The Effect of Transplant Date and Plant Spacing on Biomass Production for Floral Hemp (Cannabis sativa L.)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Experimental Design

2.3. Data and Sample Collection

2.4. Statistical Analysis

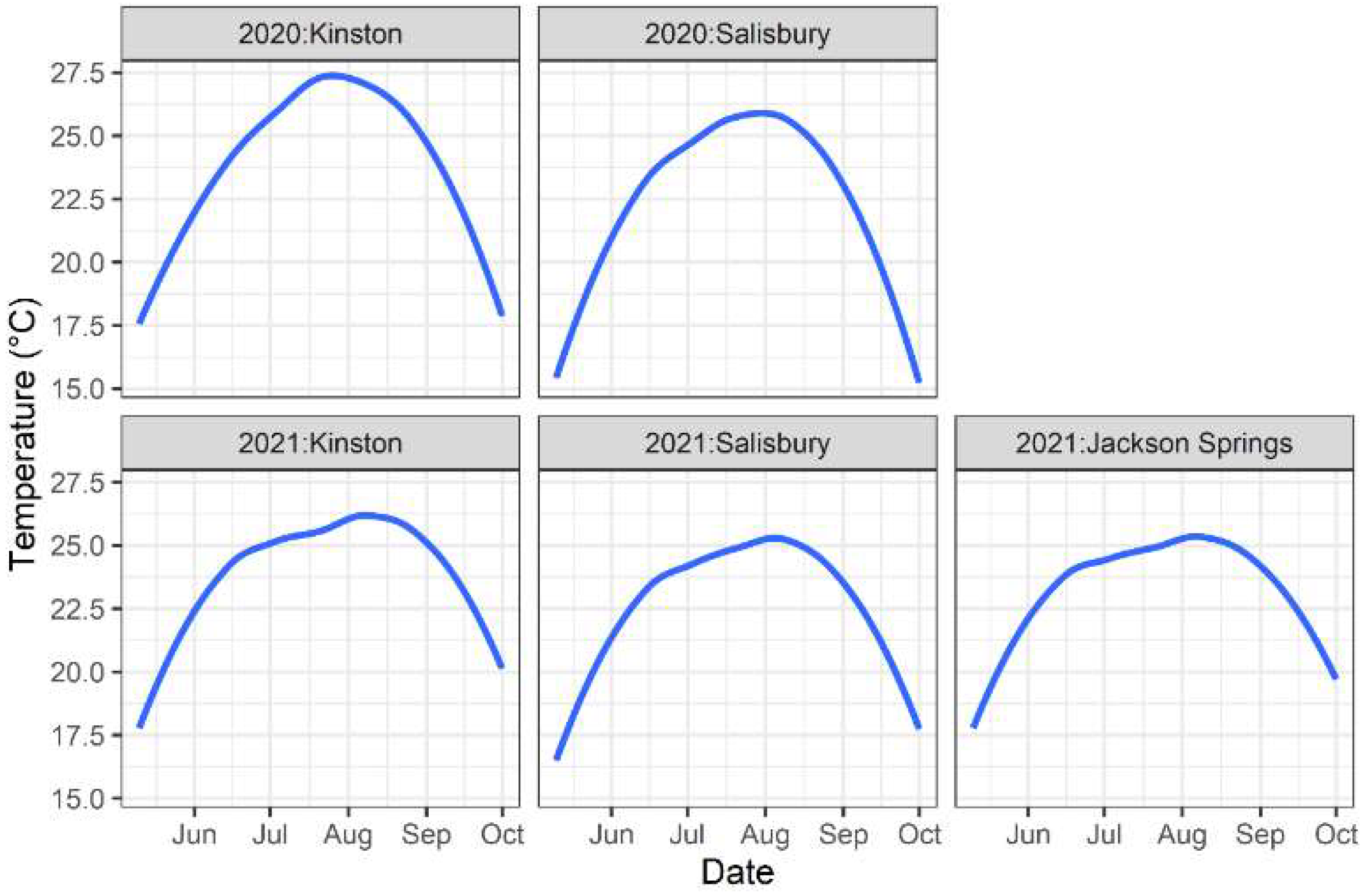

3. Results and Discussion

3.1. Transplant Date Affecting Plant Height

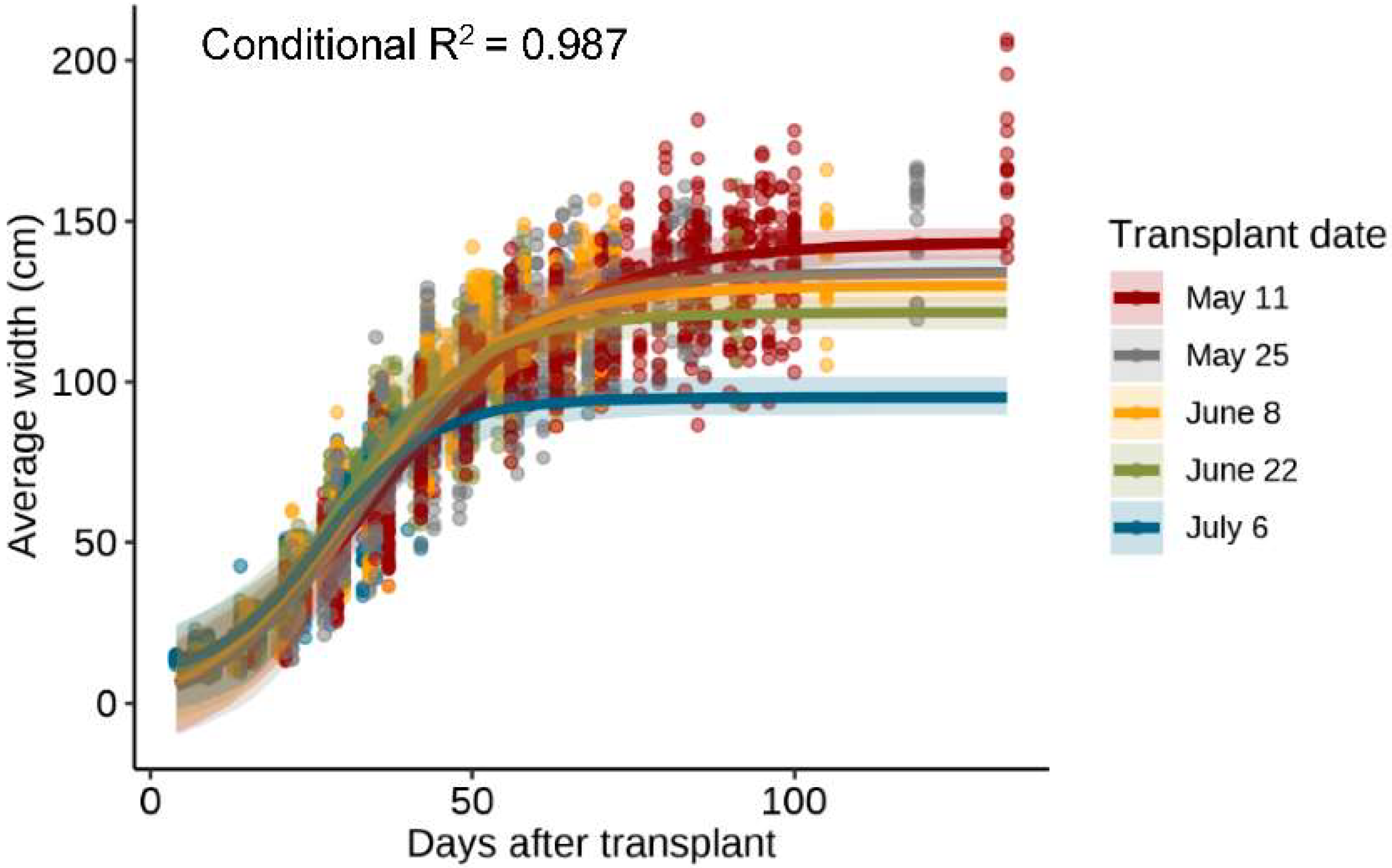

3.2. Transplant Date Affecting Plant Width

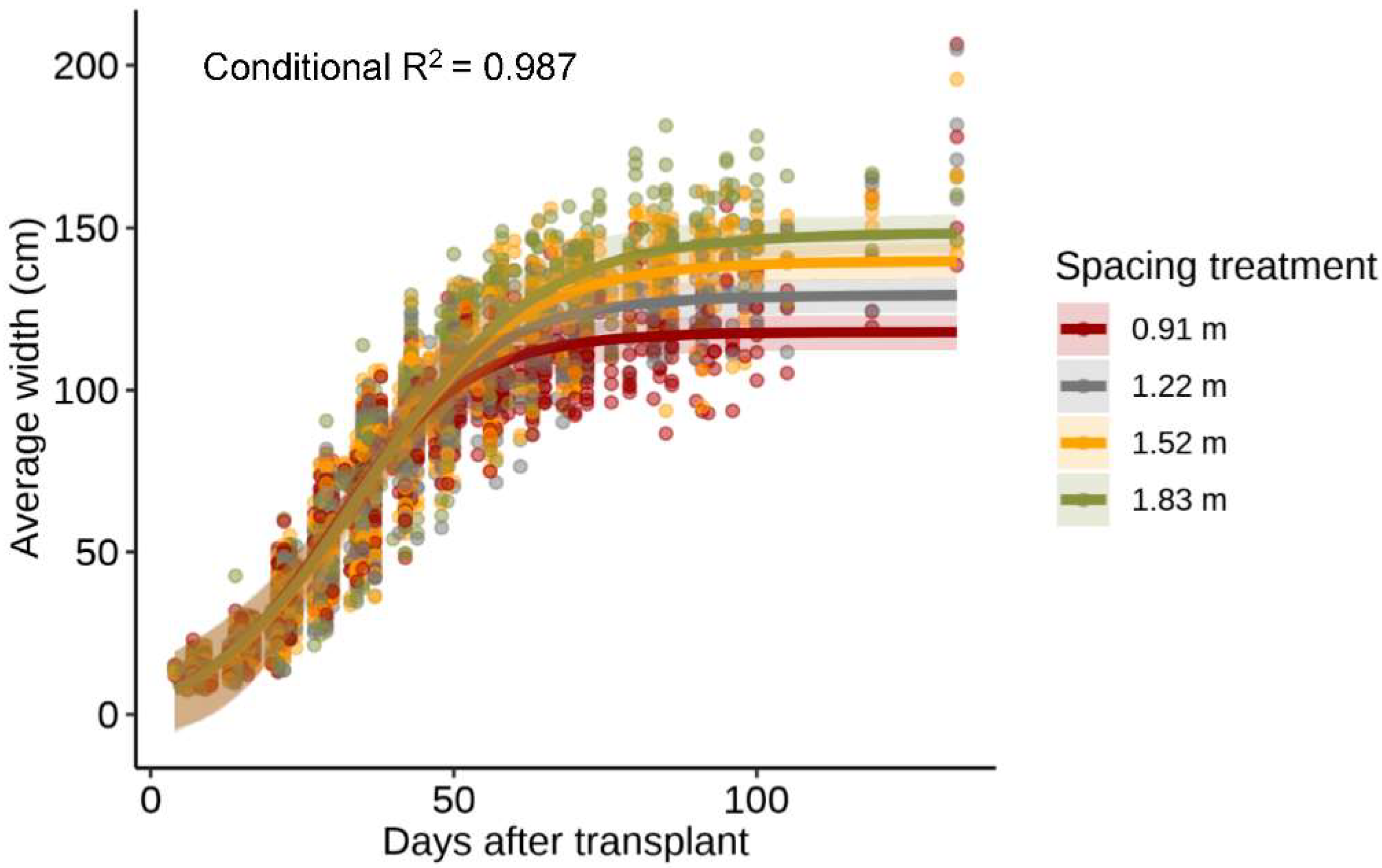

3.3. Plant Spacing Affecting Plant Width

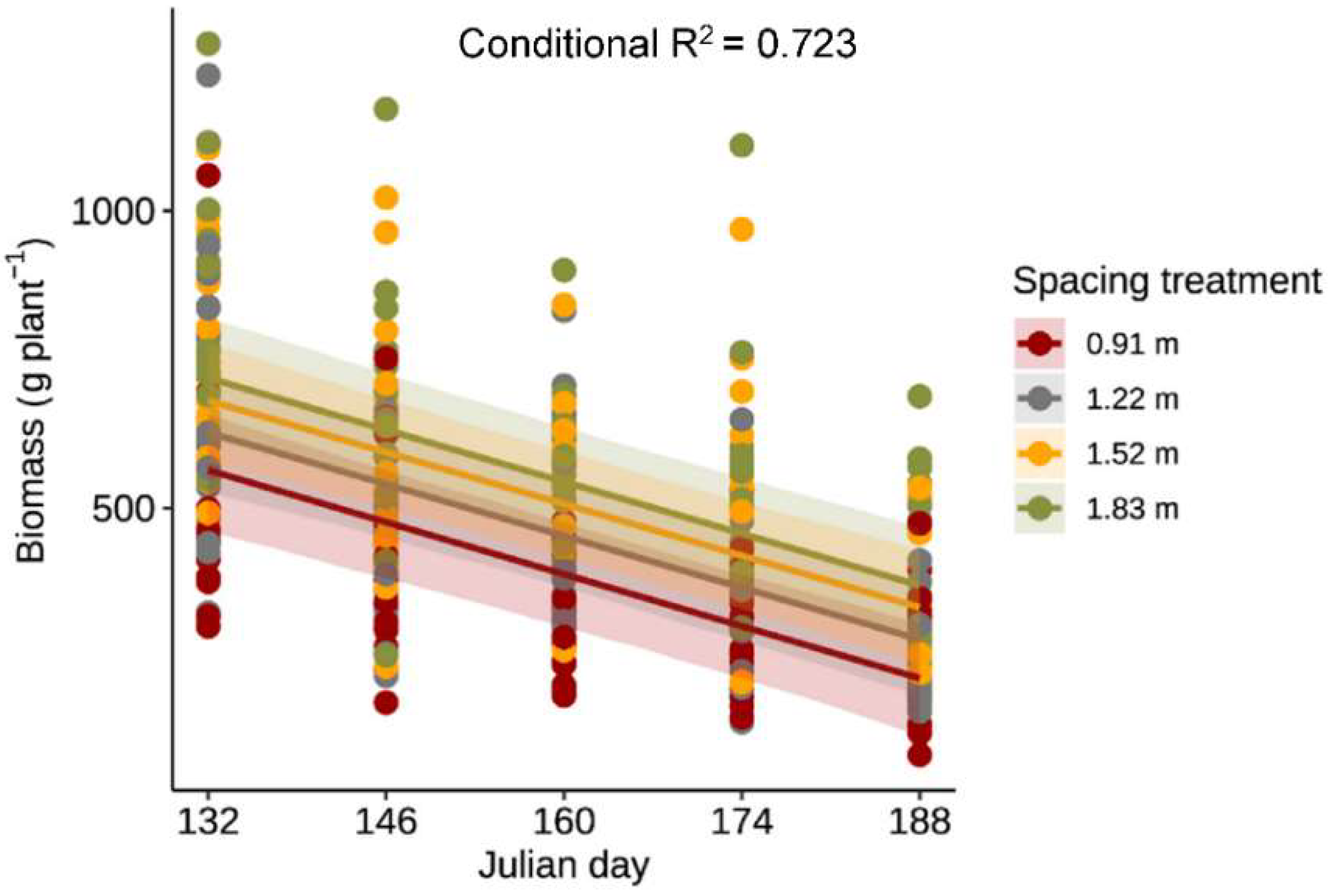

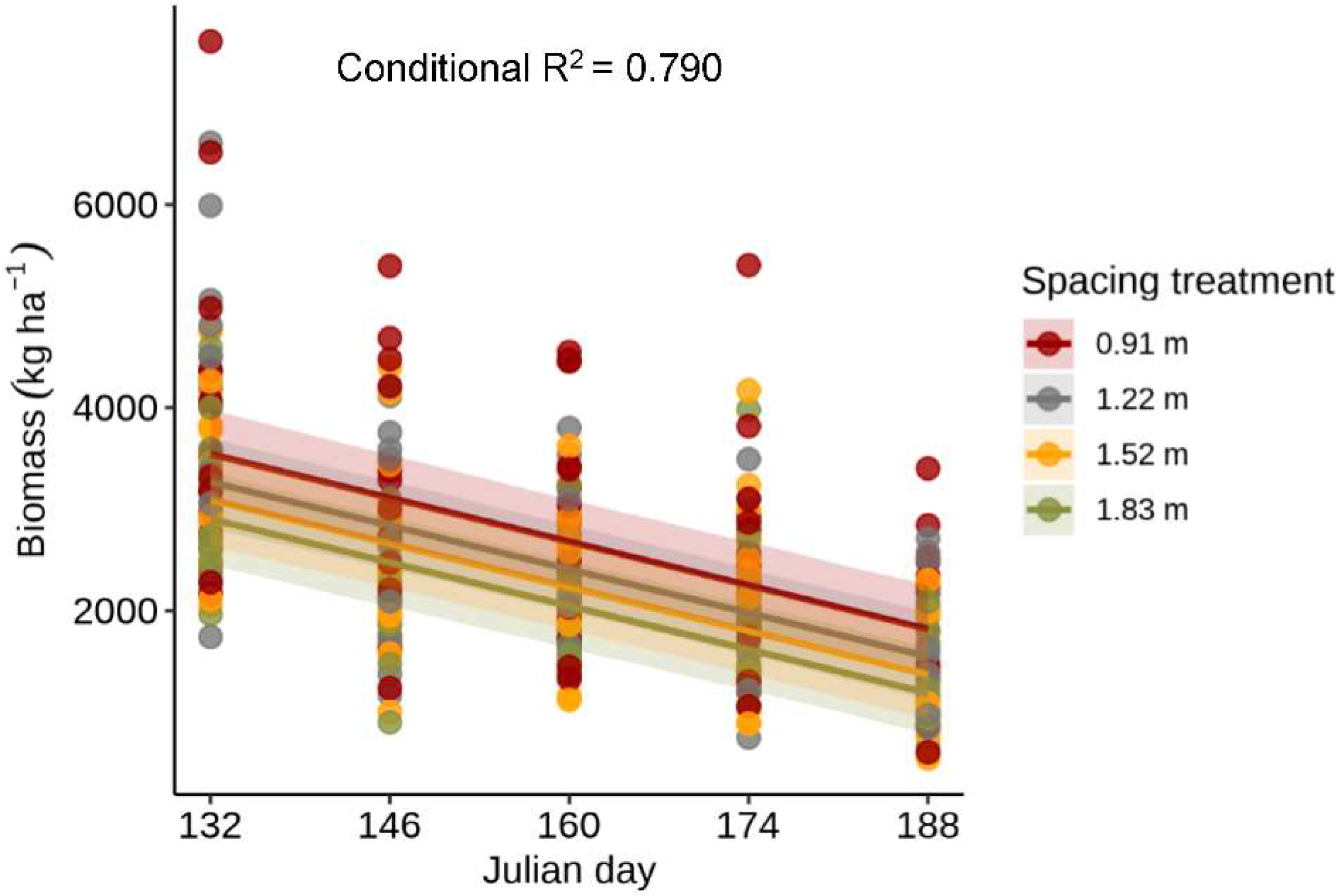

3.4. Biomass Affected by Transplant Date and Plant Spacing

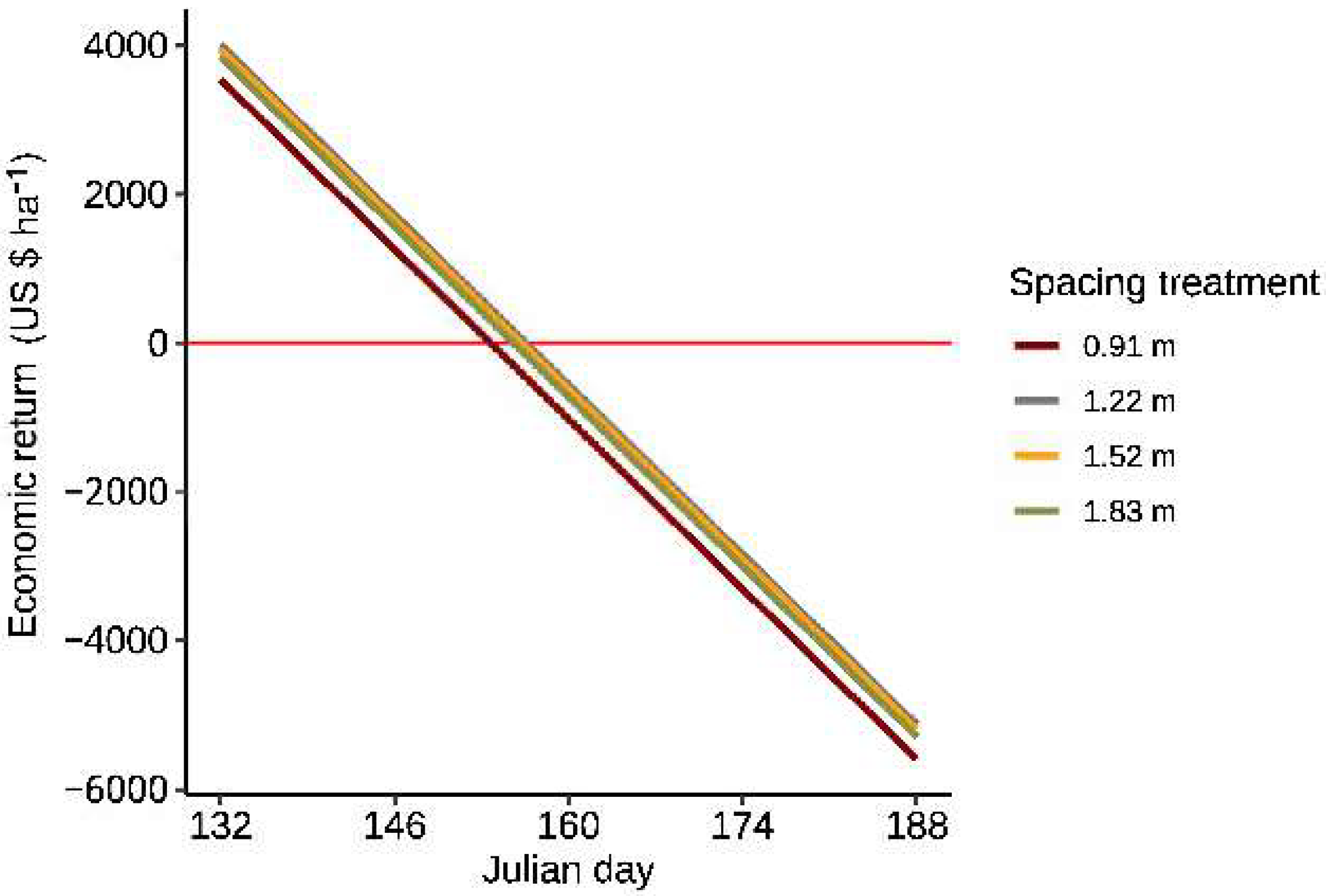

3.5. Economic Return

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hall, J.; Bhattarai, S.P.; Midmore, D.J. Review of flowering control in industrial hemp. J. Nat. Fibers 2012, 9, 23–36. [Google Scholar] [CrossRef]

- Abrams, D.I. The therapeutic effects of cannabis and cannabinoids: An update from the national academies of sciences, engineering and medicine report. Eur. J. Intern. Med. 2018, 49, 7–11. [Google Scholar] [CrossRef] [PubMed]

- Levinsohn, E.A.; Hill, K.P. Clinical uses of cannabis and cannabinoids in the United States. J. Neurol. Sci. 2020, 411, 116717. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Burgel, L.; Hartung, J.; Pflugfelder, A.; Graeff-Hönninger, S. Impact of growth stage and biomass fractions on cannabinoid content and yield of different hemp (Cannabis sativa L.) genotypes. Agronomy 2020, 10, 372. [Google Scholar] [CrossRef] [Green Version]

- Campbell, B.J.; Berrada, A.F.; Hudalla, C.; Amaducci, S.; McKay, J.K. Genotype × environment interactions of industrial hemp cultivars highlight diverse responses to environmental factors. AGE 2019, 2, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Toth, J.A.; Smart, L.B.; Smart, C.D.; Stack, G.M.; Carlson, C.H.; Philippe, G.; Rose, J.K.C. Limited effect of environmental stress on cannabinoid profiles in high-cannabidiol hemp (Cannabis sativa L.). Glob. Chang. Biol. Bioenergy 2021, 13, 1666–1674. [Google Scholar] [CrossRef]

- Yang, R.; Berthold, E.C.; Mccurdy, C.R.; Da Silva Benevenute, S.; Brym, Z.T.; Freeman, J.H. Development of Cannabinoids in Flowers of Industrial Hemp (Cannabis sativa L.): A Pilot Study. J. Agric. Food Chem. 2020, 68, 6058–6064. [Google Scholar] [CrossRef]

- Zirpel, B.; Kayser, O.; Stehle, F. Elucidation of structure-function relationship of THCA and CBDA synthase from Cannabis sativa L. J. Biotechnol. 2018, 284, 17–26. [Google Scholar] [CrossRef]

- Sengloung, T.; Kaveeta, L.; Müssig, J. Physical Properties of Traditional Thai Hemp Fiber (Cannabis sativa L.). J. Ind. Hemp 2008, 13, 20–36. [Google Scholar] [CrossRef]

- Satapathy, S.M.; Srivastava, V.K.; Majhi, P.K.; Gond, S. Effect of Delayed Time of Planting on Grain Yield and Agro-morphological Traits of Elite Rice (Oryza sativa L.) Varieties. Int. J. Plant Soil Sci. 2021, 33, 68–79. [Google Scholar] [CrossRef]

- Amaducci, S.; Errani, M.; Venturi, G. Plant population effects on fibre hemp morphology and production. J. Ind. Hemp 2002, 7, 33–60. [Google Scholar] [CrossRef]

- Tang, K.; Struik, P.C.; Yin, X.; Calzolari, D.; Musio, S.; Thouminot, C.; Bjelková, M.; Stramkale, V.; Magagnini, G.; Amaducci, S. A comprehensive study of planting density and nitrogen fertilization effect on dual-purpose hemp (Cannabis sativa L.) cultivation. Ind. Crops Prod. 2017, 107, 427–438. [Google Scholar] [CrossRef]

- da Silva Benevenute, S.; Freeman, J.H.; Yang, R. How do pinching and plant density affect industrial hemp produced for cannabinoids in open field conditions? J. Agron. 2021, 114, 618–626. [Google Scholar] [CrossRef]

- Carlson, C.H.; Stack, G.M.; Jiang, Y.; Taskrian, B.; Cala, A.R.; Toth, J.A.; Philippe, G.; Rose, J.K.C.; Smart, C.D.; Smart, L.B. Morphometric relationships and their contribution to biomass and cannabinoid yield in hybrids of hemp (Cannabis sativa). J. Exp. Bot. 2021, 72, 7694–7709. [Google Scholar] [CrossRef] [PubMed]

- Miguez, F. NLRAA: Nonlinear Regression for Agricultural Applications. R Package Version 0.98. 2021. Available online: https://cran.r-project.org/web/packages/nlraa/nlraa.pdf (accessed on 13 May 2022).

- Pinheiro, J.; Bates, D.; DebRoy, S.; Sarkar, D.; R Core Team. NLME: Linear and Nonlinear Mixed Effects Models. R Package Version 3.1-153. 2021. Available online: https://cran.r-project.org/web/packages/nlme/nlme.pdf (accessed on 13 May 2022).

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2018; Available online: https://www.R-project.org/ (accessed on 14 July 2022).

- Archontoulis, S.V.; Miguez, F.E. Nonlinear regression models and applications in agricultural research. J. Agron. 2015, 107, 786–798. [Google Scholar] [CrossRef] [Green Version]

- Pinheiro, J.C.; Bates, D.M. Mixed-Effects Models in S and S-PLUS; Springer: New York, NY, USA, 2000. [Google Scholar]

- Lenth, R.V.; Buerkner, P.; Herve, M.; Love, J.; Miguez, F.; Riebl, H.; Singmann, H. EMMEANS: Estimated Marginal Means, Aka Least-Square Means. R Package Version 1.7.2. 2022. Available online: https://cran.r-project.org/web/packages/emmeans/index.html (accessed on 13 May 2022).

- Mark, T.; Shepherd, J. Industrial Hemp Budgets 2021. University of Kentucky. Available online: https://hemp.ca.uky.edu/sites/hemp.ca.uky.edu/files/hemp_budgets_2021.xlsx (accessed on 14 July 2022).

- Hemp Benchmarks. Monthly Biomass and Refined Hemp Oil Assessed Prices. 2022. Available online: https://hemp.ca.uky.edu/sites/hemp.ca.uky.edu/files/hemp_budgets_2021.xlsx (accessed on 30 May 2022).

- Darby, H.M.; Gupta, A.; Bruce, J.; Zieglar, S. Cannabidiol Hemp Plant Spacing x Planting Date Trial. Northwest Crops Soils Program 2018, 322. Available online: https://scholarworks.uvm.edu/cgi/viewcontent.cgi?article=1321&context=nwcsp (accessed on 14 July 2022).

- Chandra, S.; Lata, H.; Khan, I.A.; ElSohly, M.A. Temperature response of photosynthesis in different drug and fiber varieties of Cannabis sativa L. Physiol. Mol. Biol. Plants. 2011, 17, 297–303. [Google Scholar] [CrossRef] [Green Version]

- Van der Werf, H.M.G.; van Geel, W.C.A.; van Gils, L.J.C.; Haverkort, A.J. Nitrogen fertilization and row width affect self-thinning and productivity of fibre hemp (Cannabis sativa L.). Field Crops Res. 1995, 42, 27–37. [Google Scholar] [CrossRef]

- Anderson, S.L.; Pearson, B.; Kjelgren, R.; Brym, Z. Response of essential oil hemp (cannabis sativa L.) growth, biomass, and cannabinoid profiles to varying fertigation rates. PLoS ONE 2021, 16, e0252985. [Google Scholar] [CrossRef]

- Bashir, M.; Akbar, N.; Iqbal, A.; Zaman, H. Effect of different sowing dates on yield and yield components of direct seeded coarse rice (Oryza sativa L). Pak. J. Agric. Sci. 2010, 47, 361–365. [Google Scholar]

- Caplan, D.; Dixon, M.; Zheng, Y. Optimal rate of organic fertilizer during the vegetative-stage for cannabis grown in two coir-based substrates. HortScience 2017, 52, 1307–1312. [Google Scholar] [CrossRef] [Green Version]

- Short, M.M. Establishing Nitrogen and Potassium Fertility Recommendations for Floral Hemp Production. NC State University Electronic Thesis & Dissertation. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2021. Available online: https://www.lib.ncsu.edu/resolver/1840.20/39177 (accessed on 14 July 2022).

- Mark, T.; Shepherd, J.; Olson, D.; Snell, W.; Proper, S.; Thornsbury, S. Economic Viability of Industrial Hemp in the United States: A Review of State Pilot Programs. United States Department of Agriculture. 2020. Available online: https://www.ers.usda.gov/webdocs/publications/95930/eib-217.pdf (accessed on 14 July 2022).

| Response | Model | Goodness-of-Fit Criteria z | |

|---|---|---|---|

| AICc | BIC | ||

| Plant height | Logistic | 23,776.61 | 23,820.53 |

| Four-Parameter Logistic | 23,761.87 | 23,818.33 | |

| Gompertz | 24,498.32 | 24,542.24 | |

| Beta growth function | 25,340.37 | 25,384.29 | |

| Four-parameter beta growth function | 25,756.81 | 25,813.27 | |

| Plant width | Logistic | 26,629.02 | 26,672.68 |

| Four-Parameter Logistic | 26,298.21 | 26,341.87 | |

| Gompertz | 26,611.26 | 26,667.38 | |

| Beta growth function | NC y | NC | |

| Four-parameter beta growth function | 27,376.02 | 27,419.68 | |

| Parameter | ||||

|---|---|---|---|---|

| Transplant Date | A cm | B cm | c Days | m cm Day−1 |

| 11 May | −1.87 c z | 105.54 a | 38.23 a | 15.05 a |

| 25 May | 3.02 b | 100.63 b | 37.42 a | 11.20 b |

| 8 June | 2.36 b | 98.72 bc | 33.87 b | 10.88 b |

| 22 June | 3.25 b | 95.64 c | 30.59 c | 10.78 b |

| 6 July | 11.48 a | 80.98 d | 28.95 c | 9.15 c |

| p-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Parameter | ||||

|---|---|---|---|---|

| Transplant Date | A cm | B cm | C Days | M cm Day−1 |

| 11 May | −25.59 c z | 148.38 a | 36.20 a | 20.57 a |

| 25 May | −15.72 bc | 136.39 b | 35.59 a | 15.94 b |

| 8 June | −18.49 bc | 127.78 c | 28.76 b | 14.90 b |

| 22 June | −12.58 b | 124.99 c | 27.25 b | 14.07 b |

| 6 July | −0.10 a | 99.09 d | 26.84 b | 11.36 c |

| p-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Spacing m | Parameter | |||

|---|---|---|---|---|

| A cm | B cm | C Days | M cm Day−1 | |

| 0.91 | −14.83 | 118.94 c z | 29.22 b | 15.33 b |

| 1.22 | −17.68 | 133.09 b | 31.45 ab | 16.46 ab |

| 1.52 | −15.94 | 136.32 ab | 33.06 a | 16.65 ab |

| 1.83 | −18.17 | 142.38 a | 33.38 a | 17.49 a |

| p-value | NS | <0.0001 | <0.0001 | 0.0158 |

| Spacing | Intercept | Slope |

|---|---|---|

| (m) | g plant−1 | g plant−1 day−1 |

| 0.91 | 1389.00 c z | −6.38 |

| 1.22 | 1473.00 b | −6.38 |

| 1.52 | 1530.99 ab | −6.38 |

| 1.83 | 1585.71 a | −6.38 |

| Spacing | Intercept | Slope |

|---|---|---|

| (m) | kg ha−1 | kg ha−1 day−1 |

| 0.91 | 7727.8 a z | −31.98 |

| 1.22 | 7453.7 b | −31.98 |

| 1.52 | 7218.7 bc | −31.98 |

| 1.83 | 7049.04 c | −31.98 |

| Spacing | Intercept | Slope |

|---|---|---|

| (m) | US$ ha−1 | US$ ha−1 day−1 |

| 0.91 | 25,069.27 | −163.098 |

| 1.22 | 25,535.26 | −163.098 |

| 1.52 | 25,472.68 | −163.098 |

| 1.83 | 25,368.68 | −163.098 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Linder, E.R.; Young, S.; Li, X.; Henriquez Inoa, S.; Suchoff, D.H. The Effect of Transplant Date and Plant Spacing on Biomass Production for Floral Hemp (Cannabis sativa L.). Agronomy 2022, 12, 1856. https://doi.org/10.3390/agronomy12081856

Linder ER, Young S, Li X, Henriquez Inoa S, Suchoff DH. The Effect of Transplant Date and Plant Spacing on Biomass Production for Floral Hemp (Cannabis sativa L.). Agronomy. 2022; 12(8):1856. https://doi.org/10.3390/agronomy12081856

Chicago/Turabian StyleLinder, Eric R., Sierra Young, Xu Li, Shannon Henriquez Inoa, and David H Suchoff. 2022. "The Effect of Transplant Date and Plant Spacing on Biomass Production for Floral Hemp (Cannabis sativa L.)" Agronomy 12, no. 8: 1856. https://doi.org/10.3390/agronomy12081856

APA StyleLinder, E. R., Young, S., Li, X., Henriquez Inoa, S., & Suchoff, D. H. (2022). The Effect of Transplant Date and Plant Spacing on Biomass Production for Floral Hemp (Cannabis sativa L.). Agronomy, 12(8), 1856. https://doi.org/10.3390/agronomy12081856