Comparative Analysis of the Thermal Insulation of Traditional and Newly Designed Protective Clothing for Foundry Workers

Abstract

:1. Introduction

2. Selection Procedure of Appropriate Assembly for the Foundry Worker Clothing

2.1. State of the Art

2.2. Materials

2.3. Measurement Methods Used for the Selection Procedure

2.4. Results of Thermal Resistance Measurements and the Final Choice

3. Measurement of Clothing Insulation on the Thermal Manikins

3.1. State of the Art

3.2. Materials

3.3. Methodology

- It is the total thermal insulation of clothing;

- Tsi is the temperature of the shell surface of the i-th manikin segment, °C;

- Ta is the air temperature in the climatic chamber, °C;

- Hci is the value of electrical power transmitted through the i-th manikin segment, W/m2;

- fi is the coefficient of the area of the i-th manikin segment calculated on the basis of Equation (2):where:

- ai is the area of the i-th manikin segment, m2;

- A is the total area of the manikin body.

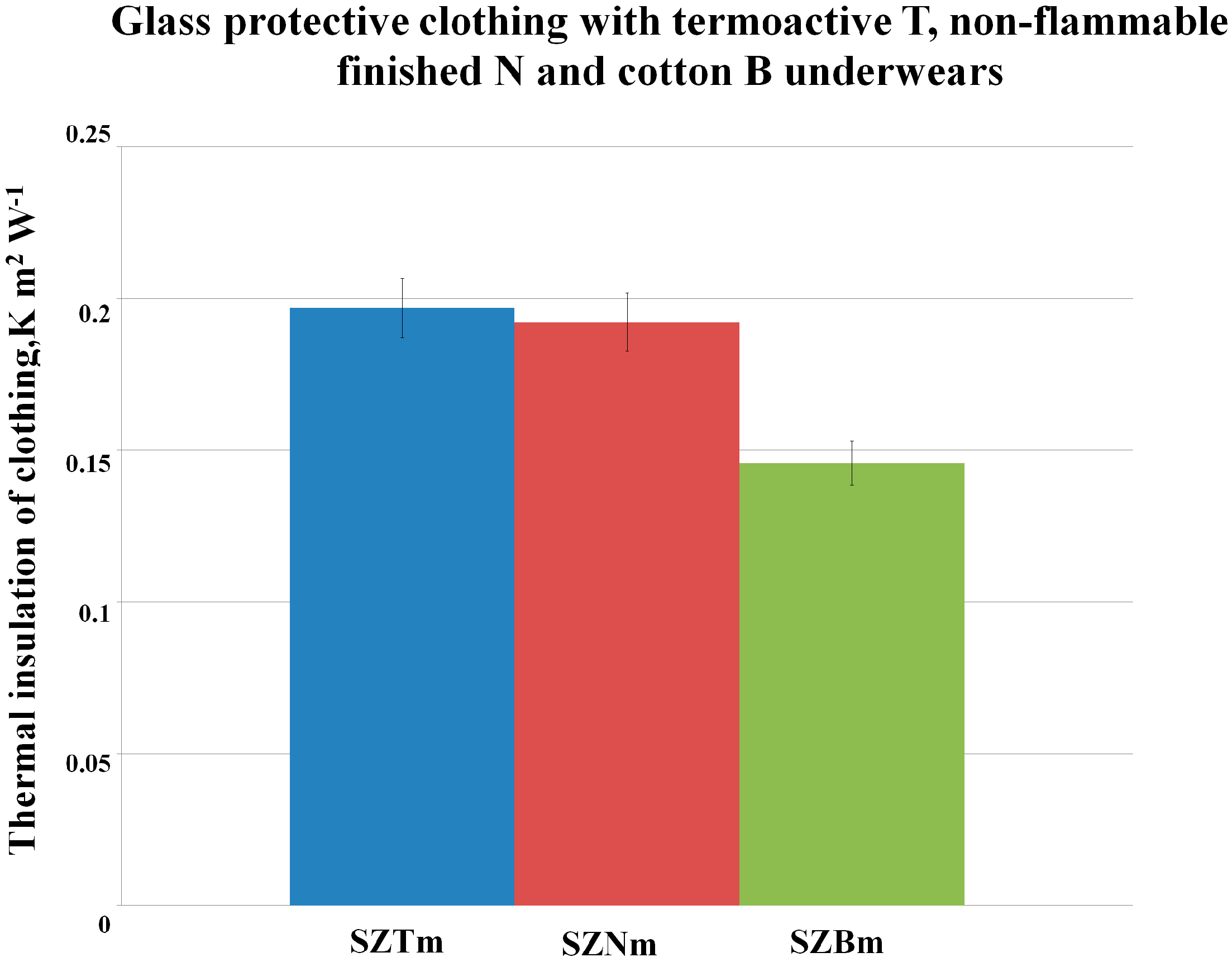

3.4. Results

4. Summary

Author Contributions

Conflicts of Interest

References

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and composite. Compos. B 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Hao, L.; Weidong, Y. Comparison of thermal protective performance of aluminized fabrics of basalt fiber and glass fiber. Fire Mater. 2011, 35, 553–560. [Google Scholar] [CrossRef]

- Singha, K. A Short Review on Basalt Fiber. Int. J. Text. Sci. 2012, 1, 19–28. [Google Scholar]

- Hrynyk, R.; Frydrych, I.; Irzmańska, E.; Stefko, A. Thermal properties of aluminized and non-aluminized basalt fabrics. Text. Res. J. 2013, 83, 1860–1872. [Google Scholar] [CrossRef]

- Xia, J.; Wang, L.; Luo, H. The present development situation and development tread of flame-retardant materials. Chin. J. Appl. Chem. 2015, 34, 1–4. [Google Scholar]

- Dolez, P.I.; Vu-Khanh, T. Recent developments and needs in material used for personal protective equipment and their testing. Int. J. Occup. Saf. Ergon. 2009, 15, 347–362. [Google Scholar] [CrossRef] [PubMed]

- Huang, N.; Wang, S. The application and development of contrapuntal aramid in protection textiles. J. Hightech. Fiber Appl. 2001, 2, 23–26. [Google Scholar]

- Qi, F.; Li, J.; Li, C. The overview of continuous basalt fiber. J. Hightech. Fiber Appl. 2006, 31, 42–46. [Google Scholar]

- Cui, Y. The basic performance of continuous basalt fiber. J. Text. Res. 2005, 26, 57–60. [Google Scholar]

- Militky, J.; Kovacic, V. Ultimate Mechanical Properties of Basalt Filaments. Text. Res. J. 1996, 66, 225–229. [Google Scholar] [CrossRef]

- Militky, J.; Kovacic, V.; Rubnerova, J. Influence of thermal treatment on tensile failure of basalt fibers. Eng. Fract. Mech. 2002, 69, 1025–1033. [Google Scholar] [CrossRef]

- Hu, X.; Chen, S. The development trend of world composite materials and development opportunities of continuous basalt fiber. J. Hightech. Fiber Appl. 2005, 30, 9–12. [Google Scholar]

- Shi, Q. The development and application of foreign basalt fiber. J. Glassfiber 2013, 4, 27–31. [Google Scholar]

- Mao, J.; Dong, W. The performance and application prospect of basalt fiber. J. Ind. Text. 2007, 10, 38–40. [Google Scholar]

- Cooke, T.F. Inorganic fibres—A literature review. J. Am. Ceram. Soc. 1991, 74, 2959–2978. [Google Scholar] [CrossRef]

- Gilewicz, P.; Dominiak, J.; Cichocka, A.; Frydrych, I. Change in Structural and Thermal Properties of Textile Fabric Packages Containing Basalt Fibres after Fatigue Bending Loading. Fibres Text. East. Eur. 2013, 21, 80–84. [Google Scholar]

- Hrynyk, R.; Frydrych, I. Study on textile assemblies with aluminized basalt fabrics destined for protective clothing. Int. J. Cloth. Sci. Tech. 2015, 27, 705–719. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. PN-EN 12127:2000: Textiles-Fabrics-Determination of Mass per Unit Area Using Small Samples (EN 12127:1997); Polish Committee for Standardization: Warsaw, Poland, 2000. [Google Scholar]

- Polish Committee for Standardization. PN-EN ISO 5084:1999: Textiles-Determination of Thickness of Textiles and Textile Products (ISO 5084:1996); Polish Committee for Standardization: Warsaw, Poland, 1999. [Google Scholar]

- International Organization for Standardization. ISO 15025:2000: Protective Clothing-Protection against Heat and Flame-Method of Test for Limited Flame Spread; International Organization for Standardization: Geneva, Switzerland, 2000. [Google Scholar]

- Polish Committee for Standardization. PN-EN 702:2002: Elements of Electrical and Optical Connection. Test Methods. Electrical Elements. Measurement of Signal Distortion of Couplers (EN 2591-702:2001); Polish Committee for Standardization: Warsaw, Poland, 2002. [Google Scholar]

- Polish Committee for Standardization. PN-EN ISO 367:1996: Heat Penetration Parameter under the Action of Flame; Polish Committee for Standardization: Warsaw, Poland, 1996. [Google Scholar]

- Polish Committee for Standardization. PN-EN ISO 6942:2005: Protective Clothing. Protection against Heat and Fire. Method of Test: Evaluation of Materials and Material Assemblies When Exposed to a Source of Radiant Heat (EN ISO 6942:2002); Polish Committee for Standardization: Warsaw, Poland, 2005. [Google Scholar]

- Polish Committee for Standardization. PN-EN ISO 9185:2009: Protective Clothing-Assessment of Resistance of Materials to Molten Metal Splash (UNI EN ISO 9185:2008); Polish Committee for Standardization: Warsaw, Poland, 2009. [Google Scholar]

- Polish Committee for Standardization. PN-EN ISO 11612:2011: Protective Clothing-Clothing to Protect against Heat and Flame (ISO 11612:2008); Polish Committee for Standardization: Warsaw, Poland, 2011. [Google Scholar]

- Redortier, B.; Voelcker, T.; Jacob, B. Manikin vs human for sports. In Proceedings of Ambience14&10I3M, Scientific Conference for Smart and Functional Textiles, Well-Being, Thermal Comfort in Clothing, Design, Thermal Manikins and Modelling, Tampere, Finland, 7–9 September 2014; Tampere University of Technology: Tampere, Filand.

- Bogdan, A.; Zwolińska, M. Future Trends in the Development of Thermal Manikins Applied for the Design of Clothing Thermal Insulation. Fibres Text. East. Eur. 2012, 93, 89–95. [Google Scholar]

- Oliviera, A.V.M.; Gaspar, A.R.; Quintela, D.A. Dynamic clothing insulation. Measurement with a thermal manikin operating under the thermal comfort regulation mode. Appl. Ergon. 2011, 42, 890–899. [Google Scholar] [CrossRef] [PubMed]

- Holmér, I. Thermal manikin history and applications. Appl. Phys. 2004, 92, 614–618. [Google Scholar]

- Konarska, M.; Sołtyński, K.; Sudoł-Szopińska, I.; Młodniak, D.; Chojnacka, A. Aspects of Standardisation in Measuring Thermal Clothing Insulation on a Thermal Manikin. Fibres Text. East. Eur. 2006, 58, 58–63. [Google Scholar]

- Fan, J.; Qian, X. New functions and applications of Walter, the sweating fabric manikin. Eur. J. Appl. Phys. 2004, 92, 641–644. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Havenith, G.; Mayor, T.S.; Kuklane, K.; Léonard, J.; Zwolinska, M.; Hodder, S.; Wong, C.; Kishino, J.; Dai, X. Clothing real evaporative resistance determined by means of a sweating thermal manikin: A new round-robin study. In Proceedings of Ambience14&10I3M, Scientific Conference for Smart and Functional Textiles, Well-Being, Thermal Comfort in Clothing, Design, Thermal Manikins and Modelling, Tampere, Finland, 7–9 September 2014; Tampere University of Technology: Tampere, Finland.

- Mayor, T.; Wang, F.; Léonard, J.; Ribeiro, M. An interlaboratory study on measurements of clothing evaporative resistance with thermal manikins. In Proceedings of The 5th European Conference on Protective Clothing and NOKOBETEF 10, Valencia, Spain, 29–31 May 2012. [CrossRef]

- Konarska, M.; Sołtyński, K.; Sudoł-Szopińska, I.; Chojnacka, A. Comparative Evaluation of Clothing Thermal Insulation Measured on a Thermal Manikin and on Volunteers. Fibres Text. East. Eur. 2007, 2, 73–79. [Google Scholar]

- Zwolińska, M. Case Study of the Impact of Motorcycle Clothing on the Human Body and its Thermal Insulation. Fibres Text. East. Eur. 2013, 21, 124–130. [Google Scholar]

- Zwolińska, M.; Bogdan, A.; Delczyk-Olejniczak, B.; Robak, D. Bulletproof Vest Thermal Insulation Properties vs. User Thermal Comfort. Fibres Text. East. Eur. 2013, 5, 105–111. [Google Scholar]

- Bogdan, A.; Sudoł-Szopińska, I.; Szopiński, T. Assessment of Textiles for Use in Operating Theatres with Respect to the Thermal Comfort of Surgeons. Fibres Text. East. Eur. 2011, 19, 65–69. [Google Scholar]

- Bendkowska, W.; Kłonowska, M.; Kopias, K.; Bogdan, A. Thermal Manikin Evaluation of PCM Cooling Vests. Fibres Text. East. Eur. 2010, 18, 70–74. [Google Scholar]

- Guo, X.-F.; Wang, Y.-Y.; Li, J. Evaluation of Adjustable Thermal Insulations of Tibetan Clothing by Manikin Testing. Fibres Text. East. Eur. 2013, 21, 87–91. [Google Scholar]

- Wang, F. Comparisons of Thermal and Evaporative Resistances of Kapok Coats and Traditional Down Coats. Fibres Text. East. Eur. 2010, 18, 75–78. [Google Scholar]

- Polish Committee for Standardization. PN-EN ISO 15831:2006: Clothing-Physiological Effects-Measurement of Thermal Insulation by Means of a Thermal Manikin (ISO 15831:2004); Polish Committee for Standardization: Warszawa, Poland, 2006. [Google Scholar]

- Thermal Manikins for Scientific and Industrial Use. Available online: http://pt-teknik.dk/thermalmanikin (accessed on 20 December 2014).

- Holmér, I. Protective Clothing in Hot Environments. Ind. Health 2006, 44, 404–413. [Google Scholar] [CrossRef] [PubMed]

| Fabric | Aluminized glass fabric ST 97 | Cotton fabric with flame-retardant finishing | Wool fabric with flame-retardant finishing | Aluminized basalt fabric | Aluminized basalt fabric |

|---|---|---|---|---|---|

| Symbol | SZ | BN | WN | BAZ | BAZ1 |

| Mass per square meter (g/m2) | 430 | 250 | 566 | 440 | 319 |

| Thickness (mm) | 0.56 | 0.60 | 5.31 | 0.49 | 0.35 |

| Weave | twill | plain | twill | twill | plain |

| Properties | SZ/BN | SZ/WN | BAZ/BN | BAZ/WN | BAZ1/BN | BAZ1/WN |

|---|---|---|---|---|---|---|

| Resistance to big metal splashes (g) | >220 3 level | >220 3 level | >220 3 level | >220 3 level | >220 3 level | >220 3 level |

| Resistance to contact heat at 250 °C | 7.4 s 1 level | 16.4 s 3 level | 8.0 s 1 level | 17.0 s 1 level | 7.8 s 1 level | 16.4 s 3 level |

| Resistance to convective heat HTI(24) (s) | 9.3 1 level | 13.5 2 level | 7.4 1 level | 13.6 2 level | 7.1 1 level | 13.4 2 level |

| Resistance to radiation heat RHTI(24) (s) | 41.9 2 level | 78.7 3 level | 150.3 4 level | 278.9 4 level | 184.7 4 level | 235.7 4 level |

| Kind of underwear | Symbol of underwear | Stitch | Mass per square meter (g/m2) | Thickness (mm) | Lk/1 (cm) | Lr/1 (cm) | Raw material content |

|---|---|---|---|---|---|---|---|

| Cotton | B | Plain | 220 | 0.81 | 10 | 17 | 100% cotton |

| Thermo-active | T | Plated plain with jacquard elements | 155 | 0.70 | 16 | 18 | 54% PA (polyamide), 44% PES (polyester), 2% Elastane |

| Non-flammable finished | N | Plated plain | 158 | 0.71 | 15 | 22 | 54% Modal Protect, 27% cotton, 19% PA (polyamide) |

| Kind of underwear | Symbol of underwear | Set of clothing |

|---|---|---|

| Cotton | B | Basalt (BAZm) |

| Thermo-active | T | Basalt (BAZm) |

| Flame-retardant | N | Basalt (BAZm) |

| Cotton | B | Glass (SZm) |

| Thermo-active | T | Glass (SZm) |

| Flame-retardant | N | Glass (SZm) |

| Number of segments | Name of segment | Area of segment (m2) |

|---|---|---|

| 1 | Left Low leg | 0.0975 |

| 2 | Right Low leg | 0.0975 |

| 3 | Left Front Thigh | 0.0858 |

| 4 | Right Front Thigh | 0.0858 |

| 5 | Left Back Thigh | 0.0858 |

| 6 | Left Back Thigh | 0.0858 |

| 7 | Pelvis | 0.0558 |

| 8 | Left Back side | 0.0408 |

| 9 | Right Back side | 0.0408 |

| 10 | Left Forearm | 0.05 |

| 11 | Right Forearm | 0.05 |

| 12 | Left Upper arm | 0.073 |

| 13 | Right Upper arm | 0.078 |

| 14 | Left Chest | 0.07 |

| 15 | Right Chest | 0.07 |

| 16 | Left Back | 0.065 |

| 17 | Right back | 0.065 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frydrych, I.; Cichocka, A.; Gilewicz, P.; Dominiak, J. Comparative Analysis of the Thermal Insulation of Traditional and Newly Designed Protective Clothing for Foundry Workers. Polymers 2016, 8, 348. https://doi.org/10.3390/polym8100348

Frydrych I, Cichocka A, Gilewicz P, Dominiak J. Comparative Analysis of the Thermal Insulation of Traditional and Newly Designed Protective Clothing for Foundry Workers. Polymers. 2016; 8(10):348. https://doi.org/10.3390/polym8100348

Chicago/Turabian StyleFrydrych, Iwona, Agnieszka Cichocka, Paulina Gilewicz, and Justyna Dominiak. 2016. "Comparative Analysis of the Thermal Insulation of Traditional and Newly Designed Protective Clothing for Foundry Workers" Polymers 8, no. 10: 348. https://doi.org/10.3390/polym8100348

APA StyleFrydrych, I., Cichocka, A., Gilewicz, P., & Dominiak, J. (2016). Comparative Analysis of the Thermal Insulation of Traditional and Newly Designed Protective Clothing for Foundry Workers. Polymers, 8(10), 348. https://doi.org/10.3390/polym8100348