Water Repellence and Oxygen and Water Vapor Barrier of PVOH-Coated Substrates before and after Surface Esterification

Abstract

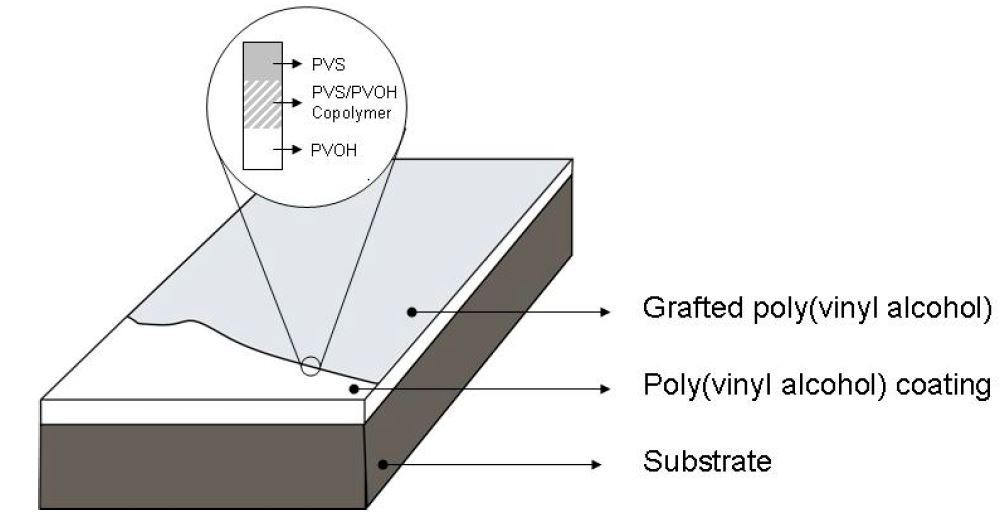

:1. Introduction

- How and to what extent do the degree of hydrolysis and the average molecular weight of PVOH influence the final material properties after grafting?

- How and to what extent does the carbon chain length of the fatty acid chloride affect the final material properties after grafting?

- Which water vapor permeation model applies for the grafted materials (pore diffusion or solubility diffusion model)?

- Does the surface esterification (grafting) support the oxygen barrier properties under single-side humidified measurement conditions?

2. Materials and Methods

2.1. Substrates

Paper and Regenerated Cellulose

| Product | Supplier | Basis weight | Thickness | Roughness front side; RMS |

|---|---|---|---|---|

| Paper for metalizing | Ahlstrom | 50.0 g/m2 | 45 μm | 0.24 μm |

| NatureFlex 42NP | Innovia Films | 60.0 g/m2 | 42 μm | 0.05 μm |

2.2. Coating and Grafting Materials

2.2.1. PVOH

| Trade names | Abbreviation used in this study | Viscosity in mPas of a 4 wt% aqueous solution at 20 °C | Degree of hydrolysis in mol% | Average molecular weight in g/mol |

|---|---|---|---|---|

| Poval 505 | P4-74 | 4.6 ± 0.4 | 73.5 ± 1.0 | 28,000 |

| Mowiol 4-88 | M4-88 | 4.0 ± 0.5 | 87.7 ± 1.0 | 31,000 |

| Mowiol 4-98 | M4-98 | 4.5 ± 0.5 | 98.4 ± 0.4 | 27,000 |

| Mowiol 6-98 | M6-98 | 6.0 ± 1.0 | 98.4 ± 0.4 | 47,000 |

| Mowiol 28-99 | M28-99 | 28 ± 2.0 | 99.4 ± 0.4 | 145,000 |

2.2.2. Fatty Acid Chlorides

| Product | Manufacturer | Chemical formula | Purity * | Boiling point * |

|---|---|---|---|---|

| Palmitoyl chloride | Merck KGaA (Darmstadt, Germany) | CH3(CH2)14COCl | ≥98% | 174 °C/0.5 kPa |

| Stearoyl chloride | TCI Deutschland GmbH (Eschborn, Germany) | CH3(CH2)16COCl | >97% | 178 °C/0.3 kPa |

2.3. Sample Preparation

2.3.1. Preparation of Aqueous PVOH Solutions

2.3.2. PVOH Coating

2.3.3. Storage

2.3.4. Chemical Grafting of Fatty Acid Chlorides onto PVOH Coated Substrates

2.4. Sample Characterization

2.4.1. Thickness

2.4.2. Water Vapor Transmission Rate

2.4.3. Oxygen Permeability

2.4.4. Contact Angle with Water

2.4.5. Infrared Spectroscopy: ATR-FTIR

3. Results and Discussion

3.1. Contact Angle with Water

3.2. WVTR before and after Grafting

| WVTR at 23 °C, (85%–0%) r.h. | Not grafted | C16 grafted | C18 grafted | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PVOH Type | Layer thickness (μm) | SD (μm) | WVTR (g/m2d) | SD (g/m2d) | WVTR (g/m2d) | SD (g/m2d) | BIF | SD | WVTR (g/m2d) | SD (g/m2d) | BIF | SD |

| Poval 505 (4-74) | 5.0 | 0.9 | 665 | 29 | 165 | 16 | 4.0 | 0.4 | 482 | 14 | 1.4 | 0.1 |

| Mowiol 4-88 | 5.8 | 0.8 | 692 | 46 | 92 | 34 | 7.6 | 2.9 | 209 | 24 | 3.3 | 0.4 |

| Mowiol 4-98 | 5.4 | 0.6 | 1017 | 42 | 54 | 5 | 18.9 | 1.8 | 117 | 22 | 8.7 | 1.7 |

| Mowiol 6-98 | 5.3 | 0.8 | 1007 | 30 | 66 | 5 | 15.2 | 1.2 | 115 | 9 | 8.7 | 0.7 |

| Mowiol 28-99 | 4.2 | 0.7 | 1046 | 61 | 60 | 4 | 17.5 | 1.7 | 125 | 19 | 8.4 | 1.3 |

3.3. Oxygen Permeability before and after Grafting

3.4. Infrared Spectroscopy: ATR-FTIR before and after Grafting

3.4.1. IR Absorption by Functional Groups

3.4.2. Approximate IR Penetration Depth

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cunha, A.G.; Gandini, A. Turning polysaccharides into hydrophobic materials: A critical review. Part 1. Cellulose. Cellulose 2010, 17, 875–889. [Google Scholar]

- Schmid, M.; Hinz, L.-V.; Wild, F.; Noller, K. Effects of hydrolysed whey proteins on the techno-functional characteristics of whey protein-based films. Materials 2013, 6, 927–940. [Google Scholar]

- Schmid, M.; Hammann, F.; Winkler, H. Technofunctional properties of films made from ethylene vinyl acetate/whey protein isolate compounds. Packag. Technol. Sci. 2013, 27, 521–533. [Google Scholar] [CrossRef]

- Schmid, M. Properties of cast films made from different ratios of whey protein isolate, hydrolysed whey protein isolate and glycerol. Materials 2013, 6, 3254–3269. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Schmid, M.; Nerney, O.M.; Wildner, J.; Smykala, L.; Lazzeri, A.; Cinelli, P. Processing and validation of whey-protein-coated films and laminates at semi-industrial scale as novel recyclable food packaging materials with excellent barrier properties. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Schmid, M.; Dallmann, K.; Bugnicourt, E.; Cordoni, D.; Wild, F.; Lazzeri, A.; Noller, K. Properties of whey protein coated films and laminates as novel recyclable food packaging materials with excellent barrier properties. Int. J. Polym. Sci. 2012, 2012. [Google Scholar] [CrossRef]

- Schmid, M.; Benz, A.; Stinga, C.; Samain, D.; Zeyer, K.P. Fundamental investigations regarding barrier properties of grafted PVOH layers. Int. J. Polym. Sci. 2012, 2012. [Google Scholar] [CrossRef]

- Endres, H.-J.; Siebert-Raths, A. Engineering Biopolymers—Markets, Manufacturing, Properties and Applications; Carl Hanser-Verlag: München, Germany, 2011. [Google Scholar]

- Endres, H.-J.; Siebert-Raths, A. Technische Biopolymere: Rahmenbedingungen, Marktsituation, Herstellung, Aufbau und Eigenschaften; Carl Hanser-Verlag: München, Germany, 2009; Volume 1. [Google Scholar]

- Roy, D.; Semsarilar, M.; Guthrie, J.T.; Perrier, S. Cellulose modification by polymer grafting: A review. Chem. Soc. Rev. 2009, 38, 2046–2064. [Google Scholar] [CrossRef] [PubMed]

- Yam, K.L. The Wiley Encyclopedia of Packaging Technology, 3rd ed.; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Cecutti, C.; Mouloungui, Z.; Gaset, A. Synthesis of new diesters of 1,4:3,6-dianhydro-d-glucitol by esterification with fatty acid chlorides. Bioresour. Technol. 1998, 66, 63–67. [Google Scholar] [CrossRef]

- Diamantoglou, M.; Kundinger, E.F. Derivatization of Cellulose in Homogeneous Reaction. In Cellulose and Cellulose Derivatives: Cellucon’93 Proceedings: Physico-Chemical Aspects and Industrial Applications; Kennedy, J.F., Phillips, G.O., Williams, P.A., Piculell, J.L., Eds.; Elsevier: Amsterdam, The Netherlands, 1995; pp. 141–152. [Google Scholar]

- Enthaler, S. Application of fatty acid chlorides in the iron-catalyzed depolymerization of polyethers. Eur. J. Lipid Sci. Technol. 2013, 115, 239–245. [Google Scholar] [CrossRef]

- Fang, J.M.; Fowler, P.A.; Tomkinson, J.; Hill, C.A.S. An investigation of the use of recovered vegetable oil for the preparation of starch thermoplastics. Carbohydr. Polym. 2002, 50, 429–434. [Google Scholar] [CrossRef]

- Grote, C.; Heinze, T. Starch derivatives of high degree of functionalization 11: Studies on alternative acylation of starch with long-chain fatty acids homogeneously in N,N-dimethyl acetamide/LiCl. Cellulose 2005, 12, 435–444. [Google Scholar]

- Sonntag, N.O.V.; Trowbridge, J.R.; Krems, I.J. Reactions of fatty acid chlorides. I. Preparation of fatty acid anhydrides. J. Am. Oil Chem. Soc. 1954, 31, 151–157. [Google Scholar]

- Aburto, J.; Alric, I.; Borredon, E. Preparation of long-chain esters of starch using fatty acid chlorides in the absence of an organic solvent. Starch-Staerke 1999, 51, 132–135. [Google Scholar] [CrossRef]

- Chang, F.; Masaki, T.; Kurachi, K.; Isobe, Y.; Onimura, K.; Oishi, T. Synthesis of polymer blends using waste pulp modified with alkyl ester groups. Kobunshi Ronbunshu 2007, 64, 254–260. [Google Scholar] [CrossRef]

- Gourson, C.; Benhaddou, R.; Granet, R.; Krausz, P.; Verneuil, B.; Branland, P.; Chauvelon, G.; Thibault, J.F.; Saulnier, L. Valorization of maize bran to obtain biodegradable plastic films. J. Appl. Polym. Sci. 1999, 74, 3040–3045. [Google Scholar] [CrossRef]

- Ratanakamnuan, U.; Atong, D.; Aht-Ong, D. Cellulose esters from waste cotton fabric via conventional and microwave heating. Carbohydr. Polym. 2012, 87, 84–94. [Google Scholar] [CrossRef]

- Vaca-Garcia, C.; Thiebaud, S.; Borredon, M.E.; Gozzelino, G. Cellulose esterification with fatty acids and acetic anhydride in lithium chloride/N,N-dimethylacetamide medium. J. Am. Oil Chem. Soc. 1998, 75, 315–319. [Google Scholar] [CrossRef]

- Yasuda, M.; Watanabe, S.; Goda, T.; Ogino, H. Synthesis of oil absorbent polymer material having hydrophobic group and evaluation of their ability. Kagaku Kogaku Ronbunshu 2010, 36, 526–531. [Google Scholar]

- Talja, R.A.; Kulomaa, T.P.S.; Labafzadeh, S.; Kyllönen, L.E.; King, A.W.T.; Kilpeläinen, I.; Poppius-Levlin, K. Cellulose esters from birch kraft pulps—New biomaterials for barrier coating. In Proceedings of the 16th International Symposium on Wood, Fiber and Pulping Chemistry, ISWFPC, Tianjin, China, 8–10 June 2011.

- Baba, T.; Nagasawa, N.; Ito, H.; Yaida, O.; Miyamoto, T. Recovery of surface properties of damaged wool fibers. Text. Res. J. 2001, 71, 885–890. [Google Scholar] [CrossRef]

- Pandey, K.K.; Nagaveni, H.C.; Mahadevan, K.M. Fungal resistance of rubber wood modified by fatty acid chlorides. Int. Biodeterior. Biodegrad. 2011, 65, 890–895. [Google Scholar] [CrossRef]

- Memmi, A.; Granet, R.; Gahbiche, M.A.; Fekih, A.; Bakhrouf, A.; Krausz, P. Fatty esters of cellulose from olive pomace and barley bran: Improved mechanical properties by metathesis crosslinking. J. Appl. Polym. Sci. 2006, 101, 751–755. [Google Scholar] [CrossRef]

- Namazi, H.; Fathi, F.; Dadkhah, A. Hydrophobically modified starch using long-chain fatty acids for preparation of nanosized starch particles. Sci. Iran. 2011, 18, 439–445. [Google Scholar]

- Neumann, U.; Wiege, B.; Warwel, S. Synthesis of hydrophobic starch esters by reaction of starch with various carboxylic acid imidazolides. Starch-Staerke 2002, 54, 449–453. [Google Scholar]

- Prakash, G.K.; Mahadevan, K.M. Enhancing the properties of wood through chemical modification with palmitoyl chloride. Appl. Surf. Sci. 2008, 254, 1751–1756. [Google Scholar]

- Salla, J.; Pandey, K.K.; Prakash, G.K.; Mahadevan, K.M. Photobleaching and dimensional stability of rubber wood esterified by fatty acid chlorides. J. Wood Chem. Technol. 2012, 32, 121–136. [Google Scholar] [CrossRef]

- Thiebaud, S.; Aburto, J.; Alric, I.; Borredon, E.; Bikiaris, D.; Prinos, J.; Panayiotou, C. Properties of fatty-acid esters of starch and their blends with LDPE. J. Appl. Polym. Sci. 1997, 65, 705–721. [Google Scholar] [CrossRef]

- Thiebaud, S.; Borredon, M.E. Solvent-free wood esterification with fatty acid chlorides. Bioresour. Technol. 1995, 52, 169–173. [Google Scholar] [CrossRef]

- Thiebaud, S.; Borredon, M.E.; Baziard, G.; Senocq, F. Properties of wood esterified by fatty-acid chlorides. Bioresour. Technol. 1997, 59, 103–107. [Google Scholar] [CrossRef]

- Shaikh, S.; Asrof Ali, S.K.; Hamad, E.Z.; Al-Nafaa, M.; Al-Jarallah, A.; Abu-Sharkh, B. Synthesis, characterization, and solution properties of hydrophobically modified poly(vinyl alcohol). J. Appl. Polym. Sci. 1998, 70, 2499–2506. [Google Scholar] [CrossRef]

- Langowski, H.-C. Permeation of gases and condensable substances through monolayer and multilayer structures. In Plastic Packaging, Interactions with Food and Pharmaceuticals, 2nd ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2008; pp. 297–347. [Google Scholar]

- Müller, K. Multilayer films for bag-in-container systems used in disposable kegs: Basic principles of possible barrier concepts. Brew. Sci. 2013, 66, 31–36. [Google Scholar]

- Axelson-Larsson, L. Oxygen permeability at high temperatures and relative humidities. Packag. Technol. Sci. 1992, 5, 297–306. [Google Scholar] [CrossRef]

- Lahtinen, K.; Kuusipalo, J. Statistical model predicting water vapor transmission rates of high-barrier-coated papers. In Proceedings of the 67th Annual Technical Conference & Exhibition, Society of Plastics Engineers, Chicago, IL, USA, 22–24 June 2009.

- Stinga, N.C. Utilisation de la chimie chromatogénique pour la conception et la réalisation de matériaux cellulosiques barrières à l’eau, aux graisses et aux gaz. Ph.D. Thesis, Universite Joseph Fourier, Grenoble, France, 2008; p. 242. [Google Scholar]

- Anonymous. Mowiol—Polyvinyl Alcohol; Kuraray Specialities Europe KSE GmbH: Frankfurt am Main, Germany, 2003. [Google Scholar]

- Samain, D. Method for Treating a Solid Material to Make it Hydrophobic, Material Obtained and Uses. US6342268, 29 January 2002. [Google Scholar]

- Schmid, M.; Samain, D. Improved barrier properties for Innovative food packaging applications by nanoscale surface modification—A chemical grafting process. In Proceedings of the BIOPOLPACK 2nd Congress on Biodegradable Polymer Packaging, Milan, Italy, 10–11 May 2012.

- Stinga, N.C.; Samain, D.; Guerin, D. Film Having Water, Grease, Gas and Water Vapour Barrier Properties. US20110014458, 20 January 2011. [Google Scholar]

- Deutsches Institut für Normung (DIN). Testing of Plastics and Elastomer Films, Paper, Board and other Sheet Materials—Determination of Water Vapour Transmission—Part 1: Gravimetric Method; Beuth Verlag GmbH: Berlin, Germany, 2001. [Google Scholar]

- Langowski, H.-C. Flexible Materialien mit ultrahohen Barriereeigenschaften. Flexible ultra high barrier materials. Vak. Forsch. Prax. 2002, 14, 297–302. [Google Scholar] [CrossRef]

- Langowski, H.-C. Stofftransport durch polymere und anorganische Schichten. Transport of substances through polymeric and inorganic layers. Vak. Forsch. Prax. 2005, 17, 6–13. [Google Scholar]

- Miesbauer, O.; Langowski, H.-C. Nanoskalige Komponenten in Barrierefolien. In Nanotechnologie in der Lebensmittelindustrie : zum Kenntnisstand nanoskaliger Wirkstoffcarrier in Lebensmitteln und Verpackungsmaterialien; Weber, H., Ed.; Behr’s Verlag: Hamburg, Germany, 2010; pp. 45–67. [Google Scholar]

- Deutsches Institut für Normung (DIN). Testing of Plastics—Determination of Gas Transmission Rate—Part 3: Oxygenspecific Carrier Gas Method for Testing of Plastic Films and Plastics Mouldings; Beuth Verlag GmbH: Berlin, Germany, 1998. [Google Scholar]

- Günzler, H.; Heise, H.M. IR-Spektrospkopie: Eine Einführung; VCH Verlagsgesellschaft mbH: Weinheim, Germany, 1996. [Google Scholar]

- Penn, L.S.; Wang, H. Chemical modification of polymer surfaces: A review. Polym. Adv. Technol. 1994, 5, 809–817. [Google Scholar] [CrossRef]

- Hallensleben, M.L. Polyvinyl compounds, others. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2000. [Google Scholar]

- Matricarde Falleiro, R.M.; Akisawa Silva, L.Y.; Meirelles, A.J.A.; Krähenbühl, M.A. Vapor pressure data for fatty acids obtained using an adaptation of the DSC technique. Therm. Acta 2012, 547, 6–12. [Google Scholar] [CrossRef]

- Hanika, M.; Langowski, H.C.; Moosheimer, U.; Peukert, W. Inorganic layers on polymer films-Influence of defects and morphology on barrier properties. Chem. Eng. Technol. 2003, 26, 605–614. [Google Scholar] [CrossRef]

- Mueller, K.; Schoenweitz, C.; Langowski, H.C. Thin laminate films for barrier packaging application—Influence of down gauging and substrate surface properties on the permeation properties. Packag. Technol. Sci. 2012, 25, 137–148. [Google Scholar] [CrossRef]

- Belitz, H.-D.; Grosch, W.; Schieberle, P. Lehrbuch der Lebensmittelchemie, 6th ed.; Springer: Berlin, Germany, 2008. (In German) [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmid, M.; Sängerlaub, S.; Miesbauer, O.; Jost, V.; Werthan, J.; Stinga, C.; Samain, D.; Stramm, C.; Noller, K.; Müller, K. Water Repellence and Oxygen and Water Vapor Barrier of PVOH-Coated Substrates before and after Surface Esterification. Polymers 2014, 6, 2764-2783. https://doi.org/10.3390/polym6112764

Schmid M, Sängerlaub S, Miesbauer O, Jost V, Werthan J, Stinga C, Samain D, Stramm C, Noller K, Müller K. Water Repellence and Oxygen and Water Vapor Barrier of PVOH-Coated Substrates before and after Surface Esterification. Polymers. 2014; 6(11):2764-2783. https://doi.org/10.3390/polym6112764

Chicago/Turabian StyleSchmid, Markus, Sven Sängerlaub, Oliver Miesbauer, Verena Jost, Johannes Werthan, Camelia Stinga, Daniel Samain, Cornelia Stramm, Klaus Noller, and Kajetan Müller. 2014. "Water Repellence and Oxygen and Water Vapor Barrier of PVOH-Coated Substrates before and after Surface Esterification" Polymers 6, no. 11: 2764-2783. https://doi.org/10.3390/polym6112764

APA StyleSchmid, M., Sängerlaub, S., Miesbauer, O., Jost, V., Werthan, J., Stinga, C., Samain, D., Stramm, C., Noller, K., & Müller, K. (2014). Water Repellence and Oxygen and Water Vapor Barrier of PVOH-Coated Substrates before and after Surface Esterification. Polymers, 6(11), 2764-2783. https://doi.org/10.3390/polym6112764