Effect of Furrow Straw Mulching and Straw Decomposer Application on Celery (Apium graveolens L.) Production and Soil Improvement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Site and Climate

2.2. Experimental Materials

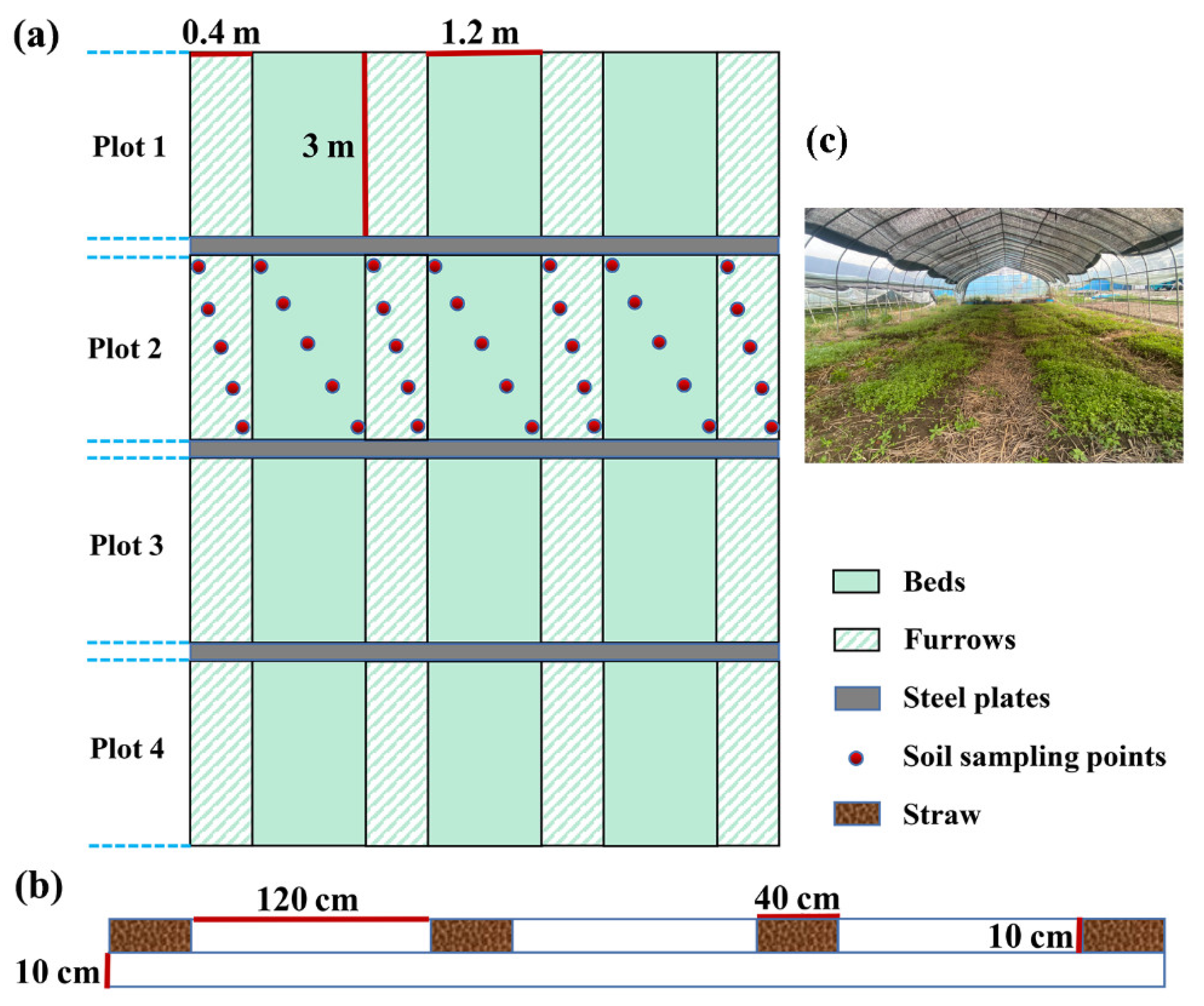

2.3. Experimental Design and Treatments

2.4. Straw Decomposition Rate

2.5. Yield and Quality Analysis

2.6. Soil Analysis

2.7. Statistical Analysis

3. Results

3.1. Different Straw Mulch Amounts

3.1.1. Straw Decomposition Rate

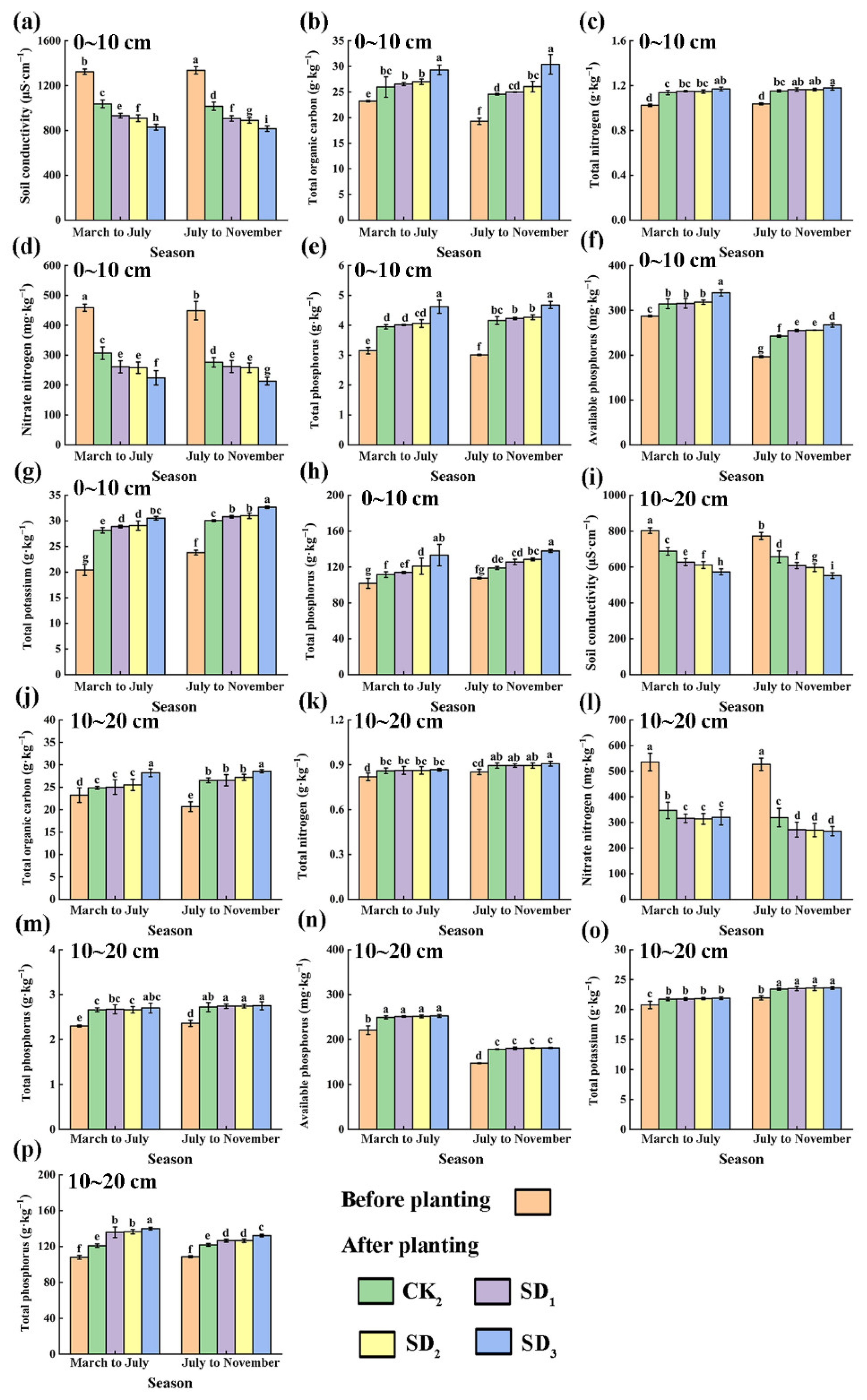

3.1.2. Changes in the Properties of Soil Layers in the Furrows at 0~10 cm

3.1.3. Changes in the Properties of Soil Layers in the Beds at 0~10 cm and 10~20 cm

3.1.4. Yield and Quality of Celery

3.2. Different Types of Straw Decomposer Application Experiment

3.2.1. Straw Decomposition Rate

3.2.2. Changes in Properties of the Soil Layer in the Furrows at 0~10 cm

3.2.3. Changes in the Properties of Soil Layers in Beds at 0~10 cm and 10~20 cm

3.2.4. Yield and Quality of Celery

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, N.-W.; Zang, L.-S.; Wang, S.; Guo, J.-Y.; Xu, H.-X.; Zhang, F.; Wan, F.-H. Biological pest management by predators and parasitoids in the greenhouse vegetables in China. Biol. Control 2014, 68, 92–102. [Google Scholar] [CrossRef]

- Huang, L.F.; Song, L.X.; Xia, X.J.; Mao, W.H.; Shi, K.; Zhou, Y.H.; Yu, J.Q. Plant-soil feedbacks and soil sickness: From mechanisms to application in agriculture. J. Chem. Ecol. 2013, 39, 232–242. [Google Scholar] [CrossRef]

- Liu, J.J.; Sui, Y.Y.; Yu, Z.H.; Shi, Y.; Chu, H.Y.; Jin, J.; Liu, X.B.; Wang, G.H. High throughput sequencing analysis of biogeographical distribution of bacterial communities in the black soils of northeast China. Soil. Biol. Biochem. 2014, 70, 113–122. [Google Scholar] [CrossRef]

- Min, X.; Song, D.; Ma, M.; Li, H.; Li, S.; Zou, G.; Du, L.; Liu, J. Effects of Agronomic Measures on Decomposition Characteristics of Wheat and Maize Straw in China. Sustainability 2022, 14, 12199. [Google Scholar] [CrossRef]

- Du, C.Y.; Abdullah, J.J.; Greetham, D.; Fu, D.N.; Yu, M.Y.; Ren, L.W.; Li, S.; Lu, D.N. Valorization of food waste into biofertiliser and its field application. J. Clean. Prod. 2018, 187, 273–284. [Google Scholar] [CrossRef]

- Genis, S.; Verdu, M.; Cucurull, J.; Devant, M. Complete feed versus concentrate and straw fed separately: Effect of feeding method on eating and sorting behavior, rumen acidosis, and digestibility in crossbred Angus bulls fed high-concentrate diets. Anim. Feed. Sci. Tech. 2021, 273, 114820. [Google Scholar] [CrossRef]

- Lu, H.; Hu, L.X.; Zheng, W.W.; Yao, S.; Qian, L. Impact of household land endowment and environmental cognition on the willingness to implement straw incorporation in China. J. Clean. Prod. 2020, 262, 121479. [Google Scholar] [CrossRef]

- Shan, A.Q.; Pan, J.Q.; Kang, K.J.; Pan, M.H.; Wang, G.; Wang, M.; He, Z.L.; Yang, X.E. Effects of straw return with N fertilizer reduction on crop yield, plant diseases and pests and potential heavy metal risk in a Chinese rice paddy: A field study of 2 consecutive wheat-rice cycles. Environ. Pollut. 2021, 288, 117741. [Google Scholar] [CrossRef]

- Sarkar, S.; Skalicky, M.; Hossain, A.; Brestic, M.; Saha, S.; Garai, S.; Ray, K.; Brahmachari, K. Management of Crop Residues for Improving Input Use Efficiency and Agricultural Sustainability. Sustainability 2020, 12, 9808. [Google Scholar] [CrossRef]

- Ouni, Y.; Lakhdar, A.; Scelza, R.; Scotti, R.; Abdelly, C.; Barhoumi, Z.; Rao, M.A. Effects of two composts and two grasses on microbial biomass and biological activity in a salt-affected soil. Ecol. Eng. 2013, 60, 363–369. [Google Scholar] [CrossRef]

- Dai, X.Q.; Li, Y.S.; Ouyang, Z.; Wang, H.M.; Wilson, G.V. Organic manure as an alternative to crop residues for no-tillage wheat-maize systems in North China Plain. Field Crop Res. 2013, 149, 141–148. [Google Scholar] [CrossRef]

- Zha, L.; Qiu, Z.; Wang, X.; Wu, J.; Zhu, L.; Bian, X.; Cao, W. Study on feasibility of straw concentrated ditch buried returning field using machine. Acta Agric. Zhejiangensis 2013, 25, 135–141. [Google Scholar]

- Mei, J.; Shen, X.; Gang, L.; Xu, H.; Wu, F.; Sheng, L. A novel lignin degradation bacteria-Bacillus amyloliquefaciens SL-7 used to degrade straw lignin efficiently. Bioresour. Technol. 2020, 310, 123445. [Google Scholar] [CrossRef] [PubMed]

- Abdulla, H.M.; El-Shatoury, S.A. Actinomycetes in rice straw decomposition. Waste Manag. 2007, 27, 850–853. [Google Scholar] [CrossRef] [PubMed]

- Wylegala, S.; Nowak, W.; Mikula, R. The effect of Saccharomyces cerevisiae on the in vitro degradability of maize grain, cellulose and wheat straw dry matter. J. Anim. Feed. Sci. 2005, 14, 315–318. [Google Scholar] [CrossRef]

- Liang, Y.S.; Yuan, X.Z.; Zeng, G.M.; Hu, C.L.; Zhong, H.; Huang, D.L.; Tang, L.; Zhao, J.J. Biodelignification of rice straw by Phanerochaete chrysosporium in the presence of dirhamnolipid. Biodegradation 2010, 21, 615–624. [Google Scholar] [CrossRef] [PubMed]

- Dinis, M.J.; Bezerra, R.M.F.; Nunes, F.; Dias, A.A.; Guedes, C.V.; Ferreira, L.M.M.; Cone, J.W.; Marques, G.S.M.; Barros, A.R.N.; Rodrigues, M.A.M. Modification of wheat straw lignin by solid state fermentation with white-rot fungi. Bioresour. Technol. 2009, 100, 4829–4835. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Qin, T.; Liu, T.; Guo, L.; Li, C.; Zhai, Z. Inclusion of microbial inoculants with straw mulch enhances grain yields from rice fields in central China. Food Energy Secur. 2020, 9, e230. [Google Scholar] [CrossRef]

- He, Z.F.; Yang, X.R.; Xiang, J.; Wu, Z.L.; Shi, X.Y.; Gui, Y.; Liu, M.Q.; Kalkhajeh, Y.K.; Gao, H.J.; Ma, C. Does Straw Returning Amended with Straw Decomposing Microorganism Inoculants Increase the Soil Major Nutrients in China’s Farmlands? Agronomy 2022, 12, 890. [Google Scholar] [CrossRef]

- Kalkhajeh, Y.K.; He, Z.F.; Yang, X.R.; Lu, Y.; Zhou, J.; Gao, H.J.; Ma, C. Co-application of nitrogen and straw-decomposing microbial inoculant enhanced wheat straw decomposition and rice yield in a paddy soil. J. Agr. Food Res. 2021, 4, 100134. [Google Scholar] [CrossRef]

- Ma, Y.C.; Liu, D.L.; Schwenke, G.; Yang, B. The global warming potential of straw-return can be reduced by application of straw-decomposing microbial inoculants and biochar in rice-wheat production systems. Environ. Pollut. 2019, 252, 835–845. [Google Scholar] [CrossRef] [PubMed]

- Nordey, T.; Deletre, E.; Mlowe, N.; Martin, T. Nethouses protect cucumber plants from insect pests and increase yields in eastern Africa. J. Hortic. Sci. Biotechnol. 2020, 95, 673–678. [Google Scholar] [CrossRef]

- Lv, H.; Zhou, W.; Dong, J.; He, S.; Chen, F.; Bi, M.; Wang, Q.; Li, J.; Liang, B. Irrigation amount dominates soil mineral nitrogen leaching in plastic shed vegetable production systems. Agric. Ecosyst. Environ. 2021, 317, 107474. [Google Scholar] [CrossRef]

- Zhong, C.; Liu, Y.; Xu, X.T.; Yang, B.J.; Aamer, M.; Zhang, P.; Huang, G.Q. Paddy-upland rotation with Chinese milk vetch incorporation reduced the global warming potential and greenhouse gas emissions intensity of double rice cropping system. Environ. Pollut. 2021, 276, 116696. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.W.; Jiang, J.Z.; Zhu, L.L.; Zhang, L.; Li, H.P.; Gu, J.F. Straw Mulching Improves Soil Fertility and Productivity of Water Spinach (Ipomoea Aquatica Forsk.) under Plastic Tunnel. Commun. Soil. Sci. Plan. 2021, 52, 2958–2970. [Google Scholar] [CrossRef]

- Zhu, Z.H.; Qian, J.Y.; Zhang, Y.X.; Zhang, H.; Dai, H.B.; Zhang, Z.P.; Miao, M.M.; Jiang, J.Z. Taro (Colocasia esculenta (L.) Schott) Yields and Soil Chemical Properties Were Improved by Row-Surface Straw Mulching. Agronomy 2022, 12, 645. [Google Scholar] [CrossRef]

- Yan, D.; Ding, K.K.; He, Y.X.; Fan, L.; Wang, S.F.; Jiang, X.Y. Strontium Uptake and Effects in Hydroponically Cultivated Celery. Water Air Soil. Poll. 2020, 231, 279. [Google Scholar] [CrossRef]

- Navarro, A.S.; Romero, J.A.; Sanjuan, M.D.; Bernardeau, M.A.; Delgado Iniesta, M.J. Medium-Term Influence of Organic Fertilization on the Quality and Yield of a Celery Crop. Agronomy 2020, 10, 1418. [Google Scholar] [CrossRef]

- Li, M.; Zhou, J.; Du, J.; Li, X.; Sun, Y.; Wang, Z.; Lin, Y.; Zhang, Y.; Wang, Y.; He, W.; et al. Comparative Physiological and Transcriptomic Analyses of Improved Heat Stress Tolerance in Celery (Apium Graveolens L.) Caused by Exogenous Melatonin. Int. J. Mol. Sci. 2022, 23, 11382. [Google Scholar] [CrossRef]

- Huang, L.; Yang, P.; Cui, H.; Sun, Z.; Ren, S.; Wang, Z. Effects of topdressing ratio and frequency on the dry matter, yield, and quality of tomato and celery under a small amount of continuous subsurface drip irrigation. Int. J. Agric. Biol. Eng. 2023, 16, 273–284. [Google Scholar] [CrossRef]

- Li, M.Y.; Hou, X.L.; Wang, F.; Tan, G.F.; Xu, Z.S.; Xiong, A.S. Advances in the research of celery, an important Apiaceae vegetable crop. Crit. Rev. Biotechnol. 2018, 38, 172–183. [Google Scholar] [CrossRef] [PubMed]

- Li, J. Sampling Soils in a Heterogeneous Research Plot. Jove-J. Vis. Exp. 2019, 143, e58519. [Google Scholar] [CrossRef]

- Schleuss, U.; Muller, F. Requirements for soil sampling in the context of ecosystem research. Sci. Total Environ. 2001, 264, 193–197. [Google Scholar] [CrossRef] [PubMed]

- Vasileva, V.; Mitova, I. Analyzing the effects of potassium fertilization on the yield and total N, K2O and P2O5 export of tomato plants. J. Cent. Eur. Agric. 2023, 24, 282–290. [Google Scholar] [CrossRef]

- Dibar, D.T.; Zhang, K.; Yuan, S.Q.; Zhang, J.Y.; Zhou, Z.Z.; Ye, X.X. Ecological stoichiometric characteristics of Carbon (C), Nitrogen (N) and Phosphorus (P) in leaf, root, stem, and soil in four wetland plants communities in Shengjin Lake, China. PLoS ONE 2020, 15, e0230089. [Google Scholar] [CrossRef]

- Sotiropoulos, T.; Therios, I.; Voulgarakis, N. Effect of Various Foliar Sprays on Some Fruit Quality Attributes and Leaf Nutritional Status of the Peach Cultivar ‘Andross’. J. Plant Nutr. 2010, 33, 471–484. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Zhao, M.R.; Wang, J.Q.; Hu, B.Y.; Chen, Q.J.; Qin, Y.; Zhang, G.Q. Effects of microbial inoculants on agronomic characters, physicochemical properties and nutritional qualities of lettuce and celery in hydroponic cultivation. Sci. Hortic-Amst. 2023, 320, 112202. [Google Scholar] [CrossRef]

- Li, M.Y.; Wang, Y.; Wei, X.H.; Wang, Z.; Wang, C.; Du, X.M.; Lin, Y.X.; Zhang, Y.T.; He, W.; Wang, X.R.; et al. Effects of pretreatment and freezing storage on the bioactive components and antioxidant activity of two kinds of celery after postharvest. Food Chem. X 2023, 18, 100655. [Google Scholar] [CrossRef]

- Skerget, M.; Kotnik, P.; Hadolin, M.; Hras, H.R.; Simonic, M.; Knez, Z. Phenols, proanthocyanidins, flavones and flavonols in some plant materials and their antioxidant activities. Food Chem. 2005, 89, 191–198. [Google Scholar] [CrossRef]

- Reichenauer, T.G.; Panamulla, S.; Subasinghe, S.; Wimmer, B. Soil amendments and cultivar selection can improve rice yield in salt-influenced (tsunami-affected) paddy fields in Sri Lanka. Environ. Geochem. Health 2009, 31, 573–579. [Google Scholar] [CrossRef]

- Wan, Q.Z.; Zhu, G.F.; Guo, H.W.; Zhang, Y.; Pan, H.X.; Yong, L.L.; Ma, H.Y. Influence of Vegetation Coverage and Climate Environment on Soil Organic Carbon in the Qilian Mountains. Sci. Rep. 2019, 9, 17623. [Google Scholar] [CrossRef] [PubMed]

- Yu, I.F.; Ho, S.B. Comparison of the Ignition Method and the Perchloric Acid Digestion Method for the Determination of Total Phosphorus in Agricultural Soils of Taiwan. Commun. Soil. Sci. Plan. 2009, 40, 1953–1963. [Google Scholar] [CrossRef]

- Yadav, S.K.; Benbi, D.K.; Toor, A.S. Effect of long-term application of rice straw, farmyard manure and inorganic fertilizer on potassium dynamics in soil. Arch. Agron. Soil. Sci. 2019, 65, 374–384. [Google Scholar] [CrossRef]

- Chen, X.M.; Fang, K.; Chen, C. Seasonal variation and impact factors of available phosphorus in typical paddy soils of Taihu Lake region, China. Water Environ. J. 2012, 26, 392–398. [Google Scholar] [CrossRef]

- Chen, J.Q.; Guo, Z.D.; Chen, H.N.; Yang, X.Y.; Geng, J.B. Effects of different potassium fertilizer types and dosages on cotton yield, soil available potassium and leaf photosynthesis. Arch. Agron. Soil. Sci. 2021, 67, 275–287. [Google Scholar] [CrossRef]

- Wang, Y.L.; Wu, P.N.; Mei, F.J.; Ling, Y.; Qiao, Y.B.; Liu, C.S.; Leghari, S.J.; Guan, X.K.; Wang, T.C. Does continuous straw returning keep China farmland soil organic carbon continued increase? A meta-analysis. J. Environ. Manag. 2021, 288, 112391. [Google Scholar] [CrossRef] [PubMed]

- Pang, H.C.; Li, Y.Y.; Yang, J.S.; Liang, Y.S. Effect of brackish water irrigation and straw mulching on soil salinity and crop yields under monsoonal climatic conditions. Agric. Water Manag. 2010, 97, 1971–1977. [Google Scholar] [CrossRef]

- Rahma, A.E.; Wang, W.; Tang, Z.J.; Lei, T.W.; Warrington, D.N.; Zhao, J. Straw mulch can induce greater soil losses from loess slopes than no mulch under extreme rainfall conditions. Agric. For. Meteorol. 2017, 232, 141–151. [Google Scholar] [CrossRef]

- Roper, M.M.; Gupta, V.V.S.R.; Murphy, D.V. Tillage practices altered labile soil organic carbon and microbial function without affecting crop yields. Aust. J. Soil Res. 2010, 48, 274–285. [Google Scholar] [CrossRef]

- Qin, X.L.; Huang, T.T.; Lu, C.; Dang, P.F.; Zhang, M.M.; Guan, X.K.; Wen, P.F.; Wang, T.C.; Chen, Y.L.; Siddique, K.H.M. Benefits and limitations of straw mulching and incorporation on maize yield, water use efficiency, and nitrogen use efficiency. Agric. Water Manag. 2021, 256, 107128. [Google Scholar] [CrossRef]

- Dong, S.; Ma, Z.; Wang, L.; Yan, C.; Liu, L.; Gong, Z.; Cui, G. Decomposition and Nutrient Release Characteristics of Incorporated Soybean and Maize Straw in Northeast China. Ekoloji Derg. 2019, 28, 2119–2129. [Google Scholar]

- Shamsi, I.H.; Jilani, G.; Zhang, G.-P.; Wei, K. Cadmium stress tolerance through potassium nutrition in soybean. Asian J. Chem. 2008, 20, 1099–1108. [Google Scholar]

- Smirnoff, N. Ascorbate biosynthesis and function in photoprotection. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2000, 355, 1455–1464. [Google Scholar] [CrossRef] [PubMed]

- De Tullio, M.C.; Arrigoni, O. Hopes, disillusions and more hopes from vitamin C. Cell. Mol. Life Sci. CMLS 2004, 61, 209–219. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, M.H.; Jaafar, H.Z.E.; Karimi, E.; Ghasemzadeh, A. Primary, Secondary Metabolites, Photosynthetic Capacity and Antioxidant Activity of the Malaysian Herb Kacip Fatimah (Labisia Pumila Benth) Exposed to Potassium Fertilization under Greenhouse Conditions. Int. J. Mol. Sci. 2012, 13, 15321–15342. [Google Scholar] [CrossRef]

- Liu, D.; Liu, W.; Zhu, D.; Guo, L.; Jin, H.; Zuo, Z.; Liu, L. Effects of phosphate fertilizer on active ingredients and antioxidant activities of Chrysanthemum morifolium. Zhongguo Zhong Yao Za Zhi Zhongguo Zhongyao Zazhi China J. Chin. Mater. Medica 2010, 35, 2236–2241. [Google Scholar]

- Wang, X.; Jia, Z.; Liang, L.; Zhao, Y.; Yang, B.; Ding, R.; Wang, J.; Nie, J. Changes in soil characteristics and maize yield under straw returning system in dryland farming. Field Crop Res. 2018, 218, 11–17. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, S.; Yuan, W.; Dong, W.; Ye, A.; Xie, X.; Chen, Y.; Liu, D.; Cai, W.; Mao, Y. Inclusion of soil carbon lateral movement alters terrestrial carbon budget in China. Sci. Rep. 2014, 4, 7247. [Google Scholar] [CrossRef]

- Nie, X.; Li, Z.; Huang, J.; Huang, B.; Zhang, Y.; Ma, W.; Hu, Y.; Zeng, G. Soil organic carbon loss and selective transportation under field simulated rainfall events. PLoS ONE 2014, 9, e105927. [Google Scholar] [CrossRef]

- Han, Y.; Guo, X.; Jiang, Y.; Xu, Z.; Li, Z. Environmental factors influencing spatial variability of soil total phosphorus content in a small watershed in Poyang Lake Plain under different levels of soil erosion. Catena 2020, 187, 104357. [Google Scholar] [CrossRef]

- Buxbaux, C.A.; Nowak, C.A.; White, E.H. Long-term soil nutrient dynamics and lateral nutrient movement in fertilized and unfertilized red pine plantations. Biogeochemistry 2001, 55, 269–292. [Google Scholar] [CrossRef]

- Gupta, M.; Sharma, M.; Singh, S.; Gupta, P.; Bajaj, B.K. Enhanced Production of Cellulase from Bacillus licheniformis K-3 with Potential for Saccharification of Rice Straw. Energy Technol. 2015, 3, 216–224. [Google Scholar] [CrossRef]

- Sun, Y.; Qu, J.; Li, R.; Li, W.; Wang, Z.; Chu, X. Optimization of the Enzyme Production Conditions of Bacillus licheniformis and Its Effect on the Degradation of Corn Straw. J. Biobased Mater. Bioenergy 2018, 12, 432–440. [Google Scholar] [CrossRef]

- Garry, P.; Vendeuvre, J.L.; Bellon-Fontaine, M.N. Surface properties and adhesion of Bacillus cereus and Bacillus subtilis to polyurethan: Influence of growth temperature. J. Dispers. Sci. Technol. 1998, 19, 1175–1197. [Google Scholar] [CrossRef]

- Stier, T.J.B.; Scalf, R.E. Nutrient-limited anaerobic growth of yeast at high temperatures. J. Cell. Comp. Physiol. 1949, 33, 446–448. [Google Scholar] [CrossRef] [PubMed]

- Mutlu-Ingok, A.; Karbancioglu-Guler, F. Effect of Temperature on the Growth and Ochratoxin a Production of the Aspergillus Section Nigri Members Isolated from Dried Figs. J. Food Saf. 2014, 34, 333–339. [Google Scholar] [CrossRef]

- Jung, Y.J.; Joung, Y.C.; Ahn, T.S. Characterization of Actinomyces Isolated from Freshwater Sponges in Lake Baikal. Korean J. Microbiol. 2011, 47, 130–136. [Google Scholar]

- Shirsole, S.S.; Mishra, T. Response of Different Media, Temperature, pH on Growth and Sporulation of Trichoderma viride. Adv. Plant Sci. 2014, 27, 77–79. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.; Zhou, W.; Yang, Q.; Jiang, J.; Miao, M. Effect of Furrow Straw Mulching and Straw Decomposer Application on Celery (Apium graveolens L.) Production and Soil Improvement. Agronomy 2023, 13, 2774. https://doi.org/10.3390/agronomy13112774

Zheng Z, Zhou W, Yang Q, Jiang J, Miao M. Effect of Furrow Straw Mulching and Straw Decomposer Application on Celery (Apium graveolens L.) Production and Soil Improvement. Agronomy. 2023; 13(11):2774. https://doi.org/10.3390/agronomy13112774

Chicago/Turabian StyleZheng, Zijian, Wangpei Zhou, Qianqian Yang, Jiezeng Jiang, and Minmin Miao. 2023. "Effect of Furrow Straw Mulching and Straw Decomposer Application on Celery (Apium graveolens L.) Production and Soil Improvement" Agronomy 13, no. 11: 2774. https://doi.org/10.3390/agronomy13112774

APA StyleZheng, Z., Zhou, W., Yang, Q., Jiang, J., & Miao, M. (2023). Effect of Furrow Straw Mulching and Straw Decomposer Application on Celery (Apium graveolens L.) Production and Soil Improvement. Agronomy, 13(11), 2774. https://doi.org/10.3390/agronomy13112774