Assessing Intra-Row Spacing Using Image Processing: A Promising Digital Tool for Smallholder Farmers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiment Location

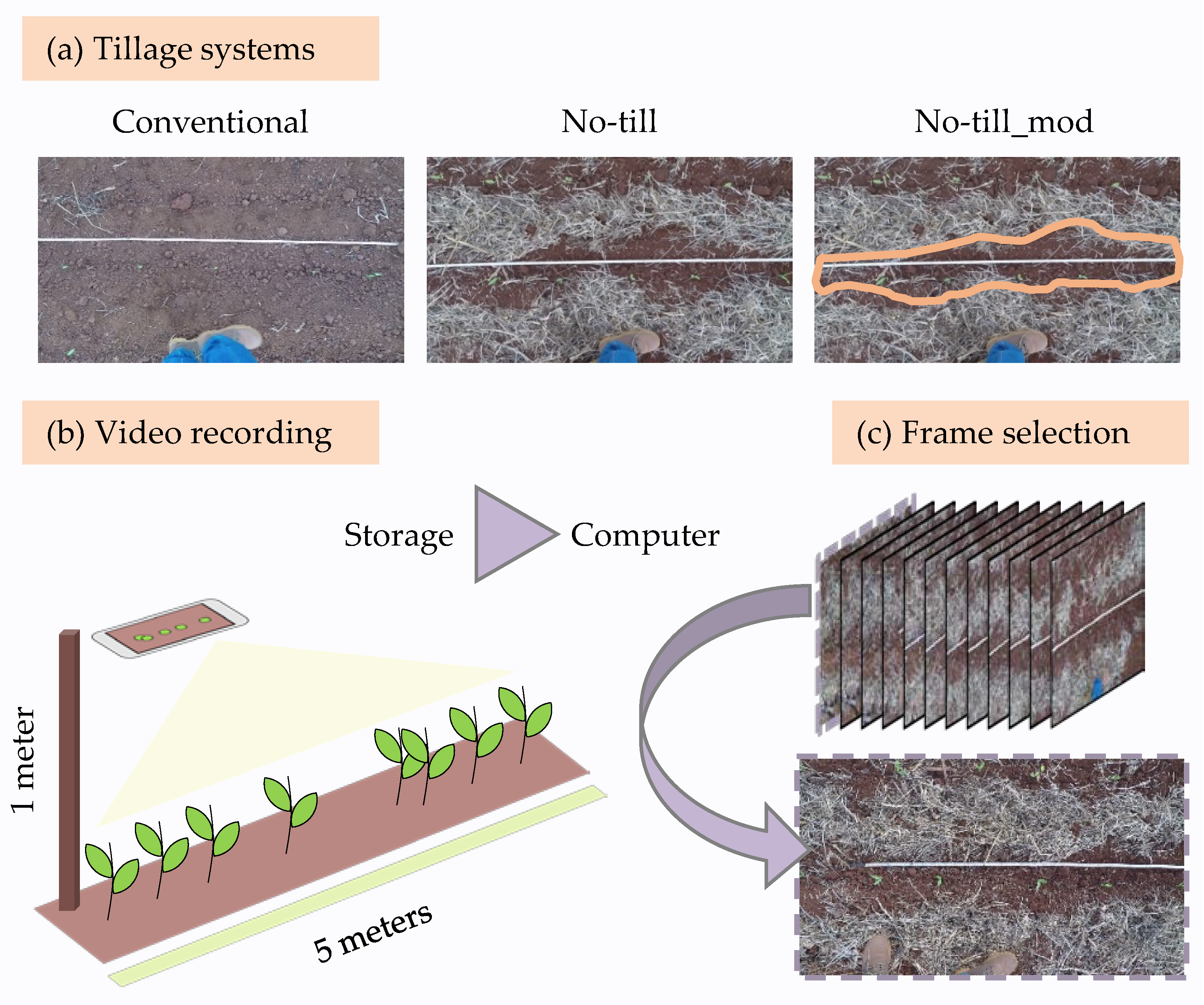

2.2. Data Collection

2.3. Image Processing

2.3.1. Pre-Processing

2.3.2. Region of Interest (ROI)

2.3.3. Local Maxima (Peaks)

2.4. Analysis

3. Results

3.1. Overall Aspects and Performance

3.2. Common Metrics in Planting Assessment

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Karayel, D.; Wiesehoff, M.; Özmerzi, A.; Müller, J. Laboratory Measurement of Seed Drill Seed Spacing and Velocity of Fall of Seeds Using High-Speed Camera System. Comput. Electron. Agric. 2006, 50, 89–96. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, L.; Evers, J.; van der Werf, W.; Zhang, W.; Duan, L. Maize Yield and Quality in Response to Plant Density and Application of a Novel Plant Growth Regulator. Field Crops Res. 2014, 164, 82–89. [Google Scholar] [CrossRef]

- Hörbe, T.A.N.; Amado, T.J.C.; Reimche, G.B.; Schwalbert, R.A.; Santi, A.L.; Nienow, C. Optimization of Within-Row Plant Spacing Increases Nutritional Status and Corn Yield: A Comparative Study. Agron. J. 2016, 108, 1962–1971. [Google Scholar] [CrossRef]

- Badua, S.A.; Sharda, A.; Strasser, R.; Ciampitti, I. Ground Speed and Planter Downforce Influence on Corn Seed Spacing and Depth. Precis. Agric. 2021, 22, 1154–1170. [Google Scholar] [CrossRef]

- Lei, X.; Hu, H.; Wu, W.; Liu, H.; Liu, L.; Yang, W.; Zhou, Z.; Ren, W. Seed Motion Characteristics and Seeding Performance of a Centralised Seed Metering System for Rapeseed Investigated by DEM Simulation and Bench Testing. Biosyst. Eng. 2021, 203, 22–33. [Google Scholar] [CrossRef]

- Xia, L.; Wang, X.; Geng, D.; Zhang, Q. Performance Monitoring System for Precision Planter Based on MSP430-CT171. In Computer and Computing Technologies in Agriculture IV; Li, D., Liu, Y., Chen, Y., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 158–165. [Google Scholar] [CrossRef] [Green Version]

- Kachman, S.D.; Smith, J.A. Alternative Measures of Accuracy in Plant Spacing for Planters Using Single Seed Metering. Trans. ASAE 1995, 38, 379–387. [Google Scholar] [CrossRef]

- Tian, H.; Wang, T.; Liu, Y.; Qiao, X.; Li, Y. Computer Vision Technology in Agricultural Automation—A Review. Inf. Process. Agric. 2020, 7, 1–19. [Google Scholar] [CrossRef]

- Sparrow, R.; Howard, M. Robots in Agriculture: Prospects, Impacts, Ethics, and Policy. Precis. Agric. 2020, 22, 818–833. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, N.; Taylor, R.K.; Raun, W.R.; Hardin, J.A. Automatic Corn Plant Location and Spacing Measurement Using Laser Line-Scan Technique. Precis. Agric. 2013, 14, 478–494. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.; Wang, N.; Taylor, R.K.; Raun, W.R. Improvement of a Ground-LiDAR-Based Corn Plant Population and Spacing Measurement System. Comput. Electron. Agric. 2015, 112, 92–101. [Google Scholar] [CrossRef]

- Nakarmi, A.D.; Tang, L. Automatic Inter-Plant Spacing Sensing at Early Growth Stages Using a 3D Vision Sensor. Comput. Electron. Agric. 2012, 82, 23–31. [Google Scholar] [CrossRef]

- Tang, L.; Tian, L.F. Plant Identification in Mosaicked Crop Row Images for Automatic Emerged Corn Plant Spacing Measurement. Trans. ASABE 2008, 51, 2181–2191. [Google Scholar] [CrossRef]

- Brilhador, A.; Serrarens, D.A.; Lopes, F.M. A Computer Vision Approach for Automatic Measurement of the Inter-Plant Spacing. In Progress in Pattern Recognition, Image Analysis, Computer Vision, and Applications; Lecture Notes in Computer Science; Pardo, A., Kittler, J., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 219–227. [Google Scholar] [CrossRef]

- Liu, S.; Baret, F.; Allard, D.; Jin, X.; Andrieu, B.; Burger, P.; Hemmerlé, M.; Comar, A. A Method to Estimate Plant Density and Plant Spacing Heterogeneity: Application to Wheat Crops. Plant Methods 2017, 13, 38. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hosseiny, B.; Rastiveis, H.; Homayouni, S. An Automated Framework for Plant Detection Based on Deep Simulated Learning from Drone Imagery. Remote Sens. 2020, 12, 3521. [Google Scholar] [CrossRef]

- Osco, L.P.; dos Santos de Arruda, M.; Gonçalves, D.N.; Dias, A.; Batistoti, J.; de Souza, M.; Gomes, F.D.G.; Ramos, A.P.M.; de Castro Jorge, L.A.; Liesenberg, V.; et al. A CNN Approach to Simultaneously Count Plants and Detect Plantation-Rows from UAV Imagery. ISPRS J. Photogramm. Remote Sens. 2021, 174, 1–17. [Google Scholar] [CrossRef]

- Anitei, M.; Veres, C.; Pisla, A. Research on Challenges and Prospects of Digital Agriculture. Proceedings 2021, 63, 67. [Google Scholar] [CrossRef]

- Deichmann, U.; Goyal, A.; Mishra, D. Will Digital Technologies Transform Agriculture in Developing Countries? Agric. Econ. 2016, 47 (Suppl. S1), 21–33. [Google Scholar] [CrossRef]

- Nally, D. Against Food Security: On Forms of Care and Fields of Violence. Glob. Soc. 2016, 30, 558–582. [Google Scholar] [CrossRef]

- Rose, D.C.; Wheeler, R.; Winter, M.; Lobley, M.; Chivers, C.-A. Agriculture 4.0: Making It Work for People, Production, and the Planet. Land Use Policy 2021, 100, 104933. [Google Scholar] [CrossRef]

- Hamuda, E.; Mc Ginley, B.; Glavin, M.; Jones, E. Automatic Crop Detection under Field Conditions Using the HSV Colour Space and Morphological Operations. Comput. Electron. Agric. 2017, 133, 97–107. [Google Scholar] [CrossRef]

- Bradski, G.; Kaehler, A. Learning OpenCV: Computer Vision with the OpenCV Library; O’Reilly Media, Inc.: Newton, MA, USA, 2008. [Google Scholar]

- van der Walt, S.; Schönberger, J.L.; Nunez-Iglesias, J.; Boulogne, F.; Warner, J.D.; Yager, N.; Gouillart, E.; Yu, T. Scikit-Image: Image Processing in Python. PeerJ 2014, 2, e453. [Google Scholar] [CrossRef] [PubMed]

- Teh, C.-H.; Chin, R.T. On Image Analysis by the Methods of Moments. In Proceedings of the CVPR’88: The Computer Society Conference on Computer Vision and Pattern Recognition, Ann Arbor, MI, USA, 5–9 June 1988; IEEE Computer Society Press: Ann Arbor, MI, USA, 1988; pp. 556–561. [Google Scholar] [CrossRef]

- Lu, H.; Cao, Z.; Xiao, Y.; Fang, Z.; Zhu, Y.; Xian, K. Fine-Grained Maize Tassel Trait Characterization with Multi-View Representations. Comput. Electron. Agric. 2015, 118, 143–158. [Google Scholar] [CrossRef]

- Forkman, J. Estimator and Tests for Common Coefficients of Variation in Normal Distributions. Commun. Stat. Theory Methods 2009, 38, 233–251. [Google Scholar] [CrossRef] [Green Version]

- Jin, X.; Liu, S.; Baret, F.; Hemerlé, M.; Comar, A. Estimates of Plant Density of Wheat Crops at Emergence from Very Low Altitude UAV Imagery. Remote Sens. Environ. 2017, 198, 105–114. [Google Scholar] [CrossRef] [Green Version]

| Methods | Precision | Recall | R² | RMSE, cm | |

|---|---|---|---|---|---|

| 7 DAP | Conv_ROI | 1.00 | 0.91 | 0.90 | 2.84 |

| Conv_Peaks | 1.00 | 1.00 | 0.92 | 2.55 | |

| Notill_mod_ROI | 1.00 | 1.00 | 0.90 | 1.86 | |

| Notill_mod_Peaks | 1.00 | 1.00 | 0.98 | 1.75 | |

| 12 DAP | Conv_ROI | 1.00 | 0.88 | 0.98 | 5.63 |

| Conv_Peaks | 1.00 | 0.93 | 0.98 | 5.05 | |

| Notill_mod_ROI | 1.00 | 0.91 | 0.71 | 4.70 | |

| Notill_mod_Peaks | 1.00 | 0.91 | 0.81 | 3.50 |

| Methods | As, cm | Std, cm | Multiple | Miss | CV | |

|---|---|---|---|---|---|---|

| Conv_field | 40 | 13 | 1 | 0 | 0.33 | |

| 7 DAP | Conv_ROI | 42 | 6 | 0 | 0 | 0.14 * |

| Conv_Peaks | 38 | 12 | 1 | 0 | 0.31 ns | |

| Notill_mod_field | 34 | 9 | 0 | 0 | 0.28 | |

| Notill_mod_ROI | 34 | 8 | 0 | 0 | 0.24 ns | |

| Notill_mod_Peaks | 34 | 8 | 0 | 0 | 0.24 ns | |

| 12 DAP | Conv_field | 31 | 18 | 4 | 2 | 0.58 |

| Conv_ROI | 27 | 17 | 1 | 2 | 0.65 ns | |

| Conv_Peaks | 27 | 16 | 3 | 2 | 0.60 ns | |

| Notill_mod_field | 36 | 9 | 1 | 0 | 0.26 | |

| Notill_mod_ROI | 35 | 8 | 1 | 0 | 0.27 ns | |

| Notill_mod_Peaks | 36 | 8 | 1 | 0 | 0.24 ns |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carreira, V.D.S.; Tedesco, D.; Carreira, A.D.S.; da Silva, R.P. Assessing Intra-Row Spacing Using Image Processing: A Promising Digital Tool for Smallholder Farmers. Agronomy 2022, 12, 301. https://doi.org/10.3390/agronomy12020301

Carreira VDS, Tedesco D, Carreira ADS, da Silva RP. Assessing Intra-Row Spacing Using Image Processing: A Promising Digital Tool for Smallholder Farmers. Agronomy. 2022; 12(2):301. https://doi.org/10.3390/agronomy12020301

Chicago/Turabian StyleCarreira, Vinicius Dos Santos, Danilo Tedesco, Alexandre Dos Santos Carreira, and Rouverson Pereira da Silva. 2022. "Assessing Intra-Row Spacing Using Image Processing: A Promising Digital Tool for Smallholder Farmers" Agronomy 12, no. 2: 301. https://doi.org/10.3390/agronomy12020301

APA StyleCarreira, V. D. S., Tedesco, D., Carreira, A. D. S., & da Silva, R. P. (2022). Assessing Intra-Row Spacing Using Image Processing: A Promising Digital Tool for Smallholder Farmers. Agronomy, 12(2), 301. https://doi.org/10.3390/agronomy12020301