Pelletization of Compost from Different Mixtures with the Addition of Exhausted Extinguishing Powders

Abstract

:1. Introduction

1.1. The Use of Exhausted Extinguishing Powders (EEP) in Compost

1.2. Pelletization as a Compost Densification Process

2. Materials and Methods

2.1. Pellet Processing

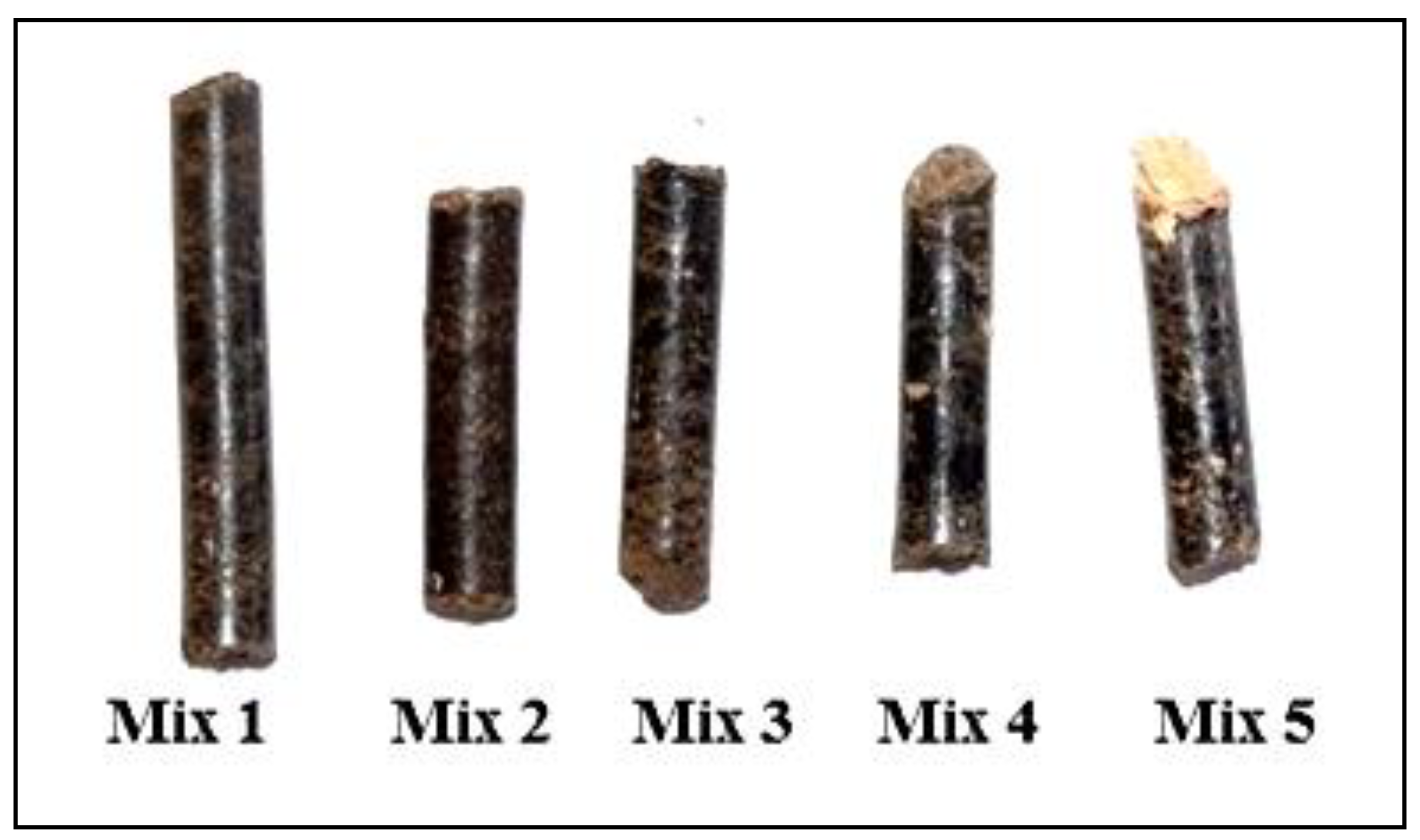

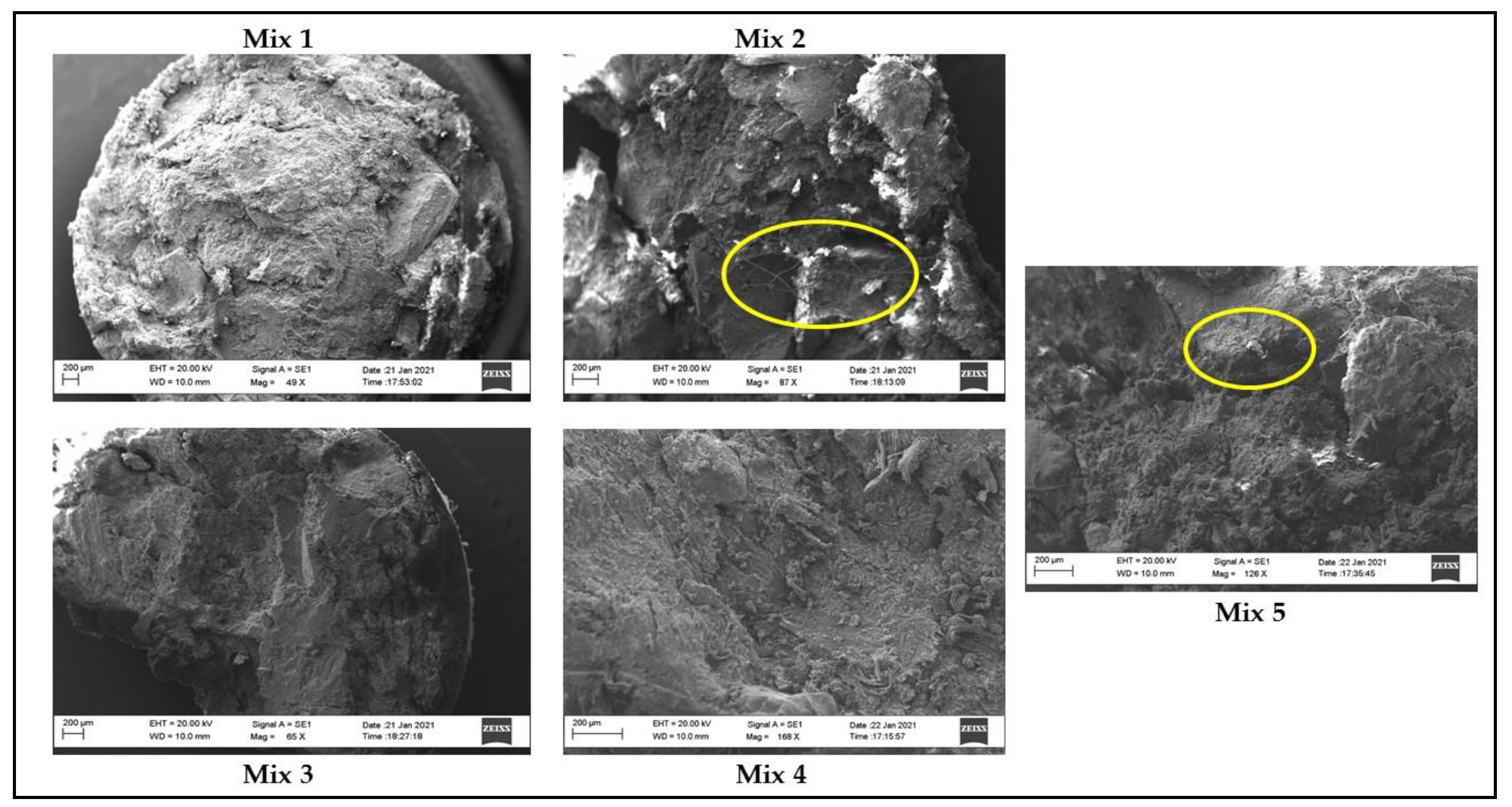

- Mixture 1: 50% compost + 30% Jatropha + 10% EEP + 10% corn starch;

- Mixture 2: 50% compost + 40% Jatropha + 10% EEP;

- Mixture 3: 50% compost + 20% Jatropha + 10% EEP + 10% corn starch + 10% wood chips;

- Mixture 4: 50% compost + 40% wood chips + 10% EEP;

- Mixture 5: 40% compost + 50% wood chips + 10% EEP.

2.2. Qualitative Analyses

2.3. Statistical Analysis

3. Results and Discussion

Physicochemical Characterization of the Pellet

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Praticò, F.G.; Moro, A.; Ammendola, R. Potential of fire extinguisher powder as a filler in bituminous mixes. J. Hazard. Mater. 2010, 173, 605–613. [Google Scholar] [CrossRef] [PubMed]

- Dotelli, G.; Viganò, E. Phosphate Recovery from Exhausted Extinguishing Powders: A Case Study of Circular Economy in the Chemical Industry. In Life Cycle Assessment in the Chemical Product Chain; Maranghi, S., Brondi, C., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Chongyang, L.; Daniel, A.B.; Sanjai, J.P. Estimating potential dust emissions from biochar amended soils under simulated tillage. Sci. Total Environ. 2018, 625, 1093–1101. [Google Scholar] [CrossRef]

- Chia, C.H.; Downie, A.; Munroe, P. Characteristics of biochar: Physical and structural properties. In Biochar for Environmental Management: Science and Technology; Earthscan Books Ltd.: London, UK, 2015; pp. 89–109. [Google Scholar]

- Hettiarachchi, L.; Jayathilake, N.; Fernando, S.; Gunawardena, S. Effects of compost particle size, moisture content and binding agents on co-compost pellet properties. Int. J. Agric. Biol. Eng. 2019, 12, 184–191. [Google Scholar] [CrossRef]

- Zajonc, O.; Frydrych, J.; Jezerska, L. Pelletization of Compost for Energy Utilization. IERI Procedia 2015, 8, 2–10. [Google Scholar] [CrossRef] [Green Version]

- Sayara, T.; Basheer-Salimia, R.; Hawamde, F.; Sánchez, A. Recycling of Organic Wastes through Composting: Process Performance and Compost Application in Agriculture. Agronomy 2020, 10, 1838. [Google Scholar] [CrossRef]

- Pampuro, N.; Bagagiolo, G.; Priarone, P.C.; Cavallo, E. Effects of pelletizing pressure and the addition of woody bulking agents on the physical and mechanical properties of pellets made from composted pig solid fraction. Powder Technol. 2017, 311, 112–119. [Google Scholar] [CrossRef]

- Jotautiene, E.; Bivainis, V.; Zinkeviciene, R.; Aboltins, A. Assessment of organic granulated manure fertilizers frictional properties. Eng. Rural Dev. 2018, 17, 1539–1544. [Google Scholar]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Zafari, A.; Kianmehr, M.H. Factors affecting mechanical properties of biomass pellet from compost. Environ. Technol. 2014, 35, 478–486. [Google Scholar] [CrossRef]

- Chew, K.W.; Chia, S.R.; Yap, Y.J.; Ling, T.C.; Tao, Y.; Show, P.L. Densification of food waste compost: Effects of moisture content and dairy powder waste additives on pellet quality. Process Saf. Environ. Prot. 2018, 116, 780–786. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Tabil, L.; Adapa, P.; Kashaninejad, M. Biomass Feedstock Pre-Processing—Part 2: Densification. Biofuels Eng. Process. Technol. 2011, 19, 439–464. [Google Scholar]

- Achten, W.M.J.; Verchot, L.; Franken, Y.J.; Mathijs, E.; Singh, V.P.; Aerts, R.; Muys, B. Jatropha bio-diesel production and use. Biomass Bioenergy. 2008, 32, 1063–1084. [Google Scholar] [CrossRef] [Green Version]

- Gubitz, G.M.; Mittelbech, M.; Trabi, M. Exploitation of tropical oil seed plant Jatropha curcas L. Bioresour. Technol. 1999, 67, 73–82. [Google Scholar] [CrossRef]

- Nalladurai, K.R.; Vance, M. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Protic, M.; Mitic, D.; Stefanovic, V. Wood pellets production technology. Saf. Eng. 2011, 1, 23–26. [Google Scholar] [CrossRef]

- Sidari, R.; Panuccio, M.R.; Papalia, T.; Gelsomino, A. A green method to treat exhausted fire-extinguishing powders for reuse as agricultural fertilizer. In Proceedings of the First Joint Meeting on Soil And Plant System Sciences (SPSS 2019), Ciheam Bari, Italy, 23–26 September 2019. [Google Scholar]

- Jiang, L.; Liang, J.; Yuan, X.; Li, H.; Li, C.; Xiao, Z.; Huang, H.; Wang, H.; Zeng, G. Co-pelletization of sewage sludge and biomass: The density and hardness of pellet. Bioresour. Technol. 2014, 166, 435–443. [Google Scholar] [CrossRef]

- ASABE. ASAE S269.4—Cubes, Pellets, and Crumbles—Definitions and Methods for Determining Density, Durability, and Moisture Content; American Society of Agricultural and Biological Engineers Standards: St. Joseph, MI, USA, 2007; pp. 624–626. [Google Scholar]

- Kambo, H.S.; Dutta, A. Strength, storage, and combustion characteristics of densified lignocellulosic biomass produced via torrefaction and hydrothermal carbonization. Appl. Energy 2014, 135, 182–191. [Google Scholar] [CrossRef]

- Briggs, J.L.; Maier, D.E.; Watkins, B.A.; Behnke, K.C. Effects of ingredients and processing parameters on pellet quality. Poult. Sci. 1999, 78, 1464–1471. [Google Scholar] [CrossRef] [PubMed]

- Mieldažys, R.; Jotautienė, E.; Jasinskas, A.; Pekarskas, J.; Zinkevičienė, R. Investigation of physical-mechanical properties and impact on soil of granulated manure compost fertilizers. J. Environ. Eng. Landsc. Manag. 2019, 27, 153–162. [Google Scholar] [CrossRef] [Green Version]

- Yaman, S.; Sahan, M.; Haykiri-Acma, H.; Sesen, K.; Küçükbayrak, S. Fuel briquettes from biomass-lignite blends. Fuel Process. Technol. 2001, 72, 1–8. [Google Scholar] [CrossRef]

- Behnke, K.C. Factors affecting pellet quality. In Maryland Nutrition Conference; Dept of Poultry Science and animal Science, College of Agricultural, University of Maryland: College Park, MD, USA, 1994. [Google Scholar]

- Franke, M.; Rey, A. Pelleting Quality. In World Grain; University of Georgia: Athens, GA, USA, 2006; Volume 4, pp. 78–79. [Google Scholar]

- McMullen, J.; Fasina, O.O.; Wood, C.W.; Feng, Y. Storage and handling characteristics of pellets from poultry litter. Appl. Eng. Agric. 2005, 21, 645–651. [Google Scholar] [CrossRef]

- Monedero, E.; Portero, H.; Lapuerta, M. Pellet blends of poplar and pine sawdust effects of material composition, additive, moisture content and compression die on pellet quality. Fuel Process. Technol. 2015, 132, 15–23. [Google Scholar] [CrossRef]

- Thomas, M.; Van der Poel, A.F.B. Physical quality of pelleted animal feed. Criteria for pellet quality. Anim. Feed Sci. Technol. 1996, 61, 89–112. [Google Scholar] [CrossRef]

- Stevens, C.A. Starch Gelatinization and the Influence of Particle Size, Steam Pressure and Die Speed on the Pelleting Process. Ph.D. Thesis, Kansas State University, Manhattan, KS, USA, 1987. [Google Scholar]

- Cavalcanti, W.B. The Effect of Ingredient Composition on the Physical Quality of Pelleted Feeds: A Mixture Experimental Approach. Ph.D. Thesis, Kansas State University, Manhattan, KS, USA, 2004. [Google Scholar]

- Zaini, I.N.; Novianti, S.; Nurdiawati, A.; Irhamna, A.R.; Aziz, M.; Yoshikawa, K. Investigation of the physical characteristics of washed hydrochar pellets madefrom empty fruit bunch. Fuel Process. Technol. 2017, 160, 109–120. [Google Scholar] [CrossRef]

- Zanetti, M.; Brandelet, B.; Marini, D.; Sgarbossa, A.; Giorio, C.; Badocco, D.; Tapparo, A.; Grigolato, S.; Rogaume, R.; Rogaume, Y.; et al. Vineyard pruning residues pellets for use in domestic appliances: A quality assessment according to the EN ISO 17225. J. Agric. Eng. 2017, 48, 99–108. [Google Scholar] [CrossRef] [Green Version]

- Fusi, A.; Bacenetti, J.; Proto, A.R.; Tedesco, D.E.; Pessina, D.; Facchinetti, D. Pellet Production from Miscanthus: Energy and Environmental Assessment. Energies 2021, 14, 73. [Google Scholar] [CrossRef]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Staggenborg, S.; Mckinney, L.; Vadlani, P.; Pei, Z.; Wang, D. Effects of the pelleting conditions on chemical composition and sugar yield of corn Stover, big bluestem, wheat straw, and sorghum stalk pellets. Bioprocess Biosyst. Eng. 2012, 35, 615–623. [Google Scholar] [CrossRef]

- Adapa, P.K.; Tabil, L.G.; Schoenau, G.J. Factors Affecting the Quality of Biomass Pellets for Biofuel and Energy Analysis of Pelleting Process. Int. J. Agric. Biofuel Energy 2013, 6, 1–12. [Google Scholar] [CrossRef]

- Ayilara, M.; Olanrewaju, O.; Babalola, O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Moisture content (%) | 25 ± 0.8 |

| pH (25 °C) | 7.5 ± 0.2 |

| EC/dS·m−1 | 4.2 ±1 |

| Total organic carbon (%) | 27 ± 0.8 |

| Total nitrogen (%) | 2.85 ± 1.2 |

| Organic nitrogen (% total) | 85 ± 0.5 |

| C/N | 9.47 ± 0.6 |

| C humic and fulvic (%) | 10.2 ± 2 |

| CrVI (mg Kg−1) | <0.1 |

| Cd (mg Kg−1) | 0.51 |

| Cu (mg Kg−1) | 68 ± 10 |

| Hg (mg Kg−1) | <0.1 |

| Ni (mg Kg−1) | 15 ± 2 |

| Pb (mg Kg−1) | 20 ± 1 |

| Zn (mg Kg−1) | 235 ± 41 |

| Salmonella spp. | not found |

| Escherichia coli (CFU g−1) | <100 UFC |

| Compound | Mix 1 | Mix 2 | Mix 3 | Mix 4 | Mix 5 |

|---|---|---|---|---|---|

| C (%) | 28.78 ± 5.24 | 28.13 ± 4.22 | 43.72 ± 3.40 | 37.07 ± 2.85 | 37.93 ± 2.41 |

| N (%) | 3.08 ± 0.45 | 3.56 ± 0.25 | 2.70 ± 0.84 | 3.33 ± 1.12 | 2.04 ± 0.71 |

| H (%) | 4.79 ± 0.82 | 3.84 ± 1.12 | 4.10 ± 0.47 | 3.53 ± 0.66 | 4.96 ± 0.22 |

| O (%) dry basis | 30.91 ± 0.36 | 25.97 ± 0.67 | 24.92 ± 1.8 | 29.79 ± 0.45 | 12.97 ± 1.42 |

| Ash (%) | 32.43 ± 1.2 | 38.49 ± 0.90 | 24.55 ± 2.32 | 26.27 ± 1.52 | 42.09 ± 0.50 |

| Moisture content (%) | 11 ± 0.4 | 11 ± 0.9 | 12 ± 0.3 | 12 ± 0.2 | 11 ± 0.7 |

| Bulk density (kg m−3) | 658 ± 3.21 | 632 ± 5.55 | 698 ± 2.12 | 712 ± 4.52 | 688 ± 6.44 |

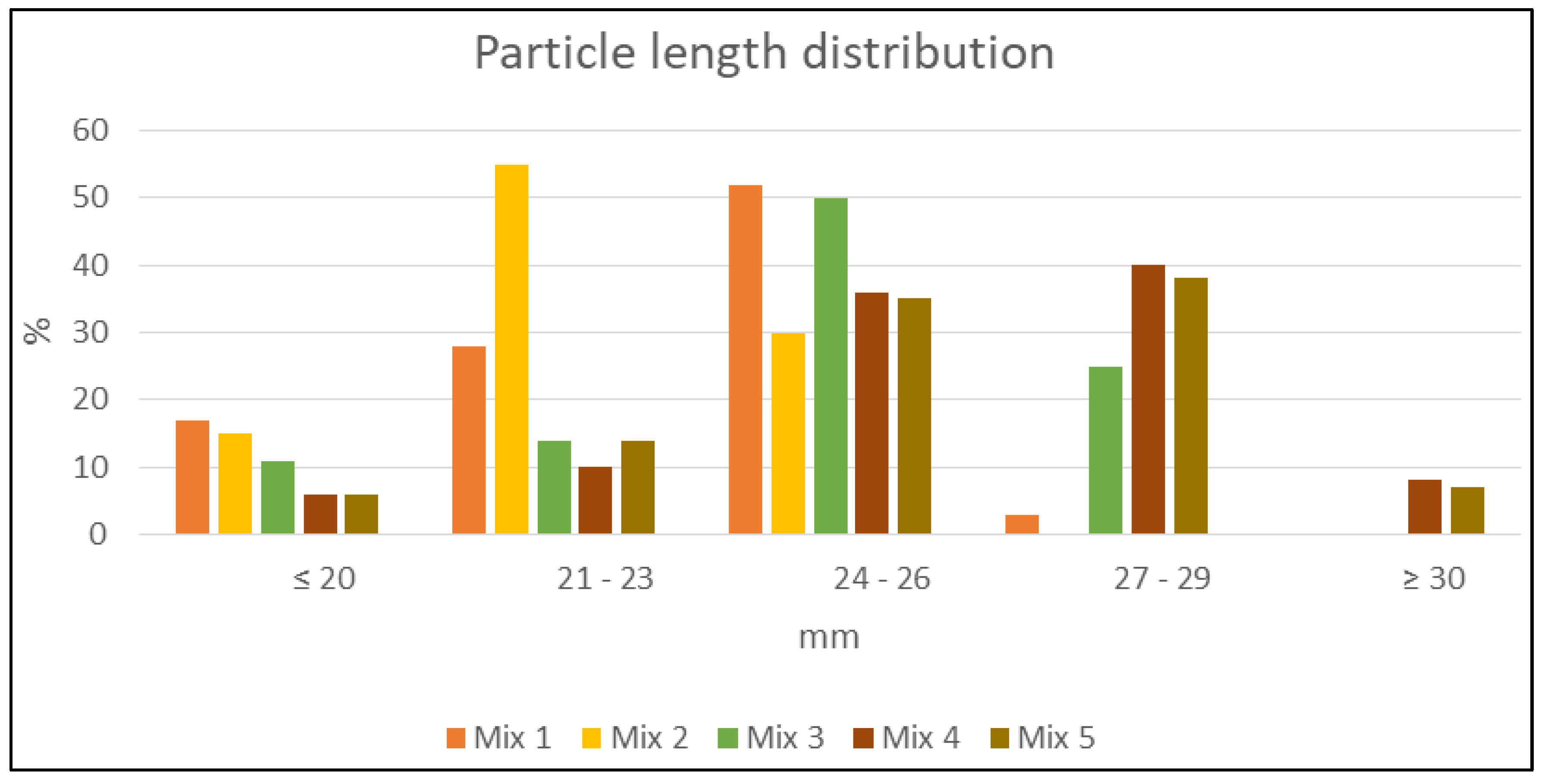

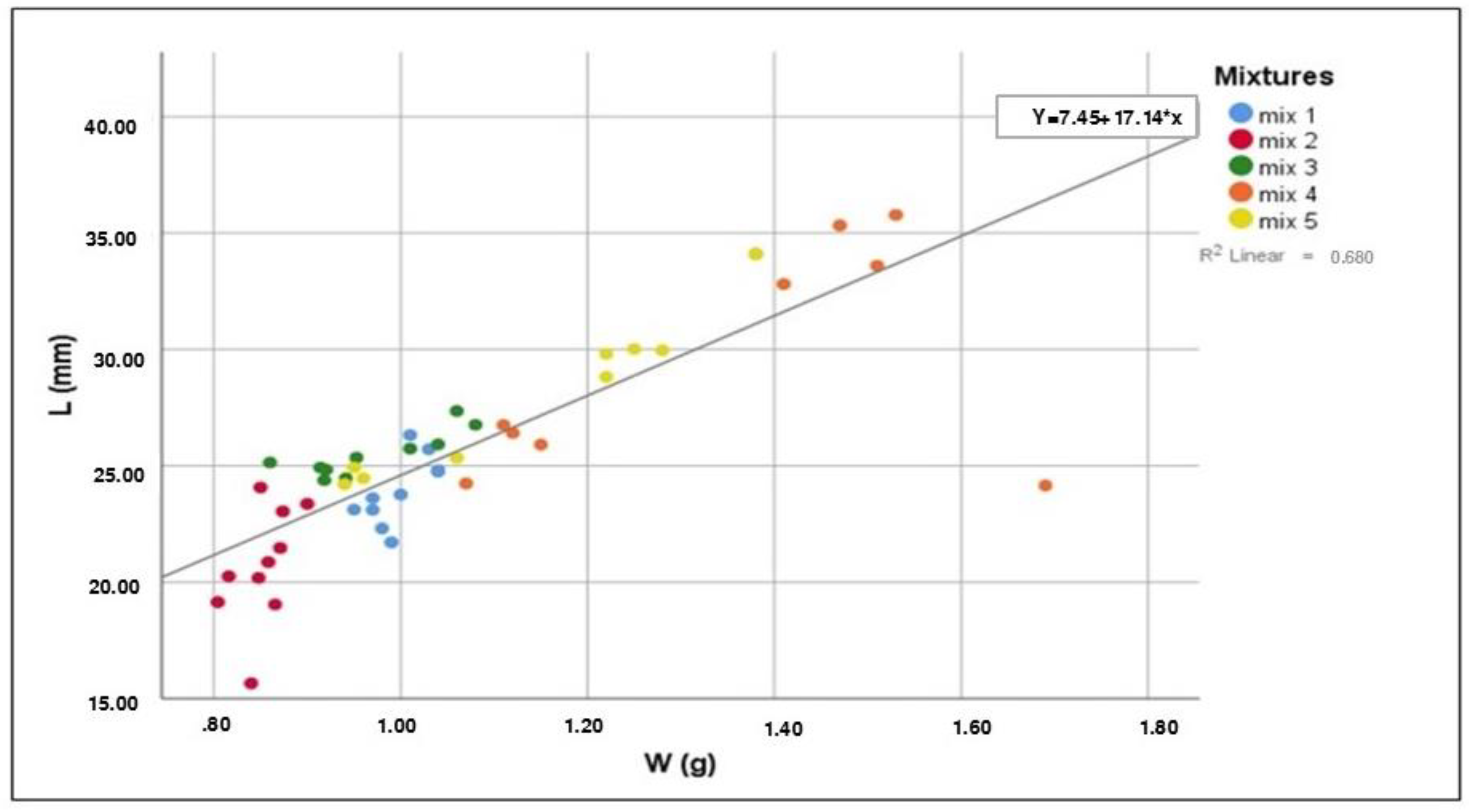

| Mixture | Minimum | Maximum | Mean | Std. Dev. | |

|---|---|---|---|---|---|

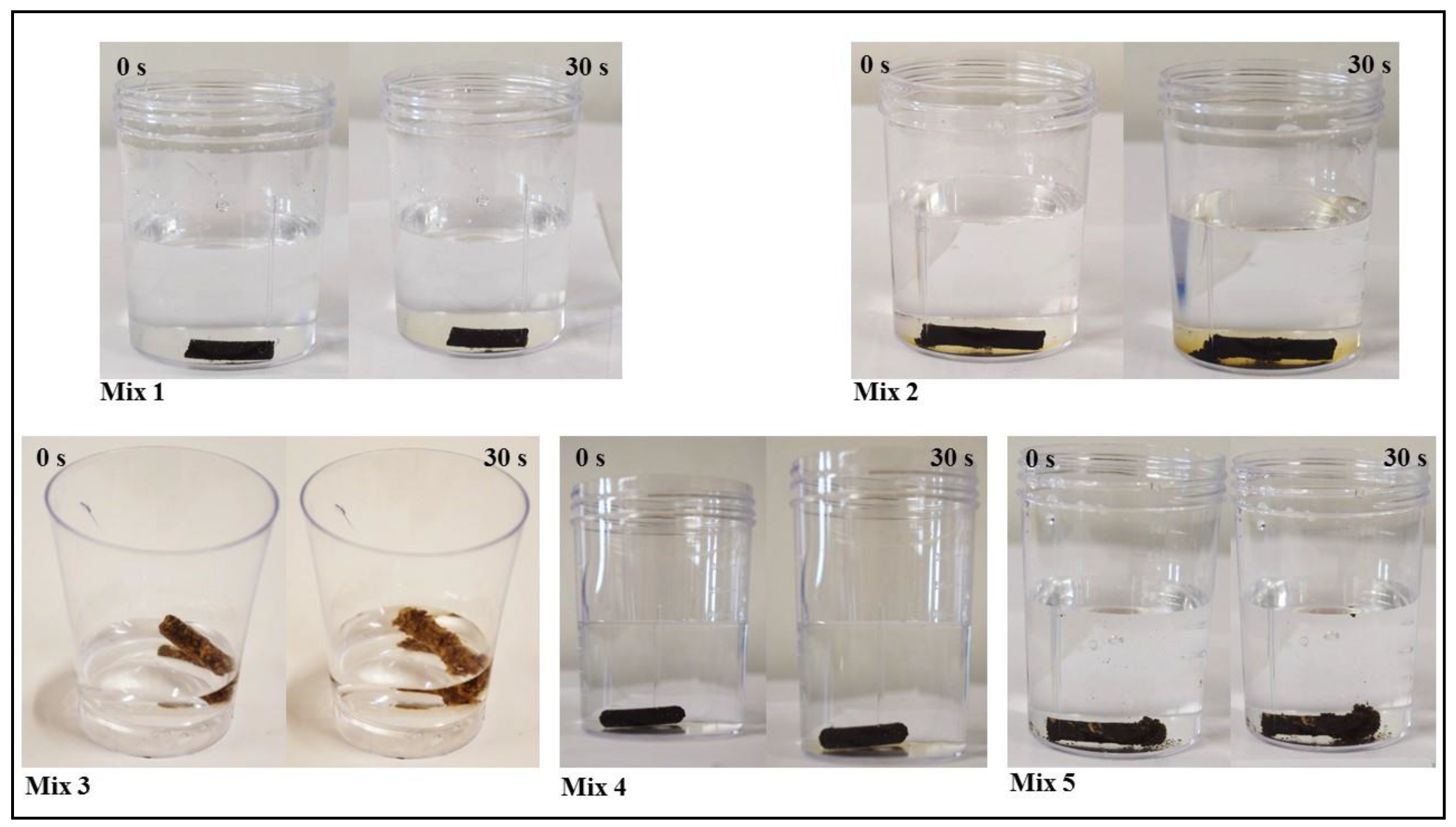

| Mix 1 | Durability % | 90.00 | 93.00 | 91.5000 | 1.08012 |

| WI % | 0.30 | 0.96 | 0.5700 | 0.21792 | |

| D mm | 5.89 | 6.27 | 6.0560 | 0.11433 | |

| L mm | 21.71 | 26.32 | 23.9200 | 1.46649 | |

| W gr | 0.95 | 1.04 | 0.9980 | 0.03155 | |

| Mix 2 | Durability % | 84.00 | 87.00 | 85.3000 | 0.94868 |

| WI % | 0.31 | 1.08 | 0.6590 | 0.26274 | |

| D mm | 5.22 | 5.55 | 5.3510 | 0.09469 | |

| L mm | 15.65 | 24.07 | 20.7060 | 2.48754 | |

| W gr | 0.80 | 0.90 | 0.8527 | 0.02811 | |

| Mix 3 | Durability % | 94.00 | 96.00 | 94.6000 | 0.69921 |

| WI % | 0.78 | 1.22 | 1.0380 | 0.13555 | |

| D mm | 5.95 | 6.21 | 6.1320 | 0.08715 | |

| L mm | 24.38 | 27.35 | 25.4850 | 0.97270 | |

| W gr | 0.86 | 1.08 | 0.9696 | 0.07319 | |

| Mix 4 | Durability % | 89.00 | 92.00 | 90.7000 | 0.94868 |

| WI % | 0.22 | 0.51 | 0.3430 | 0.10446 | |

| D mm | 5.89 | 6.06 | 5.9720 | 0.04917 | |

| L mm | 24.15 | 35.78 | 29.9080 | 4.79557 | |

| W gr | 1.07 | 1.69 | 1.3440 | 0.21629 | |

| Mix 5 | Durability % | 90.00 | 93.00 | 91.7000 | 0.94868 |

| WI % | 0.22 | 0.83 | 0.5640 | 0.20430 | |

| D mm | 5.89 | 6.06 | 5.9480 | 0.05350 | |

| L mm | 24.21 | 34.10 | 28.5740 | 3.74838 | |

| W gr | 0.94 | 1.38 | 1.1640 | 0.17283 | |

| Sum of Squares | df | Mean Square | F | Sig. | ||

|---|---|---|---|---|---|---|

| Durability % | Between groups | 459.920 | 4 | 114.980 | 131.992 | 0.000 |

| Within groups | 39.200 | 45 | 0.871 | |||

| Total | 499.120 | 49 | ||||

| WI % | Between groups | 2.575 | 4 | 0.644 | 17.164 | 0.000 |

| Within groups | 1.688 | 45 | 0.038 | |||

| Total | 4.263 | 49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papandrea, S.F.; Cataldo, M.F.; Palma, A.; Gallucci, F.; Zimbalatti, G.; Proto, A.R. Pelletization of Compost from Different Mixtures with the Addition of Exhausted Extinguishing Powders. Agronomy 2021, 11, 1357. https://doi.org/10.3390/agronomy11071357

Papandrea SF, Cataldo MF, Palma A, Gallucci F, Zimbalatti G, Proto AR. Pelletization of Compost from Different Mixtures with the Addition of Exhausted Extinguishing Powders. Agronomy. 2021; 11(7):1357. https://doi.org/10.3390/agronomy11071357

Chicago/Turabian StylePapandrea, Salvatore F., Maria F. Cataldo, Adriano Palma, Francesco Gallucci, Giuseppe Zimbalatti, and Andrea Rosario Proto. 2021. "Pelletization of Compost from Different Mixtures with the Addition of Exhausted Extinguishing Powders" Agronomy 11, no. 7: 1357. https://doi.org/10.3390/agronomy11071357

APA StylePapandrea, S. F., Cataldo, M. F., Palma, A., Gallucci, F., Zimbalatti, G., & Proto, A. R. (2021). Pelletization of Compost from Different Mixtures with the Addition of Exhausted Extinguishing Powders. Agronomy, 11(7), 1357. https://doi.org/10.3390/agronomy11071357