Synergetic Improvement of Interfacial Performance and Impact Resistance of Carbon Fiber-Reinforced Epoxy Composite via Continuous Electrochemical Oxidation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. CF Preparation Using Different Electrochemical Treatment Parameters

2.3. Preparation of CF/EP Laminates

2.3.1. Tests for Surface Physicochemical Properties

2.3.2. Monofilament Tensile Tests

2.3.3. Interfacial Shear Strength Tests

2.3.4. Low-Speed Impact and Compression Tests

3. Results and Discussion

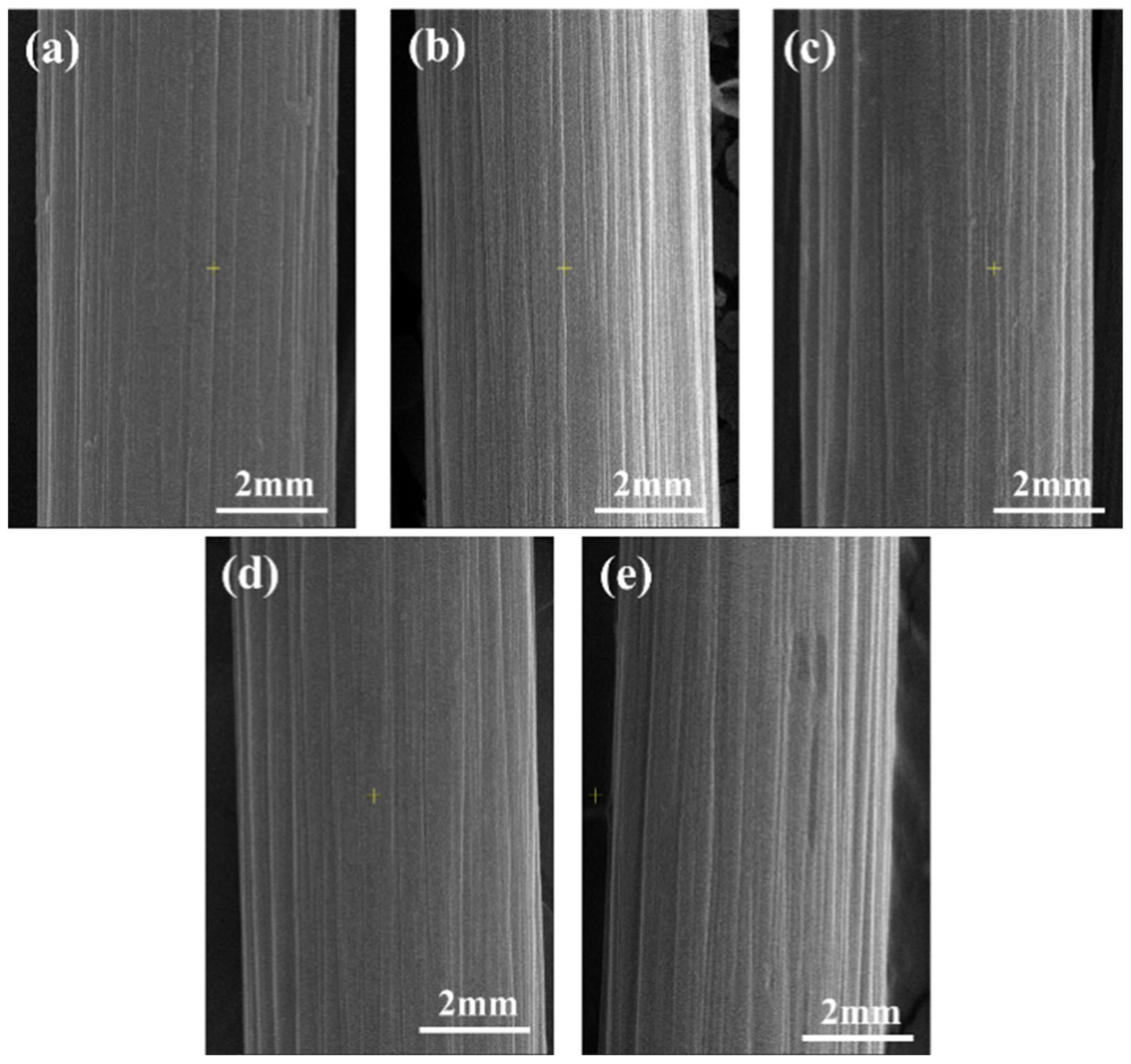

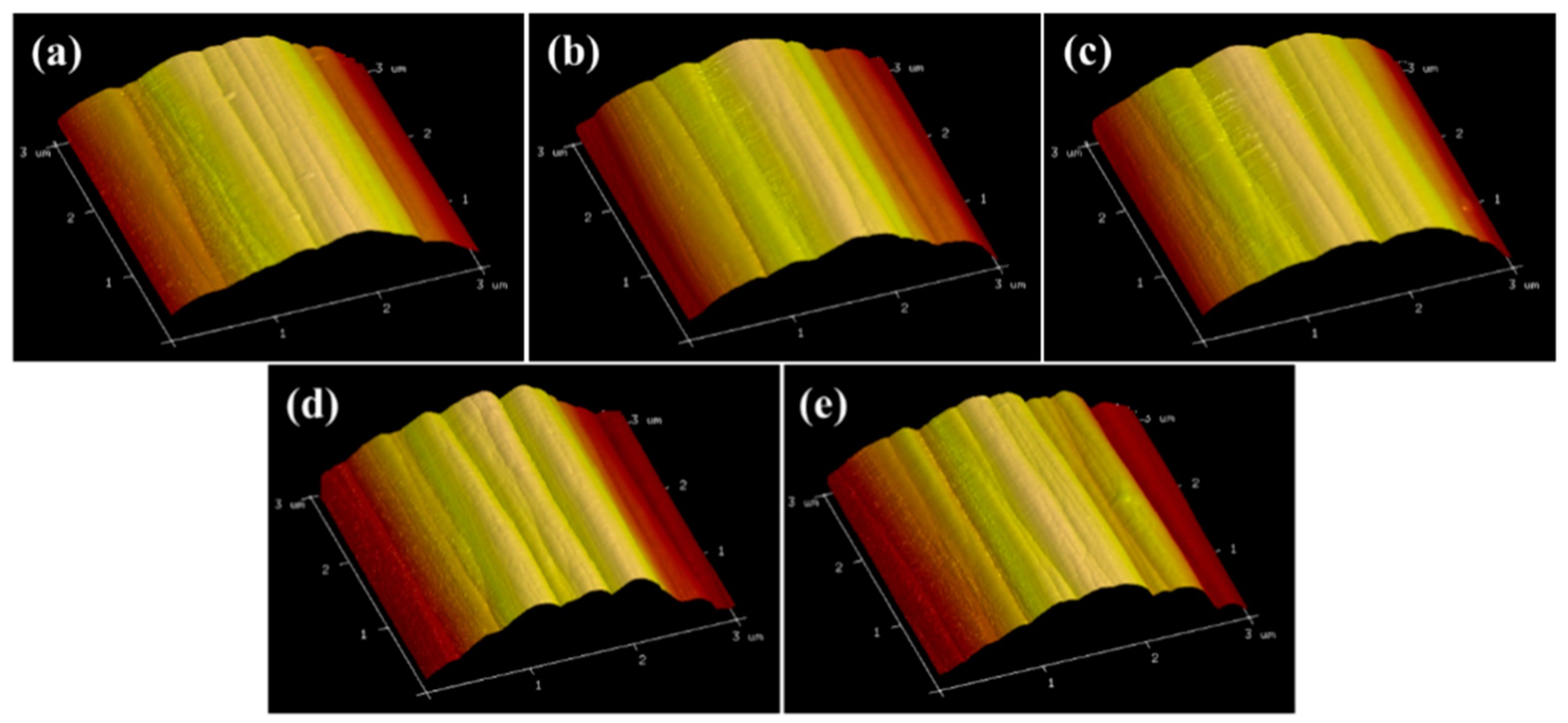

3.1. Surface Morphology

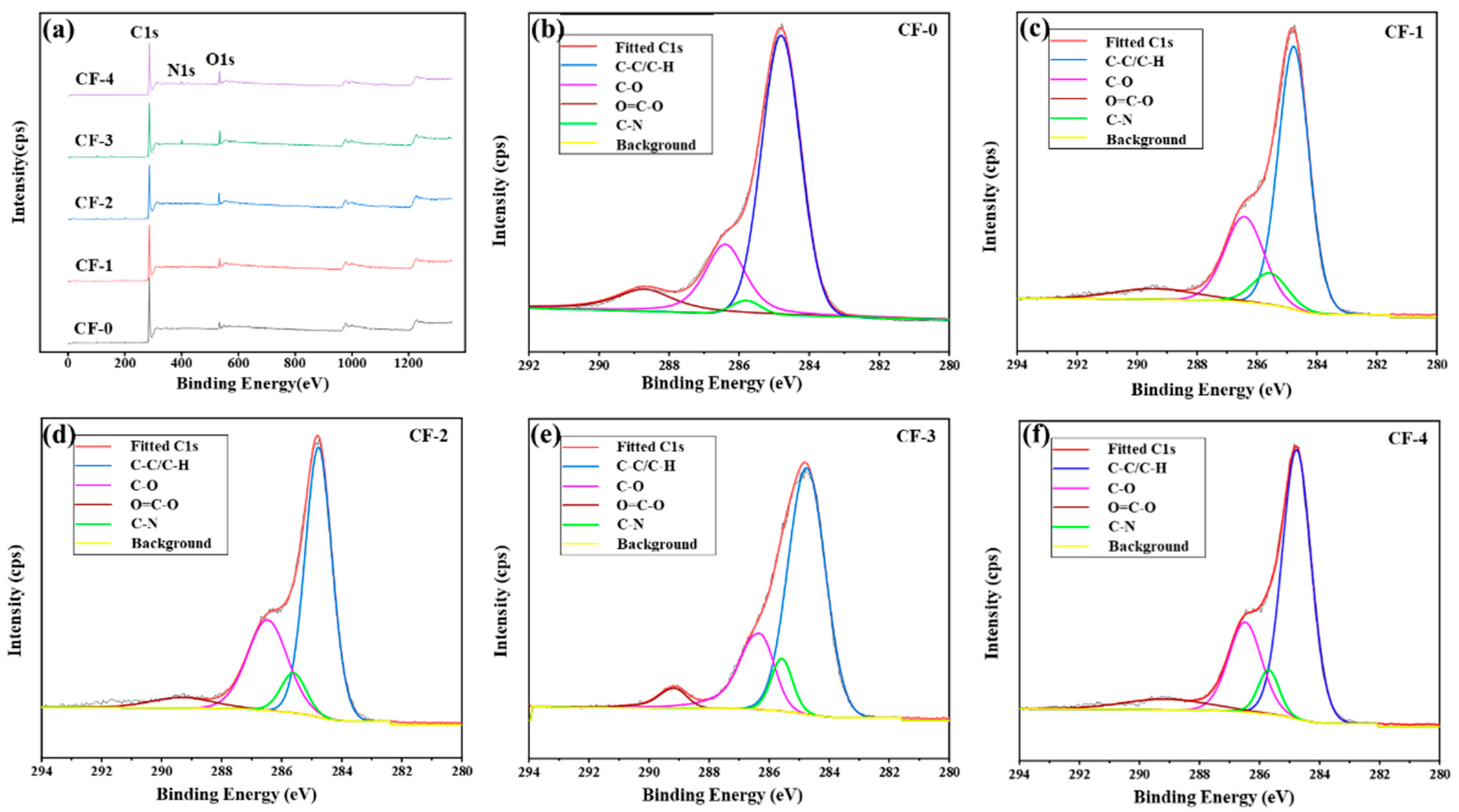

3.2. Chemical Characteristics

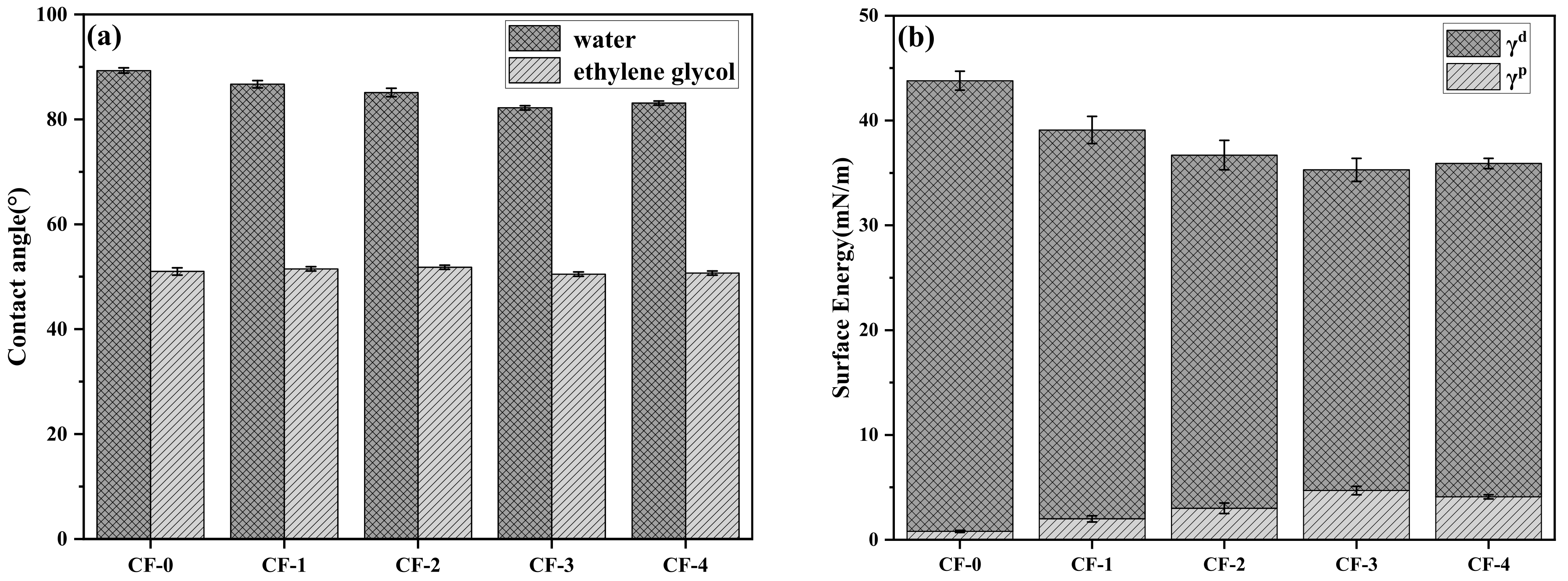

3.3. Wettability of CF

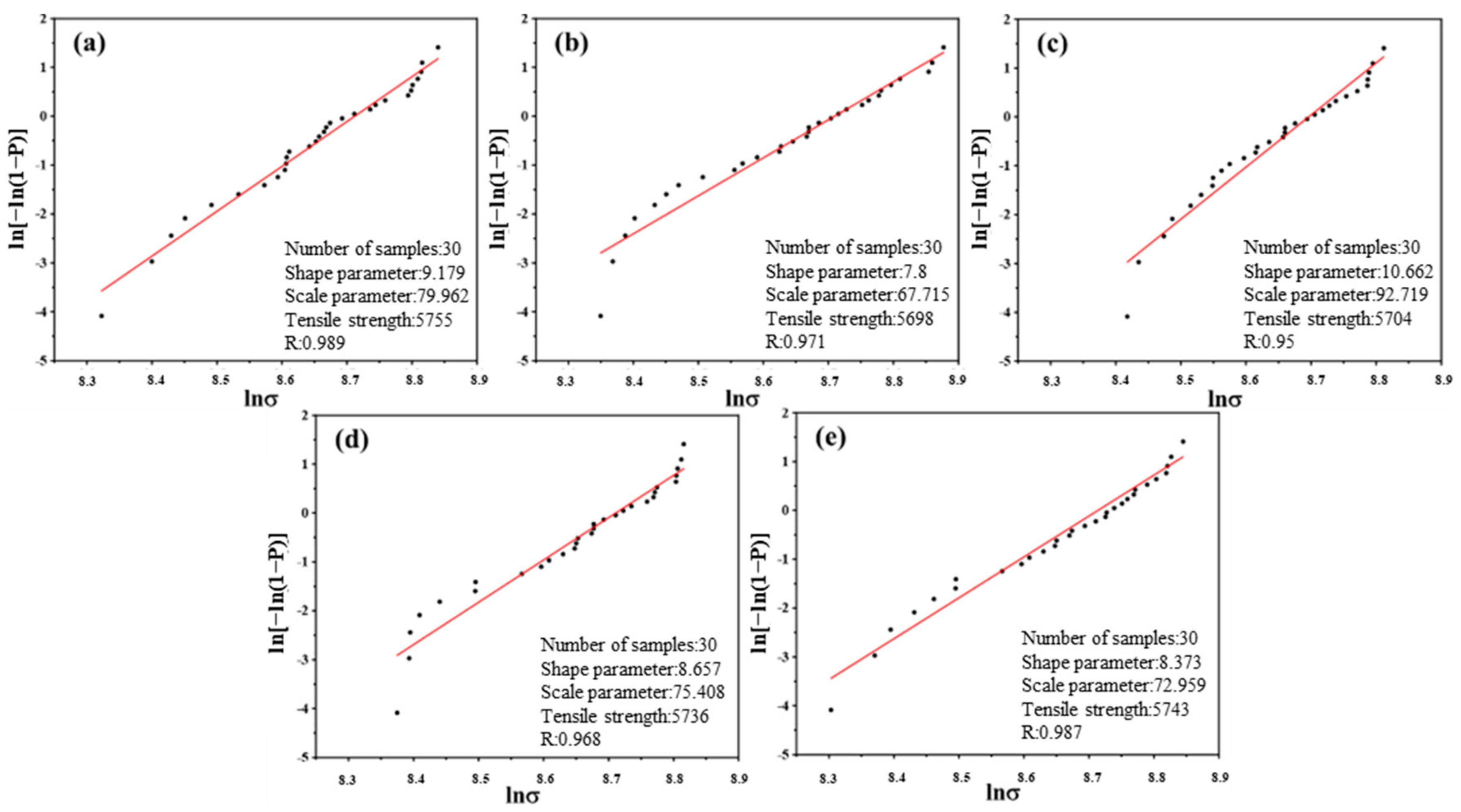

3.4. Monofilament Tensile Strength

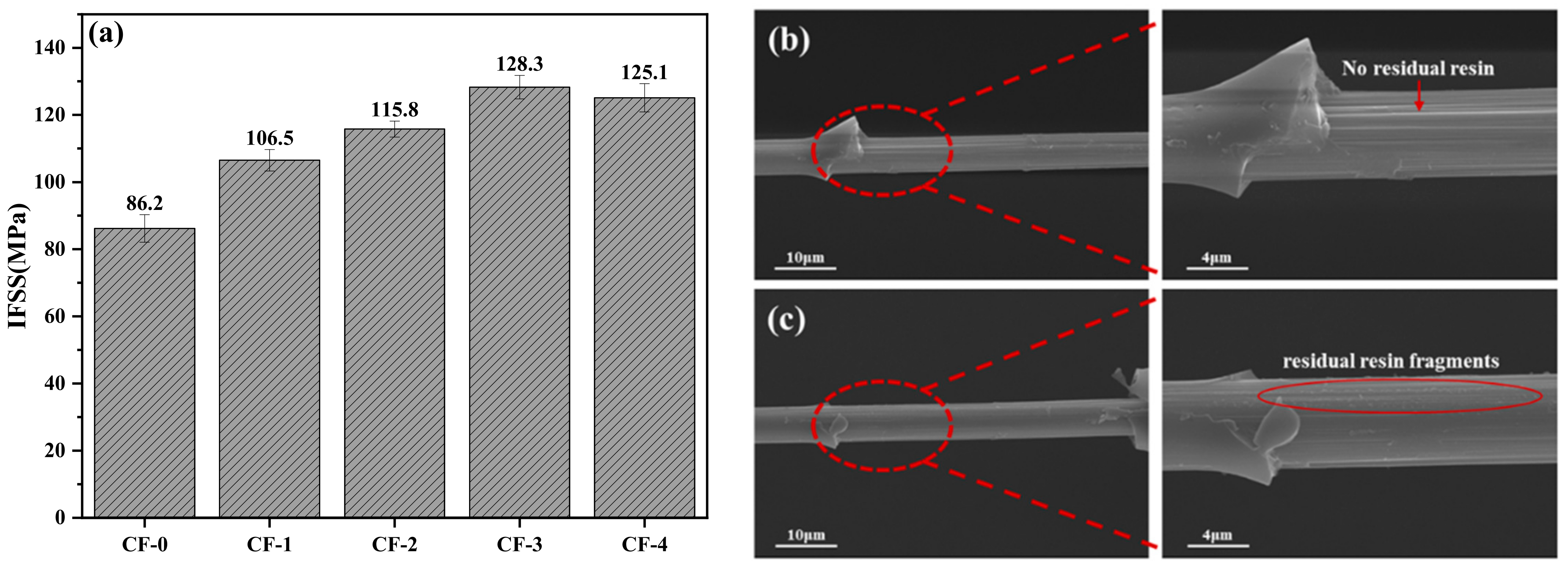

3.5. IFSS of CF/EP

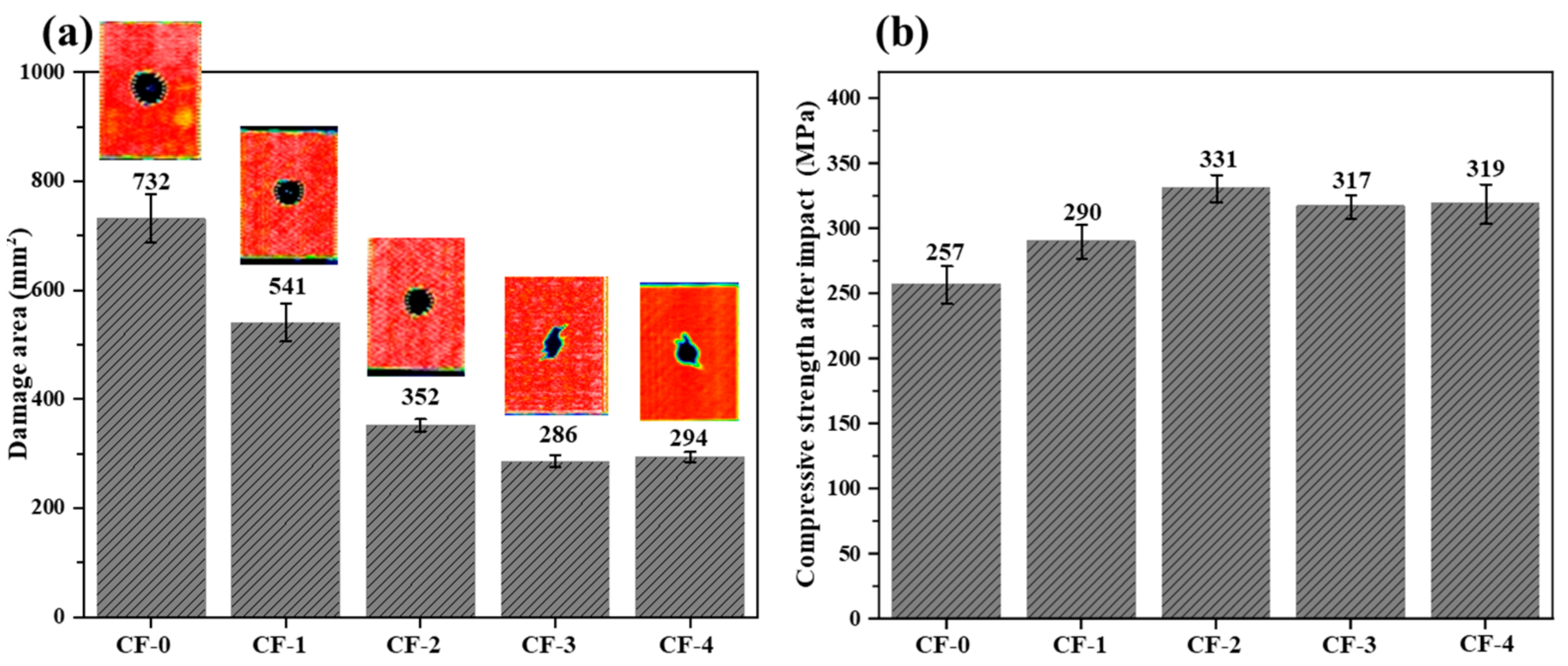

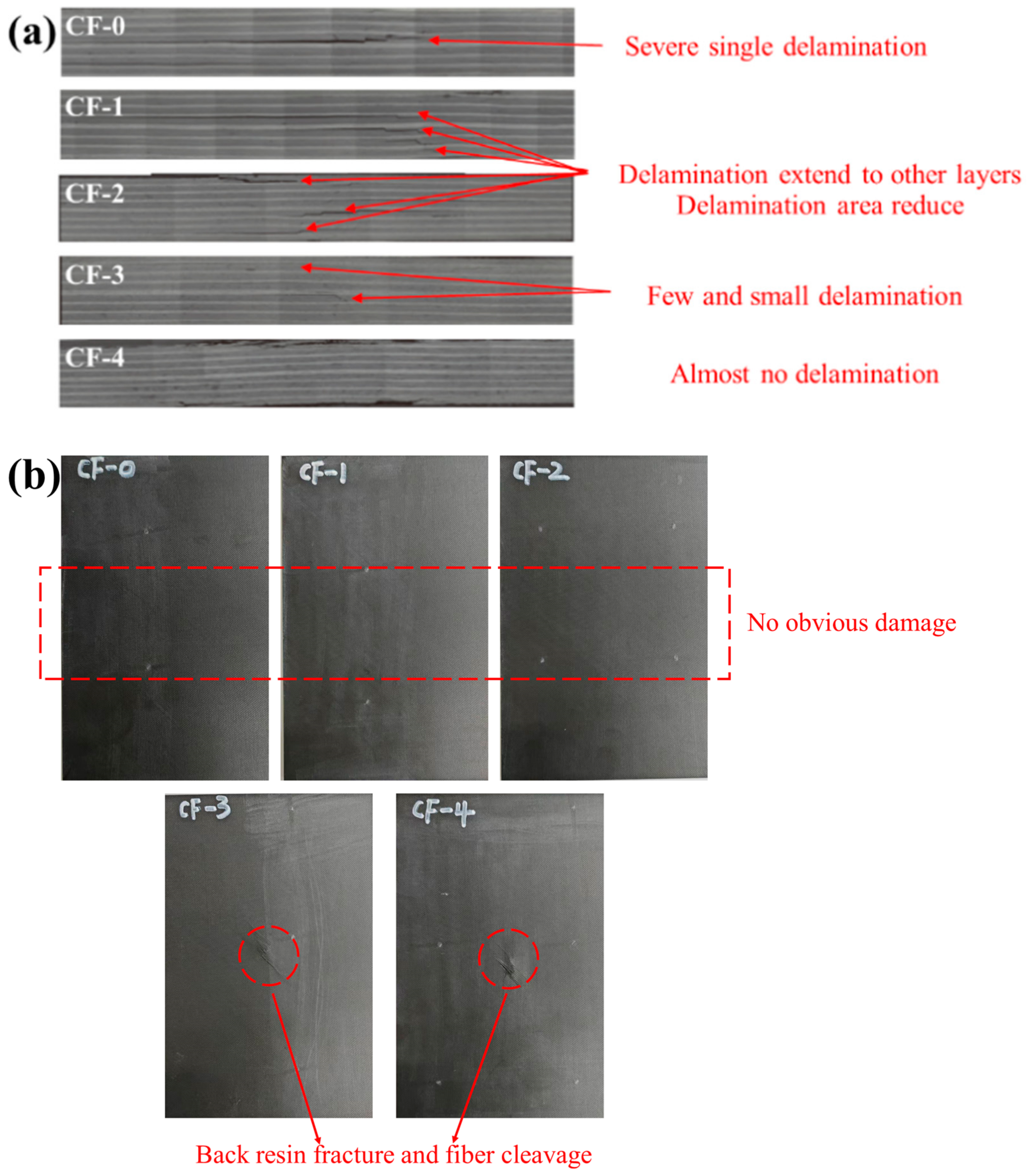

3.6. Mechanical Properties of CF/EP

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, H.; Zhang, W.; Li, B.; Zhu, J.; Wang, C.; Song, G.; Wu, G.; Yang, X.; Huang, Y.; Ma, L. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Part B Eng. 2022, 233, 109639. [Google Scholar] [CrossRef]

- Li, M.; Wang, Q.; Gu, Y.; Wang, S.; Cui, Y.; Li, Q.; Zhang, Z. Quality analysis of prepreg tow for automated fiber placement and its influencing factors. Acta Mater. Compos. Sin. 2022, 39, 4420–4430. [Google Scholar]

- Sun, J.; Han, Y.; Zhao, Z.; Wang, G.; Zhan, S.; Ding, J.; Liu, X.; Guo, Y.; Zhou, H.; Zhao, T. Improved toughness of phthalonitrile composites through synergistic toughening methods. Compos. Commun. 2021, 26, 100779. [Google Scholar] [CrossRef]

- Tanaka, F. Pioneering the carbon fiber frontier: A half-century of industry leadership and the road ahead. Compos. Part B Eng. 2024, 281, 111515. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, X.; Zhang, C.; Liu, B.; Zhang, H.; Sun, Z.; Men, Y.; Hu, W.; Shao, Z.-B. A hydrophilic Lignin-Based carbon fiber sizing agent assembled with CNTs towards strengthening epoxy resin. Chem. Eng. J. 2023, 476, 146624. [Google Scholar] [CrossRef]

- Hexcel Company. Hexply M21-180 °C (350 °F) Curing Epoxy Matrix; Hexcel Prepreg Datasheet; Hexcel Company: Stamford, CT, USA, 2017. [Google Scholar]

- Anthony, K.; Extension, K.P. Advanced Composite Materials for Aerospace Applications; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar] [CrossRef]

- Bao, J.W.; Zhong, X.Y.; Zhang, D.J.; Peng, G.Q. Progress in high strength intermediate modulus carbon fiber and its high toughness resin matrix composites in China. J. Mater. Eng. 2020, 48, 33–48. [Google Scholar]

- Arnold, M.; Henne, M.; Bender, K.; Drechsler, K. The influence of various kinds of PA12 interlayer on the interlaminar toughness of carbon fiber-reinforced epoxy composites. Polym. Compos. 2015, 36, 1249–1257. [Google Scholar] [CrossRef]

- Schoeppner, G.A.; Abrate, S. Delamination threshold loads for low velocity impact on composite laminates. Compos. Part A Appl. Sci. Manuf. 2000, 31, 903–915. [Google Scholar] [CrossRef]

- Park, S.-J.; Seo, M.-K.; Lee, J.-R. Roles of interfaces between carbon fibers and epoxy matrix on interlaminar fracture toughness of composites. Compos. Interfaces 2006, 13, 249–267. [Google Scholar] [CrossRef]

- Li, J.; Sun, F.F. The Effect of Nitric Acid Oxidization Treatment on the Interface of Carbon Fiber-Reinforced Thermoplastic Polystyrene Composite. Polym.-Plast. Technol. Eng. 2009, 48, 711–715. [Google Scholar] [CrossRef]

- Liu, J.; Tian, Y.; Chen, Y.; Liang, J. Interfacial and mechanical properties of carbon fibers modified by electrochemical oxidation in (NH4HCO3)/(NH4)2C2O4·H2O aqueous compound solution. Appl. Surf. Sci. 2010, 256, 6199–6204. [Google Scholar] [CrossRef]

- Yumitori, S.; Nakanishi, Y. Effect of anodic oxidation of coal tar pitch-based carbon fibre on adhesion in epoxy matrix: Part 1. Comparison between H2SO4 and NaOH solutions. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1051–1058. [Google Scholar] [CrossRef]

- Yumitori, S.; Nakanishi, Y. Effect of anodic oxidation of coal tar pitch-based carbon fibre on adhesion in epoxy matrix: Part 2. Comparative study of three alkaline solutions. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1059–1066. [Google Scholar] [CrossRef]

- Fukunaga, A.; Ueda, S. Anodic surface oxidation for pitch-based carbon fibers and the interfacial bond strengths in epoxy matrices. Compos. Sci. Technol. 2000, 60, 249–254. [Google Scholar] [CrossRef]

- Cao, H.L.; Huang, Y.D.; Zhang, Z.Q. Study on the mechanisms of electrochemical surface treatment of carbon fibers in H3PO4 solution. J. Aeronaut. Mater. 2004, 24, 32–35. [Google Scholar]

- Idemoto, I.; Kanematsu, Y.; Rivera Rocabado, D.S.; Ishimoto, T. Theoretical evaluation of surface oxidation effects on resin dynamics at the carbon fibre-resin interface. Mater. Today Commun. 2024, 38, 108379. [Google Scholar] [CrossRef]

- Chen, J.; Han, Z.; Sun, C.; Yang, F.; Zhang, Y.; Xu, H.; Liu, C.; Shen, C. Air-microwave simultaneously induced carbon fiber surface oxidation and magnetism adjustment by CoOx nanoparticles rapid assembly for interface enhancement and electromagnetic wave absorption of its composites. J. Colloid Interface Sci. 2025, 678, 785–794. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, M.; Zhang, Y.; Li, R.; Lin, A.; Shen, Z.; Qian, X.; Xu, P.; Peng, H.-X.; Zhu, C.; et al. Enhanced electromagnetic wave absorption performance in carbon fiber via continuous surface modification with layered double oxides. J. Alloys Compd. 2025, 1022, 180016. [Google Scholar] [CrossRef]

- Xia, S.; Guo, Q.; Yu, Y.; Li, Y.; Wang, S.; Dong, D.; Liu, Z.; Zhou, H.; Zhou, X.; Liu, Z. Surface modification of carbon fiber cloth with graphene oxide through an electrophoresis method for lithium metal anode. Carbon 2023, 203, 743–752. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, Y.; Zhang, C.; Liu, L.; Zhang, Y.; Wang, L. Effect of γ-ray irradiation grafting on the carbon fibers and interfacial adhesion of epoxy composites. Compos. Sci. Technol. 2007, 67, 3261–3270. [Google Scholar] [CrossRef]

- Shi, L.; Song, G.; Li, P.; Li, X.; Pan, D.; Huang, Y.; Ma, L.; Guo, Z. Enhancing interfacial performance of epoxy resin composites via in-situ nucleophilic addition polymerization modification of carbon fibers with hyperbranched polyimidazole. Compos. Sci. Technol. 2021, 201, 108522. [Google Scholar] [CrossRef]

- Yan, H.; Hu, D.; Dai, Y.; Zhang, X.; Yuan, H.; Li, W.; Huang, X.; Tan, Y. Self-assembly of carbon nanomaterials onto carbon fiber to improve the interfacial properties of epoxy composites. J. Mater. Sci. Technol. 2023, 161, 44–49. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, C.; Wang, Y.; Qin, J.; Cui, B.; Wang, Q.; Wei, H. Effect of Microstructures of Carbon Nanoproducts Grown on Carbon Fibers on the Interfacial Properties of Epoxy Composites. Langmuir 2022, 38, 2392–2400. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Jiang, L.; Dan, Y.; Huang, Y. Study on the inter-laminar shear properties of carbon fiber reinforced epoxy composite materials with different interface structures. Mater. Des. 2022, 214, 110417. [Google Scholar] [CrossRef]

- Eyckens, D.J.; Jarvis, K.; Barlow, A.J.; Yin, Y.; Soulsby, L.C.; Athulya Wickramasingha, Y.; Stojcevski, F.; Andersson, G.; Francis, P.S.; Henderson, L.C. Improving the effects of plasma polymerization on carbon fiber using a surface modification pretreatment. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106319. [Google Scholar] [CrossRef]

- Lapena, M.H.; Lopes, C.M.A. Improvement of aerospace thermoplastic composite adhesion to coating with dielectric barrier discharge atmospheric pressure plasma surface treatment. Plasma Process. Polym. 2023, 20, 2200081. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.; Sun, M.; Liu, Z.; Liu, H.; Xiong, S.; Li, S.; Song, J.; Wang, K. Functionalized carbon fibers with MXene via electrochemistry aryl diazonium salt reaction to improve the interfacial properties of carbon fiber/epoxy composites. J. Mater. Res. Technol. 2022, 19, 3699–3712. [Google Scholar] [CrossRef]

- Sun, M.; Li, X.; Liu, H.; Huang, C.; Wang, K.; Zhao, Y. Effect of Electrochemical Aryl Diazonium Salt Modification on Interfacial Properties of CF/PEEK Composites. Materials 2024, 17, 2899. [Google Scholar] [CrossRef]

- Avinc Akpinar, I. A study on the effects of electrochemical oxidation and silane modification applied to fibers in short carbon fiber-reinforced structural adhesives and adhesive joints. Int. J. Adhes. Adhes. 2025, 140, 104020. [Google Scholar] [CrossRef]

- Zhang, R.L.; Wang, C.G.; Liu, L.; Cui, H.Z.; Gao, B. Polyhedral oligomeric silsesquioxanes/carbon nanotube/carbon fiber multiscale composite: Influence of a novel hierarchical reinforcement on the interfacial properties. Appl. Surf. Sci. 2015, 353, 224–231. [Google Scholar] [CrossRef]

- Ji, C.X.; Chang, L.; Zhou, X.L. Study on Surface Treatment of PAN-based Carbon Fibers with Electrochemical Oxidation. Technol. Econ. Petrochem. 2013, 29, 16–23. [Google Scholar]

- Weijing, Q.; Yanhong, T.; Xuejun, Z. Electrochemical oxidation surface treatment of domestic polyacrylonitrile-based high strength and high modulus carbon fiber. Acta Mater. Compos. Sin. 2018, 35, 2449–2457. [Google Scholar]

- Mittal, J.; Bahl, O.P.; Mathur, R.B.; Sandle, N.K. IR studies of PAN fibres thermally stabilized at elevated temperatures. Carbon 1994, 32, 1133–1136. [Google Scholar] [CrossRef]

- Sun, H.; Yang, E.; Zhang, X. Optimization on surface treatment process of carbon fiber. Sci. Technol. Chem. Ind. 2016, 24, 47–49. [Google Scholar]

- Liu, J.; Wang, C.H.; Bai, Y.X. Electrochemical surface treatment and surface structure evolution of polyacrylonitrile-based carbon fibers. J. Beijing Univ. Chem. Technol. (Nat. Sci.) 2012, 39, 79–86. [Google Scholar]

- Bismarck, A.; Kumru, M.E.; Springer, J.; Simitzis, J. Surface properties of PAN-based carbon fibers tuned by anodic oxidation in different alkaline electrolyte systems. Appl. Surf. Sci. 1999, 143, 45–55. [Google Scholar] [CrossRef]

- Guo, Y.-X.; Liu, J.; Liang, J. Modification Mechanism of the Surface-treated PAN-based Carbon Fiber by Electrochemical Oxidation: Modification Mechanism of the Surface-treated PAN-based Carbon Fiber by Electrochemical Oxidation. J. Inorg. Mater. 2009, 24, 853–858. [Google Scholar] [CrossRef]

- ASTM D 4018; Standard Test Methods for Properties of Continuous Filament Carbon and Graphite Fiber Tows. C28.07. ASTM: West Conshohocken, PA, USA, 2023.

- GB/T 3362; Test Methods for Tensile Properties of Carbon Fiber Multifilament. China Quality Standards Publishing Media: Beijing, China, 2017.

- ASTM D 7136; Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. ASTM: West Conshohocken, PA, USA, 2020.

- GB/T 21239; Test Method for Compression After Impact Properties of Fiber Reinforced Plastic Laminates. China Quality Standards Publishing Media: Beijing, China, 2022.

- ISO 11566; Carbon Fibre-Determination of the Tensile Properties of Single-Filament Specimens. ISO: Geneva, Switzerland, 1996.

- GB/T 31290; Standard Test Method for Single-Filament Tensile Strength for Carbon Fiber. China Quality Standards Publishing Media: Beijing, China, 2014.

- Miller, B.; Muri, P.; Rebenfeld, L. A microbond method for determination of the shear strength of a fiber/resin interface. Compos. Sci. Technol. 1987, 28, 17–32. [Google Scholar] [CrossRef]

- ASTM D 7137; Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates. ASTM: West Conshohocken, PA, USA, 2023.

| Properties | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation (%) |

|---|---|---|---|

| Value | 5693 | 293 | 1.89 |

| Samples | CF Type | Continuous Electrochemical Treatment Parameters | |||

|---|---|---|---|---|---|

| Current Density | Temperature | Time | Electrolyte | ||

| CF-0 | T800H grade | 0 mA/cm2 | 30 °C | 70 s | NH4HCO3 solution (10 wt%) |

| CF-1 | 0.05 mA/cm2 | ||||

| CF-2 | 0.10 mA/cm2 | ||||

| CF-3 | 0.15 mA/cm2 | ||||

| CF-4 | 0.20 mA/cm2 | ||||

| Samples | CF-0 | CF-1 | CF-2 | CF-3 | CF-4 |

|---|---|---|---|---|---|

| Rq/nm | 33.6 ± 3.5 | 31.6 ± 4.0 | 34.5 ± 5.5 | 33.1 ± 6.2 | 32.9 ± 5.1 |

| Ra/nm | 29.1 ± 4.2 | 26.6 ± 4.6 | 27.4 ± 4.8 | 25.4 ± 4.1 | 25.0 ± 3.9 |

| Sample | Relative Content of Element (%) | O/C | N/C | ||

|---|---|---|---|---|---|

| C1s | O1s | N1s | |||

| CF-0 | 91.41 | 7.66 | 0.93 | 0.084 | 0.010 |

| CF-1 | 87.58 | 10.73 | 1.69 | 0.123 | 0.019 |

| CF-2 | 84.06 | 13.07 | 2.87 | 0.155 | 0.034 |

| CF-3 | 82.76 | 14.35 | 2.89 | 0.173 | 0.035 |

| CF-4 | 83.16 | 13.78 | 3.06 | 0.166 | 0.037 |

| Samples | –C–C–/–C–H | –C–O– | –C=O | –C–N– | Active Functional Group Ratio (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| B.E. (eV) | P.C. (%) | B.E. (eV) | P.C. (%) | B.E. (eV) | P.C. (%) | B.E. (eV) | P.C. (%) | ||

| CF-0 | 284.8 | 78.15 | 286.4 | 15.37 | 288.7 | 5.25 | 285.8 | 1.23 | 21.85 |

| CF-1 | 284.8 | 69.92 | 286.5 | 21.36 | 288.8 | 6.23 | 285.7 | 2.49 | 30.08 |

| CF-2 | 284.7 | 67.03 | 286.4 | 23.10 | 288.7 | 6.53 | 285.7 | 3.34 | 32.97 |

| CF-3 | 284.8 | 65.80 | 286.5 | 24.14 | 288.6 | 6.48 | 285.7 | 3.58 | 34.20 |

| CF-4 | 284.6 | 66.62 | 286.3 | 21.84 | 288.7 | 7.41 | 285.8 | 4.13 | 33.38 |

| Carbon Fiber | Number of Samples | Shape Parameter | Scale Parameter | Tensile Strength/MPa | R |

|---|---|---|---|---|---|

| CF-0 | 30 | 9.179 | 79.96 | 5755 | 0.989 |

| CF-1 | 30 | 7.800 | 67.72 | 5698 | 0.971 |

| CF-2 | 30 | 10.66 | 92.72 | 5704 | 0.950 |

| CF-3 | 30 | 8.657 | 75.41 | 5736 | 0.968 |

| CF-4 | 30 | 8.373 | 72.96 | 5743 | 0.987 |

| Sample | Peak Load (kN) | Pit Depth (mm) |

|---|---|---|

| CF-0/EP | 10.6 ± 0.06 | 0.20 ± 0.008 |

| CF-1/EP | 10.8 ± 0.09 | 0.21 ± 0.005 |

| CF-2/EP | 10.3 ± 0.10 | 0.22 ± 0.008 |

| CF-3/EP | 10.9 ± 0.02 | 0.20 ± 0.010 |

| CF-4/EP | 10.8 ± 0.06 | 0.22 ± 0.009 |

| Brand | CF-2/EP | M21/IM7 | 3900-2/T800H | M21E/IMA | X850/IM8 |

|---|---|---|---|---|---|

| CAI (MPa) | 331 | 273 | 315 | 334 | 330 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Z.; Li, W.; Liu, H.; Shen, P.; Yang, H.; Zhong, X.; Bao, J. Synergetic Improvement of Interfacial Performance and Impact Resistance of Carbon Fiber-Reinforced Epoxy Composite via Continuous Electrochemical Oxidation. Polymers 2025, 17, 1007. https://doi.org/10.3390/polym17081007

Duan Z, Li W, Liu H, Shen P, Yang H, Zhong X, Bao J. Synergetic Improvement of Interfacial Performance and Impact Resistance of Carbon Fiber-Reinforced Epoxy Composite via Continuous Electrochemical Oxidation. Polymers. 2025; 17(8):1007. https://doi.org/10.3390/polym17081007

Chicago/Turabian StyleDuan, Ziqi, Weidong Li, Hansong Liu, Pengfei Shen, Huanzhi Yang, Xiangyu Zhong, and Jianwen Bao. 2025. "Synergetic Improvement of Interfacial Performance and Impact Resistance of Carbon Fiber-Reinforced Epoxy Composite via Continuous Electrochemical Oxidation" Polymers 17, no. 8: 1007. https://doi.org/10.3390/polym17081007

APA StyleDuan, Z., Li, W., Liu, H., Shen, P., Yang, H., Zhong, X., & Bao, J. (2025). Synergetic Improvement of Interfacial Performance and Impact Resistance of Carbon Fiber-Reinforced Epoxy Composite via Continuous Electrochemical Oxidation. Polymers, 17(8), 1007. https://doi.org/10.3390/polym17081007