Carbon Footprint Assessment and Energy Budgeting of Different Annual and Perennial Forage Cropping Systems: A Study from the Semi-Arid Region of Karnataka, India

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site

2.2. Fodder Cropping System

2.3. Fodder Yield Measurement

2.4. Carbon Analysis

2.5. Energy Analysis

2.6. Statistical Analysis

3. Results

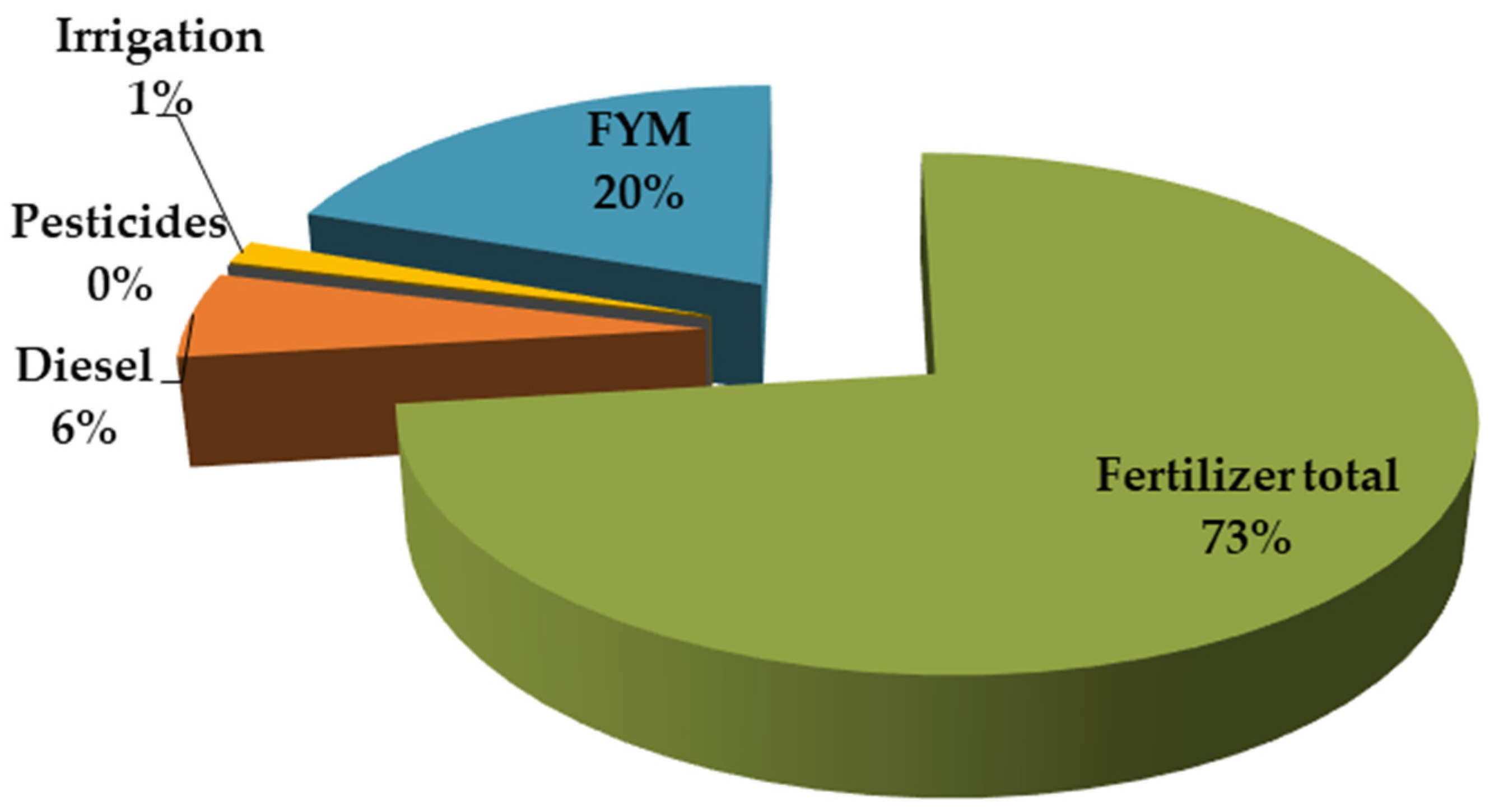

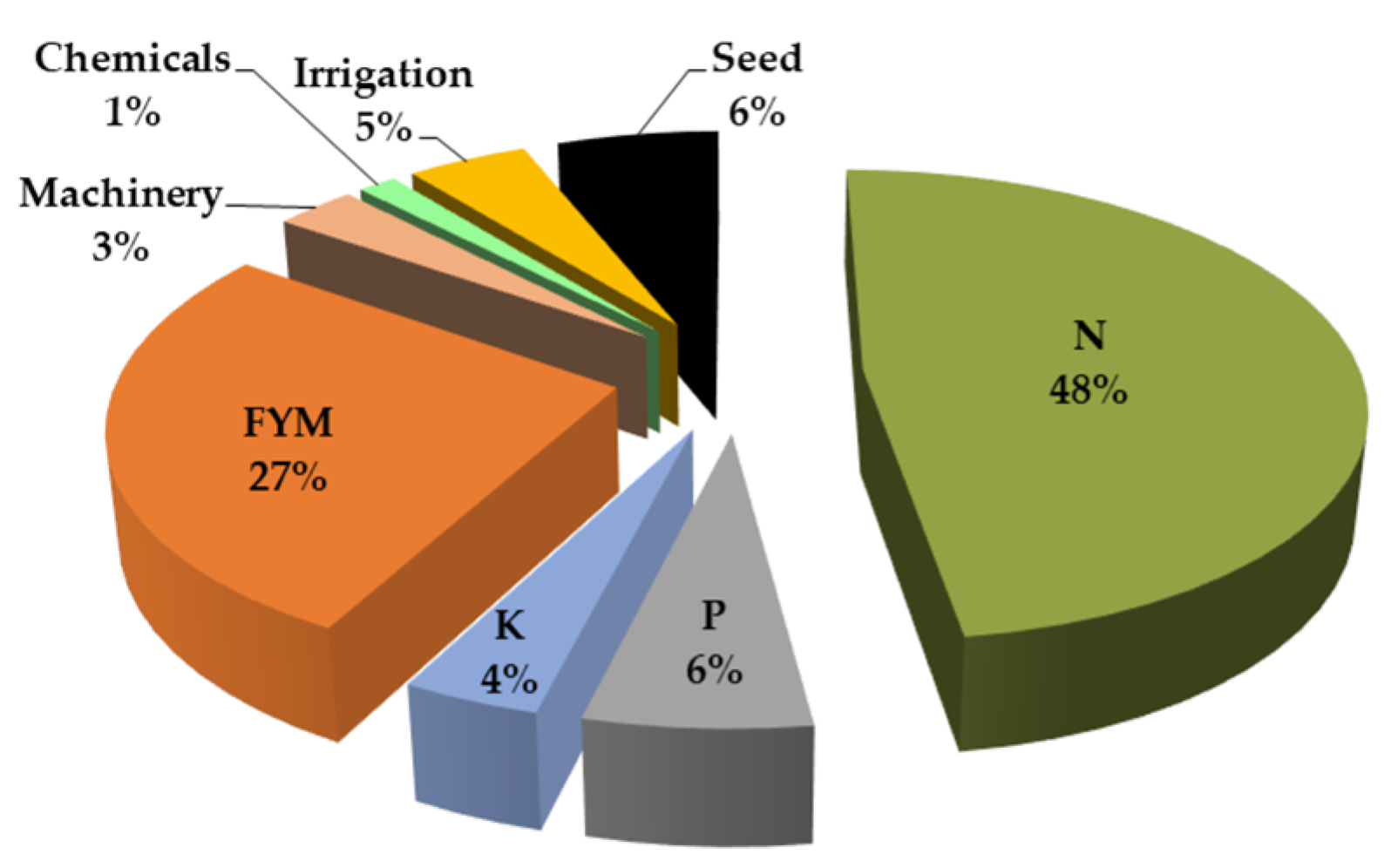

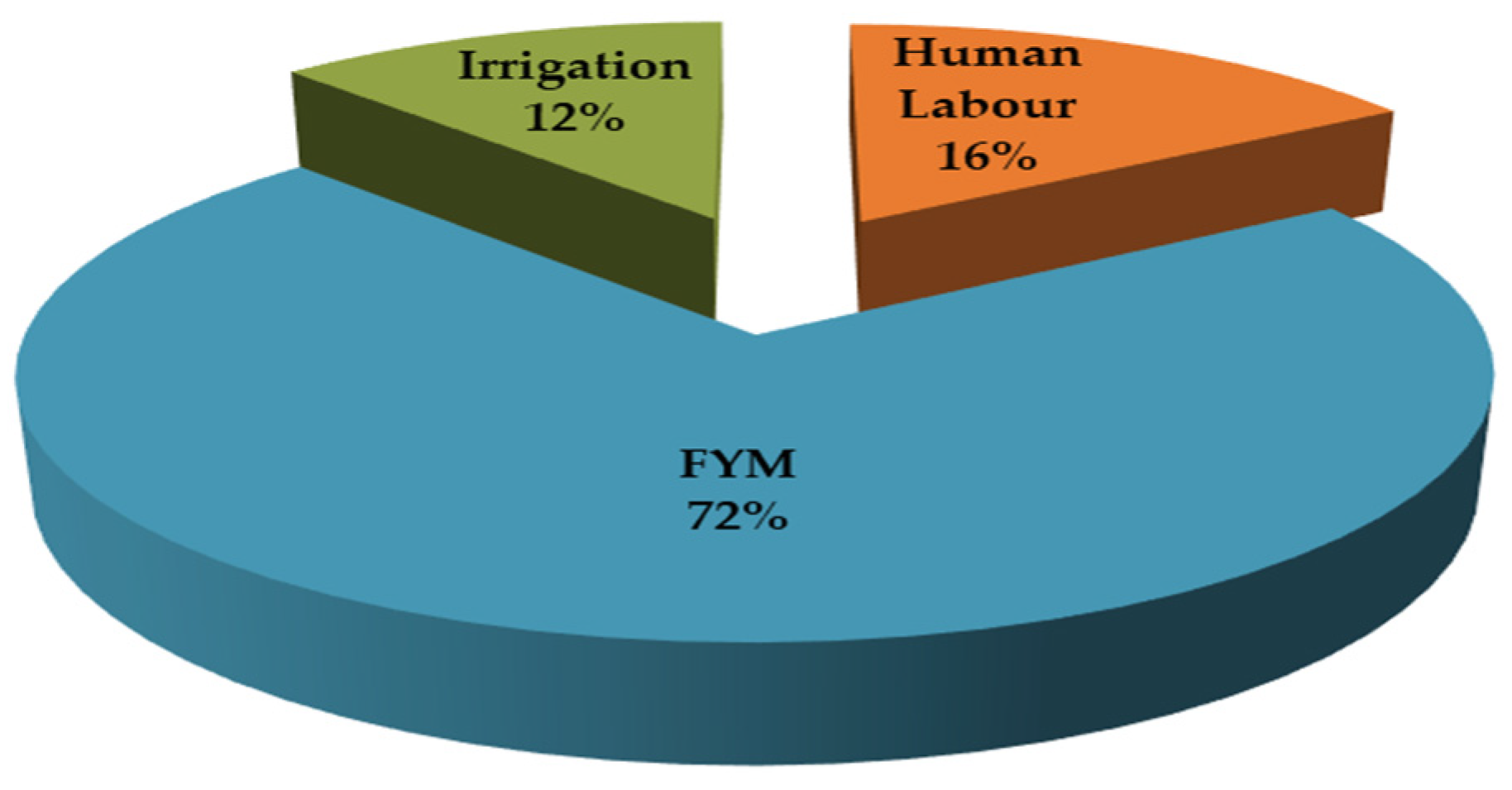

3.1. Total Carbon Input and Share of Different Inputs

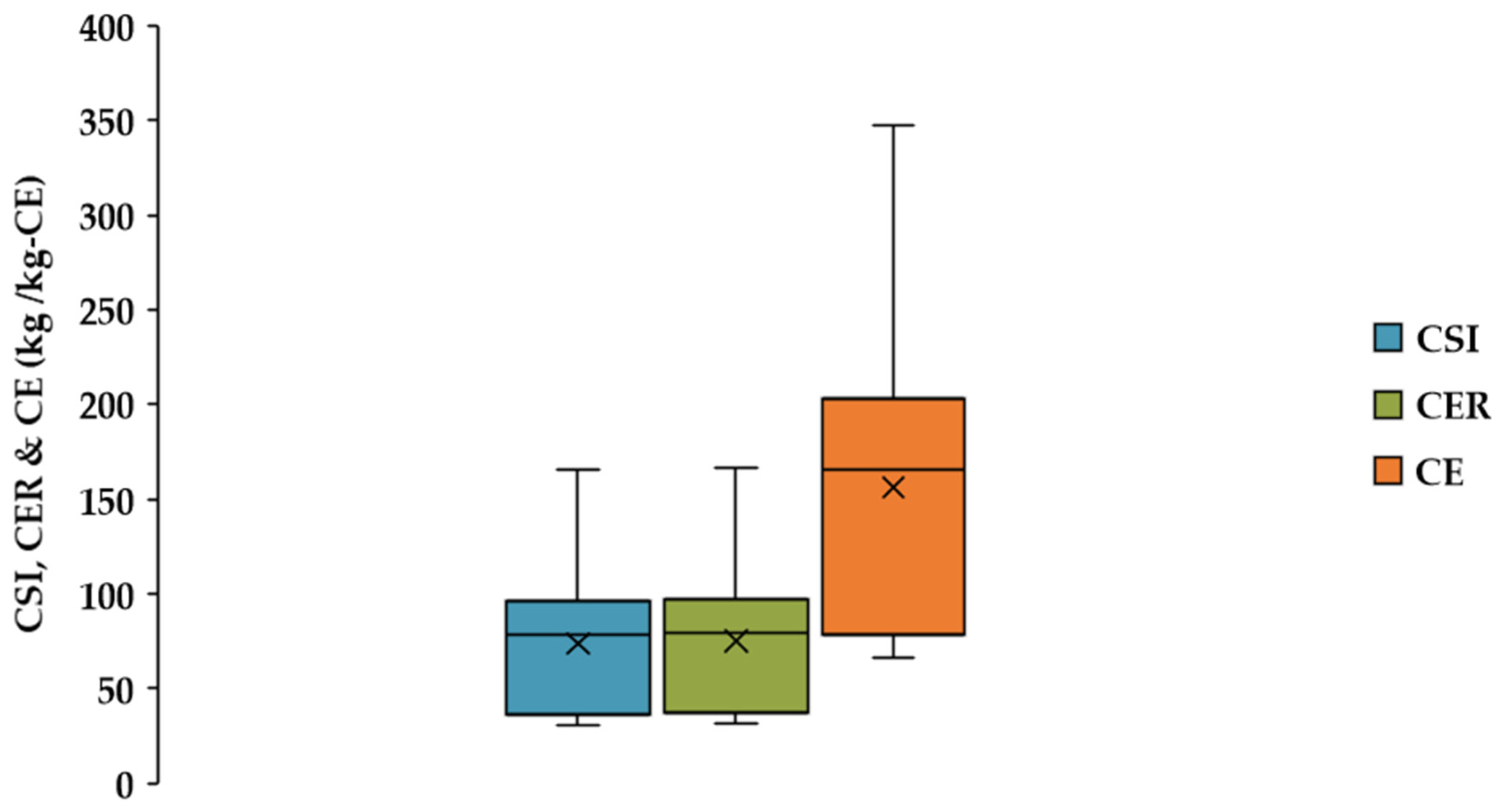

3.2. Total Carbon Output and Carbon Indices

3.3. Total Energy Input and Share of Different Inputs

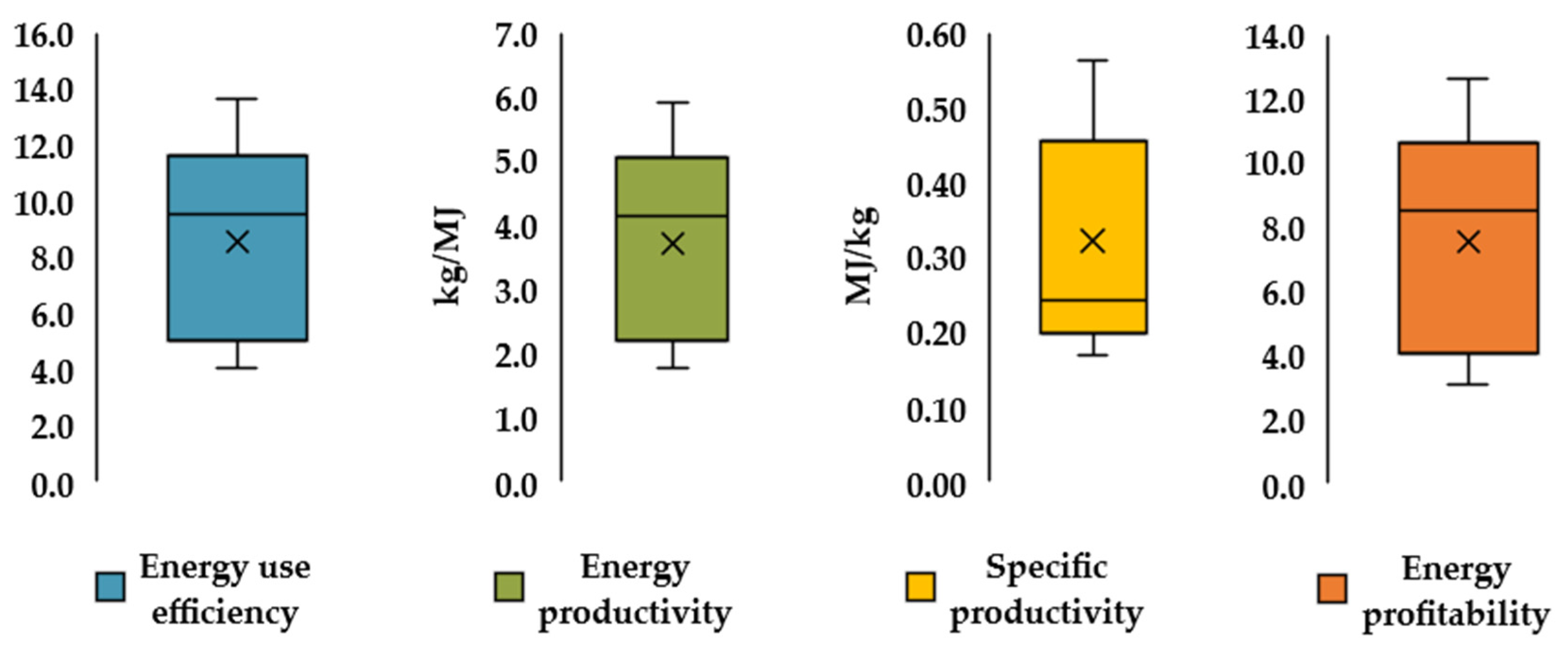

3.4. Total Energy Output and Energy Indices

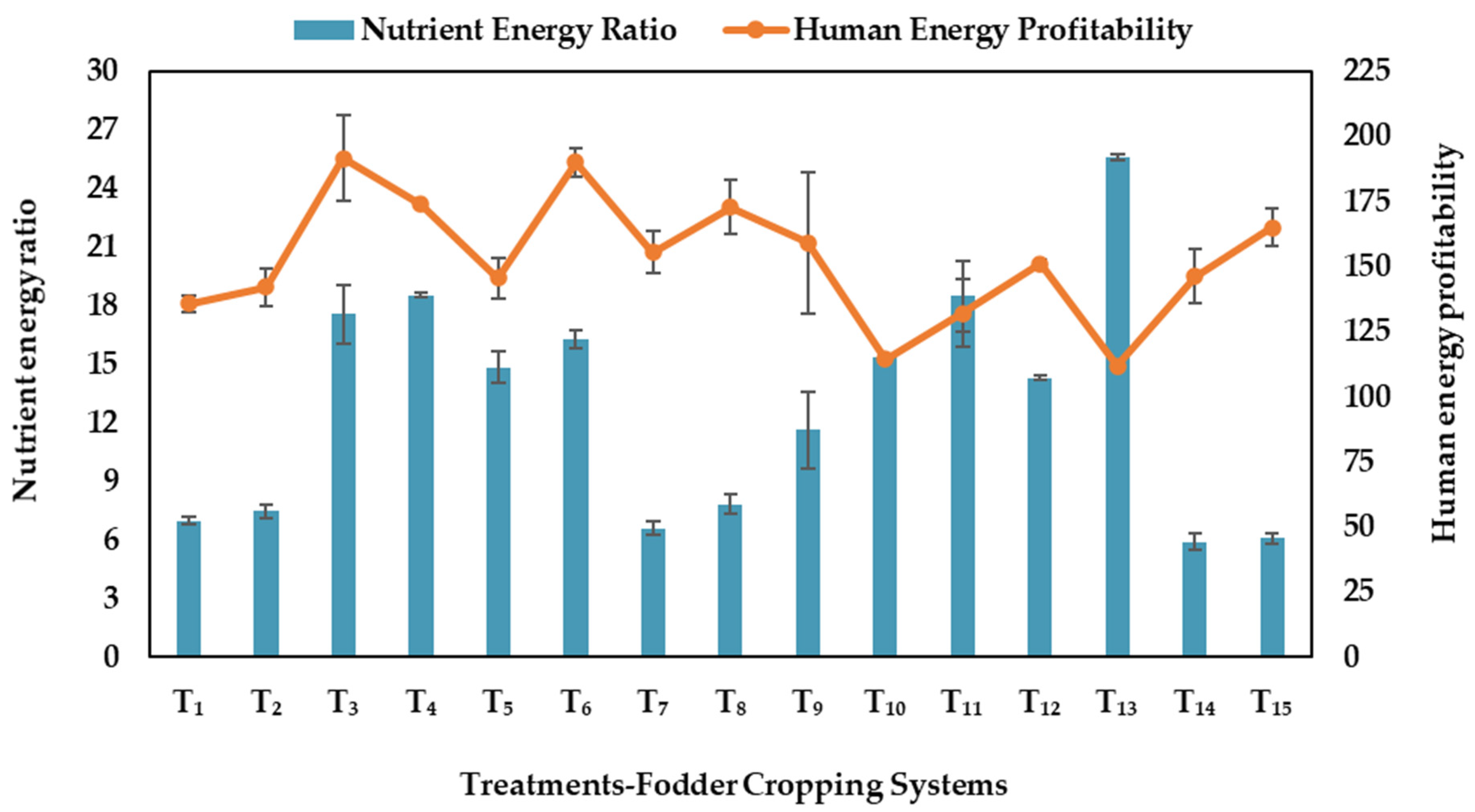

3.5. Nutrient Energy Ratio and Human Energy Profitability

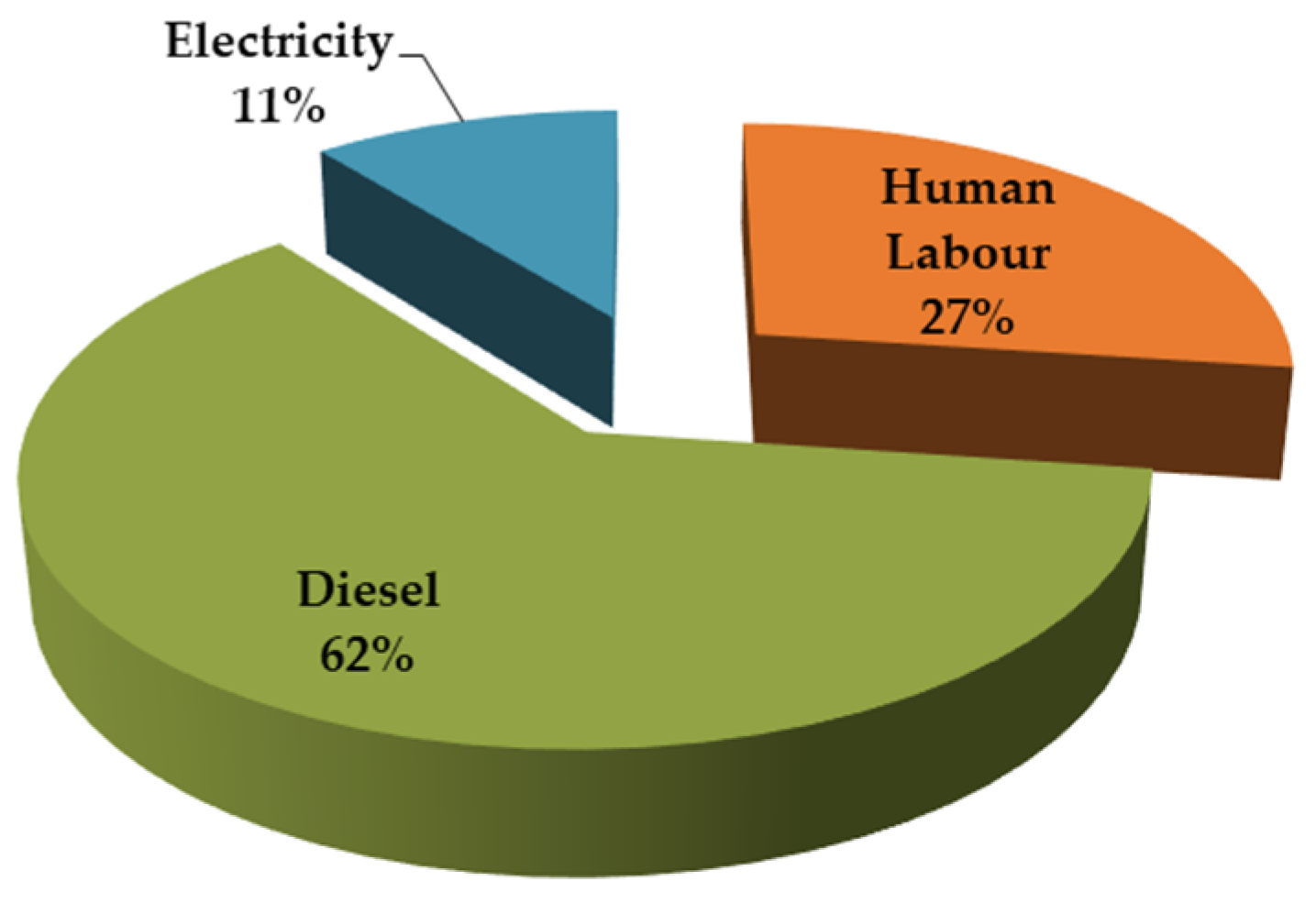

3.6. Energy Sources

4. Discussion

4.1. Carbon Input, Output and Its Indices

4.2. Energy Input, Output and Its Indices

4.3. Nutrient Energy Ratio and Human Energy Profitability

4.4. Energy Sources

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moraditochaee, M. Research energy indices of eggplant production in north of Iran. ARPN J. Agric. Biol. Sci. 2012, 7, 484–487. [Google Scholar]

- Soni, P.; Taewichit, C.; Salokhe, V.M. Energy consumption and CO2 emissions in rainfed agricultural production systems of Northeast Thailand. Agric. Syst. 2013, 116, 25–36. [Google Scholar] [CrossRef]

- Singh, R.J.; Meena, R.L.; Sharma, N.K.; Kumar, S.; Kumar, K.; Kumar, D. Economics, energy, and environmental assessment of diversified crop rotations in sub-Himalayas of India. Environ. Monit. Assess. 2016, 188, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, V.P.; Gangwar, B.; Pandey, D.K.; Gangwar, K.S. Energy auditing of diversified rice–wheat cropping systems in Indo-Gangetic plains. Energy 2009, 34, 1091–1096. [Google Scholar] [CrossRef]

- Fadavi, R.; Keyhani, A.; Mohtasebi, S.S. An analysis of energy use, input costs and relation between energy inputs and yield of apple orchard. Res. Agric. Eng. 2011, 57, 88–96. [Google Scholar] [CrossRef]

- Mishra, P.K.; Sharma, S.; Tripathi, H.; Pandey, D. Energy input for fodder crop productions under different types of farming systems. Plant Arch. 2019, 19, 1358–1362. [Google Scholar]

- IPCC. Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems; Shukla, P.R., Skea, J., Calvo Buendia, E., Masson-Delmotte, V., Pörtner, H.O., Roberts, D.C., Zhai, P., Slade, R., Connors, S., van Diemen, R., et al., Eds.; IPCC: Geneva, Switzerland, 2019; pp. 1–864, in press. [Google Scholar]

- Chen, X.; Ma, C.; Zhou, H.; Liu, Y.; Huang, X.; Wang, M.; Cai, Y.; Su, D.; Muneer, M.A.; Guo, M.; et al. Identifying the main crops and key factors determining the carbon footprint of crop production in China, 2001–2018. Resour. Conserv. Recycl. 2021, 172, 105661. [Google Scholar] [CrossRef]

- Srinivasarao, C. Programmes and Policies for Improving Fertilizer Use Efficiency in Agriculture. Indian J. Fertil. 2021, 17, 226–254. [Google Scholar]

- Annual Report, Government of India Ministry of Chemicals and Fertilizers, Department of Fertilizers, 2019–2020. Available online: https://fert.nic.in/sites/default/files/2020-09/Annual-Report-2019-20.pdf (accessed on 28 February 2022).

- Patra, S.; Mishra, P.; Mahapatra, S.C.; Mithun, S.K. Modelling impacts of chemical fertilizer on agricultural production: A case study on Hooghly district, West Bengal, India. Model. Earth Syst. Environ. 2016, 2, 180. [Google Scholar] [CrossRef]

- Usama, M.; Khalid, M.A. Fertilizer consumption in India and need for its balanced use: A review. Indian J. Environ. Protecn. 2018, 38, 564–577. [Google Scholar]

- Jha, D.; Sarin, R. Fertilizer Use in Semi-Arid Tropical India; Research Bulletin No. 9; International Crops Research Institute for Semi-Aarid Tropics: Patancheru, India, 1984. [Google Scholar]

- Tiwari, P.S.; Singh, K.K.; Sahni, R.K.; Kumar, V. Farm mechanization—Trends and policy for its promotion in India. Indian J. Agric. Sci. 2019, 89, 1555–1562. [Google Scholar]

- WRI CAIT 4.0, 2017-World Resources Institute Climate Analysis Indicators Tool. Greenhouse Gas Emissions in India, Emissions including Land-Use Change and Forestry. Global Warming Potentials are from the Intergovernmental Panel on Climate Change Second Assessment Report. September 2018. Available online: https://www.wri.org/data/cait-climate-data-explorer (accessed on 28 February 2022).

- Guignard, M.S.; Leitch, A.R.; Acquisti, C.; Eizaguirre, C.; Elser, J.J.; Hessen, D.O.; Jeyasingh, P.D.; Neiman, M.; Richardson, A.E.; Soltis, P.S.; et al. Impacts of nitrogen and phosphorus: From genomes to natural ecosystems and agriculture. Front. Ecol. Evol. 2017, 6, 70. [Google Scholar] [CrossRef]

- Sharma, N.; Singhvi, R. Effects of Chemical Fertilizers and Pesticides on Human Health and Environment: A Review. Int. J. Agric. Environ. Biotechnol. 2017, 10, 675–679. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Dey, A. Energy budgeting of crop-livestock-poultry integrated farming system in irrigated ecologies of eastern India. Indian J. Agric. Sci. 2019, 89, 1017–1022. [Google Scholar]

- Hitaj, C.; Suttles, S. Trends in U.S. Agriculture’s Consumption and Production of Energy: Renewable Power, Shale Energy, and Cellulosic Biomass, EIB-159; U.S. Department of Agriculture, Economic Research Service: Washington, DC, USA, 2016.

- Erdal, G.; Esengun, K.; Guduz, O. Energy use and economic analysis of sugar beet production in Tokat province of Turkey. Energy 2007, 32, 34–41. [Google Scholar] [CrossRef]

- Tuti, M.D.; Prakash, V.; Pandey, B.M.; Bhattacharyya, R.; Mahanta, D.; Bisht, J.K.; Kumar, M.; Mina, B.L.; Kumar, N.; Bhatt, J.C.; et al. Energy budgeting of Colocasia-based cropping systems in the Indian sub-Himalayas. Energy 2012, 45, 986–993. [Google Scholar] [CrossRef]

- Patel, P.G.; Bhut, A.C.; Gupta, P. Energy requirement for kharif maize cultivation in Panchmahal district of Gujarat. J. AgriSearch 2014, 1, 168–172. [Google Scholar] [CrossRef]

- Singh, H.N.; Kumar, M.R.; Magan, S.; Rakesh, K.; Hardev, R.; Kumar, M.V.; Manish, K. Evaluation of kharif forage crops for biomass production and nutritional parameters in Indo-Gangetic plains of India. Indian J. Anim. Nutr. 2019, 36, 25–29. [Google Scholar] [CrossRef]

- Patil, L.M.; Kauthale, V.K.; Bhalani, T.G.; Modi, D.J. Productivity, and economics of different forage production systems in south Gujarat conditions of India. Forage Res. 2018, 44, 14–18. [Google Scholar]

- Roy, A.K.; Agrawal, R.K.; Bhardwaj, N.R.; Mishra, A.K.; Mahanta, S.K. Revisiting national forage demand and availability scenario. In Indian Fodder Scenario: Redefining State Wise Status; Annual Report; ICAR-AICRP on Forage Crops and Utilization: Jhansi, India, 2019; pp. 1–21. [Google Scholar]

- Kaithwas, M.; Singh, S.; Prusty, S.; Mondal, G.; Kundu, S.S. Evaluation of legume and cereal fodders for carbohydrate and protein fractions, nutrient digestibility, energy and forage quality. Range Manag. Agrofor. 2020, 41, 126–132. [Google Scholar]

- Prajapati, B.; Tiwari, S.; Kewalanand. Effect of fodder based intercropping systems on quality of fodder. Forage Res. 2018, 43, 308–313. [Google Scholar]

- Hindoriya, P.S.; Meena, R.K.; Rakesh, K.; Singh, M.; Ram, H.; Meena, V.K.; Ginwal, D.; Dutta, S. Productivity, and profitability of cereal-legume forages vis-a-vis their effect on soil nutrient status in Indo-Gangetic Plains. Legume Res. 2019, 42, 812–817. [Google Scholar] [CrossRef]

- Zhang, J.; Yin, B.; Xie, Y.; Li, J.; Yang, Z.; Zhang, G. Legume-cereal intercropping improves forage yield, quality and degradability. PLoS ONE 2015, 10, e0144813. [Google Scholar] [CrossRef]

- Capstaff, N.M.; Miller, A.J. Improving the yield and nutritional quality of forage crops. Front. Plant Sci. 2018, 9, 535. [Google Scholar] [CrossRef]

- Abd Rabboh, A.M.; Zen El-Dein, A.A.; Ahmed, N.R. Forge yield and its quality of sudangrass and cowpea under different intercropping patterns. Al-Azhar J. Agric. Res. 2020, 45, 102–115. [Google Scholar]

- Prajapat, K.; Vyas, A.K.; Dhar, S.; Jain, N.K.; Hashim, M.; Choudhary, G.L. Energy input-output relationship of soybean-based cropping systems under different nutrient supply options. J. Environ. Biol. 2018, 39, 93–101. [Google Scholar] [CrossRef]

- Lal, R. Carbon emission from farm operations. Environ. Int. 2004, 30, 981–990. [Google Scholar] [CrossRef]

- West, T.O.; Marland, G. A synthesis of carbon sequestration, carbon emissions, and net carbon flux in agriculture: Comparing tillage practices in the United States. Agric. Ecosyst. Environ. 2002, 91, 217–232. [Google Scholar] [CrossRef]

- Sah, D. Estimation of Carbon Footprint in Cultivation of Major Agricultural Crops in India. Master’s Thesis, Submitted to University Agriculture Science Bangalore, Karnataka, India, 2017. [Google Scholar]

- Chaudhary, V.P.; Singh, K.K.; Pratibha, G.; Bhattacharyya, R.; Shamim, M.; Srinivas, I.; Patel, A. Energy conservation and greenhouse gas mitigation under different production systems in rice cultivation. Energy 2017, 130, 307–317. [Google Scholar] [CrossRef]

- Basavalingaiah, K.; Ramesha, Y.M.; Paramesh, V.; Rajanna, G.A.; Jat, S.L.; Dhar Misra, S.; Kumar Gaddi, A.; Girisha, H.C.; Yogesh, G.S.; Raveesha, S.; et al. Energy budgeting, data envelopment analysis and greenhouse gas emission from rice production system: A case study from puddled transplanted rice and direct-seeded rice system of Karnataka, India. Sustainability 2020, 12, 6439. [Google Scholar] [CrossRef]

- Sah, D.; Devakumar, A.S. The carbon footprint of agricultural crop cultivation in India. Carbon Manag. 2018, 9, 213–225. [Google Scholar] [CrossRef]

- Lu, F.; Wang, X.K.; Han, B. Assessment on the availability of nitrogen fertilization in improving carbon sequestration potential of China’s cropland soil. Chin. J. App. Ecol. 2008, 19, 2239–2250. [Google Scholar]

- Dubey, A.; Lal, R. Carbon footprint and sustainability of agricultural production systems in Punjab, India, and Ohio, USA. J. Crop Improv. 2009, 23, 332–350. [Google Scholar] [CrossRef]

- IPCC. Guidelines for National Greenhouse Gas Inventories; National Greenhouse Gas Inventories Programme: Tokyo, Japan, 2016. [Google Scholar]

- Rao, K.V.R.; Gangwar, S.; Bajpai, A.; Chourasia, L.; Soni, K. Energy assessment of rice under conventional and drip irrigation systems. In Water Resources Management; Springer: Singapore, 2018; pp. 19–29. [Google Scholar] [CrossRef]

- Sudhakara, T.M.; Srinvas, A.; Kumar, R.M.; Prakash, T.R.; Rajanna, G.A. Energy saving and profitability of rice (Oryza sativa) under mechanized and conventional system of rice intensification. Indian J. Agron. 2017, 62, 174–179. [Google Scholar]

- Paramesh, V.; Parajuli, R.; Chakurkar, E.B.; Sreekanth, G.B.; Chetan Kumar, H.B.; Gokuldas, P.P.; Mahajan, G.R.; Manohara, K.K.; Viswanatha, R.K.; Ravisankar, N. Sustainability, energy budgeting, and life cycle assessment of crop-dairy-fish-poultry mixed farming system for coastal lowlands under humid tropic condition of India. Energy 2019, 188, 116101. [Google Scholar] [CrossRef]

- Singh, K.P.; Prakash, V.; Srinivas, K.; Srivastva, A.K. Effect of tillage management on energy use efficiency and economics of soybean (Glycine max) based cropping systems under the rainfed condition in North-West Himalayan region. Soil Tillage Res. 2008, 100, 78–82. [Google Scholar] [CrossRef]

- Canakci, M.; Topakci, M.; Akinci, I.; Ozmerzi, A. Energy use pattern of some field crops and vegetable production: Case study for Antalya region, Turkey 2005. Energy Convers. Manag. 2005, 46, 655–666. [Google Scholar] [CrossRef]

- Singh, S.; Mittal, J.P. Energy in Production Agriculture; Mittal Publications: New Delhi, India, 1992. [Google Scholar]

- Rafiee, S.; Mousavi Avval, S.H.; Mohammadi, A. Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy 2010, 35, 3301–3306. [Google Scholar] [CrossRef]

- Mandal, K.G.; Saha, K.P.; Ghosh, P.K.; Hatik, M.; Bandyopadhyay, K.K. Bio-energy and economic analysis of soybean-based crop production systems in central India. Biomass Bioenergy 2002, 23, 337–345. [Google Scholar] [CrossRef]

- Taki, M.; Ajabshirchi, Y.; Mobtaker, H.G.; Abdi, R. Energy consumption, input–output relationship and cost analysis for green house productions in Esfahan province of Iran. Am. J. Exp. Agric. 2012, 2, 485–501. [Google Scholar] [CrossRef]

- Ozkan, B.; Akcaoz, H.; Fert, C. Energy input-output analysis in Turkish agriculture. Renew Energy 2004, 29, 39–51. [Google Scholar] [CrossRef]

- Lal, B.; Rajput, D.S.; Tamhankar, M.B.; Agarwal, I.; Sharma, M.S. Energy use and output assessment of food-forage production system. J. Agron. Crop Sci. 2003, 189, 57–62. [Google Scholar] [CrossRef]

- Sheoran, O.P.; Tonk, D.S.; Kaushik, L.S.; Hasija, R.C.; Pannu, R.S. Statistical Software Package for Agricultural Research Workers. In Recent Advances in Information Theory; Hasija Department of Mathematics Statistics: Hisar, India, 1998; pp. 139–143. [Google Scholar]

- Bastia, D.K.; Behera, S.K.; Panda, M.R. Impacts of soil fertility management on productivity and economics of rice and fodder intercropping systems under rainfed conditions in Odisha, India. J. Integr. Agric. 2021, 20, 3114–3126. [Google Scholar] [CrossRef]

- Ghazouani, A.; Mhamdi, N.; Znaidi, I.E.; Darej, C.; Guoiaa, N.; Hasnaoui, M.; Bouraoui, R.; Mhamdi, H. Life cycle analysis of raw milk production in Tunisia. Braz. J. Biol. Sci. 2018, 5, 249–258. [Google Scholar] [CrossRef]

- Luo, D.; Xu, G.; Luo, J.; Cui, X.; Shang, S.; Qian, H. Integrated Carbon Footprint and Economic Performance of Five Types of Dominant Cropping Systems in China’s Semiarid Zone. Sustainability 2022, 14, 5844. [Google Scholar] [CrossRef]

- Gong, H.; Li, J.; Sun, M.; Xu, X.; Ouyan, Z. Lowering carbon footprint of wheat-maize cropping system in North China Plain: Through microbial fertilizer application with adaptive tillage. J. Clean. Prod. 2020, 268, 122255. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhong, Y.; Yang, J.; Wu, Y.; Li, H.; Zheng, L. Effect of nitrogen fertilizer rates on carbon footprint and ecosystem service of carbon sequestration in rice production. Sci. Total Environ. 2019, 670, 210–217. [Google Scholar] [CrossRef]

- Ma, B.L.; Liang, B.C.; Biswas, D.K.; Morrison, M.J.; McLaughlin, N.B. The carbon footprint of maize production as affected by nitrogen fertilizer and maize-legume rotations. Nutr. Cycl. Agroecosyst. 2012, 94, 15–31. [Google Scholar] [CrossRef]

- Liu, C.; Cutforth, H.; Chai, Q.; Gan, Y. Farming tactics to reduce the carbon footprint of crop cultivation in semiarid areas. A review. Agron. Sustain. Dev. 2016, 36, 1–16. [Google Scholar] [CrossRef]

- Adom, F.; Maes, A.; Workman, C.; Clayton-Nierderman, Z.; Thoma, G.; Shonnard, D. Regional carbon footprint analysis of dairy feeds for milk production in the USA. Int. J. Life Cycle Assess. 2012, 17, 520–534. [Google Scholar] [CrossRef]

- Nan, Q.; Wang, C.; Wang, H.; Yi, Q.Q.; Wu, W.X. Mitigating methane emission via annual biochar amendment pyrolyzed with rice straw from the same paddy field. Sci. Total Environ. 2020, 746, 141351. [Google Scholar] [CrossRef]

- Recio, J.; Montoya, M.; Gin´es, C.; Sanz-Cobena, A.; Vallejo, A.; Alvarez, J.M. Joint mitigation of NH3 and N2O emissions by using two synthetic inhibitors in an irrigated cropping soil. Geoderma 2020, 373, 114423. [Google Scholar] [CrossRef]

- Chen, X.; Xu, X.; Lu, Z.; Zhang, W.; Yang, J.; Hou, Y.; Wang, X.; Zhou, S.; Li, Y.; Wu, L.; et al. Carbon footprint of a typical pomelo production region in China based on farm survey data. J. Clean. Prod. 2020, 277, 124041. [Google Scholar] [CrossRef]

- Kumar, A.; Rana, K.S.; Choudhary, A.K.; Bana, R.S.; Sharma, V.K.; Prasad, S.; Gupta, G.; Choudhary, M.; Pradhan, A.; Rajpoot, S.K.; et al. Energy budgeting and carbon footprints of zero-tilled pigeonpea—Wheat cropping system under sole or dual crop basis residue mulching and Zn-fertilization in a semi-arid agro-ecology. Energy 2021, 231, 120862. [Google Scholar] [CrossRef]

- Vourdoubas, J. Energy and agri-food systems: Production and consumption. In Zero Waste in the Mediterranean; International Centre for Advanced Mediterranean Agronomic Studies (CIHEAM)/Food and Agriculture Organization of the United Nations (FAO); Presses de Sciences Po: Paris, France, 2016; p. 155. [Google Scholar]

- Povilaitis, V.; Slepetiene, A.; Slepetys, J.; Lazauskas, S.; Tilvikiene, V.; Amaleviciute, K.; Feiziene, D.; Feiza, V.; Liaudanskiene, I.; Ceseviciene, J.; et al. The productivity and energy potential of alfalfa, fodder galega and maize plants under the conditions of the nemoral zone. Acta Agric. Scand. Sect. B Soil Plant Sci. 2016, 66, 259–266. [Google Scholar] [CrossRef]

- Budzynski, W.; Szemplinski, W.; Parzonka, A.; Sałek, T. Agricultural productivity, energy efficiency and costs associated with growing selected energy crops for biogas production. In Production and Processing of Agricultural and Aquatic Biomass for Biogas Plants and Gasification Units; Gołaszewski, J., Ed.; University Warmia and Mazury in Olsztyn: Olsztyn, Poland, 2014; pp. 11–282. [Google Scholar]

- Rautaray, S.K.; Mishra, A.; Verma, O.P. Energy efficiency, productivity and profitability of rice (Oryza sativa L.) based cropping systems for selected conservation practices. Arch. Agron. Soil Sci. 2017, 63, 1993–2006. [Google Scholar] [CrossRef]

- Alluvione, F.; Moretti, B.; Sacco, D.; Grignani, C. EUE (energy use efficiency) of cropping systems for a sustainable agriculture. Energy 2011, 36, 4468–4481. [Google Scholar] [CrossRef]

- Pandey, M. Effect of integrated nutrient management on yield, quality and uptake of nutrients in oat (Avena sativa) in alluvial soil. Ann. Plant Soil Res. 2018, 20, 1–6. [Google Scholar]

- Baba, S.H.; Wani, M.H.; Shaheen, F.A.; Zargar, B.A.; Kubrevi, S.S. Scarcity of Agricultural Labour in Cold-Arid Ladakh: Extent, Implications, Backward Bending and Coping Mechanism. Agric. Econ. Res. Rev. 2011, 24, 391–400. [Google Scholar]

- Singh, R.J.; Ahlawat, I.P.S. Energy budgeting and carbon footprint of transgenic cotton-wheat production system through peanut intercropping and FYM addition. Environ. Monit. Assess. 2015, 187, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Parajuli, R.; Knudsen, M.T.; Djomo, S.N.; Corona, A.; Birkved, M.; Dalgaard, T. Environmental life cycle assessment of producing willow, alfalfa and straw from spring barley as feedstocks for bioenergy or biorefinery systems. Sci. Total Environ. 2017, 586, 226–240. [Google Scholar] [CrossRef] [PubMed]

- Woods, J.; Williams, A.; Hughes, J.K.; Black, M.; Murphy, R. Energy and the food system. Phil. Trans. R. Soc. B 2010, 365, 2991–3006. [Google Scholar] [CrossRef] [PubMed]

- Golaszewski, J.; De Visser, C.; Brodzinski, Z.; Myhan, R.; Olba-Ziety, E.; Stolarski, M.; Buisonjé, F.; Ellen, H.; Stanghellini, C.; Van der Voort, M.; et al. State of the art on Energy Efficiency in Agriculture. Country data on energy consumption in different agro-production sectors in the European countries. Energy Effic. 2012, 1–68. [Google Scholar]

- Chel, A.; Kaushik, G. Renewable energy for sustainable agriculture. Agronomy for Sustainable Development. Agron. Sustain. Dev. 2011, 31, 91–118. [Google Scholar] [CrossRef]

- Li, J.; Cui, J.; Sui, P.; Yue, S.; Yang, J.; Ziqing, L.; Wang, D.; Chen, X.; Sun, B.; Ran, M.; et al. Valuing the synergy in the water-energy-food nexus for cropping systems: A case in the North China Plain. Ecol. Indic. 2021, 127, 107741. [Google Scholar] [CrossRef]

- Moreno, M.M.; Lacasta, C.; Meco, R.; Moreno, C. Rainfed crop energy balance of different farming systems and crop rotations in a semi-arid environment: Results of a long-term trial. Soil Tillage Res. 2011, 114, 18–27. [Google Scholar] [CrossRef]

- Zarini, R.L.; Loghmanpour, M.H.; Ramezani, M.A.; Afrouzi, H.N.; Tabatabaekoloor, R. Relationship between energy consumption and egg production in poultry in Iran. Biol. Forum Int. J. 2015, 7, 296–299. [Google Scholar]

- Manoj, K.N.; Shekara, B.G.; Sridhara, S.; Jha, P.K.; Prasad, P.V.V. Biomass Quantity and Quality from Different Year-Round Cereal–Legume Cropping Systems as Forage or Fodder for Livestock. Sustainability 2021, 13, 9414. [Google Scholar] [CrossRef]

- Sridhara, S.; Gopakkali, P.; Manoj, K.N.; Patil, K.K.R.; Paramesh, V.; Jha, P.K.; Prasad, P.V.V. Identification of Sustainable Development Priorities for Agriculture through Sustainable Livelihood Security Indicators for Karnataka, India. Sustainability 2022, 14, 1831. [Google Scholar] [CrossRef]

| Parameter | Values Recorded | |

|---|---|---|

| Soil type | Red sandy loam | |

| pH | 7.45 | |

| Electrical conductivity (EC) | 0.38 ds m−1 | |

| Organic carbon | 5.5 g kg−1 | |

| Available Nitrogen | 118.5 mg kg−1 | |

| Available Phosphorus | 22 mg kg−1 | |

| Available Potassium | 72.5 mg kg−1 | |

| Prevailed weather conditions | ||

| During 2018–2019 | During 2019–2020 | |

| Rainfall | 520.7 mm | 912.7 mm |

| Temperature | ||

| Maximum | 35.5 °C (May) | 36 °C (June) |

| Minimum | 17 °C (January) | 16.3 °C (December) |

| Relative humidity | ||

| Maximum | 95% (August) | 92% (October) |

| Minimum | 53% (May) | 35% (March) |

| Treatments | System Type | Treatment Details | Variety/Hybrid | Spacing |

|---|---|---|---|---|

| T1 | Annual monocropping | Maize–Maize–Maize | African Tall | 30 × 10 cm |

| T2 | Sorghum–Sorghum–Sorghum | Sudex Chari-1 | ||

| T3 | Oat–Oat–Oat | OS-6 | ||

| T4 | Pearl millet–Pearl millet–Pearl millet | BAIF bajra-1 | ||

| T5 | Cowpea–Cowpea–Cowpea | MFC-09-1 | ||

| T6 | Perennial monocropping | Bajra–Napier hybrid | BNH-10 | 90 × 60 cm |

| T7 | Lucerne | RL-88 | 30 × 10 cm | |

| T8 | Desmanthus | Co-1 | ||

| T9 | Sesbania | Local | ||

| T10 | Annual cereal + legume intercropping (3:1 row proportion) | Maize + Cowpea–Oat + Cowpea–Pearl millet + Cowpea | - | 30 × 10 cm |

| T11 | Sorghum + Cowpea–Maize + Cowpea–Pearl millet + Cowpea | - | ||

| T12 | Perennial cereal + legume intercropping (2:8 row proportion) | Bajra–Napier hybrid + Cowpea | - | Main crop-90 × 45 cm, intercrop-30 × 10 cm |

| T13 | Bajra–Napier hybrid + Lucerne | - | ||

| T14 | Bajra–Napier hybrid + Desmanthus | - | ||

| T15 | Bajra–Napier hybrid + Sesbania | - |

| Input Source | Emission Factor | Reference |

|---|---|---|

| Fertilizers | Nitrogen: 1.74 t-CE t−1 N fertilizer Phosphorus: 0.2 t-CE t−1 P fertilizer Potash: 0.15 t-CE t−1 K fertilizer | [39,40] |

| N fertilizer induced N2O | 1.28 t-CE t−1 N fertilizer | [41] |

| Farmyard Manure (FYM) | 0.007 × 103 t-CE t−1 FYM | [33] |

| Pesticides | 6.3 × 10−3 t-CE t−1 herbicide 5.1 × 10−3 t-CE t−1 insecticide 3.9 × 10−3 t-CE t−1 fungicide | |

| Electricity | 7.25 × 10−5 t-CE kWh−1 energy | |

| Diesel | 7.17 × 10−4 t-CE L−1 diesel | [34] |

| Input | Unit | Equivalent Energy (MJ Unit−1) | Reference |

|---|---|---|---|

| Labor | |||

| Hour | 1.96 | [45] |

| Hour | 1.57 | [45] |

| Diesel fuel | Liter | 56.31 | [46] |

| Machinery | Hour | 62.7 | [47] |

| Chemicals | Kilogram | 120 | [4] |

| Chemicals | Liter | 102 | [4] |

| Fertilizers | Kilogram | ||

| 66.14 | [48] | |

| 12.44 | [48] | |

| 11.15 | [48] | |

| 120 | [49] | |

| Farmyard manure | Kilogram | 0.3 | [50] |

| Irrigation | Cubic meter | 1.02 | [21] |

| Electricity | Kilowatt hour | 3.6 | [51] |

| Seeds | Kilogram | 15.7 | [51] |

| Output | |||

| Green fodder yield | Kilogram | 2.30 | [52] |

| Treatments | GFY (kg ha−1 Year−1) | Carbon Input (kg-CE ha−1 Year−1) * | Carbon Output (kg-CE ha−1 Year−1) | CSI | CER | Carbon Efficiency (kg kg-CE−1) |

|---|---|---|---|---|---|---|

| T1 | 104,658 fgh | 1419.5 | 50,236 fgh | 34.4 g | 35.4 g | 73.7 g |

| T2 | 90,650 ghi | 1010.3 | 43,512 ghi | 42.1 g | 43.1 g | 89.7 g |

| T3 | 82,658 i | 1247.5 | 39,676 i | 30.8 g | 31.8 g | 66.3 g |

| T4 | 85,358 hi | 1247.5 | 40,972 hi | 31.8 g | 32.8 g | 68.4 g |

| T5 | 77,817 i | 511.1 | 37,352 i | 72.1 f | 73.1 f | 152.2 f |

| T6 | 126,150 cde | 760.7 | 60,552 cde | 78.6 ef | 79.6 ef | 165.8 ef |

| T7 | 95,217 fghi | 274.0 | 45,704 fghi | 165.8 a | 166.8 a | 347.5 a |

| T8 | 79,608 i | 400.9 | 38,212 i | 94.3 cde | 95.3 cde | 198.6 cde |

| T9 | 95,992 fghi | 397.7 | 46,076 fghi | 114.9 b | 115.9 b | 241.4 b |

| T10 | 110,268 efg | 1412.9 | 52,928 efg | 36.5 g | 37.5 g | 78.0 g |

| T11 | 115,325 def | 1380.7 | 55,356 def | 39.1 g | 40.1 g | 83.5 g |

| T12 | 155,222 ab | 763.9 | 74,507 ab | 96.5 cd | 97.5 cd | 203.2 cd |

| T13 | 163,628 a | 763.9 | 78,542 a | 101.8 bc | 102.8 bc | 214.2 bc |

| T14 | 131,059 cd | 763.9 | 62,908 cd | 81.3 def | 82.3 def | 171.6 def |

| T15 | 144,002 bc | 763.9 | 69,121 bc | 89.5 cde | 90.5 cde | 188.5 cde |

| Treatments | Energy Input * (MJ ha−1 Year−1) | Energy Output (MJ ha−1 Year−1) | Energy Use Efficiency | Energy Productivity (kg MJ−1) | Specific Productivity (MJ kg−1) | Net Energy (MJ ha−1 Year−1) | Energy Profitability |

|---|---|---|---|---|---|---|---|

| T1 | 52,466 | 240,714 fgh | 4.6 f | 2.0 f | 0.5 ab | 1,882,481 def | 3.61 f |

| T2 | 38,606 | 208,495 ghi | 5.4 ef | 2.3 ef | 0.43 bc | 1,698,891 def | 4.41 ef |

| T3 | 46,550 | 190,114 i | 4.1 f | 1.8 f | 0.57 a | 1,435,641 f | 3.11 f |

| T4 | 42,912 | 196,324 hi | 4.6 f | 2 f | 0.5 ab | 1,534,121 f | 3.61 f |

| T5 | 26,230 | 178,978 i | 6.8 e | 3.0 e | 0.36 c | 1,527481 f | 5.81 e |

| T6 | 29,030 | 290,145 cde | 10.0 cd | 4.3 cd | 0.23 d | 2,611,151 c | 9.01 cd |

| T7 | 16,106 | 218,998 fghi | 13.6 a | 5.9 a | 0.17 d | 2,028,931 de | 12.61 a |

| T8 | 19,276 | 183,099 i | 9.5 d | 4.1 d | 0.24 d | 1,638,231 ef | 8.51 d |

| T9 | 19,466 | 220,781 fghi | 11.3 bc | 4.9 bc | 0.21 d | 2,013,141 de | 10.31 bc |

| T10 | 50,272 | 253,616 efg | 5.0 f | 2.2 f | 0.46 b | 2,033,431 de | 4.01 f |

| T11 | 48,935 | 265,247 def | 5.4 ef | 2.4 ef | 0.431 bc | 2,163,121 d | 4.41 ef |

| T12 | 29,200 | 357,011 ab | 12.2 ab | 5.3 ab | 0.191 d | 3,278,111 ab | 11.21 ab |

| T13 | 28,384 | 376,345 a | 13.3 a | 5.8 a | 0.171 d | 3,479,611 a | 12.31 a |

| T14 | 28,408 | 301,435 cd | 10.6 bcd | 4.6 bcd | 0.221 d | 2,730,271 c | 9.61 bcd |

| T15 | 28,552 | 331,204 bc | 11.6 bc | 5.0 bc | 0.201 d | 3,026,521 bc | 10.61 bc |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manoj, K.N.; Shekara, B.G.; Sridhara, S.; Mudalagiriyappa; Chikkarugi, N.M.; Gopakkali, P.; Jha, P.K.; Vara Prasad, P.V. Carbon Footprint Assessment and Energy Budgeting of Different Annual and Perennial Forage Cropping Systems: A Study from the Semi-Arid Region of Karnataka, India. Agronomy 2022, 12, 1783. https://doi.org/10.3390/agronomy12081783

Manoj KN, Shekara BG, Sridhara S, Mudalagiriyappa, Chikkarugi NM, Gopakkali P, Jha PK, Vara Prasad PV. Carbon Footprint Assessment and Energy Budgeting of Different Annual and Perennial Forage Cropping Systems: A Study from the Semi-Arid Region of Karnataka, India. Agronomy. 2022; 12(8):1783. https://doi.org/10.3390/agronomy12081783

Chicago/Turabian StyleManoj, Konapura Nagaraja, Bommalapura Gundanaik Shekara, Shankarappa Sridhara, Mudalagiriyappa, Nagesh Malasiddappa Chikkarugi, Pradeep Gopakkali, Prakash Kumar Jha, and P. V. Vara Prasad. 2022. "Carbon Footprint Assessment and Energy Budgeting of Different Annual and Perennial Forage Cropping Systems: A Study from the Semi-Arid Region of Karnataka, India" Agronomy 12, no. 8: 1783. https://doi.org/10.3390/agronomy12081783

APA StyleManoj, K. N., Shekara, B. G., Sridhara, S., Mudalagiriyappa, Chikkarugi, N. M., Gopakkali, P., Jha, P. K., & Vara Prasad, P. V. (2022). Carbon Footprint Assessment and Energy Budgeting of Different Annual and Perennial Forage Cropping Systems: A Study from the Semi-Arid Region of Karnataka, India. Agronomy, 12(8), 1783. https://doi.org/10.3390/agronomy12081783