Optimizing Nozzle Structure and Parameters for Continuous Fiber Prepreg Filament 3D Printing

Abstract

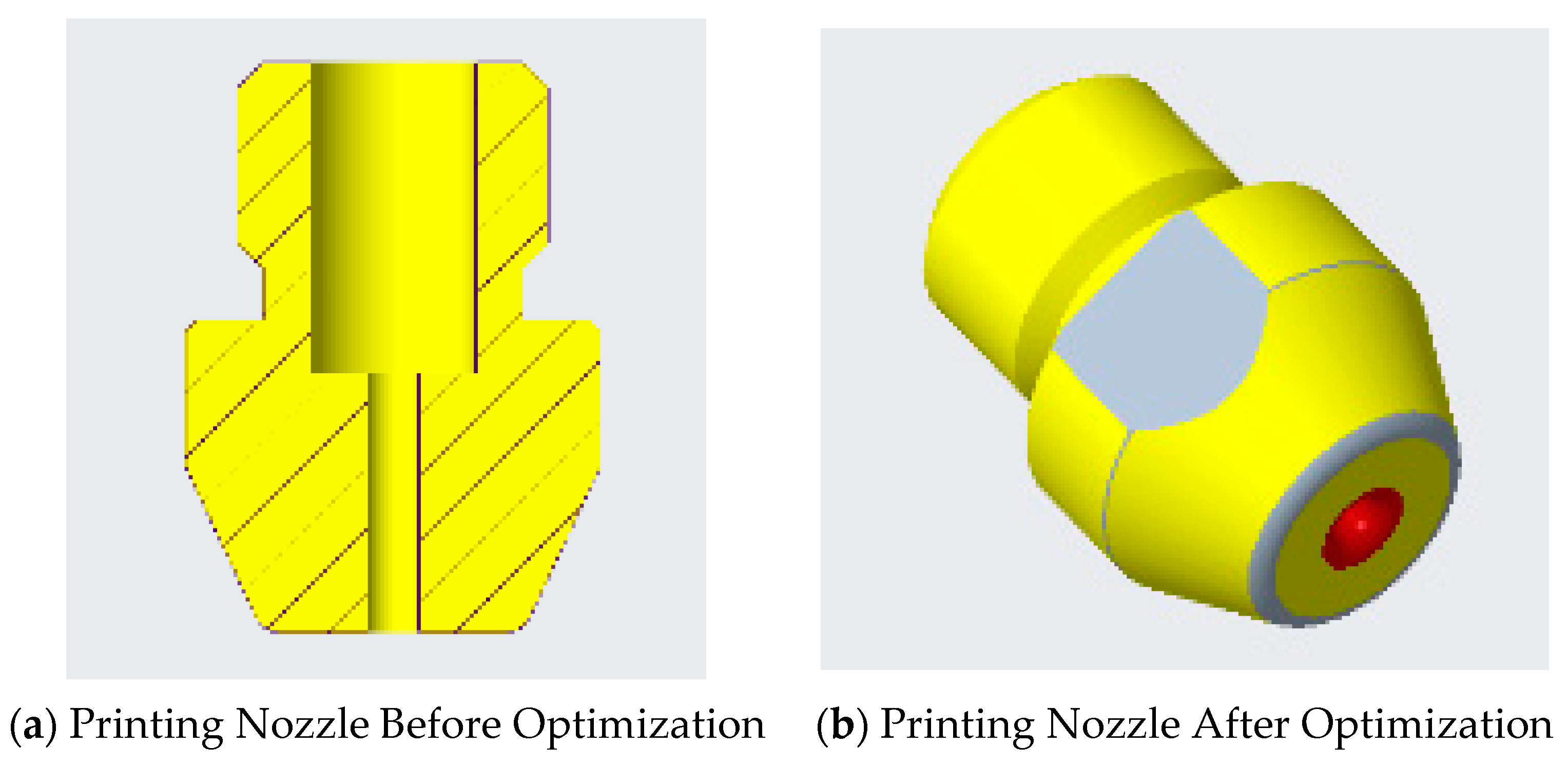

:1. Introduction

2. Materials and Methods

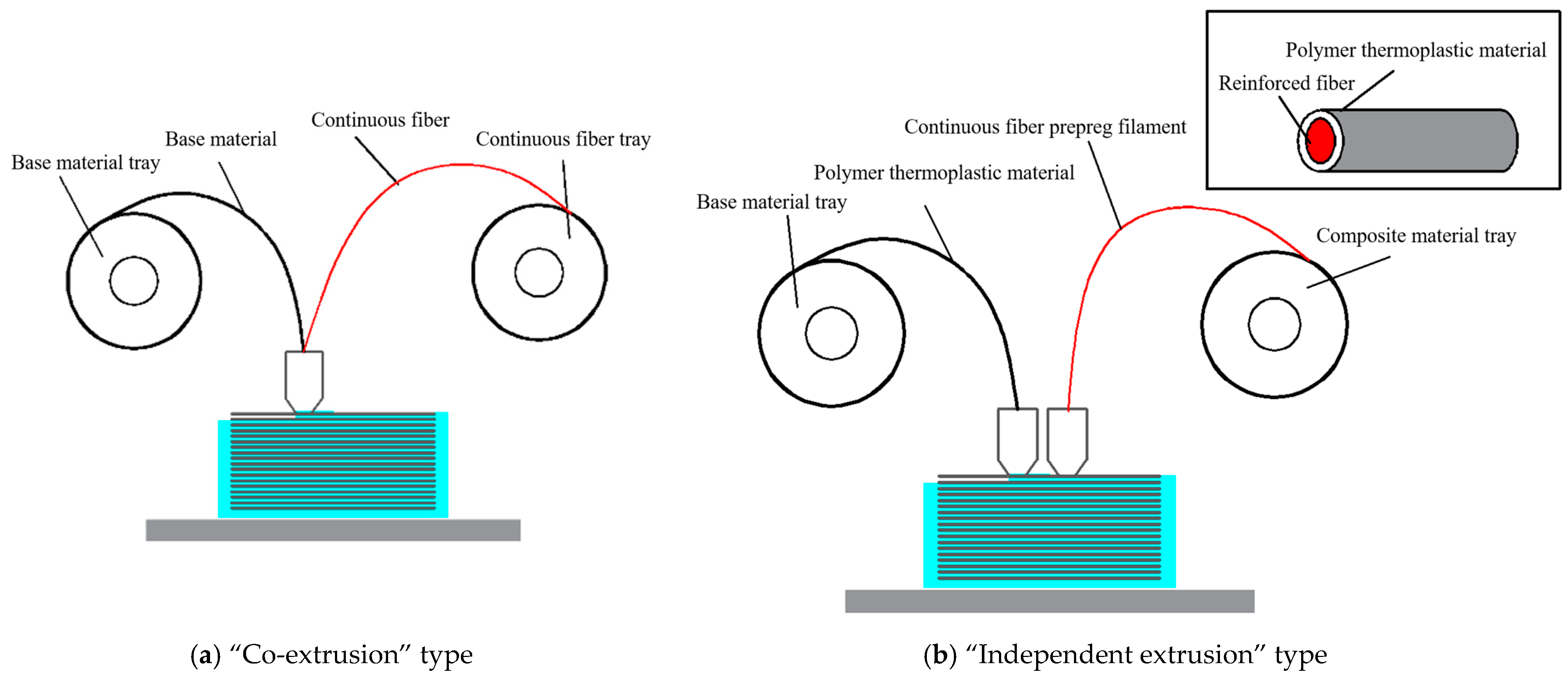

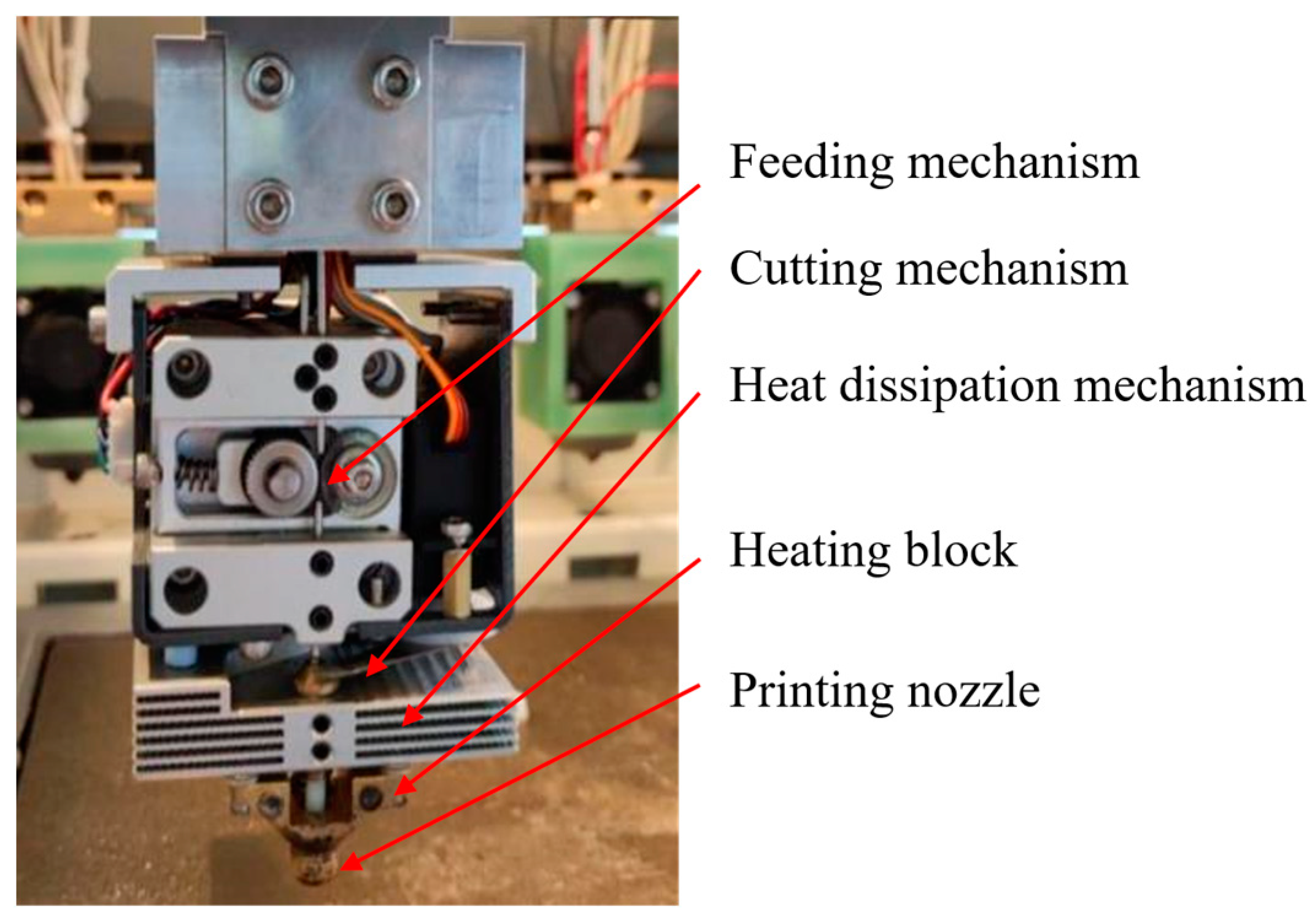

2.1. The Relationship Between Printing Process Parameters and Nozzle Structure

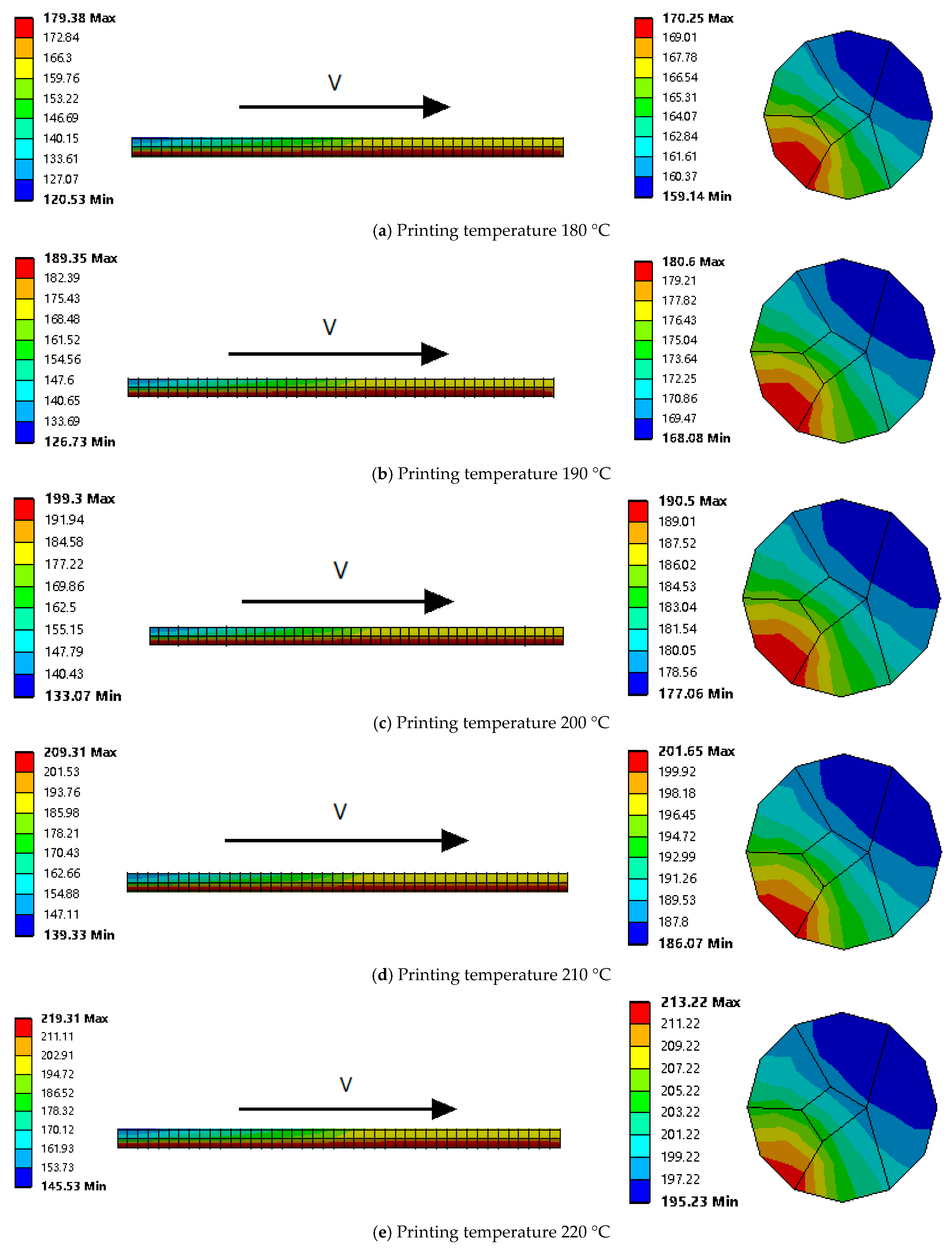

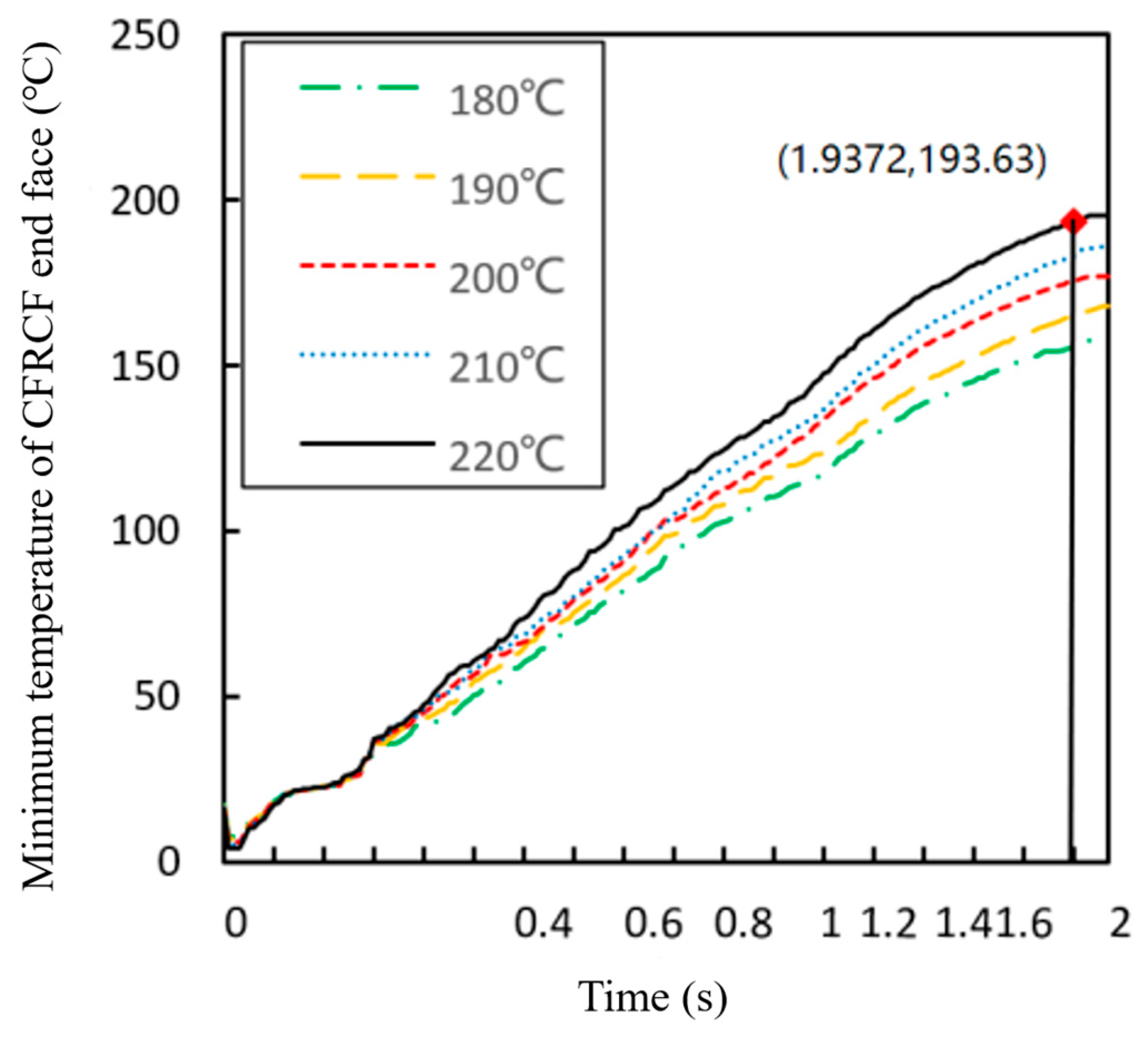

2.2. Modeling of the Continuous Fiber Prepreg Filament Printing Process

2.3. Optimization Method for Continuous Fiber Prepreg Filament Printing Process

3. Results and Discussion

3.1. Printing Principle and Scheme Verification Results and Analysis

3.2. Results and Analysis of Continuous Fiber Prepreg Filament Printing Process Optimization

3.2.1. Model Verification

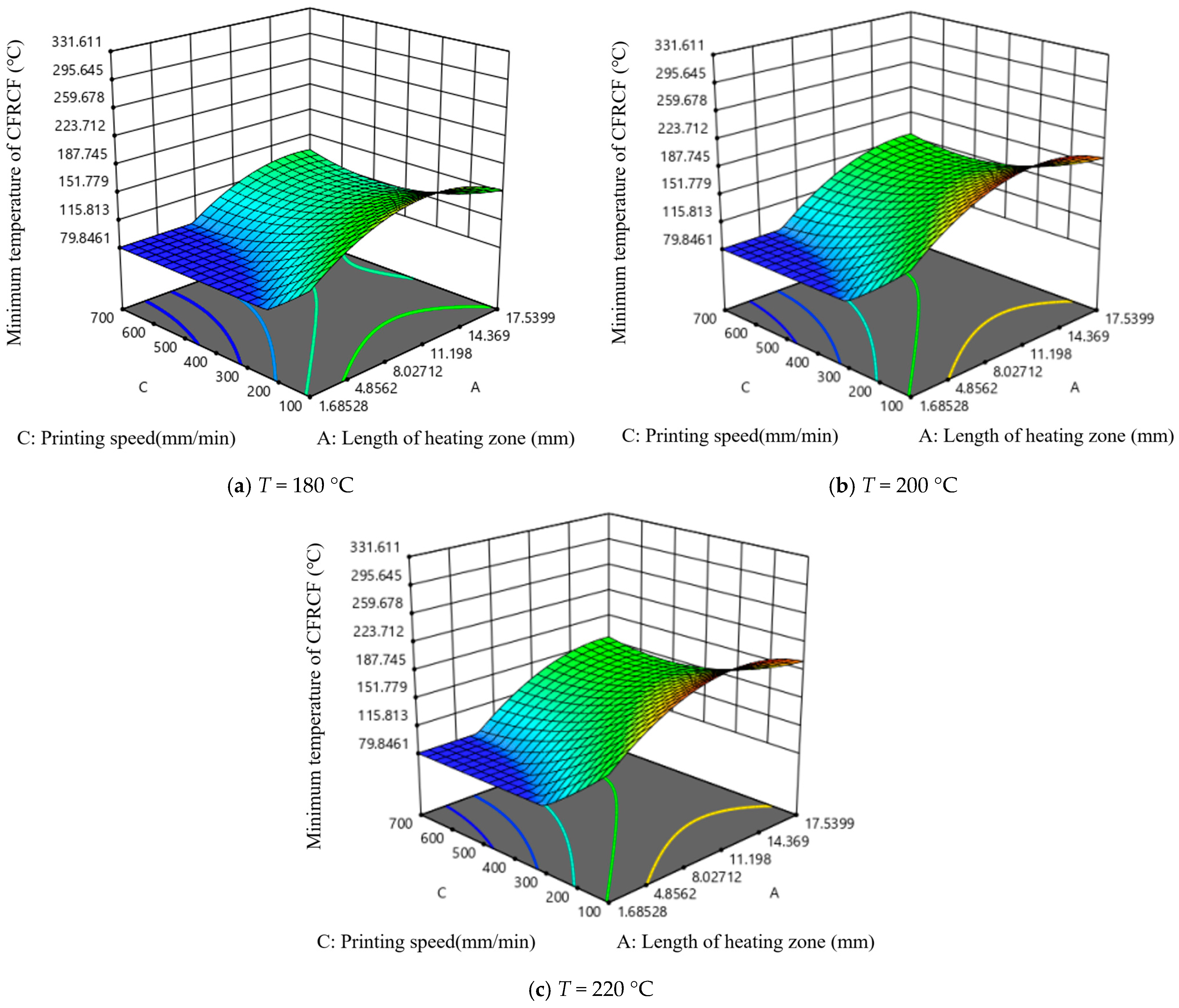

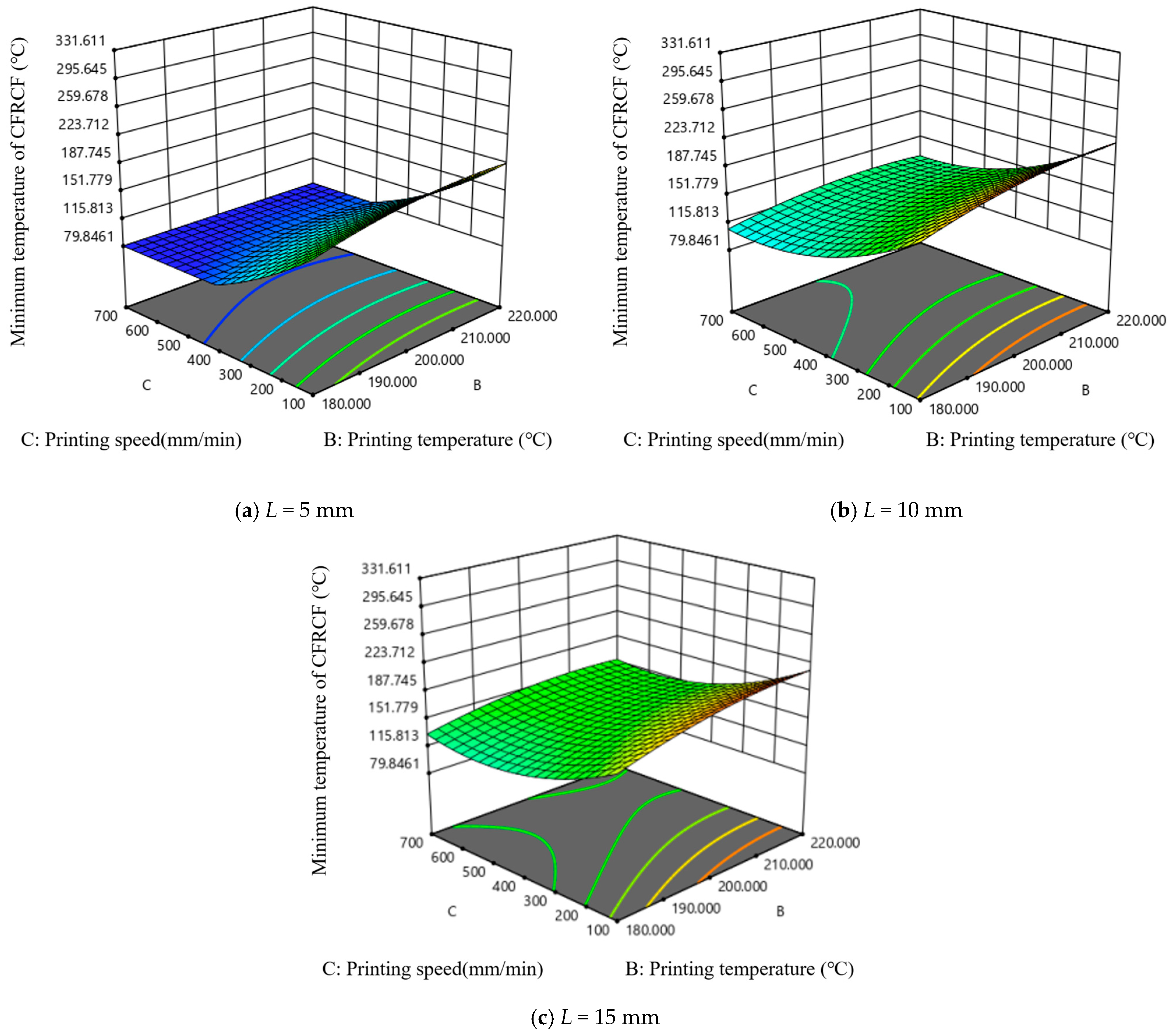

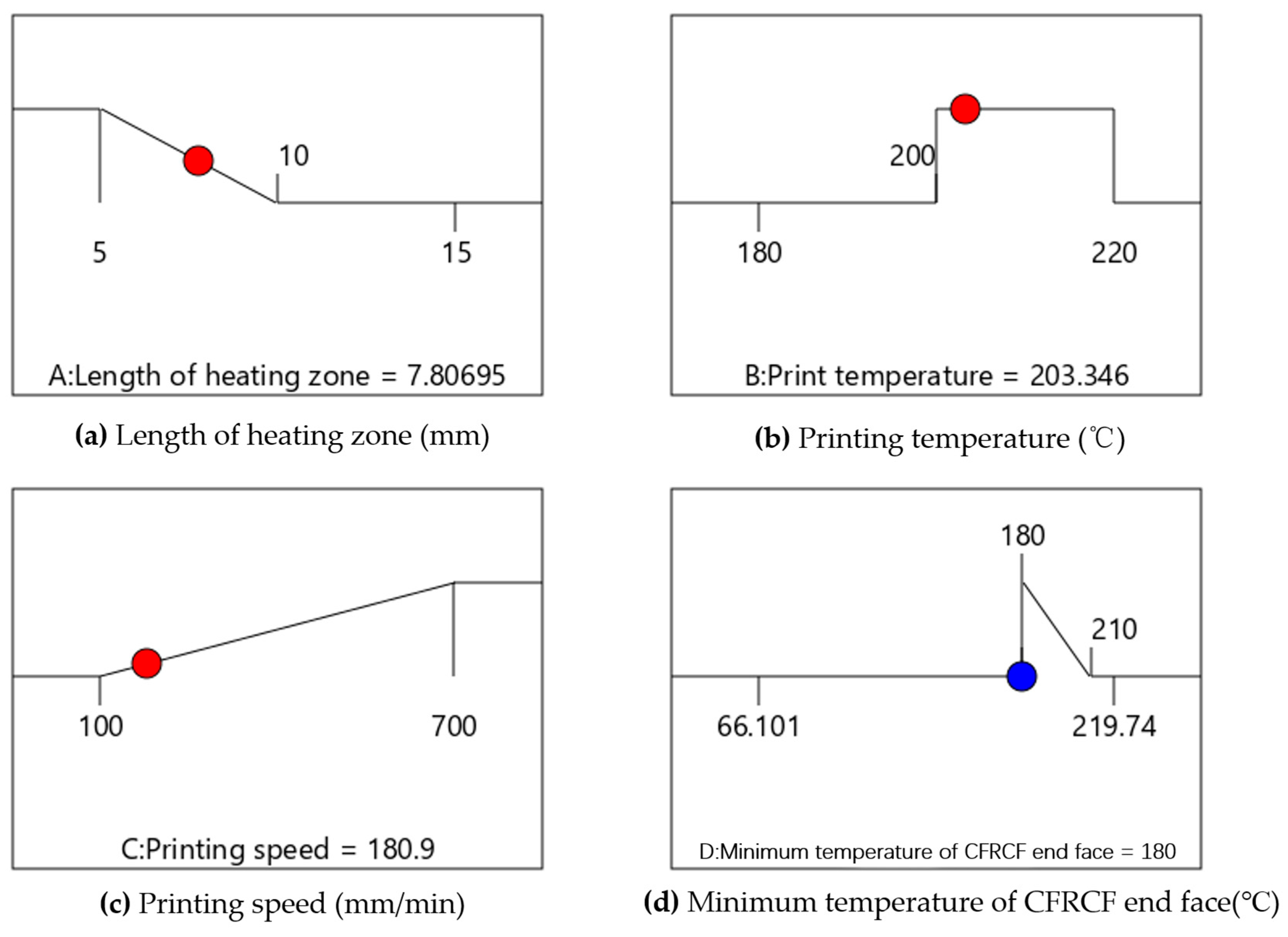

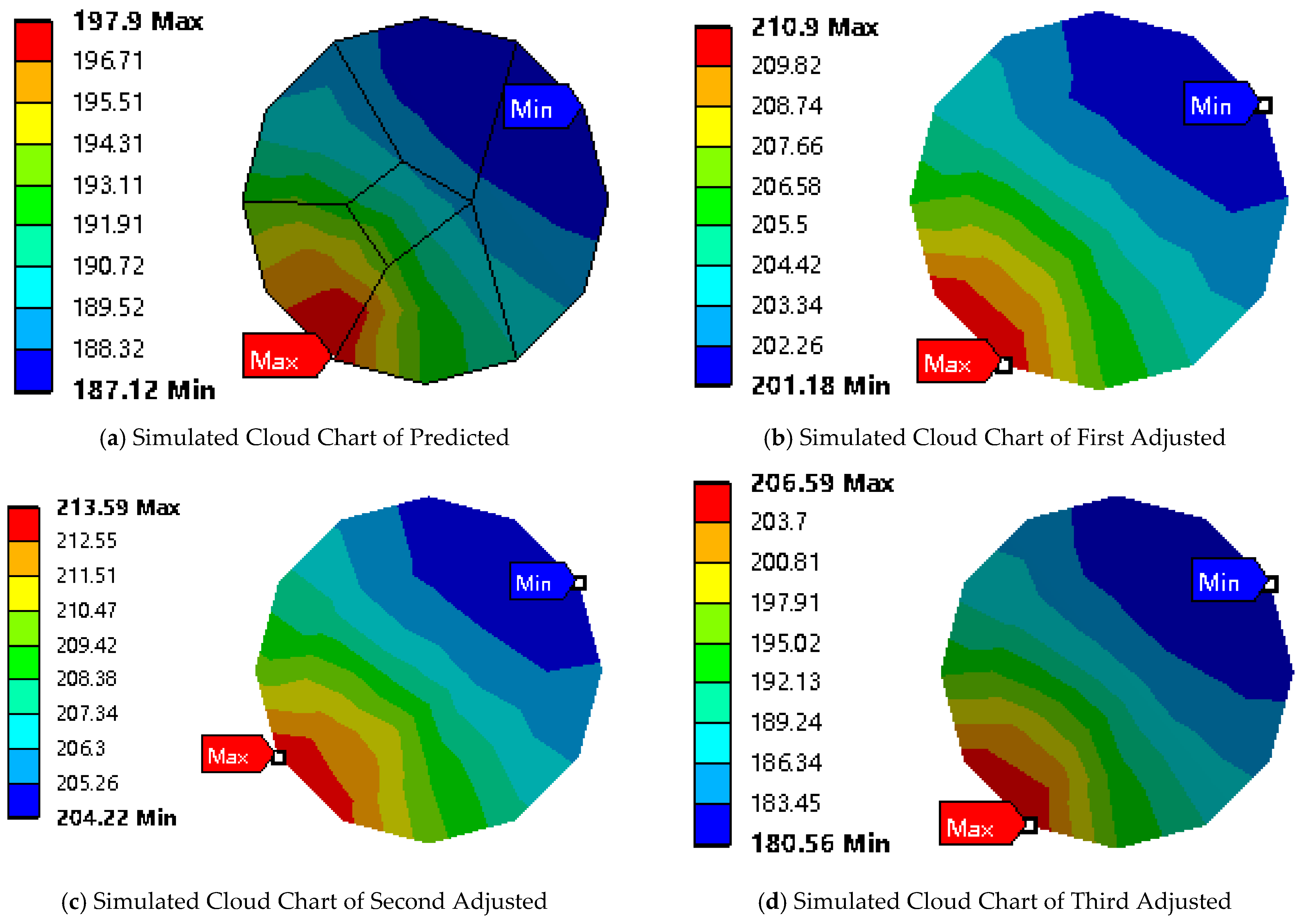

3.2.2. Parameter Optimization

3.3. Experimental Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Park, G.; Cho, N.K.; Lee, Y.; Kim, C.-S. Comprehensive parametric analyses on the mechanical performance of 3D printed continuous carbon fibre reinforced plastic. Compos. Struct. 2024, 329, 117804. [Google Scholar] [CrossRef]

- Chen, W.; Hu, Z.L.; Li, X.P.; He, J.W.; Wang, S.S.; Zhao, Y.; Li, M.J.; Zhang, J.Z. Additive manufacturing of high-strength polyamide 6 composites reinforced with continuous carbon fiber prepreg. Polym. Compos. 2024, 45, 668–679. [Google Scholar] [CrossRef]

- Liu, T.F.; Tian, X.Y.; Xue, L. Equipment and Parameter Regulation for 3D Printing of Continuous Carbon Fiber Reinforced Nylon 6 Composite Materials. Mach. Ind. Stand. Qual. 2020, 3, 27–30+38. [Google Scholar]

- Wang, Y.S.; Kong, D.K.; Zhang, Q.; Li, W.; Liu, J. Process parameters and mechanical properties of continuous glass fiber reinforced composites-polylactic acid by fused deposition modeling. J. Reinf. Plast. Compos. 2021, 40, 686–698. [Google Scholar] [CrossRef]

- Tian, X.Y.; Liu, T.F.; Wang, Q.R.; Dilmurat, A.; Li, D.; Ziegmann, G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 2017, 142, 1609–1618. [Google Scholar] [CrossRef]

- Bettini, P.; Alitta, G.; Sala, G.; Di Landro, L. Fused deposition technique for continuous fiber reinforced thermoplastic. J. Mater. Eng. Perform. 2017, 26, 843–848. [Google Scholar] [CrossRef]

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook. Compos. Part B Eng. 2021, 224, 109143. [Google Scholar] [CrossRef]

- Li, S.X.; Cheng, P.; Ahzi, S.; Peng, Y.; Wang, K.; Chinesta, F.; Correia, J.P.M. Advances in hybrid fibers reinforced polymer-based composites prepared by FDM: A review on mechanical properties and prospects. Compos. Commun. 2023, 40, 101592. [Google Scholar] [CrossRef]

- Zheng, D.H.; Yang, L.N.; Liu, L.J.; Yang, G.; Liu, Y.L. Design of 3D Printing Nozzle for Continuous Carbon Fiber Reinforced Composite Materials. J. Hebei Univ. Sci. Technol. 2021, 42, 613–618. [Google Scholar]

- Li, H.R. Analysis and Design of 3D Printer Nozzle for Carbon Fiber Composite Materials. Master’s Thesis, Inner Mongolia University of Technology, Hohhot, China, 2019. [Google Scholar]

- Swolfs, Y.; Pinho, S.T. 3D printed continuous fibre-reinforced composites: Bio-inspired microstructures for improving the translaminar fracture toughness. Compos. Sci. Technol. 2019, 182, 107731. [Google Scholar] [CrossRef]

- Li, S.L.; Wei, Z.Y.; Du, J.; Zhao, G.X.; Wang, X.; Liu, W.; Lu, B.H. Process Research on Forming Nested Parts Based on Metal 3D Printing Technology. Mater. Sci. Technol. 2016, 24, 1–7. [Google Scholar]

- Tian, X.Y.; Liu, T.F.; Yang, C.C.; Wang, Q.R.; Li, D.C. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A-Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Hu, Q.X.; Duan, Y.C.; Zhang, H.G.; Liu, D.L.; Yan, B.; Peng, F.J. Manufacturing and 3D printing of continuous carbon fiber prepreg filament. J. Mater. Sci. 2018, 53, 1887–1898. [Google Scholar] [CrossRef]

- Zhang, Z.S.; Long, Y.; Yang, Z.; Fu, K.K.; Li, Y. An investigation into printing pressure of 3D printed continuous carbon fiber reinforced composites[EB/OL]. Compos. A Appl. Sci. Manuf. 2022, 162, 107162. [Google Scholar] [CrossRef]

- Ming, Y.K.; Zhang, S.Q.; Han, W.; Wang, B.; Duan, Y.G.; Xiao, H. Investigation on process parameters of 3D printed continuous carbon fiber-reinforced thermosetting epoxy composites. Addit. Nabufacturing 2020, 33, 101184. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Chacóna, J.M.; Caminerob, M.A.; Núñezb, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive manufacturing of continuous fifibre reinforced thermoplastic composites using fused deposition modelling: Effffect of process parameters on mechanical properties. Compos. Sci. Technol. 2019, 180, 107688. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Jayaprakash, S.; Kolari, K.; Kuva, J.; Kukko, K.; Partanen, J. The role of printing parameters on the short beam strength of 3D-printed continuous carbon fibre reinforced epoxy-PETG composites. Compos. Struct. 2024, 337, 118034. [Google Scholar] [CrossRef]

- Li, H.M.; Liu, B.S.; Ge, L.; Chen, Y.; Zheng, H.Y.; Fang, D.N. Mechanical performances of continuous carbon fiber reinforced PLA composites printed in vacuum. Compos. Part B Eng. 2021, 225, 109277. [Google Scholar] [CrossRef]

- Vatandaş, B.B.; Uşun, A.; Gümrük, R. Mechanical performances of continuous carbon fiber reinforced PEEK (polyether ether ketone) composites printed in a vacuum environment. J. Manuf. Process. 2024, 120, 579–594. [Google Scholar] [CrossRef]

- Ding, Q.J.; Li, X.Y.; Zhang, D.H.; Zhao, G.; Sun, Z.J. Anisotropy of poly (lactic acid)/carbon fiber composites prepared by fused deposition modeling. J. Appl. Polym. Sci. 2020, 137, 48786. [Google Scholar] [CrossRef]

- Tóth, C.; Vas, L.M.; Kovács, N.K. Achieving gradual failure under bending by the layering design of 3D printed continuous fiber reinforced composites. Results Eng. 2024, 22, 102075. [Google Scholar] [CrossRef]

- Zhuang, Y.X.; Zou, B.; Ding, S.L.; Wang, X.F.; Liu, J.K.; Li, L. Preparation of pre-impregnated continuous carbon fiber reinforced nylon6 filaments and the mechanical properties of 3D printed composites. Mater. Today Commun. 2023, 35, 106163. [Google Scholar] [CrossRef]

- Li, S.X.; Wang, K.; Zhu, W.Y.; Peng, Y.; Ahzi, S.; Chinesta, F. Contributions of interfaces on the mechanical behavior of 3D printed continuous fiber reinforced composites. Constr. Build. Mater. 2022, 340, 127842. [Google Scholar] [CrossRef]

- Li, L.J.; Liu, W.Y.; Sun, L.Y. Mechanical characterization of 3D printed continuous carbon fiber reinforced thermoplastic composites. Compos. Sci. Technol. 2022, 227, 109618. [Google Scholar] [CrossRef]

- El Essawi, B.; Abdallah, S.; Ali, S.; Mohammed, A.N.A.; Susantyoko, R.A.; Pervaiz, S. Optimization of infill density, fiber angle, carbon fiber layer position in 3D printed continuous carbon-fiber reinforced nylon composite. Results Eng. 2024, 21, 101926. [Google Scholar] [CrossRef]

- Himika, T.A.; Olsen-Kettle, L.; Ruan, D.; Daliri, A. Effects of nozzle geometry and fiber orientation on the tensile strength of 3D printed continuous fiber reinforced composites. Addit. Manuf. 2024, 94, 104490. [Google Scholar] [CrossRef]

- Zhang, F.; Tan, Y.G.; Ma, G.F.; Zhang, J. Research on the Forming Process of Continuous Carbon Fiber Composite 3D Printing. Mach. Des. Manuf. 2019, 7, 96–98+102. [Google Scholar]

| Title | Reinforcement Material | Diameter (mm) | Wrapped Resin | Printing Temperature (°C) | Printing Layer Height (mm) | Source |

|---|---|---|---|---|---|---|

| PLA | - | 1.75 | - | 215 | 0.2 | eSUN |

| CFRCF/PLA | glass fiber, carbon fiber | 0.45 | PLA | 220 | 0.2 | self-made |

| Printing Temperature | Heating Time | Printing Forming Impact |

|---|---|---|

| T > Tb | t > tb | High printing temperature and long heating time result in rapid softening and nozzle clogging of CFRCF. |

| T > Tb | t < ta | High printing temperature and short heating time result in ineffective bonding between CFRCF and the printing surface. |

| T < Ta | t > tb | Low printing temperature and long heating time result in softening and nozzle clogging of CFRCF. |

| T < Ta | t < ta | Low printing temperature and short heating time result in ineffective bonding between CFRCF and the printing surface. |

| Name | Material | Density (kg/m3) | Elastic Modulus (GPa) | Poisson’s Ratio | Specific Heat Capacity (J/kg·°C) |

|---|---|---|---|---|---|

| Nozzle | Copper alloy | 8500 | 96 | 0.34 | 390 |

| CFRCF | PLA | 1260 | 3.45 | 0.08 | 1190 |

| Material | Surface Condition | Radiation Coefficient |

|---|---|---|

| Brass | Polished | 0.03 |

| Oxidized | 0.61 |

| Factor | Parameter | Level | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| A | Length of the heating zone (mm) | 5 | 10 | 15 |

| B | Printing temperature (°C) | 180 | 200 | 220 |

| C | Printing speed (mm/min) | 100 | 400 | 700 |

| CFRCF | PLA | 1260 | 3.5 | 0.08 |

| Std | Run | Factor 1 | Factor 2 | Factor 3 | Response 1 |

|---|---|---|---|---|---|

| A | B | C | R | ||

| 2 | 1 | 15 | 200 | 100 | 199.57 |

| 10 | 2 | 10 | 200 | 400 | 159.5 |

| 15 | 3 | 10 | 200 | 400 | 159.5 |

| 6 | 4 | 5 | 220 | 400 | 116.1 |

| 4 | 5 | 10 | 220 | 100 | 219.74 |

| 14 | 6 | 15 | 220 | 400 | 175.87 |

| 17 | 7 | 5 | 200 | 700 | 66.1 |

| 13 | 8 | 5 | 200 | 100 | 192.71 |

| 3 | 9 | 5 | 180 | 400 | 95.52 |

| 9 | 10 | 10 | 220 | 700 | 128.36 |

| 7 | 11 | 10 | 200 | 400 | 159.5 |

| 16 | 12 | 10 | 180 | 700 | 108.29 |

| 8 | 13 | 15 | 200 | 700 | 148.46 |

| 1 | 14 | 15 | 180 | 400 | 143.37 |

| 5 | 15 | 10 | 180 | 100 | 179.67 |

| 12 | 16 | 10 | 200 | 400 | 159.5 |

| 11 | 17 | 10 | 200 | 400 | 159.5 |

| Effect | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 24,254.62 | 9 | 2694.96 | 68.59 | <0.0001 |

| A—Length of the heating zone | 5732.38 | 1 | 5732.38 | 145.89 | <0.0001 |

| B—Printing temperature | 1366.54 | 1 | 1366.54 | 34.78 | 0.0006 |

| C—Printing speed | 14,490.74 | 1 | 14,490.74 | 368.79 | <0.0001 |

| AB | 35.53 | 1 | 35.53 | 0.9043 | 0.3733 |

| AC | 1242.58 | 1 | 1242.58 | 31.62 | 0.0008 |

| BC | 83.91 | 1 | 83.91 | 2.14 | 0.1873 |

| A2 | 1223.24 | 1 | 1223.24 | 31.13 | 0.0008 |

| B2 | 399.43 | 1 | 399.43 | 10.17 | 0.0153 |

| C2 | 2185.87 | 1 | 2185.87 | 55.63 | 0.0001 |

| Residual | 275.05 | 7 | 39.29 | - | - |

| Standard deviation | 6.27 | - | - | - | - |

| Median | 151.25 | - | - | - | - |

| R2 | 0.9888 | - | - | - | - |

| Adjusted R2 | 0.9744 | - | - | - | - |

| Predictive R2 | 0.8205 | - | - | - | - |

| Adeq Precision | 32.2219 | - | - | - | - |

| C.V. % | 4.14 | - | - | - | - |

| Nozzle Length L (mm) | Printing Temperature T (°C) | Printing Speed V (mm/min) | Composite Material Surface Temperature Tp (°C) | |

|---|---|---|---|---|

| Predicted Value | 7.807 | 203.346 | 180.900 | 180.000 |

| Simulated Value | 7.807 | 203.346 | 180.900 | 187.120 |

| First Adjusted Predicted Value | 8.000 | 215.635 | 197.489 | 180.000 |

| First Adjusted Simulated Value | 8.000 | 215.635 | 197.489 | 201.180 |

| Second Adjusted Simulated Value | 8.000 | 220.000 | 200.000 | 204.220 |

| Third Adjusted Simulated Value | 8.000 | 220.000 | 300.000 | 180.560 |

| Title | Reinforcing Material | Diameter (mm) | Wrapped Resin | Printing Temperature (°C) | Printing Layer Height (mm) | Source |

|---|---|---|---|---|---|---|

| printing surface PLA | - | 1.75 | - | 215 | 0.2 | Yisheng Technology |

| CGFPF/PLA | glass fiber | 0.45 | PLA | 220 | 0.2 | self-made |

| CCFPF/PLA | carbon fiber | 0.4 | PLA | 220 | 0.2 | self-made |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, S.; Zhang, Q.; Liu, B.; Li, W.; Wang, Y.; Li, F.; Liu, J. Optimizing Nozzle Structure and Parameters for Continuous Fiber Prepreg Filament 3D Printing. Polymers 2025, 17, 1014. https://doi.org/10.3390/polym17081014

Qu S, Zhang Q, Liu B, Li W, Wang Y, Li F, Liu J. Optimizing Nozzle Structure and Parameters for Continuous Fiber Prepreg Filament 3D Printing. Polymers. 2025; 17(8):1014. https://doi.org/10.3390/polym17081014

Chicago/Turabian StyleQu, Sheng, Qi Zhang, Beiying Liu, Wei Li, Yesong Wang, Feilong Li, and Jisheng Liu. 2025. "Optimizing Nozzle Structure and Parameters for Continuous Fiber Prepreg Filament 3D Printing" Polymers 17, no. 8: 1014. https://doi.org/10.3390/polym17081014

APA StyleQu, S., Zhang, Q., Liu, B., Li, W., Wang, Y., Li, F., & Liu, J. (2025). Optimizing Nozzle Structure and Parameters for Continuous Fiber Prepreg Filament 3D Printing. Polymers, 17(8), 1014. https://doi.org/10.3390/polym17081014