Design and Experiment of Gripper for Greenhouse Plug Seedling Transplanting Based on EDM

Abstract

:1. Introduction

2. Materials and Methods

2.1. Overall Design of Seedling Gripper and EDEM Simulation

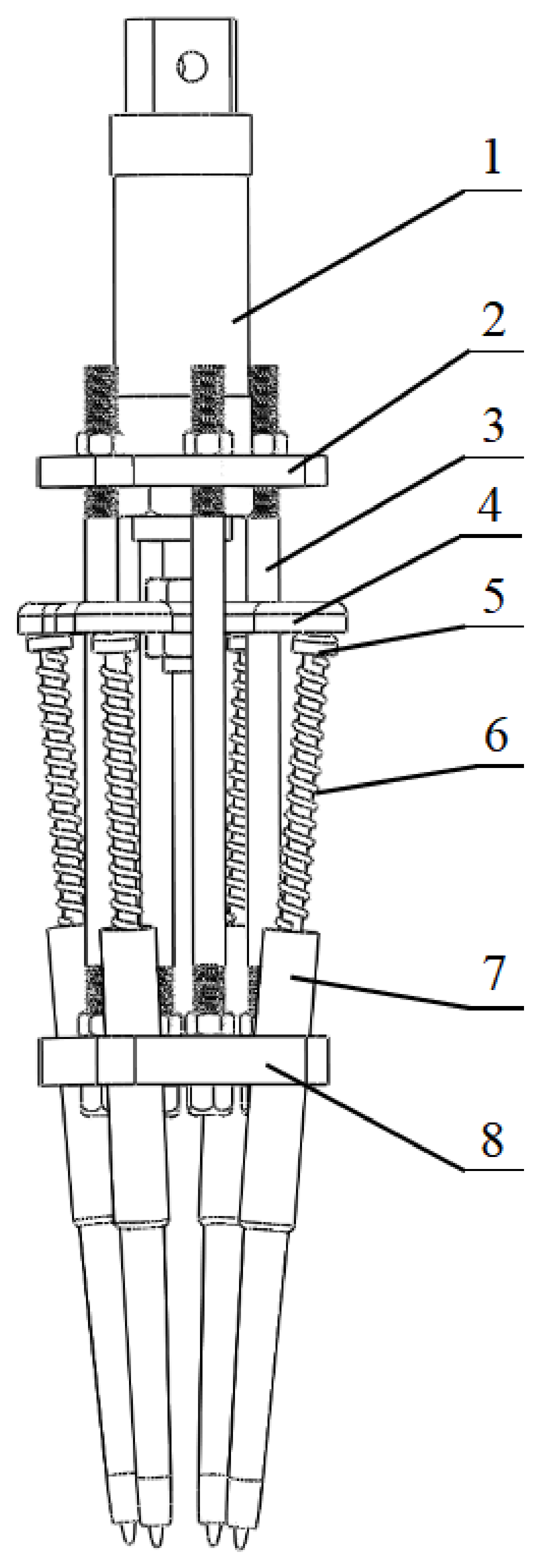

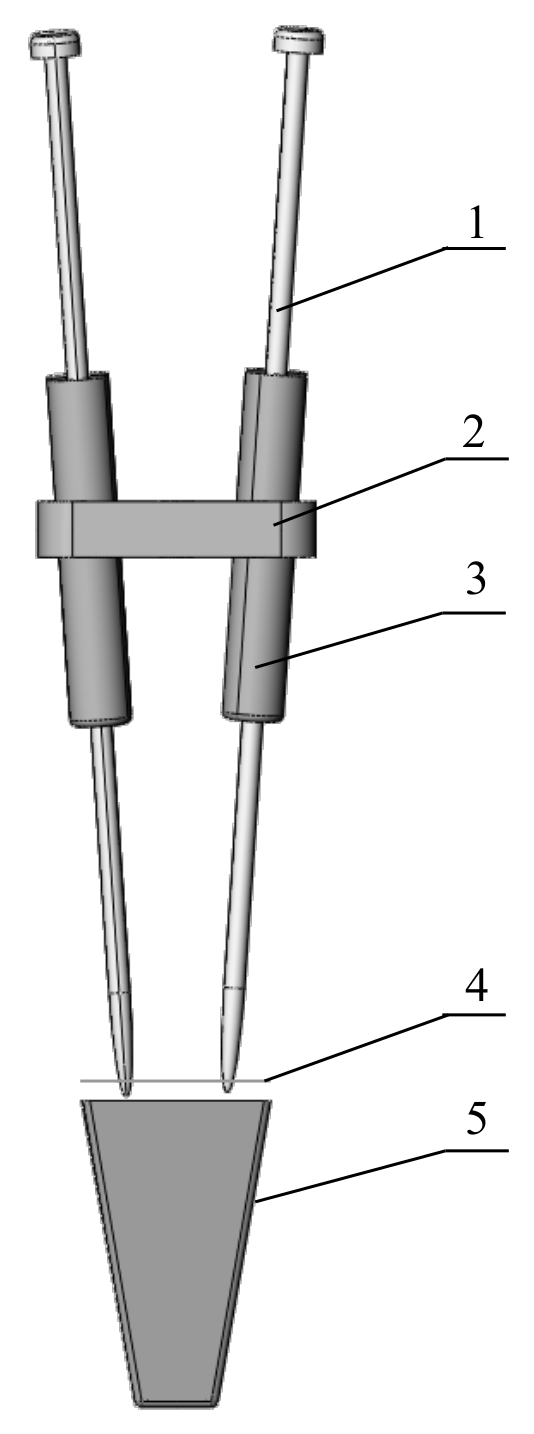

2.1.1. Structural Design and Kinematics Analysis of Gripper

2.1.2. Discrete Element Modeling and Parameter Setting

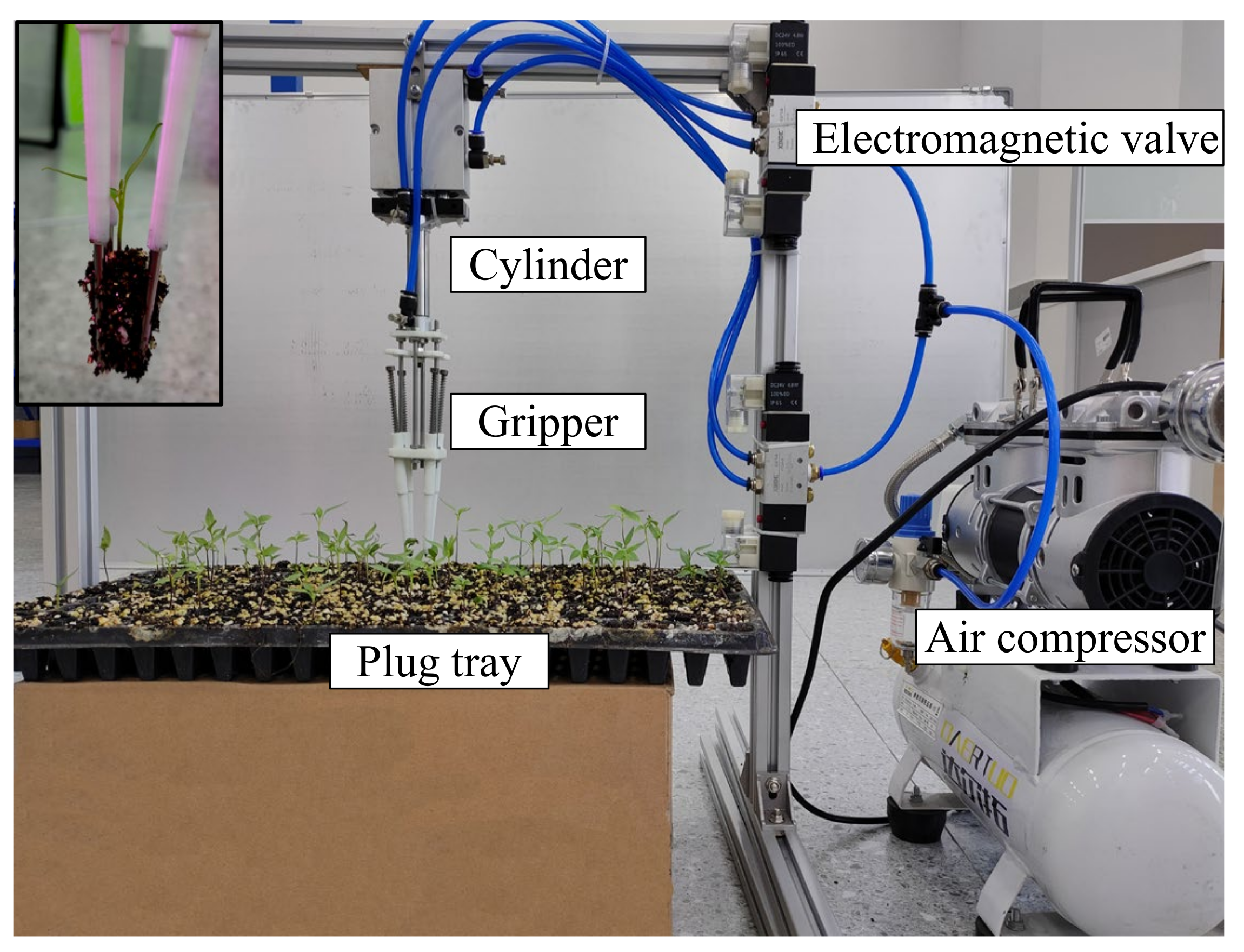

2.2. Simulation, Optimization and Prototype Test

2.2.1. Simulation Scheme

- (i)

- Steel needle diameterTheoretically, when a thick steel needle is inserted into the substrate, the extrusion force generated by the interaction with the soil will be greater than the cohesive force of the substrate block, thereby tearing the soil block. If the steel needle is too fine, it is easy to deform, which is not conducive to grasping a plug seedling. According to the traditional transplanting experience, the diameter of the steel needle ranges from 1 to 3 mm.

- (ii)

- Insertion depthThe optimal insertion depth of a steel needle is closely related to tray cell depth. If a steel needle is inserted shallowly, the substrate block at the bottom of the tray cell will break when the plug seedlings are pulled out. On the contrary, if the steel needle touches the cell bottom, it may damage the tray frame and the dense seedling roots at the bottom. According to the tray size used in the study (42 mm in depth), the insertion depth of steel needles ranged from 30 to 40 mm.

- (iii)

- Insertion and Grasping speedPre-experimental results show that the insertion and grasping speed of steel needles may have an impact on the substrate integrity. Based on testing, the insertion and grasping speed was set between 0.1 and 1 m/s.

2.2.2. Gripper Optimization Design and Test

3. Results and Discussion

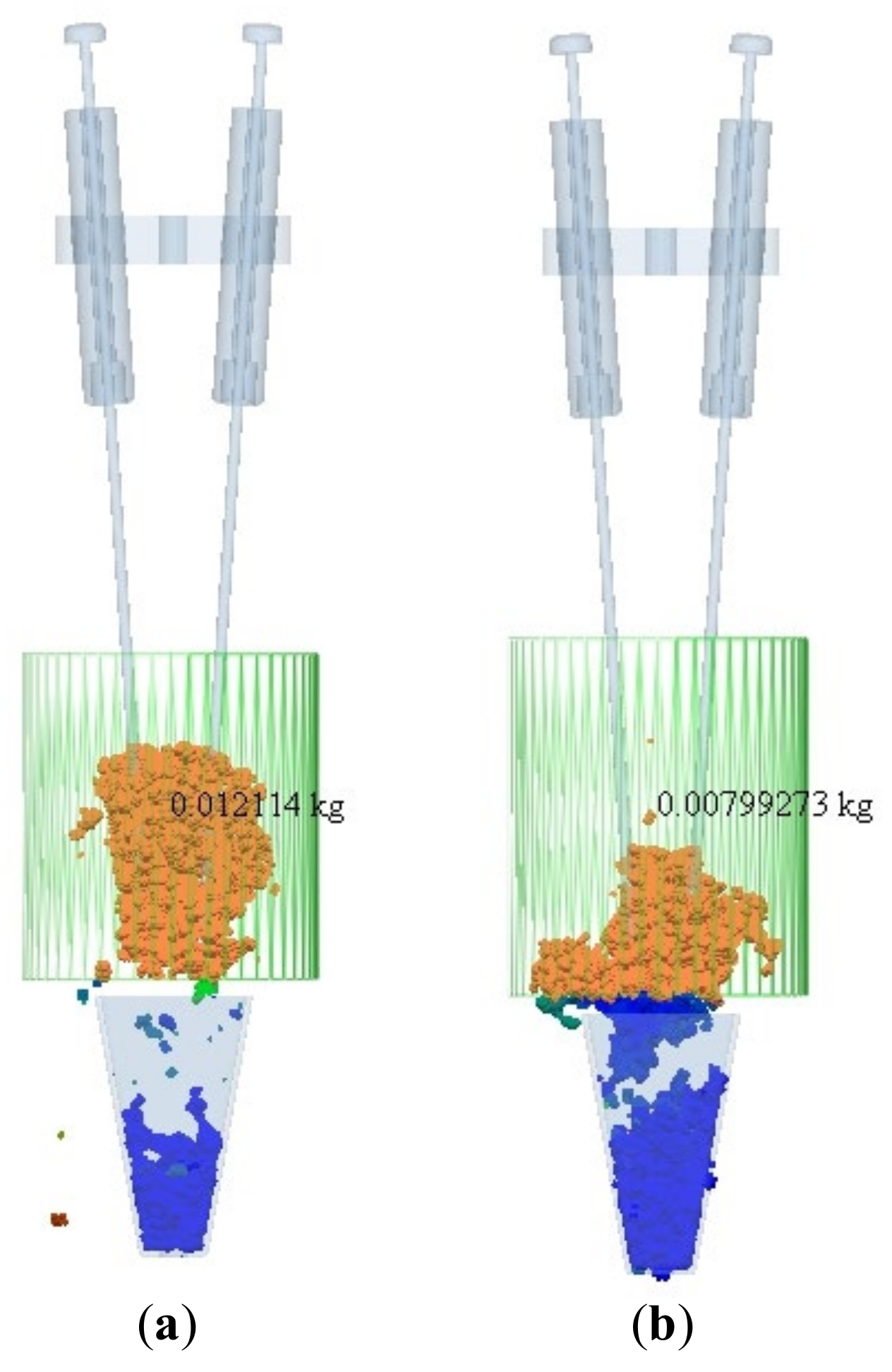

3.1. Simulation Results

3.2. Parameter Optimization and Test Results

4. Conclusions

- The insertion depth of the steel needle has a significant effect on the substrate integrity, and this factor and insertion/grasping speed have an interaction, while the other factors have no significant effect on the substrate integrity. The contribution order of factors on substrate integrity is insertion depth > needle diameter > insertion/grasping speed. Based on the simulation results, the optimized parameters of the seedling gripper are: the diameter of the steel needle is 3 mm, the insertion depth is 40 mm, and the insertion/grasping speed is 1 m/s. Under these parameters, the integrity rate of the substrate is 89.10%.

- For a practical grasping test, the maximum integrity rate of plug seedling substrate was 87.34%, and the average was 76.05%, which increased by an average of 7.25% compared with existing studies. The relative error range between test results and the optimized results was 1.98–29.45%. The reason for the large error in some experiments is that the strong level of plug seedlings cultivated indoors is not even. Therefore, the mechanized transplanting of plug seedlings should focus on the combination of agricultural machinery and agronomy. This gripper can also be used in tissue culture seedling transplanting and other situations where the grabbing object is allowed to be invaded.

- There is a small difference between the simulated data based on the discrete element method and the practical experimental data, which implies that the method is feasible to solve the interaction problem between steel needle’s and growing substrate, for it can complete the analysis and demonstration of the problem quickly and effectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wen, Y.; Zhang, L.; Huang, X.; Yuan, T.; Zhang, J.; Tan, Y.; Feng, Z. Design of and Experiment with Seedling Selection System for Automatic Transplanter for Vegetable Plug Seedlings. Agronomy 2021, 11, 2031. [Google Scholar] [CrossRef]

- Hao, X.; Li, J.; Niu, M.; Wang, J.; Li, P.; Li, H. Research on automatic transplanting method of pepper seedlings in green-house. Chin. Agric. Inf. 2019, 3, 68–78. [Google Scholar]

- Mao, C.; Luo, H.; Zhu, Y.; Zhang, B.; Xiao, X. Research status and development trend of seedling transplanting machinery. J. Chin. Agric. Mech. 2020, 1, 215–222. [Google Scholar]

- Yang, X.; Ma, Y. Current situation and development trend of vegetable mechanized seedling transplanting in facilities. J. Agric. Mech. Res. 2022, 7, 8–13. [Google Scholar]

- Ma, Z.; Li, N.; Li, T.; Chen, Z.; Yuan, T.; Li, W. Design and experiments on a transplanter with belt feeding on block seedling. J. Chin. Agric. Univ. 2015, 20, 216–222. [Google Scholar]

- Wang, C.; Liu, C.; Li, Y.; Song, J.; Wang, J.; Dong, X. Design and experiment of pneumatic punching high-speed seedling picking device for vegetable transplanter. Trans. Chin. Soc. Agric. Mach. 2021, 52, 35–51. [Google Scholar]

- Choque, M.C.J.; Alcort, S.N.F.; Prado, G.S.R. Construction of a mechanical gripper for the automatic transplantation of seedlings in a multi-cell tray. In Proceedings of the 2019 IEEE XVI International Conference on Electronics, Lima, Peru, 12–14 August 2019. [Google Scholar]

- Jiang, Z.; Hu, Y.; Jiang, H.; Tong, J. Design and force analysis of end-effector for plug seedling transplanter. PLoS ONE 2017, 12, e0180229. [Google Scholar] [CrossRef] [Green Version]

- Jorg, O.J.; Sportelli, M.; Fontanelli, M.; Frasconi, C.; Raffaelli, M.; Fantoni, G. Design, Development and Testing of Feeding Grippers for Vegetable Plug Transplanters. AgriEngineering 2021, 3, 669–680. [Google Scholar] [CrossRef]

- Li, B.; Gu, S.; Chu, Q.; Yang, Y.; Xie, Z.; Fan, K.; Liu, X. Development of transplanting manipulator for hydroponic leafy vegetables. Int. J. Agric. Biol. Eng. 2019, 12, 38–44. [Google Scholar]

- Han, L.; Kumi, F.; Mao, H.; Hu, J. Design and Tests of a Multi-pin Flexible Seedling Pick-up Gripper for Automatic Transplanting. Appl. Eng. Agric. 2019, 35, 949–957. [Google Scholar] [CrossRef]

- Choi, W.C.; Kim, D.C.; Ryu, I.H.; Kim, K.U. Development of a seedling pick–up device for vegetable transplanters. Trans. ASAE 2002, 45, 13–19. [Google Scholar]

- Wang, Y. Simulation Analysis of Structure and Effect of the Subsoiler Based on DEM. Master’s Thesis, Jilin Agricultural University, Changchun, China, 2014. [Google Scholar]

- Xu, Q.; Li, S.; Zhang, Y.; Meng, L.; Lu, H.; Xie, L. Design and test of seedling pot filling and transporting machine for citrus. Trans. CSAE 2020, 36, 66–72. [Google Scholar]

- Huangfu, K.; Zhang, X. Design and simulation of automatic transplanting device for grafted seedlings of cucurbitaceae. J. Chin. Agric. Mech. 2020, 2, 54–59. [Google Scholar]

- Gao, G.; Ma, S. Improvement of transplanting manipulator for potted flower based on discrete element analysis and Su-field analysis. Trans. Chin. Soc. Agric. Eng. 2017, 33, 35–42. [Google Scholar]

- Ma, S.; Xu, L.; Yuan, Q.; Niu, C.; Zeng, J.; Chen, C.; Wang, S.; Yuan, X. Calibration of discrete element simulation parameters of grapevine antifreezing soil and its interaction with soil-cleaning components. Trans. Chin. Soc. Agric. Eng. 2020, 36, 40–49. [Google Scholar]

- Wang, X.; Hu, H.; Wang, Q.; Li, H.; He, J.; Chen, W. Calibration method of soil contact characteristic parameters based on DEM theory. Trans. Chin. Soc. Agric. Mach. 2017, 48, 78–85. [Google Scholar]

- Feng, T. Optimization Design and Test Research of Plug Seedings End-Effector in Greenhouse. Master’s Thesis, Beijing University of Technology, Beijing, China, 2016. [Google Scholar]

- Gao, G.; Wang, K.; Sun, X. Verification for EDEM simulation of process of jacking tray-seedling by steel needle in grafting machine and parameter optimization. Trans. Chin. Soc. Agric. Eng. 2017, 33, 29–35. [Google Scholar]

- Qaun, W.; Wu, M.; Luo, H.; Chen, C.; Xie, W. Soil hole opening methods and parameters optimization of pot seedling transplanting machine for rapeseed. Trans. Chin. Soc. Agric. Eng. 2020, 36, 13–21. [Google Scholar]

- Liu, K.; Su, H.; Li, F.; Jiao, W. Research on parameter calibration of soil discrete element model based on response surface method. J. Chin. Agric. Mech. 2021, 9, 143–149. [Google Scholar]

- Xu, X.; Li, F.; Li, Y.; Shen, C.; Meng, K.; Chen, J. Design and experiment of quantitative variable pitch screw. Trans. Chin. Soc. Agric. Mach. 2019, 50, 89–97. [Google Scholar]

- Wang, P.; Zhang, X.; Huang, F.; Huang, S.; Jing, M. Design and simulation of taking-putting seedling manipulator of plug seedling transplanter. In Proceedings of the ASABE 2021 Annual International Meeting, Virtual and On Demand. 12–16 July 2021. [Google Scholar]

- Yao, S. Optimal Design and Experimental Research on Key Components of Cabbage Harvester. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2020. [Google Scholar]

- Tong, J.; Shi, H.; Wu, C.; Ding, Y.; Zhao, X.; Wang, R. Simulation and test of seedling pot grabbing by spade end-effector. Trans. Chin. Soc. Agric. Mach. 2019, 50, 107–116. [Google Scholar]

- Jin, X.; Li, R.; Ji, J.; Yuan, Y.; Li, M. Obstacle avoidance transplanting method based on Kinect visual processing. Int. J. Agric. Biol. Eng. 2021, 14, 72–78. [Google Scholar]

- Tian, Z.; Ma, W.; Yang, Q.; Yao, S.; Zhang, M.; Duan, F.; Xu, H. Research status and problem analysis of plug seedling trans-planter in greenhouse. J. Chin. Agric. Univ. 2022, 5, 22–38. [Google Scholar]

| Parameters | Value |

|---|---|

| Poisson’s ratio of peat | 0.4 |

| Shear modulus of peat/Pa | 1 × 107 |

| Density of peat/(kg·m−3) | 7.5 × 102 |

| Poisson’s ratio of tray cell | 0.42 |

| Shear modulus of tray cell/Pa | 1.06 × 109 |

| Density of tray cell/(kg·m−3) | 1.9 × 103 |

| Poisson’s ratio of steel needle | 0.3 |

| Shear modulus of steel needle/Pa | 7 × 1010 |

| Density of steel needle/(kg·m−3) | 7.8 × 103 |

| Poisson’s ratio of perlite | 0.25 |

| Shear modulus of perlite/Pa | 1 × 107 |

| Density of perlite/(kg·m−3) | 2.3 × 103 |

| Poisson’s ratio of vermiculite | 0.3 |

| Shear modulus of vermiculite/Pa | 3.2 × 106 |

| Density of vermiculite/(kg·m−3) | 2.55 × 103 |

| Gravity acceleration/(m·s−2) | 9.81 |

| Level | Factor | ||

|---|---|---|---|

| −1 | 1 | 30 | 0.1 |

| 0 | 2 | 35 | 0.55 |

| 1 | 3 | 40 | 1.0 |

| No. | Needle Diameter (mm) | Insertion Depth (mm) | Insertion and Grasping Speed (m/s) | Integrity Rate (%) |

|---|---|---|---|---|

| 1 | 2 | 35 | 0.55 | 79.45 |

| 2 | 2 | 30 | 1 | 58.38 |

| 3 | 3 | 40 | 0.55 | 86.51 |

| 4 | 3 | 35 | 1 | 74.45 |

| 5 | 2 | 35 | 0.55 | 68.91 |

| 6 | 2 | 35 | 0.55 | 74.52 |

| 7 | 1 | 35 | 1 | 71.34 |

| 8 | 2 | 40 | 1 | 88.45 |

| 9 | 1 | 40 | 0.55 | 88.76 |

| 10 | 1 | 30 | 0.55 | 53.08 |

| 11 | 2 | 35 | 0.55 | 58.81 |

| 12 | 2 | 30 | 0.1 | 70.87 |

| 13 | 3 | 35 | 0.1 | 74.81 |

| 14 | 2 | 40 | 0.1 | 73.66 |

| 15 | 1 | 35 | 0.1 | 81.16 |

| 16 | 2 | 35 | 0.55 | 64.82 |

| 17 | 3 | 30 | 0.55 | 38.14 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 1768.43 | 3 | 589.48 | 7.20 | 0.0043 |

| X1 | 52.17 | 1 | 52.17 | 0.64 | 0.4390 |

| X2 | 1708.49 | 1 | 1708.49 | 20.87 | 0.0005 |

| X3 | 7.76 | 1 | 7.76 | 0.09 | 0.7630 |

| Residual | 1063.98 | 13 | 81.84 | ||

| Lack of Fit | 803.44 | 9 | 89.27 | 1.37 | 0.4061 |

| Pure Error | 260.53 | 4 | 65.13 | ||

| Cor Total | 2832.41 | 16 |

| No. | Grabbed Weight (g) | Left Weight (g) | Integrity Rate (%) |

|---|---|---|---|

| 1 | 3.52 | 1.64 | 68.22 |

| 2 | 3.98 | 1.24 | 76.25 |

| 3 | 3.64 | 1.33 | 73.24 |

| 4 | 4.47 | 1.22 | 78.56 |

| 5 | 4.69 | 0.68 | 87.34 |

| 6 | 2.64 | 1.21 | 68.57 |

| 7 | 3.08 | 1.82 | 62.86 |

| 8 | 3.95 | 0.63 | 86.24 |

| 9 | 3.71 | 0.75 | 83.18 |

| Average | 3.74 | 1.17 | 76.05 |

| Standard deviation | 0.64 | 0.42 | 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Z.; Ma, W.; Yang, Q.; Yao, S.; Guo, X.; Duan, F. Design and Experiment of Gripper for Greenhouse Plug Seedling Transplanting Based on EDM. Agronomy 2022, 12, 1487. https://doi.org/10.3390/agronomy12071487

Tian Z, Ma W, Yang Q, Yao S, Guo X, Duan F. Design and Experiment of Gripper for Greenhouse Plug Seedling Transplanting Based on EDM. Agronomy. 2022; 12(7):1487. https://doi.org/10.3390/agronomy12071487

Chicago/Turabian StyleTian, Zhiwei, Wei Ma, Qichang Yang, Sen Yao, Xiangyu Guo, and Famin Duan. 2022. "Design and Experiment of Gripper for Greenhouse Plug Seedling Transplanting Based on EDM" Agronomy 12, no. 7: 1487. https://doi.org/10.3390/agronomy12071487

APA StyleTian, Z., Ma, W., Yang, Q., Yao, S., Guo, X., & Duan, F. (2022). Design and Experiment of Gripper for Greenhouse Plug Seedling Transplanting Based on EDM. Agronomy, 12(7), 1487. https://doi.org/10.3390/agronomy12071487