From Manual to Automated: Exploring the Evolution of Switchover Methods in Injection Molding Processes—A Review

Abstract

:1. Introduction

2. Definition and Significance of the Switchover Point

2.1. Traditional Methods for Switchover Management

- Time-dependent switchover:

- Stroke-dependent switchover:

- Pressure-dependent switchover:

- In-mold-sensor-dependent switchover (mostly cavity pressure):

2.2. Injection Molding Processes Without Switchover

2.3. A Comparison of Switchover Methods

3. Challenges and Limitations Associated with the Switchover Point

4. Technological Advances for the Switchover Point

- Lowering the impact of the influencing factors by decreasing disturbances or enhancing the process’s robustness to them. This includes strategies focused on a smooth transition between the filling and holding phase, incorporating NRV behavior, refining the switchover methods for multi-cavities, and rethinking pressure-dependent-switchover logic.

- Adaptive process control approaches leverage sensor data, simulations, or machine learning techniques to dynamically adjust the switchover point. This cluster includes step-by-step optimization methods, the use of pressure integrals, deformation-based approaches (such as mold separation and tie-bar elongation), filling simulation models, and artificial intelligence.

4.1. Lowering the Impact of the Influencing Factors

4.2. Adaptive Process Control for the Switchover Point

4.3. Summary of Findings

5. Perspectives for Future Research

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

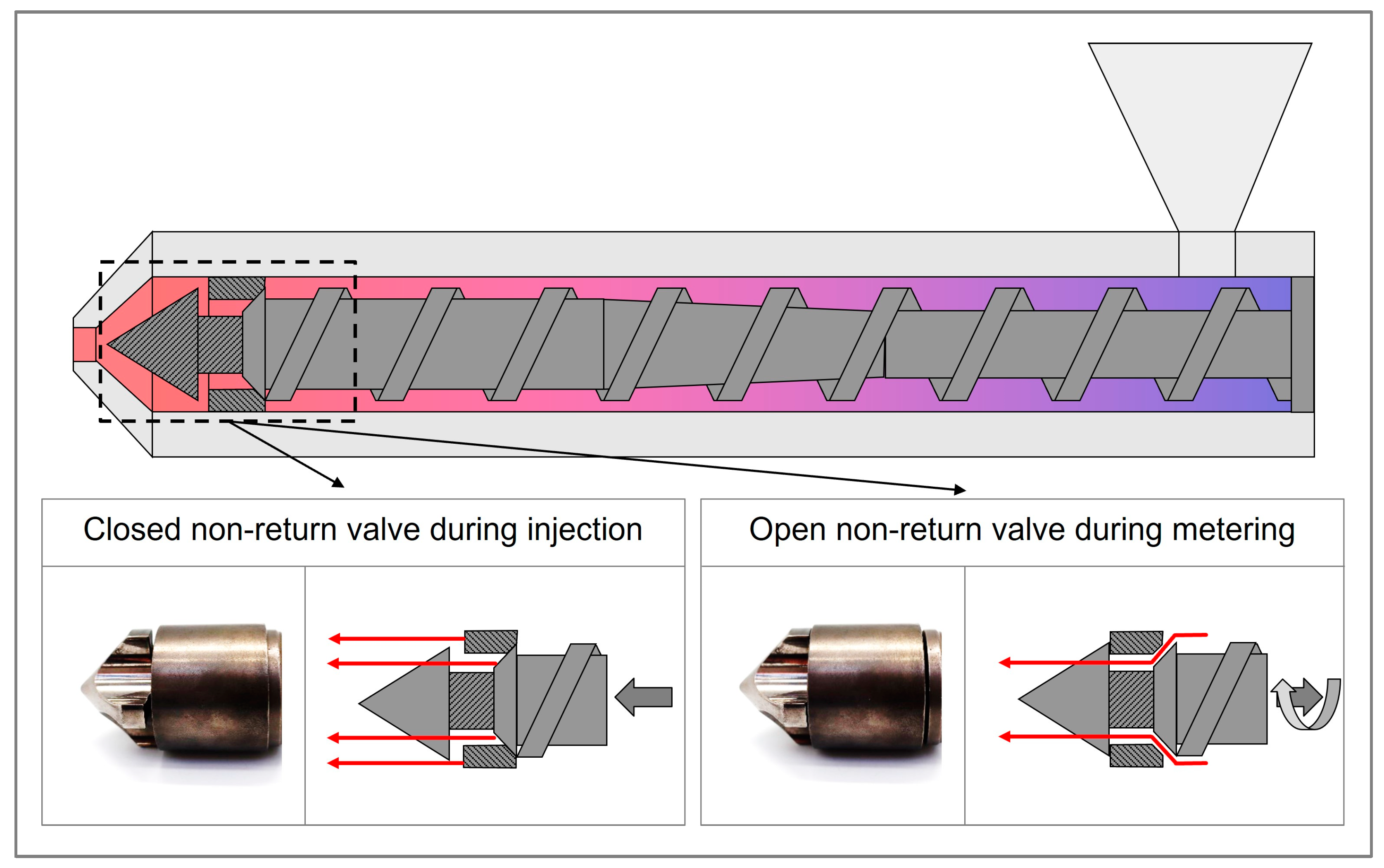

| NRV | Non-return valve |

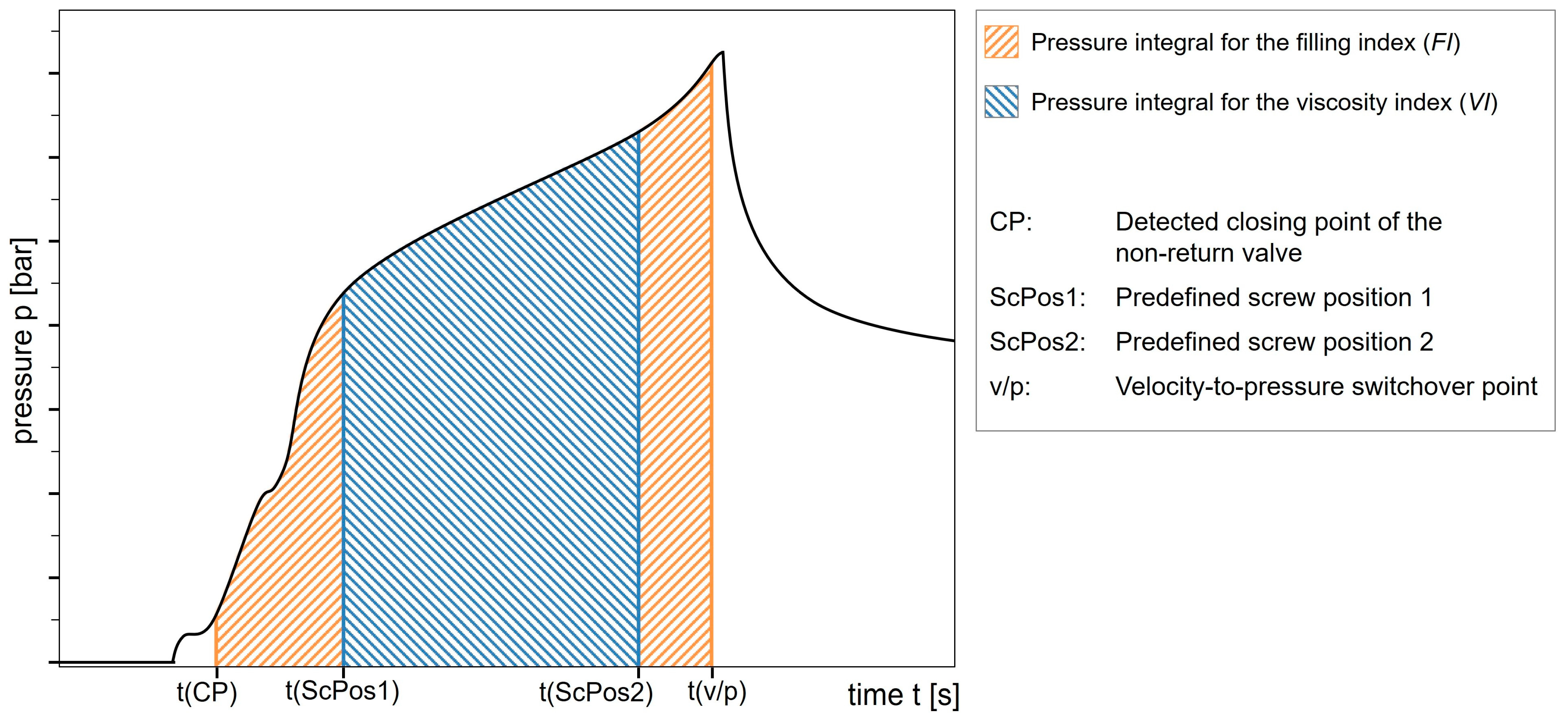

| VI | Viscosity index |

| FI | Filling index |

| MPV | Molded part volume equivalent |

| pvT | Pressure, specific volume, and temperature |

References

- Chen, J.-Y.; Zhuang, J.-X.; Huang, M.-S. Monitoring, prediction and control of injection molding quality based on tie-bar elongation. J. Manuf. Process. 2019, 46, 159–169. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Zhuang, J.-X.; Huang, M.-S. Enhancing the quality stability of injection molded parts by adjusting V/P switchover point and holding pressure. Polymer 2021, 213, 123332. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Hung, P.-H.; Huang, M.-S. Determination of process parameters based on cavity pressure characteristics to enhance quality uniformity in injection molding. Int. J. Heat Mass Transf. 2021, 180, 121788. [Google Scholar] [CrossRef]

- Wang, J.; Peng, J.; Yang, W. Filling-To-Packing Switchover Mode Based on Cavity Temperature for Injection Molding. Polym.-Plast. Technol. Eng. 2011, 50, 1273–1280. [Google Scholar] [CrossRef]

- Heinzler, F.A. Modellgestützte Qualitätsregelung Durch Eine Adaptive, Druckgeregelte Prozessführung Beim Spritzgießen. Ph.D. Thesis, Universität Duisburg-Essen, Duisburg, Germany, 2014. [Google Scholar]

- Zhao, N.-Y.; Liu, J.-F.; Su, M.-Y.; Xu, Z.-B. Measurement techniques in injection molding: A comprehensive review of machine status detection, molten resin flow state characterization, and component quality adjustment. Measurement 2024, 226, 114163. [Google Scholar] [CrossRef]

- Ageyeva, T.; Horváth, S.; Kovács, J.G. In-Mold Sensors for Injection Molding: On the Way to Industry 4.0. Sensors 2019, 19, 3551. [Google Scholar] [CrossRef]

- Liew, K.-F.; Peng, H.-S.; Huang, P.-W.; Su, W.-J. Injection Barrel/Nozzle/Mold-Cavity Scientific Real-Time Sensing and Molding Quality Monitoring for Different Polymer-Material Processes. Sensors 2022, 22, 4792. [Google Scholar] [CrossRef]

- Liou, G.-Y.; Cheng, F.-J.; Su, W.-J.; Hwang, S.-J.; Peng, H.-S.; Chu, H.-Y. Nozzle Pressure and Clamping Force Based Injection Molding Process Parameter Optimization and Adaptive Process Quality Control. In Proceedings of the 2022 25th International Conference on Mechatronics Technology (ICMT), Kaohsiung, Taiwan, 18–21 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–4, ISBN 978-1-6654-6195-5. [Google Scholar]

- Liou, G.-Y.; Su, W.-J.; Cheng, F.-J.; Chang, C.-H.; Tseng, R.-H.; Hwang, S.-J.; Peng, H.-S.; Chu, H.-Y. Optimize Injection-Molding Process Parameters and Build an Adaptive Process Control System Based on Nozzle Pressure Profile and Clamping Force. Polymers 2023, 15, 610. [Google Scholar] [CrossRef]

- Su, C.-W.; Su, W.-J.; Cheng, F.-J.; Liou, G.-Y.; Hwang, S.-J.; Peng, H.-S.; Chu, H.-Y. Optimization process parameters and adaptive quality monitoring injection molding process for materials with different viscosity. Polym. Test. 2022, 109, 107526. [Google Scholar] [CrossRef]

- Fan-Jiang, J.-C.; Su, C.-W.; Liou, G.-Y.; Hwang, S.-J.; Lee, H.-H.; Peng, H.-S.; Chu, H.-Y. Study of an Online Monitoring Adaptive System for an Injection Molding Process Based on a Nozzle Pressure Curve. Polymers 2021, 13, 555. [Google Scholar] [CrossRef]

- Edwards, R.; Diao, L.; Thomas, C.L.; Groleau, M. Cavity Based Ultrasonic Resonance Monitoring in Injection Molding. In Proceedings of the ANTEC, San Francisco, CA, USA, 5–9 May 2002. [Google Scholar]

- Zhang, J.; Zhao, P.; Zhao, Y.; Huang, J.; Xia, N.; Fu, J. On-line measurement of cavity pressure during injection molding via ultrasonic investigation of tie bar. Sens. Actuators A Phys. 2019, 285, 118–126. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, S.; Ying, J.; Fu, J. Non-destructive measurement of cavity pressure during injection molding process based on ultrasonic technology and Gaussian process. Polym. Test. 2013, 32, 1436–1444. [Google Scholar] [CrossRef]

- Huang, M.-S.; Nian, S.-C.; Chen, J.-Y. Tie-bar elongation based prediction of injection molding quality. In Proceedings of the ANTEC, Detroit, MI, USA, 18–21 March 2019. [Google Scholar]

- Chen, J.-Y.; Liu, C.-Y.; Huang, M.-S. Tie-Bar Elongation Based Filling-To-Packing Switchover Control and Prediction of Injection Molding Quality. Polymers 2019, 11, 1168. [Google Scholar] [CrossRef]

- Zheng, D.; Alleyne, A. Modeling and Control of an Electro-hydraulic Injection Molding Machine with Smoothed Fill-to-Pack Transition. J. Manuf. Sci. Eng. 2003, 125, 154–163. [Google Scholar] [CrossRef]

- Schwarz, O.; Ebeling, F.W.; Furth, B. Kunststoffverarbeitung, 11th ed.; Vogel: Würzburg, Germany, 2009; ISBN 978-3-8343-3119-9. [Google Scholar]

- Schötz, A. Abmusterung von Spritzgießwerkzeugen: Strukturierte und Analytische Vorgehensweise; Hanser, Carl: München, Germany, 2013; ISBN 978-3-446-43611-4. [Google Scholar]

- Jaroschek, C. Injection Molding for Practitioners; Hanser: Munich, Germany, 2024; ISBN 978-1-56990-292-9. [Google Scholar]

- Jaroschek, C. Offensichtliche Fortschritte und Verborgene Schätze. Kunststoffe 2013, 12, 30–36. [Google Scholar]

- Cho, J.H.; Kwon, S.Y.; Roh, H.J.; Kim, S.Y.; Lyu, M.-Y. Analysis of Cavity Pressure and Dimension of Molded Part According to V/P Switchover Position in Injection Molding. Elastomers Compos. 2017, 52, 309–316. [Google Scholar]

- Nian, S.-C.; Fang, Y.-C.; Huang, M.-S. In-mold and Machine Sensing and Feature Extraction for Optimized IC-tray Manufacturing. Polymers 2019, 11, 1348. [Google Scholar] [CrossRef]

- Jaroschek, C. Spritzgießen für Praktiker, 5th ed.; Hanser: München, Germany, 2024; ISBN 978-3-446-48056-8. [Google Scholar]

- Kulkarni, S. Robust Process Development and Scientific Molding: Theory and Practice, 3rd ed.; Hanser: München, Germany, 2024; ISBN 978-1-56990-909-6. [Google Scholar]

- Kazmer, D.O.; Velusamy, S.; Westerdale, S.; Johnston, S.; Gao, R.X. A comparison of seven filling to packing switchover methods for injection molding. Polym. Eng. Sci. 2010, 50, 2031–2043. [Google Scholar] [CrossRef]

- Knoll, J.; Heim, H.-P. Analysis of the Machine-Specific Behavior of Injection Molding Machines. Polymers 2023, 16, 54. [Google Scholar] [CrossRef]

- Kazmer, D. Robustness of Switchover Methods for Injection Molding; Society of Plastics Engineers (SPE): Danbury, CT, USA, 2010. [Google Scholar]

- Kudlik, N. Reproduzierbarkeit des Kunststoff-Spritzgießprozesses, 1st ed.; Mainz: Aachen, Germany, 1998; ISBN 9783896534125. [Google Scholar]

- Aloise, A.C.; Notte, A.J.; Rizzi, M.A. Using ram velocity to control IMM part quality. Adv. Polym. Technol. 1983, 3, 137–141. [Google Scholar] [CrossRef]

- Diao, L.; Edwards, R.; Thomas, C.L. A Comparison of Position, Cavity Pressure, and Ultrasound Sensors for Switch/Over Control in Injection Molding. In Proceedings of the Annual Technical Conference of the Society of Plastics Engineers, Nashville, TN, USA, 4–8 May 2003. [Google Scholar]

- Altonen, G.M.; Neufarth, R.E.; Schiller, G.F.; Berg, C.J., Jr. Alternative Pressure Control for an Injection Molding Apparatus. Patent US 2014/0255530 A1, 19 May 2014. [Google Scholar]

- Santini, K. Addressing the Challenge of Injection Molding Regrind—Recycling Today: Imux Technology Helps Injection Molders Increase Their Use of Recycled Plastics. Available online: https://www.recyclingtoday.com/article/addressing-the-challenge-of-injection-molding-regrind/ (accessed on 18 June 2024).

- Krantz, J.; Nieduzak, Z.; Kazmer, E.; Licata, J.; Ferki, O.; Gao, P.; Sobkowicz, M.J.; Masato, D. Investigation of pressure-controlled injection molding on the mechanical properties and embodied energy of recycled high-density polyethylene. Sustain. Mater. Technol. 2023, 36, e00651. [Google Scholar] [CrossRef]

- kunststoffFORUM. ENGEL X-MELT: Präzisions-Mikrospritzguss mit der Vollelektrischen Standardmaschine. Available online: http://www.kunststoffforum.de/information/news_artikel.php?id=3084 (accessed on 5 July 2024).

- Steinbichler, G.; Pokorny, P. Injection Moulding Process. Patent EP 1 074 374 A1, 9 July 1999. [Google Scholar]

- Huang, M.-S. Cavity pressure based grey prediction of the filling-to-packing switchover point for injection molding. J. Mater. Process. Technol. 2007, 183, 419–424. [Google Scholar] [CrossRef]

- Chang, T.C. Process Capability Comparison of Various Switchover Modes from the Filling to Packing Stages in Injection Molding. In Proceedings of the ANTEC, San Francisco, CA, USA, 5–9 May 2002. [Google Scholar]

- Chang, T.C. Robust process control in injection molding—Process capability comparison for five switchover modes. J. Inject. Molding Technol. 2002, 6, 239–246. [Google Scholar]

- Offergeld, H. Verfahren und Vorrichtung zur Optimierung der Schneckenvorlaufgeschwindigkeit beim Umschalten zwischen Einspritzphase und Nachdruckphase beim Spritzgießen. Patent DE 40 11 230 A1, 6 April 1990. [Google Scholar]

- Schubert, A. A Comparison of velocity to pressure transfer control strategies for injection molding. In Proceedings of the ANTEC, Chicago, IL, USA, 22–24 June 2009. [Google Scholar]

- Johnson, B. Determining Which In-Mold Sensors Should Be Used for V/P Transfer During Injection Molding for Three Different Injection Strategies. In Proceedings of the ANTEC, Cincinnati, OH, USA, 22–24 April 2013. [Google Scholar]

- Johnson, B. Novel V/P Transfer Actuation Method and Injection Molding Strategy and Their Comparison to Traditional Methods. In Proceedings of the ANTEC, Detroit, MI, USA, 18–21 March 2019. [Google Scholar]

- Schiffers, R. Verbesserung der Prozessfähigkeit Beim Spritzgießen Durch Nutzung von Prozessdaten und Eine Neuartige Schneckenhubführung. Ph.D. Thesis, University of Duisburg-Essen, Duisburg, Germany, 2009. [Google Scholar]

- Holzinger, G.P.; Kruppa, S.; Moser, S.; Schiffers, R. An Adaptive Filling to Packing Switchover Method for Injection Molding. In Proceedings of the 72nd Annual Technical Conference of the Society of Plastics Engineers, Las Vegas, NV, USA, 28–30 April 2014. [Google Scholar]

- Ghose, A.; Montero, M.; Odell, D. Characterization of an Injection Molding Process for Improved Part Quality. Eng. Mater. Sci. 2001. Available online: http://ode11.com/projects/tricon_report.pdf (accessed on 17 April 2025).

- Gornik, C. Abgeleitete Kenngrößen zur Optimierung nutzen. Kunststoffe 2009, 99, 30–34. [Google Scholar]

- Eben, J. Identifikation und Reduzierung realer Schwankungen durch Praxistaugliche Prozessführungsmethoden beim Spritzgießen. Ph.D. Thesis, Technische Universität Chemnitz, Chemnitz, Germany, 2014. [Google Scholar]

- Hopmann, C.; Menges, G.; Michaeli, W.; Mohren, P. Spritzgießwerkzeuge: Auslegung, Bau, Anwendung, 7th ed.; Hanser: München, Germany, 2018; ISBN 978-3-446-45390-6. [Google Scholar]

- Baesso, R.; Lucchetta, G. Switchover control in the polymer injection forming process. In Proceedings of the 66th Annual Technical Conference of the Society of Plastics Engineers 2008, Milwaukee, WI, USA, 4–8 May 2008. [Google Scholar]

- Cooney, R.; Neill, D.; Pomorski, L. An Investigation of Part Variation in Multi-Cavity Injection Molds When Using Cavity Pressure Control. In Proceedings of the ANTEC 2001 Conference Proceedings, Dallas, TX, USA, 6–10 May 2001. [Google Scholar]

- Kazmer, D.; Barkan, P. Multi-cavity pressure control in the filling and packing stages of the injection molding process. Polym. Eng. Sci. 1997, 37, 1865–1879. [Google Scholar] [CrossRef]

- Kazmer, D.; Barkan, P. The process capability of multi-cavity pressure control for the injection molding process. Polym. Eng. Sci. 1997, 37, 1880–1895. [Google Scholar] [CrossRef]

- Ortgies, M. Qualitätssicherung für viele Kavitäten: Prozessregelung automatisiert Spritzgießprozesse—Hier am Beispiel eines Würfelwerkzeugs. Kunststoffe 2021, 6, 42–44. [Google Scholar]

- Schiffers, R.; Holzinge, G.; Huster, G. Adaptive process control for stabilizing the production process in injection moulding machines. In Proceedings of the 10th International Fluid Power Conference, Dresden, Germany, 8–10 March 2016. [Google Scholar]

- Albertson, A.S.; Brendel, M.V. Investigation of Injection Molding Process Robustness for Various Molding Strategies. In Proceedings of the ANTEC, San Francisco, CA, USA, 5–9 May 2002. [Google Scholar]

- Huang, M.-S.; Nian, S.-C.; Lin, G.-T. Influence of V/P switchover point, injection speed, and holding pressure on quality consistency of injection-molded parts. J. Appl. Polym. Sci. 2021, 138, 51223. [Google Scholar] [CrossRef]

- Froehlich, C.; Kemmetmuller, W.; Kugi, A. Model-Predictive Control of Servo-Pump Driven Injection Molding Machines. IEEE Trans. Contr. Syst. Technol. 2020, 28, 1665–1680. [Google Scholar] [CrossRef]

- Froehlich, C.; Kemmetmüller, W.; Kugi, A. Control-oriented modeling of servo-pump driven injection molding machines in the filling and packing phase. Math. Comput. Model. Dyn. Syst. 2018, 24, 451–474. [Google Scholar] [CrossRef]

- Hopmann, C.; Hornberg, K. Die Umschaltproblematik und ihre Folgen: Phasenlose Prozessregelung soll den Umschaltvorgang revolutionieren. Kunststoffe 2020, 3, 82–86. [Google Scholar]

- Stemmler, S.; Ay, M.; Vukovic, M.; Abel, D.; Heinisch, J.; Hopmann, C. Cross-phase Model-based Predictive Cavity Pressure Control in Injection Molding. In Proceedings of the 2019 IEEE Conference on Control Technology and Applications (CCTA), Hong Kong, China, 19–21 August 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 360–367, ISBN 978-1-7281-2767-5. [Google Scholar]

- Hornberg, K.; Hopmann, C.; Vukovic, M.; Stemmler, S.; Abel, D. Compensation of batch fluctuations of post-consumer recyclate in injection molding by phase-unifying process control. In Proceedings of the SPE ANTEC 2023, Denver, CO, USA, 27–30 March 2023. [Google Scholar]

- Hertz, R.A.; Christensen, J.K.; Therkelsen, O.; Kristiansen, S.; Helver, C.-E.; Hansson, F.A.; Schmidt, L. A Novel Approach to Control Switchover Between Injection and Holding Phase for a Hydraulic Injection Moulding Machine. In Proceedings of the 2023 SPE Annual Technical Conference and Exhibition, ANTEC 2023, Denver, CO, USA, 27–30 March 2023. [Google Scholar]

- Lin, C.-Y.; Shen, F.-C.; Wu, K.-T.; Hwang, S.-J.; Lee, H.-H. Injection Molding Process Control of Servo-Hydraulic System. In Proceedings of the 2019 IEEE Eurasia Conference on IOT, Communication and Engineering (ECICE), Yunlin, Taiwan, 3–6 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 242–245, ISBN 978-1-7281-2501-5. [Google Scholar]

- Gornik, C.; Bleier, H.; Roth, W. Arbeit an der Spitze: Das Schließverhalten von Rückstromsperren. Kunststoffe 2001, 6, 72–74. [Google Scholar]

- Schiffers, R.; Moser, S.; Kruppa, S. Method for Volumetrically Correct Filling of Cavity of Molding Tool with Melt of Material to Be Processed in Injection Molding Process, Involves Providing Injection Molding Machine Equipped with Molding Tool. Patent DE 10 2013 111 257 B3, 11 October 2013. [Google Scholar]

- Schiffers, R.; Kruppa, S.; Moser, S. Für jeden Schuss der richtige Umschaltpunkt. Kunststoffe 2014, 11, 58–63. [Google Scholar]

- activeLock—Sumitomo (SHI) Demag. Available online: https://www.sumitomo-shi-demag.eu/activelock (accessed on 11 October 2024).

- Runge, R. Verfahren zur Steuerung des Einspritzhubes Einer Spritzgieß-Schnecke. Patent DE 10 2008 037 098 A1, 8 August 2008. [Google Scholar]

- Schmied, M.; Hochreiter, E.; Steinbichler, G. Gesteuerter Schließvorgang, höchste Gewichtskonstanz. Kunststoffe 2013, 8, 70–72. [Google Scholar]

- Präzisionsspritzguss für Kunststoff-Produkte—ENGEL. Available online: https://www.engelglobal.com/de/de/produkte/spritzgiessverfahren/praezisionsspritzguss (accessed on 20 June 2024).

- Schmied, M. Rückstromsperre für eine Plastifizierschnecke einer Spritzgießmaschine. Patent DE 10 2012 015 337 A1, 2 August 2012. [Google Scholar]

- Xaloy® Front End Components, USA. 2021. Available online: https://xaloy.com/download/front-end-components-data-sheet/?tmstv=1728641978 (accessed on 11 October 2024).

- Hiroshi, W.; Shingo, K. Injection Molding Machine Having a Freely Rotatable Screw. Patent US 7,074,028 B2, 23 December 2003. [Google Scholar]

- Ma, Y.; Xu, Y.; Dang, K.; Fu, N.; Jiao, X.; Xie, P.; Yang, W. Study on the evaluation and compensating strategy for the wear damage of non-return valve during injection molding process. Polym. Eng. Sci. 2023, 63, 811–820. [Google Scholar] [CrossRef]

- Liu, J. Erhöhung der Reproduzierbarkeit des Spritzgießprozesses durch verbesserte Plastifizierkonzepte. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2010. [Google Scholar]

- Párizs, R.D.; Török, D.; Ageyeva, T.; Kovács, J.G. Multiple In-Mold Sensors for Quality and Process Control in Injection Molding. Sensors 2023, 23, 1735. [Google Scholar] [CrossRef]

- Bader, C.; Greco, L.; Christopherus, B.; Luigi, G. Process to Determine the Switch-Over Point in the Production of an Injection-Moulded Part. Patent EP 0 707 936 (A2), 11 September 1995. [Google Scholar]

- Gao, F.; Zhao, C. Method and Apparatus for the Control of Injection Molding. Patent US 6,309,571 B2, 27 February 1998. [Google Scholar]

- Zhou, H.; Zhao, P.; Feng, W. An integrated intelligent system for injection molding process determination. Adv. Polym. Technol. 2007, 26, 191–205. [Google Scholar] [CrossRef]

- Huang, M.-S. Process for Determining the Switchover Point from the Filling Program to the Holding Program in the Injection Molding Process. Patent TW000000529995B, 19 July 2001. [Google Scholar]

- Chen, K.-C.; Huang, M.-S. A process for Determining the Switchover Point from the Filling Program to the Holding Program in the Injection Molding. Process. Patent TW00000I495428B, 30 October 2013. [Google Scholar]

- Scheckenbach, T.; Wieland, R. Verfahren und Vorrichtung zur Regelung eines Spritzgießprozesses. Patent DE 41 40 392 C2, 7 December 1991. [Google Scholar]

- Tseng, R.-H.; Wen, C.-H.; Chang, C.-H.; Chen, Y.-H.; Tsai, C.-H.; Hwang, S.-J. Nozzle Pressure- and Screw Position-Based CAE Scientific Process Parameter Setup for Injection Molding Process. Polymers 2025, 17, 198. [Google Scholar] [CrossRef]

- Cheng, F.-J.; Chang, C.-H.; Wen, C.-H.; Hwang, S.-J.; Peng, H.-S.; Chu, H.-Y. Out-of-Mold Sensor-Based Process Parameter Optimization and Adaptive Process Quality Control for Hot Runner Thin-Walled Injection-Molded Parts. Polymers 2024, 16, 1057. [Google Scholar] [CrossRef]

- Kumar, S.; Park, H.S.; Lee, C.M. Data-driven smart control of injection molding process. CIRP J. Manuf. Sci. Technol. 2020, 31, 439–449. [Google Scholar] [CrossRef]

- Pillwein, G. Verfahren zur Quantifizierung von Prozessschwankungen bei Einem einspritzvorgang Einer Spritzgiessmaschine. Patent AT 511 391 A1, 18 October 2011. [Google Scholar]

- Pillwein, G.; Giessauf, J.; Steinbichler, G. Einfaches Umschalten auf konstante Qualität. Kunststoffe 2012, 9, 31–35. [Google Scholar]

- Koppauer, H.; Pillwein, G.; Springer, K.; Kilian, F.J. Verfahren zum Festlegen eines Sollwertverlaufs. Patent AT 523126 A1, 15 October 2019. [Google Scholar]

- Sasaki, K.; Kato, F.; Totani, T.; Iimura, Y.; Koike, J.; Tamaki, M.; Yamaguchi, M. Controlling Method of Switchover of Injection Speed for Electric Injection Molding Machine. Patent 11348084 A, 5 June 1998. [Google Scholar]

- Kelly, A.L.; Woodhead, M.; Rose, R.M.; Coates, P.D. In process monitoring of polymer batch to batch variation in injection moulding. Plast. Rubber Compos. 2000, 29, 23–30. [Google Scholar] [CrossRef]

- Kruppa, S. Adaptive Prozessführung und alternative Einspritzkonzepte beim Spritzgießen von Thermoplasten. Ph.D. Thesis, Universität Duisburg-Essen, Duisburg, Germany, 2015. [Google Scholar]

- KraussMaffei Technologies GmbH. APC Plus: Stabilität, Präzision und Kosteneffizienz in der Fertigung; KraussMaffei Technologies GmbH.: Parsdorf, Germany, 2017. [Google Scholar]

- Schiffers, R.; Moser, S.; Kruppa, S.; Busl, M. Verfahren zur Bestimmung eines realen Volumens einer spritzgießfähigen Masse in einem Spritzgießprozess. Patent DE 10 2015 117 237 B3, 9 October 2015. [Google Scholar]

- Gao, H.; Huang, Z.; Li, D.; Mao, T.; Zhang, Y.; Zhou, H.; Zhoun, X. Dynamic Adjustment Method for Plastic Injection Moulding Pressure-Keeping Switchover. Patent CN000104626494A, 12 December 2014. [Google Scholar]

- Zhou, X.; Zhang, Y.; Mao, T.; Zhou, H. Monitoring and dynamic control of quality stability for injection molding process. J. Mater. Process. Technol. 2017, 249, 358–366. [Google Scholar] [CrossRef]

- Chen, Y.-S.; Wu, K.-T.; Tsai, M.-H.; Hwang, S.-J.; Lee, H.-H.; Peng, H.-S.; Chu, H.-Y. Adaptive process control of the changeover point for injection molding process. J. Low Freq. Noise Vib. Act. Control. 2019, 40, 383–394. [Google Scholar] [CrossRef]

- Xu, Y.; Xie, P.; Fu, N.; Jiao, X.; Wang, J.; Liu, G.; Dou, X.; Zha, Y.; Dang, K.; Yang, W. Self-optimization of the V/P switchover and packing pressure for online viscosity compensation during injection molding. Polym. Eng. Sci. 2022, 62, 1114–1123. [Google Scholar] [CrossRef]

- Smud, S.M.; Harper, D.O.; Deshpande, P.B.; Leffew, K.W. Advanced process control for injection molding. Polym. Eng. Sci. 1991, 31, 1081–1085. [Google Scholar] [CrossRef]

- Moritzer, E.; Neumann, M. Process Monitoring and Optimisation in Injection Moulding with the Aid of New Measuring Sensors. In Proceedings of the ANTEC, New York, NY, USA, 2–6 May 1999. [Google Scholar]

- Chen, Z.; Turng, L.-S.; Wang, K.-K. Adaptive online quality control for injection-molding by monitoring and controlling mold separation. Polym. Eng. Sci. 2006, 46, 569–580. [Google Scholar] [CrossRef]

- Chen, Z.; Turng, L.-S. Injection molding quality control by integrating weight feedback into a cascade closed-loop control system. Polym. Eng. Sci. 2007, 47, 852–862. [Google Scholar] [CrossRef]

- Zhang, P.; Xie, P.; Yang, W. Study on mold separation-based precision injection molding method. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering (MACE), Wuhan, China, 26–28 June 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 5257–5260, ISBN 978-1-4244-7737-1. [Google Scholar]

- Jaeger, A. Nur noch volle Teile. Kunststoffe 2012, 102, 42–47. [Google Scholar]

- Chen, J.-Y.; Liu, C.-Y.; Huang, M.-S. Enhancement of Injection Molding Consistency by Adjusting Velocity/Pressure Switching Time Based on Clamping Force. Int. Polym. Process. 2019, 34, 564–572. [Google Scholar] [CrossRef]

- Engel Austria GmbH. Simulation Combined with the Real World: ENGEL Sim Link Data Interface Extended to Include CADMOULD; Engel Austria GmbH.: Schwertberg, Austria, 2021. [Google Scholar]

- Wagner, P.J.; Pillwein, G. Verfahren zum Bestimmen realer Formmassenfronten und zum Abgleich von Simulationen. Patent AT 523127 A1, 15 October 2019. [Google Scholar]

- Arburg GmbH + Co., KG. aXw Control FillAssist: Unterstützung von Füllstudien mit Füllbilddarstellung 682206_DE_012021; Arburg GmbH + Co. KG.: Loßburg, Germany, 2024. [Google Scholar]

- Duffner, E.; Filz, P.F. Sehen, was im Werkzeug passiert. Kunststoffe 2019, 10, 158–161. [Google Scholar]

- Johnston, S.P.; Kazmer, D.O.; Gao, R.X. Online simulation-based process control for injection molding. Polym. Eng. Sci. 2009, 49, 2482–2491. [Google Scholar] [CrossRef]

- Huang, S.-J.; Lee, T.-H. Application of Neural Networks in Injection Moulding Process Control. Int. J. Adv. Manuf. Technol. 2003, 21, 956–964. [Google Scholar] [CrossRef]

- Zhao, P.; Zhou, H.; He, Y.; Cai, K.; Fu, J. A nondestructive online method for monitoring the injection molding process by collecting and analyzing machine running data. Int. J. Adv. Manuf. Technol. 2014, 72, 765–777. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, Y.; Mao, T.; Ruan, Y.; Gao, H.; Zhou, H. Feature extraction and physical interpretation of melt pressure during injection molding process. J. Mater. Process. Technol. 2018, 261, 50–60. [Google Scholar] [CrossRef]

- Guo, W.; Deng, F.; Meng, Z.; Hua, L.; Mao, H.; Su, J. A hybrid back-propagation neural network and intelligent algorithm combined algorithm for optimizing microcellular foaming injection molding process parameters. J. Manuf. Process. 2020, 50, 528–538. [Google Scholar] [CrossRef]

- Huang, M.-S.; Liu, C.-Y.; Ke, K.-C. Calibration of cavity pressure simulation using autoencoder and multilayer perceptron neural networks. Polym. Eng. Sci. 2021, 61, 2511–2521. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Fan-Jiang, J.-C.; Liou, G.-Y.; Cheng, F.-J.; Hwang, S.-J.; Peng, H.-S.; Chu, H.-Y. Development of an Online Quality Control System for Injection Molding Process. Polymers 2022, 14, 1607. [Google Scholar] [CrossRef]

- Wu, D.-R.; Ong, J.-B.; Chen, Y.-J.; Li, J.-C.; Peng, H.-S.; Wei, L.-J. Study of Application of Taguchi’s Method and Neural Networks to Molding Characteristics Predictions. In Proceedings of the 2023 IEEE 5th Eurasia Conference on IOT, Communication and Engineering (ECICE), Yunlin, Taiwan, 27–29 October 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 815–820, ISBN 979-8-3503-1469-4. [Google Scholar]

- Borchardt, I.; Krauß, J.; Lambers, J.; Schüder, J. Approach for inline monitoring and optimization of a thermoplastic injection molding process with Bayesian networks taking the example of the quality feature weight. Procedia CIRP 2023, 118, 851–856. [Google Scholar] [CrossRef]

- Johnson, B. Evaluation of Novel Switch to Detect the Melt Flow Front in Injection Molding. In Proceedings of the ANTEC, Detroit, MI, USA, 18–21 March 2019. [Google Scholar]

- Müller, F.; Kukla, C.; Lucyshyn, T.; Harker, M.; Rath, G.; Holzer, C. Wireless in-mold melt front detection for injection molding: A long-term evaluation. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Gornik, C. Injection Molding Method Comprises Determining Compressibility and Flowability of Molding Composition and Calculating Content of Binder in Composition or Homogeneity of the Binder-Filler Mixture from This Data. Patent DE 10 2007 030 637 A1, 2 July 2007. [Google Scholar]

- Pillwein, G. Bestimmungsverfahren für das Kompressionsverhalten eines formbaren Materials. Patent AT 517128 A1, 11 May 2015. [Google Scholar]

- Rottenwalter, G.; Tilly, M.; Bielenberg, C.; Obermeier, K. Advancements in Synthetic Data Extraction for Industrial Injection Molding. In Progress in Artificial Intelligence; Moniz, N., Vale, Z., Cascalho, J., Silva, C., Sebastião, R., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 548–560. ISBN 978-3-031-49010-1. [Google Scholar]

- Topić, N. Auswirkungen der Styrolemission Ungesättigter Polyesterharze Auf Die Eigenschaften spritzgegossener Formteile. Ph.D. Thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg, Erlangen, Germany, 2022. [Google Scholar]

- Mayer, D.; Heienbrock, S.J.; Weißer, D.F.; Deckert, M.H. Processing recycled silicone powder in liquid silicone rubber injection molding and its influence on mechanical properties. Polym. Eng. Sci. 2024, 64, 4288–4297. [Google Scholar] [CrossRef]

- Barbaroux, M.; Stalet, G.; Regnier, G.; Trotignon, J.P. Determination of the Inter-Relationships Between Processing Conditions and Properties of an Injection Molded Silicone Ring Using an Experimental Design. Int. Polym. Process. 1997, 12, 174–181. [Google Scholar] [CrossRef]

- Giboz, J.; Copponnex, T.; Mélé, P. Microinjection molding of thermoplastic polymers: A review. J. Micromech. Microeng. 2007, 17, R96–R109. [Google Scholar] [CrossRef]

- Zhao, J.; Mayes, R.H.; Chen, G.; Xie, H.; Chan, P.S. Effects of process parameters on the micro molding process. Polym. Eng. Sci. 2003, 43, 1542–1554. [Google Scholar] [CrossRef]

| Cluster | Shot-to-Shot | In-Cycle | Mold Geometry | Material | Machine | Quality Criterion |

Pressure-gradient-dependent switchover | Extracting the correspondent screw position for a sudden pressure raise [24,85] | Detecting sudden pressure rise: | Flat [1,2,4,5,9,10,11,12,14,15,16,17,38,45,49,76,78,89,93,99,102,103,104,105,106,111,113,115,117,118,120] Box-shaped [24,81,85,86,93,98,114,119] Complexity above box-shaped [56,68] N/A [13,31,46,101] | PP [4,9,10,11,12,14,49,76,86,89,93,98,99,102,103,104,111,115,117,119] HDPE [45] LDPE [14] PA6 [5,45,93] PA66 GF30 [56] PBT [5,45] PS [38,105,113,118] PPE GF30 [24] PPA [46,68] ABS [1,2,16,17,78,81,106,119] PC [38,56,68,102,103,120] PC-ABS [56,68] PVC [15,113] SAN [85] N/A [13,31,101,114] | Electric [1,2,5,14,16,17,45,46,49,68,76,86,89,93,99,101,105,106,111,119] Hydraulic [4,9,10,11,12,24,38,56,68,78,85,98,99,101,102,103,113,117,118] N/A [13,31,81,104,114,115,120] | Weight [1,2,4,5,9,10,11,12,14,17,38,45,46,49,56,68,76,78,86,89,93,98,99,102,103,104,105,106,111,113,118,119,120] Dimensions [4,49] Warpage [24,115] Peak pressure, peak pressure time, and viscosity index [117] Surface characteristics [5] Simulation image [114] Correlation with cavity pressure curves [15,16,101] Ultrasonic signal [13] Filling stage [78,81,85] Flash [78] |

Utilizing reference data | Adjusting the switchover point to keep parameter constant:

| Trigger switchover point according to the following:

| ||||

| Adjusting the reference for time- or stroke-dependent switchover | Closure of NRV:

| In-mold sensor [4,120] Closure of non-return valve detected through the following:

| ||||

Machine learning | Predicting a switchover point through the following:

| Predicting cavity pressure with the following:

| ||||

Other switchover methods |

Melt front detection without in-mold sensors: |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bielenberg, C.; Stommel, M.; Karlinger, P. From Manual to Automated: Exploring the Evolution of Switchover Methods in Injection Molding Processes—A Review. Polymers 2025, 17, 1096. https://doi.org/10.3390/polym17081096

Bielenberg C, Stommel M, Karlinger P. From Manual to Automated: Exploring the Evolution of Switchover Methods in Injection Molding Processes—A Review. Polymers. 2025; 17(8):1096. https://doi.org/10.3390/polym17081096

Chicago/Turabian StyleBielenberg, Christian, Markus Stommel, and Peter Karlinger. 2025. "From Manual to Automated: Exploring the Evolution of Switchover Methods in Injection Molding Processes—A Review" Polymers 17, no. 8: 1096. https://doi.org/10.3390/polym17081096

APA StyleBielenberg, C., Stommel, M., & Karlinger, P. (2025). From Manual to Automated: Exploring the Evolution of Switchover Methods in Injection Molding Processes—A Review. Polymers, 17(8), 1096. https://doi.org/10.3390/polym17081096