Self-Healing Polymeric Composite Material Design, Failure Analysis and Future Outlook: A Review

Abstract

:1. Introduction

2. Self-Healing Polymeric Materials and Traditional Repair Methods

2.1. Bonded Composite Repair

2.2. Welding/Fusion Bonding

2.3. In-Situ Curing of New Resin

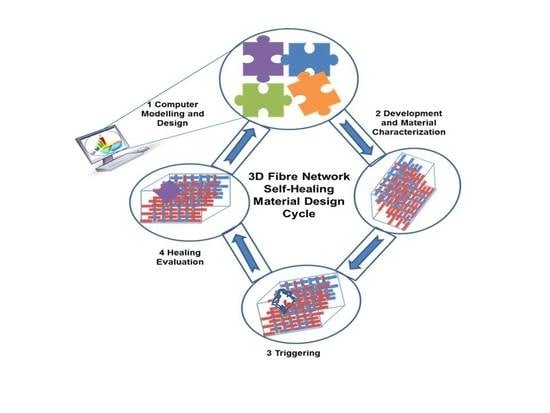

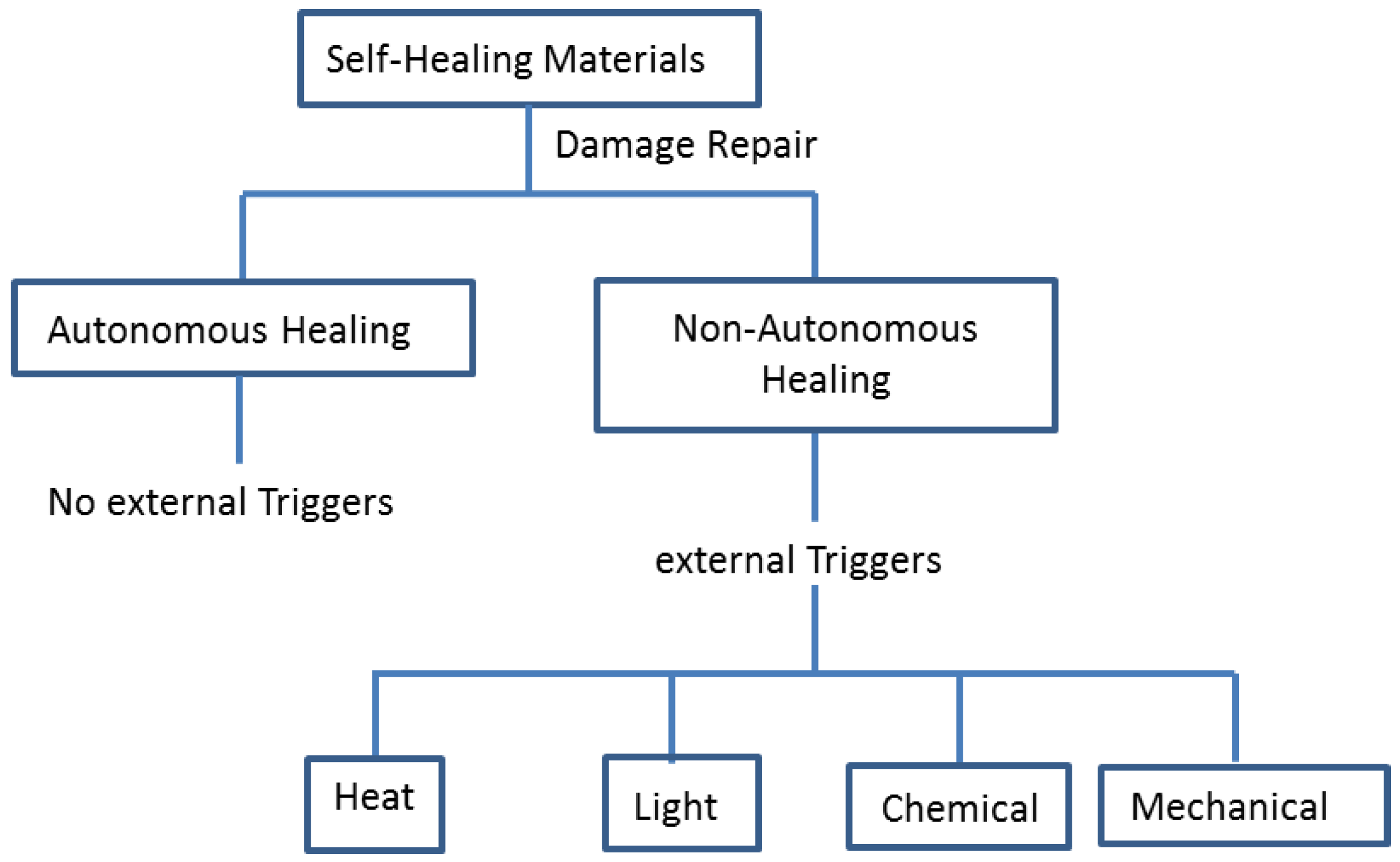

3. Self-Healing Concept

4. Extrinsic and Intrinsic Self-Healing Materials

4.1. Intrinsic Self-Repairing Materials

4.2. Intrinsic Self-Healing

4.3. Extrinsic Self-Healing Materials

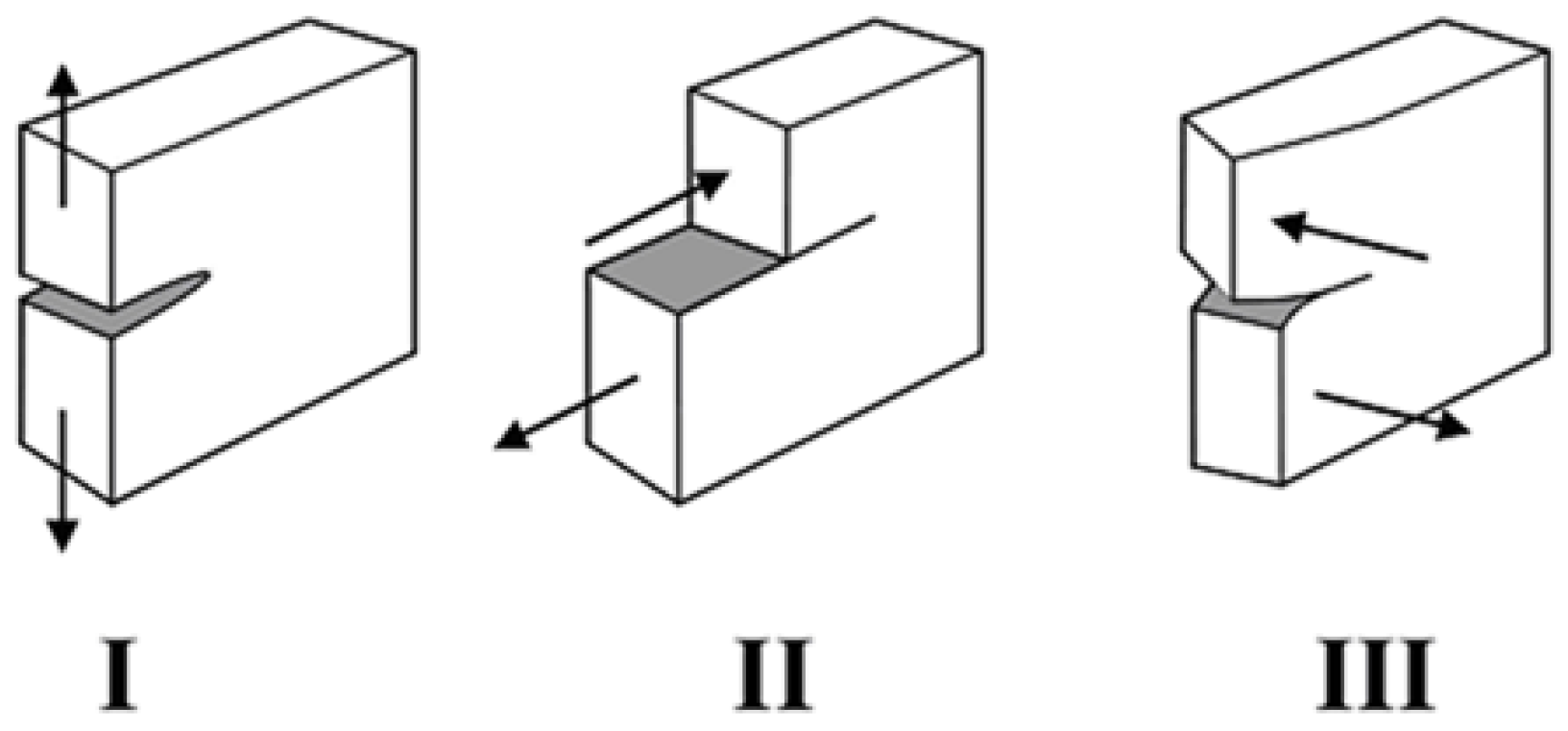

5. Fracture Mechanics of Polymeric Materials

Structural Aspect of Composite Failure

6. Early Facture Testing

6.1. Linear Elastic Fracture Mechanics

6.1.1. Griffith Theory of Brittle Fracture

6.1.2. Irwin and Orowan’s Modification to Griffith Theory of Brittle Fracture

6.1.3. Stress Intensity Factor

7. Modelling

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bonfoh, N.; Coulibaly, M.; Sabar, H. Effective properties of elastic composite materials with multi-coated reinforcements: A new micromechanical modelling and applications. Compos. Struct. 2014, 115, 111–119. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L.; Hou, M. Advances in fusion bonding techniques for joining thermoplastic matrix composites: A review. Compos. Part A Appl. Sci. Manuf. 2001, 32, 839–857. [Google Scholar] [CrossRef]

- Vinson, J.R. Adhesive bonding of polymer composites. Polym. Eng. Sci. 1989, 29, 1325–1331. [Google Scholar] [CrossRef]

- Vinson, J.R. Mechanical fastening of polymer composites. Polym. Eng. Sci. 1989, 29, 1332–1339. [Google Scholar] [CrossRef]

- Esteves, J.V.; Goushegir, S.M.; dos Santos, J.F.; Canto, L.B.; Hage, E., Jr.; Amancio-Filho, S.T. Friction spot joining of aluminum AA6181-T4 and carbon fiber-reinforced poly(phenylene sulfide): Effects of process parameters on the microstructure and mechanical strength. Mater. Des. 2014, 66, 437–445. [Google Scholar] [CrossRef]

- Grewell, D.; Benatar, A. Welding of Plastics: Fundamentals and New Developments. Int. Polym. Process. 2007, 22, 43–60. [Google Scholar] [CrossRef]

- Caminero, M.A.; Pavlopoulou, S.; Lopez-Pedrosa, M.; Nicolaisson, B.G.; Pinna, C.; Soutis, C. Analysis of adhesively bonded repairs in composites: Damage detection and prognosis. Compos. Struct. 2013, 95, 500–517. [Google Scholar] [CrossRef]

- Benyahia, F.; Albedah, A.; Bachir Bouiadjra, B. Analysis of the adhesive damage for different patch shapes in bonded composite repair of aircraft structures. Mater. Des. 2014, 54, 18–24. [Google Scholar] [CrossRef]

- Ageorges, C.; Ye, L. Resistance welding of thermosetting composite/thermoplastic composite joints. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1603–1612. [Google Scholar] [CrossRef]

- Liu, X.; Wang, G. Progressive failure analysis of bonded composite repairs. Compos. Struct. 2007, 81, 331–340. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Custódio, J.; Broughton, J.; Cruz, H. A review of factors influencing the durability of structural bonded timber joints. Int. J. Adhes. Adhes. 2009, 29, 173–185. [Google Scholar] [CrossRef]

- Rosso, M. Ceramic and metal matrix composites: Routes and properties. J. Mater. Process. Technol. 2006, 175, 364–375. [Google Scholar] [CrossRef]

- Kim, Y.H.; Woo, R.P. A theory of healing at polymer-polymer interface. Macromolecules 1983, 16, 1115–1120. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Zhang, M.Q.; Rong, M.Z. Basics of self-healing: State of the art. In Self-Healing Polymers and Polymer Composites; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 1–81. [Google Scholar]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A., Jr. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Ma, X.; Scarpa, F.; Peng, H.-X.; Allegri, G.; Yuan, J.; Ciobanu, R. Design of a hybrid carbon fibre/carbon nanotube composite for enhanced lightning strike resistance. Aerosp. Sci. Technol. 2015, 47, 367–377. [Google Scholar] [CrossRef]

- Peterson, A.M.; Kotthapalli, H.; Rahmathullah, M.A.M.; Palmese, G.R. Investigation of interpenetrating polymer networks for self-healing applications. Compos. Sci. Technol. 2012, 72, 330–336. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef] [PubMed]

- McCann, D.M.; Forde, M.C. Review of NDT methods in the assessment of concrete and masonry structures. NDT E Int. 2001, 34, 71–84. [Google Scholar] [CrossRef]

- Dimarogonas, A.D. Vibration of cracked structures: A state of the art review. Eng. Fract. Mech. 1996, 55, 831–857. [Google Scholar] [CrossRef]

- Boller, C. Next generation structural health monitoring and its integration into aircraft design. Int. J. Syst. Sci. 2000, 31, 1333–1349. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Cuc, A. Embedded non-destructive evaluation for structural health monitoring, damage detection, and failure prevention. Shock Vib. Dig. 2005, 37, 83–105. [Google Scholar] [CrossRef]

- Titman, D.J. Applications of thermography in non-destructive testing of structures. NDT E Int. 2001, 34, 149–154. [Google Scholar] [CrossRef]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Review of nondestructive testing methods for condition monitoring of concrete structures. J. Constr. Eng. 2013, 834572. [Google Scholar] [CrossRef]

- Salawu, O.S. Detection of structural damage through changes in frequency: A review. Eng. Struct. 1997, 19, 718–723. [Google Scholar] [CrossRef]

- Meure, S.; Wu, D.Y. The biomimetic approach to self healing composite development in the aerospace industry. In Proceedings of the 1st International Self-healing Materials Conference, Noordwijk aan Zee, The Netherlands, 18–20 April 2007. [Google Scholar]

- Aïssa, B.; Therriault, D.; Haddad, E.; Jamroz, W. Self-Healing materials systems: Overview of major approaches and recent developed technologies. Adv. Mater. Sci. Eng. 2012, 854203. [Google Scholar] [CrossRef]

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 2008, 33, 479–522. [Google Scholar] [CrossRef]

- Ye, L.; Lu, Y.; Su, Z.; Meng, G. Functionalized composite structures for new generation airframes: A review. Compos. Sci. Technol. 2005, 65, 1436–1446. [Google Scholar] [CrossRef]

- Hager, M.D.; Greil, P.; Leyens, C.; van der Zwaag, S.; Schubert, U.S. Self-healing materials. Adv. Mater. 2010, 22, 5424–5430. [Google Scholar]

- Trask, R.; Williams, H.; Bond, I. Self-healing polymer composites: Mimicking nature to enhance performance. Bioinspir. Biomim. 2007, 2. [Google Scholar] [CrossRef] [PubMed]

- Tzetzis, D.; Hogg, P.J. Experimental and finite element analysis on the performance of vacuum-assisted resin infused single scarf repairs. Mater. Des. 2008, 29, 436–449. [Google Scholar] [CrossRef]

- Ellyin, F.; Ozah, F.; Xia, Z. 3-D modelling of cyclically loaded composite patch repair of a cracked plate. Compos. Struct. 2007, 78, 486–494. [Google Scholar] [CrossRef]

- Katnam, K.B.; Da Silva, L.F.M.; Young, T. M Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities. Prog. Aerosp. Sci. 2013, 61, 26–42. [Google Scholar] [CrossRef]

- Baker, A. Bonded composite repair of fatigue-cracked primary aircraft structure. Compos. Struct. 1999, 47, 431–443. [Google Scholar] [CrossRef]

- Whittingham, B.; Baker, A.A.; Harman, A.; Bitton, D. Micrographic studies on adhesively bonded scarf repairs to thick composite aircraft structure. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1419–1432. [Google Scholar] [CrossRef]

- Wang, C.H.; Gunnion, A.J. On the design methodology of scarf repairs to composite laminates. Compos. Sci. Technol. 2008, 68, 35–46. [Google Scholar] [CrossRef]

- Gunnion, A.J.; Herszberg, I. Parametric study of scarf joints in composite structures. Compos. Struct. 2006, 75, 364–376. [Google Scholar] [CrossRef]

- Constantin, N.; Sandu, M.; Sorohan, Ş. Restoration of the mechanical performance of damaged Al panels using bonded composite repair patches. Inter. J. Adhes. Adhes. 2013, 42, 69–76. [Google Scholar] [CrossRef]

- Yala, A.A.; Megueni, A. Optimisation of composite patches repairs with the design of experiments method. Mater. Des. 2009, 30, 200–205. [Google Scholar] [CrossRef]

- Cheng, P.; Gong, X.-J.; Aivazzadeh, S.; Xiao, X. Experimental observation of tensile behavior of patch repaired composites. Polym. Test. 2014, 34, 146–154. [Google Scholar] [CrossRef]

- Shams, S.S.; El-Hajjar, R.F. Overlay patch repair of scratch damage in carbon fiber/epoxy laminated composites. Compos. Part A Appl. Sci. Manuf. 2013, 49, 148–156. [Google Scholar] [CrossRef]

- Typical Composite Repair Flowchart. Available online: https://en.wikipedia.org/wiki/Composite_repairs#/media/File:Figure-3-typical-composite-repair-flowchart.jpg8 (accessed on 9 September 2017).

- Takeda, N.; Okabe, Y.; Kuwahara, J.; Kojima, S.; Ogisu, T. Development of smart composite structures with small-diameter fiber Bragg grating sensors for damage detection: Quantitative evaluation of delamination length in CFRP laminates using Lamb wave sensing. Compos. Sci. Technol. 2005, 65, 2575–2587. [Google Scholar] [CrossRef]

- Kamsu-Foguem, B. Knowledge-based support in Non-Destructive Testing for health monitoring of aircraft structures. Adv. Eng. Inform. 2012, 26, 859–869. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Townsend, C.; Shah Khan, M.Z. Non-destructive detection of fatigue damage in thick composites by pulse-echo ultrasonics. Compos. Sci. Technol. 2000, 60, 23–32. [Google Scholar] [CrossRef]

- Moropoulou, A.; Labropoulos, K.C.; Delegou, E.T.; Karoglou, M.; Bakolas, A. Non-destructive techniques as a tool for the protection of built cultural heritage. Constr. Build. Mater. 2013, 48, 1222–1239. [Google Scholar] [CrossRef]

- Pramanik, A. Developments in the non-traditional machining of particle reinforced metal matrix composites. Int. J. Mach. Tools Manuf. 2014, 86, 44–61. [Google Scholar] [CrossRef]

- Müller, F.; Monaghan, J. Non-conventional machining of particle reinforced metal matrix composites. J. Mater. Process. Technol. 2001, 118, 278–285. [Google Scholar] [CrossRef]

- Gomes, W.J.S.; Beck, A.T. Optimal inspection planning and repair under random crack propagation. Eng. Struct. 2014, 69, 285–296. [Google Scholar] [CrossRef]

- Hatsukade, Y.; Kasai, N.; Kurosawa, M.; Kawai, R.; Takashima, H.; Kojima, F.; Ishiyama, A. Detection of internal cracks and delamination in carbon-fiber-reinforced plastics using SQUID-NDI system. Phys. C Supercond. 2002, 372–376, 267–270. [Google Scholar] [CrossRef]

- Popović, O.; Prokić-Cvetković, R.; Burzić, M.; Lukić, U.; Beljić, B. Fume and gas emission during arc welding: Hazards and recommendation. Renew. Sustain. Energy Rev. 2014, 37, 509–516. [Google Scholar] [CrossRef]

- Qin, R.; He, G. Mass transfer of the nickel-base alloy covered electrode with neutral flux coating during shielded metal arc welding. Int. J. Heat Mass Trans. 2014, 78, 1095–1104. [Google Scholar] [CrossRef]

- Tong, Z.; Zhentai, Z.; Rui, Z. A dynamic welding heat source model in pulsed current gas tungsten arc welding. J. Mater. Process. Technol. 2013, 213, 2329–2338. [Google Scholar] [CrossRef]

- Mohamat, S.A.; Ibrahim, I.A.; Amir, A.; Ghalib, A. The effect of flux core arc welding (FCAW) processes on different parameters. Proc. Eng. 2012, 41, 1497–1501. [Google Scholar] [CrossRef]

- Kiran, D.V.; Cho, D.W.; Song, W.H.; Na, S.J. Arc behavior in two wire tandem submerged arc welding. J. Mater. Process. Technol. 2014, 214, 1546–1556. [Google Scholar] [CrossRef]

- Stokes, V.K. Joining methods for plastics and plastic composites: An overvie. Polym. Eng. Sci. 1989, 29, 1310–1324. [Google Scholar] [CrossRef]

- Groche, P.; Wohletz, S.; Brenneis, M.; Pabst, C.; Resch, F. Joining by forming—A review on joint mechanisms, applications and future trends. J. Mater. Process. Technol. 2014, 214, 1972–1994. [Google Scholar] [CrossRef]

- Gibson, B.T.; Lammlein, D.H.; Prater, T.J.; Longhurst, W.R.; Cox, C.D.; Ballun, M.C.; Dharmaraj, K.J.; Cook, G.E.; Strauss, A.M. Friction stir welding: Process, automation, and control. J. Manuf. Process. 2014, 16, 56–73. [Google Scholar] [CrossRef]

- Jenkins, N.; Pierce, W.; Eagar, T. Particle size distribution of gas metal and flux cored arc welding fumes. Weld. J. 2005, 84, 158–163. [Google Scholar]

- Dasch, J.; D’Arcy, J. Physical and chemical characterization of airborne particles from welding operations in automotive plants. J. Occup. Environ. Hyg. 2008, 5, 444–454. [Google Scholar] [CrossRef] [PubMed]

- Klinge, S.; Bartels, A.; Steinmann, P. The multiscale approach to the curing of polymers incorporating viscous and shrinkage effects. Int. J. Solids Struct. 2012, 49, 3883–3900. [Google Scholar] [CrossRef]

- Puretskiy, N. Design of Self-Repairable Superhydrophobic and Switchable Surfaces Using Colloidal Particles; Technische Universitat Dresden: Dresden, Germany, 2013. [Google Scholar]

- Chotard, T.J.; Pasquiet, J.; Benzeggagh, M.L. Residual performance of scarf patch-repaired pultruded shapes initially impact damaged. Compos. Struct. 2001, 53, 317–331. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Sottos, N.R.; White, S.R. Nanocapsules for self-healing materials. Compos. Sci. Technol. 2008, 68, 978–986. [Google Scholar] [CrossRef]

- Blaiszik, B.; Kramer, S.; Olugebefola, S.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-healing polymers and composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Filipovic, N.; Petrovic, D.; Jovanovic, A.; Jovanovic, S.; Balos, D.; Kojic, M. DPD simulation of self-healing process of nanocoating. J. Serb. Soc. Comp. Mech. 2008, 2, 42–50. [Google Scholar]

- Ghosh, S.K. Self-Healing Materials: Fundamentals, Design Strategies, and Applications. In Self-Healing Materials; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2009; pp. 1–28. [Google Scholar]

- Fischer, H. Self-repairing materials systems—A dream or a reality? Nat. Sci. 2010, 2, 873–901. [Google Scholar] [CrossRef]

- Wang, Y.; Pham, D.T.; Ji, C. Self-healing composites: A review. Cogent Eng. 2015, 2, 1075686. [Google Scholar] [CrossRef] [Green Version]

- Guimard, N.K.; Oehlenschlaeger, K.K.; Zhou, J.; Hilf, S.; Schmidt, F.G.; Barner-Kowollik, C. Current trends in the field of self-healing materials. Macromol. Chem. Phys. 2012, 213, 131–143. [Google Scholar] [CrossRef]

- Wool, R.P. Self-healing materials: A review. Soft Mater. 2008, 4, 400–418. [Google Scholar] [CrossRef]

- Doblaré, M.; Garcı́a, J.M.; Gómez, M.J. Modelling bone tissue fracture and healing: A review. Eng. Fract. Mech. 2004, 71, 1809–1840. [Google Scholar] [CrossRef]

- Kyllönen, L.; D’Este, M.; Alini, M.; Eglin, D. Local drug delivery for enhancing fracture healing in osteoporotic bone. Acta Biomater. 2014, 11, 412–434. [Google Scholar] [CrossRef] [PubMed]

- Sangadji, S.; Schlangen, E. Mimicking none healing process to self repair concrete structure novel approach using porous network concrete. Proc. Eng. 2013, 54, 315–326. [Google Scholar] [CrossRef]

- Thomas, G.P. Self-Healing Materials—The Future of Repairs. Available online: https://www.azom.com/article.aspx?ArticleID=7902 (accessed on 18 October 2017).

- Ghaisi, M.S.; Chen, J.; Vaziri, A.; Rodriguez, E.K.; Nazarian, A. Bone fracture healing in mechanobiological modeling: A review of principles and methods. Bone Rep. 2017, 6, 87–100. [Google Scholar] [CrossRef] [PubMed]

- Billiet, S.; Hillewaere, X.K.D.; Teixeira, R.F.A.; Du Prez, F.E. Chemistry of crosslinking processes for self-healing polymers. Macromol. Rapid Commun. 2013, 34, 290–309. [Google Scholar] [CrossRef] [PubMed]

- Garcia, S.J. Effect of polymer architecture on the intrinsic self-healing character of polymers. Eur. Polym. J. 2014, 53, 118–125. [Google Scholar] [CrossRef]

- Burattini, S.; Greenland, B.W.; Chappell, D.; Colquhoun, H.M.; Hayes, W. Healable polymeric materials: A tutorial review. Chem. Soc. Rev. 2010, 39, 1973–1985. [Google Scholar] [CrossRef] [PubMed]

- Lehn, J.-M. Dynamers: Dynamic molecular and supramolecular polymers. Prog. Polym. Sci. 2005, 30, 814–831. [Google Scholar] [CrossRef]

- Chao, A.; Negulescu, I.; Zhang, D. Dynamic covalent polymer networks based on degenerative imine bond exchange; tuning the malleability and self-healing properties by solvent. Macromolecules 2016, 49, 6277–6284. [Google Scholar] [CrossRef]

- Zhang, L.; Rowan, S.J. Effect of sterics and degree of cross-linking on the mechanical properties of dynamic poly(alkylurea-urethane) networks. Macromolecules 2017, 50, 5051–5060. [Google Scholar] [CrossRef]

- Deng, G.; Li, F.; Yu, H.; Liu, F.; Liu, C.; Sun, W.; Jiang, H.; Chen, Y. Dynamic hydrogels with an environmental adaptive self-healing ability and dual responsive sol–gel transitions. ACS Macro Lett. 2012, 1, 275–279. [Google Scholar] [CrossRef]

- Kloxin, C.J.; Scott, T.F.; Adzima, B.J.; Bowman, C.N. Covalent adaptable networks (CANs): A unique paradigm in crosslinked polymers. Macromolecules 2010, 43, 2643–2653. [Google Scholar] [CrossRef] [PubMed]

- Hizal, G.; Tunca, U.; Sanyal, A. Discrete macromolecular constructs via the Diels–Alder “Click” reaction. J. Polym. Sci. Part A Polym. Chem. 2011, 49, 4103–4120. [Google Scholar] [CrossRef]

- Toncelli, C.; De Reus, D.C.; Picchioni, F.; Broekhuis, A.A. Properties of reversible diels–alder furan/maleimide polymer networks as function of crosslink density. Macromol. Chem. Phys. 2012, 213, 157–165. [Google Scholar] [CrossRef]

- García, S.J.; Fischer, H.R.; van der Zwaag, S. A critical appraisal of the potential of self healing polymeric coatings. Prog. Organ. Coat. 2011, 72, 211–221. [Google Scholar] [CrossRef]

- Canadell, J.; Goossens, H.; Klumperman, B. Self-Healing materials based on disulfide links. Macromoleculs 2011, 44, 2536–2541. [Google Scholar]

- Zhang, L.; Chen, L.; Rowan, S.J. Trapping dynamic disulfide bond in the hare segments of thermoplastic polyurethane elastomers. Macromol. Chem. Phys. 2017, 218. [Google Scholar] [CrossRef]

- Zhang, L.; Brostowitz, N.R.; Cavicchi, K.A.; Weiss, R.A. Perspective: Ionomer research and application. Macromolecules 2014, 8, 81–99. [Google Scholar] [CrossRef]

- Herbst, F.; Binder, W.H. Self-Healing Polymers via Supramolecular, Hydrogen-Bonded Networks. In Self-Healing Polymers: From Principles to Applications; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013. [Google Scholar] [CrossRef]

- Heinzamann, C.; Weder, C.; de Espinosa, L.M. Supramolecular polymers adhesive: Advanced materials inspired by nature. Chem. Soc. Rev. 2016, 45, 342–358. [Google Scholar] [CrossRef] [PubMed]

- Varley, R.J.; van der Zwaag, S. Towards an understanding of thermally activated self-healing of an ionomer systems during ballistic penetration. Acta Mater. 2008, 56, 5737–5750. [Google Scholar] [CrossRef]

- Rhaman, M.A.; Penco, M.; Spagnoli, G.; Grande, A.M.; Di Landro, L. Self-healing behavior of blends based on ionomers with ethylene/vinyl alcohol copolymer or epoxidized natural rubber. Macromol. Mater. Eng. 2011, 296, 1119–1127. [Google Scholar] [CrossRef]

- Kalista, S.J.; Ward, T.C.; Oyetunji, Z. Self-healing of poly(ethylene-co-methacrylic acid) copolymers following projectile puncture. Mech. Adv. Mater. Struct. 2007, 14, 391–397. [Google Scholar] [CrossRef]

- Varley, R.J.; Shen, S.; van der Zwaag, S. The effect of cluster plasticisation on the self healing behaviour of ionomers. Polymer 2010, 51, 679–686. [Google Scholar] [CrossRef]

- Brown, E.N.; Sottos, N.R.; White, S.R. Fracture testing of a self-healing polymer composite. Exp. Mech. 2002, 42, 372–379. [Google Scholar] [CrossRef]

- Vijayaraghavan, A.; Dornfeld, D.A. Challenges in Modeling Machining of Multilayer Materials. In Proceedings of the 8th CIRP International Workshop on Modeling of Mechining Operations, Chemnitz, Germany, 10–11 May 2005. [Google Scholar]

- Dry, C.M.; Sottos, N.R. Passive smart self-repair in polymer matrix composite materials. Smart Struct. Mater. 1993, 1916, 438–444. [Google Scholar]

- Bleay, S.M.; Loader, C.B.; Hawyes, V.J.; Humberstone, L.; Curtis, P.T. A smart repair system for polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1767–1776. [Google Scholar] [CrossRef]

- Soutis, C. Carbon fiber reinforced plastics in aircraft construction. Mater. Sci. Eng. A 2005, 412, 171–176. [Google Scholar] [CrossRef]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Harris, B. Engineering Composite Materials; Institute of Metals London: London, UK, 1986. [Google Scholar]

- Yang, Q.; Cox, B. Cohesive models for damage evolution in laminated composites. Int. J. Fract. 2005, 133, 107–137. [Google Scholar] [CrossRef]

- Soutis, C.; Duan, D.M.; Goutas, P. Compressive behaviour of CFRP laminates repaired with adhesively bonded external patches. Compos. Struct. 1999, 45, 289–301. [Google Scholar] [CrossRef]

- Phil, E.; Soutis, C. Polymer Composites in the Aerospace Industry; Elsevier: Cambridge, UK, 2014. [Google Scholar]

- Bazant, Z.P.; Planas, J. Fracture and Size Effect in Concrete and other Quasibrittle Materials; CRC Press: New York, NY, USA, 1997. [Google Scholar]

- Perez, N. Linear Elastic Fracture Mechanics. In Fracture Mechanics; Springer: New York, NY, USA, 2004; pp. 39–72. [Google Scholar]

- Shrotriya, P.; Allameh, S.; Brown, S.; Suo, Z.; Soboyejo, W. Fatigue damage evolution in silicon films for micromechanical applications. Exp. Mech. 2003, 43, 289–302. [Google Scholar] [CrossRef]

- Dorgan, K.M.; Arwade, S.R.; Jumars, P.A. Burrowing in marine muds by crack propagation: Kinematics and forces. J.Exp. Biol. 2007, 210, 4198–4212. [Google Scholar] [CrossRef] [PubMed]

- Bouchbinder, E.; Fineberg, J.; Marder, M. Dynamics of simple cracks. arXiv 2009, arXiv:0911.0173. [Google Scholar]

- Draper, D. Assessment and propagation of model uncertainty. J. R. Stat. Soc. Ser. B 1995, 57, 45–97. [Google Scholar]

- Alava, M.J.; Nukala, P.K.; Zapperi, S. Statistical models of fracture. Adv. Phys. 2006, 55, 349–476. [Google Scholar] [CrossRef]

- Larsen, C.J. Models for dynamic fracture based on Griffith’s criterion. In IUTAM Symposium on Variational Concepts with Applications to the Mechanics of Materials; Springer: Bochum, Germany, 2010; pp. 131–140. [Google Scholar]

- Erdogan, F. Fracture mechanics. Int. J. Solids Struct. 2000, 37, 171–183. [Google Scholar] [CrossRef]

- McCarron, A. A Synergistic Approach to Modeling Crack Propagation in Nanoreinforced Polymer Composites. Master’s Thesis, University of Massachusetts Amherst, Amherst, MA, USA, 2008. [Google Scholar]

- Ficher-Cripps, A.C. Linear Elastic Fracture Mechanics. In Introduction to Contact Mechanics; Springer: New York, NY, USA, 2007; pp. 31–48. [Google Scholar]

- Sneddon, I.N. The distribution of stress in the neighbourhood of a crack in an elastic solid. In Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences, Cambridge, UK, 22 October 1946; Volume 187, pp. 229–260. [Google Scholar]

- Zhu, X.-K.; Joyce, J.A. Review of fracture toughness (G, K, J, CTOD, CTOA) testing and standardization. Eng. Fract. Mech. 2012, 85, 1–46. [Google Scholar] [CrossRef]

- Radaj, D.; Vormwald, M. Extended Stress Intensity Factor Concepts. In Advanced Methods of Fatigue Assessment; Springer: Berlin/Heidlberg, Germany, 2013; pp. 101–265. [Google Scholar]

- Shmueli, J.; Eder, M.A.; Tesauro, A. A versatile stereo photogrammetry based technique for measuring fracture mode displacements in structures. Precis. Eng. 2015, 39, 38–46. [Google Scholar] [CrossRef]

- Valvo, P.S. A Physically consistent virtual crack closure technique for I/II/III mixed-mode fracture problems. Proc. Mater. Sci. 2014, 3, 1983–1987. [Google Scholar] [CrossRef]

- Ricel, J. The mechanics of crack tip deformation and extension by fatigue. In Fatigue Crack Propagation; ASTM International: Amsterdam, The Netherlands, 1966. [Google Scholar]

- Patrıcio, M.; Mattheij, R. Crack Propagation Analysis; CASA Report; Technishe Universiteit Eindhoven: Eindhoven, The Netherlands, 2007. [Google Scholar]

- Martel, S.J. Mechanics of landslide initiation as a shear fracture phenomenon. Mar. Geol. 2004, 203, 319–339. [Google Scholar] [CrossRef]

- Drenchev, L.; Sobczak, J.J. Self-Healing Materials as Biomimetic Smart Structures; Polish Academy of Sciences: Krakow, Poland, 2014. [Google Scholar]

- Mauldin, T.C. Self-Healing Polymers—The Importance of Choosing an Adequate Healing Monomer, and the Olefin Metathesis Polymerization of Agricultural Oils. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2011. [Google Scholar]

- Darabi, M.K.; Abu Al-Rub, R.K.; Little, D.N. A continuum damage mechanics framework for modeling micro-damage healing. Int. J. Solids Struct. 2012, 49, 492–513. [Google Scholar] [CrossRef]

- Liu, L.; Katsabanis, P.D. Development of a continuum damage model for blasting analysis. Int. J. Rock Mech. Min. Sci. 1997, 34, 217–231. [Google Scholar] [CrossRef]

- Maiti, S.; Geubelle, P.H. Cohesive modeling of fatigue crack retardation in polymers: Crack closure effect. Eng. Fract. Mech. 2006, 73, 22–41. [Google Scholar] [CrossRef]

- Maiti, S.; Geubelle, P.H. A cohesive model for fatigue failure of polymers. Eng. Fract. Mech. 2005, 72, 691–708. [Google Scholar] [CrossRef]

- Chowdhury, R.A.; Hosur, M.V.; Nuruddin, M.; Tcherbi-Narteh, A.; Kumar, A.; Boddu, V.; Jeelani, S. Self-healing epoxy composites: Preparation, characterization and healing performance. J. Mater. Res. Technol. 2015, 4, 33–43. [Google Scholar] [CrossRef]

- Chow, C.L.; Wang, J. An anisotropic theory of elasticity for continuum damage mechanics. Int. J. Fract. 1987, 33, 3–16. [Google Scholar] [CrossRef]

- Muc, A.; Krawiec, Z. Design of composite plates under cyclic loading. Compos. Struct. 2000, 48, 139–144. [Google Scholar] [CrossRef]

- Huang, H.; Talreja, R. Numerical simulation of matrix micro-cracking in short fiber reinforced polymer composites: Initiation and propagation. Compos. Sci. Technol. 2006, 66, 2743–2757. [Google Scholar] [CrossRef]

- Balazs, A.C. Modeling self-healing materials. Mater. Today 2007, 10, 18–23. [Google Scholar] [CrossRef]

- Patrick, J.F.; Hart, K.R.; Krull, B.P.; Diesendruck, C.E.; Moore, J.S.; White, S.R.; Sottos, N.R. Self-healing: Continuous self-healing life cycle in vascularized structural composites. Adv. Mater. 2014, 26, 4302–4308. [Google Scholar] [CrossRef] [PubMed]

- Patrick, J.F.; Sottos, N.R.; White, S.R. Microvascular based self-healing polymeric foam. Polymer 2012, 53, 4231–4240. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mphahlele, K.; Ray, S.S.; Kolesnikov, A. Self-Healing Polymeric Composite Material Design, Failure Analysis and Future Outlook: A Review. Polymers 2017, 9, 535. https://doi.org/10.3390/polym9100535

Mphahlele K, Ray SS, Kolesnikov A. Self-Healing Polymeric Composite Material Design, Failure Analysis and Future Outlook: A Review. Polymers. 2017; 9(10):535. https://doi.org/10.3390/polym9100535

Chicago/Turabian StyleMphahlele, Keletso, Suprakas Sinha Ray, and Andrei Kolesnikov. 2017. "Self-Healing Polymeric Composite Material Design, Failure Analysis and Future Outlook: A Review" Polymers 9, no. 10: 535. https://doi.org/10.3390/polym9100535

APA StyleMphahlele, K., Ray, S. S., & Kolesnikov, A. (2017). Self-Healing Polymeric Composite Material Design, Failure Analysis and Future Outlook: A Review. Polymers, 9(10), 535. https://doi.org/10.3390/polym9100535