An Efficient Structure of an Agrophotovoltaic System in a Temperate Climate Region

Abstract

:1. Introduction

2. Agrophotovoltaic Systems

3. Selection Model of the APV System

3.1. Crop Management under the APV System

3.2. Estimation Model of Electricity Generation by the APV System

3.3. Optimization Model for the Maximum Total Revenue

4. Results

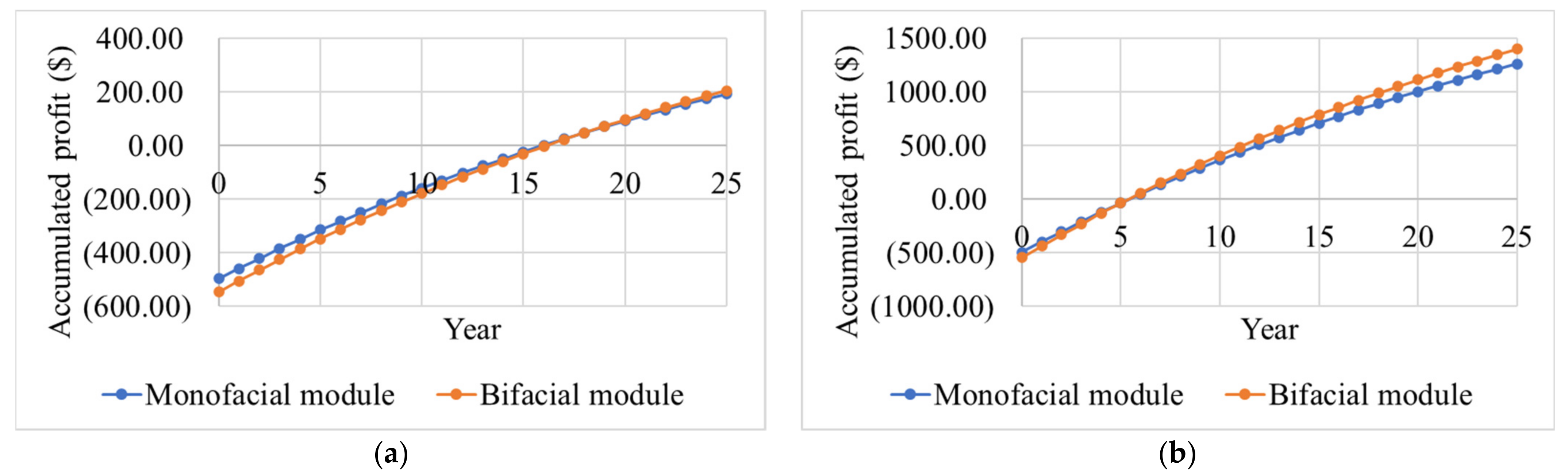

4.1. Comparison between Solar Module Types

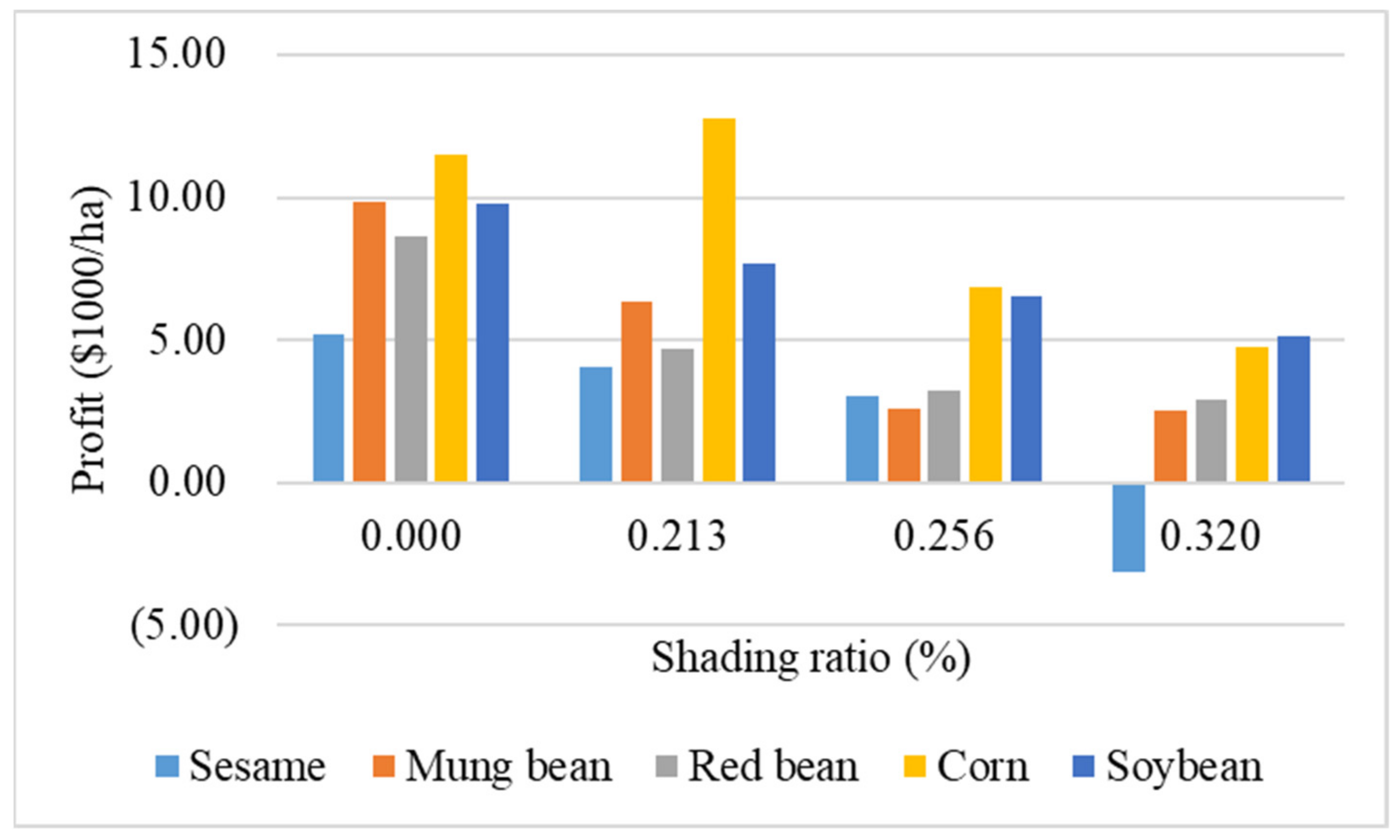

4.2. Crop Growth between Solar Module Types

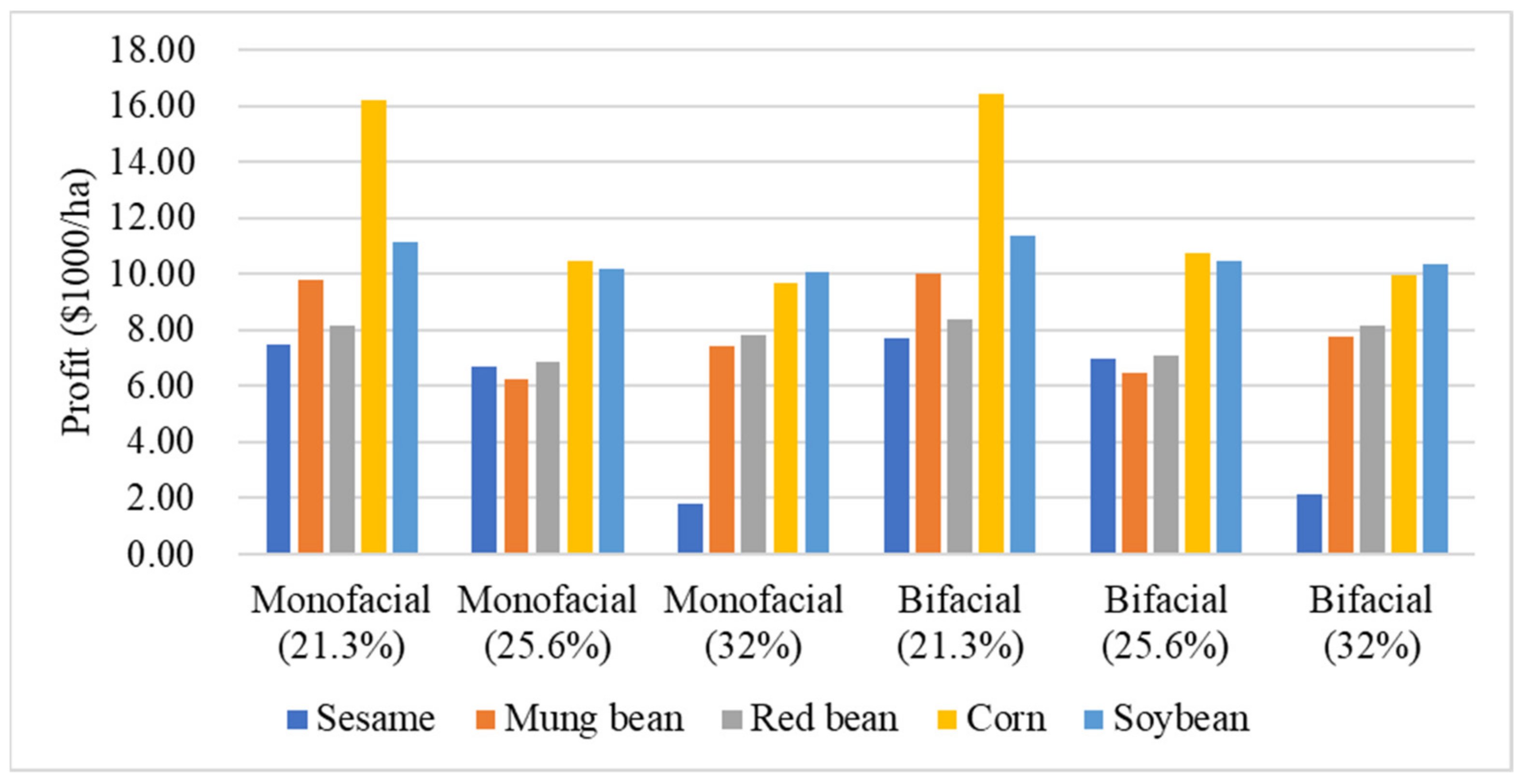

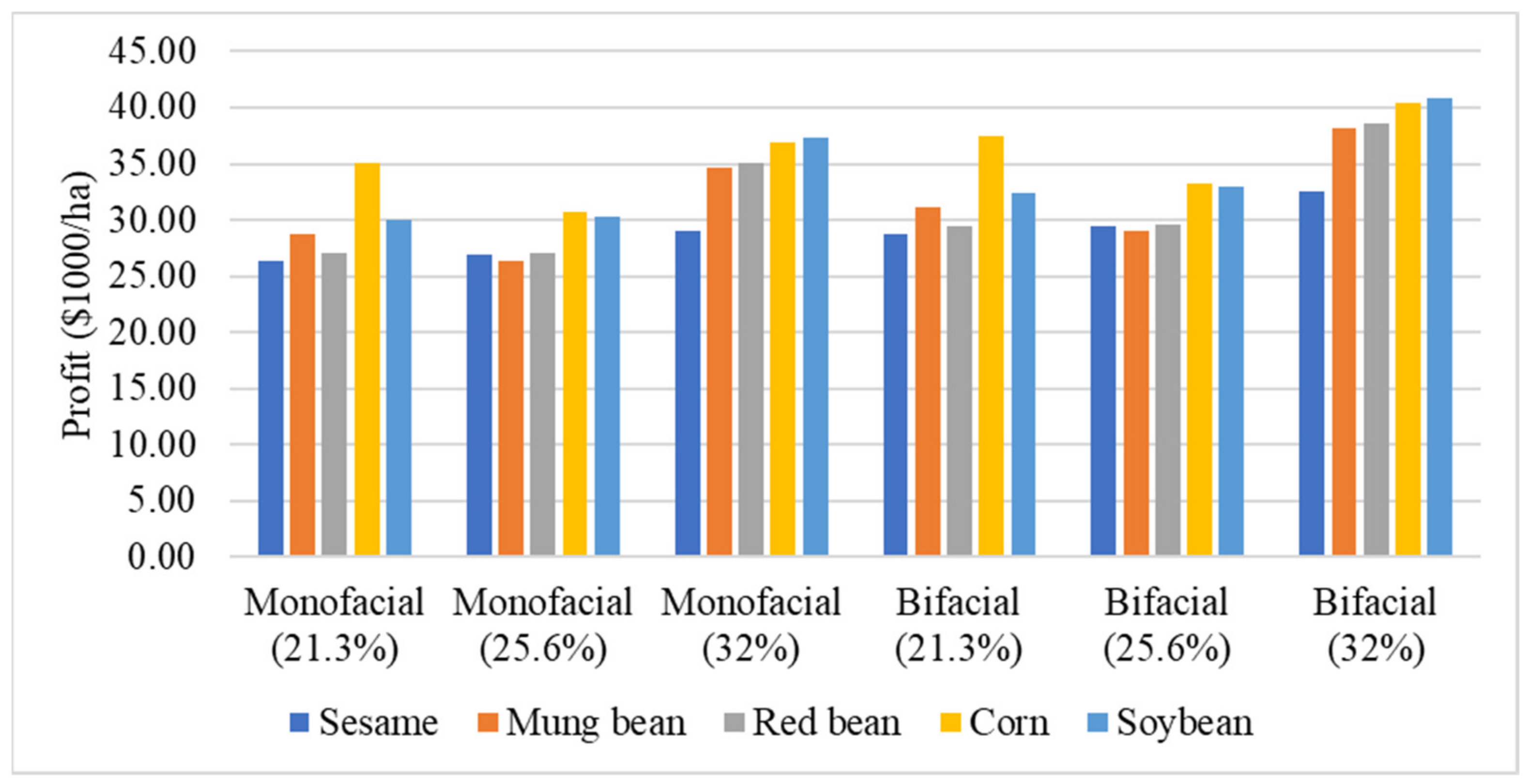

4.3. Identification of the Maximum Total Revenue for a Farmer

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kannan, N.; Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- IEA. Projected Costs of Generating Electricity 2020. Available online: https://www.iea.org/reports/projected-costs-of-generating-electricity-2020 (accessed on 16 March 2021).

- Pehl, M.; Arvesen, A.; Humpenöder, F.; Popp, A.; Hertwich, E.G.; Luderer, G. Understanding future emissions from low-carbon power systems by integration of life-cycle assessment and integrated energy modelling. Nat. Energy 2017, 2, 939–945. [Google Scholar] [CrossRef]

- Chen, W.M.; Kim, H.; Yamaguchi, H. Renewable energy in eastern Asia: Renewable energy policy review and comparative SWOT analysis for promoting renewable energy in Japan, South Korea, and Taiwan. Energy Policy 2014, 74, 319–329. [Google Scholar] [CrossRef]

- Congressional Budget Office. Impose a Tax on Emissions of Greenhous Gases. Available online: https://www.cbo.gov/budget-options/54821 (accessed on 21 December 2020).

- Korea Energy Agency. Feed in Tariff (FIT). Available online: https://www.knrec.or.kr/business/rps_support.aspx (accessed on 18 March 2021).

- HIS Markit, China’s New 2020 Climate Commitments: Beyond Peak Emissions. Available online: https://ihsmarkit.com/research-analysis/chinas-updated-2030-climate-targets-beyond-carbon-peak.html (accessed on 18 March 2021).

- IEA International Energy Agency. National Survey Report of PV Power Applications in JAPAN 2016. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/National_Survey_Report_of_PV_Power_Applications_in_Japan_-_2016.pdf (accessed on 18 March 2021).

- Ministry of Trade, Industry and Energy. The 3020 Renewable Energy Policy. Available online: https://www.etrans.or.kr/policy/04.php (accessed on 18 March 2021).

- UN Data. Global Solar Radiation. Available online: http://data.un.org/Data.aspx?d=CLINO&f=ElementCode%3A33 (accessed on 12 February 2021).

- Statistics KOREA. A Trend of Duration of Bright Sunshine in 2019. Available online: http://index.go.kr/potal/main/EachDtlPageDetail.do?idx_cd=1402 (accessed on 18 March 2021).

- Nematollahi, O.; Kim, K.C. A feasibility study of solar energy in South Korea. Renew. Sustain. Energy Rev. 2017, 77, 566–579. [Google Scholar] [CrossRef]

- Alsharif, M.H.; Kim, J.; Kim, J.H. Opportunities and challenges of solar and wind energy in South Korea: A review. Sustainability 2018, 10, 1822. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Lee, H.; Kim, H.; Jang, D.H.; Kim, H.J.; Hur, J.; Hur, K. Improvement in policy and proactive interconnection procedure for renewable energy expansion in South Korea. Renew. Sustain. Energy Rev. 2018, 98, 150–162. [Google Scholar] [CrossRef]

- Statistics Korea. Cultivated Acreage by City. Available online: https://kosis.kr/statHtml/statHtml.do?orgId=101&tblId=DT_1EB002 (accessed on 2 March 2021).

- Weselek, A.; Ehmann, A.; Zikeli, S.; Lewandowski, I.; Schindele, S.; Högy, P. Agrophotovoltaic systems: Applications, challenges, and opportunities. A review. Agron. Sustain. Dev. 2019, 39, 1–20. [Google Scholar] [CrossRef]

- Brohm, R.; Khanh, N. Dual-Use Approaches for Solar Energy and Food Production International Experience and Potentials for Viet Nam. Green Innovation and Development Centre (GreenID): Hanoi, Vietnam, 2018; pp. 51–52. [Google Scholar]

- Zohdi, T.I. A digital-twin and machine-learning framework for the design of multiobjective agrophotovoltaic solar farms. Comput. Mech. 2021, 68, 357–370. [Google Scholar] [CrossRef]

- Kim, K.A.; Shenoy, P.S.; Krein, P.T. Converter rating analysis for photovoltaic differential power processing systems. IEEE Trans. Power Electron. 2014, 30, 1987–1997. [Google Scholar] [CrossRef]

- LG. LG Solar Module Limited Warranty. Available online: https://www.lg.com/us/business/download/resources/BT00002151/BT00002151_2573.pdf (accessed on 1 April 2021).

- Kannan, R.; Leong, K.C.; Osman, R.; Ho, H.K.; Tso, C.P. Life cycle assessment study of solar PV systems: An example of a 2.7 kWp distributed solar PV system in Singapore. Sol. Energy 2006, 80, 555–563. [Google Scholar] [CrossRef]

- Kumar, A.; Chowdhury, A. Advanced radiative cooler for multi-crystalline silicon solar module. Sol. Energy 2020, 201, 751–759. [Google Scholar] [CrossRef]

- Korea Seed & Variety Service. A Supply Price of Seeds. Available online: https://www.seed.go.kr/seed/183/subview.do (accessed on 28 April 2021).

- Yoon, C.Y.; Kim, S.; An, K.N.; Kim, S. Simulated impacts of rainfall extremes on yield responses of various barley varieties in a temperate region. Int. Agrophys. 2021, 35, 119–129. [Google Scholar] [CrossRef]

- Kim, S.; Meng, C.; Son, Y.J. Simulation-based machine shop operations scheduling system for energy cost reduction. Simul. Model. Pract. Theory 2017, 77, 68–83. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S.; Cho, J.; Park, S.; Jarrín Perez, F.X.; Kiniry, J.R. Simulated biomass, climate change impacts, and nitrogen management to achieve switchgrass biofuel production at diverse sites in US. Agronomy 2020, 10, 503. [Google Scholar] [CrossRef] [Green Version]

- Korea Electric Power Corporation. A Price of the System Marginal Price. Available online: https://home.kepco.co.kr/kepco/CO/D/E/CODEPP002/list.do (accessed on 20 April 2021).

- EPSIS. Unit Price of Electricity by Type. Available online: http://epsis.kpx.or.kr/epsisnew/selectEkmaUpsBftChart.do?menuId=040701 (accessed on 1 April 2021).

- Korea Power Exchange. A Price of the Renewable Energy Certificate. Available online: https://onerec.kmos.kr/portal/index.do (accessed on 20 April 2021).

- Korea Agro-Fisheries & Food Trade Co. Sales Price of Agricultural Products. Available online: https://www.kamis.or.kr/customer/main/main.do (accessed on 20 March 2021).

- Hasanien, H.M. Performance improvement of photovoltaic power systems using an optimal control strategy based on whale optimization algorithm. Electr. Power Syst. Res. 2018, 157, 168–176. [Google Scholar] [CrossRef]

| Data Type | Monofacial Solar Modules | Bifacial Solar Modules | ||||

|---|---|---|---|---|---|---|

| 21.3% | 25.6% | 32% | 21.3% | 25.6% | 32% | |

| Number of solar modules (units) | 35 | 56 | 70 | 35 | 56 | 70 |

| Total construction cost ($) | 17,370.72 | 27,793.14 | 34,741.43 | 19,116.98 | 30,587.16 | 38,233.96 |

| Solar module cost ($) | 4961.25 | 7938.00 | 9922.50 | 5460.00 | 8736.00 | 10,920.00 |

| Structure cost ($) | 8211.81 | 13,138.90 | 16,423.63 | 9037.34 | 14,459.75 | 18,074.68 |

| Electric distribution system cost ($) | 3911.23 | 6257.97 | 7822.46 | 4304.43 | 6887.08 | 8608.85 |

| Other costs ($) 1 | 286.42 | 458.27 | 572.84 | 315.21 | 504.34 | 630.42 |

| Unit construction cost ($/module) | 496.31 | 496.31 | 496.31 | 156.00 | 156.00 | 156.00 |

| Unit construction cost ($/ha) | 153,180.91 | 163,392.97 | 220,580.51 | 168,580.05 | 179,818.72 | 242,755.27 |

| Crop Type | Planting Date | Harvesting Date | Fertilizer Rate |

|---|---|---|---|

| (N-P-K, Kg ha−1) | |||

| Sesame | June 16th | Sep. 10th | 30-30-34 |

| Mung bean | July 3rd | Sep. 14th | 30-30-34 |

| Red bean | July 3rd | Oct. 12th | 30-30-34 |

| Corn | May 26th | Aug. 18th | 150-30-60 |

| Soybean | June 17th | Oct. 24th | 29-31-32 |

| Crop Type | Material Cost ($) | Labor Cost 1 ($) | Overhead Cost 1 ($) | |||

|---|---|---|---|---|---|---|

| Seed | Fertilizer 1 | Pesticides 1 | Other 1 | |||

| Sesame | 776.98 | 43.38 | 28.06 | 22.80 | 34.43 | 347.17 |

| Mung bean | 339.93 | 43.38 | 28.06 | 22.80 | 34.43 | 347.17 |

| Red bean | 323.74 | 43.38 | 28.06 | 22.80 | 34.43 | 347.17 |

| Corn | 809.35 | 43.38 | 28.06 | 22.80 | 34.43 | 347.17 |

| Soybean | 194.24 | 43.38 | 28.06 | 22.80 | 34.43 | 347.17 |

| Average | Min | Max | Std Dev | |

|---|---|---|---|---|

| Solar radiation (MJ/m2) | 3.24 | 0.36 | 6.18 | 1.40 |

| Max temperature (°C) | 29.00 | 18.90 | 38.10 | 4.39 |

| Min temperature (°C) | 18.67 | 3.60 | 27.00 | 5.61 |

| Precipitation (mm) | 11.24 | 0.00 | 262.60 | 28.55 |

| Humidity (%) | 74.20 | 35.53 | 94.26 | 12.12 |

| Wind speed (m/s) | 1.97 | 0.91 | 19.58 | 1.70 |

| Data Type | Monofacial Solar Modules | Bifacial Solar Modules | |||||

|---|---|---|---|---|---|---|---|

| 21.3% | 25.6% | 32% | 21.3% | 25.6% | 32% | ||

| Generation duration (h/day) | Average | 3.88 | 3.88 | 3.88 | 3.88 | 3.88 | 3.88 |

| Std Dev | 1.69 | 1.69 | 1.69 | 1.69 | 1.69 | 1.69 | |

| Generation quantity (kWh/day) | Average | 55.07 | 88.11 | 110.13 | 60.98 | 97.57 | 121.96 |

| Std Dev | 23.90 | 38.24 | 47.80 | 26.47 | 42.34 | 52.93 | |

| Generation quantity (kWh/year) 1 | Average | 17,597.44 | 28,155.27 | 35,191.69 | 19,485.97 | 31,178.18 | 38,971.93 |

| Std Dev | 1039.92 | 1663.84 | 2079.66 | 1151.53 | 1842.48 | 2303.05 | |

| Unit generation quantity (kWh/day/ha) | Average | 485.59 | 517.96 | 699.25 | 537.75 | 573.60 | 774.35 |

| Std Dev | 210.75 | 224.80 | 303.47 | 233.38 | 248.94 | 336.07 | |

| Generation quantity (MWh/year/ha) 1 | Average | 155.18 | 165.52 | 223.44 | 171.83 | 183.29 | 247.44 |

| Std Dev | 9.17 | 9.78 | 13.20 | 10.15 | 10.83 | 14.62 | |

| Crop Type | Shading Levels (%) | |||

|---|---|---|---|---|

| 0 | 21.3 | 25.6 | 32 | |

| Total grain yield (Mg ha−1) | ||||

| Sesame | 0.96 | 0.89 (−7%) | 0.83 (−14%) | 0.45 (−53%) |

| Mung bean | 1.95 | 1.54 (−21%) | 1.1 (−44%) | 1.09 (−44%) |

| Red bean | 2.35 | 1.75 (−26%) | 1.52 (−35%) | 1.47 (−37%) |

| Corn | 8.09 | 8.56 (+6%) | 6.4 (−21%) | 5.63 (−30%) |

| Soybean | 3.64 | 3.15 (−13%) | 2.88 (−21%) | 2.54 (−30%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Kim, S.; Yoon, C.-Y. An Efficient Structure of an Agrophotovoltaic System in a Temperate Climate Region. Agronomy 2021, 11, 1584. https://doi.org/10.3390/agronomy11081584

Kim S, Kim S, Yoon C-Y. An Efficient Structure of an Agrophotovoltaic System in a Temperate Climate Region. Agronomy. 2021; 11(8):1584. https://doi.org/10.3390/agronomy11081584

Chicago/Turabian StyleKim, Sojung, Sumin Kim, and Chang-Yong Yoon. 2021. "An Efficient Structure of an Agrophotovoltaic System in a Temperate Climate Region" Agronomy 11, no. 8: 1584. https://doi.org/10.3390/agronomy11081584

APA StyleKim, S., Kim, S., & Yoon, C.-Y. (2021). An Efficient Structure of an Agrophotovoltaic System in a Temperate Climate Region. Agronomy, 11(8), 1584. https://doi.org/10.3390/agronomy11081584