Phytochemical Analysis and Characterization of Corn Silk (Zea mays, G5417)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Collection and Sample Preparation

2.2. Nutritional Composition of Corn Silk Powder

2.3. Mineral Analysis

2.4. Colour Analysis

2.5. Extraction of Ethanolic Extract

2.6. Determination of Total Phenolic Content (TPC), Total Flavonoid Content (TFS), and Ascorbic Acid (AA)

2.6.1. Total Phenolic Content

2.6.2. Flavonoid Content

2.6.3. Ascorbic Acid

2.7. Antioxidant Activities

2.7.1. Free Radical Scavenging Activity (FRSA)

2.7.2. ABTS Radical Scavenging Assay

2.7.3. Ferric Ion Reducing Antioxidant Power (FRAP)

2.8. Characterization of Corn Silk Powder

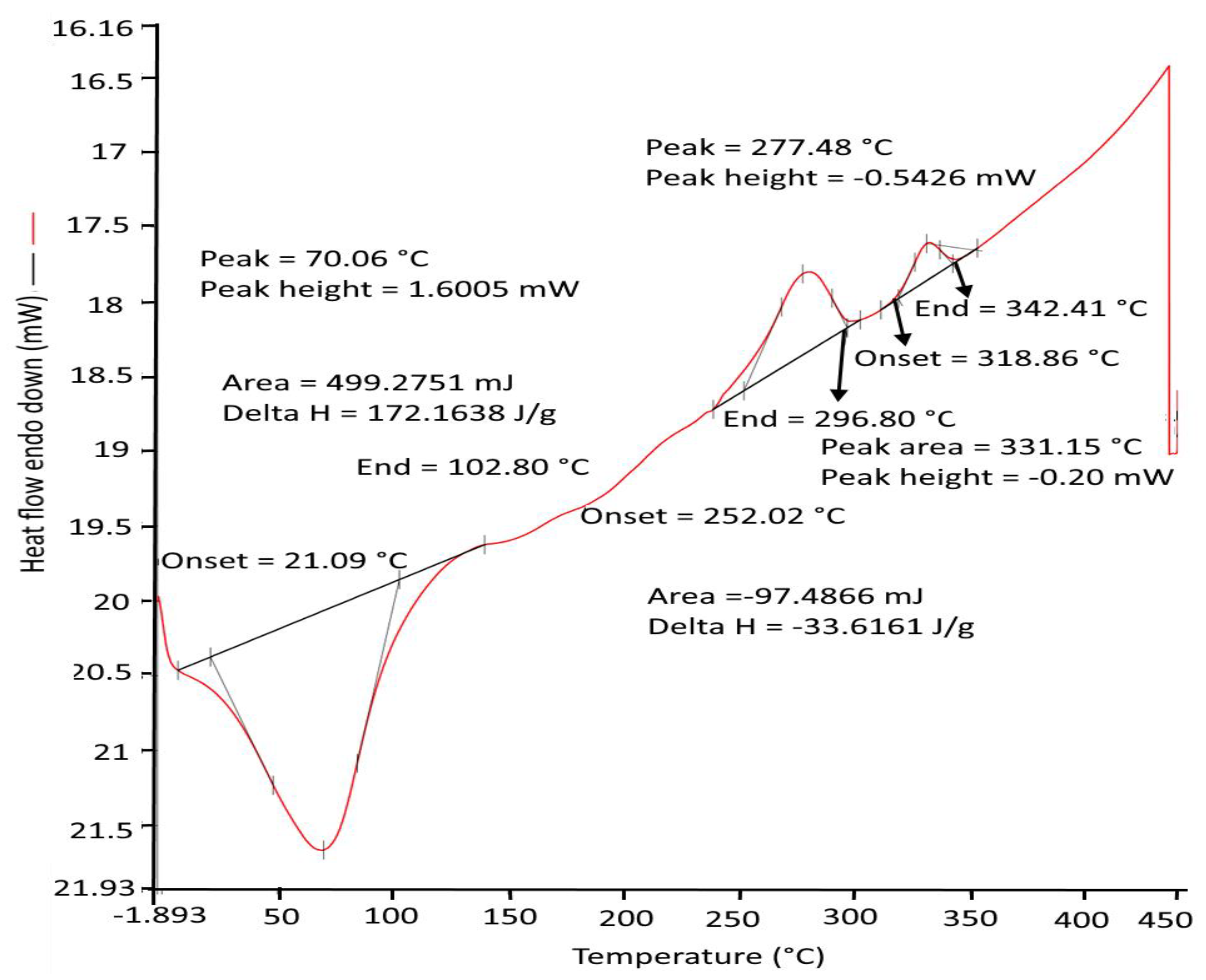

2.8.1. Differential Scanning Calorimetry

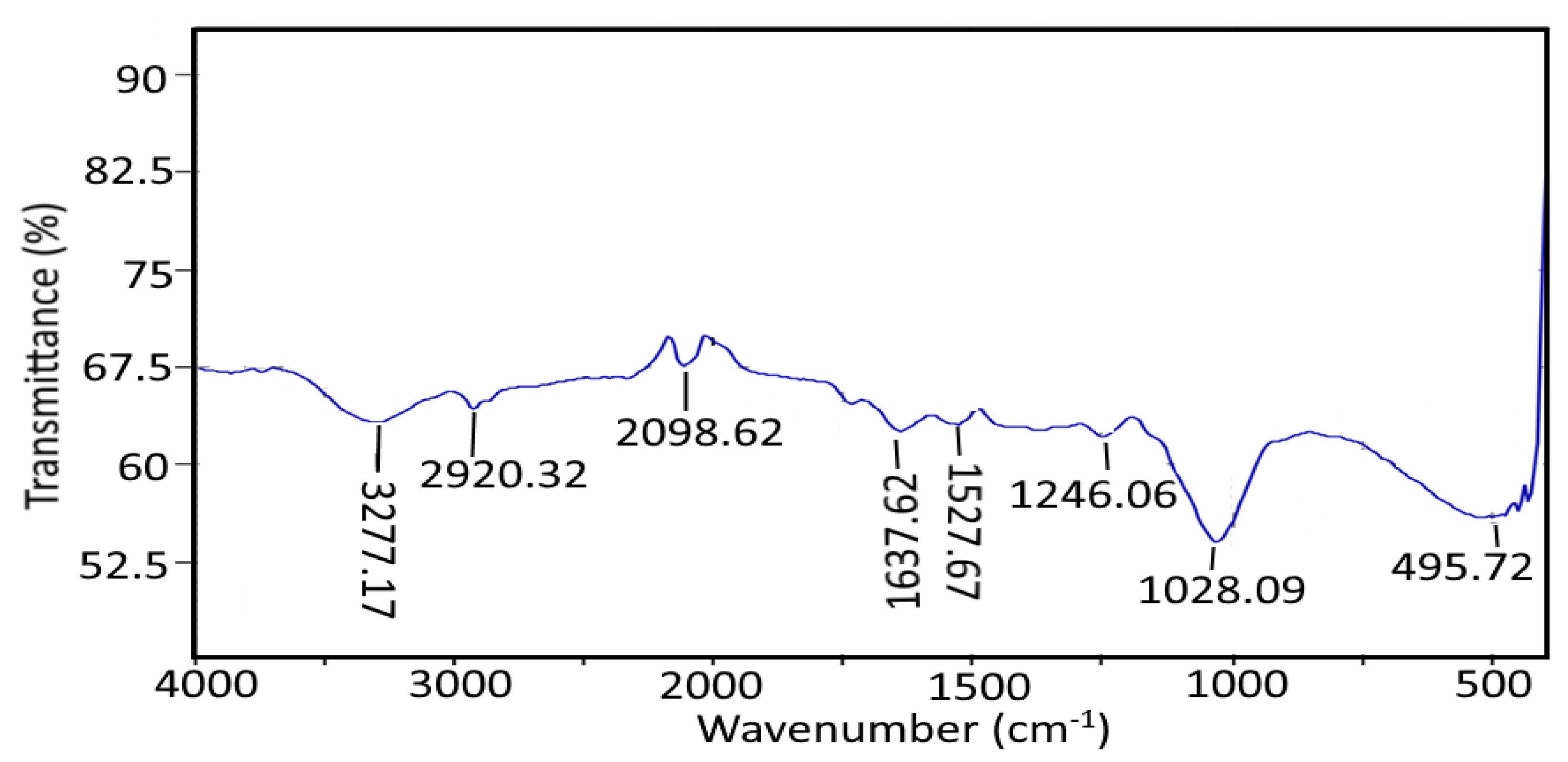

2.8.2. Fourier Transform Infrared Spectroscopy (FTIR)

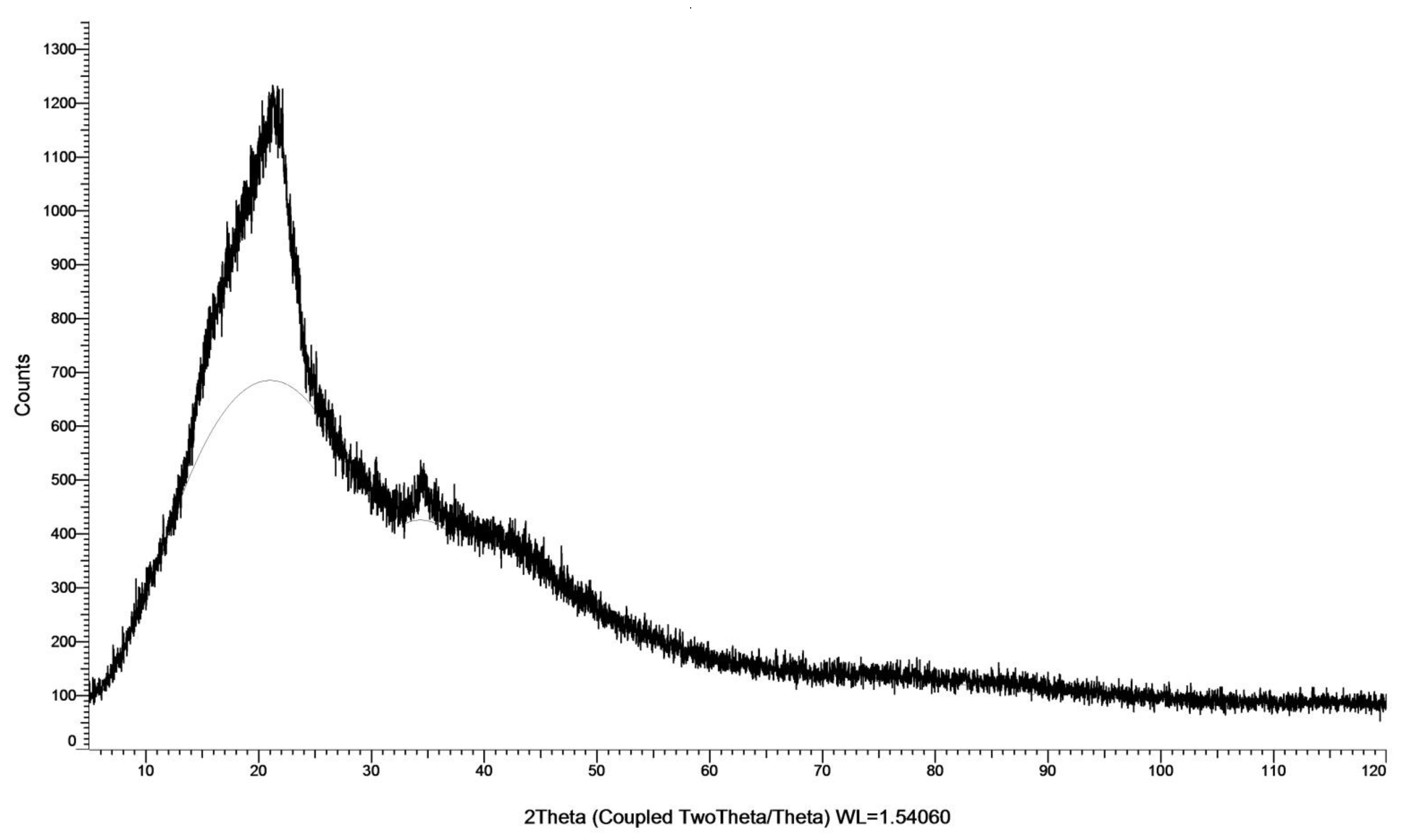

2.8.3. X-ray Diffraction

2.9. Statistical Analysis

3. Results

3.1. Nutritional Composition of Corn Silk Powder

3.2. Mineral Content

3.3. Color Analysis of Corn Silk Powder

3.4. Total Phenolic Content (TPC), Total Flavonoid Content (TFS), and Ascorbic Acid (AA)

3.5. Antioxidant Activities of Corn Silk

3.5.1. Free Radical Scavenging Activity (FRSA)

3.5.2. ABTS Activity

3.5.3. Ferric Ion Reducing Power (FRAP)

3.6. Characterization of Corn Silk Powder

3.6.1. Differential Scanning Calorimetry

3.6.2. FTIR Analysis of Corn Silk Powder

3.6.3. X-ray Diffraction

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aukkanit, N.; Kemngoen, T.; Ponharn, N. Utilization of corn silk in low fat meatballs and its characteristics. Procedia-Soc. Behav. Sci. 2014, 197, 1403–1410. [Google Scholar] [CrossRef] [Green Version]

- Ren, S.H.; Qiao, Q.Q.; Ding, X.L. Antioxidant activity of five flavones glycosides from corn silk (Stigma maydis). Czech J. Food Sci. 2013, 2, 148–155. [Google Scholar]

- Hu, Q.L.; Deng, Z. Protective effects of flavonoids from corn silk on oxidative stress induced by exhaustive exercise in mice. Afr. J. Biotechnol. 2011, 10, 3163–3167. [Google Scholar] [CrossRef] [Green Version]

- Bhuvaneshwari, K.; Sridevi, S. Analysis of nutrients and photochemical contents in corn silk (Zea Mays). Int. J. Sci. Res. 2015, 78, 2319–7064. [Google Scholar]

- Zilic, S.; Jankovic, M.; Basic, Z.; Vancetovic, J.; Maksimovic, V. Antioxidant activity, phenolic profile, chlorophyll and mineral matter content of corn silk (Zea mays L.): Comparison with medicinal herbs. J. Cereal Sci. 2016, 69, 363–370. [Google Scholar] [CrossRef]

- Zhao, W.; Yin, Y.; Yu, Z.; Liu, J.; Chen, F. Comparison of anti-diabetic effects of polysaccharides from corn silk on normal and hyperglycemia rats. Int. J. Biol. Macromol. 2012, 50, 1133–1137. [Google Scholar] [CrossRef]

- Amreen, F.; Agrawal, P.; Singh, P.P. Herbal option for diabetes: An overview. Asian Pac. J. Trop. Dis. 2012, 2, S536–S544. [Google Scholar] [CrossRef]

- Chen, S.; Chen, H.; Tian, J.; Wang, Y.; Xing, L.; Wang, J. Chemical modification, antioxidant and α-amylase inhibitory activities of corn silk polysaccharides. Carbohydr. Polym. 2013, 2, 536–544. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, T.; Liu, S.; Zhang, C.; Wang, E.; Wang, Z.; Zhang, Y.; Liu, J. Subchronic toxicity study of corn silk with rats. J. Ethnopharmacol. 2011, 137, 36–43. [Google Scholar] [CrossRef] [PubMed]

- Saheed, S.; Oladipipo, A.E.; Abdulazeez, A.A.; Olarewaju, S.A.; Ismaila, N.O.; Emmanuel, I.A.; Fatimah, Q.D.; Aisha, A.Y. Toxicological evaluations of Stigma maydis (corn silk) aqueous extract on hematological and lipid parameters in Wistar rats. Toxicol. Rep. 2012, 2, 638–644. [Google Scholar] [CrossRef] [Green Version]

- Taiwong, N. Drying temperature of corn silk tea: Physical properties, total phenolic content, antioxidant activity and flavonoid content. Food Appl. Biosci. J. 2020, 8, 38–49. [Google Scholar]

- Zhang, L.; Yang, Y.; Wang, Z. Extraction Optimization of Polysaccharides from Corn Silk and Their Antioxidant Activities in vitro and in vivo. Front. Pharmacol. 2021, 4, 2328. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2005. [Google Scholar]

- Ho, Y.M.; Nizam, W.A.; Rosli, W.R.; Ho, Y.M.; Wan Amir Nizam, W.A.; Wan Rosli, W. Antioxidative activities and polyphenolic content of different varieties of malaysian young corn ear and cornsilk. Sains. Mal. 2016, 45, 195–200. [Google Scholar]

- Ranganna, S. Handbook of Analysis and Quality Control for Fruit and Vegetable Products; Tata Mcgraw Hill: New Delhi, India, 2006. [Google Scholar]

- Pant, K.; Thakur, M.; Chopra, H.K.; Nanda, V.; Ansari, M.J.; Pietramellara, G.; Datta, R.; Pathan, S.I.; Alharbi, S.A.; Almoallim, H.S.K. Characterization and discrimination of Indian propolis based on physico-chemical, techno-functional, thermal and textural properties: A multivariate approach. J. King Saud Univ. Sci. 2021, 33, 101405. [Google Scholar] [CrossRef]

- Castillo, E.J.P.L.-D.; Azares, G.F.; Almonte, C.J.R.; Pascua, K.M.N.; Santiago, I.B.; So, E.G.C.; Umali, A.M.S.; Villamento, H.A. Effects of incorporation of microwave: Dried corn silk (Stigma maydis) powder on the quality and stability of Beef Patties. J. Phys. Conf. Ser. 2020, 1529, 32064. [Google Scholar]

- Nurhanan, A.R.; Rosli, W.I.W. Nutritional compositions and antioxidative capacity of the silk obtained from immature and mature corn. J. King Saud Univ. Sci. 2014, 26, 119–127. [Google Scholar] [CrossRef] [Green Version]

- Sadh, P.K.; Chawla, P.; Duhan, J.S. Fermentation approach on phenolic, antioxidants and functional properties of peanut press cake. Food Biosci. 2018, 22, 113–120. [Google Scholar] [CrossRef]

- Reddy, V.T.; Naga, P.P. Comparative studies on ascorbic acid content in various fruits, vegetables and leafy vegetables. Int. J. Life Sci. 2017, 5, 667–671. [Google Scholar]

- Singh, J.; Kaur, S.; Rasane, P. Evaluation of the nutritional and quality characteristics of black carrot fortified instant noodles. Curr. Nutr. Food Sci. 2018, 14, 1–8. [Google Scholar] [CrossRef]

- Rajurkar, S.; Hande, S.M. Estimation of phytochemical content and antioxidant activity of some selected traditional indian medicinal plants. Indian J. Pharm. Sci. 2011, 73, 146–151. [Google Scholar] [CrossRef] [Green Version]

- Chawla, P.; Najda, A.; Bains, A.; Nurzyńska-Wierdak, R.; Kaushik, R.; Tosif, M.M. Potential of gum arabic functionalized iron hydroxide nanoparticles embedded cellulose paper for packaging of Paneer. Nanomaterials 2021, 11, 1308. [Google Scholar] [CrossRef] [PubMed]

- Chawla, P.; Kumar, V.; Bains, A.; Singh, R.; Sadh, P.K.; Kaushik, R.; Kumar, N. Improvement of mineral absorption and nutritional properties of Citrullus vulgaris seeds using solid-state fermentation. J. Am. Coll. Nutr. 2020, 39, 628–635. [Google Scholar] [CrossRef] [PubMed]

- Stuart, B.H. Infrared Spectroscopy: Fundamentals and Applications; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2004. [Google Scholar]

- Suhag, Y.; Nayik, G.A.; Karabagias, I.K.; Nanda, V. Development and characterization of a nutritionally rich spray-dried honey powder. Foods 2021, 10, 162. [Google Scholar] [CrossRef] [PubMed]

- Matkowski, A.; Tasarz, P.; Szypua, E. Antioxidant activity of herb extracts from five medicinal plants from Lamiaceae, subfamily Lamioideae. J. Med. Plant Res. 2008, 2, 321–330. [Google Scholar] [CrossRef]

- Haslina, H.; Eva, M. Extract corn silk with variation of solvents on yield, total phenolics, total flavonoids and antioxidant activity. Indones. Food Nutr. Prog. 2017, 14, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Ren, S.C.; Liu, Z.L.; Ding, X.L. Isolation and identification of two novel flavone glycosides from corn silk (Stigma maydis). J. Med. Plant Res. 2009, 3, 1009–1015. [Google Scholar]

- Tian, S.; Sun, Y.; Chen, Z. Extraction of flavonoids from corn silk and biological activities in vitro. J. Food Qual. 2021. [Google Scholar] [CrossRef]

- Alam, E.A. Evaluation of antioxidant and antibacterial activities of Egyptian Maydis stigma (Zea mays hairs) rich in some bioactive constituents. Am. J. Sci. 2011, 7, 726–729. [Google Scholar]

- Pisoschi, A.M.; Danet, A.F.; Kalinowski, S. Ascorbic acid determination in commercial fruit juice samples by cyclic voltammetry. J. Autom. Methods Manag. Chem. 2009, 937651, 1–8. [Google Scholar] [CrossRef] [Green Version]

- El Kewawy, H.E. Evaluation of the efficacy of corn silk and vitamin D on hyperlipidemia and obesity in experimental rats. J. Dairy Sci. 2018, 2008, 169–175. [Google Scholar] [CrossRef] [Green Version]

- Sanahuja, G.; Farré, G.; Bassie, L.; Zhu, C.; Christou, P.; Capell, T. Ascorbic acid synthesis and metabolism in maize are subject to complex and genotype-dependent feedback regulation during endosperm development. Biotech. J. 2013, 8, 1221–1230. [Google Scholar] [CrossRef]

- Zheng, L.L.; Wen, G.; Yuan, M.Y.; Gao, F. Ultrasound-assisted extraction of total flavonoids from corn silk and their antioxidant activity. J. Chem. 2016, 8768130, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Cardenia, V.; Rodriguez-Estrada, M.T.; Boselli, E.; Lercker, G. Cholesterol photosensitized oxidation in food and biological systems. Biochimie 2013, 95, 473–481. [Google Scholar] [CrossRef]

- Mao, L.C.; Pan, X.; Que, F.; Fang, X.H. Antioxidant properties of water and ethanol extracts from hot air-dried and freeze-dried daylily flowers. Eur. Food Res. Technol. 2006, 222, 236–241. [Google Scholar] [CrossRef]

- Rosli, W.I.W.; Suhaiminudin, N.S. Mineral composition, heavy metal and sensory acceptability of drink developed from cornsilk (Zea mays hairs). Adv. Nat. App. Sci. 2020, 14, 14–19. [Google Scholar]

- Antoine, J.M.; Fung, L.A.H.; Grant, C.N.; Dennis, H.T.; Lalor, G.C. Dietary intake of minerals and trace elements in rice on the Jamaican market. J Food Comp. Anal. 2012, 26, 111–121. [Google Scholar]

- Sarepoua, E.; Tangwongchai, R.; Suriharn, B.; Letrat, K. Relationships between phytochemicals and antioxidant activity in corn silk. Int. Food Res. J. 2013, 20, 2073–2079. [Google Scholar]

- Nurraihana, H.; Wan Rosli, W.I.; Sabreena, S.; Norfarizan-Hanoon, N.A. Optimisation extraction procedure and identification of phenolic compounds from fractional extract of corn silk (Zea mays hair) using LC-TOF/MS system. J Food Meas. Charac. 2018, 12, 1852–1862. [Google Scholar] [CrossRef]

- Maksimović, Z.; Malenčić, Đ.; Kovačević, N. Polyphenol contents and antioxidant activity of Maydis stigma extracts. Bioresour. Technol. 2005, 96, 873–877. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pashazadeh, H.; Zannou, O.; Ghellam, M.; Koca, I.; Galanakis, C.M.; Aldawoud, T. Optimization and Enc apsulation of Phenolic Compounds Extracted from Maize Waste by Freeze-Drying, Spray-Drying, and Microwave-Drying Using Maltodextrin. Foods 2021, 10, 1396. [Google Scholar] [CrossRef] [PubMed]

- Phan, A.D.T.; Flanagan, B.M.; D’Arcy, B.R.; Gidley, M.J. Binding selectivity of dietary polyphenols to different plant cell wall components: Quantification and mechanism. Food Chem. 2017, 233, 216–227. [Google Scholar] [CrossRef]

- Dong, J.; Cai, L.; Zhu, X.; Huang, X.; Yin, T.; Fang, H.; Ding, Z. Antioxidant activities and phenolic compounds of cornhusk, corncob and Stigma maydis. J. Braz. Chem. Soc. 2014, 25, 1956–1964. [Google Scholar] [CrossRef]

- Limmatvapirat, C.; Nateesathittarn, C.; Declamation, K.; Moohummad, T.; Chinajitphan, P.; Limmatvapirat, S. Phytochemical analysis of baby corn silk extracts. J. Ayurveda Integr. Med. 2020, 11, 344–351. [Google Scholar] [CrossRef]

- Guo, Q.; Ma, Q.; Xue, Z.; Gao, X.; Chen, H. Studies on the binding characteristics of three polysaccharides with different molecular weight and flavonoids from corn silk (Maydis stigma). Carbohydr. Polym. 2018, 198, 581–588. [Google Scholar] [CrossRef] [PubMed]

- Ali, G.W.; Abd Ellatif, M.A.; Abdel-Fattah, W.I. Extraction of Natural Cellulose and Zein Protein from Corn Silk: Physico-Chemical and Biological Characterization. Biointerface Res. Appl. Chem. 2021, 11, 10614–10619. [Google Scholar]

- Mendes, C.A.D.C.; Adnet, F.A.D.O.; Leite, M.C.A.M.; Furtado, C.G.; Sousa, A.M.F.D. Chemical, physical, mechanical, thermal and morphological characterization of corn husk residue. Cellul. Chem. Technol. 2015, 49, 727–735. [Google Scholar]

- Senphan, T. Comparative studies on chemical composition and antioxidant activity of corn silk from two varieties of sweet corn and purple waxy corn as influenced by drying methods. Food Appl. Biosci. J. 2019, 7, 64–80. [Google Scholar]

- Tian, J.; Chen, H.; Chen, S.; Xing, L.; Wang, Y.; Wang, J. Comparative studies on the constituents, antioxidant and anticancer activities of extracts from different varieties of corn silk. J. Funct. Foods 2013, 4, 1526–1534. [Google Scholar]

| Parameter | Corn Silk Powder | %RSD |

|---|---|---|

| Chemical composition (g/100 g fw) | ||

| Moisture | 7.89 ± 0.49 | 0.49 |

| Fat | 0.55 ± 0.08 | 0.08 |

| Ash | 5.29 ± 0.29 | 0.29 |

| Crude fiber | 14.82 ± 0.84 | 0.84 |

| Protein | 15.29 ± 1.23 | 1.23 |

| Carbohydrate | 56.16 ± 0.66 | 0.66 |

| Water activity (aw) at 25 °C | 0.224 | 0.01 |

| Color | ||

| L* | 47.88 | 0.02 |

| a* | 3.16 | 0.01 |

| b* | 12.03 | 0.01 |

| Chroma (*) | 12.44 | 0.01 |

| Hue angle (°) | 75.27 | 0.02 |

| Parameter | Corn Silk Powder | R2 | BEC (ppm) | LoD (ppm) | %RSD |

|---|---|---|---|---|---|

| Macroelements (μg/g) | |||||

| Sodium (Na) | 3654.21 ± 2.97 | 0.9948 | 18.675 | 0.1789 | 14.3 |

| Magnesium (Mg) | 1169.05 ± 12.94 | 0.9986 | 0.069 | 0.0007 | 1.1 |

| Potassium (K) | 1135.78 ± 6.3 | 0.9960 | 0.026 | 0.0008 | 1.1 |

| Calcium (Ca) | 1338.13 ± 14.23 | 0.9958 | 1.826 | 0.0150 | 2.2 |

| Microelements (μg/g) | |||||

| Manganese (Mn) | 11.10 ± 2.15 | 0.9975 | 0.002 | 0.0003 | 0.8 |

| Copper (Cu) | 11.91 ± 1.15 | 0.9993 | 0.007 | 0.0021 | 0.6 |

| Iron (Fe) | 41.77 ± 2.67 | 0.9993 | 0.042 | 0.0011 | 0.7 |

| Zinc (Zn) | 83.75 ± 1.80 | 0.9895 | 0.041 | 0.0002 | 0.5 |

| Antioxidant Content | Corn Silk Powder | %RSD |

|---|---|---|

| Total phenolic content (mg GAE/g) | 94.10 ± 0.26 | 0.26 |

| Total flavonoid content (mg QE/100 g) | 163.93 ± 0.83 | 0.83 |

| Ascorbic acid (mg/100 g) | 270 ± 0.57 | 0.57 |

| Antioxidant activity | ||

| Free radical scavenging activity (%) | 45.40 ± 0.92 | 0.92 |

| Ferric ion reducing power (%) | 86.77 ± 0.88 | 0.88 |

| ABTS (TEAC mg/gdw) | 75.25 ± 0.59 | 0.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, J.; Inbaraj, B.S.; Kaur, S.; Rasane, P.; Nanda, V. Phytochemical Analysis and Characterization of Corn Silk (Zea mays, G5417). Agronomy 2022, 12, 777. https://doi.org/10.3390/agronomy12040777

Singh J, Inbaraj BS, Kaur S, Rasane P, Nanda V. Phytochemical Analysis and Characterization of Corn Silk (Zea mays, G5417). Agronomy. 2022; 12(4):777. https://doi.org/10.3390/agronomy12040777

Chicago/Turabian StyleSingh, Jyoti, Baskaran Stephen Inbaraj, Sawinder Kaur, Prasad Rasane, and Vikas Nanda. 2022. "Phytochemical Analysis and Characterization of Corn Silk (Zea mays, G5417)" Agronomy 12, no. 4: 777. https://doi.org/10.3390/agronomy12040777

APA StyleSingh, J., Inbaraj, B. S., Kaur, S., Rasane, P., & Nanda, V. (2022). Phytochemical Analysis and Characterization of Corn Silk (Zea mays, G5417). Agronomy, 12(4), 777. https://doi.org/10.3390/agronomy12040777