A New Insight in Determining the Percolation Threshold of Electrical Conductivity for Extrinsically Conducting Polymer Composites through Different Sigmoidal Models

Abstract

:1. Introduction

2. Materials, Methods, and Characterization

2.1. Materials

2.2. Preparation of Composites and Samples

2.3. Measurement of DC Resistivity

3. Results and Discussion

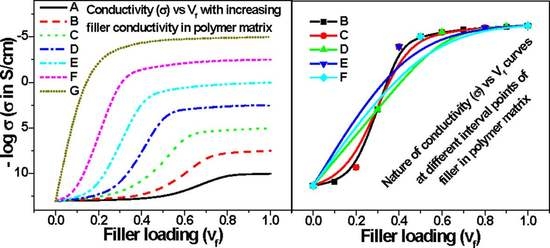

3.1. Origin of the Concept

3.2. Derivation of Percolation Threshold and Sigmoidal–Boltzmann Model

3.3. Sigmoidal–Dose Response Model

3.4. Sigmoidal–Hill Model

3.5. Sigmoidal–Logistic Model

3.6. Sigmoidal–Logistic-1 Model

3.7. Classical Percolation Theory and Model Comparison

3.8. Applicability of Sigmoidal Models to Other Published Polymer Composite Systems

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rahaman, M.; Chaki, T.K.; Khastgir, D. Temperature dependent electrical properties of conductive composites (behavior at cryogenic temperature and high temperatures). Adv. Mater. Res. 2010, 123–125, 447–450. [Google Scholar] [CrossRef]

- Rahaman, M.; Chaki, T.K.; Khastgir, D. Development of high performance EMI shielding material from EVA, NBR, and their blends: Effect of carbon black structure. J. Mater. Sci. 2011, 46, 3989–3999. [Google Scholar] [CrossRef]

- Sohi, N.J.S.; Rahaman, M.; Khastgir, D. Dielectric property and electromagnetic interference shielding effectiveness of ethylene vinyl acetate based conductive composites: Effect of different type of carbon fillers. Polym. Compos. 2011, 32, 1148–1154. [Google Scholar] [CrossRef]

- Rahaman, M.; Chaki, T.K.; Khastgir, D. High performance EMI shielding materials based on short carbon fiber filled ethylene vinyl acetate copolymer, acrylonitrile butadiene copolymer, and their blends. Polym. Compos. 2011, 32, 1790–1805. [Google Scholar] [CrossRef]

- Malliaris, A.; Turner, D.T. Influence of particle size on the electrical resistivity of compacted mixtures of polymeric and metallic powders. J. Appl. Phys. 1971, 42, 614–618. [Google Scholar] [CrossRef]

- Pramanik, P.K.; Saha, T.N.; Khastgir, D. Effect of some processing parameters on the resistivity of conductive nitrile rubber composites. Plast. Rubber Compos. Proc. Appl. 1992, 17, 179–185. [Google Scholar]

- Kirkpatrick, S. Percolation and conduction. Rev. Mod. Phys. 1973, 45, 574–588. [Google Scholar] [CrossRef]

- Grunlan, J.C.; Mehrabi, A.R.; Bannon, M.V.; Bahr, J.L. Water-based single-walled-nanotube-filled polymer composite with an exceptionally low percolation threshold. Adv. Mater. 2004, 16, 150–153. [Google Scholar] [CrossRef]

- Ehrburgerdolle, F.; Lahaye, J.; Misono, S. Percolation in carbon black powders. Carbon 1994, 32, 1363–1368. [Google Scholar] [CrossRef]

- Etemad, S.; Quan, X.; Sanders, N.A. Geometry-defined electrical interconnection by a homogeneous medium. Appl. Phys. Lett. 1986, 48, 607–609. [Google Scholar] [CrossRef]

- Hotta, S.; Rughooputh, S.D.D.V.; Heeger, A.J. Conducting polymer composites of soluble polythiophenes in polystyrene. Synth. Met. 1987, 22, 79–87. [Google Scholar] [CrossRef]

- Janzen, J. On the critical conductive filler loading in antistatic composites. J. Appl. Phys. 1975, 46, 966–969. [Google Scholar] [CrossRef]

- Slupkowski, T. Electrical conductivity of mixtures of conducting and insulating particles. Phys. Status Solidi A 1984, 83, 329–333. [Google Scholar] [CrossRef]

- Bueche, F. Electrical resistivity of conducting particles in an insulating matrix. J. Appl. Phys. 1972, 43, 4837–4838. [Google Scholar] [CrossRef]

- Sumita, M.; Asai, S.; Miyadera, N.; Jojima, E.; Miyasaka, K. Electrical conductivity of carbon black filled ethylene-vinyl acetate copolymer as a function of vinyl acetate content. Colloid Polym. Sci. 1986, 264, 212–217. [Google Scholar] [CrossRef]

- Wessling, B. Electrical conductivity in heterogeneous polymer systems. V (1): Further experimental evidence for a phase transition at the critical volume concentration. Polym. Eng. Sci. 1991, 31, 1200–1206. [Google Scholar] [CrossRef]

- Nielsen, L.E. The thermal and electrical conductivity of two-phase systems. Ind. Eng. Chem. Fundam. 1974, 13, 17–20. [Google Scholar] [CrossRef]

- Mccullough, R.L. Generalized combining rules for predicting transport properties of composite materials. Compos. Sci. Technol. 1985, 22, 3–21. [Google Scholar] [CrossRef]

- Siddiqui, U.S.; Kumar, S.; Dar, A.A. Micellization of monomeric and dimeric (gemini) surfactants in polar nonaqueous-water-mixed solvents. Colloid Polym. Sci. 2006, 284, 807–812. [Google Scholar]

- Love, B. Revisiting Boltzmann Kinetics in Applied Rheology. SPE, Plast. Res. Online Doi:10.1002/spepro.001588. Available online: http://www.4spepro.org/view.php?source=001588-2009-11-27 (accessed on 18 October 2017).

- Buelow, M.T.; Immaraporn, B.; Gellman, A.J. The transition state for surface-catalyzed dehalogenation: C–I cleavage on Pd(111). J. Catal. 2001, 203, 41–50. [Google Scholar] [CrossRef]

- Rahaman, M.; Chaki, T.K.; Khastgir, D. Determination of percolation limits of conductivity, dielectric constant, and EMI SE for conducting polymer composites using Sigmoidal Boltzmann model. Adv. Sci. Lett. 2012, 10, 115–117. [Google Scholar] [CrossRef]

- Duan, J.; Bolger, G.; Garneau, M.; Batonga, J.; Montpetit, H.; Otis, F.; Jutras, M.; Lapeyre, N.; Rhéaume, M.; Kukolj, G.; et al. The liver partition coefficient-corrected inhibitory quotient and the pharmacokinetic-pharmacodynamic relationship of directly acting anti-hepatitis C virus agents in humans. Antimicrob. Agents Chemother. 2012, 56, 5381–5386. [Google Scholar] [CrossRef] [PubMed]

- Ritz, C.; Streibig, J.C. Bioassay analysis using R. J. Stat. Softw. 2005, 12, 1–22. [Google Scholar] [CrossRef]

- Yoshimasu, T.; Oura, S.; Hirai, I.; Tamaki, T.; Kokawa, Y.; Ota, F.; Nakamura, R.; Shimizu, Y.; Kawago, M.; Hirai, Y.; et al. In Vitro evaluation of dose-response curve for paclitaxel in breast cancer. Breast Cancer 2007, 14, 401–405. [Google Scholar] [CrossRef] [PubMed]

- Levasseur, L.M.; Slocum, H.K.; Rustum, Y.M.; Greco, W.R. Modeling of the time-dependency of In Vitro drug cytotoxicity and resistance. Cancer Res. 1998, 58, 5749–5761. [Google Scholar] [PubMed]

- Testart-Paillet, D.; Girard, P.; You, B.; Freyer, G.; Pobel, C.; Tranchand, B. Contribution of modelling chemotherapy-induced hematological toxicity for clinical practice. Crit. Rev. Oncol. Hematol. 2007, 63, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Lees, P.; Cunningham, F.M.; Elliott, J. Principles of pharmacodynamics and their applications in veterinary pharmacology. J. Vet. Pharmacol. Ther. 2004, 27, 397–414. [Google Scholar] [CrossRef] [PubMed]

- Goutelle, S.; Maurin, M.; Rougier, F.; Barbaut, X.; Bourguignon, L.; Ducher, M.; Maire, P. The Hill equation: a review of its capabilities in pharmacological modelling. Fundam. Clin. Pharmacol. 2008, 22, 633–648. [Google Scholar] [CrossRef] [PubMed]

- Di Veroli, G.Y.; Fornari, C.; Goldlust, I.; Mills, G.; Koh, S.B.; Bramhall, J.L.; Richards, F.M.; Jodrell, D.I. An automated fitting procedure and software for dose-response curves with multiphasic features. Sci. Rep. 2015, 5, 14701. [Google Scholar] [CrossRef] [PubMed]

- Sebaugh, J.L.; McCray, P.D. Defining the linear portion of a sigmoid shaped curve: Bend points. Pharm. Stat. 2003, 2, 167–174. [Google Scholar] [CrossRef]

- Finney, D.J. Statistical Method in Biological Assay, 3rd ed.; Griffin: London, UK, 1978. [Google Scholar]

- De Lean, A.; Munson, P.J.; Rodbard, D. Simultaneous analysis of families of sigmoidal curves: Application to bioassay, radioligand assay, and physiological dose–response curves. Am. J. Physiol. 1978, 235, E97–E102. [Google Scholar]

- Healy, M.J.R. Statistical analysis of radioimmunoassay data. Biochem. J. 1972, 130, 207–210. [Google Scholar] [CrossRef] [PubMed]

- Pierre-François, V. Notice sur la loi que la population poursuit dans son accroissement. Corresp. Math. Phys. 1838, 10, 113–121. [Google Scholar]

- Singh, S.; Singh, K.N.; Mandjiny, S.; Holmes, L. Modeling the growth of Lactococcus lactis NCIM 2114 under differently aerated and agitated conditions in broth medium. Fermentation 2015, 1, 86–97. [Google Scholar] [CrossRef]

- Meyer, P.S.; Yung, J.W.; Ausubel, J.H. A primer on logistic growth and substitution: The mathematics of the loglet lab software. Technol. Forecast. Soc. Chang. 1999, 61, 247–271. [Google Scholar] [CrossRef]

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; Riet, K.V. Modeling of the bacterial growth curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [PubMed]

- Barrau, S.; Demont, P.; Peigney, A.; Laurent, C.; Lacabanne, C. DC and AC conductivity of carbon nanotubes-polyepoxy composites. Macromolecules 2003, 36, 5187–5194. [Google Scholar] [CrossRef] [Green Version]

- Brigandi, P.J.; Cogen, J.M.; Pearson, R.A. Electrically conductive multiphase polymer blend carbon-based composites. Polym. Eng. Sci. 2014, 54, 1–16. [Google Scholar] [CrossRef]

- Pötschke, P.; Arnaldo, M.H.; Radusch, H.-J. Percolation behavior and mechanical properties of polycarbonate composites filled with carbon black/carbon nanotube systems. Polimery 2012, 57, 204–211. [Google Scholar] [CrossRef]

- Zhang, H.-B.; Zheng, W.-G.; Yan, Q.; Jiang, Z.-G.; Yu, Z.-Z. The effect of surface chemistry of graphene on rheological and electrical properties of polymethylmethacrylate composites. Carbon 2012, 50, 5117–5125. [Google Scholar] [CrossRef]

- Coelho, P.H.S.L.; Marchesin, M.S.; Morales, A.R.; Bartoli, J.R. Electrical percolation, morphological and dispersion properties of MWCNT/PMMA nanocomposites. Mater. Res. 2014, 17, 127–132. [Google Scholar] [CrossRef]

- Soheilmoghaddam, M.; Adelnia, H.; Bidsorkhi, H.C.; Sharifzadeh, G.; Wahit, M.U.; Akos, N.I.; Yussuf, A.A. Development of ethylene vinyl acetate composites reinforced with graphene platelets. Macromol. Mater. Eng. 2017, 302, 1600260. [Google Scholar] [CrossRef]

- Chmutin, I.; Novokshonova, L.; Brevnov, P.; Yukhayeva, G.; Ryvkina, N. Electrical properties of UHMWPE/graphite nanoplates composites obtained by In Situ polymerization method. Polyolefins J. 2017, 4, 1–12. [Google Scholar]

- Ounaies, Z.; Park, C.; Wise, K.E.; Siochi, E.J.; Harrison, J.S. Electrical properties of single wall carbon nanotube reinforced polyimide composites. Compos. Sci. Technol. 2003, 63, 1637–1646. [Google Scholar] [CrossRef]

| Ingredients | Composition Parts by Weight per Hundred Parts of Polymer | Composition by Volume Fraction (Vf) | ||

|---|---|---|---|---|

| NBR Set | EVA Set | NBR Set | EVA Set | |

| EVA | ----- | 100 | ----- | 1-Vf of carbons |

| NBR | 100 | ----- | 1-Vf of carbons | ----- |

| DCP | 02 | 02 | 0.02 | 0.02 |

| TAC | 01 | 01 | 0.01 | 0.01 |

| TQ | 01 | 01 | 0.01 | 0.01 |

| CCB | 0–60 | 0–60 | 0–0.24477 | 0–0.24191 |

| PCB | 0–50 | 0–50 | 0–0.21265 | 0–0.21006 |

| SCF | 0–30 | 0–30 | 0–0.13945 | 0–0.13760 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahaman, M.; Aldalbahi, A.; Govindasami, P.; Khanam, N.P.; Bhandari, S.; Feng, P.; Altalhi, T. A New Insight in Determining the Percolation Threshold of Electrical Conductivity for Extrinsically Conducting Polymer Composites through Different Sigmoidal Models. Polymers 2017, 9, 527. https://doi.org/10.3390/polym9100527

Rahaman M, Aldalbahi A, Govindasami P, Khanam NP, Bhandari S, Feng P, Altalhi T. A New Insight in Determining the Percolation Threshold of Electrical Conductivity for Extrinsically Conducting Polymer Composites through Different Sigmoidal Models. Polymers. 2017; 9(10):527. https://doi.org/10.3390/polym9100527

Chicago/Turabian StyleRahaman, Mostafizur, Ali Aldalbahi, Periyasami Govindasami, Noorunnisa P. Khanam, Subhendu Bhandari, Peter Feng, and Tariq Altalhi. 2017. "A New Insight in Determining the Percolation Threshold of Electrical Conductivity for Extrinsically Conducting Polymer Composites through Different Sigmoidal Models" Polymers 9, no. 10: 527. https://doi.org/10.3390/polym9100527

APA StyleRahaman, M., Aldalbahi, A., Govindasami, P., Khanam, N. P., Bhandari, S., Feng, P., & Altalhi, T. (2017). A New Insight in Determining the Percolation Threshold of Electrical Conductivity for Extrinsically Conducting Polymer Composites through Different Sigmoidal Models. Polymers, 9(10), 527. https://doi.org/10.3390/polym9100527