Constructing Multifunctional Composite Paper Coated with Polypyrrole@Lignocellulosic Slurry with Humidity Sensing, Conductivity, Antibacterial, and Photothermal Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

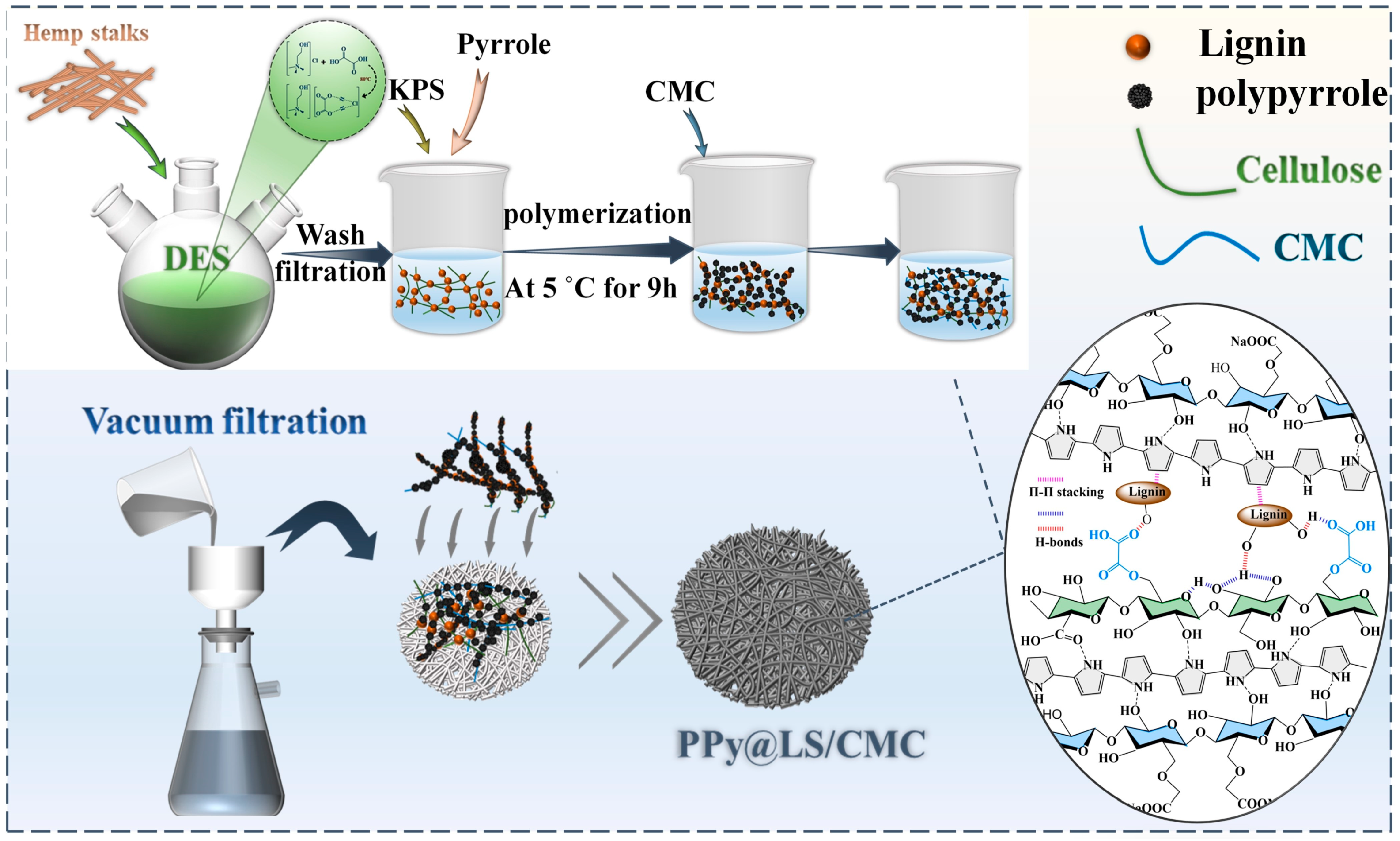

2.2. Preparation of Regenerated Lignin-Cellulose Slurry (LS) from Hemp Stalks

2.3. Preparation of PPy@LS and PPy@LS/CMC Paper-Based Composites

2.4. Characterization

3. Results and Discussion

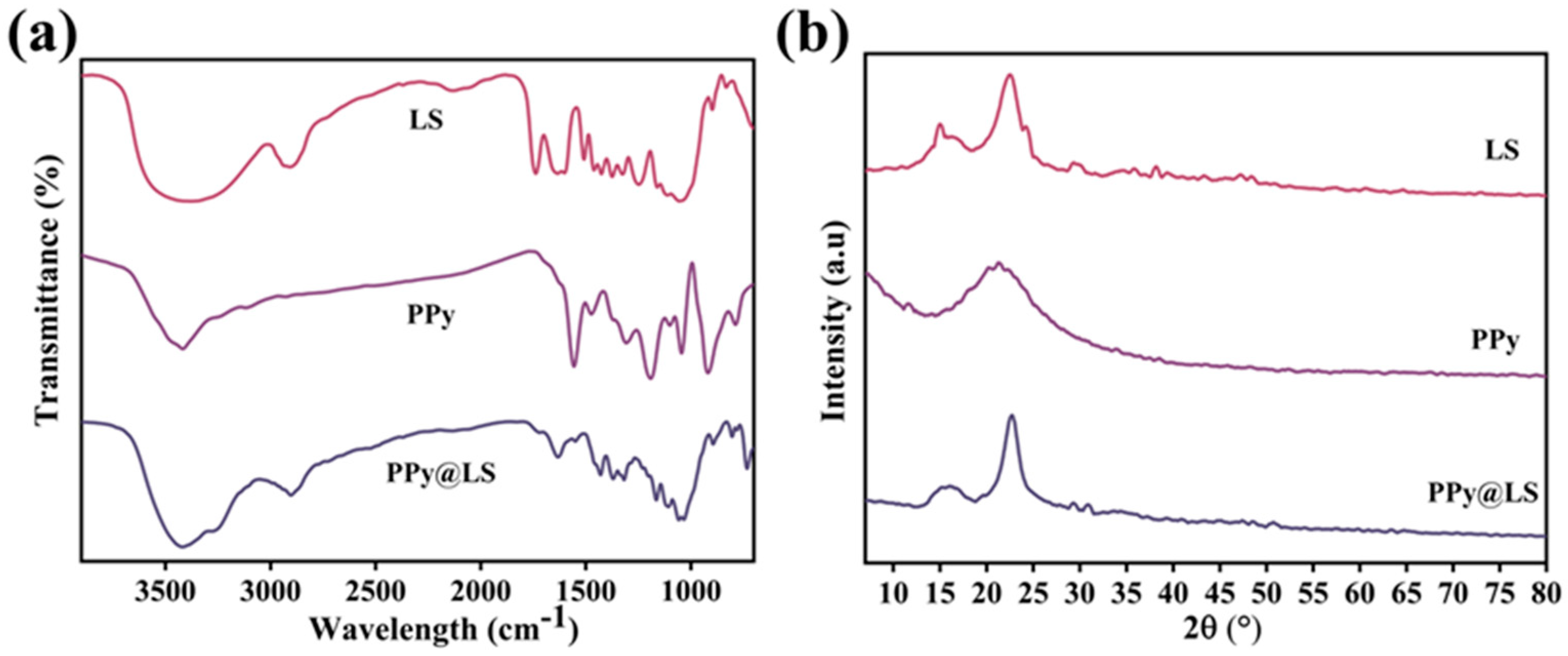

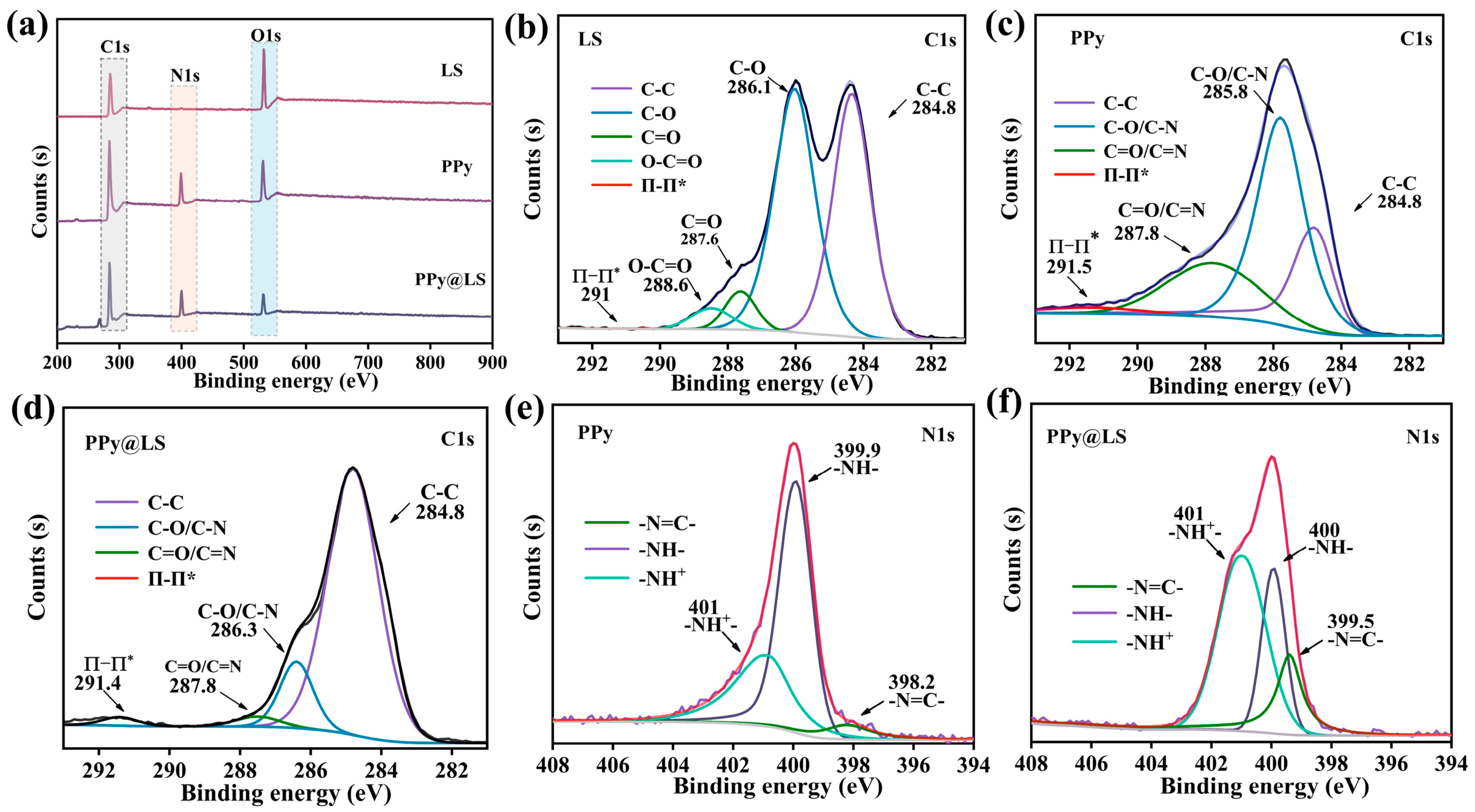

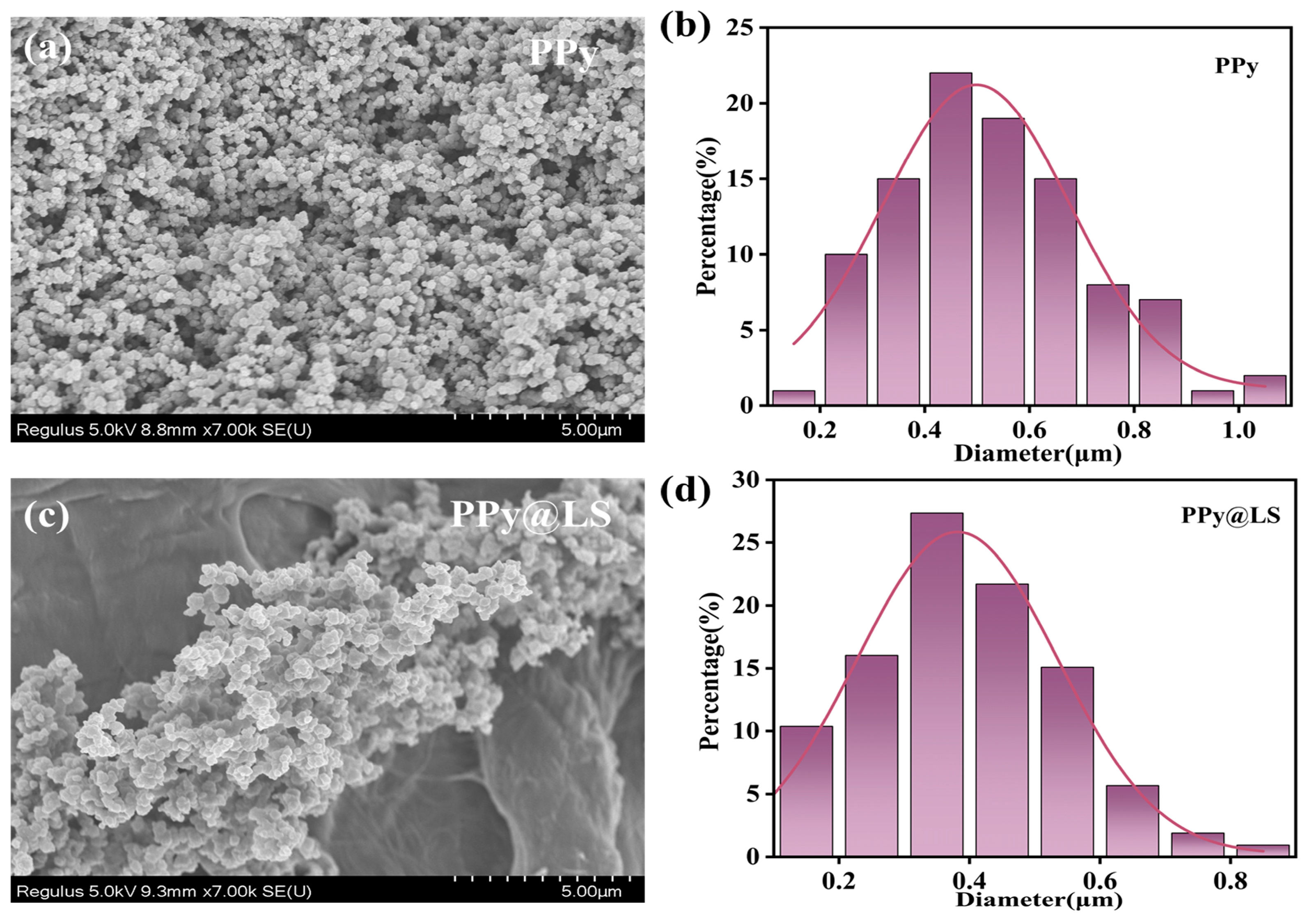

3.1. Characterization of PPy@LS

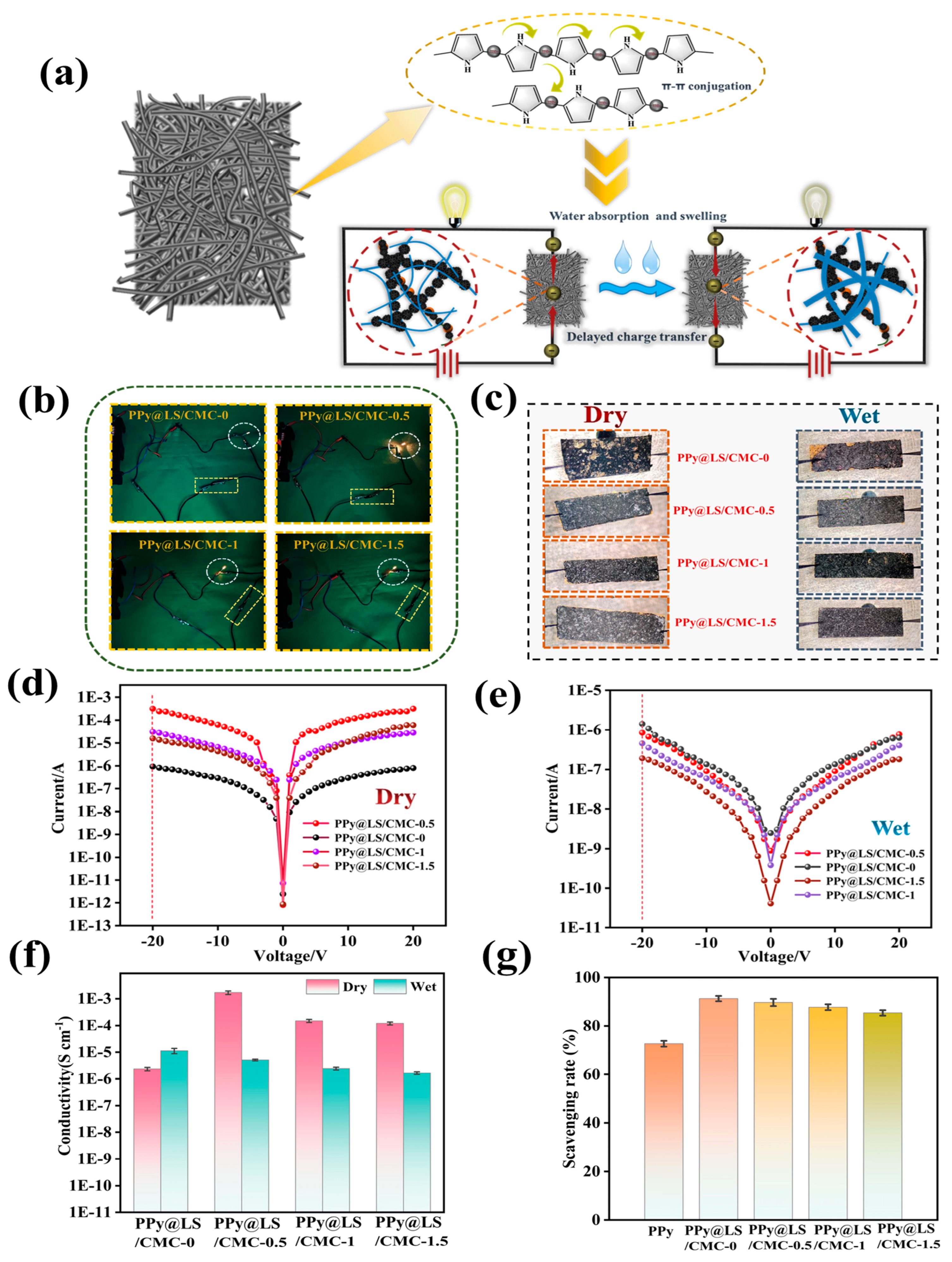

3.2. Electrical Conductivity of PPy@LS@CMC

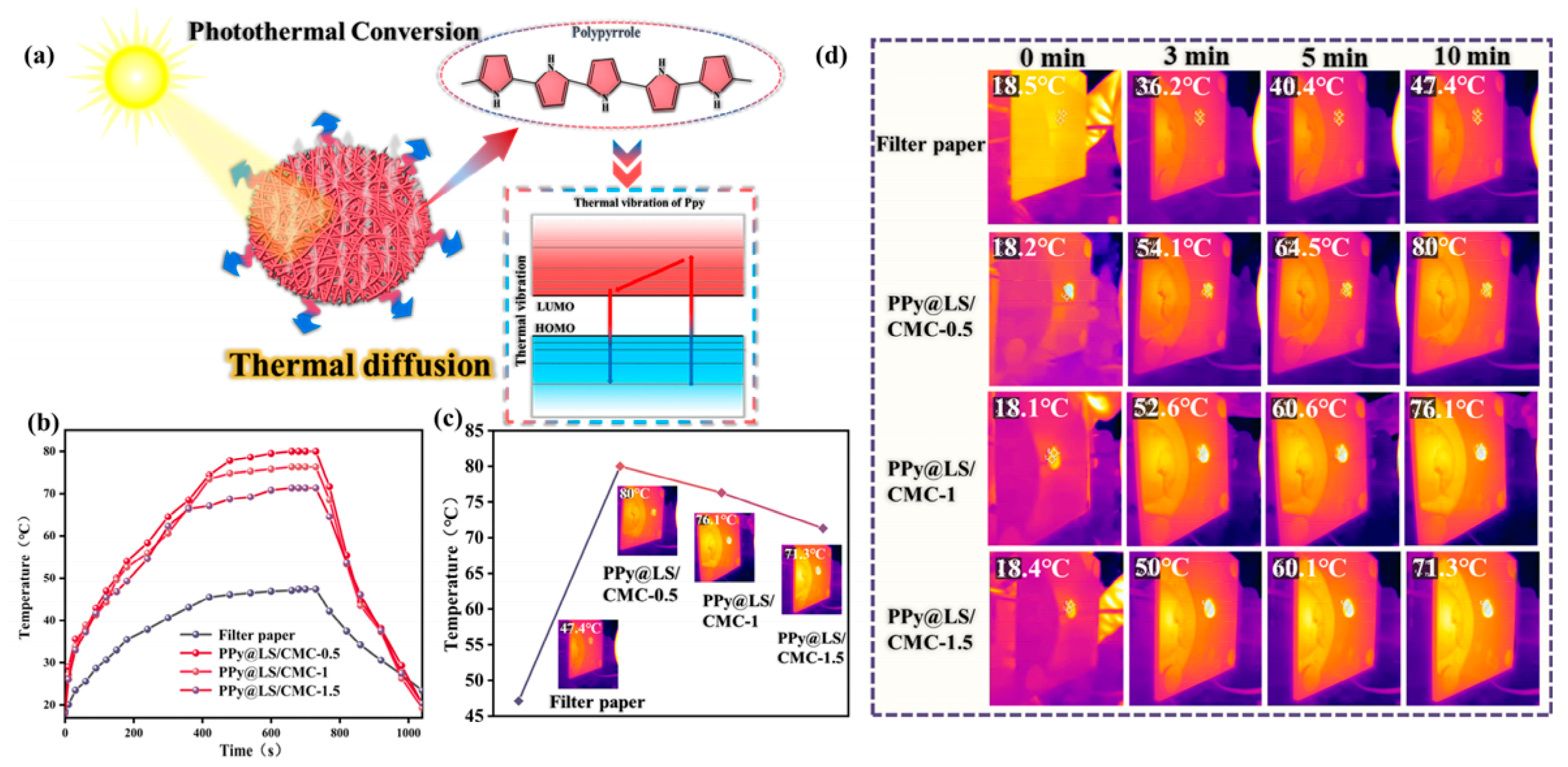

3.3. Photothermal Property of PPy@LS/CMC

3.4. Contact Angle and Antibacterial Activity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PPy | polypyrrole |

| LS | lignocellulosic slurry |

| PPy@LS | polypyrrole@ lignocellulosic slurry composite |

| PPy@LS/CMC | polypyrrole@ lignocellulosic slurry composite adhered with carboxymethylcellulose |

| FP | filter paper |

| CMC | carboxymethyl cellulose |

References

- Zhang, F.; Xu, K.; Bai, Y.; Wang, P. Multifunctional cellulose paper-based materials. Cellulose 2023, 30, 8539–8569. [Google Scholar] [CrossRef]

- Paper and Paperboard Packaging Market Size, Share, Growth and Industry Analysis, by Type (Container Board, Carton Board, Flexible Paper, and, Others), by Application (Food and Beverage, Healthcare, Retail, Consumer Goods, and, Others), Regional Insights and Forecast from 2025 to 2033. 2024. Available online: https://www.businessresearchinsights.com/market-reports/paper-and-paperboard-packaging-market-109590 (accessed on 27 February 2025).

- Yun, T.; Tao, Y.; Li, Q.; Cheng, Y.; Lu, J.; Lv, Y.; Du, J.; Wang, H. Superhydrophobic modification of cellulosic paper-based materials: Fabrication, properties, and versatile applications. Carbohydr. Polym. 2023, 305, 120570. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, M.; Lu, Z.; Tan, J.; Luo, J.; Song, S.; Ding, X.; Wang, L.; Lu, P.; Zhang, Q. Comparative study of aramid nanofiber (anf) and cellulose nanofiber (cnf). Carbohydr. Polym. 2019, 208, 372–381. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, K.; Yang, J.; Lee, G.; Shin, J.; Lau, V.W.; Kang, Y. Bifunctional conducting polymer coated cop core–shell nanowires on carbon paper as a free-standing anode for sodium ion batteries. Adv. Energy Mater. 2018, 8, 1800283. [Google Scholar] [CrossRef]

- Vinayak, V.V.; Deshmukh, K.; Murthy, V.; Pasha, S.K. Conducting polymer based nanocomposites for supercapacitor applications: A review of recent advances, challenges and future prospects. J. Energy Storage 2024, 100, 113551. [Google Scholar] [CrossRef]

- Mukhtar, T.; Manj, R.Z.A.; Khan, I.A.; Raza, Z.A.; Aslam, M. A prime synergistic bc@ppy flexible conductive matrix proposed candidate for boosting the breakthrough in smart e-textiles power supplies. Mater. Today Commun. 2024, 38, 108208. [Google Scholar] [CrossRef]

- Fan, D.; Fang, Z.; Xiong, Z.; Fu, F.; Qiu, S.; Yan, M. Self-assembled high polypyrrole loading flexible paper-based electrodes for high-performance supercapacitors. J. Colloid Interface Sci. 2024, 660, 555–564. [Google Scholar] [CrossRef]

- Fu, L.; Fu, X.; Zhao, G. Laser carving assisted preparation of polypyrrole coated paper-based supercapacitors. Chem. Phys. Lett. 2021, 765, 138290. [Google Scholar] [CrossRef]

- Li, J.; Du, Y.; Jia, R.; Xu, J.; Shen, S.Z. Flexible thermoelectric composite films of polypyrrole nanotubes coated paper. Coatings 2017, 7, 211. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, D.; Liu, R.; Xie, Y.; Li, J.; Wang, L. A coral reef-like structure fabricated on cellulose paper for simultaneous oil–water separation and electromagnetic shielding protection. ACS Omega 2020, 5, 18105–18113. [Google Scholar] [CrossRef]

- Sun, R.; Zhang, W.; Zhang, J.; Zhao, Y.; Yuan, H.; Guan, H.; Huang, C.; Ma, C.; Ge, J.; Tian, W.; et al. Flexible and conductive polypyrrole/ag/cellulose paper bar with sensitive response to multiple stimulus of ph, mist, breath and finger press. Mater. Lett. 2023, 341, 134260. [Google Scholar] [CrossRef]

- Gai, X.; Liu, C.; Meng, L.; Yu, Z.; Jiang, S.; Liu, X.; Liu, Y.; Deng, C.; Xiao, H. High-barrier, photothermal conversion, and antibacterial composite enabled by kraft lignin-coated cellulose paper for plastic replacement. ACS Sustain. Chem. Eng. 2024, 12, 18350–18361. [Google Scholar] [CrossRef]

- Hur, O.-N.; Park, S.; Park, S.; Kang, B.-H.; Lee, C.-S.; Hong, J.-Y.; Park, S.-H.; Bae, J. A study on fabrication of polypyrrole@lignin composite and electrical sensing and metal ion adsorption capabilities. Mater. Chem. Phys. 2022, 285, 126166. [Google Scholar] [CrossRef]

- Lin, W.; Han, H.; Yan, X.; Xie, J.; He, H.; Han, S.; Ning, D.; Mondal, A.K.; Wu, S.; Huang, F. Development of lignin hydrogel reinforced polypyrrole rich electrode material for supercapacitor and sensing applications. Int. J. Biol. Macromol. 2024, 273, 132962. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, S.; Huang, W.; Yang, D.; Wang, H.; Fang, Z. Mechanically strong and electrically stable polypyrrole paper using high molecular weight sulfonated alkaline lignin as a dispersant and dopant. J. Colloid Interface Sci. 2019, 556, 47–53. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Li, H.; Zhao, Q.-S.; Zhao, B. Effect of DES lignin incorporation on physicochemical, antioxidant and antimicrobial properties of carboxymethyl cellulose-based films. Int. J. Biol. Macromol. 2024, 263, 130294. [Google Scholar] [CrossRef]

- Xiao, T.; Hou, M.; Guo, X.; Cao, X.; Li, C.; Zhang, Q.; Jia, W.; Sun, Y.; Guo, Y.; Shi, H. Recent progress in deep eutectic solvent(des) fractionation of lignocellulosic components: A review. Renew. Sustain. Energy Rev. 2024, 192, 114243. [Google Scholar] [CrossRef]

- Ling, Z.; Edwards, J.V.; Guo, Z.; Prevost, N.T.; Nam, S.; Wu, Q.; French, A.D.; Xu, F. Structural variations of cotton cellulose nanocrystals from deep eutectic solvent treatment: Micro and nano scale. Cellulose 2018, 26, 861–876. [Google Scholar] [CrossRef]

- Li, C.; Huang, C.; Zhao, Y.; Zheng, C.; Su, H.; Zhang, L.; Luo, W.; Zhao, H.; Wang, S.; Huang, L.-J. Effect of choline-based deep eutectic solvent pretreatment on the structure of cellulose and lignin in bagasse. Processes 2021, 9, 384. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Yao, Y.; Li, J.; He, S.; Zhou, Y.; Li, T.; Pan, X.; Yao, Y.; Hu, L. A strong, biodegradable and recyclable lignocellulosic bioplastic. Nat. Sustain. 2021, 4, 627–635. [Google Scholar] [CrossRef]

- Mahmood, J.; Arsalani, N.; Naghash-Hamed, S.; Hanif, Z.; Geckeler, K.E. Preparation and characterization of hybrid polypyrrole nanoparticles as a conducting polymer with controllable size. Sci. Rep. 2024, 14, 11653. [Google Scholar] [CrossRef]

- Park, C.-W.; Youe, W.-J.; Kim, S.-J.; Han, S.-Y.; Park, J.-S.; Lee, E.-A.; Kwon, G.-J.; Kim, Y.-S.; Kim, N.-H.; Lee, S.-H. Effect of lignin plasticization on physico-mechanical properties of lignin/poly(lactic acid) composites. Polymers 2019, 11, 2089. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, A.; Zhu, M.; Lin, C.; Guo, Z.; Song, Y.; Li, S.; Feng, J.; Li, M.; Yan, W. Efficient removal of cr(vi) through adsorption with reduced cr(iii) sequestration by highly hydrophilic poly(pyrrole methane). Sep. Purif. Technol. 2024, 354, 129122. [Google Scholar] [CrossRef]

- Zhou, H.; Guan, Y.; Yan, X.; Pan, Z.; Xu, J.; Dai, L.; Zhang, M.; Si, C. All-lignocellulose-based hard bioplastic. Ind. Crops Prod. 2023, 193, 116164. [Google Scholar] [CrossRef]

- Li, M.; Zhou, J.; Bi, Y.-G.; Zhou, S.-Q.; Mo, C.-H. Polypyrrole/sewage sludge carbon as low-cost and high-effective catalyst for enhancing hexavalent chromium reduction and bio-power generation in dual chamber microbial fuel cells. Sep. Purif. Technol. 2021, 256, 117805. [Google Scholar] [CrossRef]

- Lahiri, A.; Yang, L.; Höfft, O.; Endres, F. Biodegradable Zn-ion battery with a lignin composite electrode and bio-ionic liquid based electrolyte: Possible in situ energy generation by lignin electrocatalysis. Mater. Adv. 2021, 2, 2676–2683. [Google Scholar] [CrossRef]

- Marcuello, C.; Foulon, L.; Chabbert, B.; Aguié-Béghin, V.; Molinari, M. Atomic force microscopy reveals how relative humidity impacts the young’s modulus of lignocellulosic polymers and their adhesion with cellulose nanocrystals at the nanoscale. Int. J. Biol. Macromol. 2020, 147, 1064–1075. [Google Scholar] [CrossRef]

- Wu, H.; Wu, L.; Lu, S.; Lin, X.; Xiao, H.; Ouyang, X.; Cao, S.; Chen, L.; Huang, L. Robust superhydrophobic and superoleophilic filter paper via atom transfer radical polymerization for oil/water separation. Carbohydr. Polym. 2018, 181, 419–425. [Google Scholar] [CrossRef]

- Chhajed, M.; Yadav, C.; Agrawal, A.K.; Maji, P.K. Esterified superhydrophobic nanofibrillated cellulose based aerogel for oil spill treatment. Carbohydr. Polym. 2019, 226, 115286. [Google Scholar] [CrossRef]

- Jiang, B.; Chen, C.; Liang, Z.; He, S.; Kuang, Y.; Song, J.; Mi, R.; Chen, G.; Jiao, M.; Hu, L. Lignin as a wood-inspired binder enabled strong, water stable, and biodegradable paper for plastic replacement. Adv. Funct. Mater. 2019, 30, 1906307. [Google Scholar] [CrossRef]

- Dong, Q.; Hong, B.; Fan, H.; Gao, C.; Huang, X.; Bai, M.; Zhou, Y.; Lai, Y. A self-adapting artificial sei layer enables superdense lithium deposition for high performance lithium anode. Energy Storage Mater. 2022, 45, 1220–1228. [Google Scholar] [CrossRef]

- Song, Q.; Zhan, Z.; Chen, B.; Zhou, Z.; Lu, C. Biotemplate synthesis of polypyrrole@bacterial cellulose/MXene nanocomposites with synergistically enhanced electrochemical performance. Cellulose 2020, 27, 7475–7488. [Google Scholar] [CrossRef]

- Guo, T.; Gu, L.; Zhang, Y.; Chen, H.; Jiang, B.; Zhao, H.; Jin, Y.; Xiao, H. Bioinspired self-assembled films of carboxymethyl cellulose–dopamine/montmorillonite. J. Mater. Chem. A 2019, 7, 14033–14041. [Google Scholar] [CrossRef]

- Budtova, T. Cellulose II aerogels: A review. Cellulose 2019, 26, 81–121. [Google Scholar] [CrossRef]

- Abdi, S.; Nasiri, M.; Mesbahi, A.; Khani, M. Investigation of uranium (vi) adsorption by polypyrrole. J. Hazard. Mater. 2017, 332, 132–139. [Google Scholar] [CrossRef]

- Song, C.-L.; Othman, J.B. Synthesis and characterization of lignin-incorporated carboxymethyl cellulose (cmc) films from oil palm lignocellulosic waste. Processes 2022, 10, 2205. [Google Scholar] [CrossRef]

- Yang, S.; Qian, X. Conductive ppy@cellulosic paper hybrid electrodes with a redox active dopant for high capacitance and cycling stability. Polymers 2022, 14, 2634. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Yang, S.; Zhu, X.; Jiang, X.; Kong, X.Z. Easy preparation of superoleophobic membranes based on cellulose filter paper and their use for water–oil separation. Cellulose 2019, 26, 6813–6823. [Google Scholar] [CrossRef]

- Guo, J.; Wang, L.; Tu, Y.; Muhammad, H.; Fan, X.; Cao, G.; Laipan, M. Polypyrrole modified bentonite nanocomposite and its application in high-efficiency removal of Cr(VI). J. Environ. Chem. Eng. 2021, 9, 106631. [Google Scholar] [CrossRef]

- Lay, M.; Méndez, J.A.; Delgado-Aguilar, M.; Bun, K.N.; Vilaseca, F. Strong and electrically conductive nanopaper from cellulose nanofibers and polypyrrole. Carbohydr. Polym. 2016, 152, 361–369. [Google Scholar] [CrossRef]

- Raghunathan, S.P.; Narayanan, S.; Poulose, A.C.; Joseph, R. Flexible regenerated cellulose/polypyrrole composite films with enhanced dielectric properties. Carbohydr. Polym. 2017, 157, 1024–1032. [Google Scholar] [CrossRef]

- Haciismailoglu, M.; Vatansever, D.; Alper, M. Polypyrrole–oxalate and polypyrrole–sulfate electrodes for supercapacitor applications. Chem. Pap. 2024, 78, 3315–3329. [Google Scholar] [CrossRef]

- Sethumadhavan, V.; Mahjoub, R.; Zuber, K.; Stanford, N.; Evans, D. Oxygenation of conducting polymers facilitated by structure-breaking anions. J. Polym. Sci. 2021, 59, 745–753. [Google Scholar] [CrossRef]

- Gao, M.-H.; Feng, W.; Qi, X.-D.; Wang, Y. Multistimuli responsive and thermoregulated capability of coaxial electrospun membranes with core-sheath structure and functional polypyrrole layer. Chin. J. Polym. Sci. 2022, 40, 1380–1388. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, B.; Pang, Y.; Guo, H.; Liu, Y. Structure and interface engineering on polypyrrole-deposited conductive paper originating from nature wood enables high performance flexible all-solid-state supercapacitors. Ind. Crops Prod. 2023, 194, 116314. [Google Scholar] [CrossRef]

- Tao, S.; Yang, Q.; Zhou, W.; Zhu, J.; Pan, H.; Xu, L.; Zhao, H.; Zhou, T.; Wang, J. Incorporation of polyvinyl alcohol in bacterial cellulose/polypyrrole flexible conductive films to enhance the mechanical and conductive performance. Int. J. Biol. Macromol. 2024, 282, 137571. [Google Scholar] [CrossRef]

- Miao, J.; Chen, Y.; Li, Y.; Cheng, J.; Wu, Q.; Ng, K.W.; Cheng, X.; Chen, R.; Cheng, C.; Tang, Z. Proton conducting polyoxometalate/polypyrrole films and their humidity sensing performance. ACS Appl. Nano Mater. 2018, 1, 564–571. [Google Scholar] [CrossRef]

- Jiao, X.; Zhang, C.; Yuan, Z. Facile and large-area preparation of polypyrrole film for low-haze transparent supercapacitors. ACS Appl. Mater. Interfaces 2018, 10, 41299–41311. [Google Scholar] [CrossRef]

- Tabačiarová, J.; Mičušík, M.; Fedorko, P.; Omastová, M. Study of polypyrrole aging by xps, ftir and conductivity measurements. Polym. Degrad. Stab. 2015, 120, 392–401. [Google Scholar] [CrossRef]

- Zhou, F.; Li, Y.; Wei, L.; Wang, S.; Lan, L.; Peng, J.; Wang, Z.; Hu, M.; Wang, F.; Wang, L.; et al. Lawn-inspired polypyrrole functionalized waste fabrics for chromium removal through a combination of adsorption and interface evaporation. Appl. Surf. Sci. 2023, 640, 158351. [Google Scholar] [CrossRef]

- Lu, W.; Jiang, D.; Wang, Z.; Zhang, X.; Ding, Q.; Zhang, Z.; Liu, X.; Bai, L.; Li, Z.; Liu, Y. Simultaneous efficient evaporation and stable electricity generation enabled by a wooden evaporator based on composite photothermal effect. Chem. Eng. J. 2024, 496, 154361. [Google Scholar] [CrossRef]

- Yue, Y.; Wang, Y.; Bai, Y.; Han, J.; Cheng, W.; Han, G.; Wu, Q.; Jiang, J. A loofah-based all-day-round solar evaporator with phenolic lignin as the light-absorbing material for a highly efficient photothermal conversion. Chem. Eng. J. 2023, 477, 147298. [Google Scholar] [CrossRef]

- Qi, Z.; Zhang, W.; Han, X.; Yang, K.; Cai, H. In-situ lignin regeneration facilitated corn straw-based photothermal evaporator with high cost-effectiveness. Ind. Crops Prod. 2024, 213, 118420. [Google Scholar] [CrossRef]

- Xi, Y.; Guo, W.; Wang, X.; Lin, X.; Lyu, G. Photothermal properties and solar water evaporation performance of lignin-based polyurethane foam composites. Langmuir 2024, 40, 7205–7214. [Google Scholar] [CrossRef] [PubMed]

- Michelin, M.; Marques, A.M.; Pastrana, L.M.; Teixeira, J.A.; Cerqueira, M.A. Carboxymethyl cellulose-based films: Effect of organosolv lignin incorporation on physicochemical and antioxidant properties. J. Food Eng. 2020, 285, 110107. [Google Scholar] [CrossRef]

- Ramirez, D.O.S.; Varesano, A.; Carletto, R.A.; Vineis, C.; Perelshtein, I.; Natan, M.; Perkas, N.; Banin, E.; Gedanken, A. Antibacterial properties of polypyrrole-treated fabrics by ultrasound deposition. Mater. Sci. Eng. C 2019, 102, 164–170. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Jia, X.; Li, Y.; Wang, S.; Song, H. Wood-based solar interface evaporation device with self-desalting and high antibacterial activity for efficient solar steam generation. ACS Appl. Mater. Interfaces 2020, 12, 47029–47037. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Q.; Wang, Y.; Wang, S.; Gibril, M.E.; Kong, F. Constructing Multifunctional Composite Paper Coated with Polypyrrole@Lignocellulosic Slurry with Humidity Sensing, Conductivity, Antibacterial, and Photothermal Properties. Polymers 2025, 17, 898. https://doi.org/10.3390/polym17070898

Ni Q, Wang Y, Wang S, Gibril ME, Kong F. Constructing Multifunctional Composite Paper Coated with Polypyrrole@Lignocellulosic Slurry with Humidity Sensing, Conductivity, Antibacterial, and Photothermal Properties. Polymers. 2025; 17(7):898. https://doi.org/10.3390/polym17070898

Chicago/Turabian StyleNi, Qingrun, Yating Wang, Shoujuan Wang, Magdi E. Gibril, and Fangong Kong. 2025. "Constructing Multifunctional Composite Paper Coated with Polypyrrole@Lignocellulosic Slurry with Humidity Sensing, Conductivity, Antibacterial, and Photothermal Properties" Polymers 17, no. 7: 898. https://doi.org/10.3390/polym17070898

APA StyleNi, Q., Wang, Y., Wang, S., Gibril, M. E., & Kong, F. (2025). Constructing Multifunctional Composite Paper Coated with Polypyrrole@Lignocellulosic Slurry with Humidity Sensing, Conductivity, Antibacterial, and Photothermal Properties. Polymers, 17(7), 898. https://doi.org/10.3390/polym17070898