Techno-Economic Viability of Agro-Photovoltaic Irrigated Arable Lands in the EU-Med Region: A Case-Study in Southwestern Spain

Abstract

:1. Introduction and Objectives

- i.

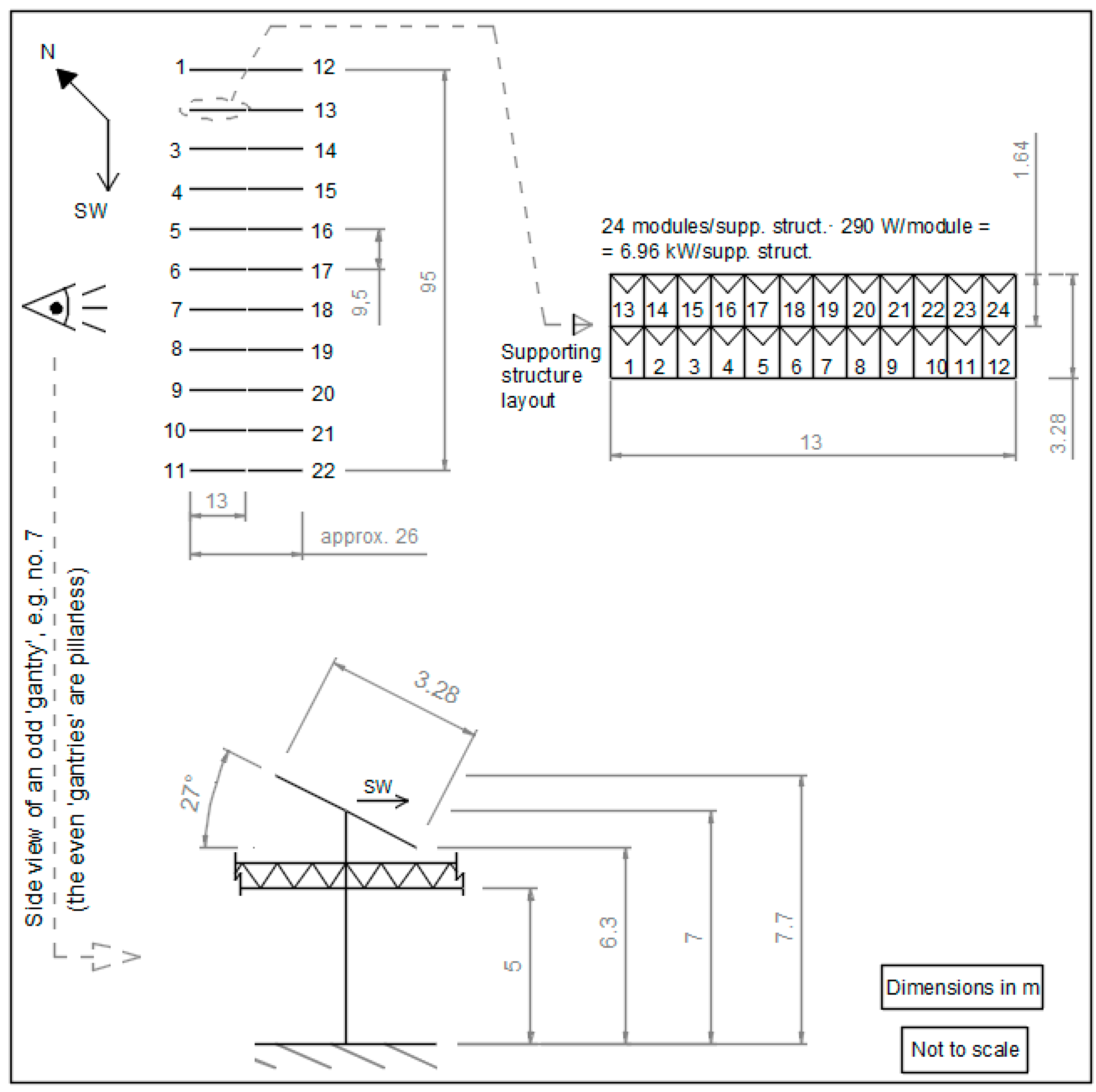

- the spacing between PV module rows in APV systems is greater, to let more irradiation pass through and hit the crop; in conventional ground-mounted PV power plants, row spacing is kept to the minimum compatible with tolerable row self-shading.

- i.

- the PV modules in APV systems are substantially heightened above the ground, to decrease shade intensity and also to allow agricultural machinery operate beneath; thus, while in conventional ground-mounted PV power plants the vertical distance of the modules bottom edge to the ground is 0.5–1 m, in APV it is 5–6 m.

- to design two irrigated annual crop rotations whereof crops are usually cultivated in the area of study and compatible with partial shading imposed by APV sheds.

- to thoroughly determine the stream of expenditure and revenues for both agricultural and electricity production, with the final aim of analyzing the profitability of APV system for each combination of APV shed orientation (due south/ southwest), source of irrigation water (surface/underground), shade-induced crop yield penalty (low/ high) and crop rotation (early potato/processing tomato).

2. Materials and Methods

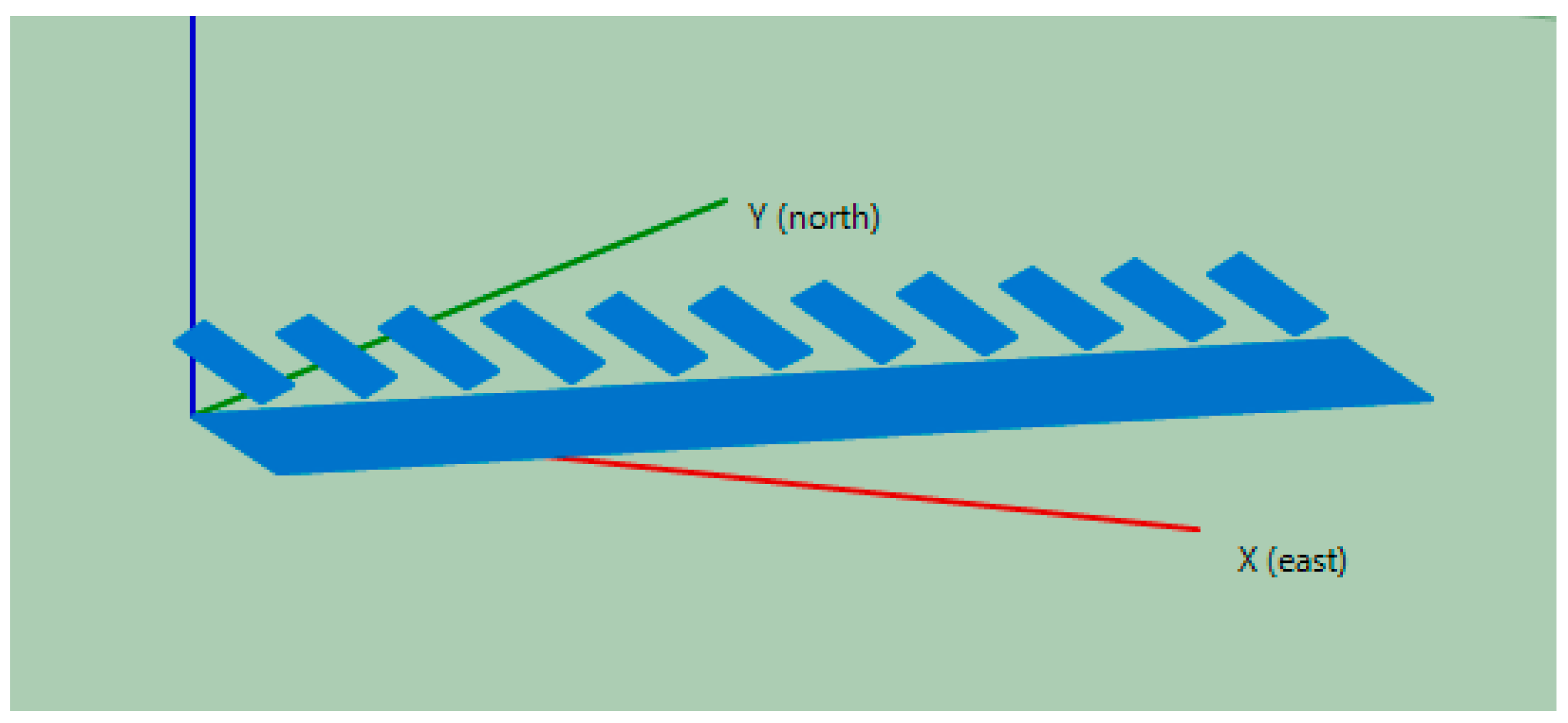

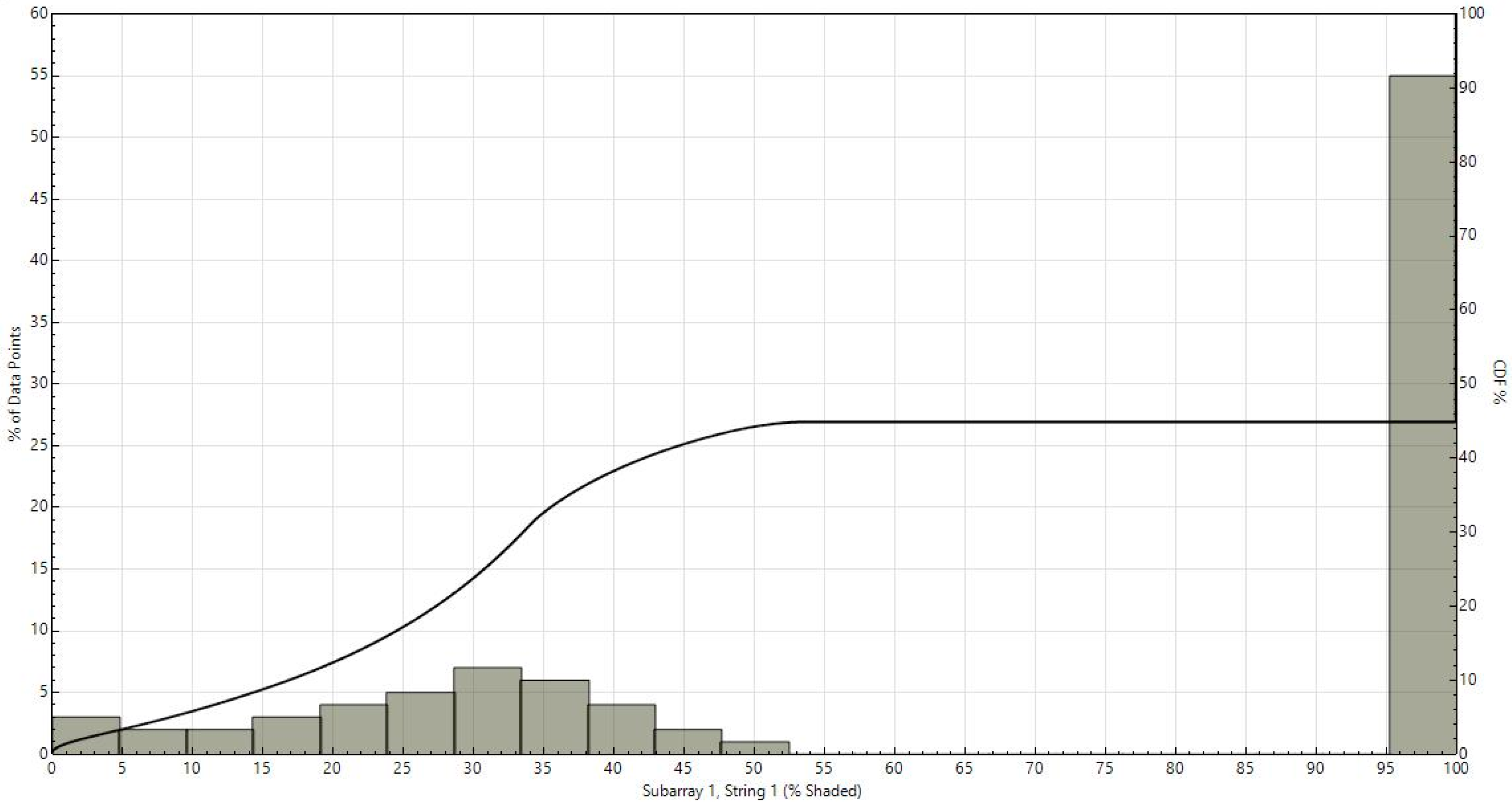

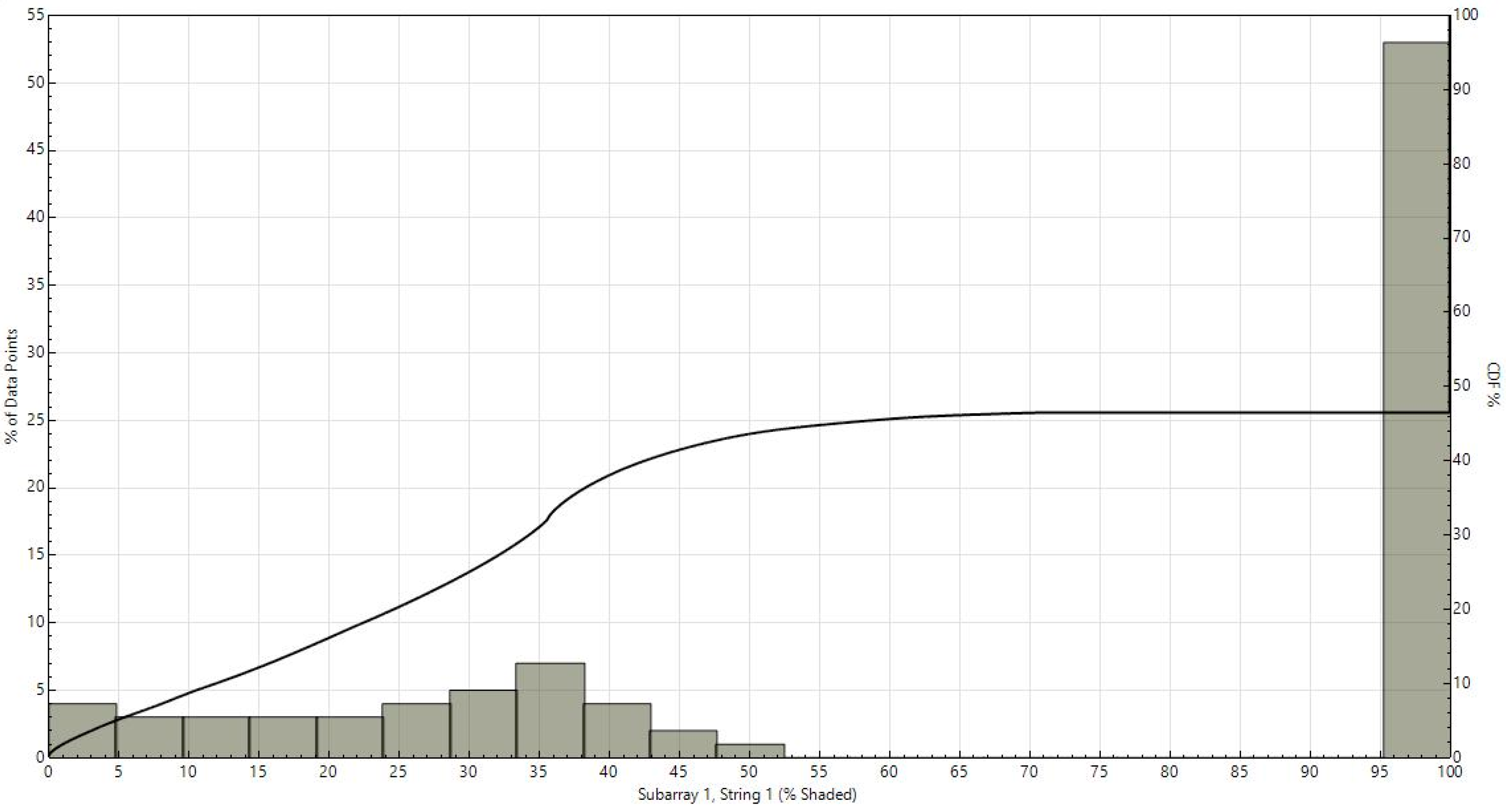

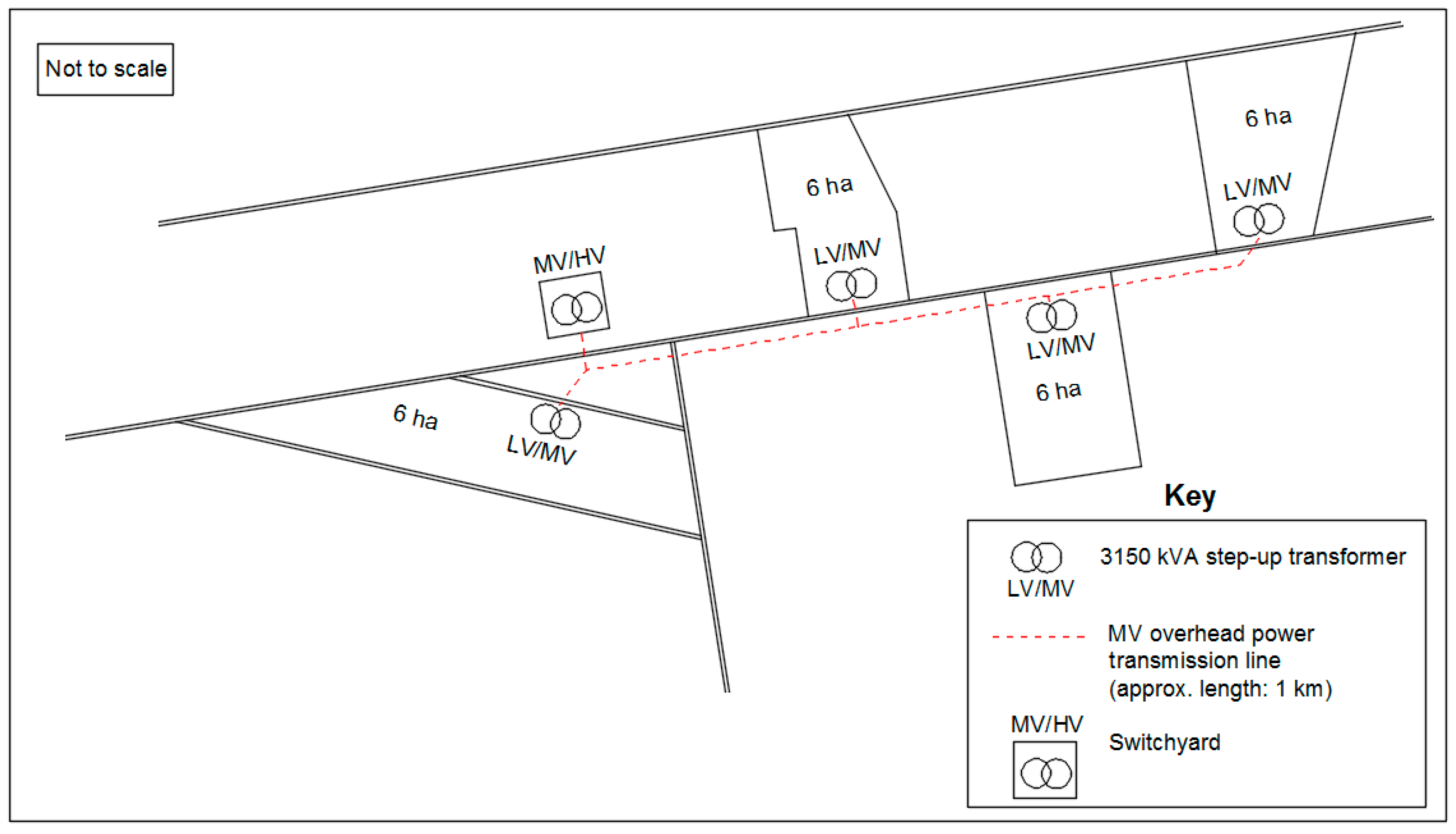

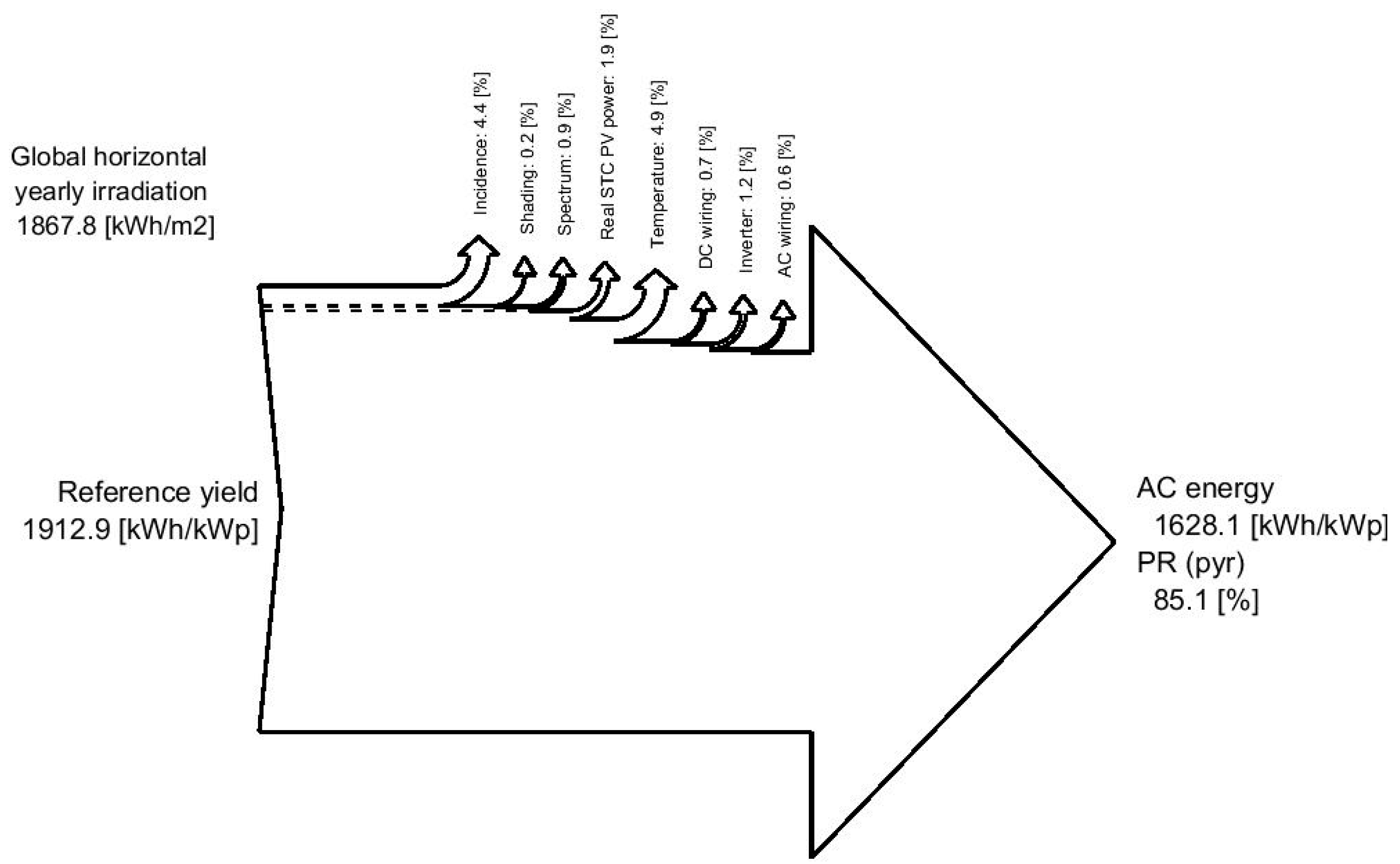

2.1. PV System

2.2. Irrigated Crops

2.3. Profitability Analysis

3. Results

4. Discussion

5. Conclusions

- two crop rotations, one of them headed by early-potato partnered with canola, faba bean, forage-maize and onion, and the other one headed by processing-tomato partnered with onion, dry-pea, carrot and melon were designed;

- the stream of expenditure and revenues for both agricultural and electric energy production was determined for a lifespan of 25 years. The internal rates of return obtained ranged from a minimum of 3.8% for the combination of southwest orientation, early-potato rotation, groundwater and high shade-induced crop-yield penalty to a maximum of 5.6% for the combination of South orientation, processing-tomato rotation, surface water and low shade-induced crop-yield penalty.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| a.s.l. | Above sea level |

| CapEx | Capital expenditures (investment cost) |

| Med | Mediterranean |

| OpEx | Operating expenditures |

| AC | Alternating current |

| APV | Agrophotovoltaic |

| BMDID | Bembézar Margen Derecha Irrigation District |

| CAP | European Union Common Agricultural Policy |

| DC | Direct current |

| EU | European Union |

| FB | Faba bean |

| FM | Forage maize |

| FTS | Future solar contract |

| GCR | Ground coverage ratio |

| GHG | Greenhouse-effect gas |

| HV | High voltage |

| ID | Irrigation district |

| IRR | Internal rate of return |

| LCoE | Levelized cost of –electric- energy |

| LER | Land equivalent ratio |

| LV | Low voltage |

| MV | Medium voltage |

| PE | Polyethylene |

| PV | Photovoltaic |

| SW | Southwest |

| TMY | Typical meteorological year |

| VIID | Valle Inferior Irrigation District |

| Symbols | |

| ph | Pressure head |

| re | Cost of equity (demanded rate of return on equity) |

| rf | Risk-free rate of return |

| rm | Stock market rate of return |

| Ct | Cash flow in the year t |

Appendix A

Appendix B

| Year | Plot 1 | Plot 2 | Plot 3 | Plot 4 |

|---|---|---|---|---|

| 2 | Melon | Onion | Carrot | Tomato |

| 3 | Onion | Carrot | Melon | Tomato |

| 4 | Carrot | Melon | Onion | Tomato |

| 5 | Tomato | Onion | Pea | Melon |

| 6 | Tomato | Onion | Onion | Onion |

| 7 | Tomato | Carrot | Carrot | Carrot |

| 8 | Melon | Tomato | Melon | Melon |

| 9 | Carrot | Tomato | Onion | Onion |

| 10 | Melon | Tomato | Carrot | Carrot |

| 11 | Onion | Melon | Tomato | Melon |

| 12 | Pea | Onion | Tomato | Onion |

| 13 | Onion | Carrot | Tomato | Pea |

| 14 | Carrot | Melon | Melon | Tomato |

| 15 | Melon | Onion | Onion | Tomato |

| 16 | Onion | Carrot | Carrot | Tomato |

| 17 | Tomato | Melon | Melon | Melon |

| 18 | Tomato | Onion | Onion | Onion |

| 19 | Tomato | Pea | Carrot | Carrot |

| 20 | Melon | Tomato | Melon | Melon |

| 21 | Onion | Tomato | Onion | Onion |

| 22 | Carrot | Tomato | Pea | Carrot |

| 23 | Melon | Melon | Tomato | Melon |

| 24 | Onion | Onion | Tomato | Onion |

| 25 | Carrot | Carrot | Tomato | Pea |

| 26 | Melon | Melon | Melon | Tomato |

Appendix C

| EUR/unit | EUR/kWp | EUR/ha (a) | No. Units Per ag. | |

|---|---|---|---|---|

| Plot of 6(5.7) ha | ||||

| (1) PV modules | 60.9 | 210.0 (b) | 116,655 | 10,919 (c) |

| (2) Galvanized steel mounting structure | 378.6 (d) | 210,312 | ||

| (3) Earthing | 0.6 (e) | 333 | ||

| (4) Lightning protection system | 9000 (f) | |||

| (5) DC switchboards (combiner boxes) | 584.0 (g) | 3.8 | 2111 | 21 |

| (6) DC cables | 35.0 (h) | 19,443 | ||

| (7) Inverters | 5100.0 (i) | 33.3 (j) | 18,505 | 21 |

| (8) AC low voltage cables | 18.4 (e) | 10,221 | ||

| (9) LV/MV Transformer | 80,500.0 (e) | 25.4 (k) | 14,124 | 1 |

| (10) MV overhead power transmission line | 1.9 (l) | 1055 | ||

| (11) Monitoring and communications | 0.9 (e) | 500 | ||

| (12) Security | 2.1 (e) | 1167 | ||

| (13) Installation works | 132,490 (m) | |||

| (14) Subtotal 1 {=Σ(1)…(13)} | 535,916 | |||

| (15) Administration costs (1%) | 5359 | |||

| (16) Designer and construction manager fees (4%) | 21,437 | |||

| (17) Subtotal 2 {= (14) + (15) + (16)} | 562,712 | |||

| (18) Subsoiling | 58 (n) | |||

| (19) TOTAL {=(17) + (18)} | 562,770 |

| Year | Total Annual Yield (a) (MWh) | Grid Access Toll (b) (EUR) | Brokerage P.W.M. Agent (c) (EUR) | Maintenance and Repair (d) (EUR) | Insurance and Video-Surv. (e) (EUR) | Internet Fee (f) (EUR) | TOTAL (EUR) |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 3 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 4 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 5 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 6 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 7 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 8 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 9 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 10 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 11 | 20,619 | 10,310 | 4124 | 26,597 | 22,798 | 10,132 | 73,961 |

| 12 | 20,516 | 10,258 | 4103 | 26,597 | 22,798 | 10,132 | 73,889 |

| 13 | 20,413 | 10,207 | 4083 | 26,597 | 22,798 | 10,132 | 73,817 |

| 14 | 20,310 | 10,155 | 4062 | 26,597 | 22,798 | 10,132 | 474,562 (g) |

| 15 | 20,207 | 10,103 | 4041 | 26,597 | 22,798 | 10,132 | 73,672 |

| 16 | 20,104 | 10,052 | 4021 | 26,597 | 22,798 | 10,132 | 73,600 |

| 17 | 20,001 | 10,000 | 4000 | 26,597 | 22,798 | 10,132 | 73,528 |

| 18 | 19,898 | 9949 | 3980 | 26,597 | 22,798 | 10,132 | 73,456 |

| 19 | 19,795 | 9897 | 3959 | 26,597 | 22,798 | 10,132 | 73,384 |

| 20 | 19,691 | 9846 | 2954 | 19,948 | 17,099 | 7599 | 57,445 |

| 21 | 19,588 | 9794 | 2938 | 19,948 | 17,099 | 7599 | 57,378 |

| 22 | 19,485 | 9743 | 2923 | 19,948 | 17,099 | 7599 | 57,311 |

| 23 | 19,382 | 9691 | 2907 | 19,948 | 17,099 | 7599 | 57,244 |

| 24 | 19,279 | 9640 | 2892 | 19,948 | 17,099 | 7599 | 57,177 |

| 25 | 19,176 | 9588 | 2876 | 19,948 | 17,099 | 7599 | 57,110 |

| 26 | 19,073 | 9536 | 2861 | 19,948 | 17,099 | 7599 | 57,043 |

Appendix D

| Costs in EUR/ha | Canola | Carrot | Forage Maize | Dry Faba Bean | Melon | Onion | Dry Pea | Early Potato | ProCessing Tomato | |

|---|---|---|---|---|---|---|---|---|---|---|

| Seed | 60 | 3900 | 170 | 60 | 3000 | 3925 | 55 | 1400 | 820 | |

| Fertilizer | 205 | 860 | 610 | 10 | 800 | 750 | 10 | 600 | 590 | |

| Plant Protection products | 115 | 650 | 50 | 60 | 505 | 230 | 60 | 250 | 510 | |

| Externalized works (mechanized harvest, etc.) | 67 | 1390 | 85 | 55 | 80 | 75 | 55 | 110 | 850 | |

| Tractor fuel | 60 | 420 | 120 | 60 | 330 | 180 | 60 | 105 | 110 | |

| Tractor & mach. Repair & Maint. | 45 | 230 | 106 | 40 | 110 | 105 | 40 | 80 | 80 | |

| Tractor & mach. Shed costs | 30 | 60 | 45 | 30 | 60 | 60 | 30 | 55 | 60 | |

| Amortization of tractor & mach. | 20 | 170 | 105 | 17 | 150 | 145 | 17 | 120 | 140 | |

| Hired labor (manual harvest) | 0 | 0 | 0 | 0 | 1125 (a) | 1035 (b) | 0 | 900 (c) | 0 | |

| Soc. Sec. contrib.for hired labor (25%) | 0 | 0 | 0 | 0 | 281 | 259 | 0 | 225 | 0 | |

| Own labor | 65 | 480 | 200 | 50 | 500 | 350 | 50 | 290 | 580 | |

| Soc. Sec. contrib.for own labor (25%) | 16 | 120 | 50 | 13 | 125 | 88 | 13 | 73 | 145 | |

| Insurances (crop, tractor) | 15 | 57 | 15 | 15 | 100 | 100 | 15 | 57 | 100 | |

| Land property tax | 70 | 70 | 35 (d) | 35 (d) | 70 | 70 | 70 | 70 | 70 | |

| Irrigation total cost | 130 | 226 | 165 (d) | 79 (d) | 192 | 224 | 132 | 186 | 205 | |

| Subtotal | 898 | 8633 | 1756 | 524 | 4260 | |||||

| Working capital interest (4%) | 36 | 345 | 70 | 21 | 170 | |||||

| Total | 934 | 8978 | 1826 | 544 | 7725 | 7899 | 631 | 4701 | 4430 |

Appendix E

Appendix E.1. Canola

Appendix E.2. Carrot

Appendix E.3. Maize

Appendix E.4. Faba Bean

Appendix E.5. Melon

Appendix E.6. Onion

Appendix E.7. Pea

Appendix E.8. Potato

Appendix E.9. Tomato

References

- Assessment of the Draft National Energy and Climate Plan of Spain. Commission Staff Working Document 2019–262 Final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Assessment of the Draft National Energy and Climate Plan of Italy. Commission Staff Working Document 2020–911; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Red Eléctrica de España. Renewable Energy in the Spanish Electricity System-2019. 2020. Available online: www.ree.es/en (accessed on 19 March 2021).

- Goetzberger, A.; Zastrow, A. On the coexistence of solar-energy conversion and plant cultivation. Int. J. Sol. Energy 1982, 1, 55–69. [Google Scholar] [CrossRef]

- Dupraz, C.; Marrou, H.; Talbot, G.; Dufour, L.; Nogier, A.; Ferard, Y. Combining solar photovoltaic panels and food crops for optimising land use: Towards new agrivoltaic schemes. Renew. Energy 2011, 36, 2725–2732. [Google Scholar] [CrossRef]

- Marrou, H.; Wery, J.; Dufour, L.; Dupraz, C. Productivity and radiation use efficiency of lettuces grown in the partial shade of photovoltaic panels. Eur. J. Agronomy 2013, 44, 54–66. [Google Scholar] [CrossRef]

- Valle, B.; Simonneau, T.; Sourd, F.; Pechier, P.; Hamard, P.; Frisson, T.; Ryckewaert, M.; Christophe, A. Increasing the total productivity of a land by combining mobile photovoltaic panels and food crops. Appl. Energy 2017, 206, 1495–1507. [Google Scholar] [CrossRef]

- Schindele, S.; Trommsdorff, M.; Schlaak, A.; Obergfell, T.; Bopp, G.; Reise, C.; Braun, C.; Weselek, A.; Bauerle, A.; Högy, P.; et al. Implementation of agrophotovoltaics: Techno-economic analysis of the price-performance ratio and its policy implications. Appl. Energy 2020, 265, 114737. [Google Scholar] [CrossRef]

- Dinesh, H.; Pearce, J.M. The potential of agrivoltaic systems. Renew. Sustain. Energy Rev. 2016, 54, 299–308. [Google Scholar] [CrossRef] [Green Version]

- SolarPower Europe. Agri-PV: How Solar Enables the Clean Energy Transition in Rural Areas. Briefing Paper. Available online: www.solarpowereurope.org (accessed on 29 December 2020).

- Bellini, E. Special Solar Panels for Agrivoltaics. 2020. Available online: https://www.pv-magazine.com/2020/07/23/special-solar-panels-for-agrivoltaics/ (accessed on 19 March 2021).

- Hassanpour Adeh, E.; Selker, J.S.; Higgins, C.W. Remarkable agrivoltaic influence on soil moisture, micrometeorology and water-use efficiency. PLoS ONE 2018, 13, e0203256. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Expósito, A.; Berbel, J. Agricultural irrigation water use in a closed basin and the impacts on water productivity: The case of the Guadalquivir river basin (southern Spain). Water 2017, 9, 136. [Google Scholar] [CrossRef] [Green Version]

- Eurostat. Agri-environmental indicator –irrigation. Statistics Explained. 16/4/2019 (data from February 2019). p. 10. Available online: https://ec.europa.eu/eurostat/statistics-explained/ (accessed on 19 March 2021).

- Schulz, V.S.; Munz, S.; Stolzenburg, K.; Hartung, J.; Weisenburger, S.; Graeff-Hönninger, S. Impact of Different Shading Levels on Growth, Yield and Quality of Potato (Solanum tuberosum L.). Agronomy 2019, 9, 330. [Google Scholar] [CrossRef] [Green Version]

- MAPA Avance del Anuario de Estadística 2019. 2020 Ministerio de Agricultura, Pesca y Alimentación. Available online: https://www.mapa.gob.es (accessed on 19 March 2021).

- Weselek, A.; Ehmann, A.; Zikeli, S.; Lewandowski, I.; Schindele, S.; Högy, P. Agrophotovoltaic systems: Applications, challenges, and opportunities. A review. Agron. Sustain. Dev. 2019, 39, 35. [Google Scholar] [CrossRef]

- Cell Solar. Polycristalline 60 Cells CSP270-290W. Available online: www.cellsolar-energy.com (accessed on 29 December 2020).

- Oberhofer, A. Spinnanker (Spider-Shaped Anchor). European Patent EP 1 750 020 B2, 7 February 2007. [Google Scholar]

- Beck, M.; Bopp, G.; Goetzberger, A.; Obergfell, T.; Reise, C.; Schindele, S. Combining PV and food crops to agrophotovoltaic- optimization of orientation and harvest. EUPVSEC Proc. 2012, 1, 4096–4100. [Google Scholar]

- NREL. System Advisor Model (SAM); 2020.11.29-R1, SSC 252.; National Renewable Energy Laboratory: Golden, CO, USA, 2020. [Google Scholar]

- SMA. Sunny HighPower Peak 3. Available online: https://www.sma.de/en/products/solarinverters/sunny-highpower-peak3.html (accessed on 19 March 2021).

- SISIFO. On-line Simulator of PV Systems. Solar Energy Institute of the Universidad Politécnica de Madrid. Web Service Supported by the European Commission with the H2020 Project MASLOWATEN. Available online: https://www.sisifo.info/en/datainput (accessed on 2 March 2021).

- Berbel, J.; Borrego-Marín, M.M.; Expósito, A.; Giannoccaro, G.; Montilla-López, N.M.; Roseta-Palma, C. Analysis of irrigation water tariffs and taxes in Europe. Water Policy 2019, 21, 806–825. [Google Scholar] [CrossRef] [Green Version]

- FENACORE. Dossier de Prensa. Federación Nacional de Comunidades de Regantes. 2017. Available online: http://www.fenacore.org/empresas/fenacoreweb/documentos/DOSSIER%20PRENSA%20FENACORE%202017.pdf (accessed on 19 March 2021).

- Masia, S.; Susnik, J.; Marras, S.; Mereu, S.; Spano, D.; Trabucco, A. Assessment of irrigated agriculture vulnerability under climate change in Southern Italy. Water 2018, 10, 209. [Google Scholar] [CrossRef] [Green Version]

- De Stefano, L.; Fornés, J.M.; López-Geta, J.A.; Villarroya, F. Groundwater use in Spain: An overview in light of the EU Water Framework Directive. Intl. J. Water Resour. Dev. 2015, 31, 640–656. [Google Scholar] [CrossRef] [Green Version]

- Consejería de Medio Ambiente y Ordenación del Territorio. El Clima de Andalucía en el Siglo XXI. 2014 Junta de Andalucía. Available online: http://www.juntadeandalucia.es/medioambiente/site/portalweb/ (accessed on 29 December 2020).

- TEXLA Renovables. Proyecto Planta Fotovoltaica Valle Inferior Solar 6 MWp. Comunidad de Regantes del Valle Inferior del Guadalquivir. 2018. Available online: www.valleinferior.es (accessed on 29 December 2020).

- Marrou, H.; Dufour, L.; Wery, J. How does a shelter of solar panels influence water flows in a soil-crop system? Eur. J. Agronomy 2013, 50, 38–51. [Google Scholar] [CrossRef]

- Barron-Gafford, G.A.; Pavao-Zuckerman, M.A.; Minor, R.L.; Sutter, L.F.; Barnett-Moreno, I.; Blackett, D.T.; Thompson, M.; Dimond, K.; Gerlak, A.K.; Nabhan, G.P.; et al. Agrivoltaics provide mutual benefits across the food–energy–water nexus in drylands. Nat. Sustain. 2019, 2, 848–855. [Google Scholar] [CrossRef]

- Hernández, V.; Hellín, P.; Fenoll, J.; Flores, P. Interaction of nitrogen and shading on tomato yield and quality. Sci. Hortic. 2019, 255, 255–259. [Google Scholar] [CrossRef]

- Berbel, J.; Expósito, A.; Gutiérrez-Martín, C.; Mateos, L. Effects of the Irrigation Modernization in Spain 2002–2015. Water Resour. Manag. 2019, 33, 1835–1849. [Google Scholar] [CrossRef]

- Hernández-Mora, N.; Martínez Cortina, L.; Llamas Madurga, M.R.; Custodio Gimena, E. Groundwater Issues in Southern EU Member States. Spain Country Report; European Academies Science Advisory Council: Brussels, Belgium, 2007. [Google Scholar]

- Comunidad de Regantes del Valle Inferior del Guadalquivir. Circular nº 1/2016. 2016. Available online: http://valleinferior.es/circular-n-1-2016_aa14.html (accessed on 19 March 2021).

- Rodríguez Díaz, J.A.; Poyato, E.C.; Pérez, M.B. Evaluation of Water and Energy Use in Pressurized Irrigation Networks in Southern Spain. J. Irrig. Drain. Eng. 2011, 137, 644–650. [Google Scholar] [CrossRef]

- Fernández García, I.; Rodríguez Díaz, J.A.; Poyato, E.C.; Montesinos, P.; Berbel, J. Effects of modernization and medium term perspectives on water and energy use in irrigation districts. Agric. Syst. 2014, 131, 56–63. [Google Scholar] [CrossRef]

- Sanchis-Ibor, C.; García-Mollá, M.; Avellà-Reus, L. Effects of drip irrigation promotion policies on water use and irrigation costs in Valencia, Spain. Hydrol. Res. 2017, 19, 165–180. [Google Scholar] [CrossRef] [Green Version]

- Karkanis, A.; Ntatsi, G.; Kontopoulou, C.-K.; Pristeri, A.; Bilalis, D.; Savvas, D. Field Pea in European Cropping Systems: Adaptability, Biological Nitrogen Fixation and Cultivation Practices. Not. Bot. Horti Agrobot. Cluj-Napoca 2016, 44, 325–336. [Google Scholar] [CrossRef] [Green Version]

- ITACYL. Plan de Monitorización de los Cultivos de Regadío en Castilla y León: Resultados de la Encuesta de Cultivos de la Campaña Agrícola 2013–2014. Junta de Castilla y León. 2015. Available online: www.inforiego.org (accessed on 19 March 2021).

- Murugarren, N. Precios de la energía en la campaña 2012. Importancia de su negociación en la gestión de las comunidades de regantes. Navarra Agraria 2013, 7–11. Available online: www.navarraagraria.com (accessed on 19 March 2021).

- OMIP. Market Bulletin MIBEL SPEL Solar Load (FTS). Available online: https://www.omip.pt/es/dados-mercado?date=2019-11-19&product=EL&zone=ES&instrument=FTS&maturity=YR (accessed on 19 March 2021).

- López-Prol, J.; Steininger, K.W.; Zilberman, D. The cannibalization effect of wind and solar in the California wholesale electricity market. Energy Econ. 2020, 85, 104552. [Google Scholar] [CrossRef]

- Zhang, H.; Flottmann, S. Source-sink manipulation in canola indicates that yield is source limited. In Proceedings of the 17th ASA Conference, Hobart, Australia, 20–24 September 2015. [Google Scholar]

- Barmon, N.C.; Bala, P.; Roy, U.K.; Azad, A.K. Growth and yield of carrot influenced by shading characters. Eco-friendly Agril. J. 2012, 5, 13–16. [Google Scholar]

- Sekiyama, T.; Nagashima, A. Solar Sharing for Both Food and Clean Energy Production: Performance of Agrivoltaic Systems for Corn, A Typical Shade-Intolerant Crop. Environments 2019, 6, 65. [Google Scholar] [CrossRef] [Green Version]

- Nasrullahzadeh, S.; Ghassemi-Golezani, K.; Javanshir, A.; Valizade, M.; Shakiba, M.R. Effects of shade stress on ground cover and grain yield of faba bean (Vicia faba L.). J. Food Agric. Environ. 2007, 5, 337–340. [Google Scholar]

- Pereira, F.; Puiatti, M.; Finger, F.; Cecon, P. Growth, assimilate partition and yield of melon charenthais under different shading screens. Hortic. Bras. 2011, 29, 91–97. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.A.A.; Larkin, A.; Singh, V.; Agarwal, Y.K. Impact of fertilizer levels on the growth and yield of onion (Allium cepa L.) under jatropha (Jetropha curcas L.) based agroforestry system. Int. Arch. App. Sci. Technol. 2019, 10, 107–113. [Google Scholar]

- Gubbels, G.H. Quality, yield and seed weight of green field peas under conditions of applied shade. Can. J. Plant Sci. 1980, 61, 213–217. [Google Scholar] [CrossRef]

- Seserman, D.M.; Veste, M.; Freese, D.; Swieter, A.; Langhof, M. Benefits of agroforestry systems for land equivalent ratio-case studies in Brandenburg and Lower Saxony, Germany. In Proceedings of the 4th European Agroforestry Conference—Agroforestry as a Sustainable Land Use, Nijmegen, The Netherlands, 28–30 May 2018; pp. 26–29. [Google Scholar]

- Guaita-Pradas, I.; Blasco-Ruiz, A. Analyzing Profitability and Discount Rates for Solar PV Plants. A Spanish Case. Sustain. J. Rec. 2020, 12, 3157. [Google Scholar] [CrossRef] [Green Version]

- Banco de España. 30-year Maturity Bonds. Spain. Financial Indicators. Daily Series. Available online: https://www.bde.es/webbde/en/estadis/infoest/sindi.html (accessed on 6 November 2020).

- Bolsas y Mercados Españoles. Annual Report. 2019. Available online: https://www.bolsasymercados.es/docs/inf_legal/ing/economico/2019/IA-BME-2019-Eng.pdf (accessed on 19 March 2021).

- Infrontanalytics. Levered/Unlevered Beta of SMA Solar Technology AG. Available online: https://www.infrontanalytics.com/fe-EN/40278ED/SMA-Solar-Technology-AG/Beta (accessed on 29 December 2020).

- Trommsdorff, M. An Economic Analysis of Agrophotovoltaics: Opportunities, Risks and Strategies towards a More Efficient land Use. Master’s Thesis, University of Freiburg, Freiburg, Germany, 2016. [Google Scholar]

- Stein, A. Utility-Scale Fixed-Tilt PV vs. Single-Axis Tracker PV: NEMS Projections to 2050. Capstone Paper. Master’s Thesis, Johns Hopkins University, Baltimore, ML, USA, 2018. Available online: https://jscholarship.library.jhu.edu/handle/1774.2/59881 (accessed on 26 November 2020).

- Amaducci, S.; Yin, X.; Colauzzi, M. Agrivoltaic systems to optimize land use for electric energy production. Appl. Energy 2018, 220, 545–561. [Google Scholar] [CrossRef]

- IDAE. Ahorro y Eficiencia Energética en la Agricultura de Regadío. 2005. Available online: www.idae.es (accessed on 19 March 2021).

- González Ruiz, J.I.; Descalzo Benito, M.J. Electricity Regulations in Spain: Overview. Thomson Reuters Practical Law. Available online: https://uk.practicallaw.thomsonreuters.com/4-529-8116?transitionType=Default&contextData=(sc.Default)&firstPage=true#co_anchor_a808110 (accessed on 29 December 2020).

- Wang, H.X.; Muñoz-García, M.A.; Moreda, G.P.; Alonso-García, M.C. Optimum inverter sizing of grid-connected photovoltaic systems based on energetic and economic considerations. Renew. Energy 2018, 118, 709–717. [Google Scholar] [CrossRef]

- Nishizawa, T.; Ito, A.; Motomura, Y.; Ito, M.; Togashi, M. Changes in fruit quality as influenced by shading of netted melon plants (Cucumis melo L. ‘Andesu’ and ‘Luster’). J. Jpn. Soc. Hort. Sci. 2000, 69, 563–569. [Google Scholar] [CrossRef]

- Willockx, B.; Herteleer, B.; Cappelle, J. Techno-economic study of agrivoltaic systems focusing on orchard crops. In Proceedings of the EUPVSEC 2020 online Conference, online, 2 September 2020. [Google Scholar]

- Schachinger, M. Module Price Index. 2020. Available online: www.pv-magazine.com/module-price-index (accessed on 4 December 2020).

- Renovables Arlumi, S.L. Anteproyecto Planta Fotovoltaica 44.95 MWn La Torre 40 S.L. 2017. Available online: https://www.juntadeandalucia.es/export/drupaljda/tramite_informacion_publica/20/07/ANTEPROYECTO%20PFV%20LA%20TORRE%2040.pdf (accessed on 19 March 2021).

- Sueta, H.E.; Mocelin, A.; Zilles, R.; Obase, P.F.; Boemeisel, E. Protection of photovoltaic systems against lightning. Experimental verifications and techno-economic analysis of protection. In Proceedings of the XII SIPDA-International Symposium on Lightning Protection, Belo Horizonte, Brazil, 7–11 October 2013; pp. 442–447. [Google Scholar]

- Cclcomponents. SMA DC String Combiner Box for STP/SHP Inverters. Available online: https://www.cclcomponents.com/sma-solar-dc-string-combiner-box-16-f2-s (accessed on 4 December 2020).

- Vartiainen, E.; Masson, G.; Breyer, C. PV LCOE in Europe 2014–30—Final Report. 2015 European PV Technology Platform Steering Committee. PV LCOE Working Group. Available online: www.eupvplattform.org (accessed on 19 March 2021).

- Vartiainen, E.; Masson, G.; Breyer, C.; Moser, D.; Román Medina, E. Impact of weighed average cost of capital, capital expenditure, and other parameters on future utility-scale PV levelised cost of electricity. Prog. Photovolt. Res. Appl. 2020, 28, 439–453. [Google Scholar] [CrossRef] [Green Version]

- Esgueva, N.A. Línea de Conexión a 20 kV, Centro de Trasformación y Planta de Generación Fotovoltaica en Valdeolivas (Cuenca). Bachelor’s Thesis, Universidad Carlos III de Madrid, Madrid, Spain, 2016. Available online: https://e-archivo.uc3m.es/handle/10016/24446 (accessed on 4 December 2020).

- Eurostat. Labour Cost Levels by NACE. Available online: https://ec.europa.eu/eurostat/web/labour-market/labour-costs (accessed on 29 December 2020).

- Más que Máquinas Agrícolas. El Blog de Maquinaria de la Revista Agricultura. Costes de Externalización de Labores. Precios de Trabajos y Faenas Agrícolas. 2014. Available online: http://www.masquemaquina.com/2014/01/costes-de-externalizacion-de-labores-y.html (accessed on 29 December 2020).

- Ministerio de Industria. Turismo y Comercio RD 1544/2011, de 31 de octubre, por el que se Establecen los Peajes de Acceso a las Redes de Transporte y Distribución que Deben Satisfacer los Productores de Energía Eléctrica; BOE 276; Ministerio de Industria, Turismo y Comercio: Madrid, Spain, 2011. [Google Scholar]

- TOTAL Gas y Electricidad España SAU. Huertos Solares: Venta a Mercado o PPAs. 2019. Available online: https://www.totalenergia.es/es/pymes/blog/huerto-Solar-parque-fotovoltaico-venta-energia-mercados-ppa (accessed on 29 December 2020).

- MAPA. Resultados Técnico-Económicos de Cultivos Hortícolas 2016; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2020. [Google Scholar]

- MAPAMA. Resultados Técnico-Económicos de Cultivos Herbáceos 2015; Ministerio de Agricultura y Pesca, Alimentación y Medio Ambiente: Madrid, Spain, 2017. [Google Scholar]

- Consejería de Economía-Consejería de Empleo. Texto Articulado del Convenio Colectivo Provincial de Sevilla Para las Faenas Agrícolas, Forestales y Ganaderas 2017–2021. Boletín Oficial de la Provincia de Sevilla, 267. 2018 Junta de Andalucía. Available online: http://www.juntadeandalucia.es/empleo/mapaNegociacionColectiva/descargarDocumento?uuid=d093aafe-ec99-11e8-94d4-b70735927673 (accessed on 4 December 2020).

| SISIFO Simulator Input Data | |

|---|---|

| Site Geographical Latitude | 37.557351° N |

| Site geographical longitude | 5.834142° W |

| Local altitude (m) | 40 |

| Meteorological data type | TMY (a) |

| PV system peak power (kWp) | 3166 |

| PV system peak power per inverter (kWp) | 153.1 |

| Inverter nominal power (kW) | 150 |

| Real power/peak power (dimensionless) | 0.98 |

| PV system peak power per transformer (kWp) | 3166 |

| Generator inclination or PV modules tilt angle (°) | 27 |

| Generator orient. or azimuth angle (°) | –45 |

| Generator height at supporting structure center (m) | 7 |

| Separation among structures (dimensionless) | 3 (b) |

| PV generator width (dimensionless) | 8 (c) |

| Deviation of back structure (dimensionless) | 0 (d) |

| LV/MV transformer power (kVA) | 3150 |

| LV/MV transformer iron losses (kW) | 32 |

| LV/MV transformer copper losses (kW) | 32 |

| DC wiring losses (% of peak power) | 2.0 |

| AC wiring losses between inverter and LV/MV transformer (% of peak power) | 2.0 |

| Soiling impact (%) | 1.0 |

| Year | Plot 1 | Plot 2 | Plot 3 | Plot 4 |

|---|---|---|---|---|

| 1 | FB-FM (a) | Canola | Potato | Onion |

| 2 | Canola | Potato | Onion | FB-FM |

| 3 | Potato | Onion | FB-FM | Canola |

| 4 | Onion | FB-FM | Canola | Potato |

| Year | Plot 1 | Plot 2 | Plot 3 | Plot 4 |

|---|---|---|---|---|

| 1 | Melon | Onion | Carrot | Tomato |

| 2 | Onion | Carrot | Melon | Tomato |

| 3 | Carrot | Melon | Onion | Tomato |

| 4 | Tomato | Onion | Pea | Melon |

| Crop Production Cost (a) under Full Sunlight (€/ha) | Savings Due to Synergetic APV Partial Shading | Crop Production Cost under APV Partial Shading (€/ha) | ||||

|---|---|---|---|---|---|---|

| Irrigation Water Saving (%) | Fertilization Saving (%) | Hail in Surance Saving (%) | Fruit Solar Protector Saving (%) | |||

| Canola | 934 | 11.5 (b) | – | – | – | 931 |

| Carrot | 8978 | 11.5 (b) | – | – | – | 8964 |

| Forage maize | 1826 | 11.5 (b) | – | – | – | 1813 |

| Dry faba bean | 544 | 11.5 (b) | – | – | – | 541 |

| Melon | 7725 | 14.0 (c) | – | 2.5 | 1.5 | 7697 |

| Onion | 7899 | 11.5 (b) | – | – | – | 7885 |

| Dry pea | 631 | 11.5 (b) | – | – | – | 628 |

| Early potato | 4701 | 9.0 (d) | – | – | – | 4694 |

| Processing tomato | 4430 | 9.0 (d) | 2.0 (e) | 2.5 | – | 4403 |

| Surface Water | Groundwater | ||||

|---|---|---|---|---|---|

| Water Use (m3/ha) | Energy Cost (b) (EUR/ha) | Total Irrigation Cost (c) (EUR/ha) | Energy Cost (e) (EUR/ha) | Total Irrigation Cost (f) (EUR/ha) | |

| Canola | 1200 | 24 | 130 | 48 | 291 |

| Carrot | 6000 | 120 | 226 | 240 | 483 |

| Maize | 5600 | 112 | 165 (d) | 224 | 346 |

| Faba bean | 1300 | 26 | 79 (d) | 52 | 174 |

| Melon | 4300 | 86 | 192 | 172 | 415 |

| Onion | 5900 | 118 | 224 | 236 | 479 |

| Pea | 1300 (a) | 26 | 132 | 52 | 295 |

| Potato | 4000 | 80 | 186 | 160 | 403 |

| Tomato | 4951 | 99 | 205 | 198 | 441 |

| Crop Yield Variation under Shading (a), High Crop-Yield Penalty (%) | Source (b) | Crop Yield Variation under Shading (c), Low Crop-Yield Penalty (%) | |

|---|---|---|---|

| Canola | –20 | [44] | –5 |

| Carrot | –10 | [45] | +5 |

| Maize | –7 | [46] | +8 |

| Faba bean | 0 | [47] | +15 |

| Melon | –17 | [48] | –2 |

| Onion | –6 | [49] | +9 |

| Pea | –15 | [50] | 0 |

| Potato | –23 | [15] | –8 |

| Tomato | –5 | [32] | +10 |

| Crop Yield under Full Sunlight (t/ha) (a) | Produce Price Paid to the Farmer (EUR/t) | Farmer Income from Produce Sale under Full Sunlight (EUR/ha) | EU-CAP Direct Payment to the Farmer (EUR/ha) (b) | Total Income under Full Sunlight (EUR/ha) | |

|---|---|---|---|---|---|

| Canola | 3.10 | 326.9 | 1013 | 35 | 1048 |

| Carrot | 49.22 | 303.4 | 14,933 | NA | 14,933 |

| Forage maize | 59.37 | 41.3 | 2452 | NA | 2452 |

| Dry faba bean | 1.79 | 223.6 | 400 | 45 | 445 |

| Melon | 34.60 | 337.7 | 11,684 | NA | 11,684 |

| Onion | 44.74 | 211.4 | 9458 | NA | 9458 |

| Dry pea | 1.79 | 220.6 | 395 | 45 | 440 |

| Potato | 30.98 | 246.2 | 7627 | NA | 7627 |

| Processing tomato | 85.00 | 72.5 | 6162 | 200 | 6362 |

| Year | PV Module Degrad. Coeff. | Specific | (kWh/ha) (a) | Total Yield (kWh) (b) | (cEUR/kWh) | Energy Sale Income (EUR) | Total PV Income (c) (EUR) |

|---|---|---|---|---|---|---|---|

| Yield | |||||||

| (kWh/kWp) | |||||||

| 1 | 0 | 0 | 0 | 0 | 0 | ||

| 2 | 1 | 1628 | 904,354 | 20,619,271 | 4.502 | 928,280 | 928,280 |

| 3 | 1 | 1628 | 904,354 | 20,619,271 | 4.502 | 928,280 | 928,280 |

| 4 | 1 | 1628 | 904,354 | 20,619,271 | 4.502 | 928,280 | 928,280 |

| 5 | 1 | 1628 | 904,354 | 20,619,271 | 4.502 | 928,280 | 928,280 |

| 6 | 1 | 1628 | 904,354 | 20,619,271 | 4.502 | 928,280 | 928,280 |

| 7 | 1 | 1628 | 904,354 | 20,619,271 | 4.502 | 928,280 | 928,280 |

| 8 | 1 | 1628 | 904,354 | 20,619,271 | 4.502 | 928,280 | 928,280 |

| 9 | 1 | 1628 | 904,354 | 20,619,271 | 4.502 | 928,280 | 928,280 |

| 10 | 1 | 1628 | 904,354 | 20,619,271 | 4.502 | 928,280 | 928,280 |

| 11 | 1 | 1628 | 904,354 | 20,619,271 | 4.277 | 881,886 | 881,886 |

| 12 | 0.995 | 1620 | 899,832 | 20,516,175 | 4.277 | 877,477 | 877,477 |

| 13 | 0.990 | 1612 | 895,310 | 20,413,078 | 4.277 | 873,067 | 873,067 |

| 14 | 0.985 | 1604 | 890,789 | 20,309,982 | 4.277 | 868,658 | 910,861 |

| 15 | 0.980 | 1595 | 886,267 | 20,206,886 | 4.277 | 864,249 | 864,249 |

| 16 | 0.975 | 1587 | 881,745 | 20,103,789 | 4.277 | 859,839 | 859,839 |

| 17 | 0.970 | 1579 | 877,223 | 20,000,693 | 4.277 | 855,430 | 855,430 |

| 18 | 0.965 | 1571 | 872,702 | 19,897,597 | 4.277 | 851,020 | 851,020 |

| 19 | 0.960 | 1563 | 868,180 | 19,794,500 | 4.052 | 802,073 | 802,073 |

| 20 | 0.955 | 1555 | 863,658 | 19,691,404 | 4.052 | 797,896 | 797,896 |

| 21 | 0.950 | 1547 | 859,136 | 19,588,308 | 4.052 | 793,718 | 793,718 |

| 22 | 0.945 | 1538 | 854,615 | 19,485,211 | 4.052 | 789,541 | 789,541 |

| 23 | 0.940 | 1530 | 850,093 | 19,382,115 | 4.052 | 785,363 | 785,363 |

| 24 | 0.935 | 1522 | 845,571 | 19,279,019 | 4.052 | 781,186 | 781,186 |

| 25 | 0.930 | 1514 | 841,049 | 19,175,922 | 4.052 | 777,008 | 777,008 |

| 26 | 0.925 | 1506 | 836,527 | 19,072,826 | 4.052 | 772,831 | 772,831 |

| IRR (%) | |||||

|---|---|---|---|---|---|

| Due-Southwest Orientation | Due-South Orientation | ||||

| Low Shade-InduceD Crop Yield Penalty | High Shade-InduceD Crop Yield Penalty | Low Shade-InduceD Crop Yield Penalty | High Shade-InduceD Crop Yield Penalty | ||

| Potato rotation | Surface Water | 4.1 | 3.9 | 5.1 | 4.8 |

| Ground Water | 4.0 | 3.8 | 5.0 | 4.8 | |

| Tomato rotation | Surface Water | 4.7 | 4.3 | 5.6 | 5.2 |

| Ground Water | 4.6 | 4.2 | 5.6 | 5.2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreda, G.P.; Muñoz-García, M.A.; Alonso-García, M.C.; Hernández-Callejo, L. Techno-Economic Viability of Agro-Photovoltaic Irrigated Arable Lands in the EU-Med Region: A Case-Study in Southwestern Spain. Agronomy 2021, 11, 593. https://doi.org/10.3390/agronomy11030593

Moreda GP, Muñoz-García MA, Alonso-García MC, Hernández-Callejo L. Techno-Economic Viability of Agro-Photovoltaic Irrigated Arable Lands in the EU-Med Region: A Case-Study in Southwestern Spain. Agronomy. 2021; 11(3):593. https://doi.org/10.3390/agronomy11030593

Chicago/Turabian StyleMoreda, Guillermo P., Miguel A. Muñoz-García, M. Carmen Alonso-García, and Luis Hernández-Callejo. 2021. "Techno-Economic Viability of Agro-Photovoltaic Irrigated Arable Lands in the EU-Med Region: A Case-Study in Southwestern Spain" Agronomy 11, no. 3: 593. https://doi.org/10.3390/agronomy11030593

APA StyleMoreda, G. P., Muñoz-García, M. A., Alonso-García, M. C., & Hernández-Callejo, L. (2021). Techno-Economic Viability of Agro-Photovoltaic Irrigated Arable Lands in the EU-Med Region: A Case-Study in Southwestern Spain. Agronomy, 11(3), 593. https://doi.org/10.3390/agronomy11030593