Textile Physical Barriers against the Chestnut Gall Wasp Dryocosmus kuriphilus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Infested Plant Material

2.2. Morphometric Analysis of D. kuriphilus

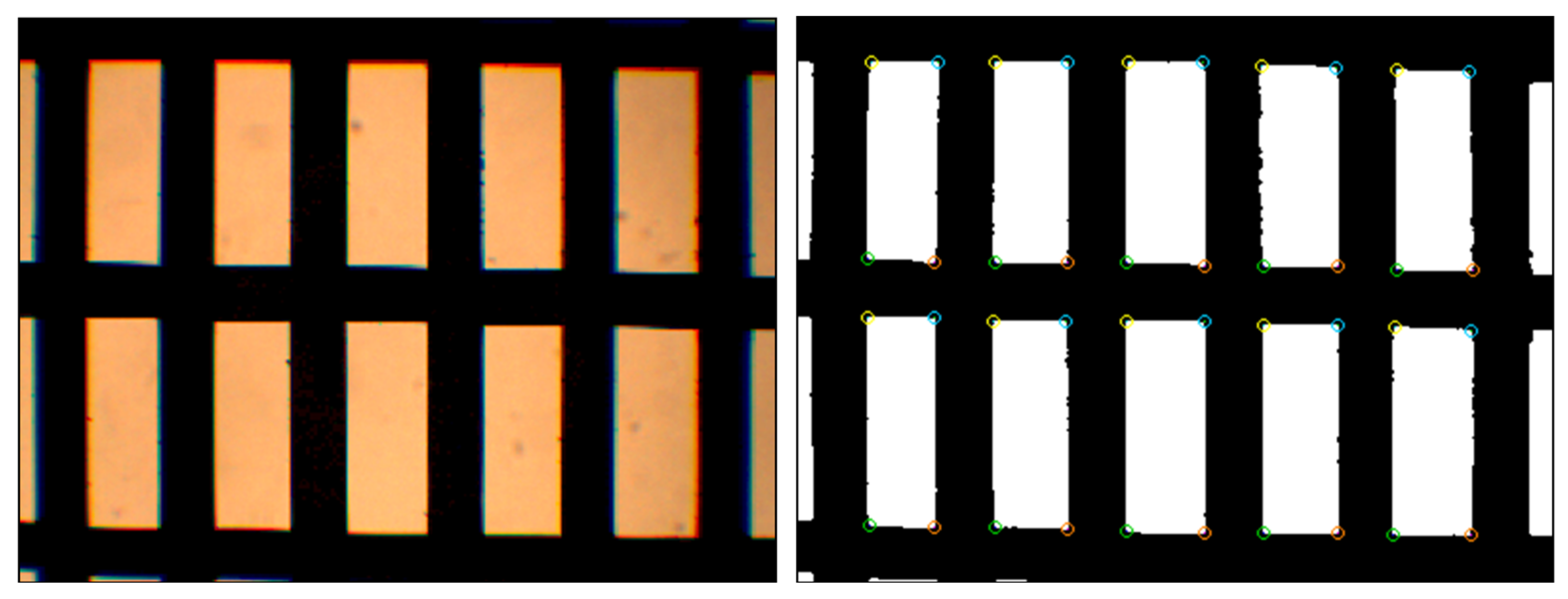

2.3. Geometric Characterization of the Selected Textiles

2.4. Theoretical Efficacy of the Textiles against D. kuriphilus

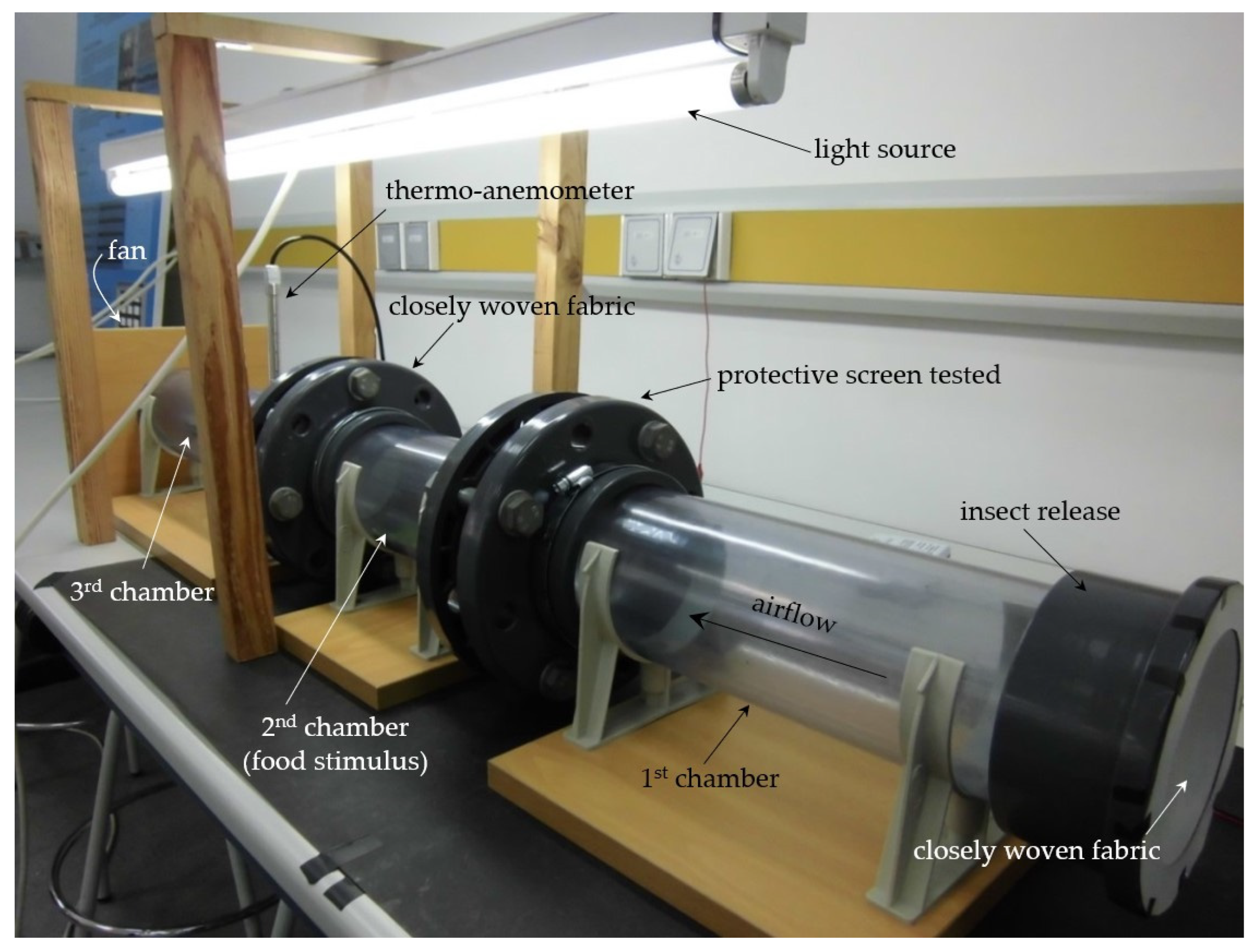

2.5. Efficacy of the Screens against D. kuriphilus Measured under Laboratory Conditions

3. Results and Discussion

3.1. Dimensions of D. kuriphilus

3.2. Geometry of Protection Screens

3.3. Efficacy of Protection Screens

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brussino, G.; Bosio, G.; Baudino, M.; Giordano, R.; Ramello, F.; Melika, G. Pericoloso insetto esotico per il castagno europeo. L’Informatore Agrar. 2002, 37, 59–61. [Google Scholar]

- EFSA Panel on Plant Health (PLH). Risk assessment of the oriental chestnut gall wasp, Dryocosmus kuriphilus for the EU territory and identification and evaluation of risk management options. EFSA J. 2010, 8, 1619. [Google Scholar] [CrossRef]

- Sartor, C.; Dini, F.; Marinoni, D.T.; Mellano, M.G.; Beccaro, G.L.; Alma, A.; Quacchia, A.; Botta, R. Impact of the Asian wasp Dryocosmus kuriphilus (Yasumatsu) on cultivated chestnut: Yield loss and cultivar susceptibility. Sci. Hortic. 2015, 197, 454–460. [Google Scholar] [CrossRef]

- Csóka, G.; Stone, G.N.; Melika, G. Non-native gall-inducing insects on forest trees: A global review. Biol. Invasions 2017, 19, 3161–3181. [Google Scholar] [CrossRef]

- Dixon, W.N.; Burns, R.E.; Stange, L.A. Oriental chestnut gall wasp Dryocosmus kuriphilus. Div. Plant Ind. Entomol. Circ. 1986, 287, 1–2. [Google Scholar]

- DOGC (Diari Oficial de la Generalitat de Catalunya). ORDRE AAM/355/2012, de 2 de novembre, per la qual s’estableixen les zones delimitades per la plaga Dryocosmus kuriphilus. DOGC Núm. 2012, 6253, 56194–56196. [Google Scholar]

- Price, P.W.; Fernandes, G.W.; Waring, G.L. Adaptive Nature of Insect Galls. Environ. Entomol. 1987, 16, 15–24. [Google Scholar] [CrossRef] [Green Version]

- Gilioli, G.; Pasquali, S.; Tramontini, S.; Riolo, F. Modelling local and long-distance dispersal of invasive chestnut gall wasp in Europe. Ecol. Model. 2013, 263, 281–290. [Google Scholar] [CrossRef]

- Gil-Tapetado, D.; Gómez, J.F.; Cabrero-Sañudo, F.J.; Nieves-Aldrey, J.L. Distribution and dispersal of the invasive Asian chestnut gall wasp, Dryocosmus kuriphilus (Hymenoptera: Cynipidae), across the heterogeneous landscape of the Iberian Peninsula. Eur. J. Entomol. 2018, 115, 575–586. [Google Scholar] [CrossRef] [Green Version]

- Graziosi, I.; Santi, F. Chesnut gall wasp (Dryocosmus kuriphilus): Spreading in Italy and new records in Bologna province. Bull. Insectology 2008, 61, 343–348. [Google Scholar]

- Aebi, A.; Schönenberger, N.; Bigler, F. Evaluating the use of Torymus sinensis against the chestnut gall wasp Dryocosmus kuriphilus in the Canton Ticino, Switzerland. Agroscope Reckenholz-Tänikon Rep. 2011, 71. Available online: https://libra.unine.ch/Publications/Alexandre_Aebi/27304 (accessed on 30 May 2022).

- Bethke, J.A.; Redak, R.A.; Paine, T.D. Screens deny specific pests entry to greenhouses. Calif. Agric. 1994, 48, 37–40. [Google Scholar] [CrossRef] [Green Version]

- Baker, J.R.; Shearin, B.A. An update on screening for the exclusion of insect pests. N. C. Flower Grow. Bull. 1994, 39, 6–11. [Google Scholar]

- Bell, M.L. Select insect screens on their exclusion capability. Greenhouse Manag. Prod. 1997, 29, 31. [Google Scholar]

- Bell, M.; Weatherley, N. Greenhuse insect screens—Making the right selection. Nurs. Pap. 2001, 1–6. [Google Scholar]

- Teitel, M.; Barak, M.; Berlinger, M.J.; Lebiush-Mordechi, S. Insect-proof screens: Their effect on roof ventilation and insect penetration. Acta Hortic. 2000, 507, 25–34. [Google Scholar] [CrossRef]

- Critten, D.L.; Bailey, B.J. A review of greenhouse engineering developments during the 1990s. Agric. For. Meteorol. 2002, 112, 1–22. [Google Scholar] [CrossRef]

- Klose, F.; Tantau, H.J. Test of insect screens—Measurement and evaluation of the air permeability and light transmission. Eur. J. Hort. Sci. 2004, 69, 235–243. [Google Scholar]

- Teitel, M. The effect of screened openings on greenhouse microclimate. Agric. For. Meteorol. 2007, 143, 159–175. [Google Scholar] [CrossRef]

- Berlinger, M.J.; Taylor, R.A.J.; Lebiush-Mordechi, S.; Shalhevet, S.; Spharim, I. Efficiency of insect exclusion screens for preventing whitefly transmission of tomato yellow leaf curl virus of tomatoes in Israel. Bull. Entomol. Res. 2002, 92, 367–373. [Google Scholar] [CrossRef]

- Berlinger, M.J.; Lebiush-Mordechai, S. Physical methods for the control of Bemisia. In Bemisia 1995: Taxonomy, Biology, Damage, Control and Management; Gerling, D., Mayer, R.T., Eds.; Intercept Ltd.: Andover, UK, 1995; pp. 617–634. [Google Scholar]

- Roberts, W.J.; Vasvary, L.; Kania, S. Screening for insect control in mechanically ventilated greenhouses. ASAE 1995, 12, 95–4541. [Google Scholar]

- Berlinger, M.J.; Lebiush-Mordechi, S.; Leeper, A. Application of screens to prevent whitefly penetration into greenhouses in the Mediterranean basin. Bull. OILB SROP 1991, 14, 105–110. [Google Scholar]

- Berlinger, M.J.; Lebiush-Mordechi, S.; Fridja, D. The effect of types of greenhouse screens on the presence of western flower thrips: A preliminary study. IOBC/WPRS Bull. 1992, 16, 13–16. [Google Scholar]

- Baker, J.R.; Jones, R.K. Screening as part of insect and disease management in the greenhouse. N.C. Flower Growers’ Bull. 1989, 34, 1–9. Available online: https://hortscans.ces.ncsu.edu/uploads/s/c/screenin_53e4f3cf4132a.pdf (accessed on 30 May 2022).

- Baker, J.R.; Jones, R.K. An update on screening as part of insect and disease management in the greenhouse. N.C. Flower Growers’ Bull. 1990, 35, 1–3. Available online: https://hortscans.ces.ncsu.edu/uploads/a/n/an_updat_53e3aebf1fc7b.pdf (accessed on 30 May 2022).

- Ross, D.S.; Gill, S.A. Insect screening for greenhouses. Univ. Md. Coll. Part. Inf. Facts 1994, 186, 21. [Google Scholar]

- Teitel, M. The effect of insect-proof screens in roof openings on greenhouse microclimate. Agric. For. Meteorol. 2001, 110, 13–25. [Google Scholar] [CrossRef]

- Dáder, B.; Legarrea, S.; Moreno, A.; Plaza, M.; Carmo-Sousa, M.; Amor, F.; Viñuela, E.; Fereres, A. Control of insect vectors and plant viruses in protected crops by novel pyrethroid-treated nets. Pest Manag. Sci. 2014, 71, 1397–1406. [Google Scholar] [CrossRef] [Green Version]

- Arthurs, S.P.; Krauter, P.C.; Gilder, K.; Heinz, K.M. Evaluation of deltamethrin-impregnated nets as a protective barrier against Western flower thrips, Frankliniella occidentalis (Thysanoptera: Thripidae) under laboratory and greenhouse conditions. Crop Prot. 2018, 112, 227–231. [Google Scholar] [CrossRef]

- Faliagka, S.; Agrafioti, P.; Lampiri, E.; Katsoulas, N.; Athanassiou, C.G. Assessment of different inert nanoparticles formulations for the control of Sitophilus oryzae, Tribolium confusum and Aphis fabae. Crop Prot. 2020, 137, 105312. [Google Scholar] [CrossRef]

- Faliagka, S.; Katsoulas, N. Silica coated insect proof screens for effective insect control in greenhouses. Biosyst. Eng. 2022, 215, 21–31. [Google Scholar] [CrossRef]

- Álvarez, A.J. Estudio de las características geométricas y del comportamiento aerodinámico de las mallas antiinsectos utilizadas en los invernaderos como medida de protección vegetal. Editor. Univ. Almer. 2010, 273, 446. [Google Scholar]

- Álvarez, A.J.; Oliva, R.M.; Valera, D.L. Software for the geometric characterisation of insect-proof screens. Comput. Electron. Agric. 2012 82, 134–144. [CrossRef]

- Álvarez, A.J.; Oliva, R.M.; Jiménez-Vargas, A.; Villegas-Vallecillos, M. A three-dimensional approach to the porous surface of screens. J. Text. Inst. 2019, 110, 639–646. [Google Scholar] [CrossRef]

- ISO 5084:1996; Textiles—Determination of thickness of textiles and textile products. International Organization for Stardardization: Geneva, Switzerland, 1996; 5p.

- Bethke, J.A.; Paine, T.D. Screen hole size and barriers for exclusion on insect pest of glasshouse crops. J. Entomol. Sci. 1991, 26, 169–177. [Google Scholar] [CrossRef]

- Oliva, R.M.; Álvarez, A.J. Factors influencing the efficacy of insect-proof screens. Acta Hortic. 2017, 1170, 1027–1034. [Google Scholar] [CrossRef]

- SPSS Statistical Package Version 27; SPSS Inc.: Chicago, IL, USA, 2022.

- Bell, M.L.; Baker, J.R. Choose a greenhouse screen based on its pest exclusion efficiency. N. C. Flower Grow. Bull. 1997, 42, 7–13. [Google Scholar]

- Bell, M.L.; Baker, J.R. Comparison of greenhouse screening materials for excluding whitefly (Homoptera: Aleyrodidae) and thips (Thysanoptera: Thripidae). J. Econ. Entomol. 2000, 93, 800–804. [Google Scholar] [CrossRef]

- Bailey, B. Screens stop insects but slow airflow. Fruit Veg. Technol. 2003, 3, 6–8. [Google Scholar]

- Martin, T.; Assogba-Komlan, F.; Houndete, T.; Hougard, J.M.; Chandre, F. Efficacy of mosquito netting for sustainable small holders’ cabbage production in Africa. J. Econ. Entomol. 2006, 99, 450–454. [Google Scholar] [CrossRef]

| Origin | n | Tx ± σ (µm) | Tz ± σ (µm) | Ax ± σ (µm) | Az ± σ (µm) |

|---|---|---|---|---|---|

| As Neves Pontevedra 42°8′14″/8°24′17″ | 82 | 732 ± 39 | 745 ± 37 | 773 ± 38 | 854 ± 28 |

| Lugo 42°59′49″/7°32′47″ | 83 | 717 ± 44 | 736 ± 48 | 762 ± 49 | 859 ± 94 |

| Mean values | 165 | 725 ± 42 | 741 ± 43 | 768 ± 45 | 857 ± 69 |

| Screen | ρy × ρx Trade Values (Threads cm−2) | ρy × ρx Measured Values (Threads cm−2) | Lpx ± σ (μm) | Lpy ± σ (μm) | Dh ± σ (μm) | φ (%) |

|---|---|---|---|---|---|---|

| 1 | 10 × 7 | 10.5 × 7.3 | 669 ± 19 | 1082 ± 33 | 281 ± 14 | 56.0 |

| 2 | 10 × 8 | 10.6 × 8.1 | 639 ± 36 | 930 ± 35 | 300 ± 13 | 51.5 |

| 3 | 10 × 10 | 10.0 × 9.6 | 715 ± 25 | 742 ± 30 | 295 ± 17 | 50.6 |

| 4 | 9 × 6 | 9.4 × 6.6 | 748 ± 72 | 1221 ± 25 | 310 ± 18 | 56.2 |

| 5 | 9 × 6 | 8.9 × 6.2 | 807 ± 36 | 1298 ± 50 | 316 ± 18 | 57.9 |

| Screen | Lpx/Lpy | tt ± σ (μm) | A2D (mm2) | A3D (mm2) | d2 (μm) | Lpy/2 (μm) |

|---|---|---|---|---|---|---|

| 1 | 0.62 | 510 ± 5 | 0.7239 | 0.7430 | 679 | 541 |

| 2 | 0.69 | 530 ± 4 | 0.5943 | 0.6127 | 649 | 465 |

| 3 | 0.96 | 460 ± 9 | 0.5305 | 0.5395 | 720 | 371 |

| 4 | 0.61 | 560 ± 7 | 0.9133 | 0.9363 | 758 | 611 |

| 5 | 0.62 | 530 ± 7 | 1.0475 | 1.0643 | 814 | 649 |

| Screen | ε (%); T (°C) | F-Value | p-Value | ||

|---|---|---|---|---|---|

| 0 m·s−1 | 1.5 m·s−1 | 3.0 m·s−1 | |||

| 1 | 98.4; 28.9 | 100; 28.4 | 100; 28.4 | 1.000 | 0.422 |

| 2 | 98.1; 29.2 | 93.8; 28.5 | 94.8; 29.7 | 0.357 | 0.714 |

| 3 | 100; 28.6 | 100; 28.4 | 100; 29.6 | --- | --- |

| 4 | 76.4; 28.6 | --- | --- | --- | |

| 5 | 64.3; 28.7 | --- | --- | --- | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez, A.J.; Oliva, R.M. Textile Physical Barriers against the Chestnut Gall Wasp Dryocosmus kuriphilus. Agronomy 2022, 12, 1728. https://doi.org/10.3390/agronomy12071728

Álvarez AJ, Oliva RM. Textile Physical Barriers against the Chestnut Gall Wasp Dryocosmus kuriphilus. Agronomy. 2022; 12(7):1728. https://doi.org/10.3390/agronomy12071728

Chicago/Turabian StyleÁlvarez, Antonio J., and Rocío M. Oliva. 2022. "Textile Physical Barriers against the Chestnut Gall Wasp Dryocosmus kuriphilus" Agronomy 12, no. 7: 1728. https://doi.org/10.3390/agronomy12071728