Environmental Consequences of Shelf Life Extension: Conventional versus Active Packaging for Fresh-Cut Salads

Abstract

:1. Introduction

2. Materials and Methods

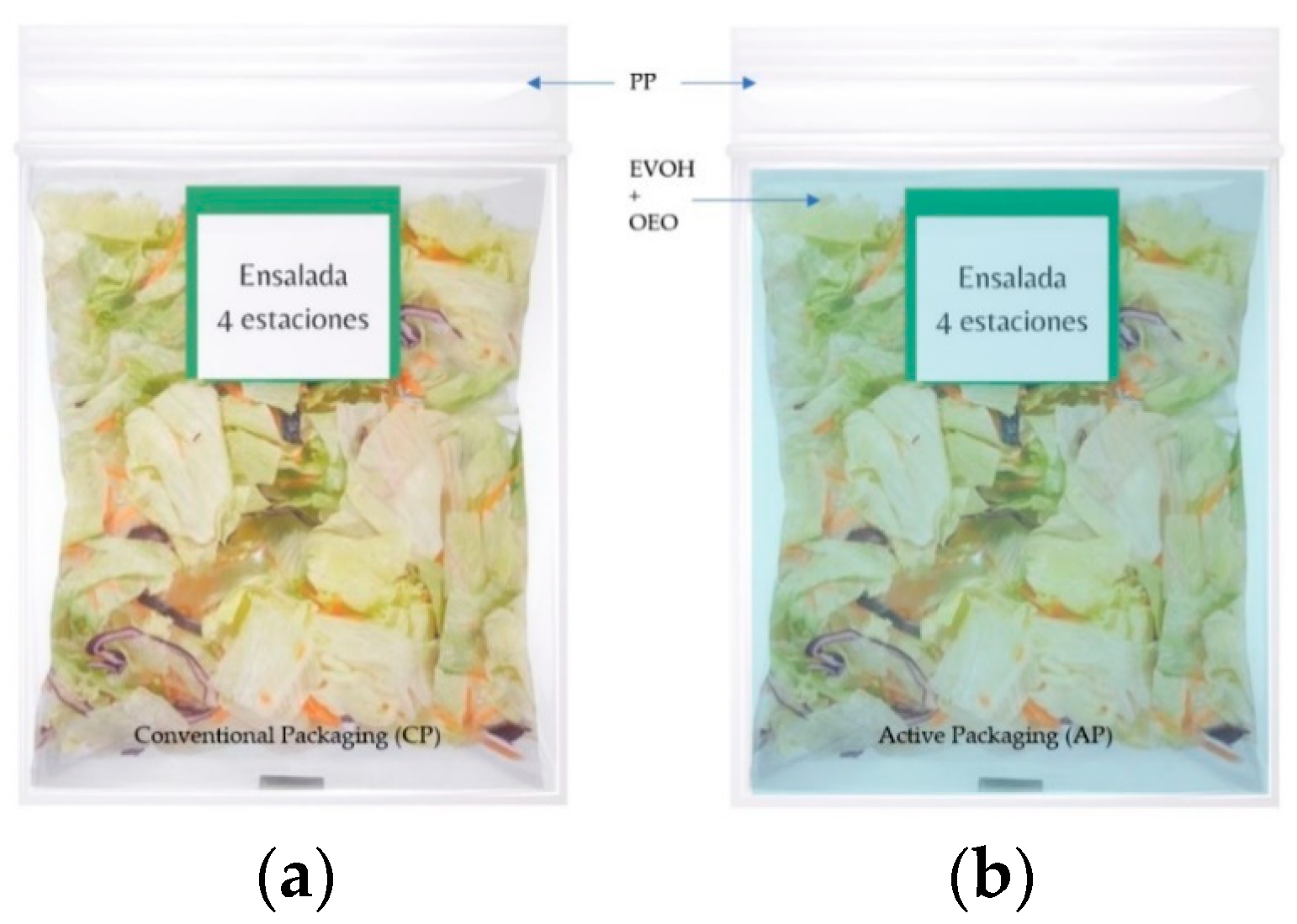

2.1. Description of Packaging and Materials

2.2. Preparation of the Active Film and Packaging of the Salad

2.3. Life Cycle Assessment (LCA)

2.3.1. Goal and Scope of the LCA

2.3.2. Functional Unit

2.3.3. Reference Flow

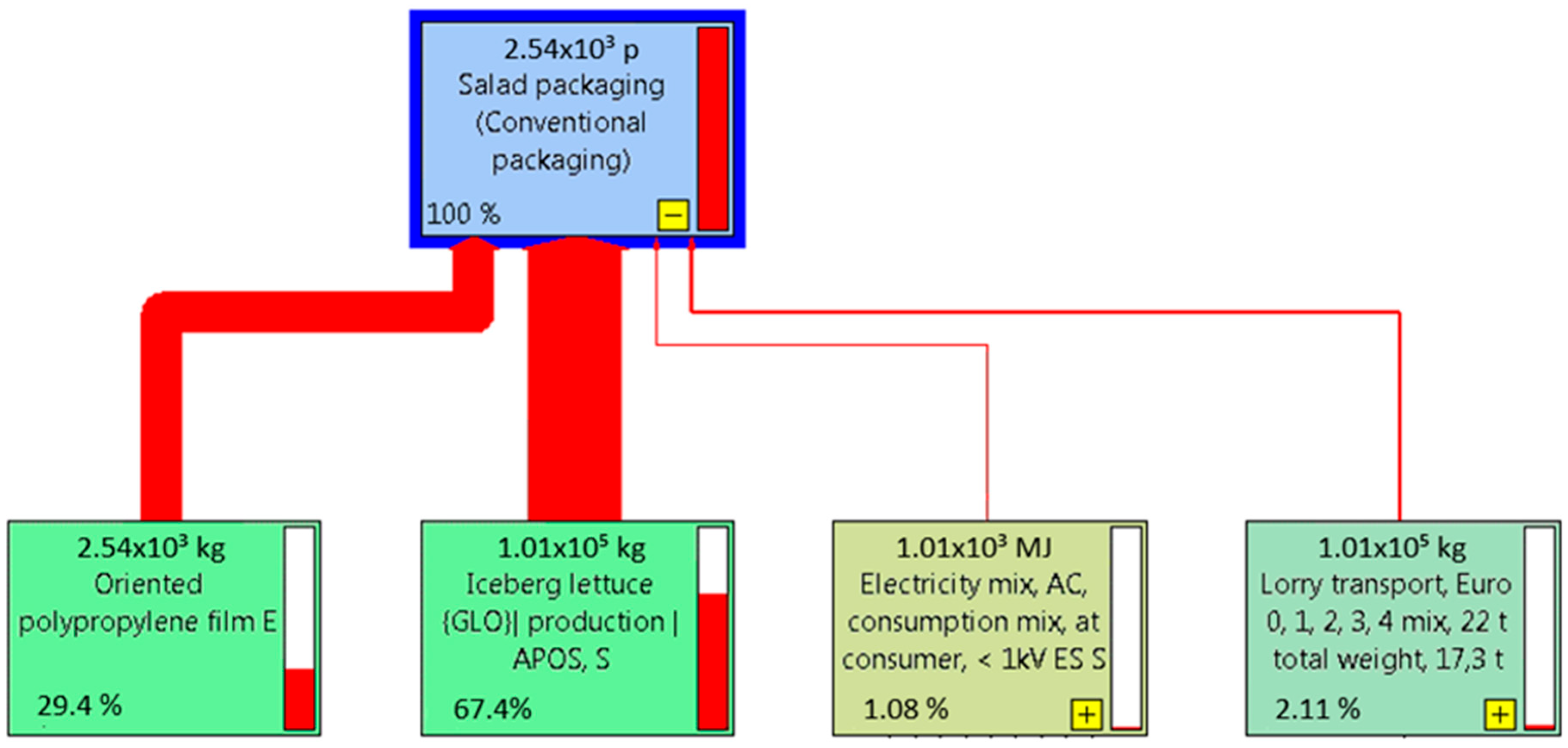

2.3.4. LCA Approach

2.3.5. System Boundaries

2.4. Life Cycle Inventory Analysis (LCIA)

2.4.1. Raw Materials Production

2.4.2. Transport

2.4.3. End of Life

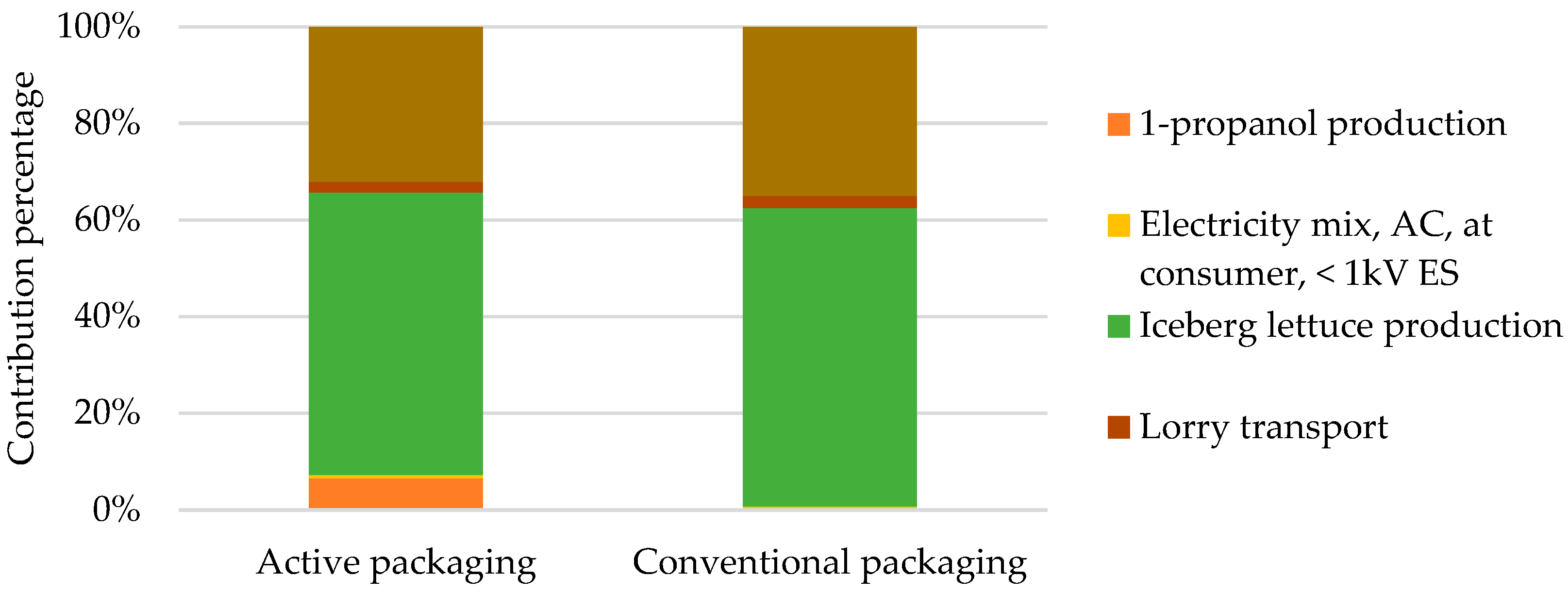

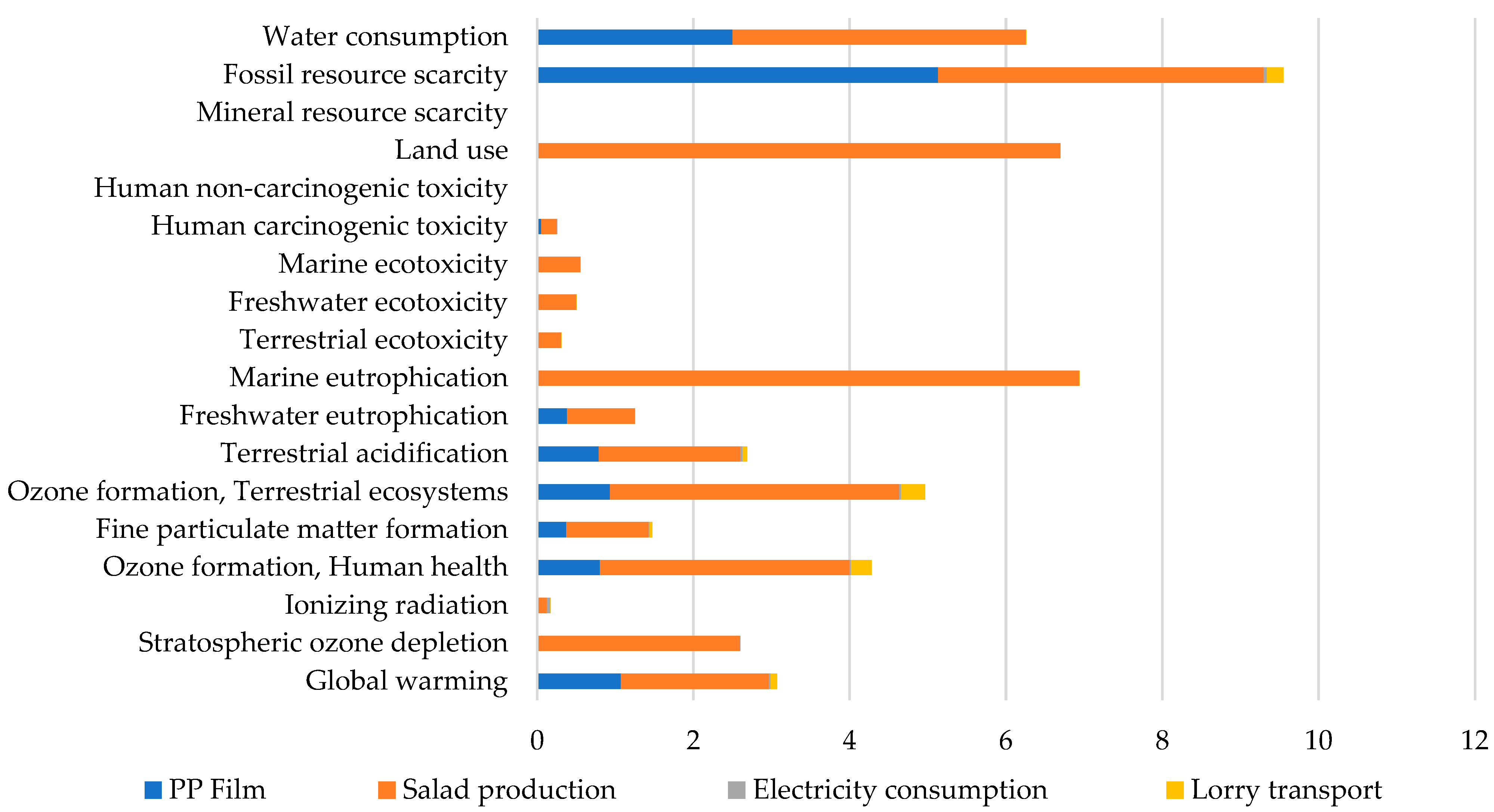

3. Results

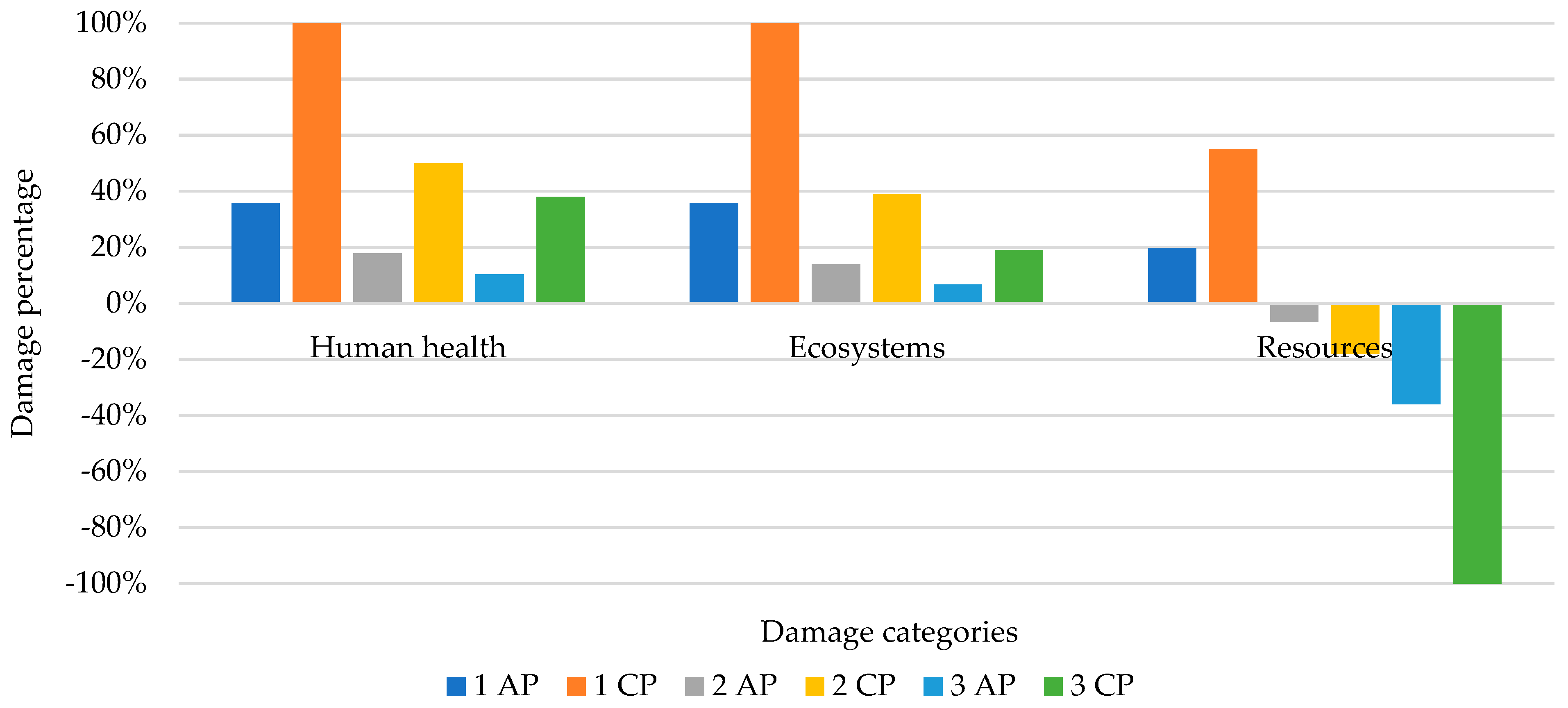

3.1. Sensitivity Analysis

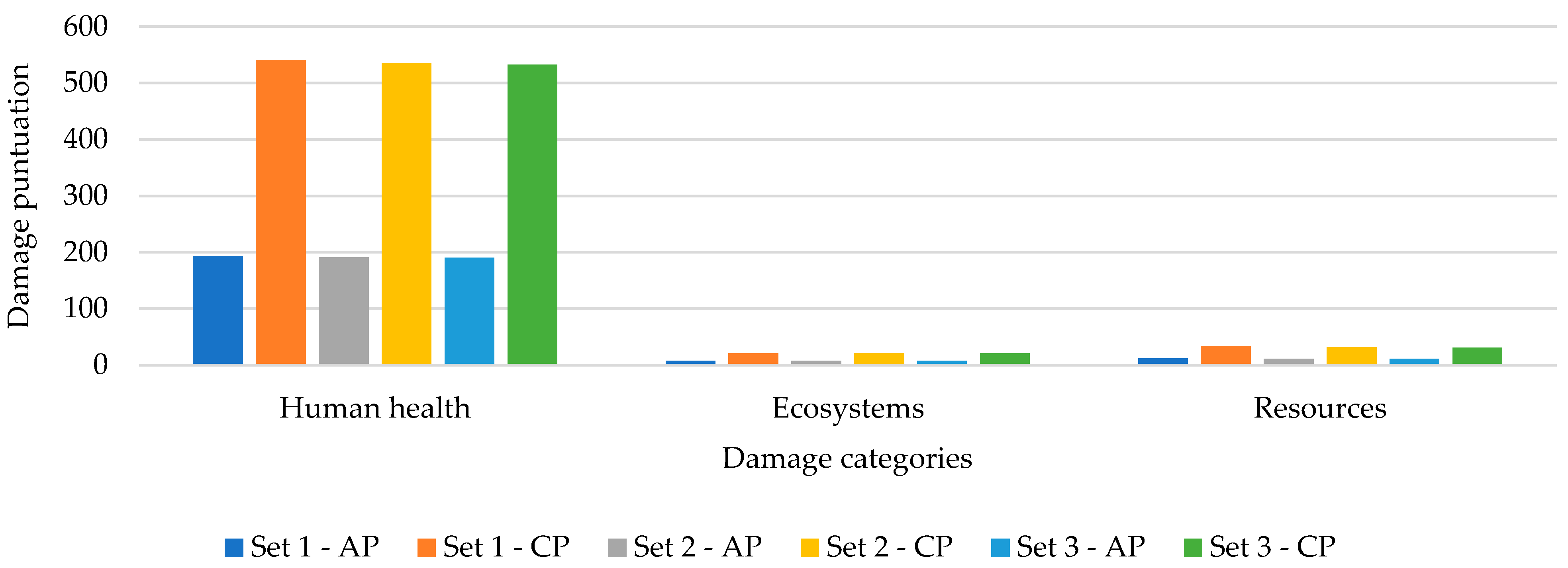

3.2. Analysis of End-of-Life Packaging Scenarios

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Environment Programme. Food Waste Index Report 2021; United Nations Environment Programme: Nairobi, Kenya, 2021. [Google Scholar]

- FAO. El estado Mundial de la Agricultura y la Alimentación. Progresos en la Lucha Contra la Pérdida y el Desperdicio de Alimentos; FAO: Roma, Italy, 2019. [Google Scholar]

- Singh, V.; Hedayetullah, M.; Zaman, P.; Meher, J. Postharvest Technology of Fruits and Vegetables: An Overview. J. Postharvest Technol. 2014, 2, 124–135. [Google Scholar]

- Jung, S.; Cui, Y.; Barnes, M.; Satam, C.; Zhang, S.; Chowdhury, R.A.; Adumbumkulath, A.; Sahin, O.; Miller, C.; Sajadi, S.M. Multifunctional bio-nanocomposite coatings for perishable fruits. Adv. Mater. 2020, 32, 1908291. [Google Scholar] [CrossRef] [PubMed]

- Packaging Gateway. US Consumers’ Shifting Preferences on Sustainable Packaging. Available online: https://www.packaging-gateway.com/features/us-consumers-shifting-preferences-on-sustainable-packaging/ (accessed on 20 October 2023).

- Ketelsen, M.; Janssen, M.; Hamm, U. Consumers’ response to environmentally-friendly food packaging—A systematic review. J. Clean. Prod. 2020, 254, 120123. [Google Scholar] [CrossRef]

- Feber, D.; Granskog, A.; Lingqvist, O.; Nordigården, D. Sustainability in Packaging: Inside the Minds of US Consumers. Available online: https://www.mckinsey.com/industries/packaging-and-paper/our-insights/sustainability-in-packaging-inside-the-minds-of-us-consumers#/ (accessed on 15 October 2023).

- Norton, V.; Waters, C.; Oloyede, O.O.; Lignou, S. Exploring consumers’ understanding and perception of sustainable food packaging in the UK. Foods 2022, 11, 3424. [Google Scholar] [CrossRef] [PubMed]

- Rico, D.; Martin-Diana, A.B.; Barat, J.; Barry-Ryan, C. Extending and measuring the quality of fresh-cut fruit and vegetables: A review. Trends Food Sci. Technol. 2007, 18, 373–386. [Google Scholar] [CrossRef]

- Morgado, C.; Pestana, J.M.; Guerra, M.M.; Brandão, C. Microbiological quality in convenient ready-to-eat vegetables during shelf life. AIMS Agric. Food 2018, 3, 372–383. [Google Scholar] [CrossRef]

- McMillin, K.W. Modified atmosphere packaging. In Food Safety Engineering; Springer: Cham, Switzerland, 2020; pp. 693–718. [Google Scholar]

- Kassim, A.; Workneh, T.S.; Laing, M.D. A review of the postharvest characteristics and pre-packaging treatments of citrus fruit. AIMS Agric. Food 2020, 5, 337–364. [Google Scholar] [CrossRef]

- Eskin, M.; Robinson, D.S. Food Shelf Life Stability: Chemical, Biochemical, and Microbiological Changes; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Mangaraj, S.; Yadav, A.; Bal, L.M.; Dash, S.K.; Mahanti, N.K. Application of Biodegradable Polymers in Food Packaging Industry: A Comprehensive Review. J. Packag. Technol. Res. 2019, 3, 77–96. [Google Scholar] [CrossRef]

- Lagaron, J.; Catalá, R.; Gavara, R. Structural characteristics defining high barrier properties in polymeric materials. Mater. Sci. Technol. 2004, 20, 1–7. [Google Scholar] [CrossRef]

- Muriel-Galet, V.; Cran, M.J.; Bigger, S.W.; Hernández-Muñoz, P.; Gavara, R. Antioxidant and antimicrobial properties of ethylene vinyl alcohol copolymer films based on the release of oregano essential oil and green tea extract components. J. Food Eng. 2015, 149, 9–16. [Google Scholar] [CrossRef]

- Gavara, R.; Catalá Moragrega, R.; López Carballo, G.; Cerisuelo, J.P.; Dominguez, I.; Muriel Galet, V.; Hernández Muñoz, P. Use of EVOH for food packaging applications. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Catalá, R.; Muriel-Galet, V.; Cerisuelo, J.; Domínguez, I.; Carballo, G.; Hernández-Muñoz, P.; Gavara, R. Antimicrobial active packaging systems based on EVOH copolymers. In Antimicrobial Food Packaging; Elsevier: Amsterdam, The Netherlands, 2016; pp. 297–303. [Google Scholar]

- Muriel-Galet, V.; Cerisuelo, J.P.; López-Carballo, G.; Aucejo, S.; Gavara, R.; Hernández-Muñoz, P. Evaluation of EVOH-coated PP films with oregano essential oil and citral to improve the shelf-life of packaged salad. Food Control. 2013, 30, 137–143. [Google Scholar] [CrossRef]

- Parliament, E. Plastic Waste and Recycling in the EU: Facts and Figures. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20181212STO21610/plastic-waste-and-recycling-in-the-eu-facts-and-figures (accessed on 8 August 2023).

- Mumbach, G.D.; de Sousa Cunha, R.; Machado, R.A.F.; Bolzan, A. Dissolution of adhesive resins present in plastic waste to recover polyolefin by sink-float separation processes. J. Environ. Manag. 2019, 243, 453–462. [Google Scholar] [CrossRef] [PubMed]

- PlastEurope. New Guidelines for Barrier Polytheylene Film/RecyClass Tests Show EVOH Concentrations Compatible for Recycling. Available online: https://www.plasteurope.com/news/RECYCLING_t243864 (accessed on 15 August 2023).

- Andersson, K.; Ohlsson, T.; Olsson, P. Life cycle assessment (LCA) of food products and production systems. Trends Food Sci. Technol. 1994, 5, 134–138. [Google Scholar] [CrossRef]

- Molina-Besch, K.; Wikström, F.; Williams, H. The environmental impact of packaging in food supply chains—Does life cycle assessment of food provide the full picture? Int. J. Life Cycle Assess. 2019, 24, 37–50. [Google Scholar] [CrossRef]

- Bassani, F.; Rodrigues, C.; Marques, P.; Freire, F. Ecodesign approach for pharmaceutical packaging based on Life Cycle Assessment. Sci. Total Environ. 2022, 816, 151565. [Google Scholar] [CrossRef] [PubMed]

- Jayakumar, A.; Radoor, S.; Kim, J.T.; Rhim, J.W.; Nandi, D.; Parameswaranpillai, J.; Siengchin, S. Recent innovations in bionanocomposites-based food packaging films–A comprehensive review. Food Packag. Shelf Life 2022, 33, 100877. [Google Scholar] [CrossRef]

- Sun, S.; Wu, Q.; Tian, X. How does sharing economy advance cleaner production? Evidence from the product life cycle design perspective. Environ. Impact Assess. Rev. 2023, 99, 107016. [Google Scholar] [CrossRef]

- Lorite, G.S.; Rocha, J.M.; Miilumäki, N.; Saavalainen, P.; Selkälä, T.; Morales-Cid, G.; Gonçalves, M.; Pongrácz, E.; Rocha, C.M.; Toth, G. Evaluation of physicochemical/microbial properties and life cycle assessment (LCA) of PLA-based nanocomposite active packaging. LWT 2017, 75, 305–315. [Google Scholar] [CrossRef]

- Vigil, M.; Pedrosa-Laza, M.; Alvarez Cabal, J.; Ortega-Fernández, F. Sustainability analysis of active packaging for the fresh cut vegetable industry by means of attributional & consequential life cycle assessment. Sustainability 2020, 12, 7207. [Google Scholar]

- Tsouti, C.; Papadaskalopoulou, C.; Konsta, A.; Andrikopoulos, P.; Panagiotopoulou, M.; Papadaki, S.; Boukouvalas, C.; Krokida, M.; Valta, K. Investigating the Environmental Benefits of Novel Films for the Packaging of Fresh Tomatoes Enriched with Antimicrobial and Antioxidant Compounds through Life Cycle Assessment. Sustainability 2023, 15, 7838. [Google Scholar] [CrossRef]

- Wohner, B.; Gabriel, V.H.; Krenn, B.; Krauter, V.; Tacker, M. Environmental and economic assessment of food-packaging systems with a focus on food waste. Case study on tomato ketchup. Sci. Total Environ. 2020, 738, 139846. [Google Scholar] [CrossRef] [PubMed]

- Ferrandez-Garcia, M.T.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Villena, M. Experimental evaluation of a new giant reed (Arundo donax L.) composite using citric acid as a natural binder. Agronomy 2019, 9, 882. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization of Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization of Standardization: Geneva, Switzerland, 2006.

- National Institute for Public Health and the Environment, Ministry of Health, Welfare and Sport. LCIA: The ReCiPe Model. Available online: https://www.rivm.nl/en/life-cycle-assessment-lca/recipe (accessed on 15 August 2023).

- European Commission’s Joint Research Centre. International Reference Life Cycle Data System (ILCD) Handbook. General Guidance for Life Cycle Assessment; European Union: Luxembourg, 2010. [Google Scholar]

- Zhang, H.; Hortal, M.; Dobon, A.; Bermudez, J.M.; Lara-Lledo, M. The effect of active packaging on minimizing food losses: Life cycle assessment (LCA) of essential oil component-enabled packaging for fresh beef. Packag. Technol. Sci. 2015, 28, 761–774. [Google Scholar] [CrossRef]

- Manfredi, M.; Fantin, V.; Vignali, G.; Gavara, R. Environmental assessment of antimicrobial coatings for packaged fresh milk. J. Clean. Prod. 2015, 95, 291–300. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics—The Facts 2022. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2022-2/ (accessed on 28 April 2023).

- Bala, A.; Arfelis, S.; Oliver-Ortega, H.; Méndez, J.A. Life cycle assessment of PE and PP multi film compared with PLA and PLA reinforced with nanoclays film. J. Clean. Prod. 2022, 380, 134891. [Google Scholar] [CrossRef]

- Settier-Ramirez, L.; López-Carballo, G.; Hernandez-Muñoz, P.; Tinitana-Bayas, R.; Gavara, R.; Sanjuán, N. Assessing the environmental consequences of shelf life extension: Conventional versus active packaging for pastry cream. J. Clean. Prod. 2022, 333, 130159. [Google Scholar] [CrossRef]

- Paes, L.A.B.; Bezerra, B.S.; Jugend, D.; Agudo, F.L. Prospects for a circular bioeconomy in urban ecosystems: Proposal for a theoretical framework. J. Clean. Prod. 2022, 380, 134939. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Castellani, V.; Sala, S. Environmental impacts of food consumption in Europe. J. Clean. Prod. 2017, 140, 753–765. [Google Scholar] [CrossRef]

- Eberle, U.; Fels, J. Environmental impacts of German food consumption and food losses. Int. J. Life Cycle Assess. 2016, 21, 759–772. [Google Scholar] [CrossRef]

- Humbert, S.; Rossi, V.; Margni, M.; Jolliet, O.; Loerincik, Y. Life cycle assessment of two baby food packaging alternatives: Glass jars vs. plastic pots. Int. J. Life Cycle Assess. 2009, 14, 95–106. [Google Scholar] [CrossRef]

- de la Caba, K.; Guerrero, P.; Trung, T.S.; Cruz-Romero, M.; Kerry, J.P.; Fluhr, J.; Maurer, M.; Kruijssen, F.; Albalat, A.; Bunting, S. From seafood waste to active seafood packaging: An emerging opportunity of the circular economy. J. Clean. Prod. 2019, 208, 86–98. [Google Scholar] [CrossRef]

- Stramarkou, M.; Boukouvalas, C.; Koskinakis, S.E.; Serifi, O.; Bekiris, V.; Tsamis, C.; Krokida, M. Life Cycle Assessment and Preliminary Cost Evaluation of a Smart Packaging System. Sustainability 2022, 14, 7080. [Google Scholar] [CrossRef]

- Vidal, R.; Martínez, P.; Mulet, E.; González, R.; López-Mesa, B.; Fowler, P.; Fang, J. Environmental assessment of biodegradable multilayer film derived from carbohydrate polymers. J. Polym. Environ. 2007, 15, 159–168. [Google Scholar] [CrossRef]

- Gómez, I.D.L.; Escobar, A.S. The dilemma of plastic bags and their substitutes: A review on LCA studies. Sustain. Prod. Consum. 2022, 30, 107–116. [Google Scholar] [CrossRef]

| Processes | Inputs/Outputs | Flows | Amounts | Units |

|---|---|---|---|---|

| Conventional Packaging Production | Inputs | PP film | 1 | kg |

| Electricity | 0.4 | MJ | ||

| Output | Conventional packaging | 1 159 | kg pcs | |

| Active Packaging Production | Inputs | PP film | 0.968 | kg |

| (EVA) Ethylene vinyl acetate copolymer | 0.032 | kg | ||

| 1-propanol | 0.14 | kg | ||

| Tap water | 0.06 | kg | ||

| Electricity | 1.2 | MJ | ||

| Output | Active packaging | 1 159 | kg pcs | |

| Product Production | Input | Salad | 0.250 | kg |

| Transportation product | 100 | km | ||

| Output | Minimally processed salad | 1 | kg | |

| Transportation to Market Point | Input | Transport | 50 | km |

| Output | Packaged salad | 1 | pcs |

| Impact Category | Units | CP | AP | Difference |

|---|---|---|---|---|

| Global warming | kg CO2 eq | 24,576.137 | 9361.626 | 15,214.511 |

| Stratospheric ozone depletion | kg CFC11 eq | 0.155 | 0.055 | 0.099 |

| Ionizing radiation | kBq Co-60 eq | 81.650 | 32.492 | 49.158 |

| Ozone formation (human health) | kg NOx eq | 88.124 | 33.502 | 54.621 |

| Fine particulate matter formation | kg PM2.5 eq | 37.638 | 14.531 | 23.107 |

| Ozone formation (terrestrial ecosystems) | kg NOx eq | 88.191 | 33.993 | 54.198 |

| Terrestrial acidification | kg SO2 eq | 110.117 | 41.592 | 68.525 |

| Freshwater eutrophication | kg P eq | 0.813 | 0.310 | 0.502 |

| Marine eutrophication | kg N eq | 31.991 | 11.432 | 20.559 |

| Terrestrial ecotoxicity | kg 1,4-DCB | 4740.788 | 1803.664 | 2937.123 |

| Freshwater ecotoxicity | kg 1,4-DCB | 12.661 | 4.561 | 8.100 |

| Marine ecotoxicity | kg 1,4-DCB | 24.177 | 8.744 | 15.432 |

| Human carcinogenic toxicity | kg 1,4-DCB | 2.651 | 1.027 | 1.623 |

| Human non-carcinogenic toxicity | kg 1,4-DCB | 76.912 | 30.297 | 46.615 |

| Land use | m2 a crop eq | 41,323.206 | 14,839.179 | 26,484.027 |

| Mineral resource scarcity | kg Cu eq | 86.702 | 32.492 | 54.209 |

| Fossil resource scarcity | kg oil eq | 9359.688 | 3589.798 | 5769.890 |

| Water consumption | m3 | 1668.440 | 599.393 | 1069.047 |

| End-of-Life Treatment | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|

| Landfill disposal | 100% | 36% | 0% |

| Recycling | 0% | 46% | 100% |

| Energy recovery | 0% | 21% | 0% |

| End-of-Life Treatment | End-of-Life Salad |

|---|---|

| Landfill disposal | 8% |

| Energy recovery | 22% |

| Composting | 70% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villanova-Estors, R.; Murcia-Velasco, D.A.; Correa-Guimarães, A.; López-Carballo, G.; Hernández-Muñoz, P.; Gavara, R.; Navas-Gracia, L.M. Environmental Consequences of Shelf Life Extension: Conventional versus Active Packaging for Fresh-Cut Salads. Agronomy 2023, 13, 2749. https://doi.org/10.3390/agronomy13112749

Villanova-Estors R, Murcia-Velasco DA, Correa-Guimarães A, López-Carballo G, Hernández-Muñoz P, Gavara R, Navas-Gracia LM. Environmental Consequences of Shelf Life Extension: Conventional versus Active Packaging for Fresh-Cut Salads. Agronomy. 2023; 13(11):2749. https://doi.org/10.3390/agronomy13112749

Chicago/Turabian StyleVillanova-Estors, Raquel, Diana Alexandra Murcia-Velasco, Adriana Correa-Guimarães, Gracia López-Carballo, Pilar Hernández-Muñoz, Rafael Gavara, and Luis Manuel Navas-Gracia. 2023. "Environmental Consequences of Shelf Life Extension: Conventional versus Active Packaging for Fresh-Cut Salads" Agronomy 13, no. 11: 2749. https://doi.org/10.3390/agronomy13112749

APA StyleVillanova-Estors, R., Murcia-Velasco, D. A., Correa-Guimarães, A., López-Carballo, G., Hernández-Muñoz, P., Gavara, R., & Navas-Gracia, L. M. (2023). Environmental Consequences of Shelf Life Extension: Conventional versus Active Packaging for Fresh-Cut Salads. Agronomy, 13(11), 2749. https://doi.org/10.3390/agronomy13112749