Development of the Technical Structure of the “Cow Energy” Concept

Abstract

:1. Introduction

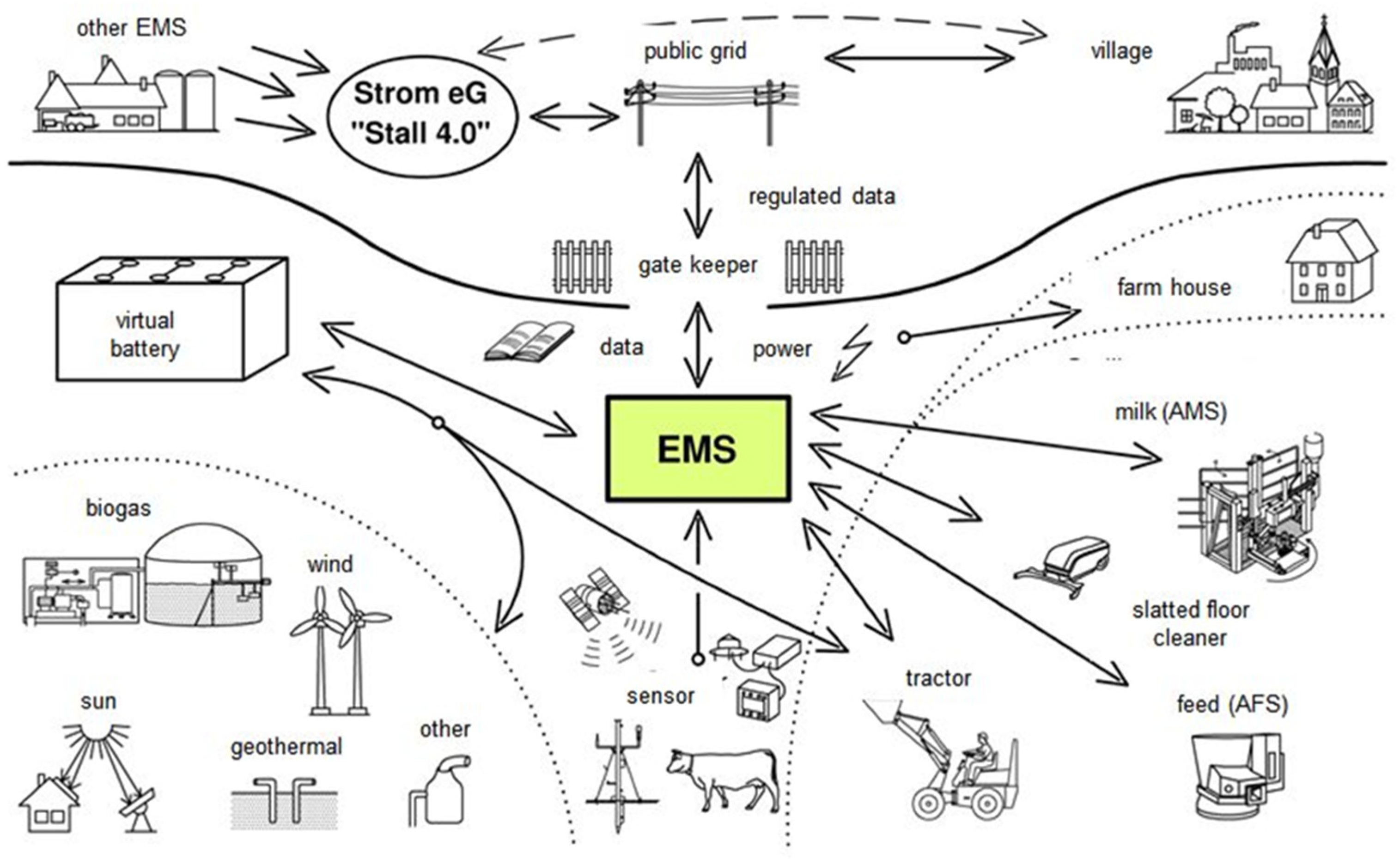

2. Materials and Methods

- Barn automation and central control of the systems;

- Energy efficiency and use of various energy storage solutions;

- Integration into the regional power supply to serve the grid;

- Sustainable barn construction;

- Safeguarding food quality and animal health;

- Animal welfare criteria and ethical aspects;

- Impact on agriculture and rural regions in southern Germany.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Gawel, E.; Paul, L.; Klaas, K.; Sebastian, S.; Jana, B.; Wolfgang, K.; Philipp, M.; Andreas, L.; Dominik, S.; Dörte, O.; et al. Die Zukunft der Energiewende in Deutschland. In Die Energiewende Verstehen-Orientieren-Gestalten; Nomos Verlagsgesellschaft mbH & Co. KG: Baden-Baden, Germany, 2017; pp. 425–446. [Google Scholar]

- Burger, B. Nettostromerzeugung im 1. Halbjahr 2020: Rekordanteil Erneuerbarer Energien von 55,8 Prozent; Press Information 16, 1 July 2020; Fraunhofer-Institut für Solare Energiesysteme ISE: Freiburg im Breisgau, Germany, 2020. [Google Scholar]

- Höwer, D.; Oberst, C.A.; Madlener, R. General regionalization heuristic to map spatial heterogeneity of macroeconomic impacts: The case of the green energy transition in NRW. Util. Policy 2019, 58, 166–174. [Google Scholar] [CrossRef]

- Spiecker, S.; Weber, C. The future of the European electricity system and the impact of fluctuating renewable energy—A scenario analysis. Energy Policy 2014, 65, 185–197. [Google Scholar] [CrossRef]

- Kühne, O.; Weber, F. Conflicts and negotiation processes in the course of power grid extension in Germany. Landsc. Res. 2018, 43, 529–541. [Google Scholar] [CrossRef]

- Sonneberg, H.; Graef, M. Energie aus der Landwirtschaft. Landtechnik 1999, 54, 16–17. [Google Scholar]

- Schoepe, M. Diversifizierung in der Landwirtschaft. Ifo Schnelld. 2011, 64, 43–47. [Google Scholar]

- Schoenleber, N.; Bahrs, E. Energetische Flurbereinigung: Regenerative Energie für eine nachhaltige regionale Energieversorgung und gesteigerte kommunale Wertschöpfung im Kontext eines Flurbereinigungsverfahrens. Ber. Über Landwirtsch. Z. Agrarpolit. Landwirtsch. 2013, 91, 1–26. [Google Scholar]

- Hefele, J.; Schäffer, E.; Adriany, A. Milchleistungsprüfung in Bayern 2020; Landeskontrollverband Bayern: München, Germany, 2020. [Google Scholar]

- Bernhardt, H. Livestock Engineering Machinery and Techniques for Cattle Husbandry. In Yearbook Agricultural Engineering 2018; Frerichs, L., Ed.; Institut für Mobile Maschinen und Nutzfahrzeuge: Braunschweig, Germany, 2019; pp. 1–13. [Google Scholar] [CrossRef]

- Höld, M.; Gräff, A.; Stumpenhausen, J.; Bernhardt, H. Integrated Dairy Farming–Basic requirements for a useful energy distribution in a dairy barn. In Proceedings of the International Conference on Agricultural Engineering CIGR-AgEng, Aarhus, Denmark, 26–29 June 2016; pp. 1–7. [Google Scholar]

- Neser, S.; Neiber, J.; Bonkoß, K. Stromverbrauch und Energieeffizienz im Landwirtschaftlichen Betrieb. Energiewende und Landwirtschaft; Ed. LfL: München, Germany, 2012; pp. 1–23. [Google Scholar]

- N.N. Faustzahlen für die Landwirtschaft; Ed. KTBL eV.: Darmstadt, Germany, 2018. [Google Scholar]

- Häußermann, U.; Döhler, H. Bauern unter Sonnen-Strom: Technik und Wirtschaftlichkeit von Fotovoltaikanlagen in der Landwirtschaft. Kuratorium für Technik und Bauwesen in der Landwirtschaft; KTBL: Darmstadt, Germany, 2011. [Google Scholar]

- Rathor, S.K.; Saxena, D. Energy management system for smart grid: An overview and key issues. Int. J. Energy Res. 2020, 44, 4067–4109. [Google Scholar] [CrossRef]

- Sola, A.V.H.; Mota, C.M.M. Influencing factors on energy management in industries. J. Clean. Prod. 2020, 248, 119263. [Google Scholar] [CrossRef]

- Lü, X.; Wu, Y.; Lian, J.; Zhang, Y.; Chen, C.; Wang, P.; Meng, L. Energy management of hybrid electric vehicles: A review of energy optimization of fuel cell hybrid power system based on genetic algorithm. Energy Convers. Manag. 2020, 205, 112474. [Google Scholar] [CrossRef]

- Farrokhifar, M.; Aghdam, F.H.; Alahyari, A.; Monavari, A.; Safari, A. Optimal energy management and sizing of renewable energy and battery systems in residential sectors via a stochastic MILP model. Electr. Power Syst. Res. 2020, 187, 106483. [Google Scholar] [CrossRef]

- Kandler, C. Modellierung von Zeitnutzungs-, Mobilitäts-und Energieprofilen zur Bestimmung der Potentiale von Energiemanagementsystemen in Haushalten. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2017. [Google Scholar]

- Mariano-Hernández, D.; Hernández-Callejo, L.; Zorita-Lamadrid, A.; Duque-Pérez, O.; Santos García, F. A review of strategies for building energy management system: Model predictive control, demand side management, optimization, and fault detect & diagnosis. J. Build. Eng. 2021, 33, 101692. [Google Scholar] [CrossRef]

- Höhendinger, M.; Krieg, H.-J.; Dietrich, R.; Rauscher, S.; Stumpenhausen, J.; Bernhardt, H. Impacts of Divergent Moving Drives on Energy Efficiency and Performance of Various AMS in Operative Conditions. Agriculture 2021, 11, 806. [Google Scholar] [CrossRef]

- Tangorra, F.M.; Calcante, A. Energy consumption and technical-economic analysis of an automatic feeding system for dairy farms: Results from a field test. J. Agric. Eng. 2018, 49, 228–232. [Google Scholar] [CrossRef]

- Da Borso, F.; Chiumenti, A.; Sigura, M.; Pezzuolo, A. Influence of automatic feeding systems on design and management of dairy farms. J. Agric. Eng. 2017, 48 (Suppl. 1), 48–52. [Google Scholar] [CrossRef] [Green Version]

- Nadjemi, O.; Nacer, T.; Hamidat, A.; Salhi, H. Optimal hybrid PV/wind energy system sizing: Application of cuckoo search algorithm for Algerian dairy farms. Renew. Sustain. Energy Rev. 2017, 70, 1352–1365. [Google Scholar] [CrossRef]

- O’Connor, S.; Ehimen, E.; Pillai, S.C.; Lyons, G.; Bartlett, J. Economic and Environmental Analysis of Small-Scale Anaerobic Digestion Plants on Irish Dairy Farms. Energies 2020, 13, 637. [Google Scholar] [CrossRef] [Green Version]

- Todde, G.; Murgia, L.; Caria, M.; Pazzona, A. Dairy Energy Prediction (DEP) model: A tool for predicting energy use and related emissions and costs in dairy farms. Comput. Electron. Agric. 2017, 135, 216–221. [Google Scholar] [CrossRef]

- Koesling, M.; Hansen, S.; Schueler, M. Variations of energy intensities and potential for improvements in energy utilisation on conventional and organic Norwegian dairy farms. J. Clean. Prod. 2017, 164, 301–314. [Google Scholar] [CrossRef]

- Shine, P.; Upton, J.; Sefeedpari, P.; Murphy, M.D. Energy Consumption on Dairy Farms: A Review of Monitoring, Prediction Modelling, and Analyses. Energies 2020, 13, 1288. [Google Scholar] [CrossRef] [Green Version]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Akbar, M.O.; Ali, M.J.; Hussain, A.; Qaiser, G.; Pasha, M.; Pasha, U.; Missen, M.S.; Akhtar, N. IoT for development of smart dairy farming. J. Food Qual. 2020, 2020, 4242805. [Google Scholar] [CrossRef]

- Cabrera, V.E.; Fadul-Pacheco, L. Future of dairy farming from the Dairy Brain perspective: Data integration, analytics, and applications. Int. Dairy J. 2021, 121, 105069. [Google Scholar] [CrossRef]

- Khalil, E.E. Introduction to energy management in smart grids. In Solving Urban Infrastructure Problems Using Smart City Technologies; Elsevier: Amsterdam, The Netherlands, 2021; pp. 399–410. [Google Scholar] [CrossRef]

- Koppenhöfer, C.; Fauser, J.; Dieter, H. Digitization of Decentralized Corporate Energy Systems: Supportive best-Practiced Methods for the Energy Domain; Ed. Gesellschaft für Informatik: Bonn, Germany, 2017. [Google Scholar]

- Daberkow, S.G.; McBride, W.D. Farm and operator characteristics affecting the awareness and adoption of precision agriculture technologies in the US. Precis. Agric. 2003, 4, 163–177. [Google Scholar] [CrossRef]

- Konrad, M.T.; Nielsen, H.Ø.; Pedersen, A.B.; Elofsson, K. Drivers of farmers’ investments in nutrient abatement technologies in five Baltic Sea countries. Ecol. Econ. 2019, 159, 91–100. [Google Scholar] [CrossRef]

- Pfeiffer, J.; Gabriel, A.; Gandorfer, M. Understanding the public attitudinal acceptance of digital farming technologies: A nationwide survey in Germany. Agric. Hum. Values 2021, 38, 107–128. [Google Scholar] [CrossRef]

- Bocklisch, T. Intelligente dezentrale Energiespeichersysteme. UWF 2014, 22, 63–70. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernhardt, H.; Höhendinger, M.; Stumpenhausen, J. Development of the Technical Structure of the “Cow Energy” Concept. Agronomy 2021, 11, 1915. https://doi.org/10.3390/agronomy11101915

Bernhardt H, Höhendinger M, Stumpenhausen J. Development of the Technical Structure of the “Cow Energy” Concept. Agronomy. 2021; 11(10):1915. https://doi.org/10.3390/agronomy11101915

Chicago/Turabian StyleBernhardt, Heinz, Martin Höhendinger, and Jörn Stumpenhausen. 2021. "Development of the Technical Structure of the “Cow Energy” Concept" Agronomy 11, no. 10: 1915. https://doi.org/10.3390/agronomy11101915

APA StyleBernhardt, H., Höhendinger, M., & Stumpenhausen, J. (2021). Development of the Technical Structure of the “Cow Energy” Concept. Agronomy, 11(10), 1915. https://doi.org/10.3390/agronomy11101915