An Investigation of the Mechanical Properties and Thermal Insulation of Foamed Rubberised Polypropylene Fibre Concrete That Incorporates a High Quantity of Crumb Rubber Granules

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportion

2.3. Sample Preparation

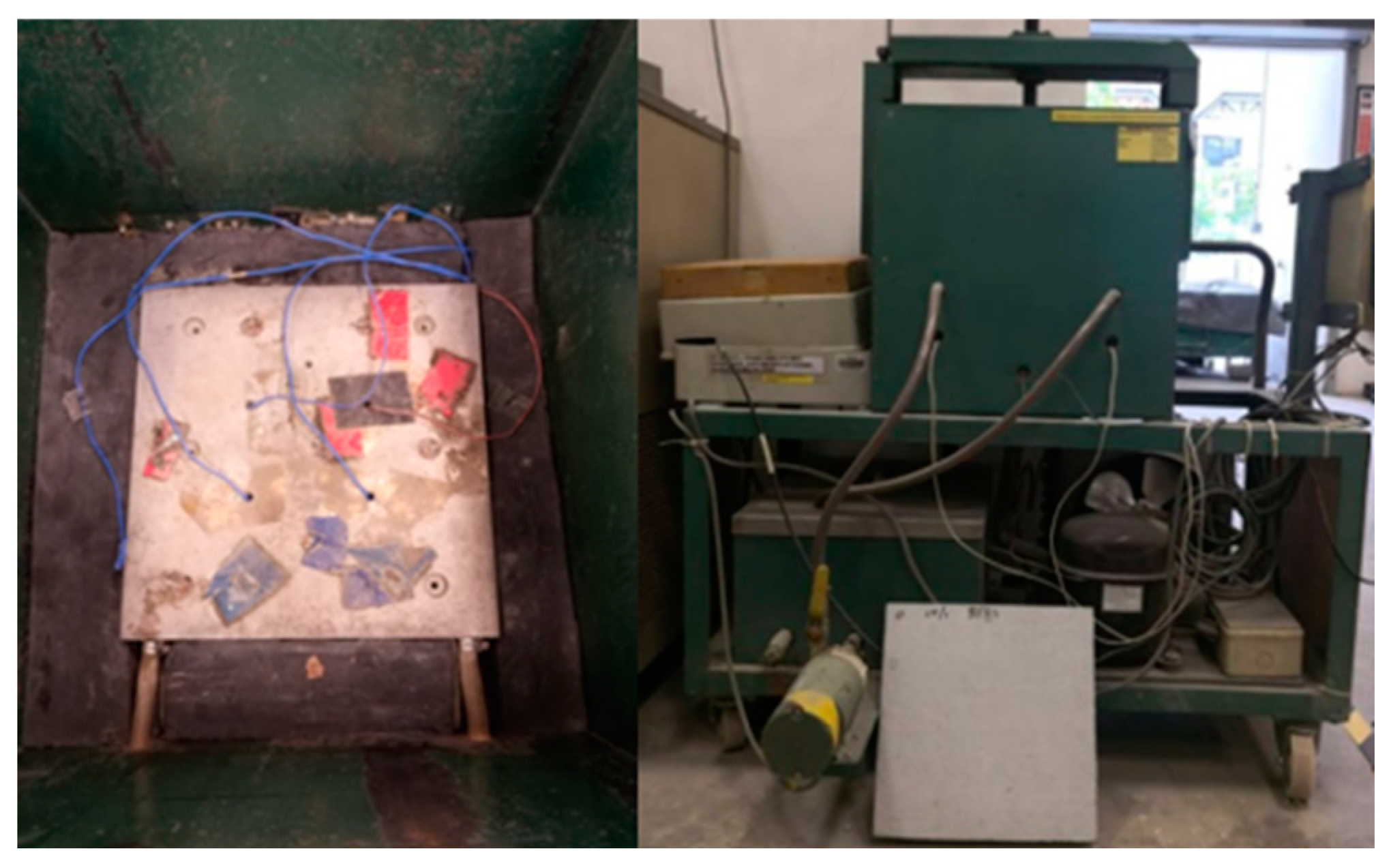

2.4. Testing Methods

3. Results and Discussions

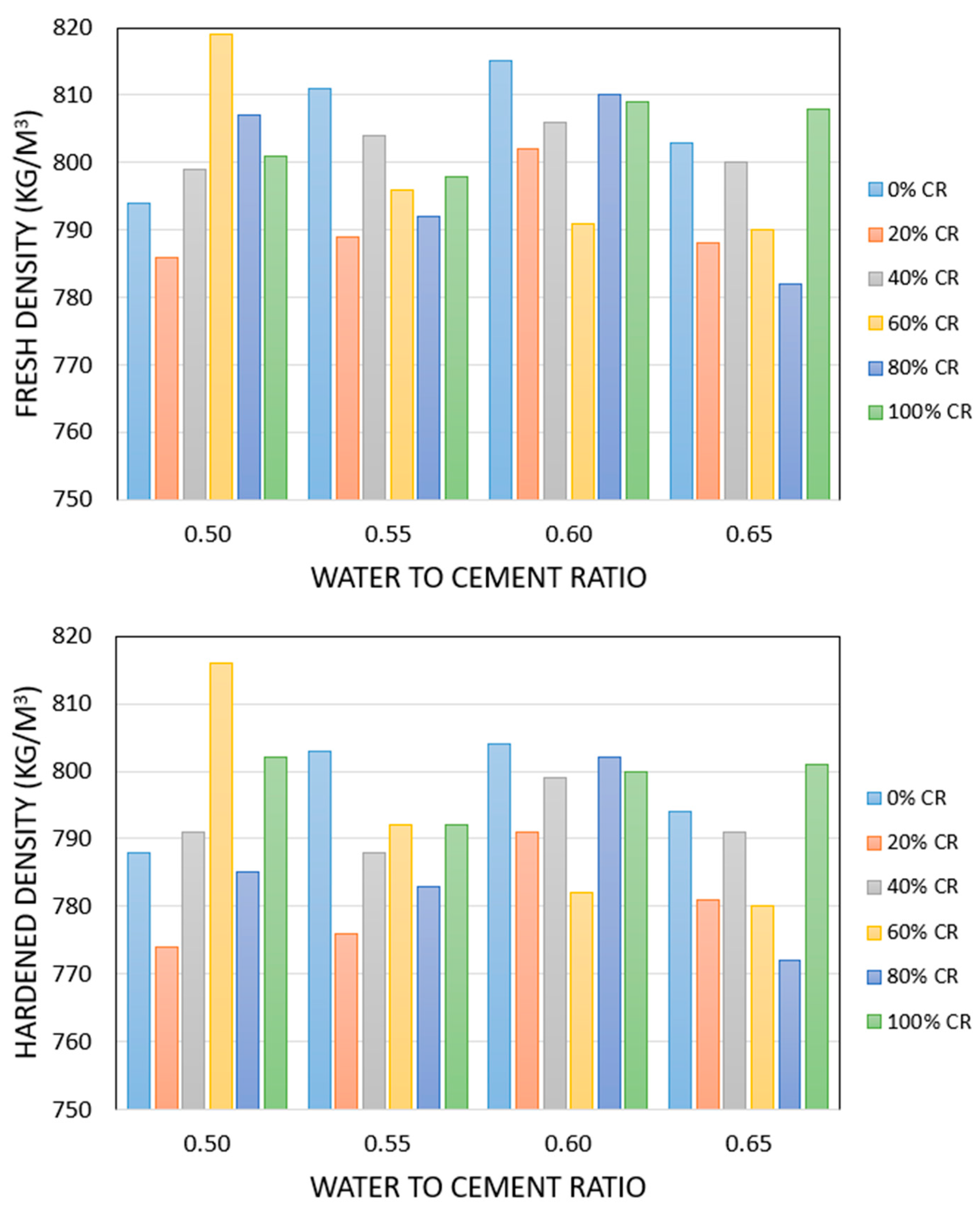

3.1. Fresh and Hardened Densities

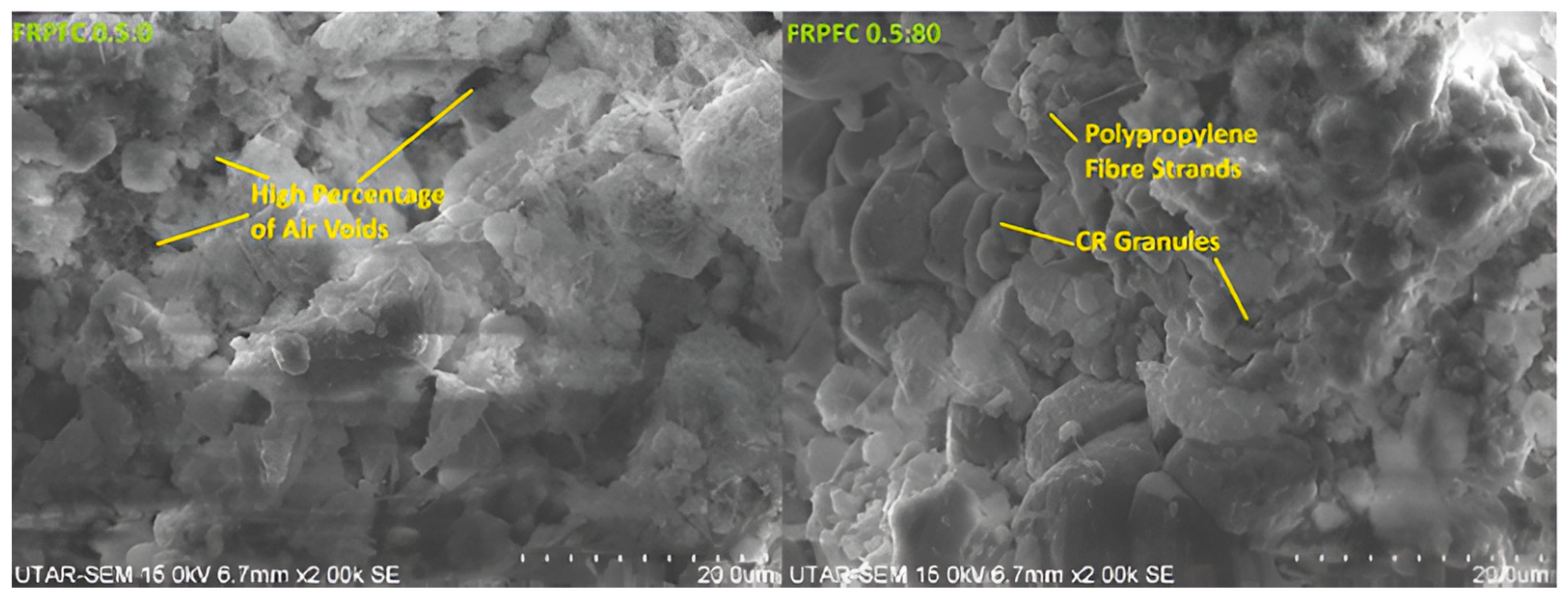

3.2. Compressive Strength

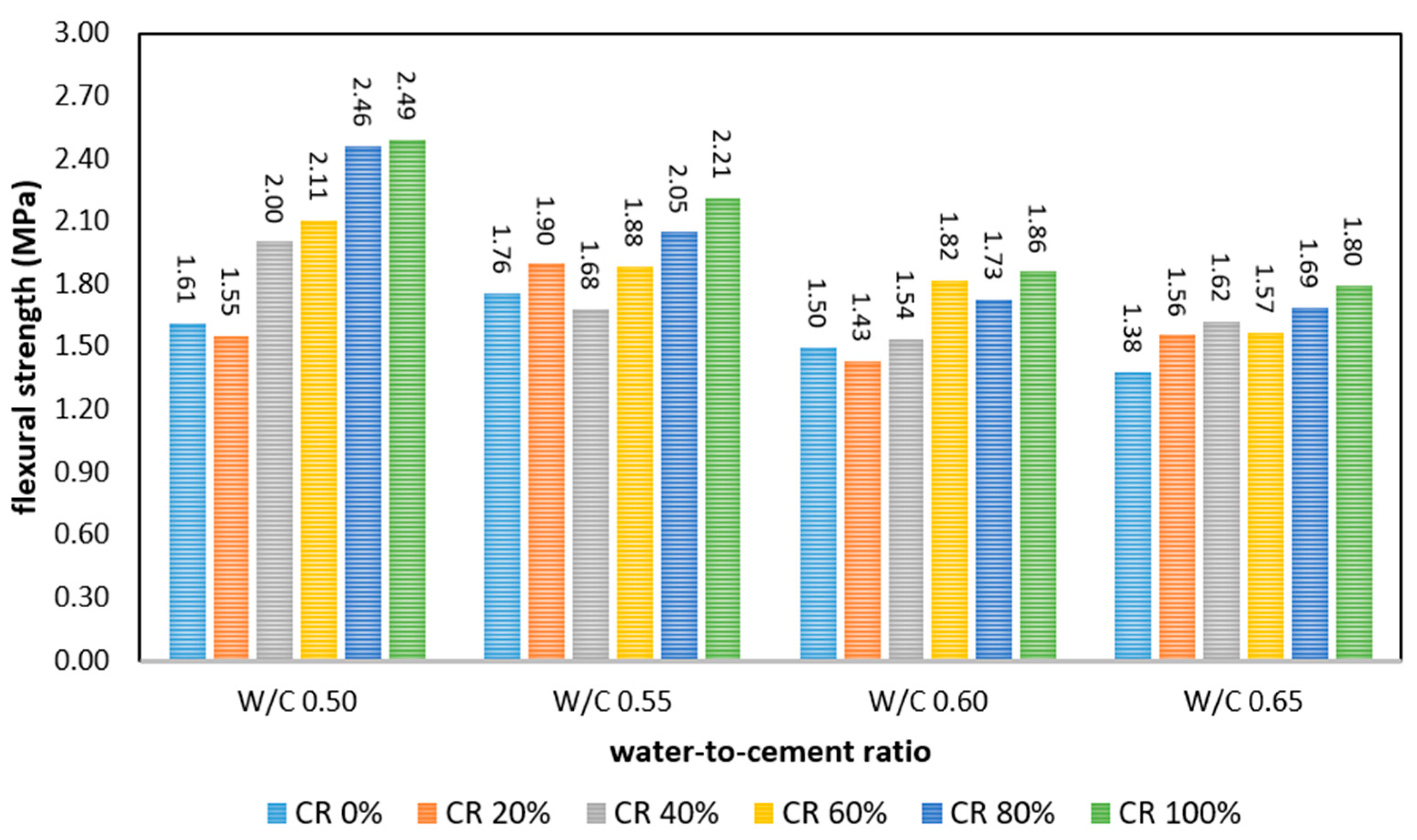

3.3. Flexural Strength

3.4. Splitting Tensile Strength

3.5. Thermal Insulation Properties

3.6. Statistical Interpretation of the Data

4. Conclusions

- FRPFC with a high volume of pre-formed foam (lesser CR granule content, i.e., <20%) exhibits a weaker mechanical strength.

- FRPFC with a 0.50 w/c ratio and 80% CR granule substitution level exhibited the highest compressive strength, 4.10 MPa.

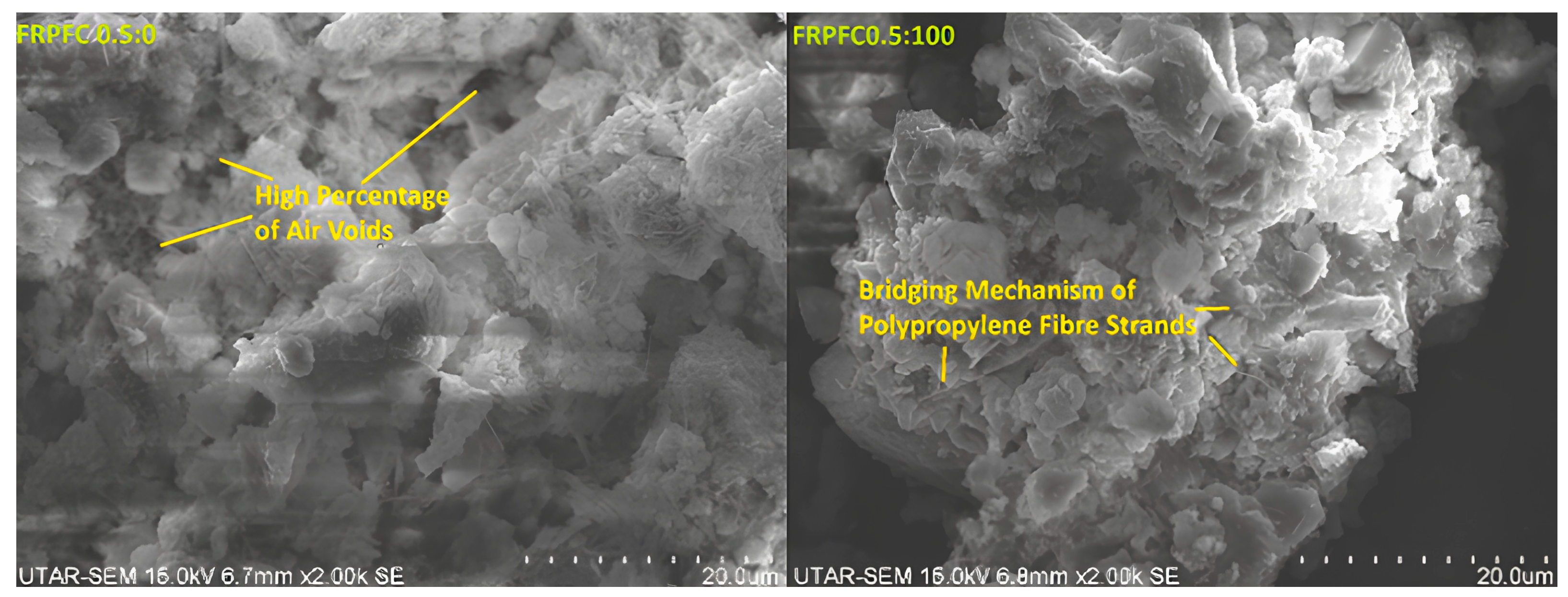

- Increasing the CR granule content in FRPFC with the moisture content between 0.50 and 0.65 improved compressive strength, splitting tensile strength and flexural strength of FRPFC. This improvement is primarily attributed to the reduced foam dosage as CR replaces sand, leading to a less porous and denser microstructure. Additionally, the crack-bridging ability of CR granules further enhanced the mechanical performance of the FRPFC.

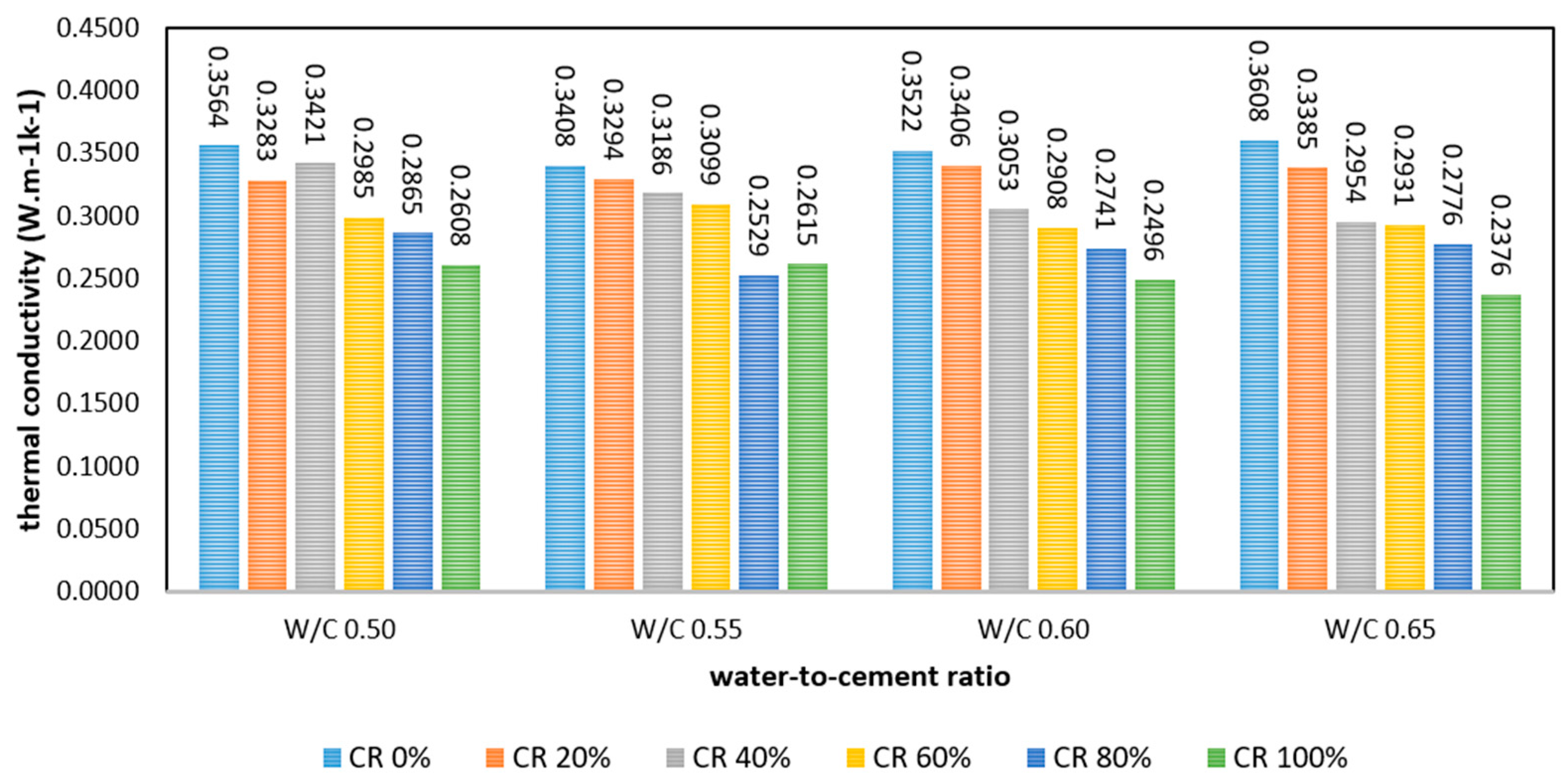

- The thermal conductivity of FRPFC remained relatively constant when the water-to-cement ratio changed within the range of 0.5 to 0.65. Meanwhile, the thermal conductivity of FRPFC was decreased with increasing CR granule portion. FRPFC0.80:100 possessed the lowest thermal conductivity, 0.2376 Wm−1K−1.

5. Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Magagula, S.I.; Lebelo, K.; Motloung, T.M.; Mokhena, T.C.; Mochane, M.J. Recent advances on waste tires: Bibliometric analysis, processes, and waste management approaches. Environ. Sci. Pollut. Res. 2023, 30, 118213–118245. [Google Scholar]

- González, A.; Adenso-Díaz, B. A review of regulated waste management in the automotive industry and the role of the circular economy. Sustainability 2021, 13, 1283. [Google Scholar]

- Sai Kishan, G.; Himath kumar, Y.; Sakthivel, M.; Vijayakumar, R.; Lingeshwaran, N. Life cycle assesment on tire derived fuel as alternative fuel in cement industry. Mater. Today Proc. 2021, 47, 5483–5488. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Youssf, O.; Mills, J.E. Influence of rubber particles on the properties of foam concrete. J. Build. Eng. 2020, 30, 101217. [Google Scholar]

- Mahat, M.; Acharya, M.; Acharya, M.; Mashal, M. Use of waste tires as transverse reinforcement and external confinement in concrete columns subjected to axial loads. Sustainability 2023, 15, 11620. [Google Scholar] [CrossRef]

- Helmy, S.H.; Tahwia, A.M.; Mahdy, M.G.; Elrahman, M.A.; Abed, M.A.; Youssf, O. The use of recycled tire rubber, crushed glass, and crushed clay brick in lightweight concrete production: A Review. Sustainability 2023, 15, 10060. [Google Scholar] [CrossRef]

- Youssf, O.; Swilam, A.; Tahwia, A.M. Performance of crumb rubber concrete made with high contents of heat pre-treated rubber and magnetized water. J. Mater. Res. Technol. 2023, 23, 2160–2176. [Google Scholar]

- Wang, L.; Huang, Y.H. Study on Rubber Particles Modified Concrete. Appl. Mech. Mater. 2013, 477–478, 953–958. [Google Scholar]

- Liu, F.; Zheng, W.; Li, L.; Feng, W.; Ning, G. Mechanical and fatigue performance of rubber concrete. Constr. Build. Mater. 2013, 47, 711–719. [Google Scholar]

- Ramamurthy, K.; Nambiar, E.K.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar]

- Hadipramana, J.; Samad, A.A.A.; Zaidi, A.M.A.; Mohammad, N.; Ali, N. Contribution of polypropylene fibre in improving strength of Foamed Concrete. Adv. Mater. Res. 2012, 626, 762–768. [Google Scholar]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Bing, C.; Zhen, W.; Ning, L. Experimental research on properties of high-strength Foamed Concrete. J. Mater. Civ. Eng. 2012, 24, 113–118. [Google Scholar]

- Lyu, X.; Elchalakani, M.; Ahmed, T.; Sadakkathulla, M.A.; Youssf, O. Residual strength of steel fibre reinforced rubberised UHPC under elevated temperatures. J. Build. Eng. 2023, 76, 107173. [Google Scholar] [CrossRef]

- Abd Allah Abd-Elaty, M.; Farouk Ghazy, M.; Hussein Khalifa, O. Mechanical and thermal properties of fibrous rubberized geopolymer mortar. Constr. Build. Mater. 2022, 354, 129192. [Google Scholar] [CrossRef]

- Ma, Z.; Ma, C.; Du, C.; Zhang, S.; Zhang, H.; Zhang, X.; Zhang, X.; Wang, J.; Tian, M.; Wang, Y. Research on dynamic mechanical properties of polypropylene fiber- modified rubber foamed concrete. Constr. Build. Mater. 2023, 404, 133282. [Google Scholar] [CrossRef]

- ASTM C138/C138M-17a; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- BS EN 12390-3:2019; Testing Hardened Concrete—Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2019.

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C293/C293M-16; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading); ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C177-19; Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus; ASTM International: West Conshohocken, PA, USA, 2019.

- Othman, R.; Jaya, R.P.; Muthusamy, K.; Sulaiman, M.; Duraisamy, Y.; Abdullah, M.M.A.B.; Przybył, A.; Sochacki, W.; Skrzypczak, T.; Vizureanu, P.; et al. Relation between density and compressive strength of Foamed Concrete. Materials 2021, 14, 2967. [Google Scholar] [CrossRef] [PubMed]

- Youssf, O.; Mills, J.E.; Hassanli, R. Assessment of the mechanical performance of Crumb Rubber Concrete. Constr. Build. Mater. 2016, 125, 175–183. [Google Scholar]

- Taha, M.M.R.; El-Dieb, A.S.; El-Wahab, M.A.A.; Abdel-Hameed, M.E. Mechanical, Fracture, and Microstructural Investigations of Rubber Concrete. J. Mater. Civ. Eng. 2008, 20, 640–649. [Google Scholar]

- Ferreira, S.R.; de Andrade Silva, F.; Lima, P.R.L.; Toledo Filho, R.D. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and Curauá fiber cement based composite system. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Jiao, Y.; Sha, T. Experimental Investigation of the Mechanical and Durability Properties of Crumb Rubber Concrete. Materials 2016, 9, 172. [Google Scholar] [CrossRef] [PubMed]

- Momeen Ul Islam, M.; Li, J.; Roychand, R.; Saberian, M. Microstructure, thermal conductivity and carbonation resistance properties of sustainable structural lightweight concrete incorporating 100% coarser rubber particles. Constr. Build. Mater. 2023, 408, 133658. [Google Scholar]

- Ulutas, E.; Tasdemir, M.; Kuvvet, N.; Korkmaz, O.F.; Duran, M.C. Mechanical, morphological, and thermal properties of polypropylene/montmorillonite polymer composite foam. Iran. Polym. J. 2025, 34, 111–121. [Google Scholar]

- Lim, Z.H.; Lee, F.W.; Mo, K.H.; Kwong, K.Z.; Yew, M.K. The influence of powdered crumb rubber on the mechanical properties and thermal performance of lightweight Foamed Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 739, 012016. [Google Scholar]

| Properties | Result |

|---|---|

| Fibre type | Single fibre |

| Length | 12 mm |

| Diameter | 0.034 mm |

| Density | 0.91 g/mm3 |

| Ultimate tensile strength | 700 MPa |

| Modulus of elasticity | 2.8 GPa |

| Sieve Size | Cumulative Percentage Passing (%) | |

|---|---|---|

| Sand | CR Granules | |

| 10 mm | 100 | 100 |

| 4.75 mm | 100 | 100 |

| 2.36 mm | 86 | 48 |

| 1.18 mm | 71 | 8 |

| 600 µm | 54 | 0 |

| 300 µm | 32 | 0 |

| 150 µm | 10 | 0 |

| Physical Properties | Result | Chemical Composition | Content |

|---|---|---|---|

| Density | 0.95 g/mm3 | Styrene butadiene rubber (SBR) | 48% |

| Ultimate tensile strength | 9 MPa | Carbon black | 31% |

| Elongation at break | 150% | Acetone extract | 15% |

| Hardness shore | 64 | Ash | 2% |

| Particle size range | 1 mm to 4 mm | Residue chemical balance | 4% |

| Designation | Material (kg/m3) | W/C | Target Density (kg/m3) | |||||

|---|---|---|---|---|---|---|---|---|

| Cement | Sand | Water | Polypropylene Fibre | Crumb Rubber | Foam | |||

| FRPFC0.5:0 | 306.85 | 306.85 | 153.42 | 4.60 | 0.00 | 28.27 | 0.50 | 800 |

| FRPFC0.5:20 | 322.26 | 257.81 | 161.13 | 4.61 | 26.75 | 27.45 | ||

| FRPFC0.5:40 | 339.30 | 203.58 | 169.65 | 4.61 | 56.34 | 26.53 | ||

| FRPFC0.5:60 | 358.24 | 143.29 | 179.12 | 4.62 | 89.22 | 25.51 | ||

| FRPFC0.5:80 | 379.42 | 75.88 | 189.71 | 4.63 | 125.99 | 24.37 | ||

| FRPFC0.5:100 | 403.26 | 0.00 | 201.63 | 4.63 | 167.39 | 23.09 | ||

| FRPFC0.55:0 | 300.97 | 300.97 | 165.54 | 4.60 | 0.00 | 27.91 | 0.55 | |

| FRPFC0.55:20 | 315.78 | 252.63 | 173.68 | 4.61 | 26.22 | 27.08 | ||

| FRPFC0.55:40 | 332.13 | 199.28 | 182.67 | 4.62 | 55.15 | 26.17 | ||

| FRPFC0.55:60 | 350.25 | 140.10 | 192.64 | 4.62 | 87.23 | 25.15 | ||

| FRPFC0.55:80 | 370.47 | 74.09 | 203.76 | 4.63 | 123.03 | 24.02 | ||

| FRPFC0.55:100 | 393.17 | 0.00 | 216.24 | 4.64 | 163.20 | 22.75 | ||

| FRPFC0.60:0 | 295.32 | 295.32 | 177.19 | 4.61 | 0.00 | 27.56 | 0.60 | |

| FRPFC0.60:20 | 309.56 | 247.65 | 185.74 | 4.61 | 25.70 | 26.73 | ||

| FRPFC0.60:40 | 325.25 | 195.15 | 195.15 | 4.62 | 54.00 | 25.82 | ||

| FRPFC0.60:60 | 342.62 | 137.05 | 205.57 | 4.62 | 85.33 | 24.81 | ||

| FRPFC0.60:80 | 361.94 | 72.39 | 217.17 | 4.63 | 120.19 | 23.68 | ||

| FRPFC0.60:100 | 383.58 | 0.00 | 230.15 | 4.64 | 159.22 | 22.42 | ||

| FRPFC0.65:0 | 289.87 | 289.87 | 188.42 | 4.61 | 0.00 | 27.23 | 0.65 | |

| FRPFC0.65:20 | 303.58 | 242.87 | 197.33 | 4.61 | 25.20 | 26.40 | ||

| FRPFC0.65:40 | 318.66 | 191.20 | 207.13 | 4.62 | 52.91 | 25.49 | ||

| FRPFC0.65:60 | 335.31 | 134.12 | 217.95 | 4.63 | 83.51 | 24.48 | ||

| FRPFC0.65:80 | 353.80 | 70.76 | 229.97 | 4.63 | 117.49 | 23.36 | ||

| FRPFC0.65:100 | 374.44 | 0.00 | 243.38 | 4.64 | 155.43 | 22.11 | ||

| Designation | Fresh Density (kg/m3) | Hardened Density (kg/m3) |

|---|---|---|

| FRPFC0.5:0 | 794 | 788 |

| FRPFC0.5:20 | 786 | 774 |

| FRPFC0.5:40 | 799 | 791 |

| FRPFC0.5:60 | 819 | 816 |

| FRPFC0.5:80 | 807 | 785 |

| FRPFC0.5:100 | 801 | 802 |

| FRPFC0.55:0 | 811 | 803 |

| FRPFC0.55:20 | 789 | 776 |

| FRPFC0.55:40 | 804 | 788 |

| FRPFC0.55:60 | 796 | 792 |

| FRPFC0.55:80 | 792 | 783 |

| FRPFC0.55:100 | 798 | 792 |

| FRPFC0.60:0 | 815 | 804 |

| FRPFC0.60:20 | 802 | 791 |

| FRPFC0.60:40 | 806 | 799 |

| FRPFC0.60:60 | 791 | 782 |

| FRPFC0.60:80 | 810 | 802 |

| FRPFC0.60:100 | 809 | 800 |

| FRPFC0.65:0 | 803 | 794 |

| FRPFC0.65:20 | 788 | 781 |

| FRPFC0.65:40 | 800 | 791 |

| FRPFC0.65:60 | 790 | 780 |

| FRPFC0.65:80 | 782 | 772 |

| FRPFC0.65:100 | 808 | 801 |

| Crumb Rubber Proportion (%) | Designation | Compressive Strength (MPa) | Splitting Tensile Strength (MPa) | Flexural Strength (MPa) | Thermal Conductivity (Wm−1K−1) |

|---|---|---|---|---|---|

| 0 | FRPFC0.5:0 | 2.64 | 0.41 | 1.61 | 0.3564 |

| FRPFC0.55:0 | 2.88 | 0.45 | 1.76 | 0.3408 | |

| FRPFC0.60:0 | 2.38 | 0.36 | 1.50 | 0.3522 | |

| FRPFC0.65:0 | 2.19 | 0.33 | 1.38 | 0.3608 | |

| 20 | FRPFC0.5:20 | 2.59 | 0.38 | 1.55 | 0.3283 |

| FRPFC0.55:20 | 3.01 | 0.45 | 1.90 | 0.3294 | |

| FRPFC0.60:20 | 2.34 | 0.33 | 1.43 | 0.3406 | |

| FRPFC0.65:20 | 2.55 | 0.37 | 1.56 | 0.3385 | |

| 40 | FRPFC0.5:40 | 3.08 | 0.34 | 2.00 | 0.3421 |

| FRPFC0.55:40 | 2.75 | 0.41 | 1.68 | 0.3186 | |

| FRPFC0.60:40 | 2.56 | 0.38 | 1.54 | 0.3053 | |

| FRPFC0.65:40 | 2.61 | 0.40 | 1.62 | 0.2954 | |

| 60 | FRPFC0.5:60 | 3.51 | 0.51 | 2.11 | 0.2985 |

| FRPFC0.55:60 | 3.14 | 0.48 | 1.88 | 0.3099 | |

| FRPFC0.60:60 | 2.93 | 0.44 | 1.82 | 0.2908 | |

| FRPFC0.65:60 | 2.53 | 0.38 | 1.57 | 0.2931 | |

| 80 | FRPFC0.5:80 | 4.10 | 0.64 | 2.46 | 0.2865 |

| FRPFC0.55:80 | 3.25 | 0.47 | 2.05 | 0.2529 | |

| FRPFC0.60:80 | 2.88 | 0.45 | 1.73 | 0.2741 | |

| FRPFC0.65:80 | 2.68 | 0.40 | 1.69 | 0.2776 | |

| 100 | FRPFC0.5:100 | 3.89 | 0.57 | 2.49 | 0.2608 |

| FRPFC0.55:100 | 3.68 | 0.58 | 2.21 | 0.2615 | |

| FRPFC0.60:100 | 2.95 | 0.44 | 1.86 | 0.2496 | |

| FRPFC0.65:100 | 2.85 | 0.42 | 1.80 | 0.2376 |

| Property | Source of Variation | Degrees of Freedom (df) | Sum of Squares (SS) | Mean Square (MS) | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Compressive Strength | Between Groups | 5 | 5.23 | 1.05 | 8.45 | 0.0002 |

| Within Groups | 18 | 2.24 | 0.12 | |||

| Total | 23 | 7.47 | ||||

| Splitting Tensile Strength | Between Groups | 5 | 0.12 | 0.024 | 4.56 | 0.0061 |

| Within Groups | 18 | 0.095 | 0.0053 | |||

| Total | 23 | 0.215 | ||||

| Flexural Strength | Between Groups | 5 | 1.45 | 0.29 | 6.78 | 0.0011 |

| Within Groups | 18 | 0.77 | 0.043 | |||

| Total | 23 | 2.22 | ||||

| Thermal Conductivity | Between Groups | 5 | 0.045 | 0.009 | 12.34 | 0.0001 |

| Within Groups | 18 | 0.013 | 0.0007 | |||

| Total | 23 | 0.058 |

| Property | F-Value | p-Value | Significance | Significant Comparisons (Tukey’s HSD) |

|---|---|---|---|---|

| Compressive Strength | 8.45 | 0.0002 | Significant | 0% vs. 80%: Mean Difference = 1.46 MPa, p = 0.0001 0% vs. 100%: Mean Difference = 1.25 MPa, p = 0.0018 20% vs. 80%: Mean Difference = 1.51 MPa, p = 0.0001 20% vs. 100%: Mean Difference = 1.30 MPa, p = 0.0009 40% vs. 80%: Mean Difference = 1.02 MPa, p = 0.0102 40% vs. 100%: Mean Difference = 0.81 MPa, p = 0.0398 |

| Splitting Tensile Strength | 4.56 | 0.0061 | Significant | 0% vs. 80%: Mean Difference = 0.23 MPa, p = 0.0198 0% vs. 100%: Mean Difference = 0.20 MPa, p = 0.0395 20% vs. 80%: Mean Difference = 0.21 MPa, p = 0.0297 20% vs. 100%: Mean Difference = 0.18 MPa, p = 0.0492 |

| Flexural Strength | 6.78 | 0.0011 | Significant | 0% vs. 80%: Mean Difference = 0.88 MPa, p = 0.0009 0% vs. 100%: Mean Difference = 0.81 MPa, p = 0.0018 20% vs. 80%: Mean Difference = 0.91 MPa, p = 0.0008 20% vs. 100%: Mean Difference = 0.84 MPa, p = 0.0015 |

| Thermal Conductivity | 12.34 | 0.0001 | Significant | 0% vs. 80%: Mean Difference = 0.0699 W/mK, p = 0.0001 0% vs. 100%: Mean Difference = 0.1188 W/mK, p = 0.0001 20% vs. 80%: Mean Difference = 0.0542 W/mK, p = 0.0018 20% vs. 100%: Mean Difference = 0.1031 W/mK, p = 0.0001 40% vs. 80%: Mean Difference = 0.0556 W/mK, p = 0.0012 40% vs. 100%: Mean Difference = 0.1045 W/mK, p = 0.0001 60% vs. 80%: Mean Difference = 0.0124 W/mK, p = 0.0398 60% vs. 100%: Mean Difference = 0.0613 W/mK, p = 0.0018 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, Z.H.; Lee, F.W.; Mo, K.H.; Chin, R.J.; Yeap, K.H.; Yew, M.K. An Investigation of the Mechanical Properties and Thermal Insulation of Foamed Rubberised Polypropylene Fibre Concrete That Incorporates a High Quantity of Crumb Rubber Granules. Polymers 2025, 17, 967. https://doi.org/10.3390/polym17070967

Lim ZH, Lee FW, Mo KH, Chin RJ, Yeap KH, Yew MK. An Investigation of the Mechanical Properties and Thermal Insulation of Foamed Rubberised Polypropylene Fibre Concrete That Incorporates a High Quantity of Crumb Rubber Granules. Polymers. 2025; 17(7):967. https://doi.org/10.3390/polym17070967

Chicago/Turabian StyleLim, Zhi Heng, Foo Wei Lee, Kim Hung Mo, Ren Jie Chin, Kim Ho Yeap, and Ming Kun Yew. 2025. "An Investigation of the Mechanical Properties and Thermal Insulation of Foamed Rubberised Polypropylene Fibre Concrete That Incorporates a High Quantity of Crumb Rubber Granules" Polymers 17, no. 7: 967. https://doi.org/10.3390/polym17070967

APA StyleLim, Z. H., Lee, F. W., Mo, K. H., Chin, R. J., Yeap, K. H., & Yew, M. K. (2025). An Investigation of the Mechanical Properties and Thermal Insulation of Foamed Rubberised Polypropylene Fibre Concrete That Incorporates a High Quantity of Crumb Rubber Granules. Polymers, 17(7), 967. https://doi.org/10.3390/polym17070967