Polymers Used in Transparent Face Masks—Characterization, Assessment, and Recommendations for Improvements Including Their Sustainability

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Basic Physical Properties

2.3. Fourier Transform Infrared (FTIR) Spectroscopy

2.4. Water Contact Angle Goniometry

2.5. Density Gradient Column

2.6. Differential Scanning Calorimetry (DSC)

2.7. Size Exclusion Chromatography (SEC)

2.8. Thermal Gravimetric Analysis (TGA)

2.9. UV-Vis Spectrometry

2.10. Stress Strain Measurements

2.11. X-Ray Fluorescence/Energy-Dispersive X-Ray (XRF/EDX) Spectroscopy

2.12. Scanning Electron Microscopy (SEM) and Energy-Dispersive X-Ray (SEM/EDX) Spectroscopy

3. Results and Discussion

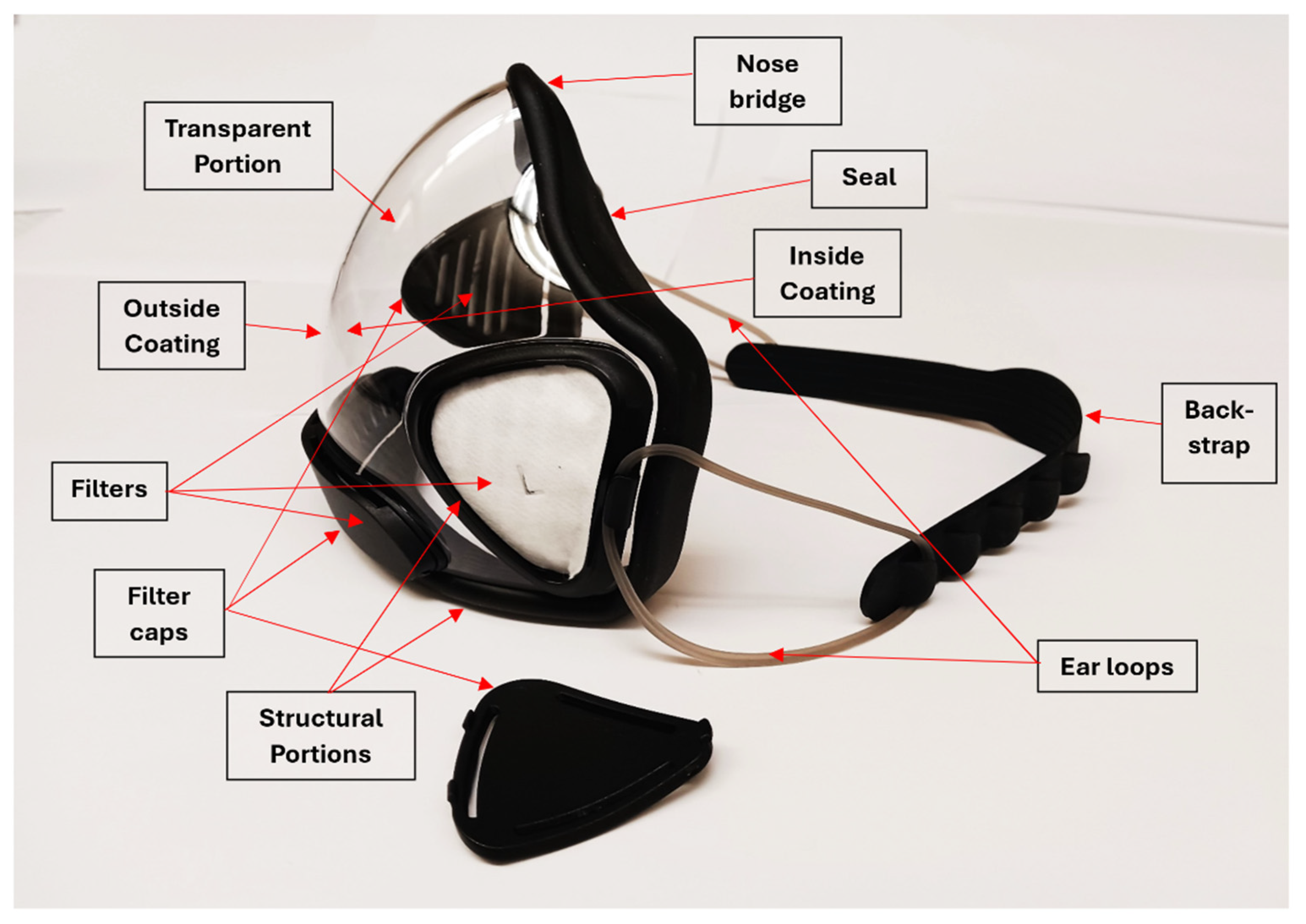

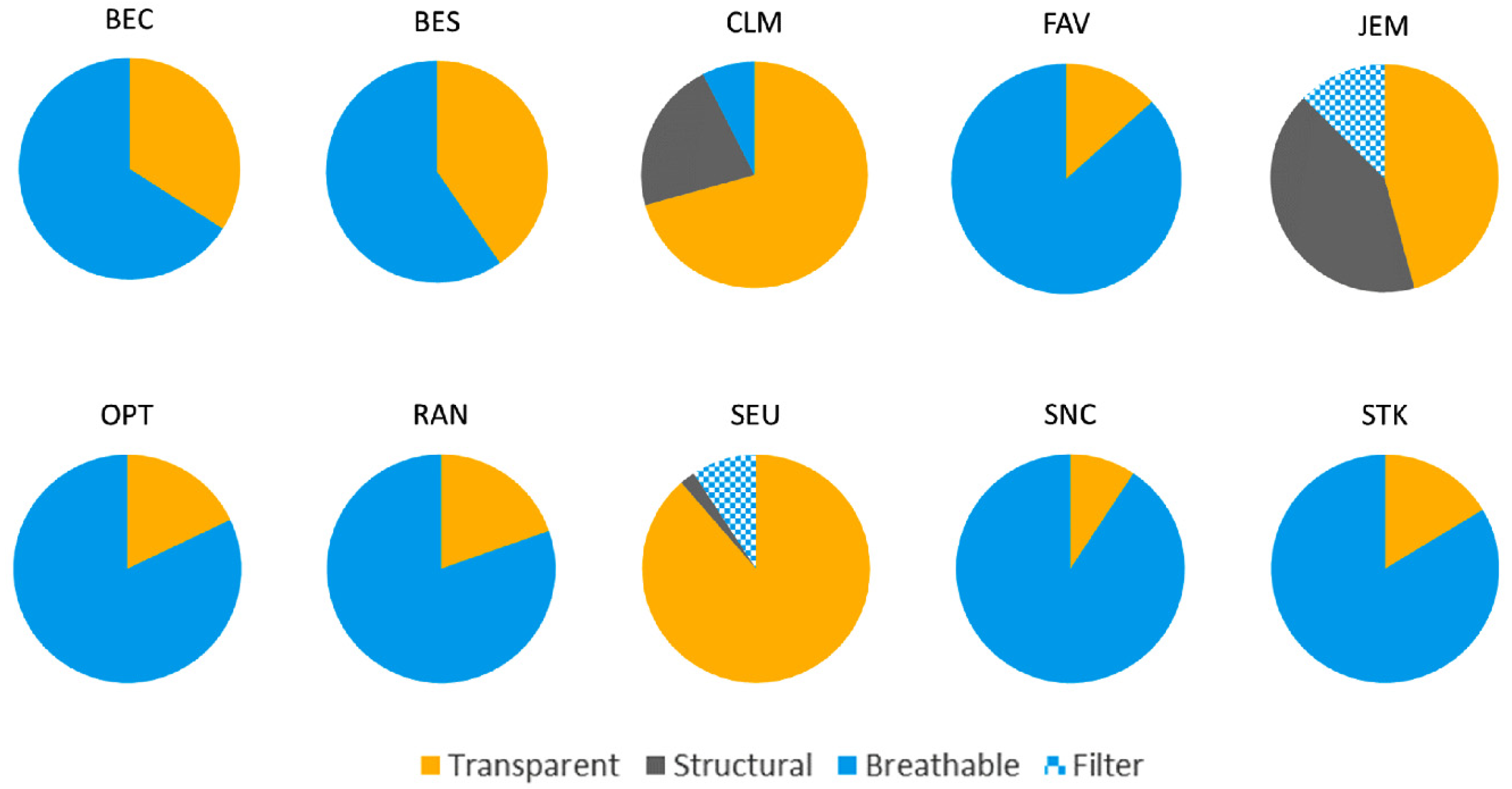

3.1. Determination of Basic Physical Properties, Including Mass and Sizes of Different Portions of Masks

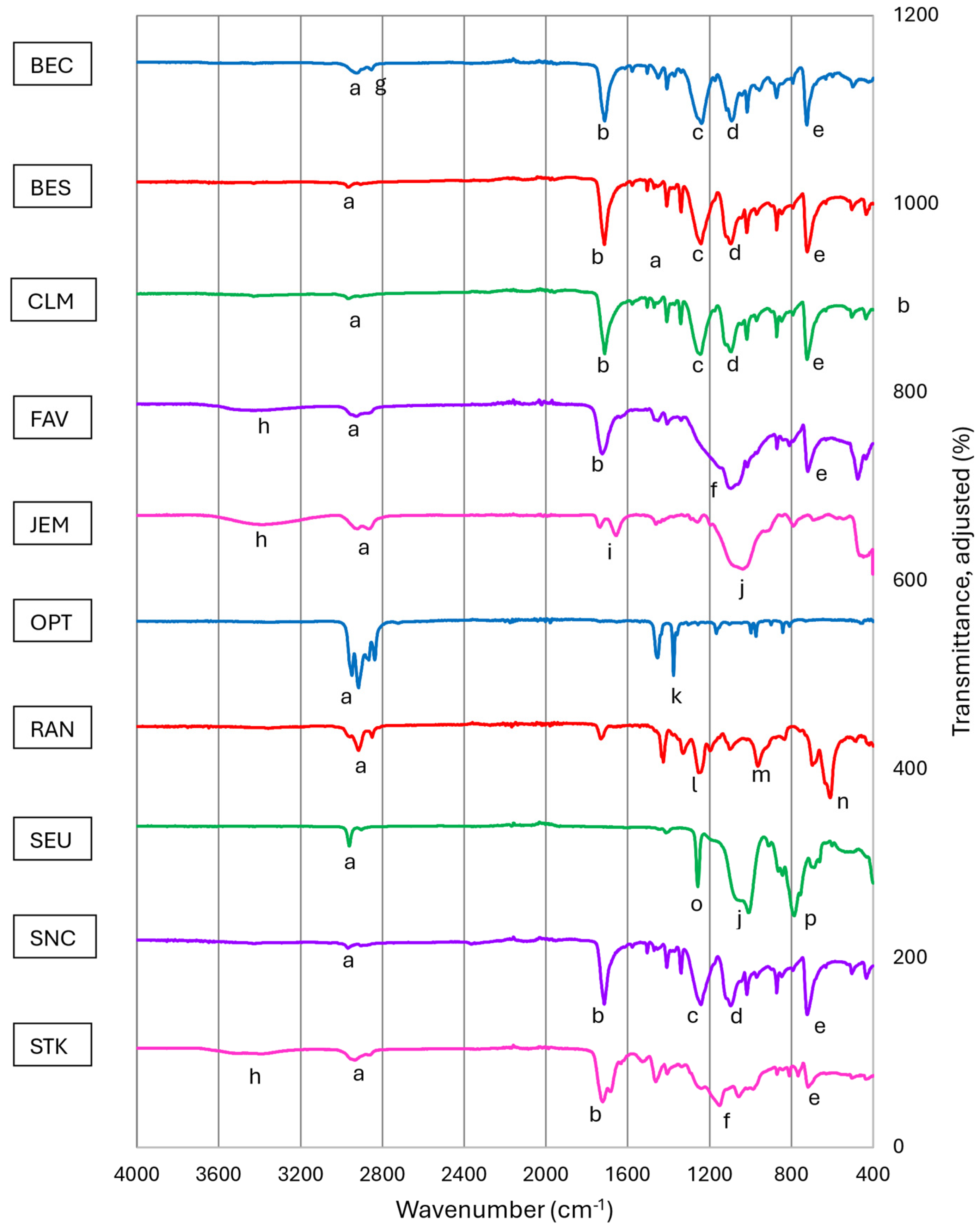

3.2. Determination of Polymer Types

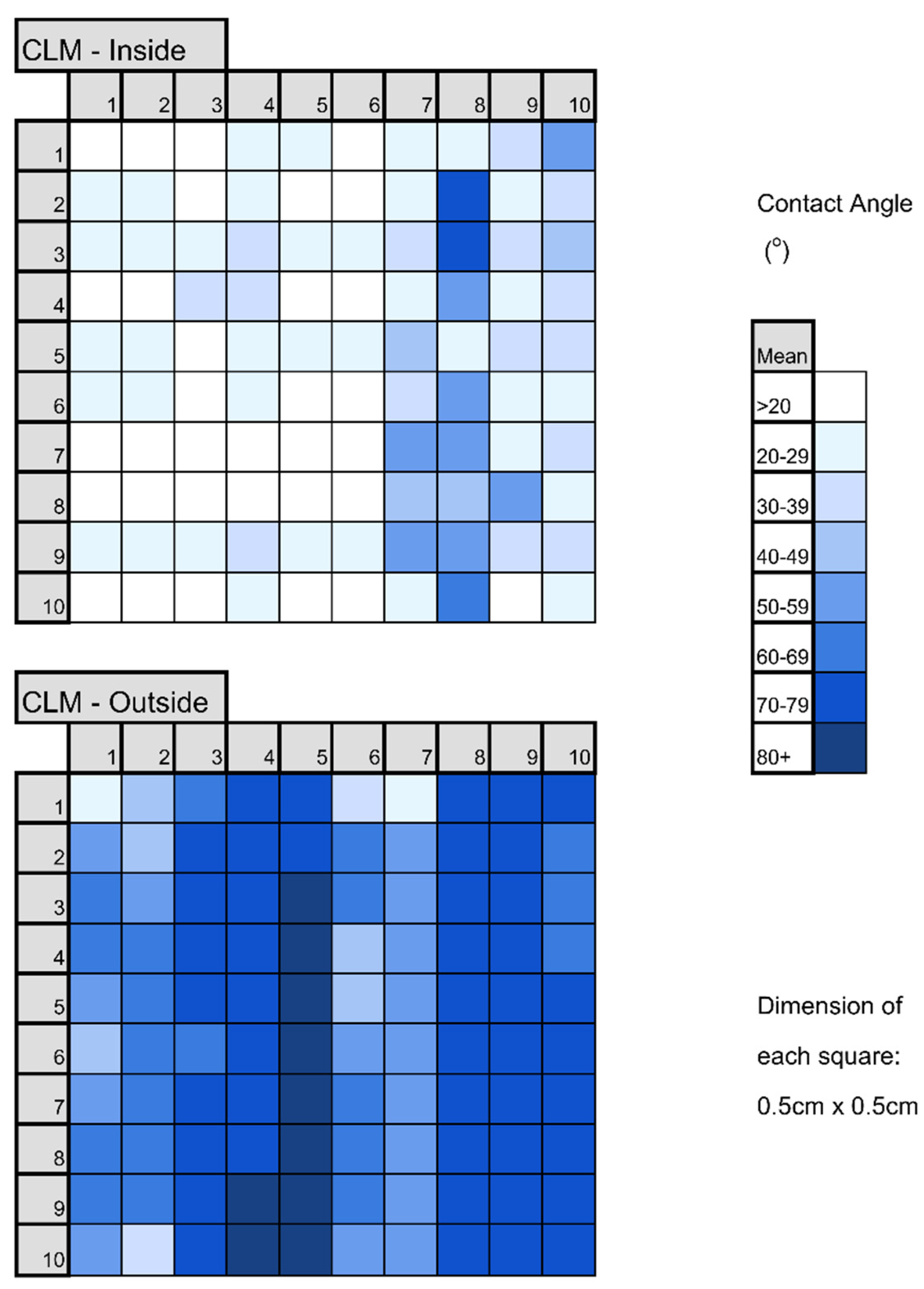

3.3. Characterization of Coatings on Transparent Portions of Face Masks

3.4. Quantitative Optical Properties—Reflectance and Haze

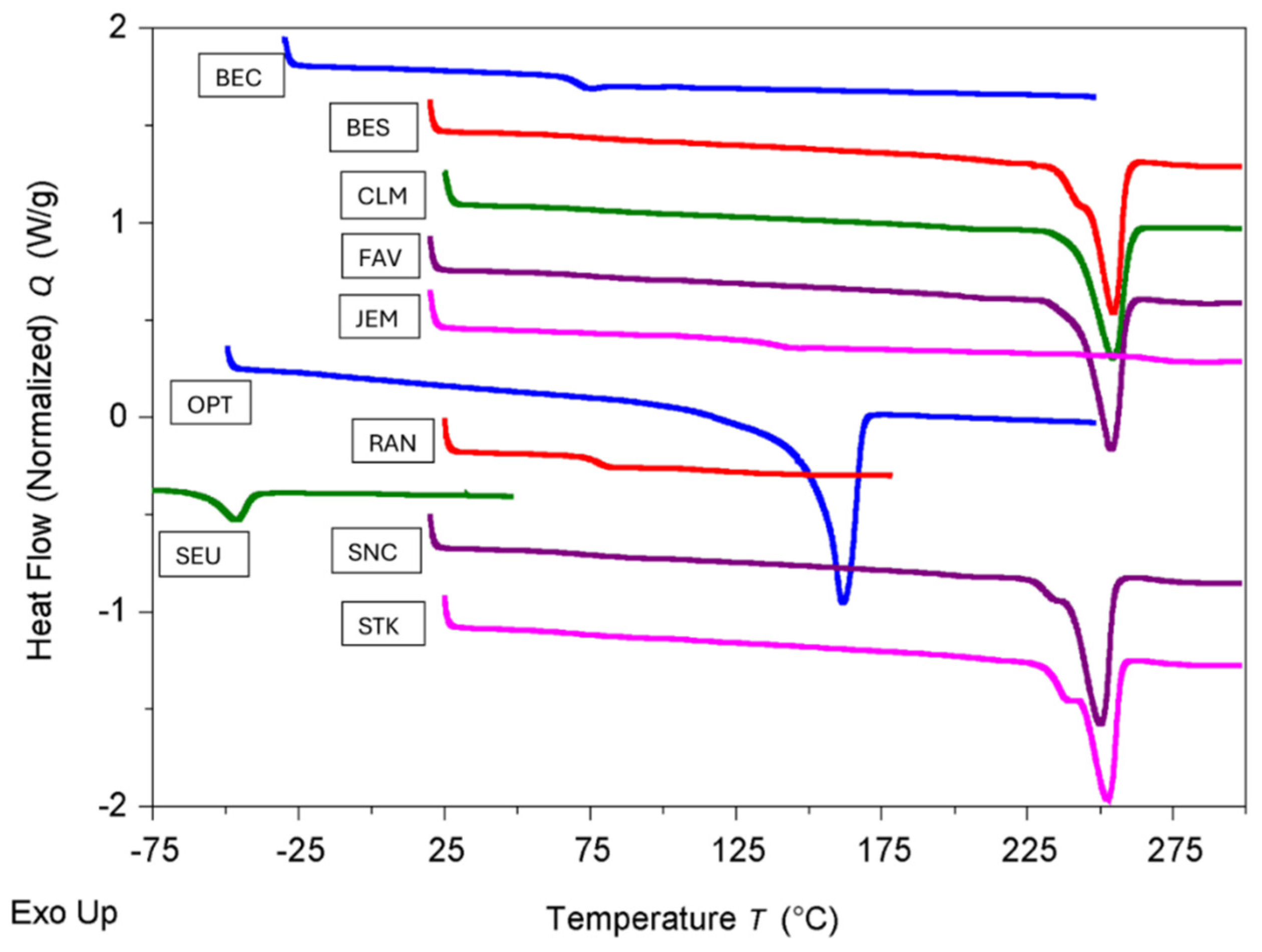

3.5. Thermal Properties, Density, and Degree of Crystallinity of Transparent Portions in Face Masks

3.6. Molecular Weight Properties

3.7. Mechanical Properties

3.8. Overall Assessment

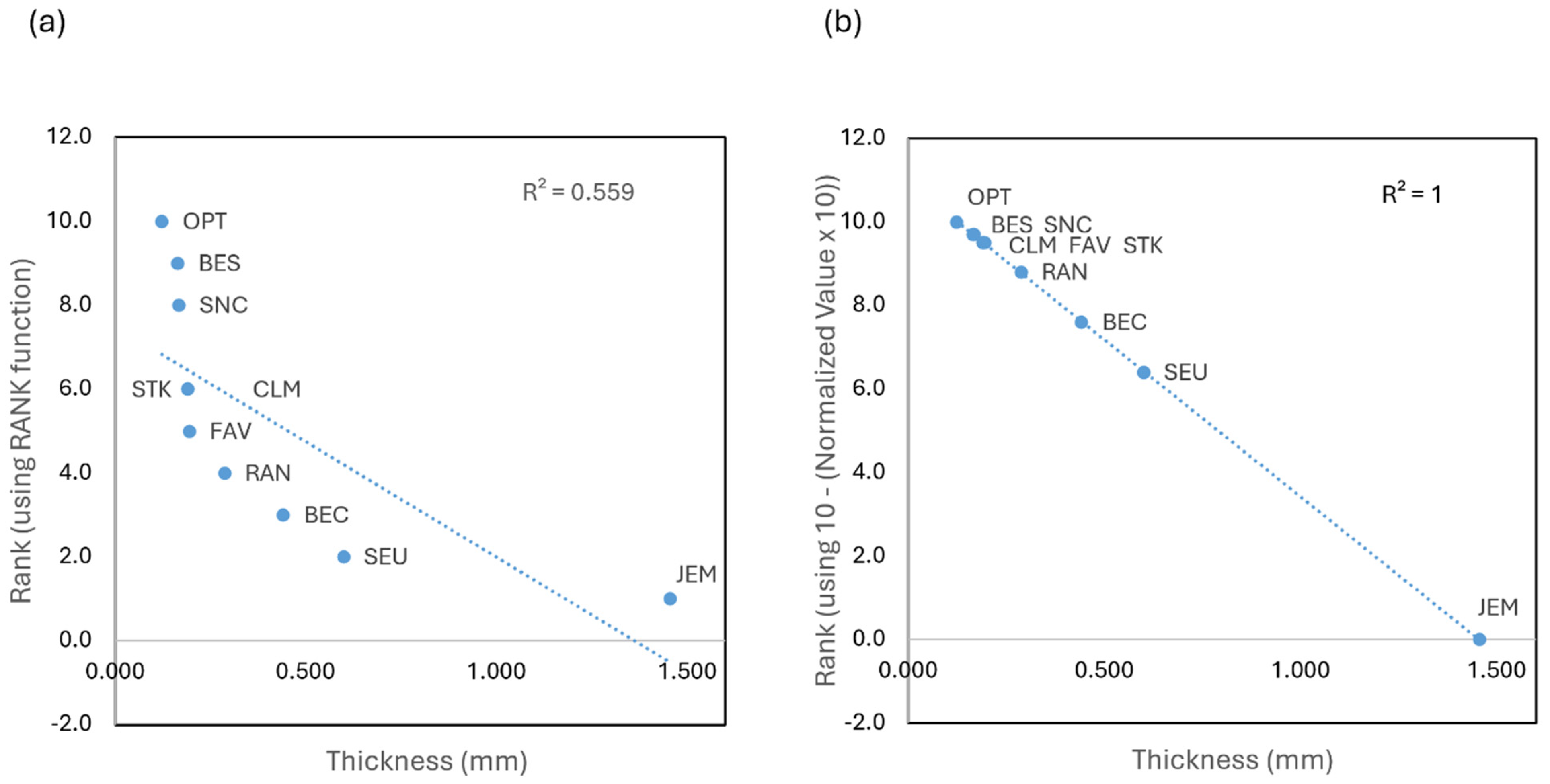

3.9. A Closer Look at the Assessment of Sustainability-Related Aspects

3.10. Recommendations for Improvements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hauser, C. The Mask Slackers of 1918. New York Times (New York, NY), 3 December 2024, Updated 10 December 2020. Available online: https://www.nytimes.com/2020/08/03/us/mask-protests-1918.html (accessed on 14 September 2024).

- Strasser, B.J.; Schlich, T. A history of the medical mask and the rise of throwaway culture. Lancet 2020, 396, 19–20. [Google Scholar] [PubMed]

- Stackhouse, C.A.; Yan, S.; Wang, L.; Kisslinger, K.; Tappero, R.; Head, A.R.; Tallman, K.R.; Takeuchi, E.S.; Bock, D.C.; Takeuchi, K.J.; et al. Characterization of Materials Used as Face Coverings for Respiratory Protection. ACS Appl. Mater. Interfaces 2021, 13, 47996–48008. [Google Scholar] [PubMed]

- Prata, J.C.; Silva, A.L.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. COVID-19 Pandemic Repercussions on the Use and Management of Plastics. Environ. Sci. Technol. 2020, 54, 7760–7765. [Google Scholar]

- Armentano, I.; Barbanera, M.; Carota, E.; Crognale, S.; Marconi, M.; Rossi, S.; Rubino, G.; Scungio, M.; Taborri, J.; Calabro, G. Polymer Materials for Respiratory Protection: Processing, End Use, and Testing Methods. ACS Appl. Polym. Mater. 2021, 3, 531–548. [Google Scholar]

- Tun, A.; Takayama, K.; Redwan, E.M.; Uversky, V.N.; Andrés, J.; Serrano-Aroca, A. Protective Face Masks: Current Status and Future Trends. ACS Appl. Mater. Interfaces 2021, 13, 56725–56751. [Google Scholar]

- Rahman, M.Z.; Hoque, M.E.; Alam, M.R.; Rouf, M.A.; Khan, S.I.; Xu, H.; Ramakrishna, S. Face Masks to Combat Coronavirus (COVID-19)—Processing, Roles, Requirements, Efficacy, Risk and Sustainability. Polymers 2022, 14, 1296. [Google Scholar] [CrossRef]

- Shanmugam, V.; Babu, K.; Garrison, T.F.; Capezza, A.J.; Olsson, R.T.; Ramakrishna, S.; Hedenqvist, M.S.; Singha, S.; Bartoli, M.; Giorcelli, M.; et al. Potential natural polymer-based nanofibres for the development of facemasks in countering viral outbreaks. J. Appl. Polym. Sci. 2021, 138, 50658. [Google Scholar]

- Soo, X.Y.D.; Wanga, S.; Yeo, C.C.J.; Li, J.; Ni, X.P.; Jiang, L.; Xuea, K.; Li, Z.; Fei, X.; Zhu, Q.; et al. Polylactic acid face masks: Are these the sustainable solutions in times of COVID-19 pandemic? Sci. Total Environ. 2022, 807, 151084. [Google Scholar]

- Cheng, H.N.; Gross, R.A. (Eds.) Sustainability & Green Polymer Chemistry Volume 1: Green Products and Processes ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2020; Volume 1372, Ch. 1. [Google Scholar]

- Wang, L.; Li, S.; Ahmad, I.M.; Zhang, G.; Sun, Y.; Wang, Y.; Sun, C.; Jiang, C.; Cui, P.; Li, D. Global face mask pollution: Threats to the environment and wildlife, and potential solutions. Sci. Total Environ. 2023, 887, 164055. [Google Scholar] [CrossRef]

- Lyu, L.; Bagchi, M.; Markoglou, N.; An, C.; Peng, H.; Bi, H.; Yang, X.; Sun, H. Towards environmentally sustainable management: A review on the generation, degradation, and recycling of polypropylene face mask waste. J. Hazard. Mater. 2024, 461, 132566. [Google Scholar]

- Bondaroff, T.P.; Cooke, S. Masks on the Beach: The impact of COVID-19 on marine plastic pollution. OceansAsia 2020, 30, 1–79. Available online: https://assets.deshsanchar.com/wp-content/uploads/2020/12/30160944/Marine-Plastic-Pollution-FINAL-1-compressed-1.pdf (accessed on 10 August 2024).

- Dharmaraj, S.; Ashokkumar, V.; Hariharan, S.; Manibharathi, A.; Show, P.L.; Chong, C.T.; Ngamcharussrivichai, C. The COVID-19 pandemic face mask waste: A blooming threat to the marine environment. Chemosphere 2021, 272, 129601. [Google Scholar]

- Chen, X.; Chen, X.; Liu, Q.; Zhao, Q.; Xiong, X.; Wu, C. Used disposable face masks are significant sources of microplastics to environment. Environ. Pollut. 2021, 285, 117485. [Google Scholar] [CrossRef]

- Pizarro-Ortega, C.L.; Dioses-Salinas, D.C.; Severini, M.D.F.; Lopez, A.D.F.; Rimondino, G.N.; Benson, N.U.; Dobaradaran, S.; De-la-Torre, G.E. Degradation of plastics associated with the COVID-19 pandemic. Mar. Pollut. Bull. 2022, 176, 113474. [Google Scholar]

- Jiang, H.; Luo, D.; Wang, L.; Zhang, Y.; Wang, H.; Wang, C.A. A review of disposable facemasks during the COVID-19 pandemic: A focus on microplastics release. Chemosphere 2023, 312, 137178. [Google Scholar]

- Carreiras-Suárez, S.; Domínguez-Ramos, L.; Lazzari, M. Study of the Long-Term Aging of Polypropylene-Made Disposable Surgical Masks and Filtering Facepiece Respirators. Polymers 2023, 15, 1001. [Google Scholar] [CrossRef] [PubMed]

- Wittmann, L.; Garnier, J.; Sakata, N.; Auzias, E.; Dumoulin, M.; Barlier, N.; Bergese, T.; Leclerc, L.; Grattard, F.; Verhoeven, P.O.; et al. Structure, Morphology, and Surface Chemistry of Surgical Masks and Their Evolution up to 10 Washing Cycles. ACS Appl. Polym. Mater. 2023, 5, 2282–2288. [Google Scholar]

- Straten, B.; Ligtelijn, S.; Droog, L.; Putman, E.; Dankelman, J.; Weiland, N.H.S.; Horeman, T.A. A life cycle assessment of reprocessing face masks during the COVID-19 pandemic. Sci. Rep. 2021, 11, 17680. [Google Scholar]

- Erjavec, A.; Volmajer Valh, J.; Hribernik, S.; Kraševac Glaser, T.; Fras Zemljič, L.; Vuherer, T.; Neral, B.; Brunčko, M. Advance Analysis of the Obtained Recycled Materials from Used Disposable Surgical Masks. Polymers 2024, 16, 935. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Kilmartin-Lynch, S.; Boroujeni, M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021, 769, 145527. [Google Scholar]

- World Report on Hearing. Available online: https://www.who.int/publications/i/item/9789240021570 (accessed on 29 August 2024).

- Behm, G.W.; Norton, R.L. (International Business Machines Corporation) See-Through Mask to Facilitate Communication in Environments Requiring the Wearing of a Mask. U.S. Patent Application 20080092897, 18 October 2006. [Google Scholar]

- Marini, M.; Ansani, A.; Paglieri, F.; Caruana, F.; Viola, M. The impact of facemasks on emotion recognition, trust attribution and re-identification. Sci. Rep. (Nat. Publ. Group) 2021, 11, 5577. [Google Scholar]

- Tavanai, E.; Rouhbakhsh, N.; Roghani, Z. A review of the challenges facing people with hearing loss during the COVID-19 outbreak: Toward the understanding the helpful solutions. Audit. Vestib. Res. 2021, 30, 62–73. [Google Scholar]

- B. Hurwitz on ‘Universal Design’ in Seo, H. “Clear Masks Help the Hard of Hearing, but They Could Benefit Everybody”, Popular Science. 2020. Available online: https://www.popsci.com/story/health/clear-masks-options-accessibility/ (accessed on 10 October 2024).

- Vincent, M.; Edwards, P. Disposable surgical face masks for preventing surgical wound infection in clean surgery. Cochrane Database Syst. Rev. 2016, CD002929, 1–23. [Google Scholar] [CrossRef] [PubMed]

- Diaz, J.H. A New Transparent Disposable Plastic Face Mask for Children and Adults. Anesthesiology 1993, 78, 1195–1196. [Google Scholar] [CrossRef]

- Alenezi, H.; Cam, M.E.; Edirisinghe, M. A novel reusable anti-COVID-19 transparent face respirator with optimized airflow. Bio-Des. Manuf. 2021, 4, 1–9. [Google Scholar]

- Avossa, J.; Batt, T.; Pelet, T.; Sidjanski, S.P.; Schönenberger, K.; Rossi, R.M. Polyamide Nanofiber-Based Air Filters for Transparent Face Masks. ACS Appl. Nano Mater. 2021, 4, 12401–12406. [Google Scholar]

- He, H.; Gao, M.; Illés, B.; Molnar, K. 3D Printed and Electrospun, Transparent, Hierarchical Polylactic Acid Mask Nanoporous Filter. Int. J. Bioprinting 2020, 6, 278. [Google Scholar]

- Atcherson, S.R.; McDowell, B.R.; Howard, M.P. Acoustic effects of non-transparent and transparent face coverings. J. Acoust. Soc. Am. 2021, 149, 2249–2254. [Google Scholar]

- LThibodeau, M.; Thibodeau-Nielsen, R.B.; Tran, C.M.Q.; de Souza Jacob, R.T. Communicating During COVID-19: The Effect of Transparent Masks for Speech Recognition in Noise. Ear Hear. 2021, 42, 772–781. [Google Scholar]

- Miyazaki, Y.; Kamatani, M.; Suda, T.; Wakasugi, K.; Matsunaga, K.; Kawahara, J.I. Effects of wearing a transparent face mask on perception of facial expressions. Iperception 2022, 13, 1–18. [Google Scholar]

- McCrackin, S.D.; Ristic, J. Improving masked communication: The case for transparent masks. Front. Commun. 2024, 9, 1371142. [Google Scholar]

- Available online: https://www.cdc.gov/niosh/npptl/topics/respirators/disp_part/n95list1.html (accessed on 16 December 2024).

- GB2626-2019; Respiratory Protective Equipment—Non-Powered Air-Purifying Particle Respirator. Standardization Administration of China (SAC): Beijing, China, 2019.

- KMOEL-2017-64; Standards for Classification of Chemical Substances and Hazard Communication. The Korean Ministry of Employment and Labor (KMOEL): Sejong-si, Republic of Korea.

- Available online: https://www.fda.gov/medical-devices/coronavirus-covid-19-and-medical-devices/face-masks-barrier-face-coverings-surgical-masks-and-respirators-covid-19 (accessed on 16 December 2024).

- Farzaneh, S.; Shirinbayan, M. Processing and Quality Control of Masks: A Review. Polymers 2022, 14, 291. [Google Scholar] [CrossRef] [PubMed]

- Durán, I.R.; Laroche, G. Current trends, challenges, and perspectives of anti-fogging technology: Surface and material design, fabrication strategies, and beyond. Progr. Mater. Sci. 2019, 99, 106–186. [Google Scholar]

- Gong, X.; Yu, H.; Wang, L.; Liu, X.; Ren, S.; Huang, Y.; Huang, Z. Recent progress in the mechanisms, preparations and applications of polymeric antifogging coatings. Adv. Colloid Interface Sci. 2022, 309, 102794. [Google Scholar]

- Chu, J.; Tian, G.; Feng, X. Recent advances in prevailing antifogging surfaces: Structures, materials, durability, and beyond. Nanoscale 2023, 15, 11366–11402. [Google Scholar]

- Wahab, I.F.; Bushroa, A.R.; Teck, S.W.; Azmi, T.T.; Ibrahim, M.Z.; Lee, J.W. Fundamentals of antifogging strategies, coating techniques and properties of inorganic materials; a comprehensive review. J. Mater. Res. Technol. 2023, 23, 687–714. [Google Scholar]

- Sangermano, M.; Messori, M. Scratch Resistance Enhancement of Polymer Coatings. Macromol. Mater. Eng. 2010, 295, 603–612. [Google Scholar]

- Gomez, I.J.; Wu, J.; Roper, J.; Beckham, H.; Meredith, J.C. High Throughput Screening of Mechanical Properties and Scratch Resistance of Tricomponent Polyurethane Coatings. ACS Appl. Polym. Mater. 2019, 1, 3064–3073. [Google Scholar] [CrossRef]

- Bauer, F.; Gläsel, H.-J.; Decker, U.; Ernst, H.; Freyer, A.; Hartmann, E.; Sauerland, V.; Mehnert, R. Trialkoxysilane grafting onto nanoparticles for the preparation of clear coat polyacrylate systems with excellent scratch performance. Prog. Org. Coat. 2003, 47, 147–153. [Google Scholar]

- Day, T.; Naughton, D. Cleaning and anti-reflective (AR) hydrophobic coating of glass surface: A review from materials science perspective. J. Sol.-Gel. Sci. Technol. 2016, 77, 1–27. [Google Scholar] [CrossRef]

- El-Hiti, G.A.; Ahmed, D.S.; Yousif, E.; Al-Khazrajy, O.S.; Abdallh, M.; Alanazi, S.A. Modifications of Polymers through the Addition of Ultraviolet Absorbers to Reduce the Aging Effect of Accelerated and Natural Irradiation. Polymers 2022, 14, 20. [Google Scholar]

- Scherer, K.; Soerjawinata, W.; Schaefer, S.; Kockler, I.; Ulber, R.; Lakatos, M.; Bröckel, U.; Kampeis, P.; Wahl, M. Influence of wettability and surface design on the adhesion of terrestrial cyanobacteria to additive manufactured biocarrier. Bioprocess Biosyst. Eng. 2022, 45, 931–941. [Google Scholar] [CrossRef]

- Homola, T.; Wu, L.Y.L.; Cernák, M. Atmospheric Plasma Surface Activation of Poly(Ethylene Terephthalate) Film for Roll-To-Roll Application of Transparent Conductive Coating. J. Adhes. 2014, 90, 296–309. [Google Scholar]

- Jankowski, P.; Ogonczyk, D.; Kosinski, A.; Lisowski, W.; Garstecki, P. Hydrophobic modification of polycarbonate for reproducible and stable formation of biocompatible microparticles. Lab A Chip 2011, 11, 748–752. [Google Scholar]

- Schonherr, H.; Hruska, Z.; Vancso, J.G. Surface Characterization of Oxyfluorinated Isotactic Polypropylene Films: Scanning Force Microscopy with Chemically Modified Probes and Contact Angle Measurements. Macromolecules 1998, 31, 3679–3685. [Google Scholar]

- Sant’Ana, P.L.; Bortoleto, J.R.R.; da Cruz, N.C.; Rangel, E.C.; Durrant, S.F.; Schreiner, W.H. Surface functionalization of polyvinyl chloride by plasma immersion techniques. Polimeros 2020, 30, e2020044. [Google Scholar]

- Bao, W.N.; Liang, X.D.; Liu, X.Y.; Gao, Y.F.; Wang, J.F. Effects of AC and DC Corona on the Surface Properties of Silicone Rubber: Characterization by Contact Angle Measurements and XPS High Resolution Scan. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2911–2919. [Google Scholar]

- Koncke, U.; Zachmann, H.G.; BaltaCalleja, F.J. New aspects concerning the structure and degree of crystallinity in high-pressure-crystallized poly(ethylene terephthalate). Macromolecules 1996, 29, 6019–6022. [Google Scholar]

- Wu, J.; Papanikolaou, K.G.; Cheng, F.; Addison, B.; Cuthbertson, A.A.; Mavrikakis, M.; Huber, G.W. Kinetic Study of Polyvinyl Chloride Pyrolysis with Characterization of Dehydrochlorinated PVC. ACS Sustain. Chem. Eng. 2024, 12, 7402–7413. [Google Scholar] [CrossRef]

- Van Krevelen, D.W. Properties of Polymers; Elsevier Science, Publishing Company: Amsterdam, The Netherlands, 1990. [Google Scholar]

- Milbrandt, A.; Coney, K.; Badgett, A.; Beckham, G.T. Quantification and evaluation of plastic waste in the United States. Resour. Conserv. Recycl. (RCR) 2022, 183, 106363. [Google Scholar]

- Available online: https://napcor.com/news/2023-pet-bottle-recycling-reach-new-heights/#:~:text=The%20United%20States%20(US)%20PET%20bottle%20collection,recycling%20rate%20in%20the%20US%20since%201996 (accessed on 16 December 2024).

- Radin Mohamed, R.M.S.; Misbah, G.S.; Wurochekke, A.A.; Mohd Kassim, A.H.B. Energy Recovery from Polyethylene Terephthalate(PET) Recycling Process. GSTF Int. J. Engineer. Technol. (JET) 2014, 2, 39–44. [Google Scholar]

- Alsabri, A.; Tahir, F.; Al-Ghamdi, S.G. Life-Cycle Assessment of Polypropylene Production in the Gulf Cooperation Council (GCC) Region. Polymers 2021, 13, 3793. [Google Scholar] [CrossRef] [PubMed]

- Gervet, B.; Nordell, N. The Use of Crude Oil in Plastic Making Contributes to Global Warming; Lulea University of Technology: Lulea, Sweden, 2007; pp. 1–6. Available online: https://www.researchgate.net/publication/266469821 (accessed on 20 September 2024).

- Marczak, H. Energy Inputs on the Production of Plastic Products. J. Ecol. Eng. 2022, 23, 146–156. [Google Scholar] [CrossRef]

- Suzuki, M.; Tachibana, Y.; Kasuya, K. Biodegradability of poly(3-hydroxyalkanoate) and poly(ε-caprolactone) via biological carbon cycles in marine environments. Polym. J. 2021, 53, 47–66. [Google Scholar] [CrossRef]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Papageorgiou, D.G.; Terzopoulou, Z.; Bikiaris, D.N. Production of bio-based 2, 5-furan dicarboxylate polyesters: Recent progress and critical aspects in their synthesis and thermal properties. Eur. Polym. J. 2016, 83, 202–229. [Google Scholar] [CrossRef]

- Pang, J.; Zheng, M.; Sun, R.; Wang, A.; Wang, X.; Zhang, T. Synthesis of ethylene glycol and terephthalic acid from biomass for producing PET. Green Chem. 2016, 18, 342–359. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(ethylene terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef]

- Pérez-Camargo, M.I.P.R.A.; Hernández, R.R.; Müller, A.J. A review on current strategies for the modulation of Thermomechanical, Barrier, and Biodegradation Properties of Poly (Butylene Succinate) (PBS) and its Random Copolymers. Polymers 2022, 14, 1025. [Google Scholar] [CrossRef]

- Demyttenaere, S.M.; Samonte, J.R.; Reilly, L.T.; Andelija, A.; Strohm, B.M.; Kovach, T.; Oakes, S.A.; Keeley, R.P.; Takacs, G.A.; Miri, M.J. Aliphatic polyesters based on 1, 4-butanediol and even numbered C4-C20 dicarboxylic acids-synthesis and properties including after surface treatment by VUV photo-oxidation. J. Polym. Res. 2023, 30, 331. [Google Scholar] [CrossRef]

- Parisi, L.R.; Scheibel, D.M.; Lin, S.; Bennett, E.M.; Lodge, J.S.; Miri, M.J. Eugenol as renewable comonomer compared to 4-penten-1-ol in ethylene copolymerization using a palladium aryl sulfonate catalyst. Polymer 2017, 114, 319–328. [Google Scholar]

- Jung, S.; Yang, J.-Y.; Byeon, E.-Y.; Kim, D.-G.; Lee, D.-G.; Ryoo, S.; Lee, S.; Shin, C.-W.; Jang, H.W.; Kim, H.J. Copper-Coated Polypropylene Filter Face Mask with SARS-CoV-2 Antiviral Ability. Polymers 2021, 13, 1367. [Google Scholar] [CrossRef] [PubMed]

| Entry No. | Brand Name | Abbreviation | Approx. Price Range per Mask in USD | Information at Amazon or Specific Website, as of 30 November 2024 |

|---|---|---|---|---|

| 1 | BEclear | BEC | n. a. | https://www.facebook.com/BEmask.org/ |

| 2 | Bendshape | BES | 5–10 | https://kangaroo-ruby-a78y.squarespace.com/shop |

| 3 | ClearMask | CLM | 5–10 | https://www.theclearmask.com |

| 4 | FaceView | FAV | 2–5 | https://faceviewmask.com |

| 5 | Jelli M1 | JEM | 30–40 | https://jellim.com |

| 6 | Optrel | OPT | 1–2 | https://optrel.us |

| 7 | RafiNova | RAN | 3–7 | https://rafinova.com |

| 8 | SeeUS95 | SEU | 48–85 | https://seeus-95.com |

| 9 | SafeN’Clear | SNC | 1–1.5 | https://safenclear.com |

| 10 | Stek | STK | 3–4 | https://stekcare.com |

| 11 | Protective Health Gear | PHG | 0.6–1 | https://protectivehealthgear.com |

| Abbreviation | General Comments Provided by the Manufacturers from Their Websites and on Packaging |

|---|---|

| BEC | Lightweight, transparent, reusable, recyclable, inexpensive, KF94 mask + BeClear Adapter; “nerd wax antifog” is pre-applied. |

| BES | Anti-fog transparent front. ≥98% BFE, ≥98% PFE @ 0.1 micron (“Highest filtration”; reusable—up to 10X or 80 hours; remark on sizes mentioned, but not posted. |

| CLM | FDA cleared (class II), CE marked (class I); applicable ASTM level 3 and EN 14683 standards; anti-fog technology, latex-free; in package: polyurethane foam; adult and child size. |

| FAV | This product meets requirements for KN95 and effectively filters at least 95% of particles; latex-free; Nonwoven complex fiber, melt-blown nonwoven fiber, hydrophilic Toray film, nylon and spandex ear loops, polyurethane sponge nose strip, aluminum nose strip; disposable. |

| JEM | Comes with replaceable filters (20 sets of three-piece filters that last from 2 to 3 weeks with regular wear, USD 5 ea.); anti-fog surface; breakdown: 29.92% PC, 31.93% nylon, 37.94% silica gel, 0.21% melt-blown |

| OPT | The P.Air Clear N95 Respirator is the world’s first NIOSH-approved and FDA-cleared face mask with a transparent window; latex-free; anti-fog coating. In package: straps: latex-free elastic; nose clip: metal; nose foam: polyurethane; window: polypropylene; filter: polypropylene. |

| RAN | BPA-free clear panel; tie-behind and ear loop styles; adjustable nose bridge; no anti-fog coating (recommended to obtain); four mask sizes (adult, teen, kids, little kids). |

| SEU | Adhesive on perimeter, gentle to the skin. Will adhere directly to face for better seal; reusable/washable with soap and water; BIO-FILTER 95% filtration efficacy; Washable filter with no rating, comparable to cloth mask; main part made of “silicon”; filters: PLA, bamboo. Anti-fog coating. The filter is N95-approved; large and small size. |

| SNC | Single-use, disposable; Level 1: FDA-registered and approved device meets ASTM Level 1 surgical mask standards; Level 3: ASTM Level 3, fog-resistant; “Fog resistant” window. |

| STK | Reusable for one week, anti-fog-coated; antimicrobial cover (3-(trimethoxysilyl) propyldimethyloctadecyl ammonium chloride); nonwoven fabric (exterior, lining, filter), polyester (nose wire), spandex (string), PET film; anti-fog; scratch resistance. |

| PHG | Completely solid (used as reference); NIOSH-approved N95 respirator; adult and child sizes. |

| Standard | N95 | KN95 | KF94 |

|---|---|---|---|

| Country | United States | China | South Korea |

| Standard | NIOSH | GB2626-2019 | KMOEL-2017-64 |

| Filtration Efficiency | ≥95% of particles 0.3 microns or larger | ≥95% of particles 0.3 microns or larger | ≥94% of particles 0.3 microns or larger |

| Typical shape | E.g., cup style or duckbill style | E.g., flat-fold or tent like style | E.g., larger cup or boat style |

| Fit | Tight | Less tight than N95 | Less tight than KN95 |

| Fastenings | Two headbands | Two ear loops | Two ear loops |

| Applications | Healthcare, other industries | Public, healthcare | Public |

| Other categorizations | RS2: reusable DS2: disposable | - | - |

| References | [37] | [38] | [39] |

| Mask ID | Mass (g) | Total Area (cm2) | Transparent Area (cm2) | Thickness of Transparent Part (mm) | Functionality of Portion of Total Area (%) | Seal | Wider Gaps Between Mask and Face | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Trans-paent | Structural | Breathable | Filter | |||||||

| BEC | 15.30 | 444.37 | 151.49 | 0.441 | 34.09 | 0.00 | 65.91 | 0.00 | No | Top |

| BES | 8.75 | 301.64 | 121.83 | 0.165 | 40.39 | 0.00 | 59.61 | 0.00 | No | No |

| CLM | 9.07 | 192.69 | 131.28 | 0.l90 | 68.13 | 21.03 * | 7.22 * | 0.00 | No | Sides |

| FAV | 8.72 | 317.88 | 42.44 | 0.195 | 13.35 | 0.00 | 86.65 | 0.00 | No | No |

| JEM | 78.31 | 242.67 | 111.07 | 1.456 | 45.77 | 41.67 | 0.00 | 12.55 | Yes | No |

| OPT | 7.36 | 274.97 | 49.33 | 0.123 | 17.94 | 0.00 | 82.06 | 0.00 | No | No |

| RAN | 21.45 | 268.74 | 52.81 | 0.288 | 19.65 | 0.00 | 80.35 | 0.00 | No | No |

| SEU | 45.68 | 208.33 | 184.62 | 0.600 | 88.62 | 2.15 | 0.00 | 9.23 | Yes | No |

| SNC | 5.94 | 288.76 | 26.91 | 0.168 | 9.32 | 0.00 | 90.68 | 0.00 | No | No |

| STK | 6.90 | 290.96 | 47.57 | 0.190 | 16.35 | 0.00 | 83.65 | 0.00 | No | No |

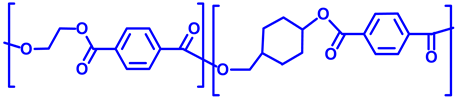

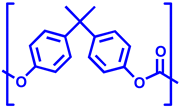

| Entry No. | Mask ID | Polymer Name | Polymer Acronym | Polymer’s Repeat Unit |

|---|---|---|---|---|

| 1 | BEC | Polyethylene terephthalate glycol (with 1,4-cyclohexane-dimethanol) | PETG |  |

| 2 3 4 9 10 | BES CLM FAV SNC STK | Polyethylene terephthalate | PET |  |

| 5 | JEM | Polycarbonate | PC |  |

| 6 | OPT | Isotactic polypropylene | iPP |  |

| 7 | RAN | Polyvinyl chloride | PVC |  |

| 8 | SEU | Silicon rubber (crosslinked) | SR |  |

| Mask ID | Transparent Portion | Breath-Able Portion | Filter | Structural Portion | Nose Bridge | Ear Loop a | Seal or Adhesive |

|---|---|---|---|---|---|---|---|

| BEC | PETG | iPP | - | - | iPP-coated wire b | Nylon 6 | (Chin gel: PU strip: PMMAc) |

| BES | PET | iPP | - | - | Al strip | PET | - |

| CLM | PET | PU foam | - | PU foam | PU foam | PET | - |

| FAV | PET | iPP | - | - | PU foam d | Nylon 6/spandex | - |

| JEM | SiO2/PC | - | iPP | Nylon | SR | SR e | SR |

| OPT | iPP | iPP | - | - | PU foam | NBR | - |

| RAN | PVC | Cotton/PET | - | - | PVC-coated wire | PET | - |

| SEU | SR | - | PLA | PLA | (Sil. adhes. strip) | - | Sil. adhes. strips for sides |

| SNC | PET | PET | - | - | Al strip | PET | - |

| STK | PET | iPP | - | - | iPP-coated wire | Nylon 6/spandex | - |

| PHG | - | iPP | - | - | Al strip | Nylon 6 | - |

| Mask Type | Contact Angle of Main Portion a | Inside Coating | Outside Coating | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (Main Material in Transparent Portion) | Element (wt.%) by XRF /EDX b | Element (wt.%) by SEM /EDX c | Contact Angle of Coating d | Contact Angle, Std. Dev. e | Element (wt.%) by XRF /EDX b | Element (wt.%) by SEM /EDX c | Contact Angle of Coating d | Contact Angle, Std. Dev. e | |

| BEC (PETG) | 65–86 [51] | C: 67.5 O: 32.5 | C: 76.3 O: 23.7 | 74.9 | 4.18 | C: 70.2 O: 29.7 | C: 77.5 O: 22.5 | 73.3 | 1.89 |

| BES (PET) | 66–81 [52] | C: 71.3 O: 28.5 | C: 77.4 O: 22.6 | 62.5 | 8.99 | C: 71.0 O: 28.8 | C: 77.8 O: 22.2 | 60.0 | 8.75 |

| CLM (PET) | 66–81 [52] | C: 70.5 O: 29.2 | C: 77.5 O: 22.5 | 28.0 | 13.0 f | C: 71.7 O: 28.1 | C: 76.7 O: 23.3 | 67.1 | 22.0 f |

| FAV (PET) | 66–81 [52] | C: 55.8 O: 40.9 Si: 2.97 | C: 66.1 O: 32.2 Si: 1.59 | 11.7 | 0.65 | C: 54.3 O: 42.1 Si: 3.09 | C: 76.4 O: 23.6 | 72.6 | 0.15 |

| JEM (/SiO2/ PC) | 82–84 [53] | C: 53.9 Si: 43.8 | C: 62.9 O: 29.3 Si: 7.87 | 18.2 | 2.08 | O: 53.2 Si: 44.4 | C: 62.8 O: 29.7 Si: 7.44 | 19.7 | 1.43 |

| OPT (iPP) | 99–102 [54] | C: 99.9 | C: 98.8 O: 1.24 | 53.2 | 2.71 | C: 98.7 O: 1.20 | C: 100 | 53.6 | 3.88 |

| RAN (PVC) | 76–87 [55] | Cl: 99.7 | C: 79.7 Cl: 20.3 | 76.6 | 2.61 | Cl: 99.7 | C: 79.6 Cl: 20.4 | 78.8 | 2.23 |

| SEU (SR) | 112 [56] | Si: 77.5 O: 22.0 | C: 56.1 O: 24.0 Si: 19.9 | 87.2 | 0.07 | Si: 77.7 O: 21.8 Al: 0.48 | C: 57.7 O: 22.5 Si:19.8 | 88.2 | 4.80 |

| SNC (PET) | 66–81 [52] | C: 71.4 O: 28.3 | C: 75.5 O: 24.5 | 44.7 | 2.33 | C: 77.2 O: 22.7 | C: 75.9 O: 24.1 | 51.2 | 3.33 |

| STK (PET) | 66–81 [52] | C: 68.1 O: 31.6 | C: 75.8 O: 24.2 | 10.1 | 0.40 | C: 70.4 O: 29.3 | C: 72.0 O: 25.3 N: 2.72 | 74.9 | 4.08 |

| Mask ID | UV-Vis Reflectance (%) | UV-Vis Haze (%) |

|---|---|---|

| BEC | 3.0 | 1.82 |

| BES | 4.3 | 0.71 |

| CLM | 4.0 | 2.06 |

| FAV | 2.7 | 0.51 |

| JEM | 3.1 | 0.97 |

| OPT | 5.4 | 8.04 |

| RAN | 2.3 | 2.46 |

| SEU | 4.6 | 2.44 |

| SNC | 5.4 | 2.15 |

| STK | 3.3 | 0.73 |

| Mask | Density (g/mL) | Crystallinity from Density | Glass Transition Temp.(°C) | Melting Temp. (°C) | Degree of Crystallinity (°C) | Decom- Position Onset Temp. (°C) | Decom- Position Temp. (°C) | TGA Residue % at 700 °C |

|---|---|---|---|---|---|---|---|---|

| BEC | 1.3332 | - | 67.9 | - | - | 391 | 408 | 5.8 |

| BES | 1.3880 | 44.17 | 73.3 | 254.5 | 55.70 | 422 | 451 | 11.3 |

| CLM | 1.3900 | 45.83 | 74.1 | 254.6 | 50.67 | 454 | 491 | 11.2 |

| FAV | 1.3932 | 48.50 | 75.0 | 252.9 | 55.88 | 376 | 419 | 13.9 |

| JEM | 1.2024 | - | 138.0 | - | - | 451 | 500 | 23.8 |

| OPT | 0.9180 | 76.92 | −14.9 | 162.6 | 93.53 | 352 | 425 | 0 |

| RAN | 1.3700 | - | 77.0 | - | - | 275/411 | 285/416 | 7.0 |

| SEU | 1.2388 | - | Not observed | - | - | 540 | 588 | 34.6 |

| SNC | 1.3916 | 47.17 | 72.9 | 250.2 | 54.55 | 408 | 452 | 5.3 |

| STK | 1.3900 | 45.83 | 66.2 | 252.6 | 54.22 | 408 | 441 | 8.8 |

| Mask ID | Mw (g/mol) | Mn (g/mol) | PDI |

|---|---|---|---|

| BEC | 58,500 | 29,300 | 1.99 |

| BES | 45,400 | 25,000 | 1.82 |

| CLM | 44,900 | 24,900 | 1.80 |

| FAV | n.d. | n.d. | n.d. |

| JEM | 19,667 | 13,400 | 1.64 |

| OPT | 338,000 | 54,100 | 6.26 |

| RAN | 188,000 | 141,000 | 1.33 |

| SEU | n.a. | n.a. | n.a. |

| SNC | 43,100 | 26,200 | 1.64 |

| STK | 45,000 | 26,500 | 1.70 |

| Mask | Tensile Strength a (MPa) | Std. Dev. | Strain (%) | Std. Dev. | Modulus (MPa) | Std. Dev |

|---|---|---|---|---|---|---|

| BEC | 51.7 | 6.23 | 371.3 | 30.15 | 1390 | 121.0 |

| BES | 189.0 | 13.2 | 172.7 | 39.26 | 4060 b | 288.9 b |

| CLM | 179.0 | 8.56 | 100.6 | 21.54 | 3570 | 168.0 |

| FAV | 166.0 | 4.17 | 200.0 | 21.85 | 3450 | 116.0 |

| JEM | 68.2 | 4.09 | 60.6 | 13.54 | 2230 | 91.1 |

| OPT | 28.5 | 1.77 | 636.9 | 107.07 | 1000 | 44.3 |

| RAN | 57.5 | 1.34 | 139.3 | 47.94 | 2040 | 36.9 |

| SEU | 0.248 | 0.07 | 186.6 | 41.03 | 0.391 | 0.1 |

| SNC | 122.0 | 14.33 | 99.0 | 32.69 | 3190 | 35.4 |

| STK | 148.0 | 19.67 | 170.0 b | 24.74 b | 3280 | 51.4 |

| Mask ID | Protection-Specific Filter | Rank | Weight | Points per Property |

|---|---|---|---|---|

| BEC | No | 0 | 1.0 | 0 |

| BES | No | 0 | 1.0 | 0 |

| CLM | No | 0 | 1.0 | 0 |

| FAV | No | 0 | 1.0 | 0 |

| JEM | Yes | 10 | 1.0 | 10.0 |

| OPT | No | 0 | 1.0 | 0 |

| RAN | No | 0 | 1.0 | 0 |

| SEU | Yes | 10 | 1.0 | 10.0 |

| SNC | No | 0 | 1.0 | 0 |

| STK | No | 0 | 1.0 | 0 |

| Mask Type | Sustainability Thickness | Rank (1) Using RANK Function, for Descending Order | Rank (2a) from Normalized Value, for Ascending Order | Rank (2b) = 10 − Rank (2a), for Descending Order | Weight | Points per Property |

|---|---|---|---|---|---|---|

| BEC | 0.441 | 3 | 2.4 | 7.6 | 1.0 | 7.6 |

| BES | 0.165 | 9 | 0.3 | 9.7 | 1.0 | 9.7 |

| CLM | 0.190 | 6 | 0.5 | 9.5 | 1.0 | 9.5 |

| FAV | 0.195 | 5 | 0.5 | 9.5 | 1.0 | 9.5 |

| JEM | 1.456 | 1 | 10.0 | 0.0 | 1.0 | 0 |

| OPT | 0.123 | 10 | 0.0 | 10.0 | 1.0 | 10 |

| RAN | 0.288 | 4 | 1.2 | 8.8 | 1.0 | 8.8 |

| SEU | 0.600 | 2 | 3.6 | 6.4 | 1.0 | 6.4 |

| SNC | 0.168 | 8 | 0.3 | 9.7 | 1.0 | 9.7 |

| STK | 0.190 | 6 | 0.5 | 9.5 | 1.0 | 9.5 |

| Mask ID | Protection | Visibility | Comfort | Sustainability | Total |

|---|---|---|---|---|---|

| (pts) | (pts) | (pts) | (pts) | (pts) | |

| BEC | 28.4 | 39.9 | 35.7 | 37.4 | 141.1 |

| BES | 31.1 | 53.9 | 25.3 | 41.4 | 152.7 |

| CLM | 18.6 | 47.4 | 29.3 | 41.8 | 137.1 |

| FAV | 35.7 | 60.4 | 32.3 | 36.4 | 164.8 |

| JEM | 40.8 | 60.7 | 23.8 | 14.3 | 139.6 |

| OPT | 34.9 | 32.6 | 56.0 | 42.0 | 165.5 |

| RAN | 40.2 | 49.7 | 34.1 | 42.4 | 166.4 |

| SEU | 52.0 | 41.4 | 40.3 | 33.7 | 167.4 |

| SNC | 32.1 | 38.4 | 29.3 | 39.7 | 139.5 |

| STK | 33.9 | 61.4 | 31.7 | 42.3 | 169.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miller, K.E.; Jahn, A.-C.; Strohm, B.M.; Demyttenaere, S.M.; Nikolai, P.J.; Behm, B.D.; Paracha, M.S.; Miri, M.J. Polymers Used in Transparent Face Masks—Characterization, Assessment, and Recommendations for Improvements Including Their Sustainability. Polymers 2025, 17, 937. https://doi.org/10.3390/polym17070937

Miller KE, Jahn A-C, Strohm BM, Demyttenaere SM, Nikolai PJ, Behm BD, Paracha MS, Miri MJ. Polymers Used in Transparent Face Masks—Characterization, Assessment, and Recommendations for Improvements Including Their Sustainability. Polymers. 2025; 17(7):937. https://doi.org/10.3390/polym17070937

Chicago/Turabian StyleMiller, Katie E., Ann-Carolin Jahn, Brian M. Strohm, Shao M. Demyttenaere, Paul J. Nikolai, Byron D. Behm, Mariam S. Paracha, and Massoud J. Miri. 2025. "Polymers Used in Transparent Face Masks—Characterization, Assessment, and Recommendations for Improvements Including Their Sustainability" Polymers 17, no. 7: 937. https://doi.org/10.3390/polym17070937

APA StyleMiller, K. E., Jahn, A.-C., Strohm, B. M., Demyttenaere, S. M., Nikolai, P. J., Behm, B. D., Paracha, M. S., & Miri, M. J. (2025). Polymers Used in Transparent Face Masks—Characterization, Assessment, and Recommendations for Improvements Including Their Sustainability. Polymers, 17(7), 937. https://doi.org/10.3390/polym17070937