Higher Temperatures during Grain Filling Affect Grain Chalkiness and Rice Nutrient Contents

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site and Plant Material

2.2. Experiment Setup

2.3. Sample Preparation of Milled Rice

2.4. Classification of Grain Chalkiness

2.4.1. Protein Contents

2.4.2. Amylose Content

2.4.3. Mineral Nutrient Concentrations

2.5. Statistical Analyses

3. Results

3.1. Dates of Growth Stages and Environmental Conditions during Growth of Each Treatmet Group

3.2. Grain Size and Changes in Grain Weight and Amylose and Protein Contents

3.3. Mineral Concentrations by the Chalky Ratio in Treatment Groups

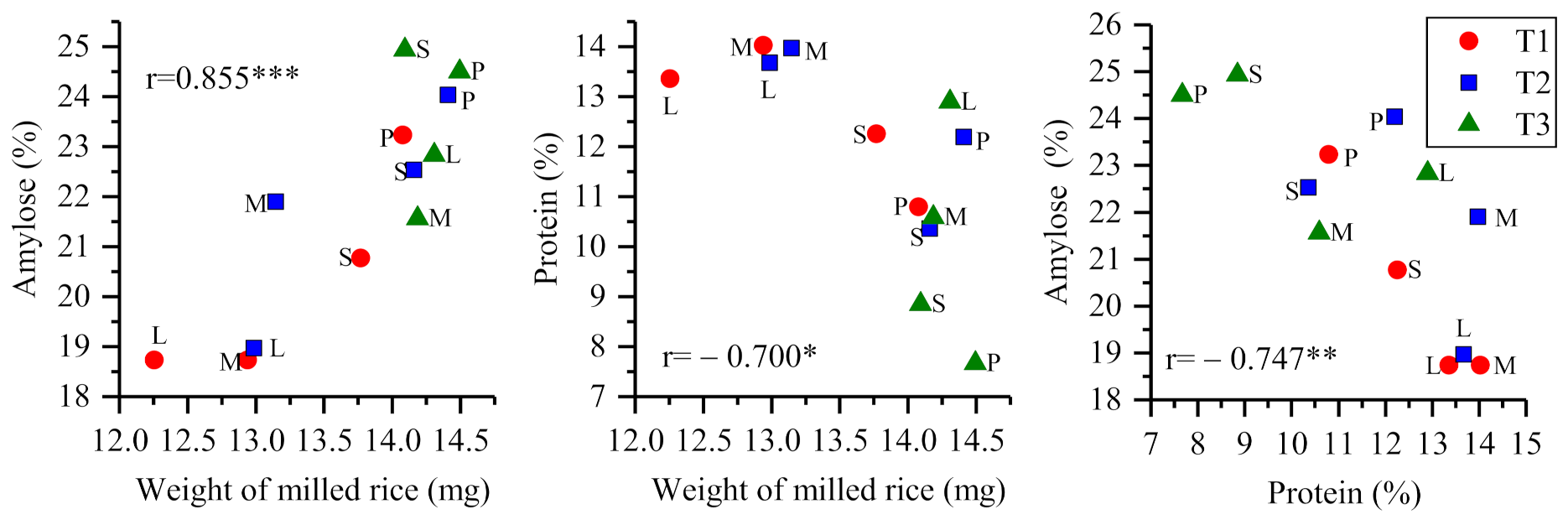

3.4. Mutual Correlation between Grain Weights of Milled Rice, Amylose, Protein, and Mineral Contents

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Khush, G.S. What it will take to Feed 5.0 Billion Rice consumers in 2030. Plant Mol. Biol. 2005, 59, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Muthayya, S.; Hall, J.; Bagriansky, J.; Sugimoto, J.; Gundry, D.; Matthias, D.; Prigge, S.; Hindle, P.; Moench-Pfanner, R.; Maberly, G. Rice Fortification: An Emerging Opportunity to Contribute to the Elimination of Vitamin and Mineral Deficiency Worldwide. Food Nutr. Bull. 2012, 33, 296–307. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.; Byerlee, D.; Dawe, D.; Dobermann, A.; Mohanty, S.; Rozelle, S.; Hardy, B. Rice in the Global Economy: Strategic Research and Policy Issues For Food Security; International Rice Research Institute: Los Baños, Philippines, 2010; pp. 1–477. [Google Scholar]

- Peng, S.; Huang, J.; Sheehy, J.E.; Laza, R.C.; Visperas, R.M.; Zhong, X.; Centeno, G.S.; Khush, G.S.; Cassman, K.G. Rice yields decline with higher night temperature from global warming. Proc. Natl. Acad. Sci. USA 2004, 101, 9971–9975. [Google Scholar] [CrossRef]

- Zhao, C.; Liu, B.; Piao, S.; Wang, X.; Lobell, D.B.; Huang, Y.; Huang, M.; Yao, Y.; Bassu, S.; Ciais, P.; et al. Temperature increase reduces global yields of major crops in four independent estimates. Proc. Natl. Acad. Sci. USA 2017, 114, 9326–9331. [Google Scholar] [CrossRef] [PubMed]

- Kinose, Y.; Masutomi, Y.; Shiotsu, F.; Hayashi, K.; Ogawada, D.; Gomez-Garcia, M.; Matsumura, A.; Takahashi, K.; Fukushi, K. Impact assessment of climate change on the major rice cultivar Ciherang in Indonesia. J. Agric. Meteorol. 2020, 76, 19–28. [Google Scholar] [CrossRef]

- Morita, S.; Wada, H.; Matsue, Y. Countermeasures for heat damage in rice grain quality under climate change. Plant Prod. Sci. 2016, 19, 1–11. [Google Scholar] [CrossRef]

- Jenner, C. Starch Synthesis in the Kernel of Wheat Under High Temperature Conditions. Funct. Plant Biol. 1994, 21, 791–806. [Google Scholar] [CrossRef]

- Okada, M.; Iizumi, T.; Hayashi, Y.; Yokozawa, M. Projecting climate change impacts both on rice quality and yield in Japan. J. Agric. Meteorol. 2011, 67, 285–295. [Google Scholar] [CrossRef]

- Masutomi, Y.; Takimoto, T.; Shimamura, M.; Manabe, T.; Arakawa, M.; Shibota, N.; Ooto, A.; Azuma, S.; Imai, Y.; Tamura, M. Rice grain quality degradation and economic loss due to global warming in Japan. Environ. Res. Commun. 2019, 1, 121003. [Google Scholar] [CrossRef]

- Imai, K.; Coleman, D.; Yanagisawa, T. Increase in atmospheric partial pressure of carbon dioxide and growth and yield of rice (Oryza sativa L.). Jpn. J. Crop Sci. 1985, 54, 413–418. [Google Scholar] [CrossRef][Green Version]

- Horie, T.; Matsui, T.; Nakagawa, H.; Omasa, K. Effects of elevated CO2 and global climate change on rice yield in Japan. In Climate Change and Plants in East Asia; Springer Science and Business Media LLC: Tokyo, Japan, 1996; pp. 39–56. [Google Scholar]

- Hasegawa, T.; Sakai, H.; Tokida, T.; Nakamura, H.; Zhu, C.; Usui, Y.; Yoshimoto, M.; Fukuoka, M.; Wakatsuki, H.; Katayanagi, N.; et al. Rice cultivar responses to elevated CO2 at two free-air CO2 enrichment (FACE) sites in Japan. Funct. Plant Biol. 2013, 40, 148–159. [Google Scholar] [CrossRef]

- Lieffering, M.; Kim, H.-Y.; Kobayashi, K.; Okada, M. The impact of elevated CO2 on the elemental concentrations of field-grown rice grains. Field Crops Res. 2004, 88, 279–286. [Google Scholar] [CrossRef]

- Zhu, C.; Kobayashi, K.; Loladze, I.; Zhu, J.; Jiang, Q.; Xu, X.; Liu, G.; Seneweera, S.; Ebi, K.L.; Drewnowski, A.; et al. Carbon dioxide (CO2) levels this century will alter the protein, micronutrients, and vitamin content of rice grains with potential health consequences for the poorest rice-dependent countries. Sci. Adv. 2018, 4, eaaq1012. [Google Scholar] [CrossRef]

- Chaturvedi, A.K.; Bahuguna, R.N.; Pal, M.; Shah, D.; Maurya, S.; Jagadish, K.S. Elevated CO2 and heat stress interactions affect grain yield, quality and mineral nutrient composition in rice under field conditions. Field Crops Res. 2017, 206, 149–157. [Google Scholar] [CrossRef]

- Myers, S.S.; Zanobetti, A.; Kloog, I.; Huybers, P.; Leakey, A.; Bloom, A.J.; Carlisle, E.; Dietterich, L.H.; Fitzgerald, G.; Hasegawa, T.; et al. Increasing CO2 threatens human nutrition. Nat. Cell Biol. 2014, 510, 139–142. [Google Scholar] [CrossRef] [PubMed]

- Smith, M.R.; Myers, S.S. Impact of anthropogenic CO2 emissions on global human nutrition. Nat. Clim. Chang. 2018, 8, 834–839. [Google Scholar] [CrossRef]

- Van, T.K.; Burja, K.; Nga, T.T.; Kong, K.; Berger, J.; Gardner, M.; Dijkhuizen, M.A.; Hop, L.T.; Tuyen, L.D.; Wieringa, F.T. Organoleptic qualities and acceptability of fortified rice in two Southeast Asian countries. Ann. N. Y. Acad. Sci. 2014, 1324, 48–54. [Google Scholar] [CrossRef]

- Black, R.E.; Allen, L.H.; Bhutta, Z.A.; Caulfield, L.E.; De Onis, M.; Ezzati, M.; Mathers, C.; Rivera, J. Maternal and child undernutrition: Global and regional exposures and health consequences. Lancet 2008, 371, 243–260. [Google Scholar] [CrossRef]

- FAO. Sustainable Nutrition Security—Restoring the Bridge Between Agriculture and Health; FAO: Rome, Italy, 2012; pp. 1–34. Available online: http://www.fao.org/docrep/017/me785e/me785e.pdf (accessed on 14 December 2020).

- Tashiro, T.; Ebata, M. Studies on white-belly rice kernel IV. Opaque rice endosperm viewed with a scanning electron microscope. Prod. Crop Sci. Soc. Jpn. 1975, 44, 205–214. [Google Scholar] [CrossRef]

- Hakata, M.; Kuroda, M.; Miyashita, T.; Yamaguchi, T.; Kojima, M.; Sakakibara, H.; Mitsui, T.; Yamakawa, H. Suppression of α-amylase genes improves quality of rice grain ripened under high temperature. Plant Biotechnol. J. 2012, 10, 1110–1117. [Google Scholar] [CrossRef]

- Wakamatsu, K.; Sasaki, O.; Uezono, I.; Tanaka, A. Effects of high air temperature during the ripening period on the grain quality of rice in warm regions of Japan. Jpn. J. Crop Sci. 2007, 76, 71–78. [Google Scholar] [CrossRef]

- Miyazaki, A.; Ikeda, A.; Yonemaru, J.; Morita, S.; Yamamoto, Y. Relationships among the chalkiness, kernel size and endosperm cell morphology of rice kernels at different spikelet positions within a panicle. Plant Prod. Sci. 2018, 21, 225–232. [Google Scholar] [CrossRef]

- Nagato, K.; Ebata, M. Effects of High Temperature during Ripening Period on the Development and the Quality of Rice Kernels. Jpn. J. Crop Sci. 1965, 34, 59–66. [Google Scholar] [CrossRef]

- Morita, S. The occurrences of immature grain with white portions and deep ditch, and grain weight decrease in rice under high temperature during ripening. J Agric. Sci. 2005, 60, 442–446. [Google Scholar]

- Feng, F.; Li, Y.; Qin, X.; Liao, Y.; Siddique, K. Changes in Rice Grain Quality of Indica and Japonica Type Varieties Released in China from 2000 to 2014. Front. Plant Sci. 2017, 8, 1863. [Google Scholar] [CrossRef] [PubMed]

- Deng, F.; Li, Q.; Chen, H.; Zeng, Y.; Li, B.; Zhong, X.; Wang, L.; Ren, W. Relationship between chalkiness and the structural and thermal properties of rice starch after shading during grain-filling stage. Carbohydr. Polym. 2021, 252, 117212. [Google Scholar] [CrossRef] [PubMed]

- Mackill, D.J.; Khush, G.S. IR64: A high-quality and high-yielding mega variety. Rice 2018, 11, 18. [Google Scholar] [CrossRef]

- International Rice Research Institute (IRRI), 2004. Rice Knowledge Bank. Available online: http://www.knowledgebank.irri.org/training/fact-sheets/postharvest-management/rice-quality-fact-sheet-category/item/physical-quality-of-milled-rice-fact-sheet (accessed on 5 August 2020).

- Juliano, B.O. A simplified assay for milled-rice amylose. Cereal Sci. Today 1971, 16, 334–360. [Google Scholar]

- Nakamura, S.; Suzuki, K.; Haraguchi, K.; Takemoto, Y.; Juliano, B.O.; Ohtsubo, K. Cultivar Identification and Palatability Estimation of 14 Typical Philippine Rice Cultivars by the PCR Method. Nippon. Shokuhin Kagaku Kogaku Kaishi 2006, 53, 634–643. [Google Scholar] [CrossRef][Green Version]

- Patindol, J.A.; Siebenmorgen, T.J.; Wang, Y.-J. Impact of environmental factors on rice starch structure: A review. Starch Stärke 2015, 67, 42–54. [Google Scholar] [CrossRef]

- Kondo, M.; Ishimaru, T.; Sanoh, Y.; Umemoto, T. Research directions on grain ripening under high temperature in rice. J Agric. Sci. 2005, 60, 462–470. [Google Scholar]

- Seo, S.; Chamura, S. Occurrence of varietal differences in protein, phosphorus and potassium content in brown rice, and Influence of temperature and shading during the ripening period on it. Jpn. Crop Sci. 1980, 49, 199–204. [Google Scholar] [CrossRef]

- Asaoka, M.; Okuno, K.; Sugimoto, Y.; Kawakami, J.; Fuwa, H. Effect of Environmental Temperature During Development of Rice Plants on Some Properties of Endosperm Starch. Starch Stärke 1984, 36, 189–193. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Lam, S.K.; Liu, X.; Pan, G. Responses of wheat and rice grain mineral quality to elevated carbon dioxide and canopy warming. Field Crops Res. 2020, 249, 107753. [Google Scholar] [CrossRef]

- Trenberth, K.E.; Fasullo, J.; Smith, L. Trends and variability in column-integrated atmospheric water vapor. Clim. Dyn. 2005, 24, 741–758. [Google Scholar] [CrossRef]

- Ge, L.-Q.; Cang, L.; Liu, H.; Zhou, D.-M. Effects of warming on uptake and translocation of cadmium (Cd) and copper (Cu) in a contaminated soil-rice system under Free Air Temperature Increase (FATI). Chemosphere 2016, 155, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Zhenghui, L.; Zhang, X.; Wang, Z.; Lei, J.; Liu, Z.; Li, G.; Wang, S.; Ding, Y. Chalky part differs in chemical composition from translucent part of japonica rice grains as revealed by a notched-belly mutant with white-belly. J. Sci. Food Agric. 2016, 96, 3937–3943. [Google Scholar] [CrossRef] [PubMed]

| Treatment | Transplanting | Heading | Maturing | Mean Air Temperature (°C) | |

|---|---|---|---|---|---|

| Growing Season | Grain-Filling (20 DAH) | ||||

| T1 | 20 May | 15 August | 25 September | 25.0 | 29.1 |

| T2 | 3 June | 23 August | 5 October | 25.3 | 28.2 |

| T3 | 17 June | 8 September | 23 October | 24.2 | 23.5 |

| Treatment | Grain Length (mm) | Grain Width (mm) | Grain Thickness (mm) |

|---|---|---|---|

| T1 | 6.27 ± 0.04 b | 2.12 ± 0.02 a | 1.83 ± 0.001 a |

| T2 | 6.44 ± 0.03 b | 2.06 ± 0.02 ab | 1.83 ± 0.001 a |

| T3 | 6.58 ± 0.03 a | 2.03 ± 0.02 b | 1.81 ± 0.002 b |

| Classification | T1 | T2 | T3 | ||||

|---|---|---|---|---|---|---|---|

| Weight of milled rice (mg) | P | 14.08 ± 0.09 | a | 14.41 ± 0.66 | a | 14.49 ± 0.05 | a |

| S | 13.77 ± 0.17 | a | 14.16 ± 0.86 | a | 14.09 ± 0.06 | b | |

| M | 12.94 ± 0.46 | ab | 13.15 ± 1.03 | b | 14.19 ± 0.13 | ab | |

| L | 12.26 ± 0.13 | b | 12.99 ± 0.53 | b | 14.31 ± 0.08 | ab | |

| Amylose (%) | P | 23.2 ± 2.0 | a | 24.0 ± 1.2 | a | 24.5 ± 0.7 | a |

| S | 20.8 ± 0.4 | a | 22.5 ± 0.4 | a | 24.9 ± 0.5 | a | |

| M | 18.7 ± 0.5 | a | 21.9 ± 1.0 | a | 21.6 ± 0.7 | b | |

| L | 18.7 ± 1.1 | a | 19.0 ± 1.8 | a | 22.8 ± 0.6 | ab | |

| Protein (%) | P | 10.8 ± 0.5 | b | 12.2 ± 0.7 | ab | 7.7 ± 1.8 | b |

| S | 12.3 ± 1.4 | ab | 10.4 ± 0.9 | b | 8.8 ± 0.2 | ab | |

| M | 14.0 ± 0.8 | a | 14.0 ± 1.0 | a | 10.6 ± 0.7 | ab | |

| L | 13.4 ± 0.4 | ab | 13.7 ± 0.5 | ab | 12.9 ± 1.0 | ab | |

| Classification | T1 | T2 | T3 | Classification | T1 | T2 | T3 | ||

|---|---|---|---|---|---|---|---|---|---|

| P | 1852 ± 92 b | 1614 ± 47 a | 1592 ± 40 a | P | 660 ± 16 ab | 753 ± 39 a | 850 ± 28 a | ||

| K | S | 1807 ± 26 b | 1700 ± 255 a | 1338 ± 52 b | Mg | S | 629 ± 37 b | 776 ± 95 a | 661 ± 36 b |

| (μg/g) | M | 2287 ± 155 a | 1810 ± 133 a | 1456 ± 64 ab | (μg/g) | M | 860 ± 76 a | 838 ± 22 a | 751 ± 32 ab |

| L | 2003 ± 53 ab | 1679 ± 153 a | 1524 ± 9 ab | L | 712 ± 46 ab | 863 ± 105 a | 756 ± 23 ab | ||

| P | 235 ± 15 a | 234 ± 6 a | 173 ± 34 a | P | 297 ± 4 ab | 174 ± 12 a | 116 ± 21 a | ||

| Na | S | 266 ± 55 a | 202 ± 42 a | 205 ± 9 a | Ca | S | 233 ± 13 b | 162 ± 31 a | 110 ± 15 a |

| (μg/g) | M | 266 ± 18 a | 174 ± 25 a | 177 ± 32 a | (μg/g) | M | 370 ± 38 a | 165 ± 27 a | 124 ± 13 a |

| L | 232 ± 8 a | 187 ± 36 a | 212 ± 11 a | L | 312 ± 17 ab | 200 ± 33 a | 130 ± 12 a | ||

| P | 27.1 ± 0.7 b | 32.4 ± 1.5 a | 27.7 ± 0.1 a | P | 24.1 ± 0.9 a | 15.2 ± 1.6 a | 12.5 ± 0.3 a | ||

| Zn | S | 27.7 ± 1.8 b | 30.0 ± 0.7 a | 22.6 ± 0.6 b | Cu | S | 21.7 ± 1.0 a | 11.8 ± 0.8 b | 8.8 ± 1.3 a |

| (μg/g) | M | 34.1 ± 0.7 a | 33.8 ± 1.2 a | 21.6 ± 0.8 b | (μg/g) | M | 23.3 ± 0.9 a | 12.4 ± 1.2 b | 7.3 ± 0.1 a |

| L | 33.0 ± 0.9 a | 32.3 ± 0.7 a | 20.6 ± 1.4 b | L | 23.2 ± 2.0 a | 12.2 ± 1.2 b | 7.5 ± 0.1 a | ||

| P | 16.7 ± 3.2 b | 23.3 ± 0.9 ab | 26.3 ± 1.8 a | P | 11.0 ± 0.1 a | 8.3 ± 0.9 a | 6.8 ± 0.2 a | ||

| Mn | S | 19.7 ± 0.3 ab | 20.0 ± 0.6 b | 25.3 ± 1.5 a | Fe | S | 9.4 ± 0.5 a | 8.2 ± 0.1 a | 5.7 ± 0.5 a |

| (μg/g) | M | 26.0 ± 0.0 a | 25.7 ± 3.3 ab | 26.3 ± 1.8 a | (μg/g) | M | 11.7 ± 0.5 a | 8.5 ± 1.0 a | 5.4 ± 0.4 a |

| L | 27.0 ± 0.6 a | 30.7 ± 1.9 ab | 33.0 ± 4.0 a | L | 11.4 ± 1.0 a | 9.4 ± 0.9 a | 5.3 ± 0.5 a | ||

| P | 3.1 ± 0.3 a | 3.4 ± 0.3 a | 2.5 ± 0.1 a | P | 0.61 ± 0.03 b | 0.64 ± 0.01 a | 0.27 ± 0.07 a | ||

| Ni | S | 2.9 ± 0.3 a | 3.2 ± 0.1 a | 1.8 ± 0.1 b | Mo | S | 0.67 ± 0.03 b | 0.61 ± 0.02 a | 0.26 ± 0.07 a |

| (μg/g) | M | 2.6 ± 0.3 a | 2.4 ± 0.1 b | 1.6 ± 0.1 c | (μg/g) | M | 0.85 ± 0.02 a | 0.75 ± 0.06 a | 0.28 ± 0.05 a |

| L | 2.6 ± 0.4 a | 2.2 ± 0.1 b | 1.4 ± 0.0 bc | L | 0.85 ± 0.04 a | 0.74 ± 0.06 a | 0.35 ± 0.06 a |

| Weight of Milled Rice | Amylose | Protein | K | Mg | Na | Ca | Zn | Cu | Mn | Fe | Ni | Mo | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight of milled rice | 1.000 | ||||||||||||

| Amylose | 0.855 *** | 1.000 | |||||||||||

| Protein | −0.700 * | −0.747 ** | 1.000 | ||||||||||

| K | −0.648 * | −0.683 * | 0.574 | 1.000 | |||||||||

| Mg | −0.173 | −0.213 | 0.253 | 0.202 | 1.000 | ||||||||

| Na | −0.268 | −0.341 | 0.404 | 0.718 ** | −0.304 | 1.000 | |||||||

| Ca | −0.607 * | −0.631 * | 0.490 | 0.949 *** | −0.057 | 0.789 ** | 1.000 | ||||||

| Zn | −0.664 * | −0.532 | 0.549 | 0.622 * | 0.460 | 0.185 | 0.474 | 1.000 | |||||

| Cu | −0.476 | −0.457 | 0.284 | 0.864 *** | −0.239 | 0.771 ** | 0.925 *** | 0.456 | 1.000 | ||||

| Mn | −0.170 | −0.204 | 0.165 | -0.121 | 0.428 | −0.240 | −0.219 | −0.271 | −0.448 | 1.000 | |||

| Fe | −0.692 * | −0.621 * | 0.557 | 0.865 *** | 0.073 | 0.577 * | 0.857 *** | 0.812 ** | 0.853 *** | −0.423 | 1.000 | ||

| Ni | −0.037 | −0.025 | -0.016 | 0.427 | −0.189 | 0.371 | 0.448 | 0.549 | 0.647 * | −0.833 *** | 0.659 * | 1.000 | |

| Mo | −0.778 ** | −0.745 ** | 0.772 | 0.797 ** | 0.126 | 0.522 | 0.749 ** | 0.850 *** | 0.688 * | −0.282 | 0.926 *** | 0.544 | 1.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shimoyanagi, R.; Abo, M.; Shiotsu, F. Higher Temperatures during Grain Filling Affect Grain Chalkiness and Rice Nutrient Contents. Agronomy 2021, 11, 1360. https://doi.org/10.3390/agronomy11071360

Shimoyanagi R, Abo M, Shiotsu F. Higher Temperatures during Grain Filling Affect Grain Chalkiness and Rice Nutrient Contents. Agronomy. 2021; 11(7):1360. https://doi.org/10.3390/agronomy11071360

Chicago/Turabian StyleShimoyanagi, Rikako, Mitsuru Abo, and Fumitaka Shiotsu. 2021. "Higher Temperatures during Grain Filling Affect Grain Chalkiness and Rice Nutrient Contents" Agronomy 11, no. 7: 1360. https://doi.org/10.3390/agronomy11071360

APA StyleShimoyanagi, R., Abo, M., & Shiotsu, F. (2021). Higher Temperatures during Grain Filling Affect Grain Chalkiness and Rice Nutrient Contents. Agronomy, 11(7), 1360. https://doi.org/10.3390/agronomy11071360