu, W.; Guo, C.; Liu, Z.; Zhong, W.; Ke, Y. Grafting macromolecular chains on the surface of graphene oxide through crosslinker for antistatic and thermally stable polyethylene terephthalate nanocomposites. RSC Adv. 2022, 12, 33329–33339. [Google Scholar] [CrossRef]

- Soni, S.K.; Thomas, B.; Thomas, S.B.; Tile, P.S.; Sakharwade, S.G. Carbon nanotubes as exceptional nanofillers in polymer and polymer/fiber nanocomposites: An extensive review. Mater. Today Commun. 2023, 37, 107358. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Chen, J.; Yan, L.; Song, W.; Xu, D. Interfacial characteristics of carbon nanotube-polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 149–169. [Google Scholar] [CrossRef]

- Ali, A.; Koloor, S.S.R.; Alshehri, A.H.; Arockiarajan, A. Carbon nanotube characteristics and enhancement effects on the mechanical features of polymer-based materials and structures—A review. J. Mater. Res. Technol. 2023, 24, 6495–6521. [Google Scholar] [CrossRef]

- Ali, Z.; Yaqoob, S.; Yu, J. Critical review on the characterization, preparation, and enhanced mechanical, thermal, and electrical properties of carbon nanotubes and their hybrid filler polymer composites for various applications. Compos. Part C Open Access 2024, 13, 100434. [Google Scholar] [CrossRef]

- Fenta, E.W.; Mebratie, B.A. Advancements in carbon nanotube-polymer composites: Enhancing properties and applications through advanced manufacturing techniques. Heliyon 2024, 10, e36490. [Google Scholar] [CrossRef]

- Rathinavel, S.; Priyadharshini, K.; Panda, D. A review on carbon nanotube: An overview of synthesis, properties, functionalization, characterization, and the application. Mater. Sci. Eng. B 2021, 268, 115095. [Google Scholar] [CrossRef]

- Maghimaa, M.; Sagadevan, S.; Boojhana, E.; Is Fatimah, J.; Lett, A.; Moharana, S.; Garg, S.; Al-Anber, M.A. Enhancing biocompatibility and functionality: Carbon nanotube-polymer nanocomposites for improved biomedical applications. J. Drug Deliv. Sci. Technol. 2024, 99, 105958. [Google Scholar] [CrossRef]

- Eatemadi, A.; Daraee, H.; Karimkhanloo, H.; Kouhi, M.; Zarghami, N.; Akbarzadeh, A.; Hanifehpour, Y.; Joo, S.W. Carbon nanotubes: Properties, synthesis, purification, and medical applications. Nanoscale Res. Lett. 2014, 9, 393. [Google Scholar] [CrossRef]

- Zaporotskova, I.V.; Elbakyan, L.S. Obtaining New Dental Materials Reinforced with Carbon Nanotubes. J. Nano Electron. Phys. 2016, 8, 03047. [Google Scholar]

- Pathak, R.; Punetha, V.D.; Bhatt, S.; Punetha, M. Carbon nanotube-based biocompatible polymer nanocomposites as an emerging tool for biomedical applications. Eur. Polym. J. 2023, 196, 112257. [Google Scholar] [CrossRef]

- Bowland, C.C.; Wang, Y.; Naskar, A.K. Development of nanoparticle embedded sizing for enhanced structural health monitoring of carbon fiber composites. In Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure 2017, Portland, OR, USA, 25–29 March 2017. [Google Scholar]

- Ozdemir, N.; Zhang, T.; Aspin, I.; Scarpa, F.; Hadavinia, H.; Song, Y. Toughening of carbon fibre reinforced polymer composites with rubber nanoparticles for advanced industrial applications. Express Polym. Lett. 2016, 10, 394–407. [Google Scholar] [CrossRef]

- Yang, S. Properties, applications, and prospects of carbon nanotubes in the construction industry. Archit. Struct. Constr. 2023, 3, 289–298. [Google Scholar] [CrossRef]

- Cheremisinoff, N.P. Condensed Encyclopedia of Polymer Engineering Terms Book; Butterworth-Heinemann: London, UK, 2001. [Google Scholar]

- Greene, J.P. Automotive Plastics and Composites Materials and Processing A volume in Plastics Design Library Book; William Andrew: Norwich, NY, USA, 2021. [Google Scholar]

- Campo, E.A. Selection of Polymeric Materials; William Andrew: Norwich, NY, USA, 2008. [Google Scholar]

- Yamamoto, T.; Luo, C.; Ide, K.; Aoki, K.; Jian, Y.-K.; Huang, Y.H.; Uetsuji, Y. Fused filament fabrication and mechanical characterization of hybrid reinforced polypropylene composites with talc fillers and cellulose nanofibers. Compos. Part A Appl. Sci. Manuf. 2025, 188, 108536. [Google Scholar] [CrossRef]

- Lee, B.H.; Cho, J.W.; Kim, K.H. Crystallization, orientation, and mechanical properties of laser-heated photothermally drawn polypropylene/multi-walled carbon nanotube fibers. Eur. Polym. J. 2017, 91, 70–80. [Google Scholar] [CrossRef]

- Michailidis, N.; Petousis, M.; Moutsopoulou, A.; Argyros, A.; Ntintakis, I.; Papadakis, V.M.; Nasikas, N.; Vidakis, N. Engineering response of biomedical grade isotactic polypropylene reinforced with titanium nitride nanoparticles for material extrusion three-dimensional printing. Eur. J. Mater. 2024, 4, 2340944. [Google Scholar] [CrossRef]

- van Erp, T.B.; Reynolds, C.T.; Bilotti, E.; Peijs, T. Nanoclay assisted ultra-drawing of polypropylene tapes. Nanocomposites 2019, 5, 114–123. [Google Scholar] [CrossRef]

- Leontiadis, K.; Achilias, D.S.; Tsivintzelis, I. Effect of the Filler Modification on the Thermal and Mechanical Properties of Composite Polypropylene/Wollastonite Drawn Fibers. Polymers 2023, 15, 2986. [Google Scholar] [CrossRef]

- Vidakis, N.; Michailidis, N.; Argyros, A.; Mountakis, N.; Papadakis, V.; Spiridaki, M.; Moutsopoulou, A.; Sfakiotakis, E.; Petousis, M. A coherent optimization course of the silicon nitride nanofiller load in medical grade isotactic polypropylene for material extrusion additive manufacturing: Rheology, engineering response, and cost-effectiveness. Colloid Polym. Sci. 2024, 302, 843–860. [Google Scholar] [CrossRef]

- Hadi, N.J.; Mohamed, D.J. Study the Relation Between Flow, Thermal and Mechanical Properties of Waste Polypropylene Filled Silica Nanoparticles. Key Eng. Mater. 2017, 724, 28–38. [Google Scholar] [CrossRef]

- Hadi, J.; Saad, N.A.; Mohamed, D.H. Thermal Behavior of Calcium Carbonate and Zinc Oxide Nanoparticles Filled Polypropylene by Melt Compounding. Res. J. Appl. Sci. Eng. Technol. 2016, 13, 265–272. [Google Scholar] [CrossRef]

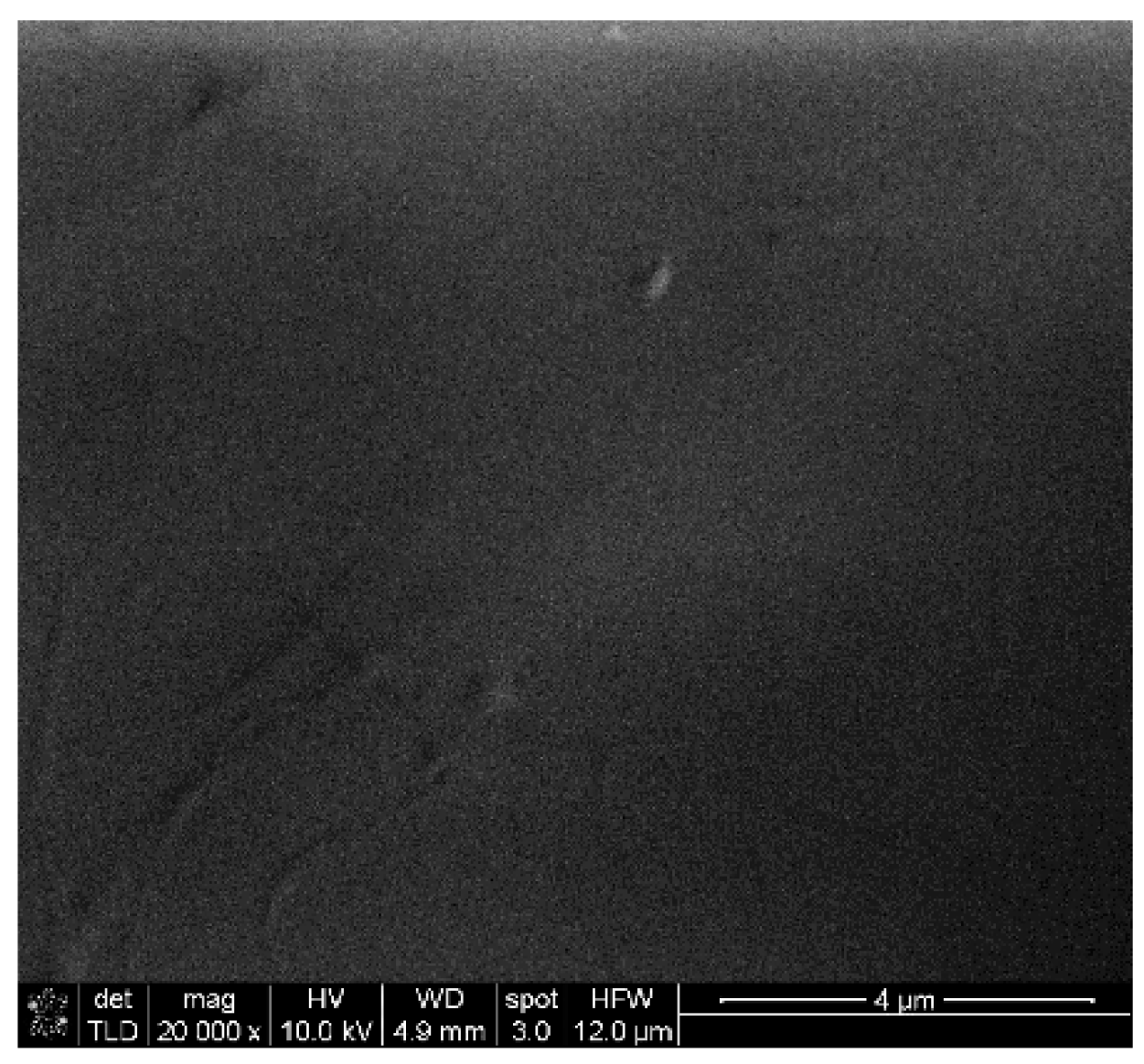

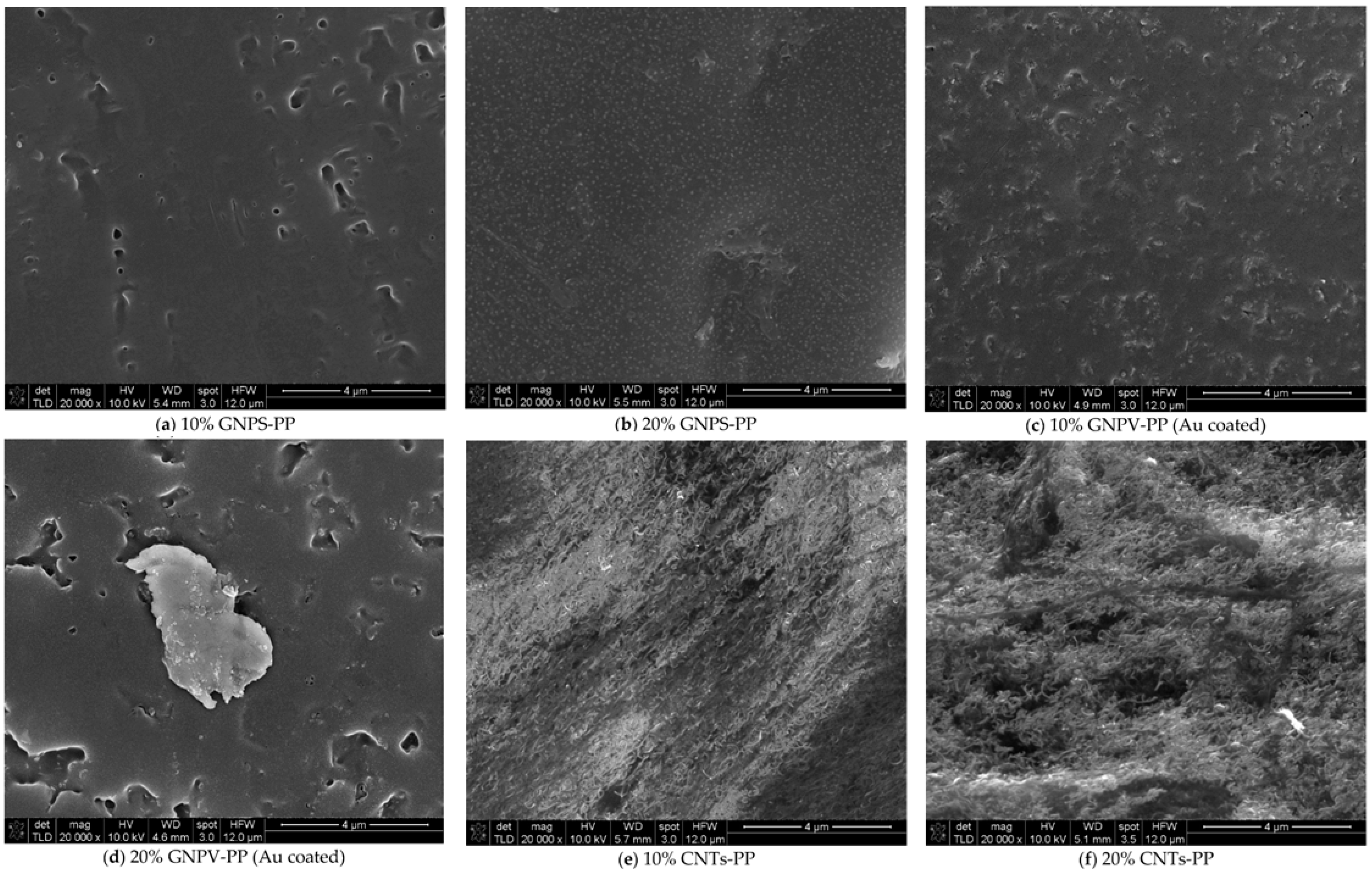

- Zaccone, M.; Frache, A.; Torre, L.; Armentano, I.; Monti, M. Effect of Filler Morphology on the Electrical and Thermal Conductivity of PP/Carbon-Based Nanocomposites. J. Compos. Sci. 2021, 5, 196. [Google Scholar] [CrossRef]

- Wang, C.; Wu, Y.-J.; Fang, C.-Y.; Tsai, C.-W. Electrospun nanofiber-reinforced polypropylene composites: Nucleating ability of nanofibers. Compos. Sci. Technol. 2016, 126, 1–8. [Google Scholar] [CrossRef]

- Zhang, J.; Panwar, A.; Bello, D.; Jozokos, T.; Isaacs, J.A.; Barry, C.; Mead, J. The effects of recycling on the properties of carbon nanotube-filled polypropylene composites and worker exposures. Environ. Sci. Nano 2016, 3, 409–417. [Google Scholar] [CrossRef]

- Pathak, A.K.; Yokozeki, T. Recycled Carbon Nanofiber-Polypropylene Nanocomposite: A Step towards Sustainable Structural Material Development. J. Compos. Sci. 2022, 6, 332. [Google Scholar] [CrossRef]

- Zhao, J.; Geng, Z.; Wang, S.; Xu, Z.; Wang, Q.; Zhang, D. Recyclable Carbon Nanotube/Thiol-Ended Hyperbranched Polymer Nanocomposite: Implication for Flexible Wearable Devices. ACS Appl. Nano Mater. 2024, 7, 12334. [Google Scholar] [CrossRef]

- Zdiri, K.; Elamri, A.; Hamdaoui, M.; Harzallah, O.; Khenoussi, N.; Brendlé, J. Reinforcement of recycled PP polymers by nanoparticles incorporation. Green Chem. Lett. Rev. 2018, 11, 296–311. [Google Scholar] [CrossRef]

- Ratanawilai, T.; Raksarak, N. Properties of polypropylene composites as function of reinforcement by plant fibers. Ind. Crops Prod. 2024, 222, 120025. [Google Scholar] [CrossRef]

- Velásquez, E.; López de Dicastillo, C.; Patiño Vidal, C.; Copello, G.; Reyes, C.; Guarda, A.; Galotto, M.J. Feasibility of Valorization of Post-Consumer Recycled Flexible Polypropylene by Adding Fumed Nanosilica for Its Potential Use in Food Packaging toward Sustainability. Polymers 2023, 15, 1081. [Google Scholar] [CrossRef]

- Tariq, M.; Utkarsh; Syed, N.A.; Behravesh, A.H.; Pop-Iliev, R.; Rizvi, G. Optimization of Filler Compositions of Electrically Conductive Polypropylene Composites for the Manufacturing of Bipolar Plates. Polymers 2023, 15, 3076. [Google Scholar] [CrossRef]

- Yetgin, S.H. Effect of multi walled carbon nanotube on mechanical, thermal and rheological properties of polypropylene. J. Mater. Res. Technol. 2019, 8, 4725–4735. [Google Scholar] [CrossRef]

- Bansal, S.; Kumar, N.; Jindal, P. Effect of MWCNT Composition on the Hardness of PP/MWCNT Composites. Mater. Today Proc. 2017, 4, 3867–3871. [Google Scholar] [CrossRef]

- Wang, P.-H.; Sarkar, S.; Gulgunje, P.; Verghese, N.; Kumar, S. Structure and rheological behavior of polypropylene interphase at high carbon nanotube concentration. Polymer 2018, 150, 10–25. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Charlier, J.C.; Hernández, E. Electronic, thermal and mechanical properties of carbon nanotubes. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2004, 362, 2065–2098. [Google Scholar] [CrossRef] [PubMed]

- Dresselhaus, M.S.; Dresselhaus, G.; Avouris, P. Carbon Nanotubes: Synthesis, Structure, Properties, and Application; Springer: Berlin/Heidelberg, Germany, 2000; p. 464. [Google Scholar]

- Zaporotskova, I.V. Uglerodnye i Neuglerodnye Nanomaterialy i Kompozitnye Struktury na Ikh Osnove: Stroenie i Elektronnye Svoistva [Carbon and Non-Carbon Nanotubes and Composite Structures on Their Basis: Structure and Electronic Properties]; Izd-vo VolGU: Volgograd, Russia, 2009; p. 490. [Google Scholar]

- D’yachkov, P.N. Elektronnye Svoistva i Primenenie Nanotrubok [Electronic Properties and Applications of Nanotubes]; BI-NOM, Laboratoriya Znanii: Moscow, Russia, 2010; p. 488. [Google Scholar]

- Spitalsky, Z.; Tasis, D.; Papagelis, K. Costas Galiotis Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

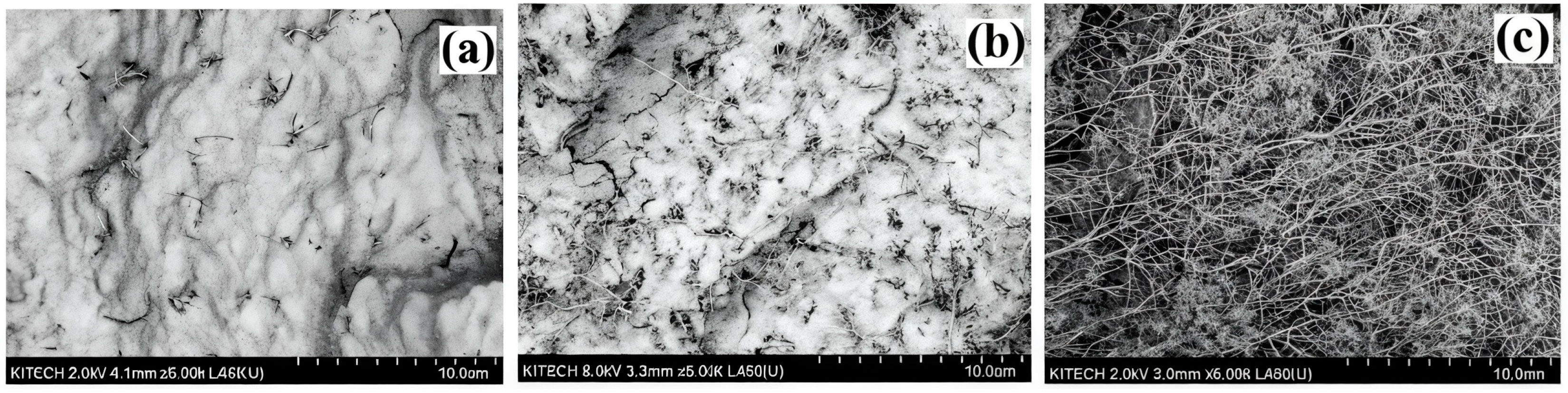

- Kim, G.M.; Kil, T.; Lee, H.K. A novel physicomechanical approach to dispersion of carbon nanotubes in polypropylene composites. Compos. Struct. 2021, 258, 113377. [Google Scholar] [CrossRef]

- Hilding, J.; Grulke, E.A.; Zhang, Z.G.; Lockwood, F. Dispersion of Carbon Nanotubes in Liquids. J. Dispers. Sci. Technol. 2007, 24, 1–41. [Google Scholar] [CrossRef]

- Polat, G.; Canbolat, I.E.; Uzunoğlu, A.; Kotan, H. Effect of milling time, MWCNT content, and annealing temperature on microstructure and hardness of Fe/MWCNT nanocomposites synthesized by high-energy ball milling. Adv. Powder Technol. 2021, 32, 3107–3116. [Google Scholar] [CrossRef]

- Rosemary, M.J. Manufacturing Techniques for Carbon Nanotube-Polymer Composites. In Handbook of Carbon Nanotubes; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Parnian, P.; D’Amore, A. Fabrication of high-performance cnt reinforced polymer composite for additive manufacturing by phase inversion technique. Polymers 2021, 13, 4007. [Google Scholar] [CrossRef]

- Elbakyan, L.; Zaporotskova, I. Composite Nanomaterials Based on Polymethylmethacrylate Doped with Carbon Nanotubes and Nanoparticles: A Review. Polymers 2024, 16, 1242. [Google Scholar] [CrossRef]

- Sahli, M.L.; Barriere, T.; Roizard, X.; Assoul, M. Investigating mechanical, thermal and rheological properties of polypropylene/carbon nanotubes composites. Microsyst. Technol. 2020, 26, 3023–3027. [Google Scholar] [CrossRef]

- Mi, D.; Zhao, Z.; Bai, H. Effects of Orientation and Dispersion on Electrical Conductivity and Mechanical Properties of Carbon Nanotube/Polypropylene Composite. Polymers 2023, 15, 2370. [Google Scholar] [CrossRef]

- Martínez-Colunga, J.G.; Cruz-Delgado, V.J.; Sánchez-Valdés, S.; Mata-Padilla, J.M.; Valle, L.F.R.-D.; Espinoza-Martínez, A.B.; Benavides, R.; Ramírez-Vargas, E.; Rodriguez-Gonzalez, J.A.; Lara-Sanchez, J.F.; et al. Application of ultrasonic radiation for the development of polypropylene/multi-walled carbon nanotubes nanocomposites and its effect on the PP chemical degradation. Iran. Polym. J. 2024, 33, 1751–1764. [Google Scholar] [CrossRef]

- Stanciu, N.-V.; Stan, F.; Sandu, I.-L.; Fetecau, C.; Turcanu, A.-M. Thermal, Rheological, Mechanical, and Electrical Properties of Polypropylene/Multi-Walled Carbon Nanotube Nanocomposites. Polymers 2021, 12, 187. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.; Hwang, S.; Jung, B.; Shim, J. Characterizations of Polypropylene/Single-Walled Carbon Nanotube Nanocomposites Prepared by the Novel Melt Processing Technique with a Controlled Residence Time. Processes 2021, 9, 1395. [Google Scholar] [CrossRef]

- Sabet, M.; Soleimani, H. The Impact of Carbon Nanotube on the Thermal Properties of Polypropylene. Defect Diffus. Forum 2023, 429, 191–208. [Google Scholar] [CrossRef]

- Patil, J.; Patil, H.; Sankpal, R.; Rathod, D.; Patil, K.; Kubade, P.R.; Kulkarni, H.B. Studies on mechanical and thermal performance of carbon nanotubes/polypropylene nanocomposites. Mater. Today Proc. 2021, 46, 7182–7186. [Google Scholar] [CrossRef]

- Sabet, M. Multi-walled carbon nanotube reinforcement in polypropylene nanocomposites: Comprehensive analysis of thermal behavior, mechanical properties, and dispersion characteristics. J. Therm. Anal. Calorim. 2024, 149, 3165–3179. [Google Scholar] [CrossRef]

- Niu, X.; Chen, Y.; Li, Z.; Guo, T.; Ren, M.; Chen, Y. Study on the Properties of Multi-Walled Carbon Nanotubes (MWCNTs)/Polypropylene Fiber (PP Fiber) Cement-Based Materials. Polymers 2024, 16, 41. [Google Scholar] [CrossRef]

- Stan, F.; Turcanu, A.-M.; Fetecau, C. Analysis of Viscoelastic Behavior of Polypropylene/Carbon Nanotube Nanocomposites by Instrumented Indentation. Polymers 2020, 12, 2535. [Google Scholar] [CrossRef]

- Bisht, P.S.; Arora, G.; Pathak, H. Strain-rate sensitivity analysis of microwave processed polypropylene-carbon nanotube composites. J. Eng. Res. 2024, in press. [Google Scholar] [CrossRef]

- Jia, Y.; Peng, K.; Gong, X.-L.; Zhang, Z. Creep and recovery of polypropylene/carbon nanotube composites. Int. J. Plast. 2011, 27, 1239–1251. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Mahmoodi, M.J.; Ansari, R. Creep performance of CNT polymer nanocomposites -An emphasis on viscoelastic interphase and CNT agglomeration. Compos. Part B Eng. 2019, 168, 274–281. [Google Scholar] [CrossRef]

- Wu, C.; Wu, R.; Tam, L.-H. The creep behavior of semicrystalline carbon nanotube/polypropylene nanocomposite: A coarse-grained molecular study. Polym. Degrad. Stab. 2022, 196, 109834. [Google Scholar] [CrossRef]

- Arash, B.; Park, H.S.; Rabczuk, T. Mechanical properties of carbon nanotube reinforced polymer nanocomposites: A coarse-grained model. Compos. Part B Eng. 2015, 80, 92–100. [Google Scholar] [CrossRef]

- Sabet, M. Enhancing the thermal and crystallization properties of polypropylene through carbon nanotube integration: A comprehensive investigation. Iran. Polym. J. 2024, 33, 727–741. [Google Scholar] [CrossRef]

- Xu, F.; Sadrzadeh, A.; Xu, Z.; Yakobson, B.I. Can carbon nanotube fibers achieve the ultimate conductivity?—Coupled-mode analysis for electron transport through the carbon nanotube contact. J. Appl. Phys. 2013, 114, 063714. [Google Scholar] [CrossRef]

- Ameli, A.; Nofar, M.; Park, C.B.; Pötschke, P.; Rizvi, G. Polypropylene/carbon nanotube nano/microcellular structures with high dielectric permittivity, low dielectric loss, and low percolation threshold. Carbon 2014, 71, 206–217. [Google Scholar] [CrossRef]

- Gulrez, S.K.; Ali Mohsin, M.; Shaikh, H.; Anis, A.; Pulose, A.M.; Yadav, M.K.; Qua, E.H.P.; Al-Zahrani, S. A review on electrically conductive polypropylene and polyethylene. Polym. Compos. 2014, 35, 900–914. [Google Scholar] [CrossRef]

- Zhao, K.; Li, S.; Huang, M.; Shi, X.; Zheng, G.; Liu, C.; Dai, K.; Shen, C.; Yin, R.; Guo, J.Z. Remarkably Anisotropic Conductive MWCNTs/Polypropylene Nanocomposites with Alternating Microlayers. Chem. Eng. J. 2018, 358, 924–935. [Google Scholar] [CrossRef]

- Li, C.; Jiao, Z.; Xiong, L.; Yang, W. Electrical conductivity of carbon nanotube/polypropylene composites prepared through microlayer extrusion technology. J. Polym. Eng. 2017, 37, 795–804. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Mishra, J.; Hatui, G.; Nayak, G.C. Conductive Polymer Composites Based on Carbon Nanomaterials. In Conducting Polymer Hybrids. Springer Series on Polymer and Composite Materials; Kumar, V., Kalia, S., Swart, H., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Wang, J.; Kazemi, Y.; Wang, S.; Hamidinejad, M.; Mahmud, M.B.; Pötschke, P.; Park, C.B. Enhancing the electrical conductivity of PP/CNT nanocomposites through crystal-induced volume exclusion effect with a slow cooling rate. Compos. Part B Eng. 2020, 183, 107663. [Google Scholar] [CrossRef]

- Balam, A.; Pech-Pisté, R.; Valdez-Nava, Z.; Gamboa, F.; Castillo-Atoche, A.; Avilés, F. A Comparative Study of the Electrical and Electromechanical Responses of Carbon Nanotube/Polypropylene Composites in Alternating and Direct Current. Sensors 2022, 22, 484. [Google Scholar] [CrossRef] [PubMed]

- Zaccone, M.; Armentano, I.; Cesano, F.; Scarano, D.; Frache, A.; Torre, L.; Monti, M. Effect of Injection Molding Conditions on Crystalline Structure and Electrical Resistivity of PP/MWCNT Nanocomposites. Polymers 2020, 12, 1685. [Google Scholar] [CrossRef]

- Alimoradi, Y.; Nourisefat, M.; Nazokdast, H. Concurrent effect of shear flow and CNT presence on crystallization behavior and electrical properties of polypropylene based nanocomposites: A comprehensive structure-property investigation. J. Compos. Mater. 2024, 58, 13. [Google Scholar] [CrossRef]

- Coppola, B.; Di Maio, L.; Incarnato, L.; Tulliani, J.-M. Preparation and Characterization of Polypropylene/Carbon Nanotubes (PP/CNTs) Nanocomposites as Potential Strain Gauges for Structural Health Monitoring. Nanomaterials 2020, 10, 814. [Google Scholar] [CrossRef]

- Tudose, I.V.; Mouratis, K.; Ionescu, O.N.; Romanitan, C.; Pachiu, C.; Tutunaru-Brincoveanu, O.; Suchea, M.P.; Koudoumas, E. Comparative Study of Graphene Nanoplatelets and Multiwall Carbon Nanotubes-Polypropylene Composite Materials for Electromagnetic Shielding. Nanomaterials 2022, 12, 2411. [Google Scholar] [CrossRef]

- Kaushal, A.; Singh, V. Electromagnetic interference shielding response of multiwall carbon nanotube/polypropylene nanocomposites prepared via melt processing technique. Polym. Compos. 2021, 42, 1148–1154. [Google Scholar] [CrossRef]

- Kaushal, A.; Singh, V. Excellent electromagnetic interference shielding performance of polypropylene/carbon fiber/multiwalled carbon nanotube nanocomposites. Polym. Compos. 2022, 43, 3708–3715. [Google Scholar] [CrossRef]

- Elbakyan, L.; Zaporotskova, I.; Hayrapetyan, D. Nanocomposite Material Based on Polyvinyl Alcohol Modified with Carbon Nanotubes: Mechanism of Formation and Electronic Energy Structure. J. Compos. Sci. 2024, 8, 54. [Google Scholar] [CrossRef]

- Frisch, M.J.; Trucks, G.W.; Schlegel, H.B.; Scuseria, G.E.; Robb, J.R.; Cheeseman, G.; Scalmani, V.; Barone, B.; Mennucci, G.A.; Petersson, H.; et al. Gaussian 09; Revision A.1; Gaussian, Inc.: Wallingford, CT, USA, 2009. [Google Scholar]

- Elbakyan, L.S. Quantum Chemical Calculations using the Gaussian Software Package and the Gaussview Graphics Editor: Textbook; Publishing House of the VolSU: Volgograd, Russia, 2022; 81p. [Google Scholar]

| Nanofiller | Improved Properties | References |

|---|---|---|

| TiN | Mechanical (tensile strength, bending, impact strength, microhardness) | [30] |

| Si3N4 | Mechanical (tensile modulus of elasticity, bending strength) | [33] |

| Si | Rheological (flow rate) | [34] |

| CaCO3 | Mechanical (hardness and impact strength), crystallinity, thermal conductivity | [35] |

| Carbon nanofiber (CNF) | Mechanical (flexural strength) and thermal | [39] |

| Nanoclay (NC) | Mechanical (tensile strength, Young’s modulus), thermal and rheological properties | [41] |

| Graphene | Mechanical (tensile strength, modulus of elasticity) and electrical conductivity | [41] |

| Vegetable fibers (coconut, oil palm, and corn plant fibers) | Mechanical (the exception of flexural strength), thermal and fire-resistant characteristics | [42] |

| Nanosilica (NS) | Mechanical characteristics (Young’s modulus, tensile strength) | [43] |

| Types of CNT | Active Center | Adsorption Distance, Rad, Å | Adsorption Energy, ∆Ea, meV |

|---|---|---|---|

| SWCNT | H | 2.6 | 1.6 |

| MWCNT | H | 2.9 | 3.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elbakyan, L.; Zaporotskova, I. Polypropylene Modified with Carbon Nanomaterials: Structure, Properties and Application (A Review). Polymers 2025, 17, 517. https://doi.org/10.3390/polym17040517

Elbakyan L, Zaporotskova I. Polypropylene Modified with Carbon Nanomaterials: Structure, Properties and Application (A Review). Polymers. 2025; 17(4):517. https://doi.org/10.3390/polym17040517

Chicago/Turabian StyleElbakyan, Lusine, and Irina Zaporotskova. 2025. "Polypropylene Modified with Carbon Nanomaterials: Structure, Properties and Application (A Review)" Polymers 17, no. 4: 517. https://doi.org/10.3390/polym17040517

APA StyleElbakyan, L., & Zaporotskova, I. (2025). Polypropylene Modified with Carbon Nanomaterials: Structure, Properties and Application (A Review). Polymers, 17(4), 517. https://doi.org/10.3390/polym17040517