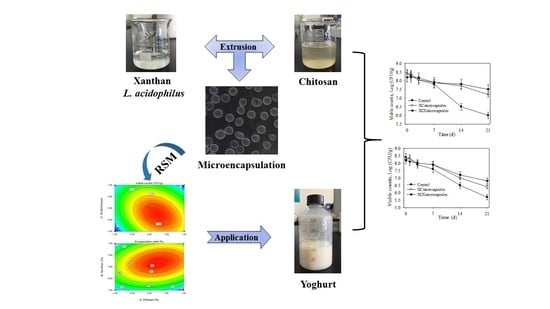

Microencapsulation of Lactobacillus Acidophilus by Xanthan-Chitosan and Its Stability in Yoghurt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Xanthan and Chitosan Solutions

2.2. Microorganism

2.3. Encapsulation Procedure and Encapsulation Yield

2.4. Box-Behnken Design (BBD) and Statistical Analysis

2.5. Storage Stability of Free Cells, Optimized L. acidophilus Encapsulation (XC and XCX) in Yoghurt

3. Results and Discussion

3.1. Optimization of Encapsulation Conditions by RSM

3.1.1. Effect of Chitosan Concentration, Xanthan Concentration, and XLM/Chitosan on Viable Counts

3.1.2. Effect of Chitosan Concentration, Xanthan Concentration, and XLM/Chitosan on Encapsulation Yield

3.1.3. Verification of the Model

3.2. Storage Stability of Encapsulated L. acidophilus (XC and XCX) in Yogurt

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Corona-Hernandez, R.I.; Álvarez-Parrilla, E.; Lizardi-Mendoza, J.; Islas-Rubio, A.R.; Rosa, L.; Wall-Medrano, A. Structural stability and viability of microencapsulated probiotic bacteria: A review. Compr. Rev. Food Sci. Food Saf. 2013, 12, 614–628. [Google Scholar] [CrossRef]

- Manichanh, C.; Reeder, J.; Gibert, P.; Varela, E.; Llopis, M.; Antolin, M. Reshaping the gut microbiome with bacterial transplantation and antibiotic intake. Genome Res. 2010, 20, 1411–1419. [Google Scholar] [CrossRef] [PubMed]

- Ying, D.Y.; Schwander, S.; Weerakkody, R.; Sanguansri, L.; Gantenbein-Demarchi, C.; Augustin, M.A. Microencapsulated Lactobacillus rhamnosus GG in whey protein and resistant starch matrices: Probiotic survival in fruit juice. J. Funct. Foods 2013, 5, 98–105. [Google Scholar] [CrossRef]

- Schell, D.; Beermann, C. Fluidized bed microencapsulation of Lactobacillus reuteri with sweet whey and shellac for improved acid resistance and in vitro gastro-intestinal survival. Food Res. Int. 2014, 62, 308–314. [Google Scholar] [CrossRef]

- Behboudi-Jobbehdar, S.; Soukoulis, C.; Yonekura, L.; Fisk, I. Optimization of spray-drying process conditions for the production of maximally viable microencapsulated L. acidophilus NCIMB 701748. Dry Technol. 2013, 31, 1274–1283. [Google Scholar] [CrossRef]

- Prisco, A.D.; Mauriello, G. Probiotication of foods: A focus on microencapsulation tool. Trends Food Sci. Technol. 2016, 48, 27–39. [Google Scholar] [CrossRef]

- Cook, M.T.; Tzortzis, G.; Charalampopoulos, D.; Khutoryanskiy, V.V. Production and evaluation of dry alginate-chitosan microcapsules as an enteric delivery vehicle for probiotic bacteria. Biomacromolecules 2011, 12, 2834–2840. [Google Scholar] [CrossRef] [PubMed]

- Kanmani, P.; Kumar, R.S.; Yuvaraj, N.; Paari, K.A.; Pattukumar, V.; Arul, V. Effect of cryopreservation and microencapsulation of lactic acid bacterium Enterococcus Faecium MC13 for long-term storage. Biochem. Eng. J. 2011, 58, 140–147. [Google Scholar] [CrossRef]

- Burgain, J.; Scher, J.; Lebeer, S.; Vanderleyden, J.; Cailliez-Grimal, C.; Corgneau, M. Significance of bacterial surface molecules interactions with milk proteins to enhance microencapsulation of Lactobacillus rhamnosus GG. Food Hydrocoll. 2014, 41, 60–70. [Google Scholar] [CrossRef]

- Albertinia, B.; Passerini, N.; Cruciani, F.; Sabatino, M.D.; Rodriguez, L.; Brigidi, P. Development of microparticulate systems for intestinal delivery of Lactobacillus acidophilus and Bifidobacterium lactis. Eur. J. Pharm. Sci. 2010, 40, 359–366. [Google Scholar] [CrossRef] [PubMed]

- Tanzina, H.; Avik, K.; Ruhul, A.K.; Bernard, R.; Monique, L. Encapsulation of probiotic bacteria in biopolymeric system. Crit. Rev. Food Sci. 2013, 53, 909–916. [Google Scholar] [CrossRef]

- Argin, S.; Kofinas, P.; Lo, Y.M. The cell release kinetics and the swelling behavior of physically crosslinked xanthan–chitosan hydrogels in simulated gastrointestinal conditions. Food Hydrocoll. 2014, 40, 138–144. [Google Scholar] [CrossRef]

- Cook, M.T.; Tzortzis, G.; Charalampopoulos, D.; Khutoryanskiy, V.V. Microencapsulation of probiotics for gastrointestinal delivery. J. Controll. Release 2012, 162, 56–67. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, L.; Yang, T.; Song, Y.; Shu, G.; Chen, H. Effect of xanthan-chitosan-xanthan double layer encapsulation on survival of Bifidobacterium BB01 in simulated gastrointestinal conditions, bile salt solution and yogurt. LWT—Food Sci. Technol. 2017, 81, 274–280. [Google Scholar] [CrossRef]

- Sanem, A.S.; Peter, K.; Ymartin, L. Effect of complexation conditions on xanthan-chitosan polyelectrolyte complex gels. Food Hydrocoll. 2009, 23, 202–209. [Google Scholar] [CrossRef]

- Magnin, D.; Dumitriu, S.; Chornet, E. Immobilization of enzymes into a polyionic hydrogel: Chitoxan. J. Bioact. Compat. Polym. 2003, 18, 355–373. [Google Scholar] [CrossRef]

- Chen, H.; Song, Y.J.; Liu, N.N.; Wan, H.C.; Shu, G.W.; Liao, N. Effect of complexation conditions on microcapsulation of Lactobacillus acidophilus in xanthan-chitosan polyelectrolyte complex gels. Acta Sci. Pol. Technol. Aliment. 2015, 14, 207–213. [Google Scholar] [CrossRef] [PubMed]

- Shoji, A.S.; Oliveira, A.C.; Balieiro, J.C.C.; Freitas, O.; Thomazini, M.; Heinemann, R.J.B. Viability of L. acidophilus microcapsules and their application to buffalo milk yoghurt. Food Bioprod. Process. 2013, 91, 83–88. [Google Scholar] [CrossRef]

- Mkadmini, H.K.; Hammami, M.; Rihouey, C.; Le, C.D.; Ksouri, R.; Majdoub, H. Optimization extraction of polysaccharide from Tunisian Zizyphus lotus fruit by response surface methodology: Composition and antioxidant activity. Food Chem. 2016, 212, 476–484. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Wang, M. Optimization of deep eutectic solvent-based ultrasound-assisted extraction of polysaccharides from dioscorea opposita thunb. Int. J. Biol. Macromol. 2016, 95, 675–681. [Google Scholar] [CrossRef] [PubMed]

- Ghavi, P.P. Modeling and optimization of ultrasound-assisted extraction of polysaccharide from the roots of althaea officinalis. J. Food Process. Preserv. 2015, 39, 2107–2118. [Google Scholar] [CrossRef]

- El-Dieb, S.M.; Rabo, F.H.R.A.; Badran, S.M.; El-Fattah, A.M.A.; Elshaghabee, F.M.F. The growth behaviour and enhancement of probiotic viability in bioyoghurt. Int. Dairy J. 2012, 22, 44–47. [Google Scholar] [CrossRef]

- Ribeiro, M.C.E.; Chaves, K.S.; Gebara, C.; Infante, F.N.S.; Grosso, C.R.F.; Gigante, M.L. Effect of microencapsulation of Lactobacillus acidophilus LA-5 on physicochemical, sensory and microbiological characteristics of stirred probiotic yoghurt. Food Res. Int. 2014, 66, 424–431. [Google Scholar] [CrossRef]

- Soma, P.K. Optimization of Xanthan Chitosan Polyelectrolytic Hydrogels for Microencapsulation of Probiotic Bacteria. Ph.D. Dissertation, University of Maryland, College Park, MD, USA, 2011. [Google Scholar]

- Heidebach, T.; Först, P.; Kulozik, U. Microencapsulation of probiotic cells for food applications. Crit. Rev. Food Sci. 2012, 52, 291–311. [Google Scholar] [CrossRef] [PubMed]

- Brinques, G.B.; Maz, A. Effect of microencapsulation on survival of Lactobacillus plantarum in simulated gastrointestinal conditions, refrigeration, and yogurt. J. Food Eng. 2011, 103, 123–128. [Google Scholar] [CrossRef]

- Kailasapathy, K. Survival of free and encapsulated probiotic bacteria and their effect on the sensory. LWT—Food Sci. Technol. 2017, 39, 1221–1227. [Google Scholar] [CrossRef]

| Variable | Level | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| A Chitosan (%) | 0.64 | 0.67 | 0.70 |

| B Xanthan (%) | 0.72 | 0.75 | 0.78 |

| C XLM/chitosan | 1:2.4 | 1:2.6 | 1:2.8 |

| RUN | A | B | C | Y1 (1010 CFU·g−1) | Y2 (%) |

|---|---|---|---|---|---|

| 1 | −1 | 1 | 0 | 1.03 | 67.5 |

| 2 | 1 | −1 | 0 | 1.05 | 60.6 |

| 3 | 0 | 1 | 1 | 0.90 | 61.8 |

| 4 | 0 | −1 | 1 | 0.99 | 70.3 |

| 5 | 1 | 0 | −1 | 1.13 | 76.9 |

| 6 | 0 | 0 | 0 | 1.37 | 90.1 |

| 7 | 0 | 0 | 0 | 1.35 | 89.6 |

| 8 | 0 | 1 | −1 | 1.21 | 77.8 |

| 9 | 1 | 1 | 0 | 1.19 | 80.3 |

| 10 | 1 | 0 | 1 | 1.09 | 78.3 |

| 11 | 0 | 0 | 0 | 1.31 | 86.9 |

| 12 | −1 | −1 | 0 | 0.90 | 64.4 |

| 13 | −1 | 0 | 1 | 1.0 | 73.2 |

| 14 | −1 | 0 | −1 | 1.20 | 70.2 |

| 15 | 0 | −1 | −1 | 0.90 | 61.4 |

| Source | SS | DF | MS | F Value | p Value | Sig |

|---|---|---|---|---|---|---|

| Model | 41.32 | 9 | 4.59 | 21.49 | 0.0003 | *** |

| A | 1.36 | 1 | 1.36 | 6.37 | 0.0396 | * |

| B | 3.00 | 1 | 3.00 | 14.05 | 0.0072 | ** |

| C | 2.64 | 1 | 2.64 | 12.38 | 0.0097 | ** |

| AB | 2.5 × 10−3 | 1 | 2.5 × 10−3 | 0.012 | 0.9169 | - |

| AC | 0.64 | 1 | 0.64 | 3.00 | 0.1271 | - |

| BC | 4.00 | 1 | 4.00 | 18.72 | 0.0035 | * |

| A2 | 3.43 | 1 | 3.43 | 16.05 | 0.0051 | ** |

| B2 | 16.05 | 1 | 16.05 | 75.13 | <0.0001 | *** |

| C2 | 7.42 | 1 | 7.42 | 34.73 | 0.0006 | *** |

| Error | 1.50 | 7 | 0.21 | - | - | - |

| Lack of fit | 1.09 | 3 | 0.36 | 3.55 | 0.1261 | - |

| Pure error | 0.41 | 4 | 0.10 | - | - | - |

| Total | 42.82 | 16 | - | - | - | - |

| Source | SS | DF | MS | F Value | p Value | Sig |

|---|---|---|---|---|---|---|

| Model | 1637.36 | 9 | 181.97 | 21.86 | 0.0013 | ** |

| A | 54.08 | 1 | 54.08 | 6.50 | 0.0382 | * |

| B | 117.81 | 1 | 117.81 | 14.15 | 0.0071 | ** |

| C | 0.91 | 1 | 0.91 | 0.11 | 0.7504 | - |

| AB | 68.89 | 1 | 68.89 | 8.28 | 0.0238 | * |

| AC | 0.64 | 1 | 0.64 | 0.077 | 0.7896 | - |

| BC | 155.00 | 1 | 155.0 | 18.62 | 0.0035 | ** |

| A2 | 178.85 | 1 | 178.85 | 21.48 | 0.0024 | ** |

| B2 | 749.57 | 1 | 749.57 | 90.04 | <0.0001 | *** |

| C2 | 200.03 | 1 | 200.03 | 24.03 | 0.0017 | ** |

| Error | 58.27 | 7 | 8.32 | - | - | - |

| Lack of fit | 45.26 | 3 | 15.09 | 4.64 | 0.0862 | - |

| Pure error | 13.01 | 4 | 3.25 | - | - | - |

| Total | 1696.04 | 16 | - | - | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, G.; He, Y.; Chen, L.; Song, Y.; Meng, J.; Chen, H. Microencapsulation of Lactobacillus Acidophilus by Xanthan-Chitosan and Its Stability in Yoghurt. Polymers 2017, 9, 733. https://doi.org/10.3390/polym9120733

Shu G, He Y, Chen L, Song Y, Meng J, Chen H. Microencapsulation of Lactobacillus Acidophilus by Xanthan-Chitosan and Its Stability in Yoghurt. Polymers. 2017; 9(12):733. https://doi.org/10.3390/polym9120733

Chicago/Turabian StyleShu, Guowei, Yunxia He, Li Chen, Yajuan Song, Jiangpeng Meng, and He Chen. 2017. "Microencapsulation of Lactobacillus Acidophilus by Xanthan-Chitosan and Its Stability in Yoghurt" Polymers 9, no. 12: 733. https://doi.org/10.3390/polym9120733

APA StyleShu, G., He, Y., Chen, L., Song, Y., Meng, J., & Chen, H. (2017). Microencapsulation of Lactobacillus Acidophilus by Xanthan-Chitosan and Its Stability in Yoghurt. Polymers, 9(12), 733. https://doi.org/10.3390/polym9120733