Integrated Strategies for Controlling Water Cut in Mature Oil Fields in Kazakhstan

Abstract

1. Introduction

Theoretical Justification of Polymer Flooding

- Optimal polymer concentration: 0.10–0.15%

- Reduction in water mobility under reservoir conditions: 35–50%

- Increase in oil displacement efficiency: 15–20%

- Optimal polymer solution viscosity for Kumkol conditions: 10–15 cP.

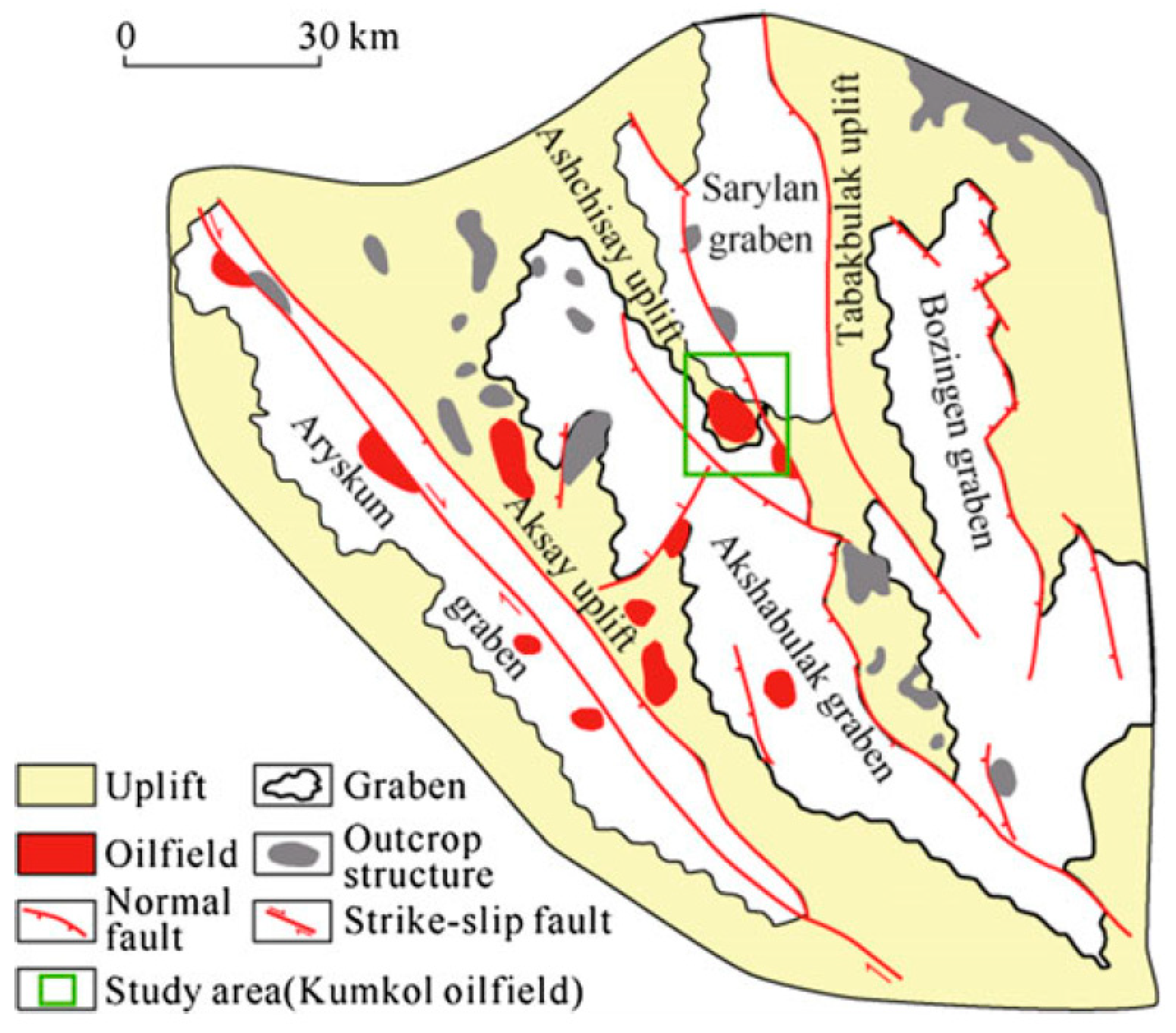

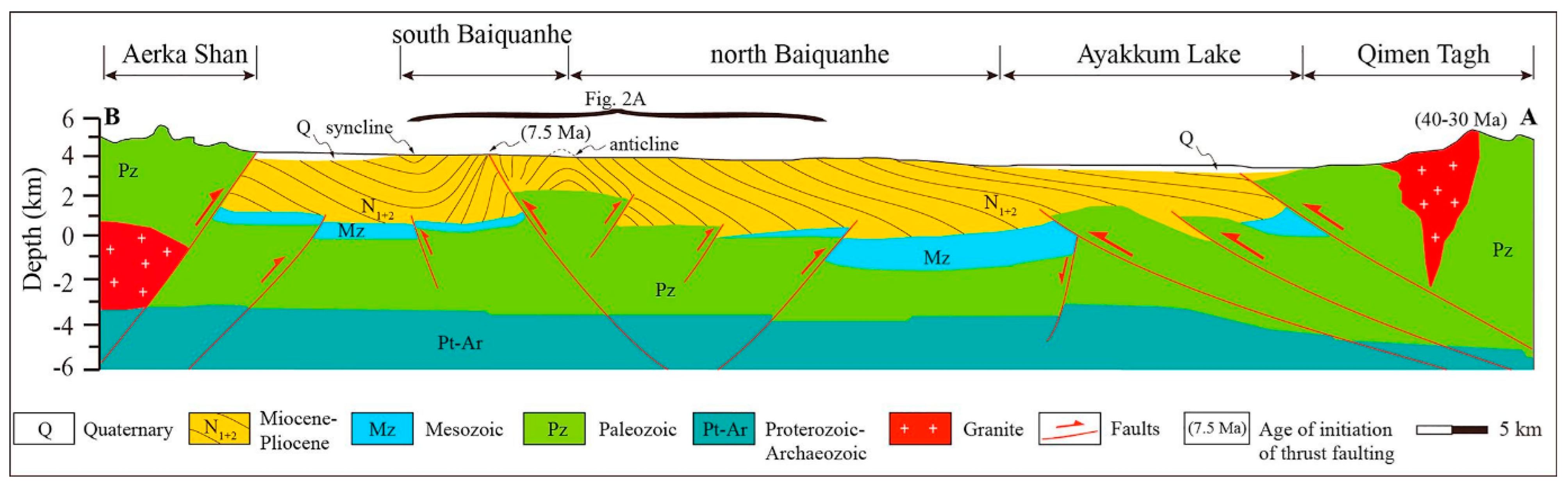

2. Geological and Hydrocarbon Potential of the Kumkol and East Kumkol Deposits

2.1. Geological Setting

- Horizon M-I: A layered, arched oil deposit with dimensions of 14.2 × 4.6 km and a height of 48.7 m.

- Horizon M-II: A massive oil deposit, 5.2 × 2.7 km in size and 25 m high.

- Horizon J-I: Contains the largest oil-bearing area with a layered, arched deposit measuring 19.7 × 8.8 km and 133.3 m in height (gas cap: 43.8 m; oil zone: 89.5 m).

- Horizon J-II: Features a layered, arched deposit with dimensions of 18 × 7.8 km and oil-bearing and gas-bearing areas of 61,249 and 2728 thousand m2, respectively.

- Horizon J-III: Comprises three deposits, including a gas-capped oil deposit and two smaller accumulations, with oil-bearing areas up to 38,083 thousand m2.

- Horizon J-IV: A lithologically limited gas and oil deposit, 4.0 × 5.8 km in size and 37.3 m in oil thickness.

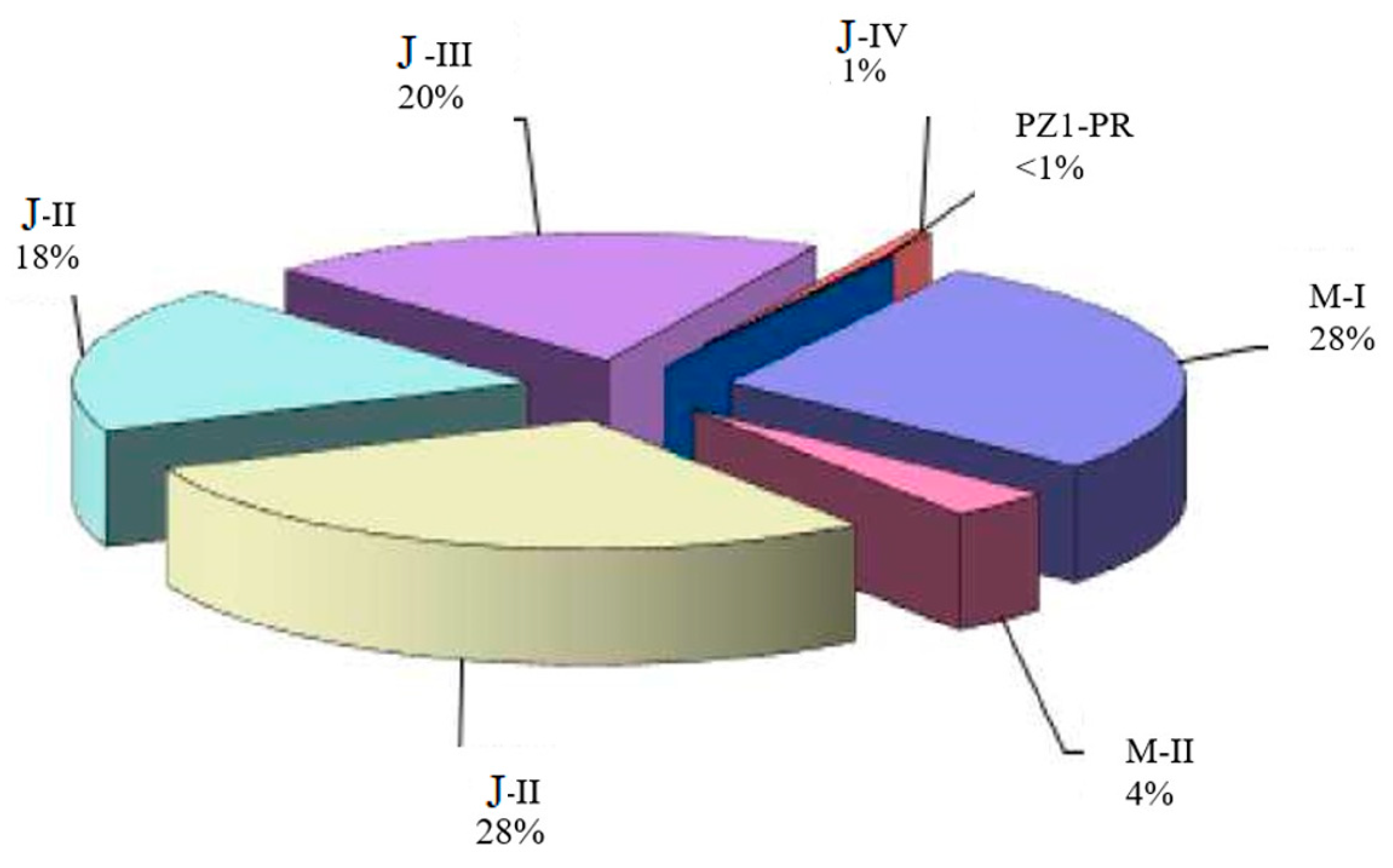

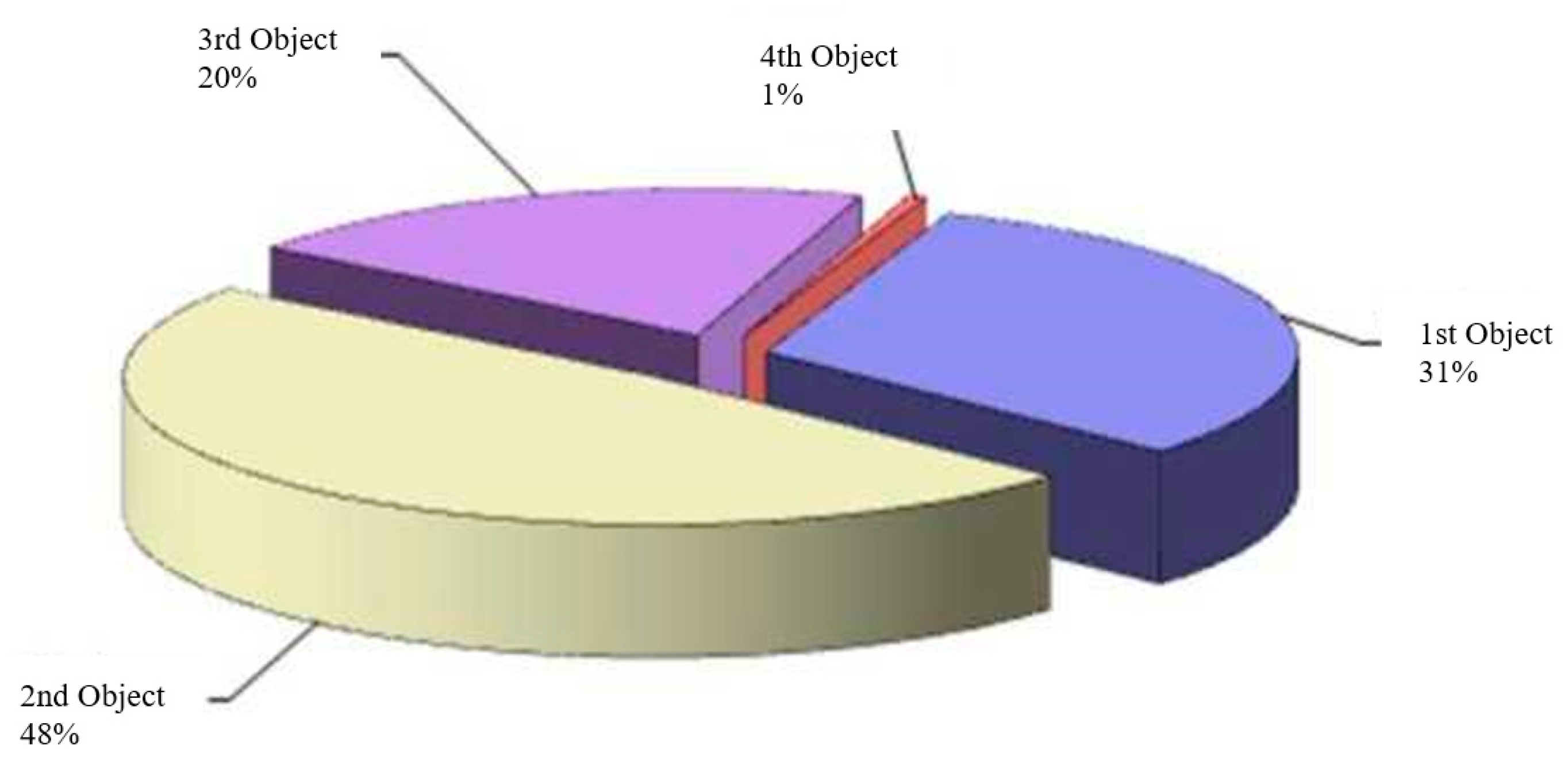

2.2. Hydrocarbon Potential

3. Data and Methods

4. Results and Discussion

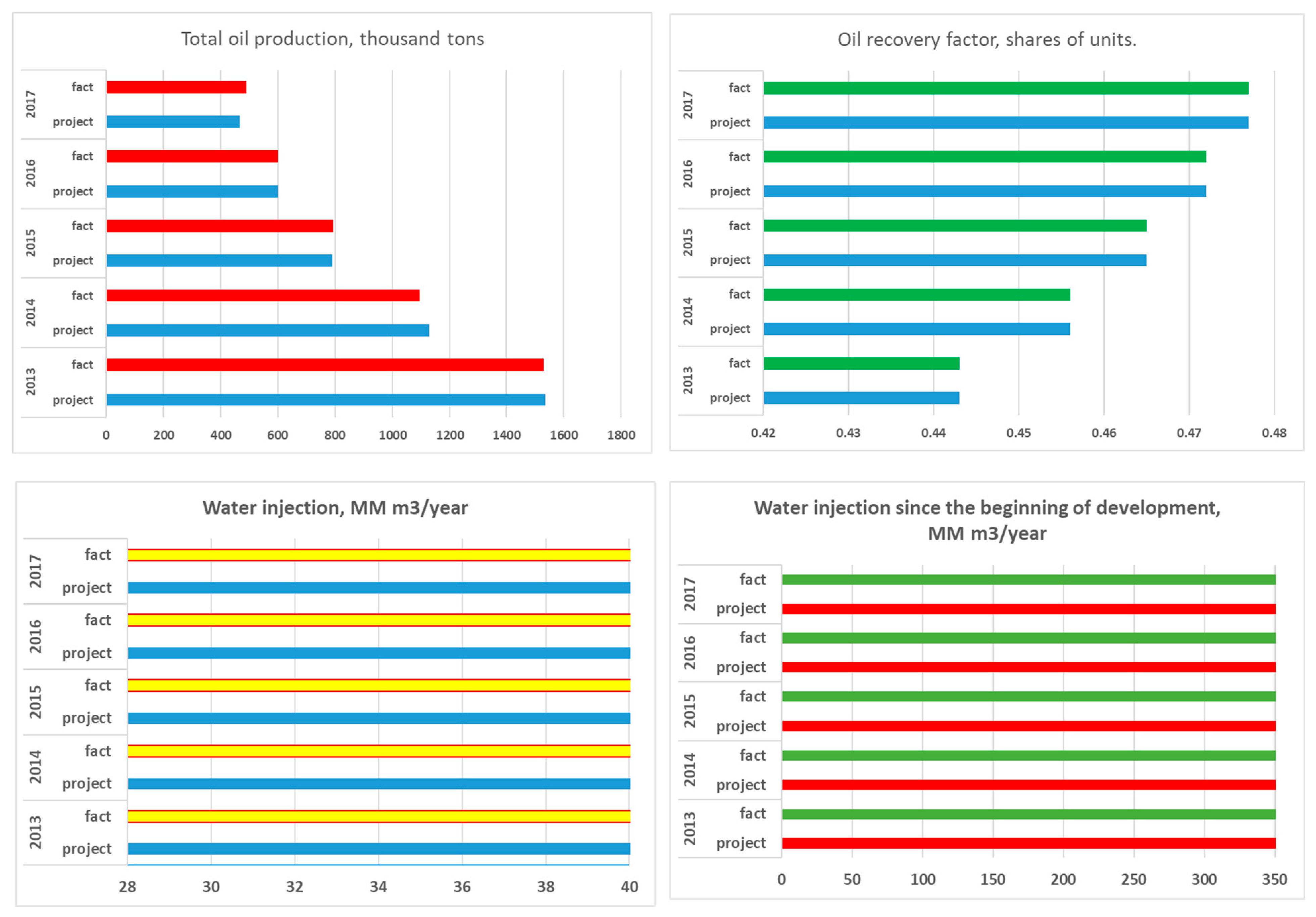

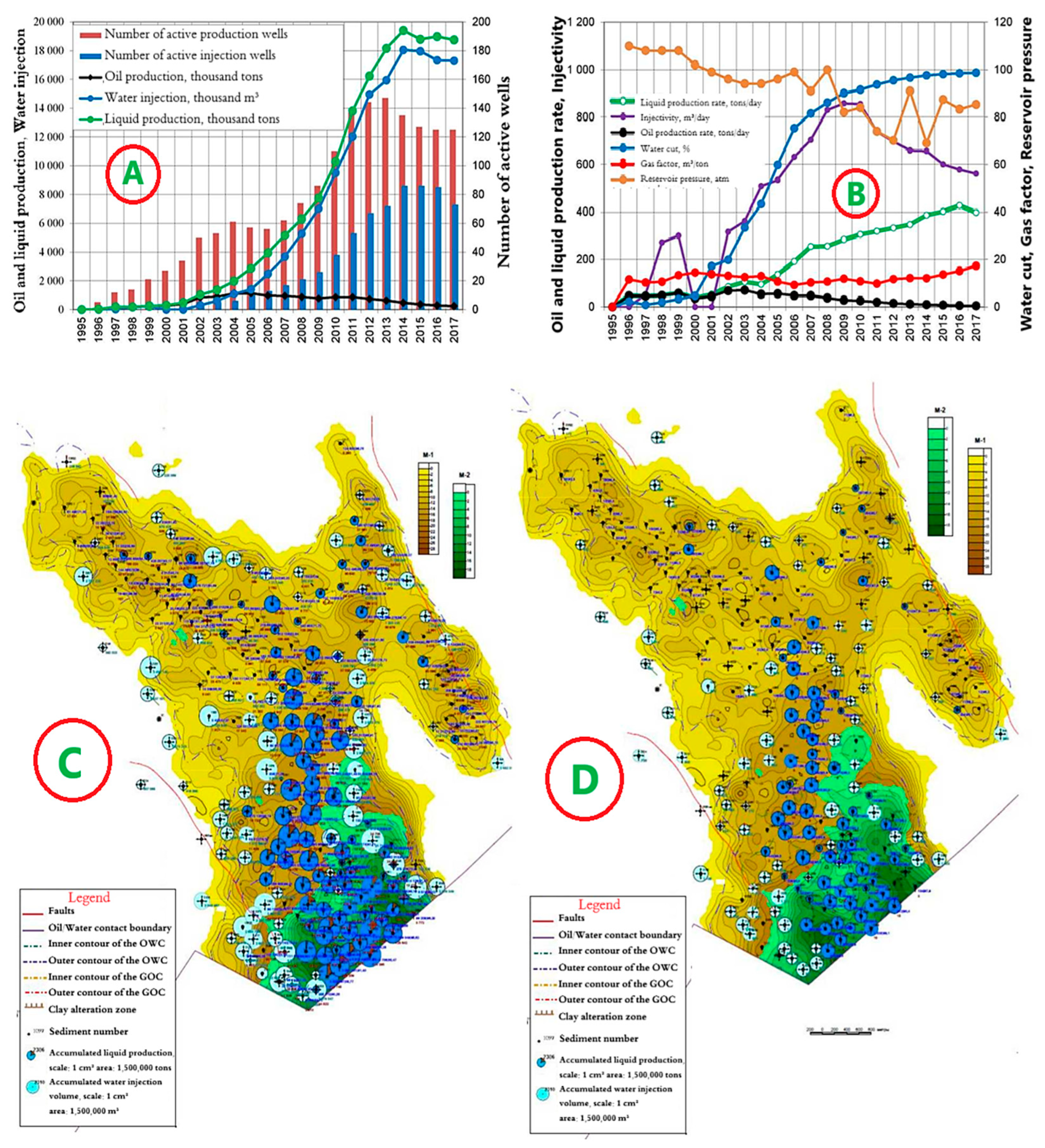

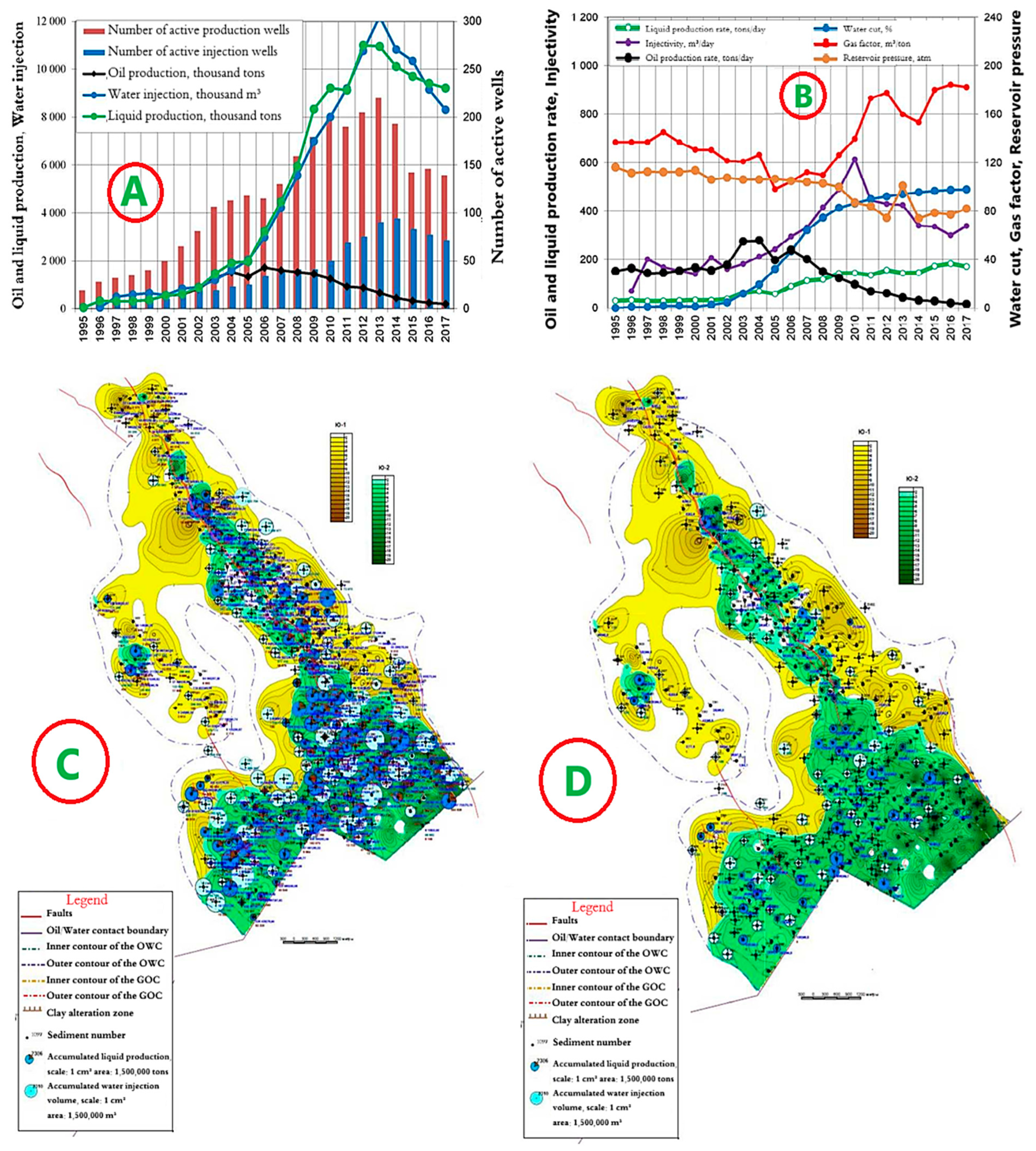

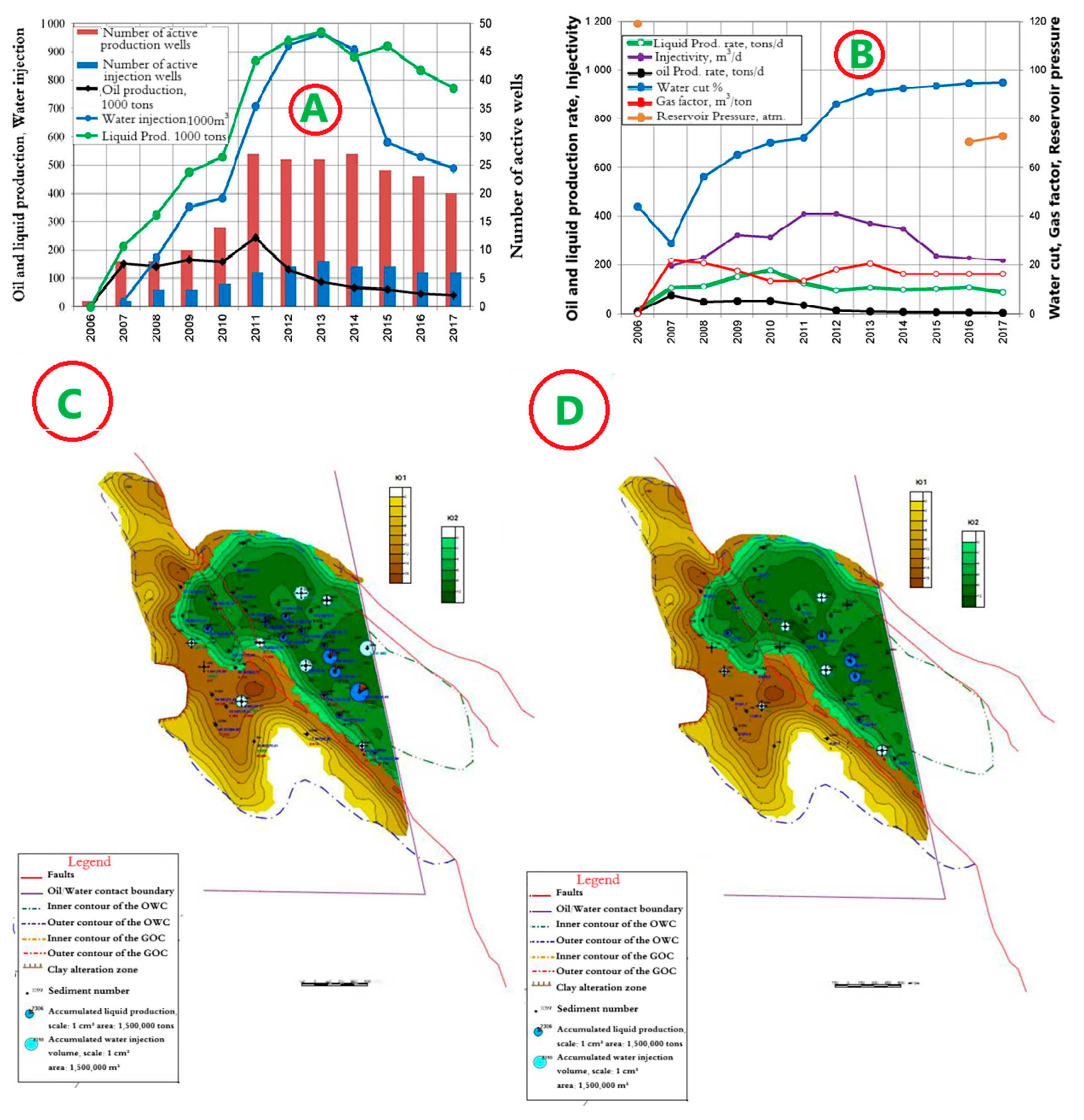

4.1. Horizon Object I—Kumkol Field

4.2. Horizon Object II—Kumkol Field

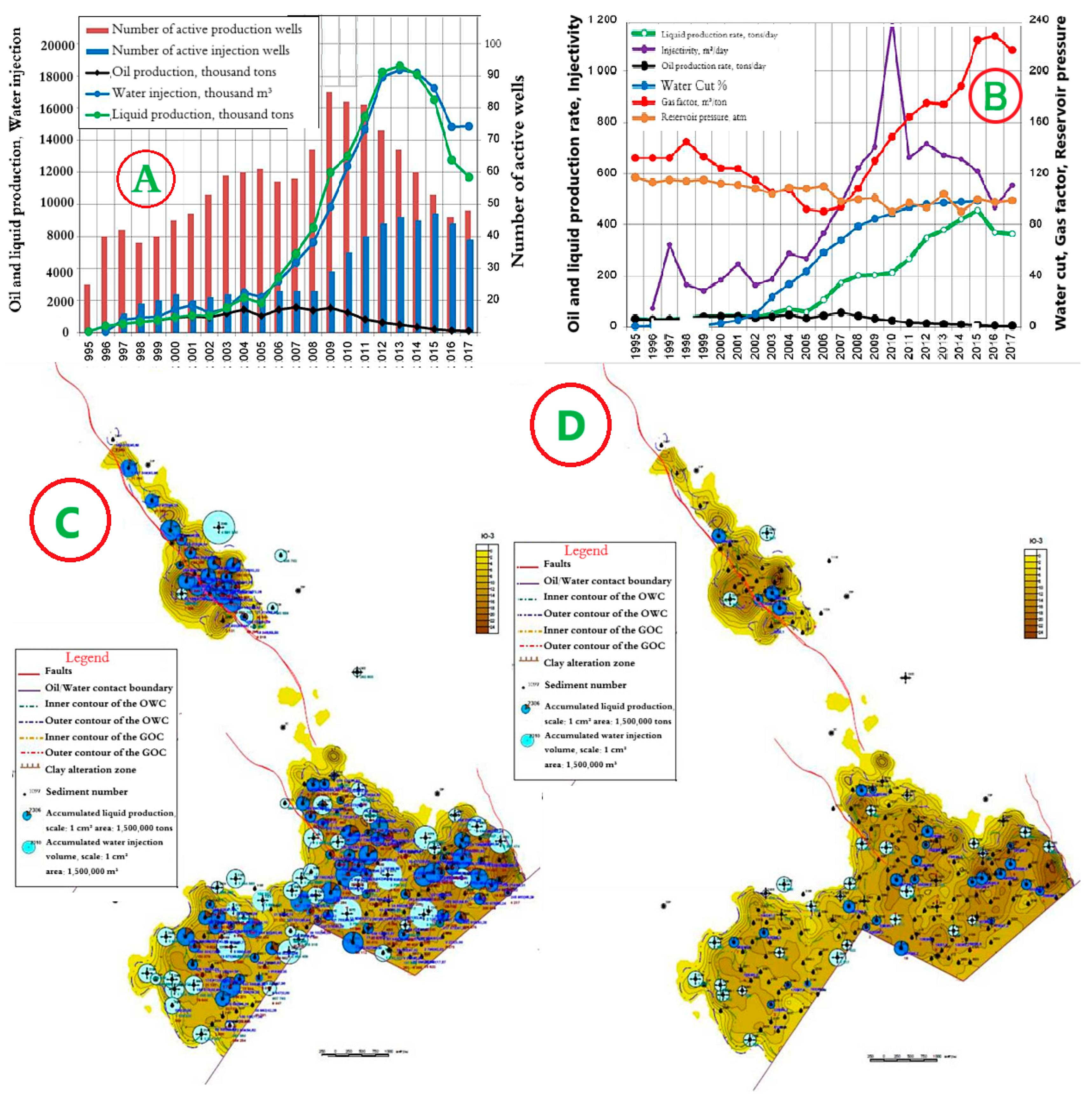

4.3. Horizon Object III—Kumkol Field

4.4. Horizon Object IV—Kumkol Field

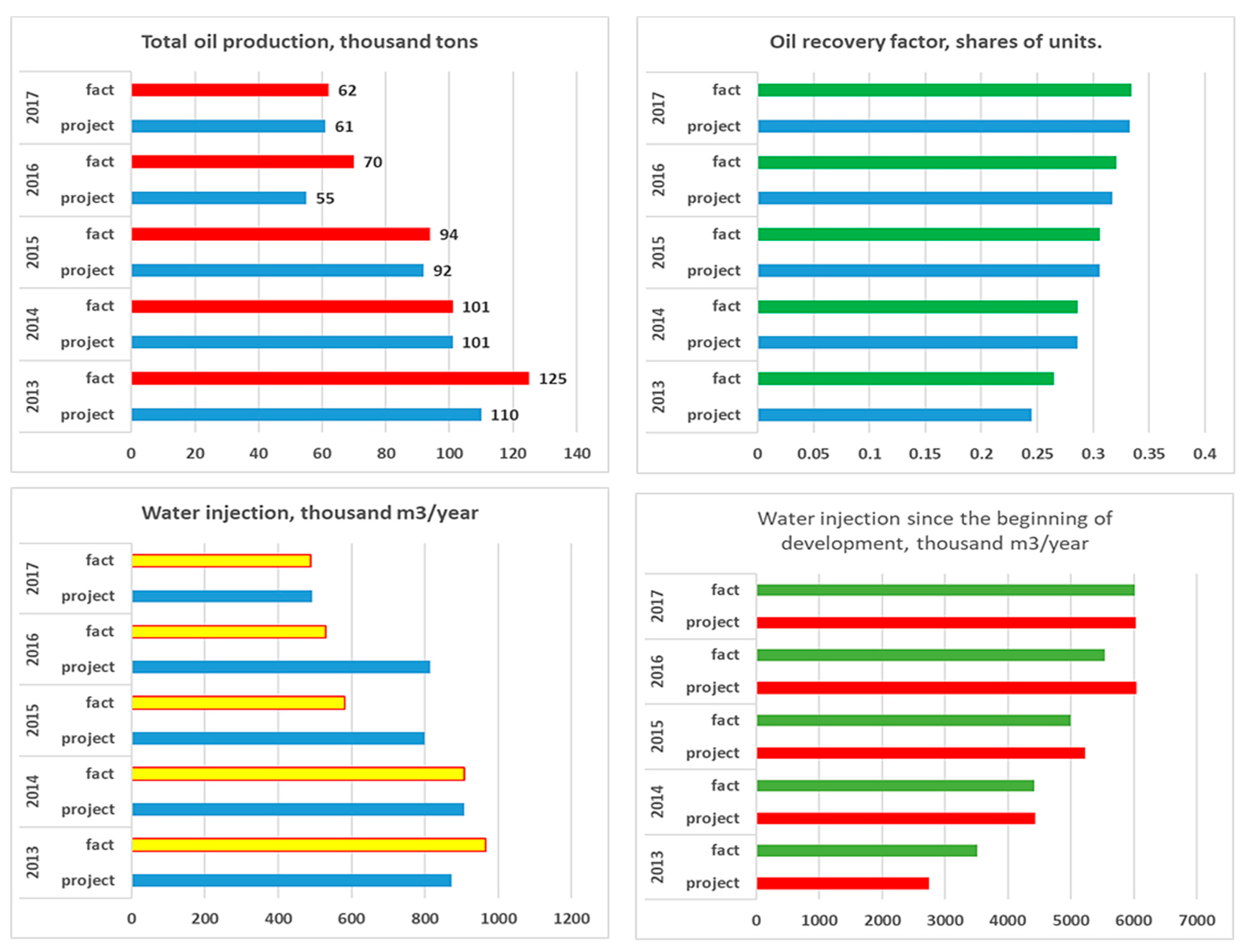

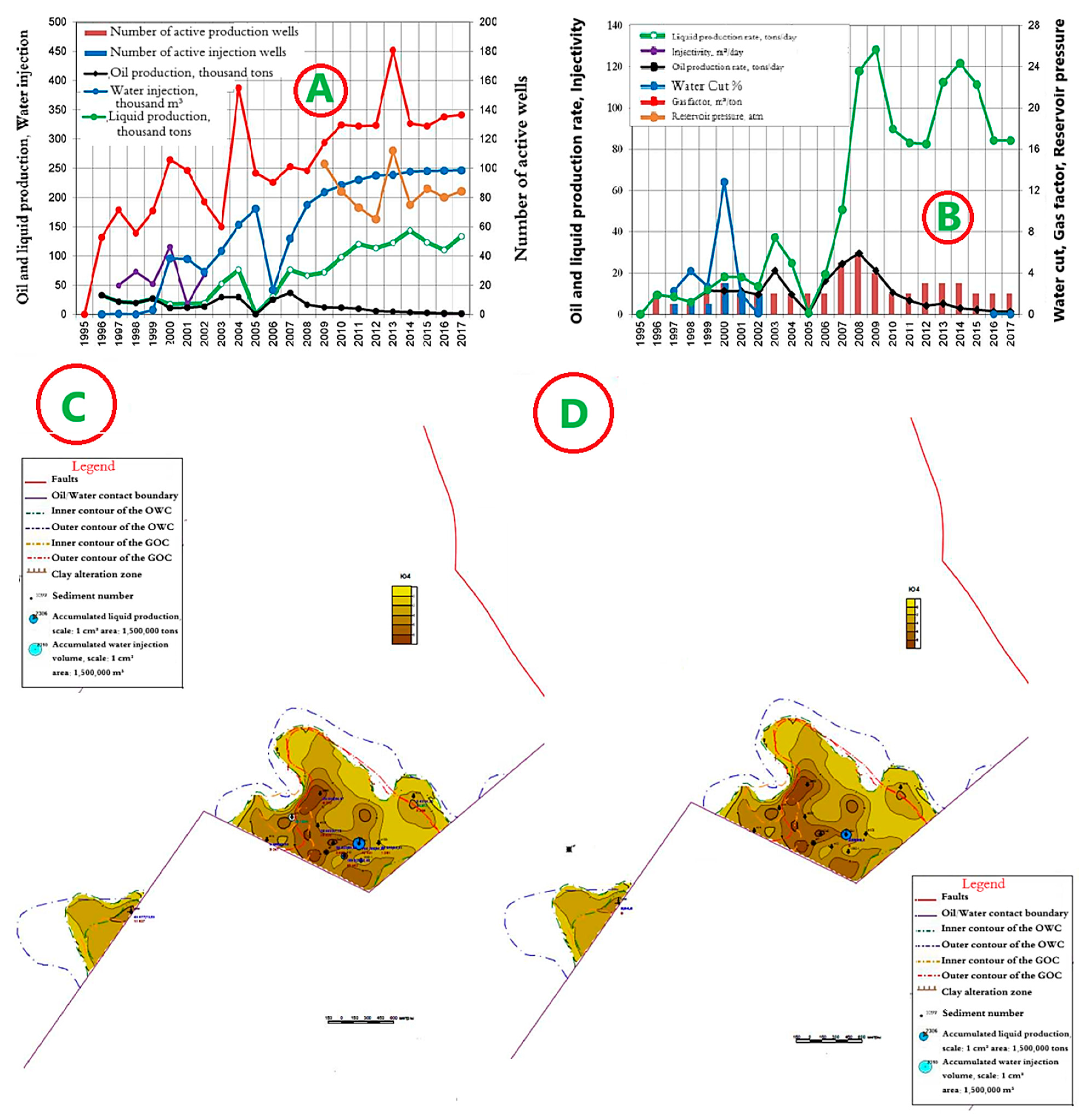

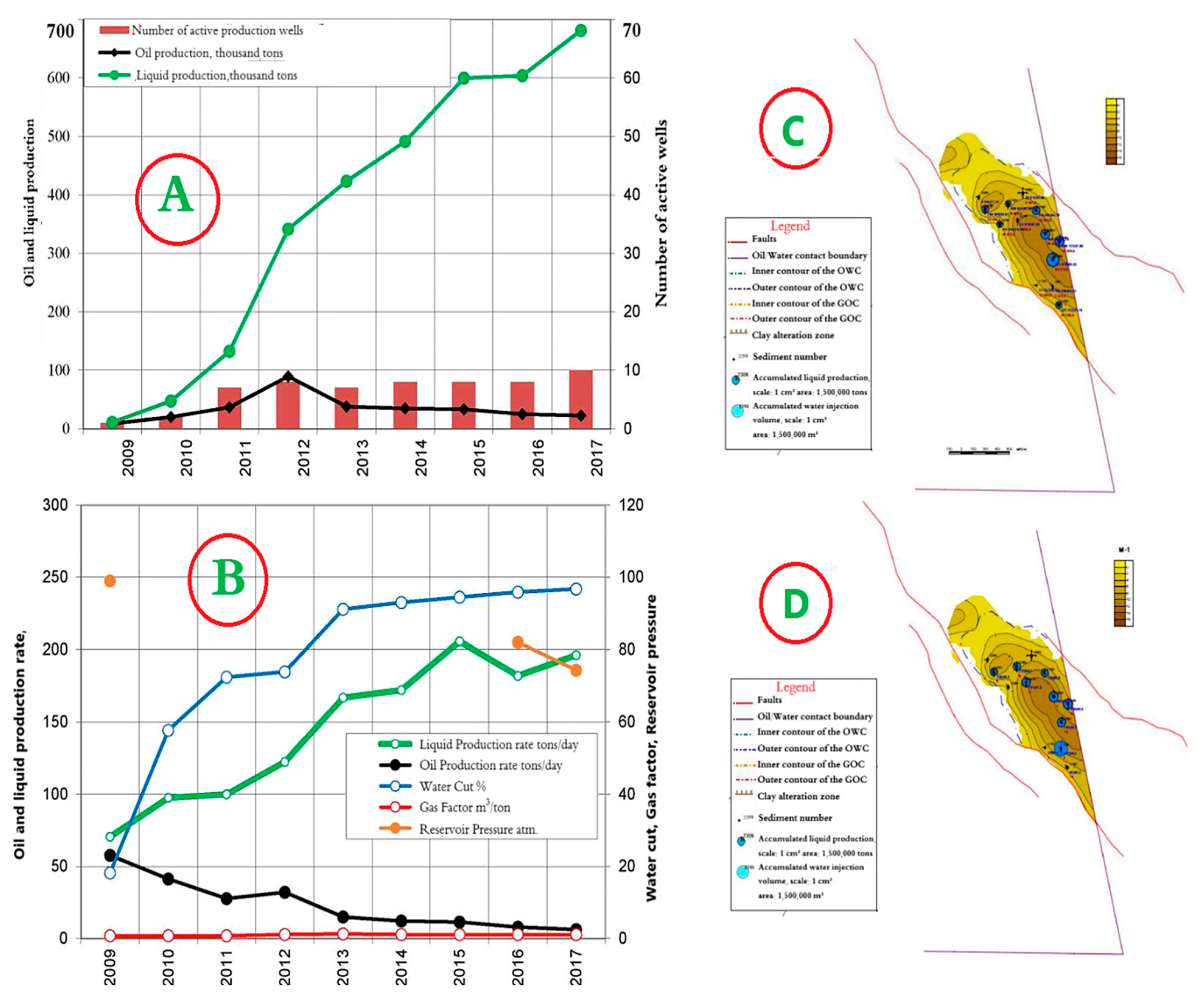

4.5. Horizon Object I—East Kumkol Field

4.6. Horizon Object II—East Kumkol Field

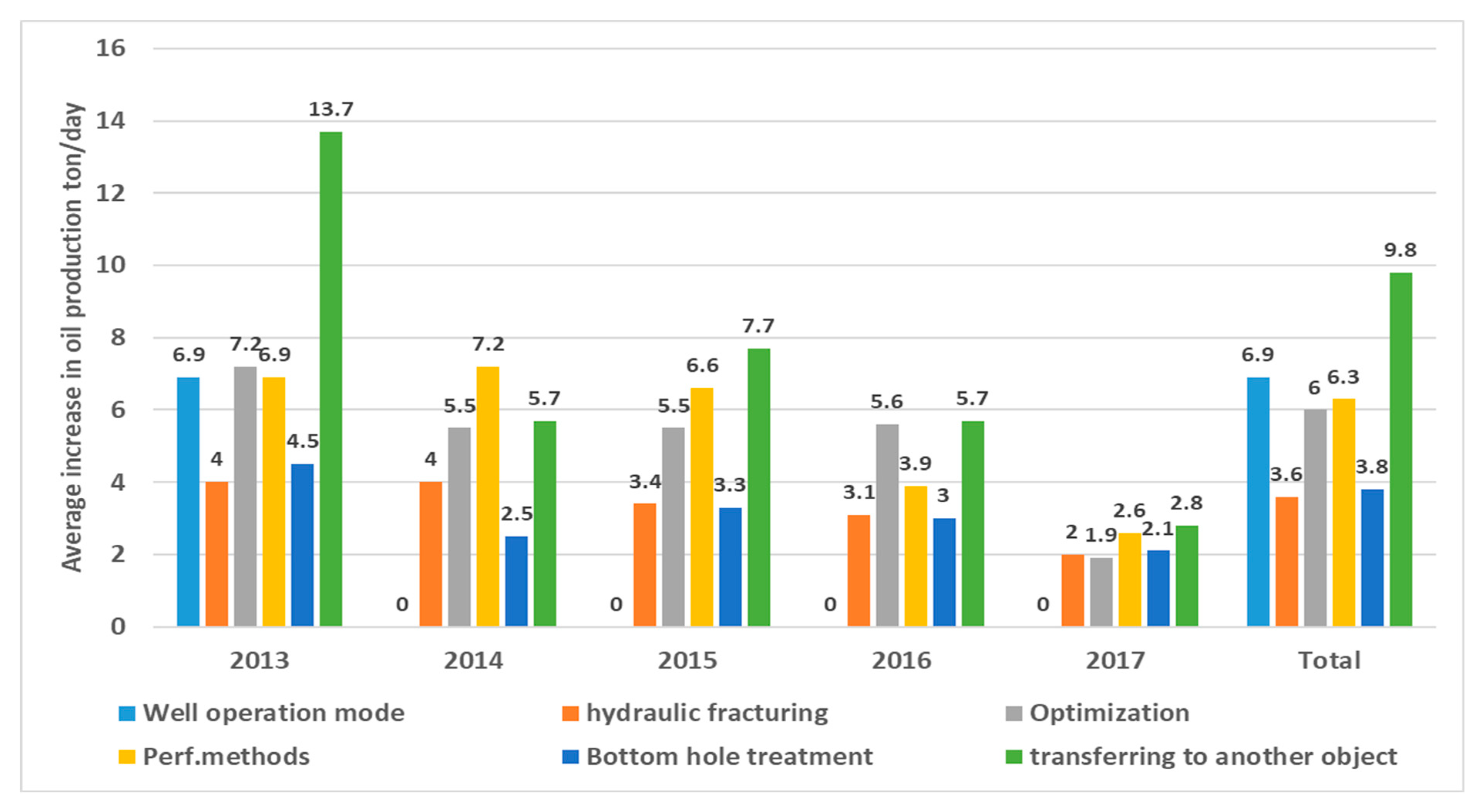

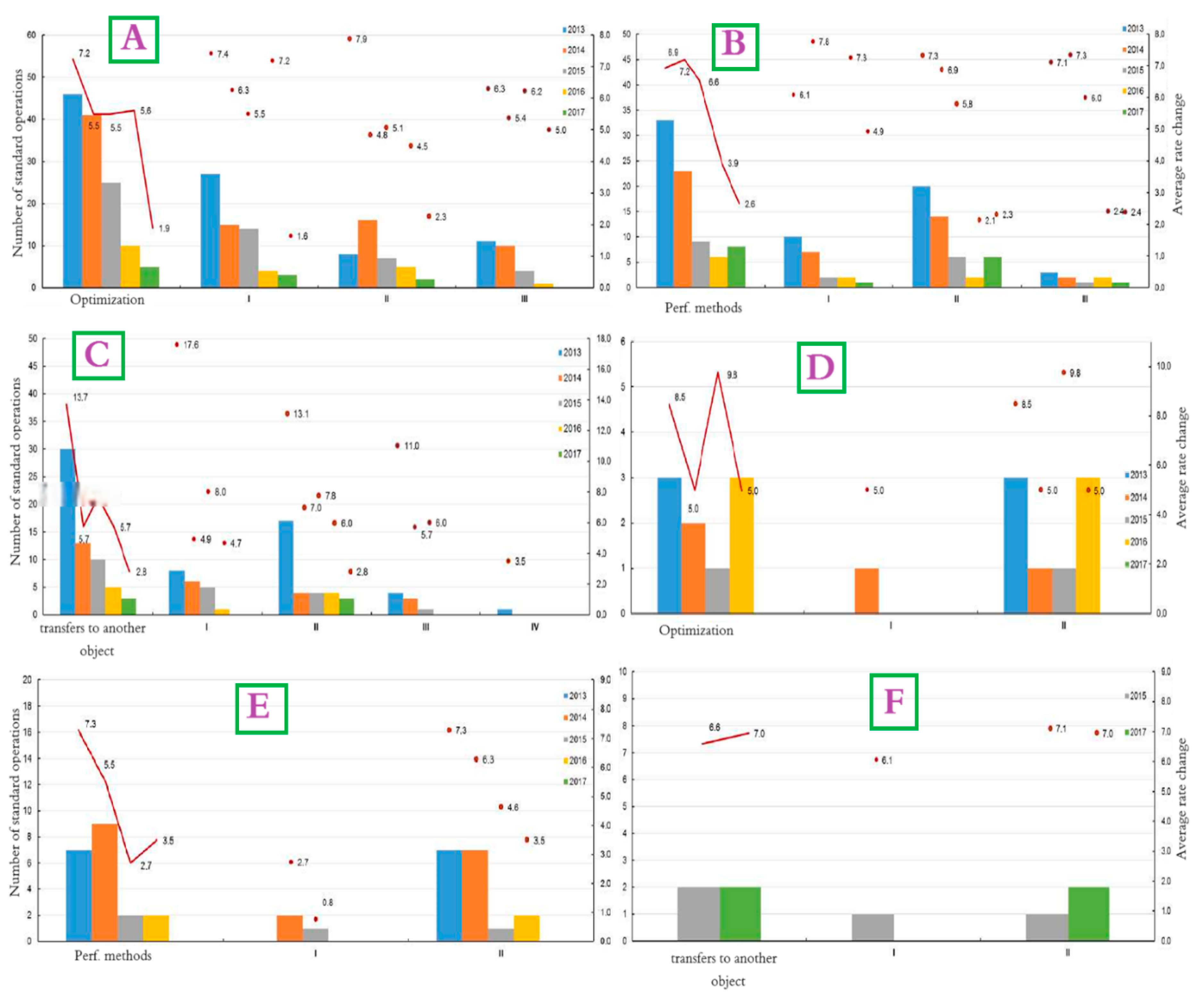

4.7. Well Interventions for Kumkol Field

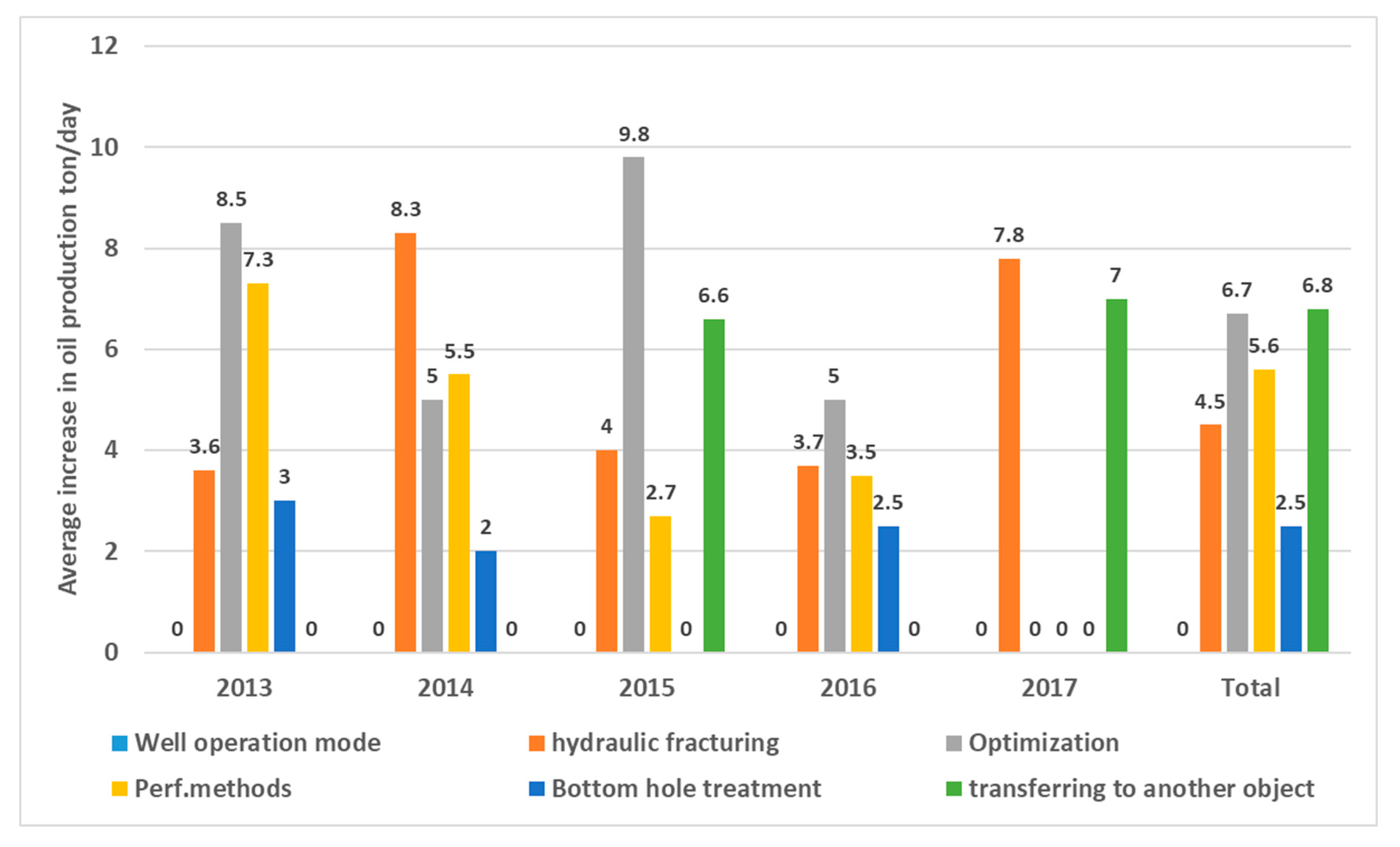

4.8. Well Interventions for East Kumkol Field

5. Economic and Technological Feasibility of Polymer Flooding

6. Conclusions

- Implementation of polymer flooding as the primary EOR strategy in high-water-cut reservoirs to improve mobility control and enhance sweep efficiency.

- Optimization of polymer selection based on formation temperature, water salinity, and polymer rheology to ensure long-term stability and efficiency.

- Integration of polymer flooding with existing water management strategies to minimize water production and extend the economic life of the reservoir.

- Continued monitoring and numerical modeling to evaluate the long-term performance of polymer flooding and adjust injection strategies accordingly.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, A.; Alabdrabalnabi, M.; Ramadan, M.A.; Aljawad, M.S.; Almohsin, A.; Azad, M. A Review of Recent Developments in Nanomaterial Agents for Water Shutoff in Hydrocarbon Wells. ACS Omega 2024, 9, 14728–14746. [Google Scholar] [CrossRef]

- Ying, Z. Research on the Adjustment Strategy and Effect Evaluation of Oilfield in the Late Stage of Water Drive with Ultra High Water Cut. In E3S Web of Conferences; EDP Sciences: Occitania, France, 2024; Volume 554, p. 01006. [Google Scholar] [CrossRef]

- Khatib, Z.; Verbeek, P. Water to value–produced water management for sustainable field development of mature and green fields. In SPE International Conference and Exhibition on Health, Safety, Environment, and Sustainability? SPE: Richardson, TX, USA, 2002. [Google Scholar] [CrossRef]

- You, H.; Ping, W.; Xiang, T.; Dong, X.X.; JiHong, L.; Tran, T.; Partono, Y.J.; Kok, J.; Yang, L.; Balka, S. Horizontal Well Best Practices to Reverse Production Decline in Mature Fields in South China Sea. In SPE Asia Pacific Oil and Gas Conference and Exhibition; SPE: Richardson, TX, USA, 2008. [Google Scholar] [CrossRef]

- Romo, G.A.; Leyva, H.H.; Aguilar, R.B.; Campos, C.C.; Eoff, L.; Dalrymple, D. Advanced technology to reduce water cut: Case studies from the Pemex southern region. SPE Prod. Oper. 2010, 25, 139–144. [Google Scholar] [CrossRef]

- Palyanitsina, A.; Safiullina, E.; Byazrov, R.; Podoprigora, D.; Alekseenko, A. Environmentally safe technology to increase efficiency of high-viscosity oil production for the objects with advanced water cut. Energies 2022, 15, 753. [Google Scholar] [CrossRef]

- Lakatos, I.; Lakatos-Szabo, J. Global oil demand and role of chemical EOR methods in the 21st century. Int. J. Oil Gas Coal Technol. 2008, 1, 46–64. [Google Scholar] [CrossRef]

- Tao, W.; Shenglai, Y.; Weihong, Z.; Wanjiang, B.; Min, L.; Yu, L.; Yuan, Z.; Jin, Z.; Wei, Z.; Lan, C.; et al. Law and countermeasures for the casing damage of oil production wells and water injection wells in Tarim Oilfield. Pet. Explor. Dev. 2011, 38, 352–361. [Google Scholar] [CrossRef]

- Du, Y.; Guan, L.; Liang, H. Advances of produced water management. In Proceedings of the PETSOC Canadian International Petroleum Conference, PETSOC, Calgary, AB, Canada, 7–9 June 2005. [Google Scholar] [CrossRef]

- Moradpour, H.; Chapoy, A.; Tohidi, B. Bimodal model for predicting the emulsion-hydrate mixture viscosity in high water cut systems. Fuel 2011, 90, 3343–3351. [Google Scholar] [CrossRef]

- Tizzano, D.; Colella, L.; Bardini, S.; Moriggi, S.; Giardini, R.; Renna, S.; Sala, C.; Nobili, M. Redevelopment of water ultra-mature (85% water cut) field: Case history. In Abu Dhabi International Petroleum Exhibition and Conference; SPE: Richardson, TX, USA, 2014; p. D021S034R004. [Google Scholar] [CrossRef]

- Al-Dujaili, A.N.; Shabani, M.; AL-Jawad, M.S. Effect of Heterogeneity on Recovery Factor for Carbonate Reservoirs. A Case Study for Mishrif Formation in West Qurna Oilfield, Southern Iraq. Iraqi J. Chem. Pet. Eng. 2023, 24, 103–111. [Google Scholar] [CrossRef]

- Lu, H.; Fu, B.; Shi, P.; Xue, G.; Li, H. Late-Miocene thrust fault-related folding in the northern Tibetan Plateau: Insight from paleomagnetic and structural analyses of the Kumkol basin. J. Asian Earth Sci. 2018, 156, 246–255. [Google Scholar] [CrossRef]

- Chuanzhi, C.; Xiaoyan, Z. A Study on the Development Technology of Sidetracking Wells in Fault Block Reservoirs During the High Water Cut Stage. Pet. Sci. Technol. 2013, 31, 465–471. [Google Scholar] [CrossRef]

- Zeinijahromi, A.; Al-Jassasi, H.; Begg, S.; Bedrikovetski, P. Improving sweep efficiency of edge-water drive reservoirs using induced formation damage. J. Pet. Sci. Eng. 2015, 130, 123–129. [Google Scholar] [CrossRef]

- He, Y.; Cheng, S.; Li, L.; Mu, G.; Zhang, T.; Xu, H.; Qin, J.; Yu, H. Waterflood direction and front characterization with four-step work flow: A case study in changqing oil field China. SPE Reserv. Eval. Eng. 2017, 20, 708–725. [Google Scholar] [CrossRef]

- Wang, H.; Mu, L.; Shi, F.; Dou, H. Production prediction at ultra-high water cut stage via Recurrent Neural Network. Pet. Explor. Dev. 2020, 47, 1084–1090. [Google Scholar] [CrossRef]

- Aldhaheri, M.; Wei, M.; Alhuraishawy, A.; Bai, B. Field performances, effective times, and economic assessments of polymer gel treatments in controlling excessive water production from mature oil fields. J. Energy Resour. Technol. 2021, 143, 080804. [Google Scholar] [CrossRef]

- Ahn, S.; Lee, K.; Choe, J.; Jeong, D. Numerical approach on production optimization of high water-cut well via advanced completion management using flow control valves. J. Pet. Explor. Prod. Technol. 2023, 13, 1611–1625. [Google Scholar] [CrossRef]

- Pandit, Y.K.; Mahto, V.; Udayabhanu, G.; Ravishankar, B.; Dhandi, M. Preparation, characterization, and evaluation of a nanomaterial reinforced particle gel system for the control of excessive water production in the mature oil fields. Geoenergy Sci. Eng. 2024, 235, 212707. [Google Scholar] [CrossRef]

- Aktassov, K.; Karlykhanov, Y.; Tleukhabyluly, O.; Imagambetov, K.; Folefac, A.; Uxukbayev, G.; Abonaem, K.; Muratbekov, S.; Channa, T. Enhancing Projects Value by Embedding the Full-Scale Production System into Reservoir Model—A Case Study of Karachaganak Field, Kazakhstan. In Abu Dhabi International Petroleum Exhibition and Conference; SPE: Richardson, TX, USA, 2020; p. D041S097R002. [Google Scholar] [CrossRef]

- Akhmetzhan, S.; Churikova, L.; Kalesheva, G.; Mukambetkaliyeva, A. A review study on an integrated method for solving problems associated with the re-development of waterflooded fields. GEOMATE J. 2023, 25, 85–92. [Google Scholar] [CrossRef]

- Soroush, M.; Roostaei, M.; Hosseini, S.A.; Mohammadtabar, M.; Pourafshary, P.; Mahmoudi, M.; Ghalambor, A.; Fattahpour, V. Challenges and potentials for sand and flow control and management in the sandstone oil fields of Kazakhstan: A literature review. SPE Drill. Complet. 2021, 36, 208–231. [Google Scholar] [CrossRef]

- Yi, L.; Guo, E.; Hua, X.; Zhu, A.; Wang, C.; Guan, W.; Wang, Y.; Zheng, X.; Zhao, Y. Gas-Steam Composite Stimulation: A Strategy for a Heavy Oil Reservoir with High Water Cut in Kazakhstan. In SPE Annual Caspian Technical Conference; SPE: Richardson, TX, USA, 2022; p. D012S003R004. [Google Scholar] [CrossRef]

- Moldabayeva, G.Z.; Metaxa, G.P.; Alisheva, Z. Theoretical bases for the implementation of the processes to reduce viscosity in the conditions of natural reservation. News Natl. Acad. Sci. Repub. Kazakhstan Ser. Geol. Tech. Sci. 2019, 5, 138–143. [Google Scholar] [CrossRef]

- Imanbayev, B.A.; Sagyndikov, M.S.; Kushekov, R.M.; Tajibayev, M.O. Evaluation and scientific justification of polymer flooding application in the Uzen oilfield. Kazakhstan J. Oil Gas Ind. 2022, 4, 9–27. [Google Scholar] [CrossRef]

- Shi, J.; Jin, Z.; Fan, T.; Liu, Q.; Zhang, F.; Fan, X. Sequence development, depositional filling evolution, and prospect forecast in northern Aryskum Depression of South Turgay Basin, Kazakstan. Energy Explor. Exploit. 2016, 34, 621–642. [Google Scholar] [CrossRef]

- Ghassemi, M.R.; Garzanti, E. Geology and geomorphology of Turkmenistan: A review. Geopersia 2019, 9, 125–140. [Google Scholar] [CrossRef]

- Seitov, N.; Tulegenova, G.P. Geodynamical Nature of the Formation of Large Plates of Platforms, Jointed in North Caspian Oil and Gas Basin. Int. J. Environ. Sci. Educ. 2016, 11, 9657–9668. [Google Scholar]

- Chen, L.; Zhao, L.; Cao, H.; Wang, J.; Zhao, W.; Fu, L.; Luo, E.; Hao, F.; Zhang, X. Studies on EOR of Sandstone Oilfield with Low Viscosity and High Salinity During High Water Cut Stage—A Case of Kumkol Oilfield in Kazakhstan. In Proceedings of the International Field Exploration and Development Conference 2018; Springer: Singapore, 2020; pp. 1663–1683. [Google Scholar] [CrossRef]

- Shi, J.Y.; Fan, T.L.; Zhou, J.; Yu, D.F.; Ai, X. Several typical seismic facies in South Turgay Basin and the geological meaning. Sci. Technol. Eng. 2015, 15, 133–138. [Google Scholar]

- Ozdoyev, S.M.; Tileuberdi, N. The geological prerequisites for increasing oil production at the North Karamandybas field. News Natl. Acad. Sci. Repub. Kazakhstan Ser. Geol. Tech. Sci. 2017, 4, 276–280. [Google Scholar]

- Ozdoyev, S.M.; Abduev, N.S.; Popov, V.A.; Tileuberdi, N.; Dong, M.H. Common and differing geological features of the Alakol and Chinese Dzungarian troughs in view of their oil-and-gas prospects. News Natl. Acad. Sci. Repub. Kazakhstan Ser. Geol. Tech. Sci. 2019, 4, 6–11. [Google Scholar] [CrossRef]

- Ozdoyev, S.; Popov, V.; Tileuberdi, N.; Huadong, M. The balkhash depression sediment paleogeology and oil-gas prospects. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology and Mining Ecology Management, SGEM, Albena, Bulgaria, 16–25 August 2020; pp. 799–804. [Google Scholar] [CrossRef]

- Ai, X.; Wang, H.; Sun, B. Automatic identification of sedimentary facies based on a support vector machine in the Aryskum Graben, Kazakhstan. Appl. Sci. 2019, 9, 4489. [Google Scholar] [CrossRef]

- Nikishin, A.M.; Ziegler, P.A.; Abbott, D.; Brunet, M.F.; Cloetingh, S.A.P.L. Permo–Triassic intraplate magmatism and rifting in Eurasia: Implications for mantle plumes and mantle dynamics. Tectonophysics 2002, 351, 3–39. [Google Scholar] [CrossRef]

- Mukanov, A. Oil Rim Development by Waterflooding: Lessons Learned from the South Turgai Basin Case Studies. In Abu Dhabi International Petroleum Exhibition and Conference; SPE: Richardson, TX, USA, 2022; p. D021S057R003. [Google Scholar] [CrossRef]

- Basin, T. Analysis of Seismic Response Characteristics of Coal-Bearing Sandstone Reservoirs in the Middle and Lower Jurassic in the South. In Proceedings of the International Field Exploration and Development Conference 2023; Springer Nature: Berlin/Heidelberg, Germany, 2024; Volume 2, p. 234. [Google Scholar] [CrossRef]

- Yin, W.; Zhang, M.J.; Ji, Z.F. Check for updates Fine Exploration of South Turgay Rift Basin, Kazakhstan. In Proceedings of the International Field Exploration and Development Conference 2023; Springer Nature: Berlin/Heidelberg, Germany, 2024; Volume 2, p. 462. [Google Scholar] [CrossRef]

- Petrov, O.V.; Pospelov, I.I.; Kheraskova, T.N.; Tomurtogoo, O.; Bingwei, C.; Liudong, R. Tectonic Domains of Central Asia. In Tectonics of Asia (Northern, Central and Eastern Asia); Springer: Berlin/Heidelberg, Germany, 2021; pp. 113–212. [Google Scholar]

- Han, C.; Tian, J.; Hu, C.; Liu, H.; Wang, W.; Huan, Z.; Feng, S. Lithofacies characteristics and their controlling effects on reservoirs in buried hills of metamorphic rocks: A case study of late Paleozoic units in the Aryskum depression, South Turgay Basin, Kazakhstan. J. Pet. Sci. Eng. 2020, 191, 107137. [Google Scholar] [CrossRef]

- Filip’yev, G.P. Structural Relationship Between Triassic-Jurassic and Cretaceous-Cenozoic of the Aryskum Zone of South Turgay with Respect to Oil and Gas; Datapages, Inc.: Tulsa, OK, USA, 1991. [Google Scholar]

- Zhao, L.; Wang, J.; Chen, L.; Chen, X.; Fan, Z.; Zhang, X.; Tian, Z. Influences of sandstone superimposed structure and architecture on waterflooding mechanisms: A case study of Kumkol Oilfield in South Turgay Basin, Kazakhstan. Pet. Explor. Dev. 2014, 41, 96–104. [Google Scholar] [CrossRef]

- Ministry of Energy Report. In Annual Review of Oil Reserves in Kazakhstan; Government of Kazakhstan Publications: Astana, Kazakhstan, 2020.

- Energy Development Review. Cumulative Production Trends in Central Asian Oil Fields. 2021; unpublished report.

- Kazakhstan Energy Forum. In Proceedings of the 2023 Kazakh Energy Forum: Challenges in Sustaining Oil Production, Almaty, Kazakhstan, 6–8 November 2023.

- Technological Innovations in Enhanced Oil Recovery. Oil Gas Technol. J. 2022, 19, 101–112.

- Tileuberdi, N.; AL-Dujaili, A.N.; Mashrapova, M.; Togizov, K.; Sanatbekov, M.; Yergali, A. Optimizing oil recovery by low-pressure nitrogen injection: An experiment case study. ES Mater. Manuf. 2024, 25, 1189. [Google Scholar] [CrossRef]

- Tileuberdi, N.; Gussenov, I. Review on miscible, immiscible, and progressive nitrogen injection for enhanced oil recovery. Energy Rep. 2024, 12, 360–367. [Google Scholar] [CrossRef]

| Temperature (°C) | Polymer Solution Viscosity (cP) | Polymer Solution Viscosity (Pa·s) |

|---|---|---|

| 30 | 25 | 0.025 |

| 40 | 20 | 0.020 |

| 50 | 15 | 0.015 |

| 60 | 12 | 0.012 |

| 70 | 10 | 0.010 |

| 80 | 8 | 0.008 |

| Polymer Concentration (ppm/%) | Oil Recovery Factor (%) |

|---|---|

| 500 | 40 |

| 1000 (0.10%) | 50 |

| 1500 (0.15%) | 55 |

| 2000 (0.20%) | 57 |

| 2500 (0.25%) | 58 |

| Polymer Type | Solution Viscosity (cP) | Increase in Oil Recovery Factor (%) |

|---|---|---|

| Polyacrylamide | 10–15 | 15–20 |

| Crosslinked Polyacrylamide | 20–30 | 20–25 |

| Polymer with Nanoparticles | 30–40 | 25–30 |

| Parameter | Value |

|---|---|

| Average Reservoir Temperature | 52–60 °C |

| Formation Water Salinity | 49.784 mg/L |

| Oil Viscosity | 1–10 cP |

| Reservoir Permeability | 100–500 mD |

| Porosity | 18–22% |

| Water Cut | 98.4% |

| Oil Recovery Factor (ORF) | 35–50% |

| Horizon, Object | Number of Wells Used for Determination | Sandiness Coefficient, Units | Coefficient of Dismemberment, Fractions of Units | Distribution Coefficient, Fractions of Units | ||

|---|---|---|---|---|---|---|

| Average | Variations | Average | Variations | |||

| M-I | 628 | 0.621 | 0.048 | 2.70 | 0.123 | 1 |

| M-II | 440 | 0.756 | 0.022 | 7.70 | 0.213 | 1 |

| J-I | 931 | 0.540 | 0.175 | 4.07 | 0.214 | 0.997 |

| J-II | 765 | 0.712 | 0.086 | 2.11 | 0.216 | 0.976 |

| J-III | 610 | 0.777 | 0.032 | 2.24 | 0.229 | 0.954 |

| J-IV | 188 | 0.465 | 0.316 | 2.55 | 0.380 | 0.977 |

| PZ-PR | 100 | 0.491 | 0.365 | 3.14 | 0.235 | 0.929 |

| Parameter/Horizon | M-I | M-II | J-I | J-II | J-III | J-IV | Total | P.Z. |

|---|---|---|---|---|---|---|---|---|

| Number of samples | 95 | 132 | 378 | 257 | 241 | 52 | 1155 | 95 |

| Horizon | Method | Name | K, 10−3 µm2 | φ, Fraction | Soi, Units |

|---|---|---|---|---|---|

| M-I | Laboratory Research cores | Average value | 2584 | 0.293 | |

| Coefficient of variation | 0.82263 | 0.00026 | |||

| Geophysical Research wells | Average value | 0.26 | 0.56 | ||

| Coefficient of variation | 0.006 | 0.041 | |||

| M-II | Laboratory Research cores | Average value | 1337 | 0.266 | |

| Coefficient of variation | 1.3043 | 0.0158 | |||

| Geophysical Research wells | Average value | 0.27 | 0.57 | ||

| Coefficient of variation | 0.001 | 0.034 | |||

| J-I | Laboratory Research cores | Average value | 313 | 0.242 | |

| Coefficient of variation | 3.9669 | 0.0338 | |||

| Geophysical Research wells | Average value | 0.23 | 0.61 | ||

| Coefficient of variation | 0.077 | 0.048 | |||

| J-II | Laboratory Research cores | Average value | 1891 | 0.264 | |

| Coefficient of variation | 7.9627 | 0.03141 | |||

| Geophysical Research wells | Average value | 0.25 | 0.64 | ||

| Coefficient of variation | 0.008 | 0.05 | |||

| J-III | Laboratory Research cores | Average value | 634 | 0.234 | |

| Coefficient of variation | 2.5279 | 0.0216 | |||

| Geophysical research wells | Average value | 0.25 | 0.64 | ||

| Coefficient of variation | 0.016 | 0.05 | |||

| J-IV | Laboratory Research cores | Average value | 145.9 | 0.215 | |

| Coefficient of variation | 5.5997 | 0.0323 | |||

| Geophysical Research wells | Average value | 0.21 | 0.54 | ||

| Coefficient of variation | 0.134 | 0.029 | |||

| PZ + PR | Laboratory Research cores | Average value | 0.2 | 0.077 | |

| Coefficient of variation | |||||

| Geophysical Research wells | Average value | 0.14 | 0.54 | ||

| Coefficient of variation | 0.02 | 0.029 |

| Horizon | Determination Method | Name | Permeability, 10−3 µm2 | Porosity, Fractions of Units | Initial Oil Saturation, Units |

|---|---|---|---|---|---|

| M-I | Laboratory Research cores | Average value | 1.8 | 0.289 | |

| Coefficient of variation | 0.039–6.323 | 0.204–0.336 | |||

| Geophysical Research wells | Average value | 0.26 | 0.51 | ||

| Coefficient of variation | 0.013 | 0.015 | |||

| J-I | Laboratory Research cores | Average value | 0.23 | 0.239 | |

| Coefficient of variation | 0.024–1.082 | 0.192–0.281 | |||

| Geophysical Research wells | Average value | 0.21 | 0.58 | ||

| Coefficient of variation | 0.035 | 0.034 | |||

| J-II | Laboratory Research cores | Average value | 3.952 | 0.277 | |

| Coefficient of variation | 0.015–12.041 | 0.179–0.327 | |||

| Geophysical Research wells | Average value | 0.24 | 0.59 | ||

| Coefficient of variation | 0.022 | 0.031 |

| Parameter | Terms and Conditions | Surface Tension (a), Dyne/cm | Wetting Angle (θ), ° | Density of Oil, kg/m3 | Density of Water, kg/m3 |

|---|---|---|---|---|---|

| Water–gas | Laboratory | 72 | 0 | ||

| Oil–water | Laboratory | 30 | 30 | 660 | 1051 |

| Oil–water | Layer | 30 | 30 | 660 | 1051 |

| Objects | Initial Oil Reserves, Thousand Tons | Current Reserves, Thousand Tons | ||||||

|---|---|---|---|---|---|---|---|---|

| On the State Balance Sheet | ||||||||

| Geological | Extractable | Geological | Extractable | |||||

| ABC1 | C2 | ABC1 | C2 | ABC1 | C2 | ABC1 | C2 | |

| I/MI + II | 27.685 | - | 16.302 | - | 14.316 | - | 2933 | - |

| II/J-T + J-II | 41.300 | 58 | 25.308 | 35 | 22.497 | 58 | 6506 | 35 |

| III/J-III | 17.484 | - | 10.358 | - | 8275 | - | 1149 | - |

| IV/J-IV+ (PZ1- PR) | 684 | - | 288 | - | 461 | - | 65 | - |

| Total | 87.153 | 58 | 52.256 | 35 | 45.550 | 58 | 10.653 | 35 |

| Objects | Initial Reserves of Dissolved Gas, Million m3 | Current Reserves, Million m3 | ||||||

|---|---|---|---|---|---|---|---|---|

| On the State Balance Sheet | ||||||||

| Geological | Extractable | Geological | Extractable | |||||

| ABC1 | C2 | ABC1 | C2 | ABC1 | C2 | ABC1 | C2 | |

| I/MI + II | 340 | - | 200 | - | 184 | - | 44 | - |

| II/J-T + J-II | 5454 | 0.4 | 3341 | 0.2 | 3048 | 0.4 | 935 | 0.2 |

| III/J-III | 2290 | - | 1357 | - | 1100 | - | 167 | - |

| IV/J-IV+ (PZ1- PR) | 126 | - | 54 | - | 96 | - | 24 | - |

| Total | 8210 | 0.4 | 4953 | 0.2 | 4428 | 0.4 | 1170 | 0.2 |

| Objects | Initial Oil Reserves, Thousand Tons | Current Reserves, Thousand Tons | ||||||

|---|---|---|---|---|---|---|---|---|

| On the State Balance Sheet | ||||||||

| Geological | Extractable | Geological | Extractable | |||||

| ABC1 | C2 | ABC1 | C2 | ABC1 | C2 | ABC1 | C2 | |

| I/MI | 622 | - | 305 | - | 314 | - | −2 | - |

| II/J-T + J-II | 4164 | - | 1717 | - | 2875 | - | 427 | - |

| Total | 4786 | - | 2022 | - | 3189 | - | 425 | - |

| Objects | Initial Reserves of Dissolved Gas, Million m3 | Current Reserves, Million m3 | ||||||

|---|---|---|---|---|---|---|---|---|

| On the State Balance Sheet | ||||||||

| Geological | Extractable | Geological | Extractable | |||||

| ABC1 | C2 | ABC1 | C2 | ABC1 | C2 | ABC1 | C2 | |

| I/MI | 0.5 | - | 0.2 | - | 0.2 | - | −0.1 | - |

| P/UT + P | 79.8 | - | 32 | - | 58 | - | 10 | - |

| Total | 80 | - | 32 | - | 58 | - | 10 | - |

| Method | Cost ($/m3 of Oil Produced) | Average Increase in Oil Recovery (%) |

|---|---|---|

| Hydraulic Fracturing (HF) | 20–30 | 5–10 |

| Water Shut-off Treatments | 15–25 | 8–12 |

| Polymer Flooding | 10–15 | 15–20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alisheva, Z.; Nadirov, K.; Al-Dujaili, A.N.; Bimbetova, G.; Nadirova, Z.; Zhantasov, M.; Tileuberdi, N.; Dauletuly, A. Integrated Strategies for Controlling Water Cut in Mature Oil Fields in Kazakhstan. Polymers 2025, 17, 829. https://doi.org/10.3390/polym17070829

Alisheva Z, Nadirov K, Al-Dujaili AN, Bimbetova G, Nadirova Z, Zhantasov M, Tileuberdi N, Dauletuly A. Integrated Strategies for Controlling Water Cut in Mature Oil Fields in Kazakhstan. Polymers. 2025; 17(7):829. https://doi.org/10.3390/polym17070829

Chicago/Turabian StyleAlisheva, Zhanat, Kazim Nadirov, Ahmed N. Al-Dujaili, Gulmira Bimbetova, Zhanna Nadirova, Manap Zhantasov, Nurbol Tileuberdi, and Ansagan Dauletuly. 2025. "Integrated Strategies for Controlling Water Cut in Mature Oil Fields in Kazakhstan" Polymers 17, no. 7: 829. https://doi.org/10.3390/polym17070829

APA StyleAlisheva, Z., Nadirov, K., Al-Dujaili, A. N., Bimbetova, G., Nadirova, Z., Zhantasov, M., Tileuberdi, N., & Dauletuly, A. (2025). Integrated Strategies for Controlling Water Cut in Mature Oil Fields in Kazakhstan. Polymers, 17(7), 829. https://doi.org/10.3390/polym17070829