Design of and Experiment with Seedling Selection System for Automatic Transplanter for Vegetable Plug Seedlings

Abstract

:1. Introduction

2. Materials and Methods

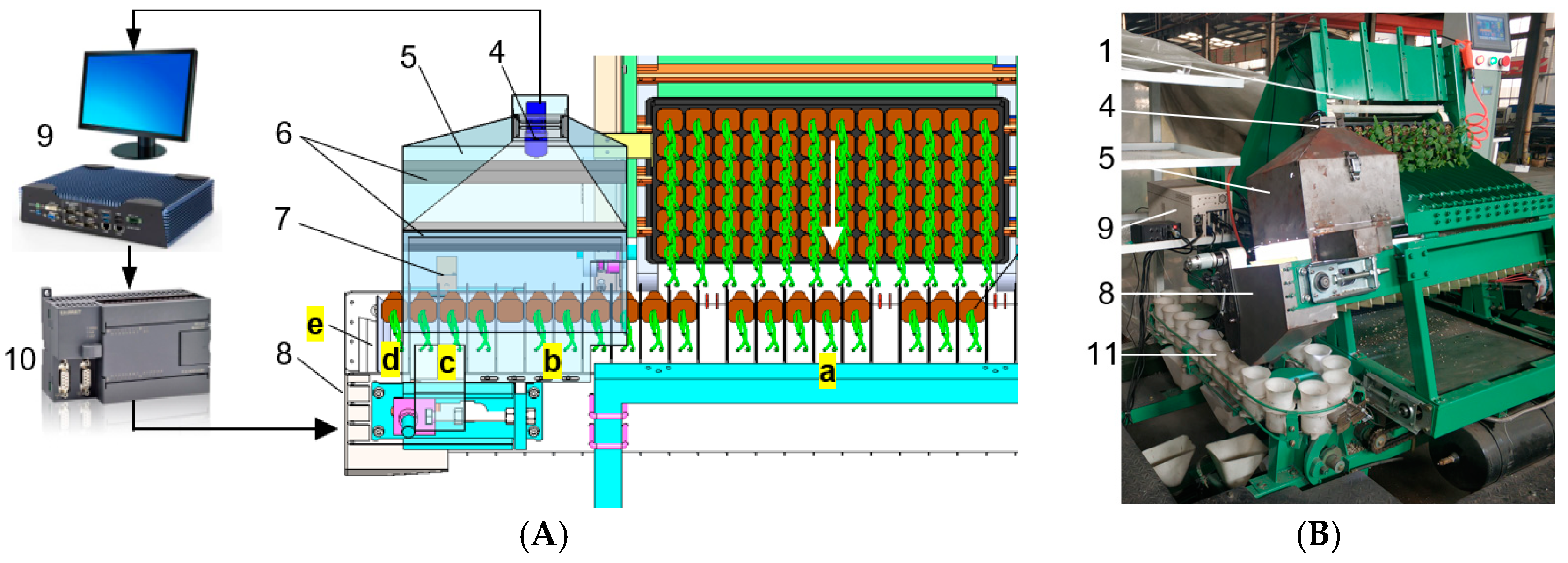

2.1. Scheme of Seedling Selection System of Plug Seedling Automatic Transplanter

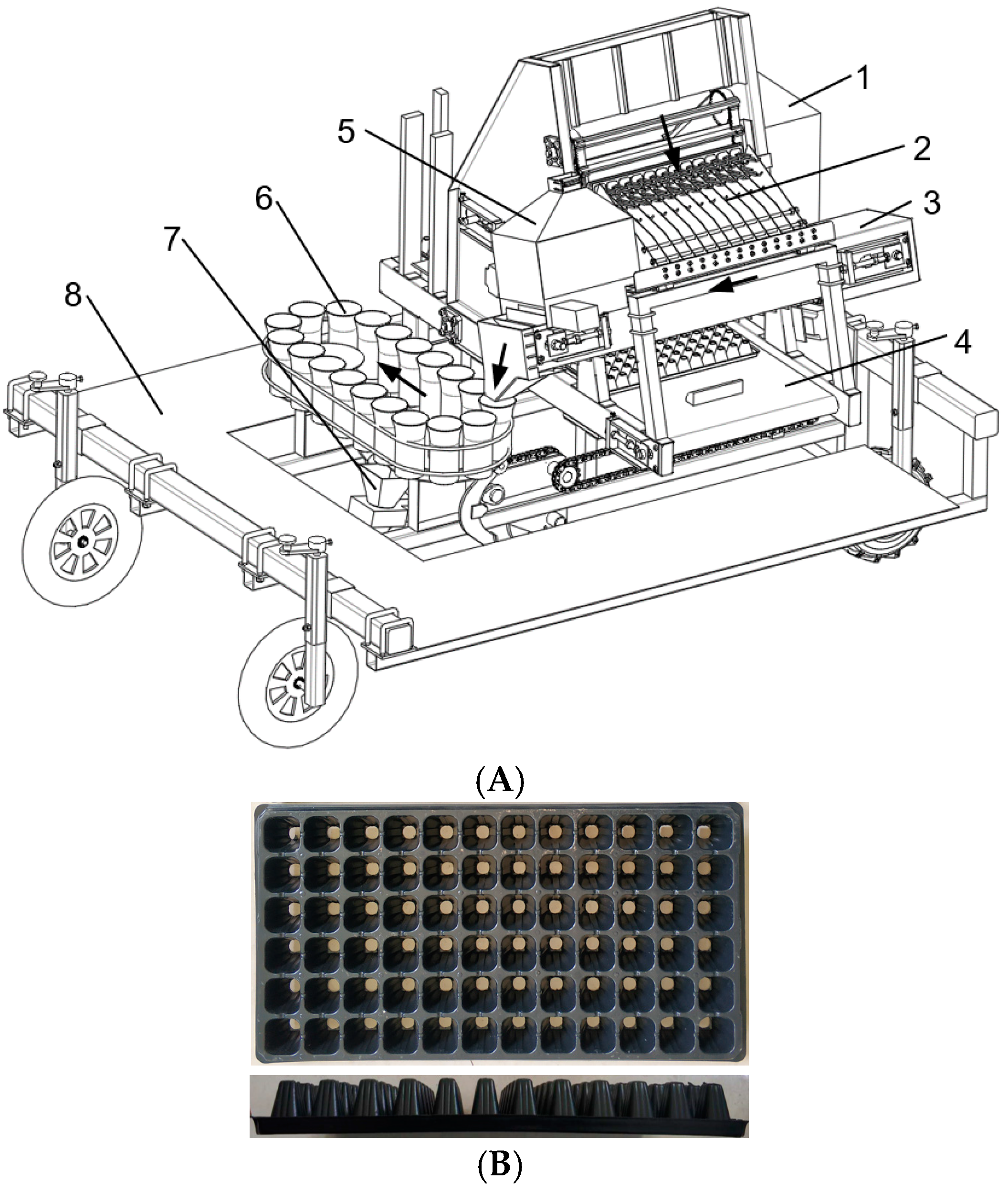

2.1.1. Overall Design of Automatic Transplanter

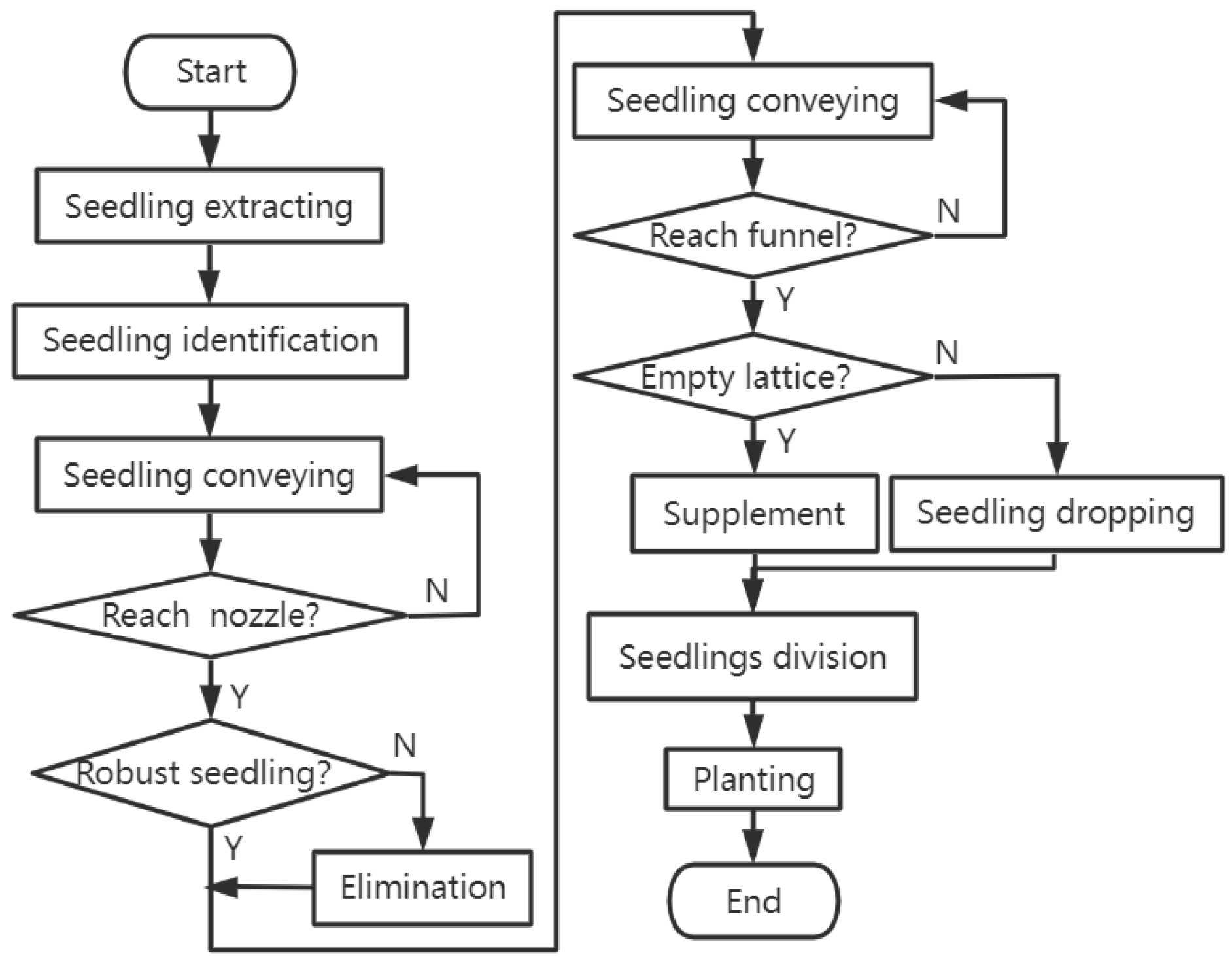

2.1.2. Working Principle of the Seedling Selection System

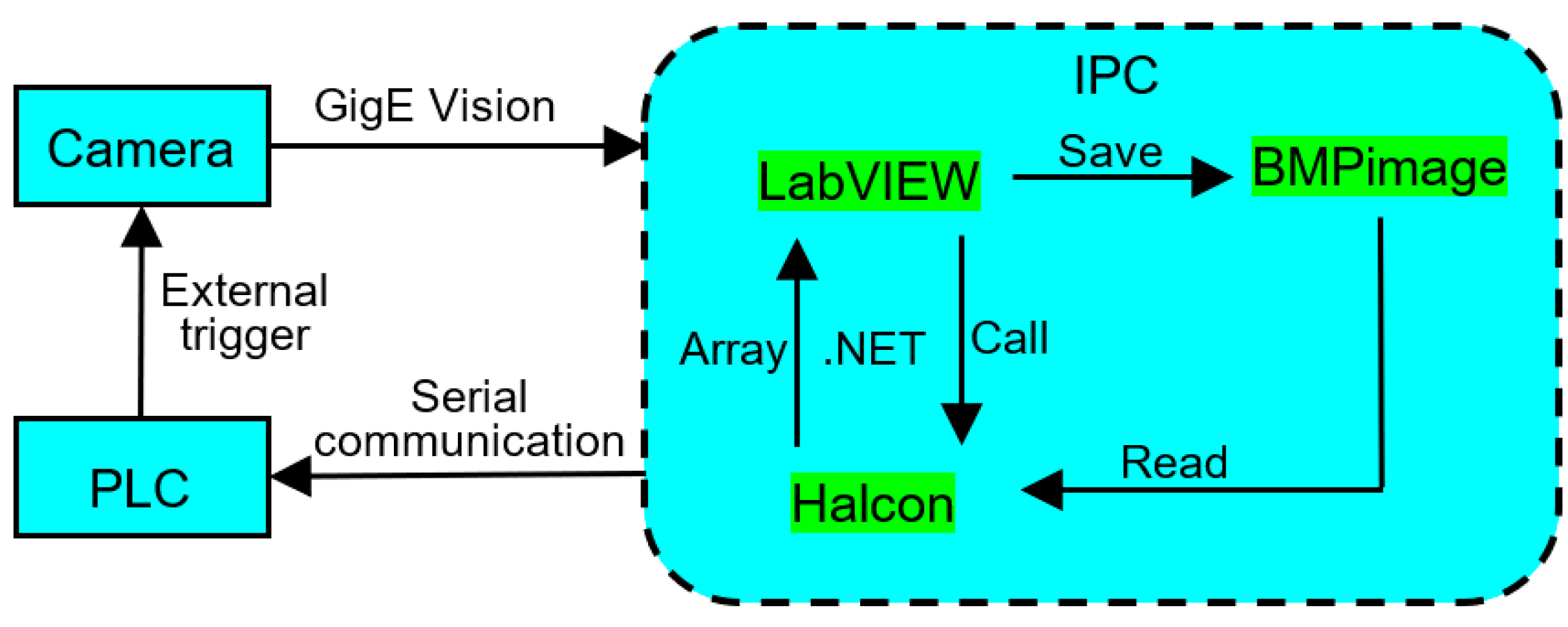

2.1.3. Plug Seedling Identification Software

2.2. Characteristic Extraction and Classifying of Plug Seedlings

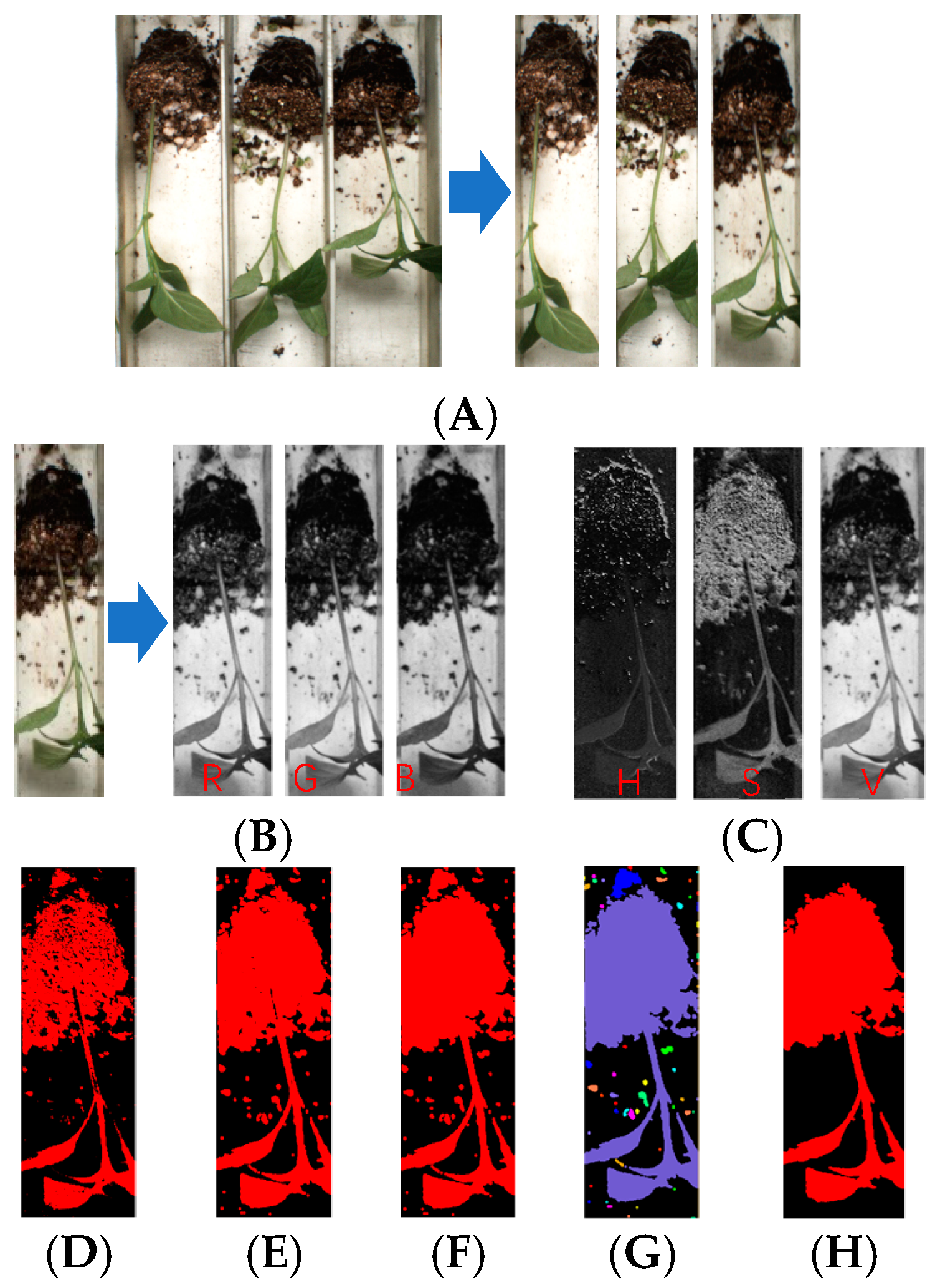

2.2.1. Image Acquisition and Segmentation

2.2.2. Characteristic Extraction of Plug Seedlings

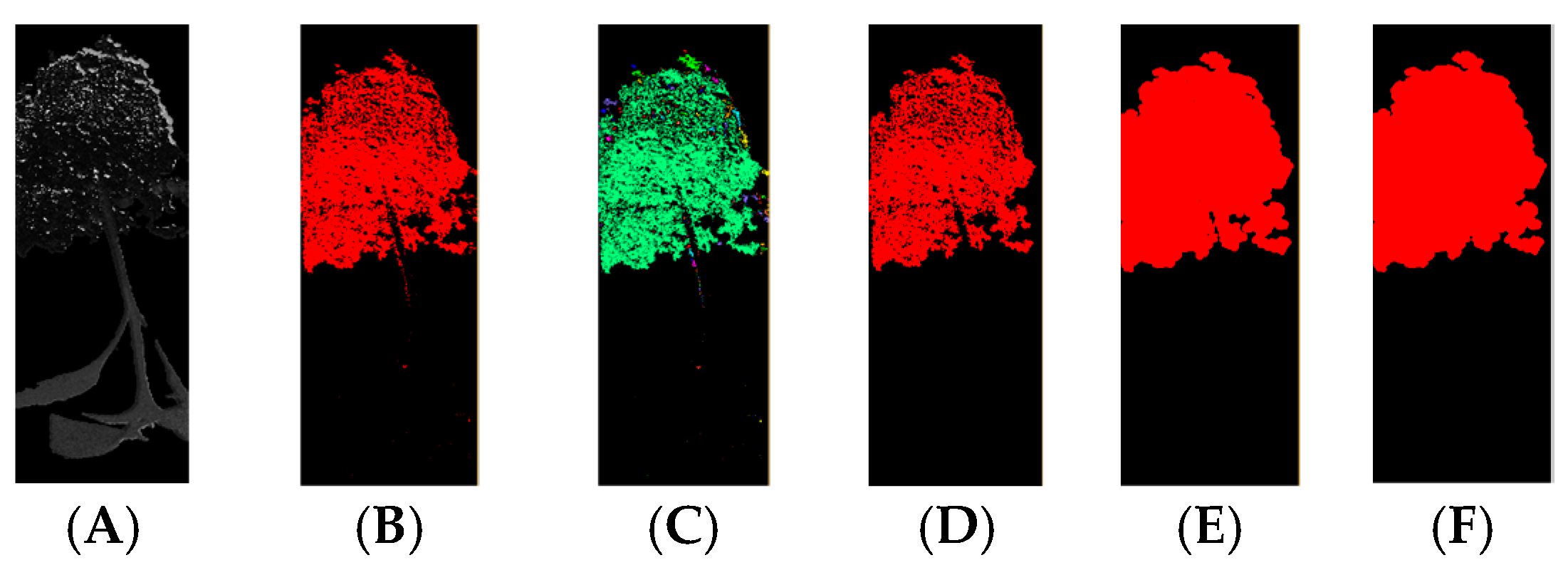

2.2.3. Characteristic Extraction of Plug Bodies

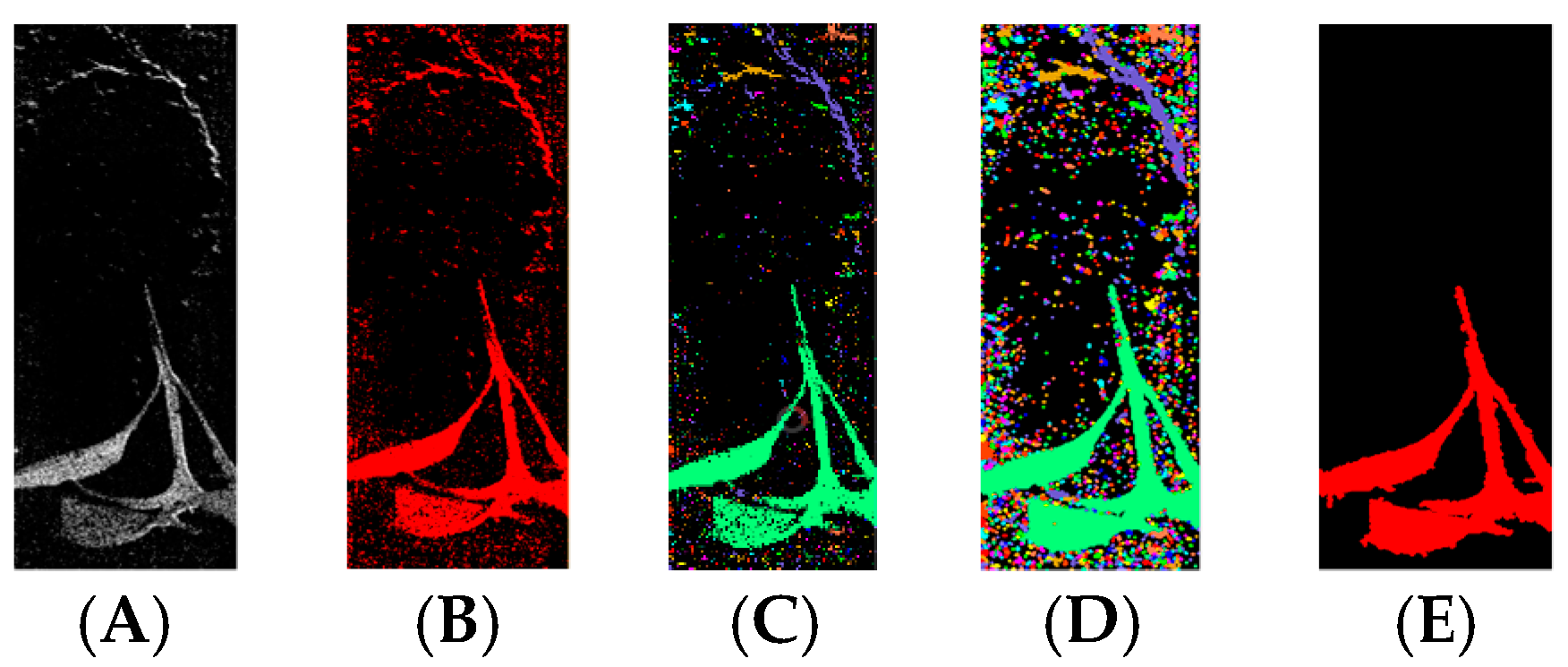

2.2.4. Characteristic Extraction of Stems and Leaves

2.2.5. Classification of Plug Seedlings

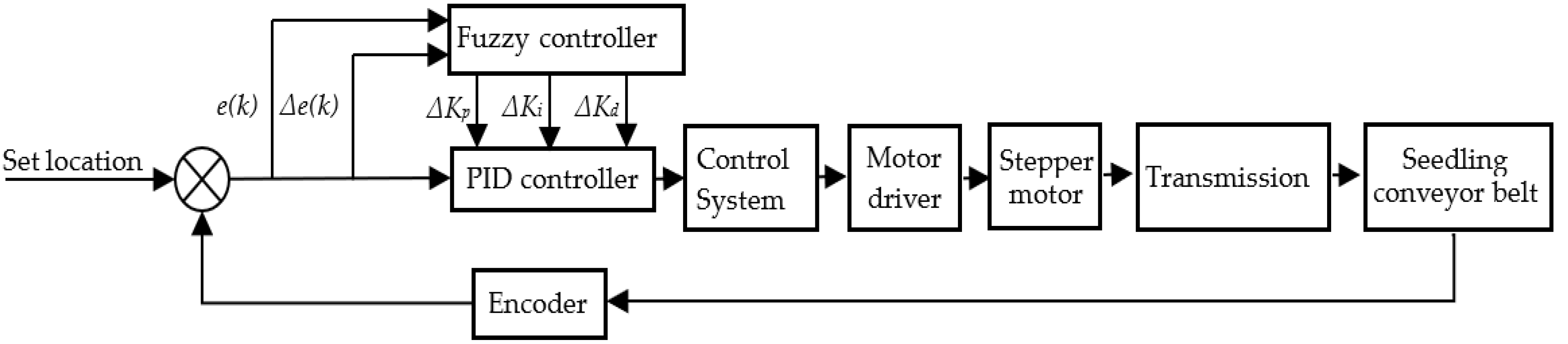

2.3. Adaptive Fuzzy PID Control Algorithms for Seedling Conveyor Device

2.3.1. Precision Analysis of Seedling Conveyor Device

2.3.2. The Composition of Adaptive Fuzzy PID Control Algorithm

2.3.3. Implementation of Adaptive Fuzzy PID Control Algorithm

3. Results and Discussion

3.1. Experiment Conditions

3.2. Experiment Method and Index

3.3. Results and Analysis

3.4. Discussion

4. Conclusions

- The seedling selection system of automatic transplanter for vegetable plug seedlings was developed to realize the identification of plug seedlings, the elimination of unqualified seedlings and the replenishment of seedlings. It is composed of an IPC installed with plug seedling identification software, an industrial camera, two strip light sources, a light box, a PLC control system, a nozzle, and seedling conveyor device. With the cooperation of the PLC control system and the plug seedling identification software, all parts of the automatic transplanter coordinate and cooperate to complete the seedling extraction, plug seedling identification, unqualified seedling elimination, and seedling replenishment.

- The plug seedling identification software was built by LabVIEW, VAS, and Halcon. The characteristics extraction algorithms for plug seedling, stem leaves, and plug body were designed using image processing, such as image cropping, segmentation, dilation, merging, and filling. The plug seedlings on the conveyor belt were identified and the result was sent from IPC to PLC to conduct real-time seedling elimination or seedling replenishment.

- The adaptive fuzzy PID controller was designed to control the seedling conveyor belt. The controller revised the PID control parameters in real time based on the conveyor belt position deviation value e(k) and deviation value change rate Δe(k) to realize fast and accurate seedling conveyance and seedling replenishment.

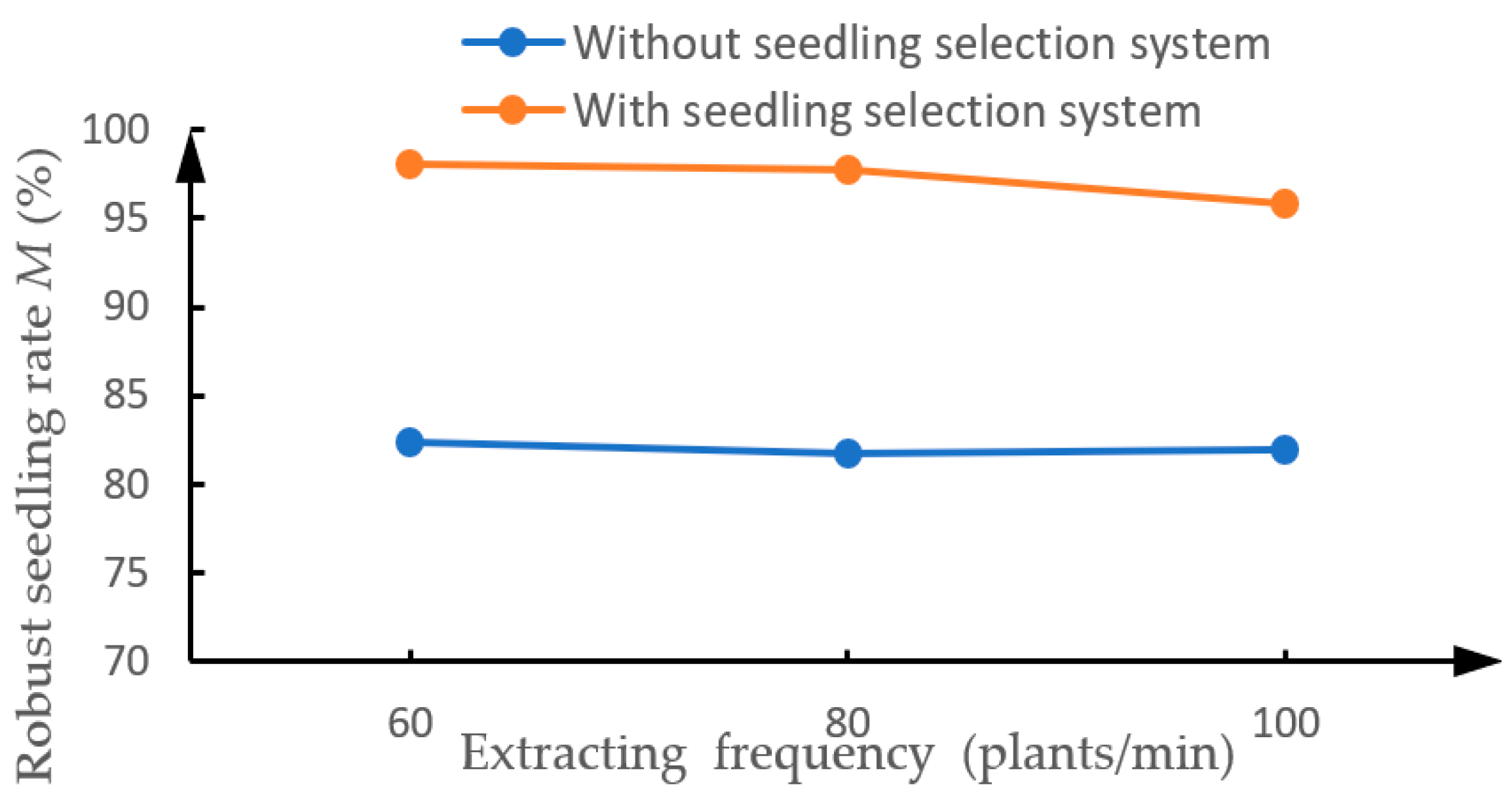

- Taking the seedling identification success rate and the robust seedling rate as the test indicators, the comparative field experiment of seedling transplanting was conducted on the seedling extracting frequencies of 60, 80, and 100 plants/min. The experimental results indicate that when the seedling selection system was turned on, the success rates of plug seedling identification were 98.84%, 98.38%, and 96.99%, respectively, and the robust seedling rates were 98.05%, 97.78%, and 95.83%, respectively. The robust seedling rates were increased by 15.64%, 16.07%, and 13.89%, in contrast to turning off the seedling selection system. In addition, the data of the comparative field experiment show that the growth rates of robust seedlings will decline with increasing seedling extracting frequencies, but the overall growth rates of robust seedlings reach more than 13%. This study provides a reference for the further improvement of transplanting quality of the automatic transplanter for vegetable plug seedlings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jin, X.; Che, J.; Chen, Y. Weed identification using deep learning and image processing in vegetable plantation. IEEE Access 2021, 9, 10940–10950. [Google Scholar] [CrossRef]

- Dong, Y.; Fu, Z.; Stankovski, S.; Wang, S.; Li, X. Nutritional Quality and Safety Traceability System for China’s Leafy Vegetable Supply Chain Based on Fault Tree Analysis and QR Code. IEEE Access 2020, 8, 161261–161275. [Google Scholar] [CrossRef]

- Yang, Q.; Xu, L.; Shi, X.; Ibrar, A.; Mao, H.; Hu, J.; Han, L. Design of seedlings separation device with reciprocating movement seedling cups and its controlling system of the full-automatic plug seedling transplanter. Comput. Electron. Agric. 2018, 147, 131–145. [Google Scholar] [CrossRef]

- Mao, H.; Han, L.; Hu, J.; Kumi, F. Development of a pincette-type pick-up device for automatic transplanting of greenhouse seedlings. Appl. Eng. Agric. 2014, 30, 547–556. [Google Scholar]

- Rahul, K.; Raheman, H.; Paradkar, V. Design and development of a 5R 2DOF parallel robot arm for handling paper pot seedlings in a vegetable transplanter. Comput. Electron. Agric. 2019, 166, 105014. [Google Scholar] [CrossRef]

- Schmoldt, D. Precision agriculture and information technology. Comput. Electron. Agric. 2001, 30, 5–7. [Google Scholar] [CrossRef]

- Hu, X.; Sun, L.; Zhou, Y.; Ruan, J. Review of operational management in intelligent agriculture based on the Internet of Things. Front. Eng. Manag. 2020, 7, 309–322. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, X.; Jin, X.; Liu, Z.; Zhu, L.; Sun, X.; Zou, Z.; Liu, B. Design and experiment on transplanter pot seed-ling disk conveying and positioning control system. Trans. Chin. Soc. Agric. Eng. 2015, 31, 47–52. [Google Scholar]

- Zhou, S.; Shi, H.; Guo, L.; Guo, W.; Jin, H.; Zhou, J. Autonomous guidance for rice transplanter fusion of machine vision and global positioning system. In Proceedings of the 2018 ASABE Annual International Meeting, American Society of Agricultural and Biological Engineers, Detroit, MI, USA, 29 July–1 August 2018. [Google Scholar]

- Tai, Y.W. Machine vision assisted robotic seedling transplanting. Trans. ASAE 1994, 37, 661–667. [Google Scholar] [CrossRef]

- Ryu, K.; Kim, G.; Han, J. AE—Automation and Emerging Technologies: Development of a Robotic Transplanter for Bedding Plants. J. Agric. Eng. Res. 2001, 78, 141–146. [Google Scholar] [CrossRef]

- Tong, J.H.; Li, J.B.; Jiang, H.Y. Machine vision techniques for the evaluation of seedling quality based on leaf area. Biosyst. Eng. 2013, 115, 369–379. [Google Scholar] [CrossRef]

- Tong, J.; Shi, H.; Wu, C.; Jiang, H.; Yang, T. Skewness correction and quality evaluation of plug seedling images based on Canny operator and Hough transform. Comput. Electron. Agric. 2018, 155, 461–472. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, X.; Liang, X.; Wang, J.; Wu, C.; Chen, J. Plug hole positioning and seedling shortage detecting system on automatic seedling supplementing test-bed for vegetable plug seedlings. Trans. Chin. Soc. Agric. Eng. 2018, 34, 35–41. [Google Scholar]

- Yang, Z.; Zhang, W.; Li, W.; Chen, Y. Monocular vision-based method for direction adjustment of transplanting potted-seedling leaves. Trans. Chin. Soc. Agric. Eng. 2014, 30, 26–33. [Google Scholar]

- Yang, Z.; Zhang, W.; Wei, L.; Chen, Y.; Song, P. Information acquisition method of potted-seedling transplanting fitness using monocular vision. Trans. Chin. Soc. Agric. Eng. 2014, 30, 112–119. [Google Scholar]

- Xin, J.; Xinwu, D.; Jiangtao, J.; Zhitao, H.; Chuanhua, Y. Automatic detection and controlling system of pot seedlingsfor transplanters. Int. Agric. Eng. J. 2015, 24, 143–151. [Google Scholar]

- Tie, S. Development and test of automatic corn seedling transplanter. Nongye Gongcheng Xuebao Trans. Chin. Soc. Agric. Eng. 2015, 31, 23–30. [Google Scholar] [CrossRef]

- Wei, X.; Bao, S.; Liu, X.; Liu, C.; Mao, H. Design and Experiment on Potted-seedling Automatic Transplanter Control System for Motion Coordinating. Trans. Chin. Soc. Agric. Mach. 2016, 12, 1–7. [Google Scholar]

- Wen, Y.; Zhang, J.; Tian, J.; Duan, D.; Li, X. Design of a traction double-row fully automatic transplanter for vegetable plug seedlings. Comput. Electron. Agric. 2021, 182, 106017. [Google Scholar] [CrossRef]

- Chen, L.; Deng, Z.; Wang, Y.; Zhou, H. Design of interferometer direction finding experimental teaching system based on LabVIEW. Exp. Technol. Manag. 2020, 37, 143–146, 188. [Google Scholar]

- Bao, X.; Jia, H.; Lang, C. A Novel Hybrid Harris Hawks Optimization for Color Image Multilevel Thresholding Segmentation. IEEE Access 2019, 7, 76529–76546. [Google Scholar] [CrossRef]

- Vala, M.; Baxi, A. A Review on Otsu Image Segmentation Algorithm. Int. J. Adv. Res. Comput. Eng. Technol. 2013, 2, 387–389. [Google Scholar]

- Tang, H.; Wu, E.X.; Ma, Q.; Gallagher, D.; Perera, G.; Zhuang, T. MRI brain image segmentation by multi-resolution edge detection and region selection. Comput. Med. Imaging Graph. 2000, 24, 349–357. [Google Scholar] [CrossRef]

- Khan, M.F.; Aadil, F.; Maqsood, M.; Bukhari, S.; Hussain, M.; Nam, Y. Moth Flame Clustering Algorithm for Internet of Vehicle (MFCA-IoV). IEEE Access 2018, 7, 11613–11629. [Google Scholar] [CrossRef]

- Xu, X.; Xu, S.; Jin, L.; Song, E. Characteristic analysis of Otsu threshold and its applications. Pattern Recognit. Lett. 2011, 32, 956–961. [Google Scholar] [CrossRef]

- Zhang, G.; Wen, Y.; Tan, Y.; Yuan, T.; Zhang, J.; Chen, Y.; Zhu, S.; Duan, D.; Tian, J.; Zhang, Y. Identification of cabbage seedling defects in a fast automatic transplanter based on the maxiou algorithm. Agronomy 2020, 10, 65. [Google Scholar] [CrossRef] [Green Version]

- Woebbecke, D.M.; Meyer, G.E.; Von Bargen, K.; Mortensen, D.A. Color Indices for Weed Identification Under Various Soil, Residue, and Lighting Conditions. Trans. ASAE 1995, 38, 259–269. [Google Scholar] [CrossRef]

- Liu, J.; Cao, W.; Xu, H.; Tian, D.; Ouyang, Y. Adaptive fuzzy-PID control of accurate orientation for auto-detect seedling supply device. Trans. Chin. Soc. Agric. Eng. 2017, 33, 37–44. [Google Scholar]

- Wang, Q.; Cao, W.; Zhang, Z.; Zhang, P.; Wang, P. Location control of automatic pick-up plug seedlings mechanism based on adaptive Fuzzy-PID. Trans. Chin. Soc. Agric. Eng. 2013, 29, 32–39. [Google Scholar]

| Correction Parameter | e(k) Subset | NL | NM | NS | ZO | PS | PM | PL | |

|---|---|---|---|---|---|---|---|---|---|

| Δe(k) Subset | |||||||||

| ΔKp, ΔKi, ΔKd | N | PL/NS/NS | NL/PS/PL | PL/PS/NL | PS/PS/NS | PL/PS/NL | NL/PS/PS | PL/NL/NS | |

| Z | PL/NS/NS | NL/PS/PS | PS/PS/NS | PS/ZO/NS | PS/PS/NS | NL/PS/PL | PS/NS/NS | ||

| P | PS/NL/ZO | NL/PS/PL | PL/PL/NL | PS/PS/NS | PS/PL/NL | NL/PS/PS | PL/NS/ZO | ||

| Extracting Frequency (plants/min) | Without Seedling Selection System | With Seedling Selection System | ||||

|---|---|---|---|---|---|---|

| Robust Seedling Number W | Robust Seedling Rate M (%) | Success Number Q | Robust Seedling Number W | Success Rate F (%) | Robust Seedling Rate M (%) | |

| 60 | 118 | 81.94 | 142 | 118 | 98.61 | 98.33 |

| 120 | 83.33 | 143 | 118 | 99.31 | 98.33 | |

| 118 | 81.94 | 142 | 117 | 98.61 | 97.5 | |

| Average value | 118.66 | 82.41 | 142.33 | 117.66 | 98.84 | 98.05 |

| 80 | 118 | 81.94 | 143 | 119 | 99.31 | 99.17 |

| 117 | 81.25 | 141 | 116 | 97.92 | 96.67 | |

| 118 | 81.94 | 141 | 117 | 97.92 | 97.5 | |

| Average value | 117.67 | 81.71 | 141.67 | 117.33 | 98.38 | 97.78 |

| 100 | 117 | 81.25 | 139 | 115 | 96.53 | 95.83 |

| 119 | 82.64 | 139 | 114 | 96.53 | 95 | |

| 118 | 81.94 | 141 | 116 | 97.92 | 96.67 | |

| Average value | 118 | 81.94 | 139.67 | 115 | 96.99 | 95.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, Y.; Zhang, L.; Huang, X.; Yuan, T.; Zhang, J.; Tan, Y.; Feng, Z. Design of and Experiment with Seedling Selection System for Automatic Transplanter for Vegetable Plug Seedlings. Agronomy 2021, 11, 2031. https://doi.org/10.3390/agronomy11102031

Wen Y, Zhang L, Huang X, Yuan T, Zhang J, Tan Y, Feng Z. Design of and Experiment with Seedling Selection System for Automatic Transplanter for Vegetable Plug Seedlings. Agronomy. 2021; 11(10):2031. https://doi.org/10.3390/agronomy11102031

Chicago/Turabian StyleWen, Yongshuang, Leian Zhang, Xuemei Huang, Ting Yuan, Junxiong Zhang, Yuzhi Tan, and Zhongbin Feng. 2021. "Design of and Experiment with Seedling Selection System for Automatic Transplanter for Vegetable Plug Seedlings" Agronomy 11, no. 10: 2031. https://doi.org/10.3390/agronomy11102031

APA StyleWen, Y., Zhang, L., Huang, X., Yuan, T., Zhang, J., Tan, Y., & Feng, Z. (2021). Design of and Experiment with Seedling Selection System for Automatic Transplanter for Vegetable Plug Seedlings. Agronomy, 11(10), 2031. https://doi.org/10.3390/agronomy11102031