1. Introduction

Loquat (

Eriobotrya japonica Lindl.), popular all over the world owing to the mild subacid, and sweet taste of its fruit, has been classified as a non-climacteric fruit with a very short postharvest life, with fruit decaying quickly after harvest, and losing titratable acidity, taste, and juiciness, and internal browning occurring rapidly during shelf life [

1]. Chilling injury, browning, and purple spots are major problems, and the fruits are susceptible to various postharvest diseases, especially from mechanical injury and fruit processing [

2].

Loquat cultivars show a wide diversity of fruit colors that is strictly related to the carotenoids content and distribution in fruit skin and flesh [

3]. In addition to vitamins and minerals, loquat fruit is rich in phenolics and carotenoids. The bioactive components of loquat fruit include flavonoids, triterpenic acids, and carotenoids and show remarkably high scavenging activity against chemically generated radicals, thus making it effective in inhibiting oxidation of human low-density lipoproteins [

2].

Loquat fruit suffer a quick senescence after harvest, and postharvest life is approximately 10 days in ambient conditions due to microbial decay, damage, and nutritional loss [

4]. During postharvest storage, loquat fruit is affected by lignification, juiciness loss, internal browning, and microbial decay, which cause quality degradation and reduce its commodity value [

4]. Several studies have reported that refrigeration has become one of the key postharvest factors and can combine with different treatments, as well as hot air application, modified atmosphere, chemical and natural compounds, packaging, and edible coating to extend loquat fruits’ postharvest life [

1,

3,

4,

5].

Edible coatings with semipermeable films can provide an alternative to a modified atmosphere—which is very expensive and not extensively used in commercial situations—by reducing cost, quality changes, and quantitative losses through the modification and control of the internal fruit atmosphere [

3].

In recent years, significant changes in human lifestyles have produced an increase in popularity of fresh-cut foods that are ready to eat, and the consumption of minimally processed fruit and vegetables has undergone a sharp increase.

Cutting operations remove fruit epicarp that normally protects the internal tissue from microbiological invasion while allowing juices to leak from the inner tissues on the fruit surface. These effects of cutting explain the reason why microbial growth is much greater on a minimally processed product as compared with the corresponding intact product, and for that reason large microbiological populations, including potentially high levels of human pathogens, may develop on the surface of cut produce [

6].

Among new postharvest management strategies of environment-friendly fresh fruit handling, the application of natural edible coatings has been reported to be very effective [

7]. Edible coatings can act as a semipermeable barrier against gases and water vapor; can modify fruit tissue metabolism by affecting respiration rate, decreasing moisture and firmness loss, preserving the color, transporting antimicrobial, antioxidant, and other preservatives, controlling microbial growth, and maintaining fruit quality for a longer period [

8].

A recent edible coating is the mucilage extracted from cladodes of

Opuntia ficus-indica, which has been effectively used as a coating material, particularly for highly perishable fruits, minimally processed products, and fresh cut or sliced ones [

7,

8,

9,

10,

11,

12,

13,

14].

Studies have reported that

O. ficus-indica edible coating positively affected fruit quality, reducing water transpiration and browning, maintaining fruit fresh weight, visual score values, fruit firmness, nutraceutical attributes, and controlling microbial growth, resulting in a longer storage period [

8].

O. ficus-indica mucilage is a complex carbohydrate mixture composed of variable amounts of L-arabinose, D-galactose, L-rhamnose, and D-xylose, as well as galacturonic acid and quite large amounts of polyphenols, which could produce natural edible coating with a high nutraceutical value, useful for fruit and food preservation [

7].

Despite several studies reporting the positive effect of edible coating when combined with low temperature and adequate humidity on handling and storage of loquat fruit, there is a lack of knowledge on the impact of coating treatments on the overall qualitative, sensorial, and nutraceutical value of minimally processed loquat fruits during cold storage. Few studies have reported results on postharvest performance of minimally processed loquat fruits [

15], and no information exists on shelf life behavior of minimally processed loquat fruit treated with edible coatings.

Therefore, the aim of the present study was to evaluate the effect of the application of O. ficus-indica mucilage as an edible coating on pomological, physiochemical, sensorial and nutraceutical parameters, and microbial growth of minimally processed white-flesh Martorana and orange-red-flesh Gigante Rossa loquat cultivars during cold storage at 5 ± 0.5 °C and 90% RH.

2. Materials and Methods

2.1. Loquat Fruit Samples

Loquat, Eriobotrya japonica Lindl, white-flesh (cv. Martorana—MRT) and orange-red-flesh (cv. Gigante Rossa—GR) fruits were harvested from commercial orchards located in Palermo (38°04′ N, 13°23′ E, 99–104 m a.s.l.). Loquat fruits were hand-picked at the ripe stage (light orange peel), suitable for the fresh fruit market and were quickly moved to the laboratory. Immediately after harvest, fruit quality parameters were analyzed using 30 fruits of each cultivar.

Loquat fruits were then washed under tap water, sanitized by immersion in 200 mg kg−1 of sodium hypochlorite for 5 min, and left to dry at room temperature (~25 °C). Afterwards, fruits were peeled manually in a refrigerated room at 9 ± 1 °C. Only peeled fruits with no external injuries were selected, and fruit processing operations were carried out in sanitary conditions at 15 °C.

2.2. Fresh Mucilage Extraction and Application

One-year-old cladodes were collected from four-year-old

O. ficus-indica (OFI) plants of the cultivar “Gialla”, located in the Department of Agricultural, Food and Forest Sciences, University of Palermo (38°7′4.0800″ N 13°22′11.2800″ E, 29 m a.s.l). Cladodes (one-year-old cladodes) were harvested for mucilage extraction and moved to the laboratory where they were processed for mucilage extraction, using a modified patented method of Du Toit and De Witt developed in South Africa [

8,

16].

Cladodes were washed with chlorinated water to improve mucilage shelf life and to remove impurities and spines. Cladodes chlorenchyma was removed with a peeler to obtain pure high-quality mucilage. Cladodes were then sliced into squares and cooked in a microwave oven (900 W) for 3–5 min, until soft. The cooked soft cladode pieces were then mixed using an Omni Mixer Homogenizer (mod. Omni-Mixer. 17,107, Dupont Instruments Sorvall, Texas City, TX, USA) to aid the mucilage extraction. The obtained pulp was then centrifuged using a Sigma centrifuge (mod. 6K15, Sigma Laborzentrifugen GmbH, Osterode am Harz, Germany) at 8117× g for 15 min at 4 °C, to separate the liquid mucilage from the solids. The mucilage was then decanted and weighed while the solid material left in the falcon tubes was discarded. No chemicals were used during this extraction process and as such, the extracted mucilage obtained was natural and unadulterated by chemicals. Work surface area and cutting tools were washed and sanitized with 200 mg kg−1 of sodium hypochlorite before and during fruit processing.

After cutting, loquat fruits were divided into two treatment groups for each cultivar (control: MRT and GR CTR and coated: MRT and GR OFI-EC). Each sampling group consisted in 5 replicates (3 fruits each) for each of 5 sampling dates, plus 25 replicates (3 fruits each) for sensory analysis and visual score (5 replicates for each sampling date) and 5 replicates (3 fruits each) for weight loss and respiration monitoring.

Loquat fruit OFI samples for each cultivar (MRT OFI-EC and GR OFI-EC) were treated with OFI mucilage, and loquat CTR samples (MRT CTR and GR CTR) were treated with distilled water and used as a control. Mucilage edible coating and distilled water were applied using an atomizing spray system (flow rate: 1 L h

−1; air pressure: 50 kPa) [

8,

17]. Soon after coating, all fruits were air-dried at room temperature for 15′ (~25 °C); then, coated and uncoated samples (OFI-EC and CTR), were placed in rigid polypropylene retail boxes 25 × 20 cm retail boxes (3 peeled loquat fruits to each box), sealed with 35 µm microperforated polypropylene film (O

2 permeability: ∼12,000 mL m

−2 d

−1 atm

−1; CO

2 permeability: ∼13,000 mL m

−2 d

−1 atm

−1 at 5 °C) and stored at 5 ± 0.5 °C and 95% RH for 13 days.

2.3. Quality Parameters: Firmness, Soluble Solid Content, Titratable Acidity, Color, and Weight Loss

The quality of white and orange-red-flesh minimally processed loquat fruits was assessed soon after coating (0 d) and at 3, 5, 7, 10, and 13 days of storage at 5 °C. For each sampling date and experimental treatment, five samples (3 fruits for each) of loquat fruits were randomly chosen and analyzed.

Fruit firmness was measured using a digital penetrometer (TR model 53,205, Turoni, Forlì, Italy) incorporating an 8 mm-diameter probe, after removal of a small piece of peel.

Average values were calculated from the results of 15 fruits’ measurements (2 measurements per fruit) for each treatment and cultivar at each sampling date.

Extractable juice was determined by the weight loss from tissue disks (after centrifuging for 10 min at 1500×

g at ambient temperature [

4]. The results of extractable juice were expressed as the percentage fresh weight loss of the tissue plugs after centrifugation.

After firmness determinations, fruit pulp was homogenized and used to measure total soluble solids (TSS) content and titratable acidity (TA). Total soluble solids content (TSS) was determined by a digital refractometer (Palette PR-32, Atago Co., Ltd., Tokyo, Japan); titratable acidity (TA) was measured by titration of 10 mL homogenized fruit flesh juice with 0.1 N NaOH to an endpoint of pH 8.1 and expressed as the percentage of citric acid (mod. S compact titrator, Crison Instruments, Barcelona, Spain).

Weight loss for each loquat fruit cultivar was calculated using 5 packages for each treatment (5 boxes of 3 fruits × 2 treatments per cultivar) and expressed as the percentage reduction with respect to the initial time, using a two-decimal precision digital balance (mod. CENT-2 10000, Gibertini, Milan, Italy).

where W

i is the initial weight, and W

s is the weight measured during storage.

Minimally processed loquat fruits’ external color for each cultivar and treatment were measured at two opposite points on each fruit using a colorimeter (Chroma Meter CR-400 C, Minolta, Osaka, Japan). CIE L*a*b* coordinates were recorded as L* (lightness), a* (positive values for reddish colors and negative values for greenish colors), and b* (positive values for yellowish colors and negative values for bluish colors).

2.4. Headspace Gas Composition

In packages, O2 and CO2 partial pressure were measured immediately before quality evaluation, using an O2 and CO2 portable analyzer (Dansensor Checkpoint, Mocon, Minneapolis, MN, USA) after 0, 3, 5, 7, 10, and 13 days at 5 °C using 5 packages for each cultivar and treatment.

2.5. Nutraceutical Attributes

Total phenolic content, carotenoids, ascorbic acid content, and antioxidant activity of minimally processed loquat fruits of each cultivar were assessed soon after coating (0 d) and at 3, 5, 7, 10, and 13 days of storage at 5 °C. For each sampling date and experimental treatment (MRT-CTR, GR-CTR, and MRT OFI-EC, GR OFI-EC), three samples were randomly chosen and analyzed.

2.5.1. Fruit Extract Preparation

Loquat fruit samples were frozen at −80 °C until extract preparation. The frozen samples were thawed and chopped and the seeds were separated from the pulp. The pulp was homogenized, and fruit extracts were prepared as previously described with minor changes [

18]. Briefly, ten grams of the whole homogenate was weighed and then extracted with MeOH using a 1:5 (

w/v) ratio. Samples were mixed by vortex for 5 min and sonicated at room temperature for 15 min (~25 °C). The mixtures were allowed to stand for 2 h at room temperature. After centrifugation (10 min at 8000×

g, 4 °C) the supernatants were filtered, portioned, and stored at −20 °C. The extraction procedure was repeated to obtain three different technical replicates.

2.5.2. Total Phenolic and Total Carotenoids Content

Total phenolic content (TPC) of extracts from treated and untreated fruits of each loquat cultivar was determined by the reduction of phosphotungstic–phosphomolybdic acid (Folin–Ciocalteu’s reagent) to blue pigments, in alkaline solution according to Folin–Ciocalteu’s method [

19]. Total phenolic content was expressed as mg gallic acid (GA) equivalent (GAE).

The total carotenoids were extracted in flesh loquat fruits as described by Petriccione et al. [

3] and determined spectrophotometrically according to Kichtenthaler and Wellburn [

20]. Results were expressed as milligrams per 100 g fresh weight (FW), all measurements were done in three replicates.

2.5.3. DPPH and Hydroxyl Radical Scavenging Analysis

The 1,1-diphenyl-2-picrylhydrazyl (DPPH) radical scavenging analysis was performed on 2 g of frozen tissue with 5 mL 50% (

v/v) ethanol according to Wang et al. [

4]. The homogenate was centrifuged at 12,000×

g for 20 min at 4 °C, then the supernatant was collected. The reaction mixture consisted of 0.1 mL supernatant and 1.9 mL 120 μmol L

−1 DPPH. Results were calculated using the following formula: DPPH radical scavenging activity (%) = [(A0 − A1)/A0] × 100, with A0 referring to absorbance of the control, A1 referring to absorbance of the samples. DPPH radical scavenging was expressed as a percentage.

The hydroxyl radical scavenging analysis was performed on 2 g of frozen tissue with 5 mL 50% (

v/v) ethanol according to Wang et al. [

4]. The homogenate was centrifuged at 12,000× g for 20 min at 4 °C, then the supernatant was collected. The reaction mixture consisted of 0.5 mL supernatant, 1.5 mL salicylic acid, 2 mL water, and 0.1 mL 0.3% H

2O

2. Results were calculated following the formula: hydroxyl radical scavenging (%) = [(A0 − A1)/A0] × 100, with A0 referring to absorbance of the control, A1 referring to absorbance of the samples. The hydroxyl radical scavenging was expressed as a percentage.

2.5.4. Ascorbic Acid Content

Ascorbic acid in MRT and GR- CTR and MRT and GR-OFI samples was determined by extracting 10 g of blended fruit sample in 100 mL metaphosphoric acid (HPO

3), then filtering it through Whatman no. 1 filter paper. A volume of 10 mL filtered solution was determined volumetrically with the 2–6 dichlorophenol-indophenol reagent until a slightly pink coloration was observed and persisted for 15 s [

21]. The ascorbic acid content was expressed in mg/100 g FW.

2.6. Sensory Analysis and Visual Score

On each sampling date, 5 boxes (3 fruits in each) for each treatment (MRT and GR- CTR, and MRT and GR-OFI) were subjected to sensory evaluation. The sensory profile was constructed by a panel of 10 judges trained in a few preliminary meetings: by using commercial fruit, the judges generated a list of descriptors. Sensory analysis was focused on appearance, sweetness, acidity, aroma, off-flavor development, taste, texture, juiciness, and overall acceptance. The different descriptors were quantified using a ten-point intensity scale where the digit 1 indicates the descriptor absence while the digit 10 the full intensity [

7,

8]. The order of presentation was randomized between judges. Water was provided for rinsing between samples.

On each sampling date, 5 boxes (3 fruits in each) for each treatment (MRT and GR- CTR, and MRT and GR- OFI) were also evaluated by each judge for the visual score. Visual appearance score resulted from the medium value of color, visible structural integrity, and visual appearance [

8]. The different descriptors were quantified using a subjective 5–1 rating scale with 5 = very good, 4 = good, 3 = sufficient, 2 = poor (limit of edibility), and 1 = very poor (inedible) [

8]. A score of 3 was the limit of marketability. The order of presentation was randomized between judges.

2.7. Microbiological Characterization of O. ficus-indica Mucilage Edible Coating

2.7.1. Determination of Antibacterial Activity

O. ficus-indica mucilage edible coating was tested against several bacterial strains of food origin representing spoilage and pathogenic bacterial groups. In particular,

Pseudomonas endophytica and

P. fluorescens were chosen among spoilage bacteria, while

Escherichia coli,

Listeria monocytogenes,

Salmonella Enteritidis, and

Staphylococcus aureus were among the main food-borne bacterial pathogens. All indicator strains were reactivated in Brain Heart Infusion (BHI) broth (Condalab, Madrid, Spain). The incubation was carried out for 24 h at 37 °C, excepting

Pseudomonas strains, which were incubated at 25 °C. The antibacterial activity of

O. ficus-indica mucilage edible coating was tested by the paper disc diffusion (PDD) method [

22] using sterile water as a negative control, while streptomycin (10%

w/v) was a positive control [

23]. The inhibitory activity was evaluated after 24 h of incubation at 25 °C and 37 °C for spoilage and pathogenic bacteria, respectively, and was scored positive only in case of a definite clear area around the paper discs. The tests were carried out in triplicate.

2.7.2. Plate Count

One milliliter of

O. ficus-indica mucilage edible coating was directly subjected to decimal serial dilutions (1:10) in Ringer’s solution (Sigma-Aldrich, Milan, Italy) and the microbial suspensions were used for the search of the main undesired communities, including both spoilage and pathogenic populations. The inoculation, cultivation, and incubation of the different microbial groups occurred as described by Passafiume et al. [

17]. Briefly, total mesophilic microorganisms (TMM) and total psychotrophic microorganisms (TPM) were detected on plate count agar (PCA),

Pseudomonas spp. on

Pseudomonas agar base (PAB) with added fucidin cephaloridine supplement (CFC), members of the Enterobacteriaceae family on violet red bile glucose agar (VRBGA), coagulase-positive staphylococci (CPS) on Baird Parker (BP) supplemented with rabbit plasma fibrinogen (RPF),

Listeria monocytogenes on

Listeria selective agar base with SR0140E supplement,

Salmonella spp. and

Escherichia coli on Hektoen enteric agar (HEA), and yeasts and molds on yeast extract peptone dextrose (YPD) agar supplemented with chloramphenicol (0.1 g/L) to prevent bacterial growth. All media and chemicals were purchased from Microbiol Diagnostici (Uta, Italy). Plate counts were performed in triplicate.

2.8. Microbiological Analyses of Loquat Fruit

Coated and untreated loquat samples (25 g) from each cultivar were homogenized in 225 mL of Ringer’s solution (Sigma-Aldrich) by a stomacher Bag-Mixer 400 (Interscience, Saint Nom, France) for 3 min at the highest speed (blending power 4). Homogenized samples were then serially diluted. O. ficus-indica mucilage edible coating was diluted as reported above and the cell suspensions were subjected to the enumeration of spoilage and pathogenic microorganisms. Plate counts were performed in triplicate at each collection time (soon after production and after 3, 5, 7, 10, and 13 days of refrigerated storage).

2.9. Statistical Analyses

All data were submitted to one-way analysis of variance (ANOVA) and means were separated with Tukey’s test at p ≤ 0.05. The statistical analysis was carried out using Systat 10 (Systat, Chicago, IL, USA).

4. Discussion

Loquat fruits are a non-climacteric fruit, with a short postharvest life due to an intrinsic predisposition to physical damage and microbial decay. The fruit decays quickly after harvest, and losses in firmness, taste, and juiciness occur rapidly during postharvest life [

1].

Loquat fruit are easily bruised and scratched, and the damaged areas usually later turn brown or black in air. In addition, low temperature injury is one of the major limitations for long-term cold storage of loquat fruit. Fruit processing as well as peeling could allow producers to also sell to the market loquat fruits that present large purple spotted areas in the epicarp, which are usually considered unmarketable.

Fruit texture is an important quality attribute in minimally processed fruits, as the enzymatic reactions due to fruit processing operations (peeling, slicing, etc.) lead to rapid losses in firmness [

24]. In our study, the highest fruit firmness values were measured in OFI coated samples in both cultivars during the cold storage period, showing the ability of mucilage to preserve fruit structure (

Table 1). This effect on fruit firmness could be attributed to calcium content in

Opuntia ficus-indica (OFI) mucilage, which preserves the fruit cell wall integrity by interacting with the pectic acid in the cell walls to form calcium pectate [

25]. Previous studies reported that fruit calcium pre-harvest and postharvest treatments increased calcium content in the fruit, maintaining firmness in strawberry [

13], fig [

26], guava fruits [

27], peach [

28], and cactus pear fruits [

8].

Our study showed the positive effect of polysaccharidic coatings, such as cactus pear mucilage, that act as a barrier reducing losses in firmness, as reported in previous studies [

8]. Indeed, MRT OFI-EC and GR OFI-EC samples reported firmness values 1.1 times higher than MRT CTR and GR CTR samples at end of the cold storage period, enhancing their resistance to mechanical damage during storage and, thereby, reducing economic losses during the food chain.

TSS, TA, extractable juice, and ascorbic acid content are important indicators to measure the quality of loquat fruit; the changes in composition and content affect the fruit’s taste and acceptance. Concerning chemical parameters, there was evidence of slight changes in terms of TSS and TA during storage in both MRT and GR CTR and MRT and GR OFI-EC samples (

Table 1). OFI-EC edible coating inhibited the decrease of TSS, TA, extractable juice, and ascorbic acid content in both cultivars; the edible coating treatment, in terms of TSS content, was more effective in

Gigante Rossa loquat fruit, showing higher values on all sampling dates. In contrast, the ascorbic acid content in

Martorana loquat fruits was higher than that in

Gigante Rossa ones. The effect of OFI-EC edible coating on limiting the reduction of TSS and juiciness loss was probably related to reducing respiration, transpiration, and metabolic activity, thereby retarding the senescence process of loquat fruit, in a similar way to that reported by Wang et al. [

4] with nano-SiO

2 packing treatment.

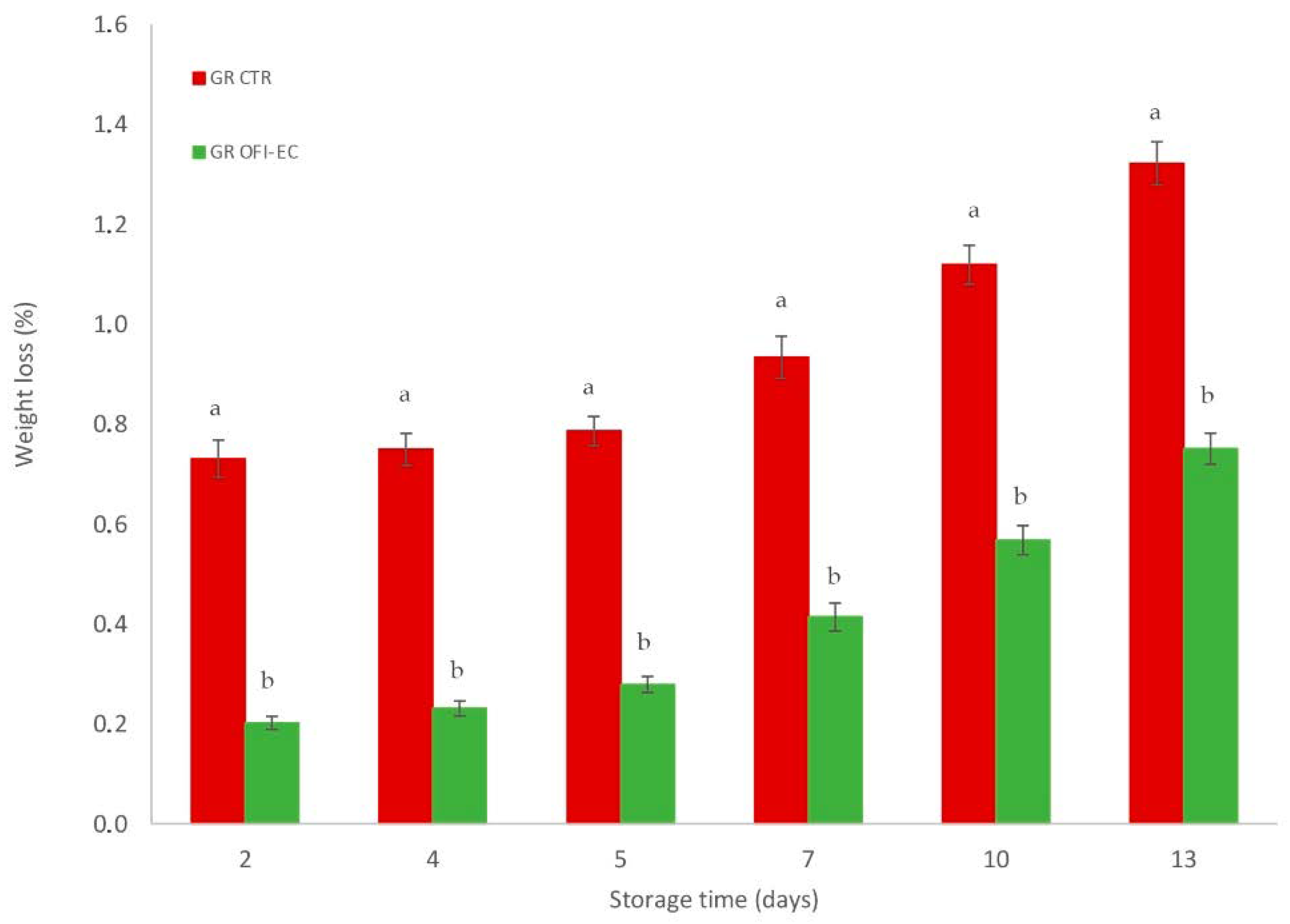

One of the most beneficial effects of edible coating is the maintenance of high RH inside the fruit packaging, with OFI mucilage acting as a barrier to water transfer, reducing the weight loss [

10]. The results of our study showed that the weight loss of minimally processed loquat fruit was positively affected by OFI mucilage coating; indeed, MRT and GR coated samples showed weight loss values 1.5 times higher than MRT and GR uncoated ones (

Figure 1 and

Figure 2). OFI edible coating was significantly effective in preventing weight loss in both cultivars, as reported by previous studies on strawberry [

7,

13], kiwifruit [

29], and cactus pear [

8].

Color is one of the main factors that affect consumer fruit choice and acceptability, and the pulp of loquat fruit contains carotenoids, vitamins B1 and B2 and nicotinamide [

2].

Carotenoids are mainly responsible for the color of loquat fruit, the most abundant ones being β-carotene, β-cryptoxanthin, lutein, violaxanthin, α- carotene, and γ-carotene [

30]. Flesh browning is a serious problem for postharvest storage and processing of loquat fruit; the fruit turns brown rapidly when peeled or crushed. During storage, fruit browning occurs from the core area and is accompanied by lignification of the flesh tissue [

2].

In our study, MRT and GR uncoated loquat fruits’ brightness decreased significantly during cold storage, while MRT and GR coated samples showed slight change in brightness during cold storage with values 1.4 and 1.8 times higher than those of MRT and GR uncoated ones at the end of the cold storage period (

Figure 3). Fruit color decrease and browning are mainly caused by enzymatic oxidation of endogenous polyphenols into quinones, which are then polymerized with other quinones and amines to form brown pigments [

2].

OFI mucilage edible coating has the potential to act as an effective barrier against gaseous exchange between the environment and coated fruit by reducing O

2 permeability and promoting CO

2 accumulation in the atmosphere around the fruit [

10].

In-package CO

2 and O

2 concentration increased and decreased (

Figure 4A,B), respectively, during the cold storage period in both treatments (CTR and OFI-EC). In-package atmosphere values fluctuated between 0.04 and 12.07 kPa, and 0.04 and 8.20 kPa for CO

2 in MRT and GR uncoated loquat fruits, respectively and between 20 and 6.07 kPa, and 20 and 7.11 kPa in MRT and GR uncoated loquat fruits, respectively, for O

2 from the beginning to the end of the cold storage period (

Figure 4A,B). In-package atmosphere values fluctuated between 0.04 and 5.13 kPa, and 0.04 and 4.00 kPa for CO

2 in MRT and GR coated loquat fruits, respectively, and between 20 and 9.27 kPa, and 20 and 11.23 kPa in MRT and GR coated loquat fruits, respectively, for O

2 from the beginning to the end of the cold storage period (

Figure 4A,B). Differences among treatments (CTR and OFI-EC) were consistent during storage, with significant reduction of the respiration rate of coated loquat fruits in both treatments, confirming the gas barrier properties of OFI mucilage on the fruits, as reported elsewhere [

8,

31].

Several studies showed that phenolic compounds acted as non-enzymatic antioxidant and their accumulation might play a strong role in free radical scavenging and keeping cells from the oxidative damage caused by free radicals in fruits and vegetables [

4,

32]. The antioxidant capacity after the processing operations could be increased by some factors (i.e., phenols, betalains, vitamin C) and decreased by others, and its trend would reflect the contribution given by each individual factor [

24].

Our study showed that OFI edible coating treatment increased total phenolic content in both cultivars which, accompanied with higher levels of DPPH and hydroxyl radical scavenging rate in MRT and GR coated loquat fruits (

Table 2), reduced the damage of reactive oxygen species (ROS). Our results confirmed that total phenolic content was positively correlated with DPPH and hydroxyl radical scavenging capacities, and negatively correlated with the ROS damage in loquat fruit, as reported by several other studies [

4,

32]. OFI edible coating treatment did not affect the total carotenoids content in either cultivar.

Furthermore,

Martorana loquat fruits showed higher total phenolic content than

Gigante Rossa ones, contributing to higher DPPH and hydroxyl radical scavenging capacities, which could be related to the varietal and genetic difference. The significant difference in terms of antioxidant capacity between white-flesh and orange-red-flesh loquat cultivars was also observed in other studies [

4,

5,

33]. Our study showed that OFI edible coating, with the increase of total phenolic content, could play a positive role in scavenging reactive oxygen species, contributing to protecting cell membrane peroxidation and damage, therewith delaying the loquat fruit senescence.

Loquat is a very perishable fruit, and its shelf life is usually influenced by postharvest decay determined by bacteria, yeasts, and molds [

2,

34]. For this reason, as with all minimally processed fruits and vegetables, the evaluation of microbial composition of loquat fruits deserves particular attention [

35]. In this study,

O. ficus-indica mucilage was characterized for antibacterial activity and microbial load before edible coating application on loquat fruits. The inhibitory activity was determined against spoilage and pathogenic bacteria commonly associated with foods of plant origin [

36,

37,

38]. Only

E. coli was resistant to the

O. ficus-indica mucilage edible coating assayed. Interestingly, the coating strongly inhibited

Pseudomonas, which are responsible for the alteration of different vegetables and fruits [

39], and

L. monocytogenes,

S. Enteritidis, and

St. aureus, which are responsible for outbreaks associated with vegetables consumed raw [

40]. Neither bacteria nor fungi developed from the serial dilutions of the

O. ficus-indica mucilage analyzed. The absence of microorganisms at detectable levels in

O. ficus-indica mucilage has already been reported by Liguori et al. [

7,

8]. None of the loquat fruit samples analyzed revealed the presence of pathogenic bacteria. The same trend was reported by Allegra et al. [

29] in kiwifruit slices coated with

O. ficus-indica mucilage as edible coating. TMM, TPM, pseudomonads, yeasts, and molds in control and treated fruits appeared at seven days of refrigerate storage and increased over time. This trend was previously reported by other authors for loquat fruits uncoated and treated with edible films extracted from cherry and apricot tree gums [

41]. Although bacteria and fungi increased during storage in coated loquat fruits, cell densities observed in untreated fruits were 1 log cycle higher. This trend is mainly due to the ability of

O. ficus-indica mucilage edible coatings to reduce the microbial growth in fresh-cut fruits [

42].

The sensory analysis showed that judges preferred mucilage coated samples at each sampling date of the cold storage period, as reported by previous studies on other fruits [

7,

8,

26,

29]. MRT OFI-EC and GR OFI-EC loquat fruits samples were preferred by the panelist in all the descriptors that gave mean scores of 7.4 and 8.0 to overall acceptance, respectively, at the end of the cold storage period (5 °C), while MRT CTR and GR CTR had mean scores of 6.2 and 6.8 in overall acceptance, respectively, at the end of the cold storage period (5 °C) (

Figure 6 and

Figure 7). Panelists gave scores 1.6 times higher in terms of overall acceptance to MRT OFI-EC and GR OFI-EC loquat fruits samples, respectively, than MRT CTR and GR CTR ones, at the end of the cold storage period (5 °C). The mucilage coating did not negatively affect the natural taste of loquat fruits, which is an important aspect regarding the use of edible coatings when taste modification is undesirable; indeed, OFI edible coating exalted some important parameters, as well as aroma, sweetness, and taste, that are particularly appreciated by consumers.

OFI-EC loquat fruits had the highest visual quality scores until the end of the cold storage period, while MRT OFI-EC samples were above the limit of marketability until 10 days of cold storage and edibility until the end of the cold storage period; GR OFI-EC samples were still above the marketability and edibility threshold during the storage period, while MRT CTR and GR CTR samples were marketable until 3 days of cold storage and edible until the first 6 days of storage (

Figure 8 and

Figure 9). As reported by previous studies [

7,

8,

29], mucilage coating positively affects the overall appearance of loquat during cold storage, which had a severe descending trend in uncoated loquat fruits.

5. Conclusions

The aim of our study was to assess the effects of O. ficus-indica mucilage-based coating on quality, nutraceutical value, microbiological growth, and sensorial parameters of minimally processed white-flesh Martorana and orange-red-flesh Gigante Rossa loquat fruits during cold storage.

Our data showed a significant effect of mucilage coating on preserving quality, nutraceutical value, sensorial parameters, and improving postharvest life of minimally processed loquat fruits. O. ficus-indica mucilage had a barrier effect on loquat minimally processed fruit during cold storage, reflected by coated samples having lower weight loss, higher firmness, and a lower respiration rate than uncoated ones, after 13 days of cold storage at 5 °C. This factor could reduce economic losses; loquat fruit are easily bruised and scratched, and the damaged areas usually later turn brown or black in air.

OFI-EC edible coating inhibited the decrease of TSS, TA, extractable juice, and ascorbic acid content in both cultivars; the edible coating treatment, in terms of TSS content, was more effective in Gigante Rossa loquat fruit, showing higher values on all sampling dates. In contrast, the ascorbic acid content in Martorana loquat fruits was higher than that in Gigante Rossa ones.

Furthermore, OFI edible coating, with an increase of total phenolic content, could play a positive role in scavenging reactive oxygen species, contributing to protecting cell membrane peroxidation and damage, therewith delaying the loquat fruit senescence.

The application of edible coating of O. ficus-indica mucilage was not able to inhibit microbial growth below the detection limit during the entire period of analysis but reduced significantly their development in coated loquat fruits of Martorana and Gigante Rossa cultivars.

Visual quality and sensorial analysis showed that judges had a higher preference for coated loquat fruits than uncoated ones at the end of the cold storage period. Furthermore, mucilage coating did not negatively affect the natural taste of loquat fruits, which is an important aspect regarding the use of edible coatings when taste modification is undesirable. Indeed, mucilage coating exalted some important parameters, as well as firmness, brightness, aroma, sweetness, and taste, which are particularly appreciated by consumers.

Our study suggested that minimally fruit processing, as well as coating with O. ficus-indica mucilage, could improve peeled loquat fruits’ shelf life and allow producers to also sell to the market loquat fruits that present large spotted areas in the epicarp, which are usually considered unmarketable.