Effect of Chloride Salicylic Acid Ionic Liquids on Cotton Topping and High-Temperature Resistance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

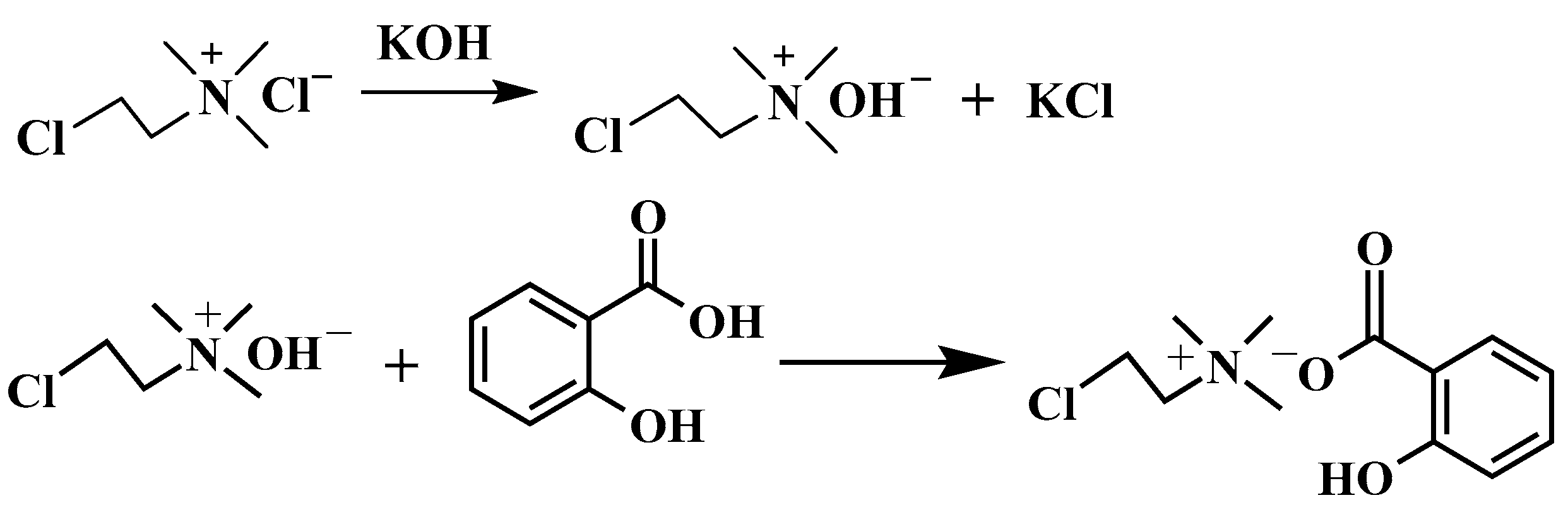

2.2. Preparation of CSILs

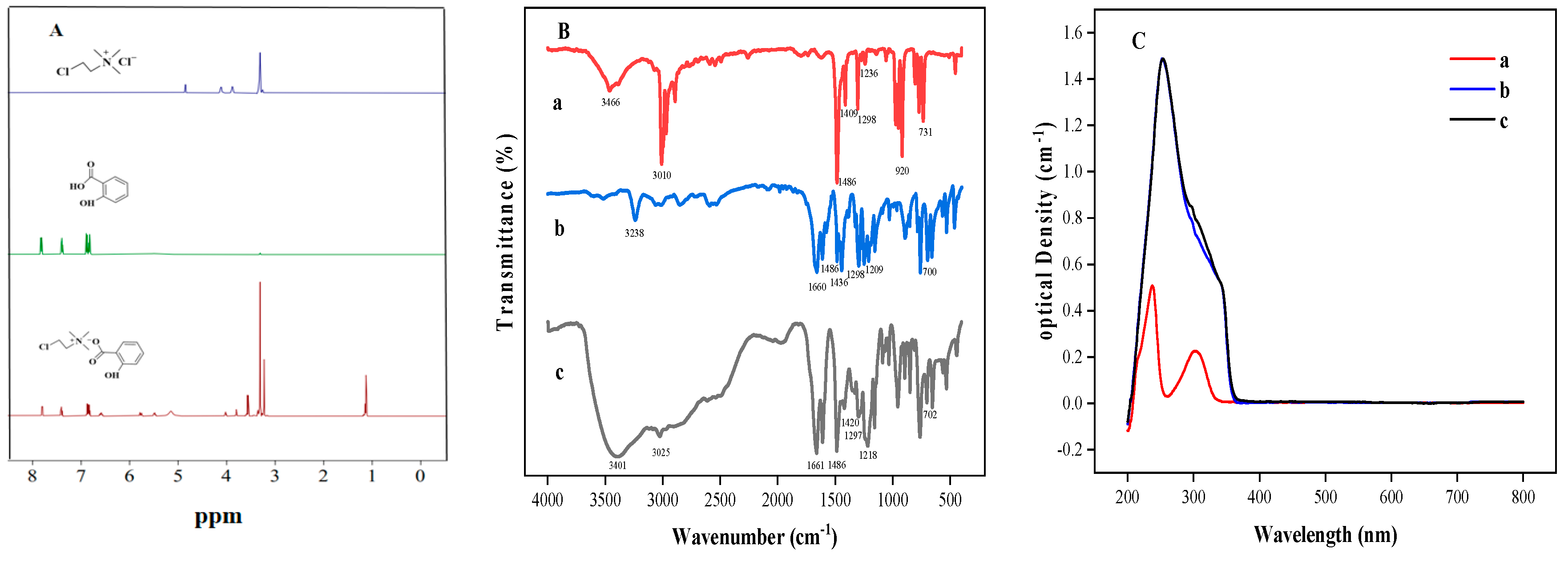

2.3. Characterization of CSILs

2.4. Overview of the Study Site

2.5. Experimental Design

2.6. Sampling and Determination

2.6.1. Plant Architecture Characteristics

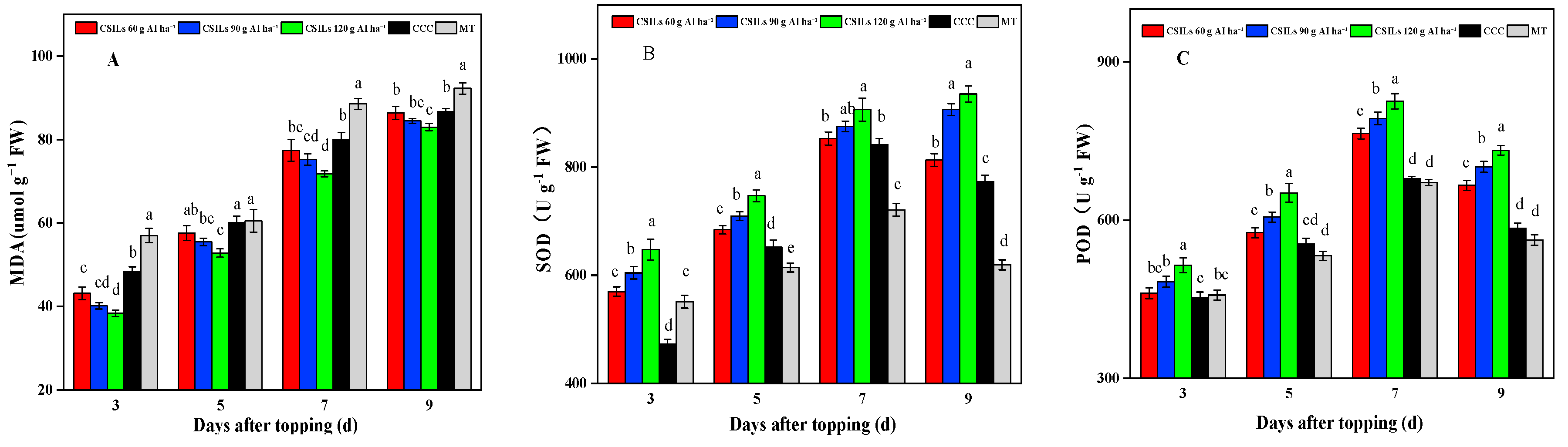

2.6.2. Determination of Antioxidant Enzyme Activity in Cotton

2.6.3. Yield Components and Cotton Fiber Quality

2.7. Data Analysis

3. Results

3.1. Preparation of CSILs

3.2. Characterization of CSILs

3.3. Solubility and Surface Tension of CSILs

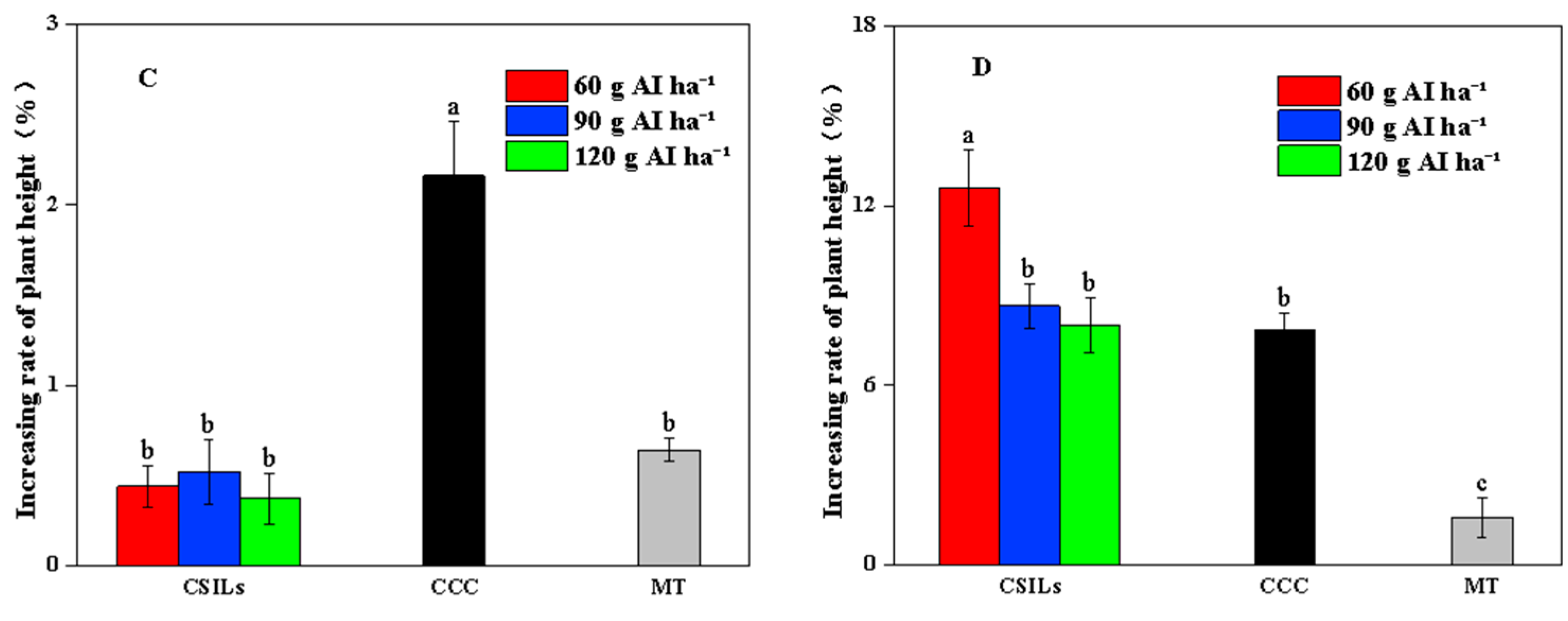

3.4. Effect of CSILs on Cotton Plant Height

3.5. Effect of CSILs on Antioxidant Enzyme Activity in Cotton

3.6. Effects of CSILs on Cotton Canopy Structure

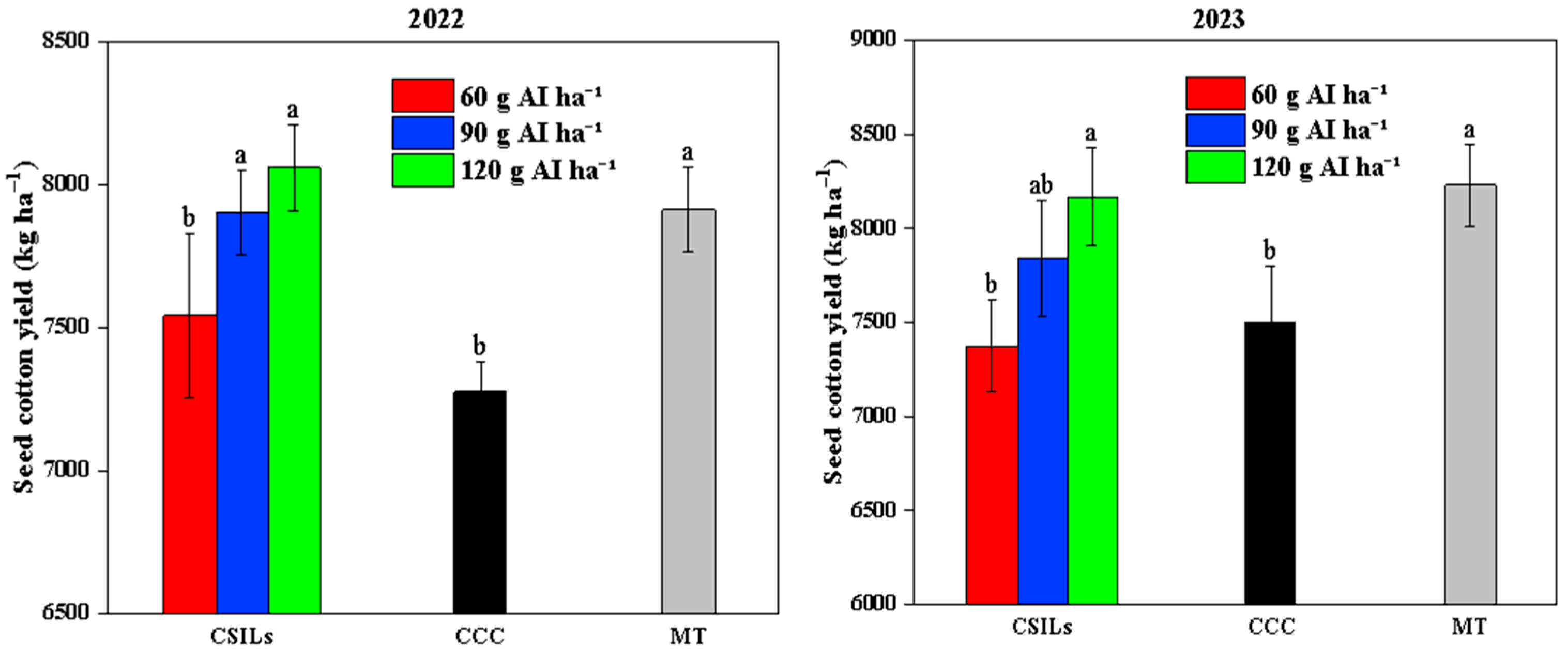

3.7. Effect of CSILs on Cotton Yield

3.8. Effect of CSILs on Cotton Fiber Quality

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CCC | chlormequat chloride |

| CSILs | chlormequat chloride salicylic acid ionic liquids |

| MT | manual topping |

| SA | salicylic acid |

References

- Ren, X.; Zhang, L.Z.; Du, M.W.; Evers, J.B.; van der Werf, W.; Tian, X.L.; Li, Z.H. Managing mepiquat chloride and plant density for optimal yield and quality of cotton. Field Crops Res. 2013, 149, 1–10. [Google Scholar] [CrossRef]

- Dai, J.L.; Luo, Z.; Li, W.J.; Zhang, D.M.; Lu, H.Q.; Li, Z.H.; Xin, C.S.; Kong, X.Q.; Eneji, A.E.; Dong, H.Z. A simplified pruning method for profitable cotton production in the Yellow River valley of China. Field Crops Res. 2014, 164, 22–29. [Google Scholar] [CrossRef]

- Yang, Y.M.; Ouyang, Z.; Yang, Y.H.; Liu, X.J. Simulation of the effect of pruning and topping on cotton growth using cotton2k model. Field Crops Res. 2008, 106, 126–137. [Google Scholar] [CrossRef]

- Dou, Z.C.; Fang, Z.H.; Han, X.Q.; Liu, Y.P.; Duan, L.; Zeeshan, M.; Arshad, M. Comparison of the effects of chemical topping agent sprayed by a uav and a boom sprayer on cotton growth. Agronomy 2022, 12, 1625. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhou, C.J.; Zhang, J.S.; Li, S.L.; Yun, Y.L.; Tian, X.L. Effect of chemical detopping on the canopy and yield of cotton (Gossypium hirsutum L) in south Xinjiang. Cotton Sci. 2011, 23, 329–333. [Google Scholar]

- Dong, C.L.; Luo, H.H.; Zhang, Y.L.; Zhang, W.F. Research on Cotton Agronomic Traits and Chemical Topping Effect after Spraying Flumetralin. Xinjiang Agric. Sci. 2013, 50, 1985–1990. [Google Scholar]

- Yang, C.X.; Zhang, W.F.; Xu, S.Z.; Sui, L.; Liang, F.B.; Dong, H.Y. Effects of Spraying Chemical Topping Agents on Canopy Structure and Canopy Photosynthetic Production in Cotton. Sci. Agric. Sin. 2016, 49, 1674–1684. [Google Scholar]

- Wang, D.; Jiang, W.L.; Ma, Y.J.; Ma, X.Y.; Ren, X.L.; Hu, H.Y.; Ma, Y. Effects of Mepiquat Chloride and Chlorocholine Chloride (CCC) on Cotton Growth under Different Application Methods. China Cotton. 2018, 45, 37–40+46. [Google Scholar]

- Rademacher, W. Plant growth regulators: Backgrounds and uses in plant production. J. Plant Growth Regul. 2015, 34, 845–872. [Google Scholar] [CrossRef]

- Bons, H.K.; Kaur, M. Role of plant growth regulators in improving fruit set, quality and yield of fruit crops: A review. J. Hortic. Sci. Biotechnol. 2019, 95, 137–146. [Google Scholar] [CrossRef]

- Liang, F.B.; Yang, C.X.; Sui, L.L.; Xu, S.Z.; Yao, H.S.; Zhang, W.F. Flumetralin and dimethyl piperidinium chloride alter light distribution in cotton canopies by optimizing the spatial configuration of leaves and bolls. J. Integr. Agric. 2020, 19, 1777–1788. [Google Scholar] [CrossRef]

- Pettigrew, W.T. The effect of higher temperatures on cotton lint yield production and fiber quality. Crop Sci. 2008, 48, 278–285. [Google Scholar] [CrossRef]

- Min, L.; Li, Y.Y.; Hu, Q.; Zhu, L.F.; Gao, W.H.; Wu, Y.L.; Ding, Y.H.; Liu, S.M.; Yang, X.Y.; Zhang, X.L. Sugar and auxin signaling pathways respond to high-temperature stress during anther development as revealed by transcript profiling analysis in cotton. Plant Physiol. 2014, 164, 1293–1308. [Google Scholar] [CrossRef] [PubMed]

- Zahid, K.R.; Ali, F.; Shah, F.; Younas, M.; Shah, T.; Shahwar, D.; Hassan, W.; Ahmad, Z.; Qi, C.; Lu, Y.L.; et al. Response and tolerance mechanism of cotton Gossypium hirsutum L. To elevated temperature stress: A review. Front. Plant Sci. 2016, 7, 937. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Min, L.; Wang, J.D.; Li, Y.Y.; Wu, Y.L.; Hu, Q.; Ding, Y.H.; Wang, M.J.; Liang, Y.J.; Gong, Z.L.; et al. A combination of genome-wide and transcriptome-wide association studies reveals genetic elements leading to male sterility during high temperature stress in cotton. New Phytol. 2021, 231, 165–181. [Google Scholar] [CrossRef] [PubMed]

- Horváth, E.; Szalai, G.; Janda, T. Induction of abiotic stress tolerance by salicylic acid signaling. J. Plant Growth Regul. 2007, 26, 290–300. [Google Scholar] [CrossRef]

- Dat, J.F.; Lopez-Delgado, H.; Foyer, C.H.; Scott, I.M. Parallel changes in H2O2 and catalase during thermotolerance induced by salicylic acid or heat acclimation in mustard seedlings. Plant Physiol. 1998, 116, 1351–1357. [Google Scholar] [CrossRef]

- Senaratna, T.; Touchell, D.; Bunn, E.; Dixon, K. Acetyl salicylic acid (aspirin) and salicylic acid induce multiple stress tolerance in bean and tomato plants. J. Plant Growth Regul. 2000, 30, 157–161. [Google Scholar] [CrossRef]

- Ashraf, M.; Akram, N.A.; Arteca, R.N.; Foolad, M.R. The physiological, biochemical and molecular roles of brassinosteroids and salicylic acid in plant processes and salt tolerance. CRC Crit. Rev. Plant Sci. 2010, 29, 162–190. [Google Scholar] [CrossRef]

- Kang, H.M.; Saltveit, M.E. Chilling tolerance of maize, cucumber and rice seedling leaves and roots are differentially affected by salicylic acid. Physiol. Plant 2002, 115, 571–576. [Google Scholar] [CrossRef]

- Barros, T.C.; de Mello Prado, R.; Roque, C.G.; Arf, M.V.; Vilela, R.G. Silicon and salicylic acid in the physiology and yield of cotton. J. Plant Nutr. 2019, 42, 458–465. [Google Scholar] [CrossRef]

- Lei, Z.G.; Chen, B.H.; Koo, Y.-M.; MacFarlane, D.R. Introduction: Ionic liquids. Chem. Rev. 2017, 117, 6633–6635. [Google Scholar] [CrossRef] [PubMed]

- Stoimenovski, J.; Dean, P.M.; Izgorodina, E.I.; MacFarlane, D.R. Protic pharmaceuticalionic liquids and solids: Aspects of protonics. Faraday Discuss. 2012, 154, 335–352. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Qin, L.; Mu, T.C.; Xue, Z.M.; Gao, G.H. Are ionic liquids chemically stable? Chem. Rev. 2017, 117, 7113–7131. [Google Scholar] [CrossRef]

- Lepre, L.F.; Andre, D.; Denis-Quanquin, S.; Gautier, A.V.; Pádua, A.A.H.; Gomes, M.C. Ionic liquids can enable the recycling of fluorinated greenhouse gases. ACS Sustain. Chem. End. 2019, 7, 16900–16906. [Google Scholar] [CrossRef]

- Tang, G.; Niu, J.F.; Tang, J.Y.; Yang, J.L.; Zhou, Z.Y.; Gao, Y.H.; Chen, X.; Tang, R.; Tian, Y.Y.; Li, Y.; et al. Development of poly (ionic liquids) based on mepiquat chloride with improved rainfastness and long-lasting activity on growth regulation of cotton plant. ACS Sustain. Chem. Eng. 2020, 8, 14996–15004. [Google Scholar] [CrossRef]

- Cravotto, G.; Boffa, L.; Lévêque, J.-M.; Estager, J.; Draye, M.; Bonrath, W. A speedy one-pot synthesis of second-generation ionic liquids under ultrasound and/or microwave irradiation. Aust. J. Chem. 2007, 60, 946–950. [Google Scholar] [CrossRef]

- Boruń, A. Conductance and ionic association of selected imidazolium ionic liquids in various solvents: A review. J. Mol. Liq. 2019, 276, 214–224. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, B.L. Measurements of proline and malondialdehyde content and antioxidant enzyme activities in leaves of drought stressed cotton. Bio Protocol 2016, 6, e1913. [Google Scholar] [CrossRef]

- Han, H.Y.; Du, M.W.; Wang, F.Y.; Chen, B.; Tian, X.L. Effects of DPC+ Application dose on agronomic and economic traits of cotton in northern Xinjiang. Southwest China J. Agric. Sci. 2019, 32, 327–330. [Google Scholar]

- Liu, C.; Zhang, J.S.; Wei, X.; Xu, X.X. Effects of mepiquat chloride on physiological indicators of leaf function and characteristics of yield of hybrid cotton in south Xinjiang. Cotton Sci. 2014, 26, 122–129. [Google Scholar]

- Zafar, M.M.; Manan, A.; Razzaq, A.; Zulfqar, M.; Saeed, A.; Kashif, M.; Khan, A.I.; Sarfraz, Z.; Mo, H.J.; Iqbal, M.S.; et al. Exploiting Agronomic and Biochemical Traits to Develop Heat Resilient Cotton Cultivars under Climate Change Scenarios. Agronomy 2021, 11, 1885. [Google Scholar] [CrossRef]

- López-Hernández, F.; Cortés, A.J. Last-generation genome-environment associations reveal the genetic basis of heat tolerance in common bean (Phaseolus vulgaris L.). Front. Genet. 2019, 10, 954. [Google Scholar] [CrossRef]

- Cortés, A.J.; López-Hernández, F.; Osorio-Rodriguez, D. Predicting Thermal Adaptation by Looking into Populations’ Genomic Past. Front. Genet. 2020, 11, 1093. [Google Scholar] [CrossRef] [PubMed]

- Zafar, M.M.; Zhang, Y.F.; Farooq, M.A.; Ali, A.; Firdous, H.; Haseeb, M.; Fiaz, S.; Shakeel, A.; Razzaq, A.; Ren, M.Z. Biochemical and Associated Agronomic Traits in Gossypium hirsutum L. under High Temperature Stress. Agronomy 2022, 12, 1310. [Google Scholar] [CrossRef]

- Zafar, M.M.; Chattha, W.S.; Khan, A.I.; Zafar, S.; Subhan, M.; Saleem, H.; Ali, A.; Ijaz, A.; Anwar, Z.; Qiao, F.; et al. Drought and heat stress on cotton genotypes suggested agro-physiological and biochemical features for climate resilience. Front. Plant Sci. 2023, 14, 1265700. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Tang, J.Y.; Tian, J.S.; Du, M.W.; Gou, L.; Zhang, Y.L.; Zhang, W.F. Different concentrations of chemical topping agents affect cotton yield and quality by regulating plant architecture. Agronomy 2023, 13, 1741. [Google Scholar] [CrossRef]

- Lou, S.; Du, M.W.; Gao, F.; Tian, X.L.; Zhang, P.Z.; Li, J.; Duan, L.S. The Effect of New Nano-Released 1, 1-Dimethyl-Piperidinium Chloride (DPC) Drip Application on Cotton Agronomic Traits. Agronomy 2023, 13, 1543. [Google Scholar] [CrossRef]

- Kaggwa-Asiimwe, R.; Andrade-Sanchez, P.; Wang, G.Y. Plant architecture influences growth and yield response of upland cotton to population density. Field Crops Res. 2013, 145, 52–59. [Google Scholar] [CrossRef]

- Chen, M.Z.; Yang, Y.L.; Wang, Y.X.; Tian, J.S.; Xu, S.Z.; Liu, N.N.; Dang, K.; Zhang, W.F. Plant Type Characteristics and Evolution of Main Economic Characters in Early Maturing Upland Cotton Cultivar Replacement in Xinjiang. Sci. Agric. Sin. 2019, 52, 3279–3290. [Google Scholar]

- Wang, F.Y.; Han, H.Y.; Lin, H.; Chen, B.; Kong, X.H.; Ning, X.Z.; Wang, X.W.; Yu, Y.; Liu, J.D. Effects of planting patterns on yield, quality, and defoliation in machine-harvested cotton. J. Integr. Agric. 2019, 18, 2019–2028. [Google Scholar] [CrossRef]

- Sultana, F.; Dev, W.; Zhang, Z.G.; Wang, Y.R.; Chen, J.L.; Wang, J.; Khan, H.; Tajo, S.M.; Li, Y.B. The consequences of plant architecture and spatial distribution of light interception on cotton growth and yield. Int. J. Agric. Biosci. 2023, 12, 153–158. [Google Scholar]

- Sarwar, M.; Saleem, M.F.; Ullah, N.; Rizwan, M.; Ali, S.; Shahid, M.R.; Alamri, S.A.; Alyemeni, M.N.; Ahmad, P. Exogenously applied growth regulators protect the cotton crop from heat-induced injury by modulating plant defense mechanism. Sci. Rep. 2018, 8, 17086. [Google Scholar] [CrossRef] [PubMed]

| Year | Date | Daily High Temperature (°C) | Average Relative Humidity (%) |

|---|---|---|---|

| 2022 | 7.3 | 32 | 35 |

| 7.4 | 35 | 41 | |

| 7.5 | 37 | 34 | |

| 7.6 | 37 | 33 | |

| 7.7 | 34 | 32 | |

| 7.8 | 33 | 40 | |

| 7.9 | 34 | 46 | |

| 7.10 | 30 | 35 | |

| 7.11 | 35 | 47 | |

| 7.12 | 34 | 47 | |

| 7.13 | 33 | 50 | |

| 7.14 | 35 | 48 | |

| 7.15 | 35 | 64 | |

| 7.16 | 34 | 54 | |

| 7.17 | 36 | 49 | |

| 2023 | 7.8 | 36 | 58 |

| 7.9 | 35 | 45 | |

| 7.10 | 36 | 48 | |

| 7.11 | 36 | 46 | |

| 7.12 | 37 | 44 | |

| 7.13 | 35 | 38 | |

| 7.14 | 36 | 47 | |

| 7.15 | 37 | 39 | |

| 7.16 | 40 | 40 | |

| 7.17 | 39 | 35 | |

| 7.18 | 38 | 29 | |

| 7.19 | 38 | 40 | |

| 7.20 | 38 | 33 | |

| 7.21 | 36 | 38 | |

| 7.22 | 37 | 40 |

| Treatment | Water Solubility | Surface Tension (mN/m) |

|---|---|---|

| CCC | + | 70.30 ± 0.02 a |

| SA | − | 64.44 ± 0.02 b |

| CSILs | + | 38.19 ± 0.02 c |

| Year | Treatment | Length of the Inverted Fruit Branch (cm) | Length of the Second Fruit Branch (cm) | Length of the Inverted Third Fruit Branch (cm) | Length of the Inverted Four Fruit Branch (cm) |

|---|---|---|---|---|---|

| 2022 | CSILs 60 g AI ha−1 | 6.10 ± 0.53 b | 6.80 ± 0.52 c | 9.10 ± 0.36 c | 10.50 ± 0.70 bc |

| CSILs 90 g AI ha−1 | 3.17 ± 0.58 c | 6.07 ± 0.55 c | 7.30 ± 0.37 d | 9.77 ± 0.56 c | |

| CSILs 120 g AI ha−1 | 2.40 ± 0.36 c | 4.20 ± 0.36 d | 6.13 ± 0.41 e | 8.27 ± 0.68 d | |

| CCC | 7.87 ± 0.70 a | 9.10 ± 0.36 b | 11.47 ± 0.65 b | 10.77 ± 0.65 ab | |

| MT | 8.83 ± 0.65 a | 10.83 ± 1.15 a | 12.73 ± 0.80 a | 11.57 ± 0.50 a | |

| 2023 | CSILs 60 g AI ha−1 | 6.22 ± 0.46 b | 6.78 ± 0.43 c | 9.41 ± 0.44 c | 10.64 ± 0.81 bc |

| CSILs 90 g AI ha−1 | 3.28 ± 0.39 c | 6.15 ± 0.44 c | 7.74 ± 0.64 d | 9.47 ± 0.60 c | |

| CSILs 120 g AI ha−1 | 2.38 ± 0.25 c | 4.05 ± 0.28 d | 6.08 ± 0.33 e | 8.35 ± 0.63 d | |

| CCC | 8.08 ± 0.79 a | 9.46 ± 0.45 b | 11.88 ± 0.85 b | 11.08 ± 0.91 ab | |

| MT | 8.97 ± 0.86 a | 11.23 ± 0.88 a | 12.95 ± 0.92 a | 11.95 ± 0.84 a |

| Year | Treatment | Upper Half Mean Length (mm) | Uniformity Index (%) | Micronaire | Fiber Strength (cN/tex) | Elongation (%) |

|---|---|---|---|---|---|---|

| 2022 | CSILs 60 g AI ha−1 | 29.57 ± 0.49 a | 85.7 ± 1.28 a | 4.92 ± 0.44 a | 32.61 ± 0.26 b | 8.17 ± 0.35 ab |

| CSILs 90 g AI ha−1 | 30.1 ± 1.28 a | 86.03 ± 0.61 a | 4.87 ± 0.33 a | 34.25 ± 1.22 a | 8.5 ± 0.17 a | |

| CSILs 120 g AI ha−1 | 29.58 ± 1.42 a | 85.43 ± 0.67 a | 5.06 ± 0.26 a | 34.45 ± 1.08 a | 8.3 ± 0.15 ab | |

| CCC | 30.1 ± 0.83 a | 85.67 ± 1.39 a | 4.71 ± 0.34 a | 30.70 ± 0.72 c | 8.05 ± 0.08 b | |

| MT | 30.75 ± 1.25 a | 86.37 ± 0.15 a | 4.67 ± 0.37 a | 31.55 ± 0.78 bc | 8.37 ± 0.06 ab | |

| 2023 | CSILs 60 g AI ha−1 | 30.12 ± 0.65 a | 86.78 ± 1.53 a | 4.85 ± 0.13 a | 33.79 ± 0.66 ab | 8.23 ± 0.42 b |

| CSILs 90 g AI ha−1 | 31.23 ± 1.13 a | 87.55 ± 1.87 a | 4.97 ± 0.14 a | 35.27 ± 1.20 a | 8.65 ± 0.30 a | |

| CSILs 120 g AI ha−1 | 31.08 ± 0.96 a | 88.48 ± 1.94 a | 5.12 ± 0.03 a | 35.84 ± 1.99 a | 8.54 ± 0.25 ab | |

| CCC | 31.22 ± 1.39 a | 86.58 ± 1.23 a | 4.79 ± 0.24 a | 31.77 ± 1.57 b | 8.21 ± 0.20 b | |

| MT | 31.88 ± 0.86 a | 88.12 ± 3.05 a | 4.63 ± 0.17 a | 32.78 ± 1.88 ab | 8.47 ± 0.24 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, Y.; Liu, J.; Hao, B.; Xu, R.; Zhang, J.; Xiao, H.; Wan, S.; Chen, G.; Dong, H. Effect of Chloride Salicylic Acid Ionic Liquids on Cotton Topping and High-Temperature Resistance. Agronomy 2023, 13, 2905. https://doi.org/10.3390/agronomy13122905

Ji Y, Liu J, Hao B, Xu R, Zhang J, Xiao H, Wan S, Chen G, Dong H. Effect of Chloride Salicylic Acid Ionic Liquids on Cotton Topping and High-Temperature Resistance. Agronomy. 2023; 13(12):2905. https://doi.org/10.3390/agronomy13122905

Chicago/Turabian StyleJi, Yuxi, Jie Liu, Bin Hao, Ruichuan Xu, Jianwei Zhang, Haibing Xiao, Sumei Wan, Guodong Chen, and Hongqiang Dong. 2023. "Effect of Chloride Salicylic Acid Ionic Liquids on Cotton Topping and High-Temperature Resistance" Agronomy 13, no. 12: 2905. https://doi.org/10.3390/agronomy13122905

APA StyleJi, Y., Liu, J., Hao, B., Xu, R., Zhang, J., Xiao, H., Wan, S., Chen, G., & Dong, H. (2023). Effect of Chloride Salicylic Acid Ionic Liquids on Cotton Topping and High-Temperature Resistance. Agronomy, 13(12), 2905. https://doi.org/10.3390/agronomy13122905