Optimizing Peach Tree Canopy Architecture for Efficient Light Use, Increased Productivity and Improved Fruit Quality

Abstract

:1. Introduction

2. Fruit Quality

3. Rootstocks

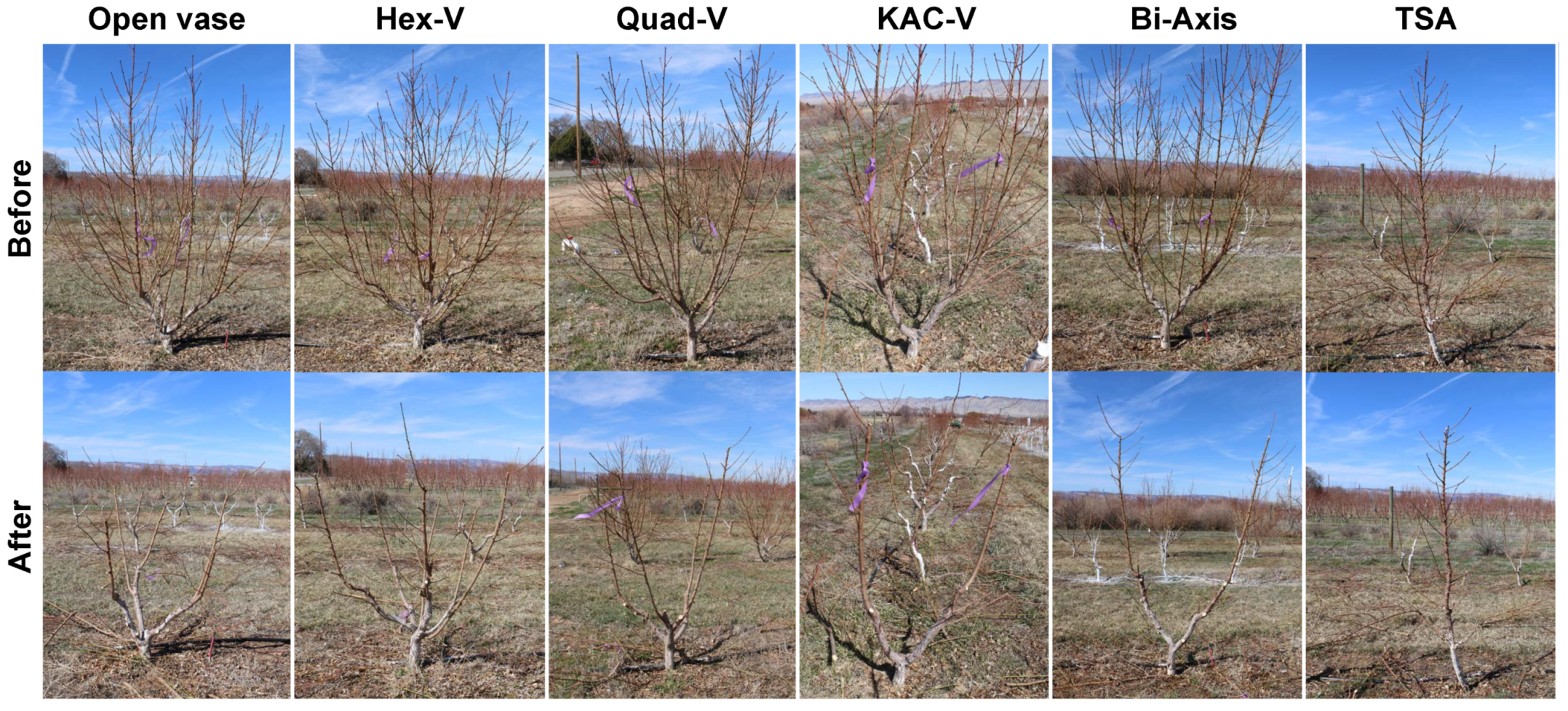

4. Training Systems

4.1. Low-Density Planting Systems

Open Vase

4.2. Medium-Density Systems

4.2.1. Delayed Vasette

4.2.2. Palmette

4.2.3. Quad-V

4.2.4. Hex-V

4.3. High-Density Planting Systems

4.3.1. Central Leader Systems (Fusetto, Tall Spindle Axe, Slender Spindle Axe)

4.3.2. Y-Shaped Systems (Tatura Trellis, KAC-V, Bi-Axis)

4.3.3. Cordon Systems

4.4. Ultra High-Density Planting Systems

Meadow Orchards

5. Impact of Training Systems on Light Relations, Production and Fruit Quality

5.1. Training Systems and Light Relations

5.2. Training Systems and Productivity

5.3. Training Systems and Fruit Quality

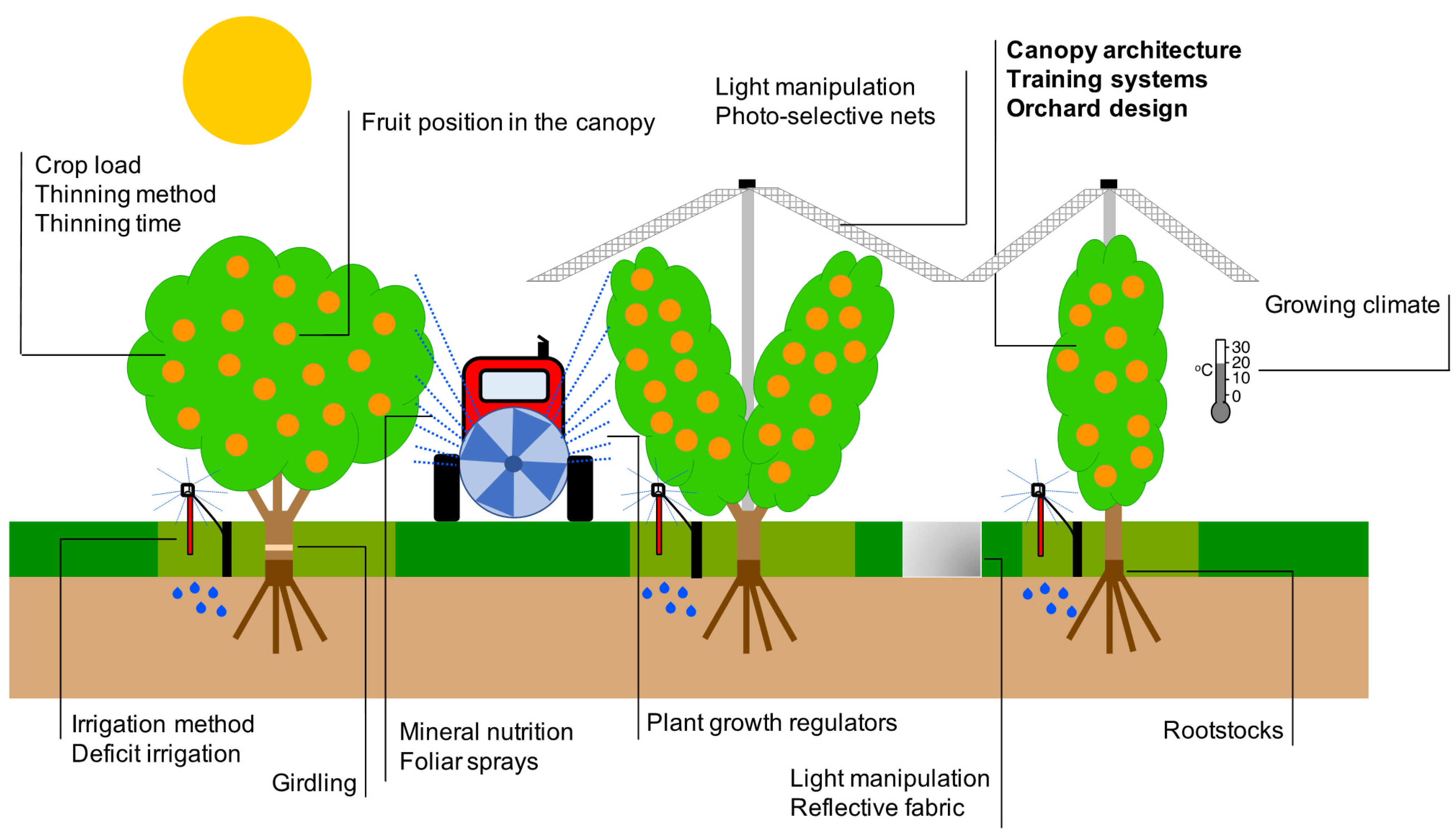

Controlling for Confounding Variables to Elicit the True Impact of Preharvest Factors on Peach Fruit Quality

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- FAO. FAOSTAT. 2019. Available online: http://www.fao.org/faostat/en/#home (accessed on 31 July 2021).

- USDA-National Agricultural Statistics Service. 2019. Available online: http://www.nass.usda.gov/ (accessed on 31 July 2021).

- Minas, I.S.; Tanou, G.; Molassiotis, A. Environmental and orchard bases of peach fruit quality. Sci. Hortic. 2018, 235, 307–322. [Google Scholar] [CrossRef]

- Crisosto, C.H.; Labavitch, J.M. Developing a quantitative method to evaluate peach (Prunus persica) flesh mealiness. Postharvest Biol. Techonol. 2002, 25, 151–158. [Google Scholar] [CrossRef]

- Crisosto, C.H.; Costa, G. Preharvest factors affecting peach quality. In The Peach: Botany, Production and Uses; CABI: Cambridge, MA, USA, 2008; pp. 536–549. [Google Scholar]

- Crisosto, C.H.; Crisosto, G.M. Relationship between ripe soluble solids concentration (RSSC) and consumer acceptance of high and low acid melting flesh peach and nectarine (Prunus persica (L.) Batsch) cultivars. Postharvest Biol. Techonol. 2005, 38, 239–246. [Google Scholar] [CrossRef]

- Testoni, A. Momento di raccolta, qualita, condizionamento e confezionamento delle pesche. In Proceedings of the Symposium La Peschicoltura Veronese Alle Soglie Del, Verona, Italy, 25 February 1995; pp. 327–354. [Google Scholar]

- Hilaire, C. The peach industry in France: State of art, research and development. In Proceedings of the First Mediterranean Peach Symposium, Agrigento, Italy, 10 September 2003; pp. 27–34. [Google Scholar]

- Minas, I.S.; Blanco-Cipollone, F.; Sterle, D. Accurate non-destructive prediction of peach fruit internal quality and physiological maturity with a single scan using near infrared spectroscopy. Food Chem. 2021, 335, 127626. [Google Scholar] [CrossRef]

- Serra, S.; Anthony, B.; Masia, A.; Giovannini, D.; Musacchi, S. Determination of Biochemical Composition in Peach (Prunus persica L. Batsch) Accessions Characterized by Different Flesh Color and Textural Typologies. Foods 2020, 9, 1452. [Google Scholar] [CrossRef]

- Giovannoni, J.; Nguyen, C.; Ampofo, B.; Zhong, S.; Fei, Z. The epigenome and transcriptional dynamics of fruit ripening. Annu. Rev. Plant Bio. 2017, 68, 61–84. [Google Scholar] [CrossRef]

- Anthony, B.M.; Chaparro, J.M.; Prenni, J.E.; Minas, I.S. Early metabolic priming under differing carbon sufficiency conditions influences peach fruit quality development. Plant Physiol. Biochem. 2020, 157, 416–431. [Google Scholar] [CrossRef]

- Ziosi, V.; Noferini, M.; Fiori, G.; Tadiello, A.; Trainotti, L.; Casadoro, G.; Costa, G. A new index based on vis spectroscopy to characterize the progression of ripening in peach fruit. Postharvest Biol. Techonol. 2008, 49, 319–329. [Google Scholar] [CrossRef]

- Costa, G.; Noferini, M.; Fiori, G.; Torrigiani, P. Use of Vis/NIR spectroscopy to assess fruit ripening stage and improve management in post-harvest chain. Fresh Prod. 2009, 1, 35–41. [Google Scholar]

- Reighard, G.L.; Loreti, F. Rootstock development. In The Peach: Botany, Production and Uses; Layne, D.R., Bassi, D., Eds.; CABI: Cambridge, MA, USA, 2008; pp. 193–220. [Google Scholar]

- Layne, R.E.C. Peach rootstocks. In Rootstocks for Fruit Crops; Rom, R.C., Carlson, R.F., Eds.; Wiley: Hoboken, NJ, USA, 1987. [Google Scholar]

- Reighard, G.; Bridges, J.W.; Archbold, D.; Wolfe, D.; Atucha, A.; Pokharel, R.; Autio, W.; Beckman, T.; Black, B.; Lindstrom, T.; et al. NC-140 Peach Rootstock Testing in Thirteen U.S. states. Acta Hortic. 2015, 225–232. [Google Scholar] [CrossRef]

- Reighard, G.L.; Bridges, J.W.; Archbold, D.; Atucha, A.; Autio, W.; Beckman, T.; Black, B.; Chavez, D.J.; Coneva, E.; Day, K.; et al. Nine-year rootstock performance of the NC-140 ‘Redhaven’ peach trial across 13 states. J. Am. Pomol. Soc. 2020, 74, 45–56. [Google Scholar]

- Loreti, F.; Massai, R. The High Density Peach Planting System: Present Status and Perspectives. Acta Hortic. 2002, 377–390. [Google Scholar] [CrossRef]

- Loreti, F.; Massai, R. State of the Art on Peach Rootstocks and Orchard Systems. Acta Hortic. 2006, 253–268. [Google Scholar] [CrossRef]

- Perry, R.; Reighard, G.; Ferree, D.; Barden, J.; Beckman, T.; Brown, G.; Cummins, J.; Durner, E.; Johnson, S.; Layne, R.; et al. Performance of the 1984 NC-140 cooperative peach rootstock planting. J. Am. Pomol. Soc. 2000, 54, 6–10. [Google Scholar]

- Autio, W.; Robinson, T.; Black, B.; Blatt, S.; Cochran, D.; Cowgill, W.; Hampson, C.; Hoover, E.; Lang, G.; Miller, D.; et al. Budagovsky, Geneva, Pillnitz, and Malling apple rootstocks affect ‘Hon-eycrisp’ performance over the first five years of the 2010 NC-140 ‘Honeycrisp’ Apple Rootstock Trials. J. Am. Pomol. Soc. 2017, 71, 149–166. [Google Scholar]

- Autio, W.; Robinson, T.; Blatt, S.; Cochran, D.; Francescato, P.; Hoover, E.; Kushad, M.; Lang, G.; Lordan, J.; Miller, D.; et al. Budagovsky, Geneva, Pillnitz, and Malling apple rootstocks affect ‘Honeycrisp’ performance over eight years in the 2010 NC-140 ‘Honeycrisp’ apple rootstock trial. J. Am. Pomol. Soc. 2020, 74, 182–195. [Google Scholar]

- Musacchi, S.; Gagliardi, F.; Serra, S. New Training Systems for High-density Planting of Sweet Cherry. HortScience 2015, 50, 59–67. [Google Scholar] [CrossRef]

- Lang, G. The cherry industries in the USA: Current trends and future perspectives. Acta Hortic. 2019, 1235, 119–132. [Google Scholar] [CrossRef]

- Robinson, T.; Hoying, S.; Sazo, M.M.; DeMarree, A.; Dominguez, L. A Vision for Apple Orchard Systems of the Future. Fruit Q 2013, 21, 11–16. [Google Scholar]

- Minas, I.; Cipollone, F.B.; Sterle, D. Near infrared spectroscopy can non-destructively assess the effect of canopy position and crop load on peach fruit maturity and quality. Acta Hortic. 2020, 1281, 407–412. [Google Scholar] [CrossRef]

- Faust, M. Physiology of Temperate Zone Fruit Trees; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1989. [Google Scholar]

- Grossman, Y.; DeJong, T. Training and Pruning System Effects on Vegetative Growth Potential, Light Interception, and Cropping Efficiency in Peach Trees. J. Am. Soc. Hortic. Sci. 1998, 123, 1058–1064. [Google Scholar] [CrossRef] [Green Version]

- Corelli-Grappadelli, L.; Marini, R.P. Orchard Planting Systems. In The Peach: Botany, Production and Uses; Layne, D.R., Bassi, D., Eds.; CABI: Cambridge, MA, USA, 2008; p. 264. [Google Scholar]

- Chalmers, D.J.; Mitchell, P.D.; Jerie, P.H. The physiology of growth control of peach and pear trees using reduced irrigation. In Proceedings of the International Workshop on Controlling Vigor in Fruit Trees, Beltsville, MD, USA, 26–28 July 1983; Volume 146, pp. 143–150. [Google Scholar]

- Génard, M.; Baret, F. Spatial and Temporal Variation of Light inside Peach Trees. J. Am. Soc. Hortic. Sci. 1994, 119, 669–677. [Google Scholar] [CrossRef] [Green Version]

- Gullo, G.; Motisi, A.; Zappia, R.; Dattola, A.; Diamanti, J.; Mezzetti, B. Rootstock and fruit canopy position affect peach [Prunus persica (L.) Batsch] (cv. Rich May) plant productivity and fruit sensorial and nutritional quality. Food Chem. 2014, 153, 234–242. [Google Scholar] [CrossRef]

- Robinson, T.L. Interaction of Tree Form and Rootstock on Light Interception, Yield and Efficiency of ’Empire’, ’Delicious’ and ’Jonagold’ apple Trees Trained to Different Systems. Acta Hortic. 1997, 451, 327–436. [Google Scholar] [CrossRef]

- Nuzzo, V.; Dichio, B.; Palese, A.M.; Xiloyannis, C. Productivity and fruit quality in peach trees [Prunus persica (L.) Batsch]. The effect of the training system and light availability. Atti VI Giorn. Sci. SOI 2003, 1, 215–216. [Google Scholar]

- Lauri, P.-E.; Grappadelli, L.C. Tree Architecture, Flowering and Fruiting—Thoughts on Training, Pruning and Ecophysiology. Acta Hortic. 2014, 291–298. [Google Scholar] [CrossRef]

- DeJong, T.; Day, K.; Johnson, R. Physiological and Technological Barriers to Increasing Production Efficiency and Economic Sustainability of Peach Production Systems in California. Acta Hortic. 2008, 415–422. [Google Scholar] [CrossRef]

- DeJong, T.M.; Day, K.R. Designing the Orchard. In Peaches, Plums, and Nectarines: Growing and Handling for Fresh Market; UCANR Pub.: Oakland, CA, USA, 1989; p. 3331. [Google Scholar]

- Day, K.R.; DeJong, T.M.; Johnson, R.S. Orchard-system configurations increase efficiency, improve profits in peaches and nectarines. Calif. Agric. 2005, 59, 75–79. [Google Scholar] [CrossRef] [Green Version]

- Neri, D.; Massetani, F.; Murri, G. Pruning and Training Systems: What Is Next? Acta Hortic. 2015, 429–443. [Google Scholar] [CrossRef]

- Grappadelli, L.C. The Palmette Training System. Acta Hortic. 1998, 513, 329–336. [Google Scholar] [CrossRef]

- Day, K.R.; Johnson, R.S.; DeJong, T.M. Evaluation of new techniques for improving stone fruit production, fruit quality, and storage performance: High density training trials. In California Tree Fruit Agreement Research Report; California Tree Fruit Agreement Annual Research: Sacramento, CA, USA, 1993; Volume 7. [Google Scholar]

- Chalmers, D.; Van Den Ende, B.; Van Heek, L. Productivity and mechanization of the Tatura Trellis orchard [Peaches, pears, apricots]. HortScience 1978, 13, 517–521. [Google Scholar]

- DeJong, T.M.; Day, K.R.; Doyle, J.F.; Johnson, R.S. The Kearney Agricultural Center perpendicular “V” (KAC-V) or-chard system for peaches and nectarines. HortTechnology 1994, 4, 362–367. [Google Scholar] [CrossRef] [Green Version]

- Long, L.E.; Lang, G.A.; Whiting, M.D.; Musacchi, S. Cherry training systems. PNW Ext. 2015, 667, 1–63. [Google Scholar]

- Tustin, D.; Van Hooijdonk, B.; Breen, K. The Planar Cordon—New planting systems concepts to improve light utilisation and physiological function to increase apple orchard yield potential. Acta Hortic. 2018, 1–12. [Google Scholar] [CrossRef]

- Zhang, J.; Whiting, M.D.; Zhang, Q. Diurnal pattern in canopy light interception for tree fruit orchard trained to an upright fruiting offshoots (UFO) architecture. Biosyst. Eng. 2015, 129, 1–10. [Google Scholar] [CrossRef]

- DeJong, T.M.; Tsuji, W.; Doyle, J.F.; Grossman, Y.L. Comparative economic efficiency of four peach production systems in California. HortScience 1999, 34, 73–78. [Google Scholar] [CrossRef]

- Rogers, H.T. Stick with cling peaches. West. Fruit Grow. 1986, 106, 12. [Google Scholar]

- DeJong, T.; Tsuji, W.; Doyle, J.; Grossman, Y. Do high density systems really pay?—Evaluation of high density systems for cling peaches. Acta Hortic. 1997, 599–604. [Google Scholar] [CrossRef]

- Hudson, J.P. Meadow orchards. Agriculture 1971, 78, 157. [Google Scholar]

- Erez, A. Meadow orchard for the peach. Sci. Hortic. 1976, 5, 43–48. [Google Scholar] [CrossRef]

- Erez, A. Peach Meadow Orchards. Acta Hortic. 1985, 405–412. [Google Scholar] [CrossRef]

- Palmer, J.W.; Wünsche, J.N.; Meland, M.; Hann, A. Annual dry-matter production by three apple cultivars at four within-row spacings in New Zealand. J. Hortic. Sci. Biotechnol. 2002, 77, 712–717. [Google Scholar] [CrossRef]

- Wünsche, J.N.; Lakso, A.N. The Relationship between Leaf Area and Light Interception by Spur and Extension Shoot Leaves and Apple Orchard Productivity. HortScience 2000, 35, 1202–1206. [Google Scholar] [CrossRef] [Green Version]

- Sansavini, S.; Corelli-Grappadelli, L. Yield and Light Efficiency for High Quality Fruit in Apple and Peach High Density Planting. Acta Hortic. 1997, 559–568. [Google Scholar] [CrossRef]

- Lordan, J.; Francescatto, P.; Dominguez, L.I.; Robinson, T.L. Long-term effects of tree density and tree shape on apple orchard performance, a 20 year study—Part 1, agronomic analysis. Sci. Hortic. 2018, 238, 303–317. [Google Scholar] [CrossRef]

- Lordan, J.; Gomez, M.; Francescatto, P.; Robinson, T.L. Long-term effects of tree density and tree shape on apple or-chard performance, a 20 year study—Part 2, economic analysis. Sci. Hortic. 2019, 244, 435–444. [Google Scholar] [CrossRef]

- Giuliani, R.; Magnanini, E.; Corelli-Grappadelli, L. Whole Canopy Gas Exchanges and Light Interception of Three Peach Training Systems. Acta Hortic. 1998, 309–318. [Google Scholar] [CrossRef]

- Robinson, T.L.; Wünsche, J.; Lakso, A. The influence of orchard system and pruning severity on yield, light interception, conversion efficiency, partitioning index and leaf area index. In Proceedings of the V International Symposium on Orchard and Plantation Systems 349, Tel-Aviv, Israel, 21–26 June 1992; pp. 123–128. [Google Scholar]

- Uberti, A.; Santana, A.S.; Lugaresi, A.; do Prado, J.; Louis, B.; Damis, R.; de Oliveira Fischer, D.L.; Giacobbo, C.L. Initial productive development of peach trees under modern training systems. Sci. Hortic. 2020, 272, 109527. [Google Scholar] [CrossRef]

- De Salvador, F.; Fideghelli, C. Peach Training Systems to Improve Management Efficiency and to Reduce Costs. Acta Hortic. 1993, 349, 33–38. [Google Scholar] [CrossRef]

- Rufato, L.; Rossi, A.; Picolotto, L.; Parizoto, E.; Fachinello, J. Evaluation of vegetative and productive response of two peach training systems (y system and central leader) in an icm orchard. Acta Hortic. 2004, 711–715. [Google Scholar] [CrossRef]

- Giovannini, D.; Monastra, F. Tipologie e forme di allevamento per la peschicoltura meridionale. In Frutticoltura ad Alta Densità; Sansavini, S., Errani, A., Eds.; Edagricole: Bologna, Italy, 1998; pp. 217–236. [Google Scholar]

- Caruso, T.; Di Vaio, C.; Inglese, P.; Pace, L.S. Crop load and fruit quality distribution within canopy of ‘Spring Lady’ peach trees trained to ‘central leader’ and ‘Y shape’. In Proceedings of the IV International Peach Symposium 465, Bordeaux, France, 22–26 June 1997; pp. 621–628. [Google Scholar]

- Farina, V.; Bianco, R.L.; Inglese, P. Vertical Distribution of Crop Load and Fruit Quality within Vase- and Y-shaped Canopies of `Elegant Lady’ Peach. HortScience 2005, 40, 587–591. [Google Scholar] [CrossRef] [Green Version]

- Génard, M.; Bruchou, C. Multivariate analysis of within-tree factors accounting for the variation of peach fruit quality. Sci. Hortic. 1992, 52, 37–51. [Google Scholar] [CrossRef]

- Wagenmakers, P.S.; Callesen, O. Light distribution in apple orchard systems in relation to production and fruit quality. J. Hortic. Sci. 1995, 70, 935–948. [Google Scholar] [CrossRef]

- Lewallen, K.S.; Marini, R.P. Relationship between Flesh Firmness and Ground Color in Peach as Influenced by Light and Canopy Position. J. Am. Soc. Hortic. Sci. 2003, 128, 163–170. [Google Scholar] [CrossRef] [Green Version]

- Anthony, B.M.; Chaparro, J.M.; Sterle, D.G.; Prenni, J.E.; Minas, I.S. Metabolic signatures of the true physiological impact of canopy light environment on peach fruit quality. Environ. Exp. Bot. 2021, 191, 104630. [Google Scholar] [CrossRef]

- Anthony, B.; Serra, S.; Musacchi, S. Optimization of Light Interception, Leaf Area and Yield in “WA38”: Comparisons among Training Systems, Rootstocks and Pruning Techniques. Agronomy 2020, 10, 689. [Google Scholar] [CrossRef]

- Testolin, R.; Costa, G. Net photosynthesis: Sources of variation in peach canopy. Adv. Hortic. Sci. 1991, 5, 35–39. [Google Scholar]

| Rootstock | Country Origin | Genetic Origin |

|---|---|---|

| ControllerTM5 (K146-43) | UC-Davis *, CA, USA | P. salicina × P. persica |

| ControllerTM6 (HBOK 27) | UC-Davis, CA, USA | P. persica × P. persica |

| ControllerTM7 (HBOK 32) | UC-Davis, CA, USA | P. persica × P. persica |

| ControllerTM8 (HBOK 10) | UC-Davis, CA, USA | P. persica × P. persica |

| MP-29 | University of Florida, FL, USA | P. umbellata × P. persica |

| P. americana | USA | P. americana |

| Lovell | G.W. Thissell, Winters, CA, USA | P. persica |

| Hansen 536 | UC-Davis, CA, USA | P. amygdalus × P. persica |

| KV 10123 | USDA Kearneysville, WV, USA | P. persica |

| KV 10127 | USDA Kearneysville, WV, USA | P. persica |

| Nemaguard | USDA, USA | P. persica × P. davidiana |

| Guardian® | USDA/Clemson, SC, USA | P. persica |

| Bright’s Hybrid #5 | Brights Nursery, CA, USA | P. dulcis × P. persica |

| Viking | Zaiger Genetics, inc., CA, USA | unknown interspecific cross |

| Atlas | Zaiger Genetics, inc., CA, USA | unknown interspecific cross |

| Rootpac®R | Agromillora, Spain | P. cerasifera × P. amygdalus |

| Rootpac®70 | Agromillora, Spain | P. persica × (P. amygdalus × P. persica) |

| Rootpac®40 | Agromillora, Spain | (P. dulcis × P. persica) × (P. dulcis × P. persica) |

| Rootpac®20 | Agromillora, Spain | P. besseyi × P. persica |

| Microbac (Replantpac) | Agromillora, Spain | P. domestica |

| Fortuna | Russia | P. cerasifera × P. persica |

| Krymsk®1 | Krymsk Exp. Breeding Station, Russia | P. tomentosa × P. cerasifera |

| Krymsk®86 | Krymsk Exp. Breeding Station, Russia | P. cerasifera × P. persica |

| Empyrean®2 (Penta) | ISF, Italy | P. domestica |

| Empyrean®3 (Tetra) | ISF, Italy | P. domestica |

| Imperial California | Italy | P. domestica |

| GF677 | INRA, France | P. amygdalus × P. persica |

| System | No. of Primary Leaders | Spacing (m) (Intra- × Inter-Row) | Trees ha−1 | Tree Height (m) |

|---|---|---|---|---|

| Low-Density Planting (LDP) | ||||

| Open Vase | 3 | 3.5–5.0 × 4.0–5.0 | 220–550 | 2.2–5.0 |

| Medium-Density Planting (MDP) | ||||

| Delayed Vasette | 4 | 3.5 × 4.5 | 600–800 | 3.0–4.0 |

| Palmette | 1 | 2.0–3.5 × 4.0–4.5 | 600–900 | 3.5–4.5 |

| Hex-V | 6 | 3.0 × 4.5 | 750 | 2.0–2.5 |

| Quad-V | 4 | 2.5–3.0 × 4.5 | 900–1000 | 2.5–3.0 |

| High-Density Planting (HDP) | ||||

| Fusetto or Tall Spindle Axe (TSA) | 1 | 1.5–2.0 × 4.0 | 1250–2000 | 2.8–3.5 |

| Slender Spindle Axe (SSA) | 1 | 1.2–1.5 × 3.5–4.0 | 1500–2445 | 3.0–3.7 |

| Y-Shaped (Bi-Axis, KAC-V) | 2 | 1.5–2.0 × 4.0–4.5 | 900–2000 | 3.0–5.5 |

| Cordon Systems | 1–2 | 2.4 × 4.0 | 900 | <2.5 |

| Ultra High-Density Planting (UHDP) | ||||

| Meadow Orchard | 1–2 | 0.4–1.0 × 1.3–4.8 | 2700–19,000 | 1.5–2.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anthony, B.M.; Minas, I.S. Optimizing Peach Tree Canopy Architecture for Efficient Light Use, Increased Productivity and Improved Fruit Quality. Agronomy 2021, 11, 1961. https://doi.org/10.3390/agronomy11101961

Anthony BM, Minas IS. Optimizing Peach Tree Canopy Architecture for Efficient Light Use, Increased Productivity and Improved Fruit Quality. Agronomy. 2021; 11(10):1961. https://doi.org/10.3390/agronomy11101961

Chicago/Turabian StyleAnthony, Brendon M., and Ioannis S. Minas. 2021. "Optimizing Peach Tree Canopy Architecture for Efficient Light Use, Increased Productivity and Improved Fruit Quality" Agronomy 11, no. 10: 1961. https://doi.org/10.3390/agronomy11101961

APA StyleAnthony, B. M., & Minas, I. S. (2021). Optimizing Peach Tree Canopy Architecture for Efficient Light Use, Increased Productivity and Improved Fruit Quality. Agronomy, 11(10), 1961. https://doi.org/10.3390/agronomy11101961