Rotary Ripper: A Possible Solution to Increase the Efficiency of Tillage Operations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tractor and Implements

2.2. Sensors and Acquisition System

- SPN 544 and PGN 65251: ‘Engine Reference Torque’ reports the maximum engine torque available (Mr) at a sampling rate of 0.2 Hz.

- SPN 513 and PGN 61444: ‘Actual Engine—Percent Torque’ reports the torque (Me) as a percentage of Mr at a sampling rate of 50 Hz.

- SPN 513 and PGN 5398: ‘Nominal Friction—Per cent Torque’, denoted as Mf, reports the sum of the engine frictional and thermodynamic loss, pumping torque loss, and losses of fuel, oil, and cooling pumps as a percentage of Mr at a sampling rate of 20 Hz.

- SPN 190 and PGN 61444: ‘Engine Speed’ reports the revolution speed of the engine crankshaft (ne) at a sampling rate of 10 Hz.

- SPN 1883 and PGN 65090: ‘Rear PTO Output Shaft Speed’ reports the speed of the rear PTO (npto) at a sampling rate of 10 Hz.

- SPN 183 and PGN 65266: ‘Engine Fuel Rate’ reports the fuel consumed by the engine per unit of time (f) at a sampling rate of 10 Hz.

- SPN 1873 and PGN 65093: ‘Rear Hitch Position’ reports the position of the rear three-point hitch at a sampling rate of 10 Hz.

- SPN 8768 and PGN 8960, ‘Hitch Information—Rear in Work’ reports the status of the rear three-point linkage (TPH), which is equivalent to 1 when the TPH is in working position and 0 when the TPH is lifted. It is denoted as Htph and measured at a sampling rate of 10 Hz.

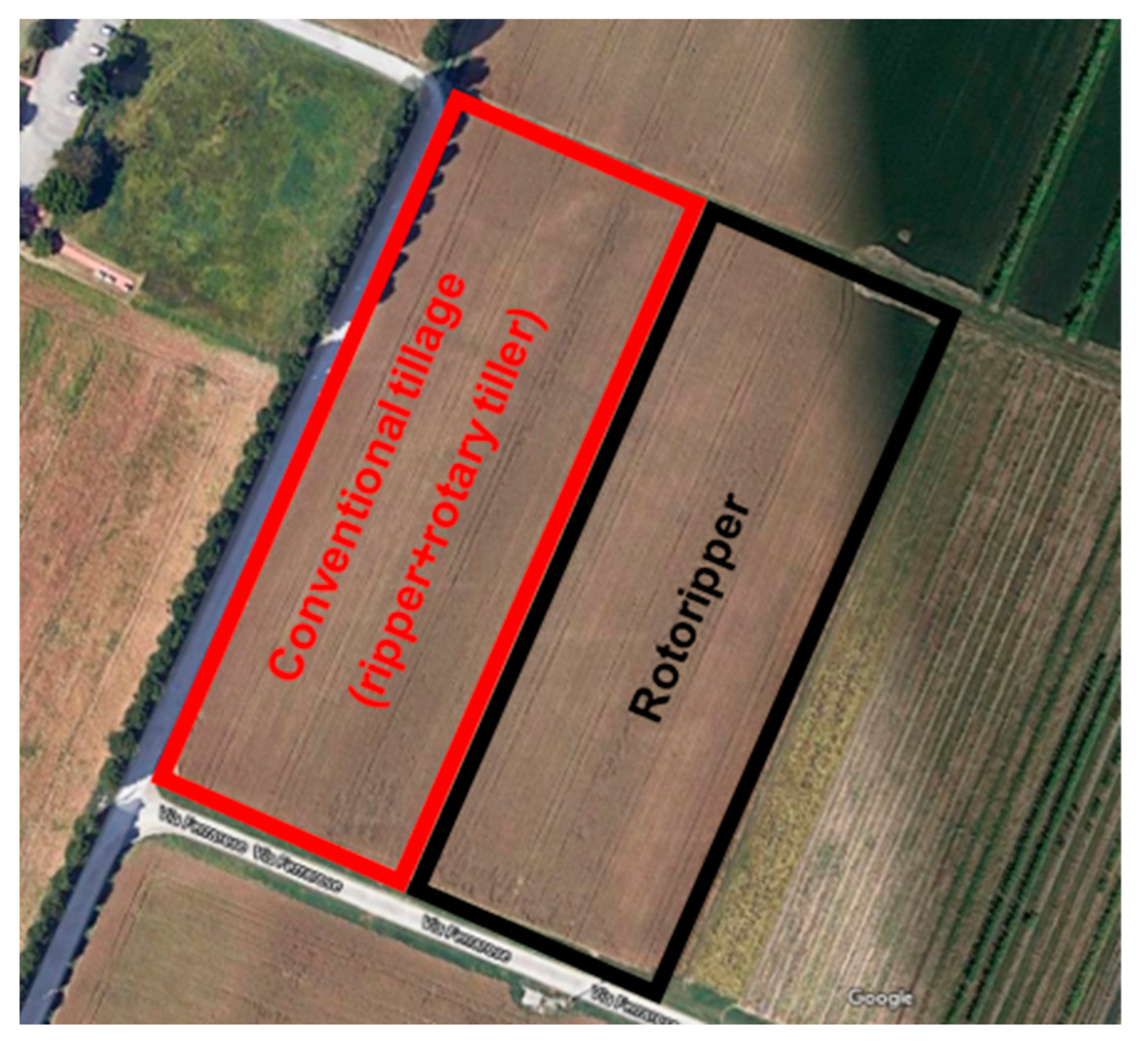

2.3. Experimental Sites and Soil Characteristics

2.4. Test Conditions and Experimental Design

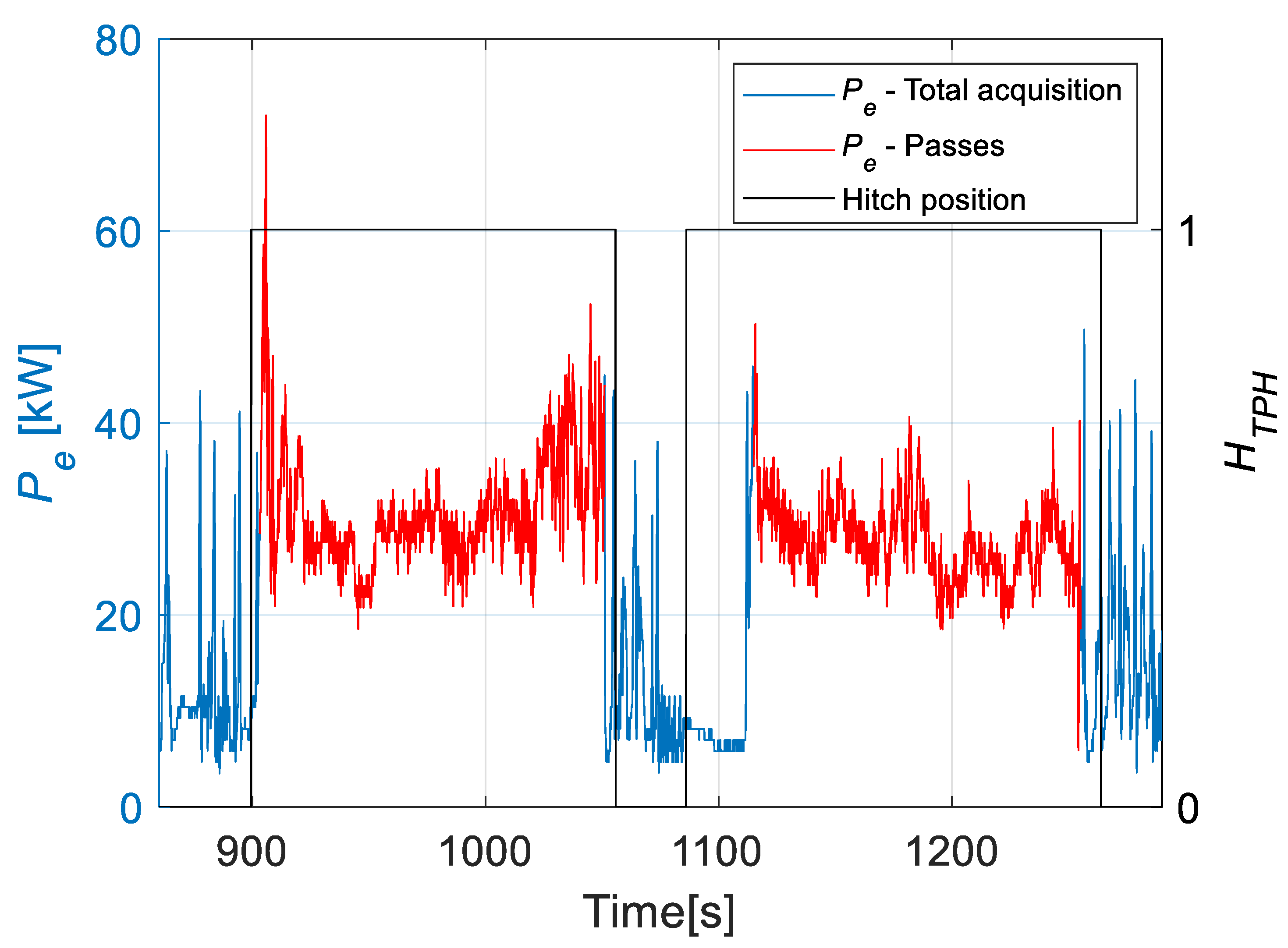

2.5. Field Operation Data Analysis

2.6. Economic Evaluation

3. Results

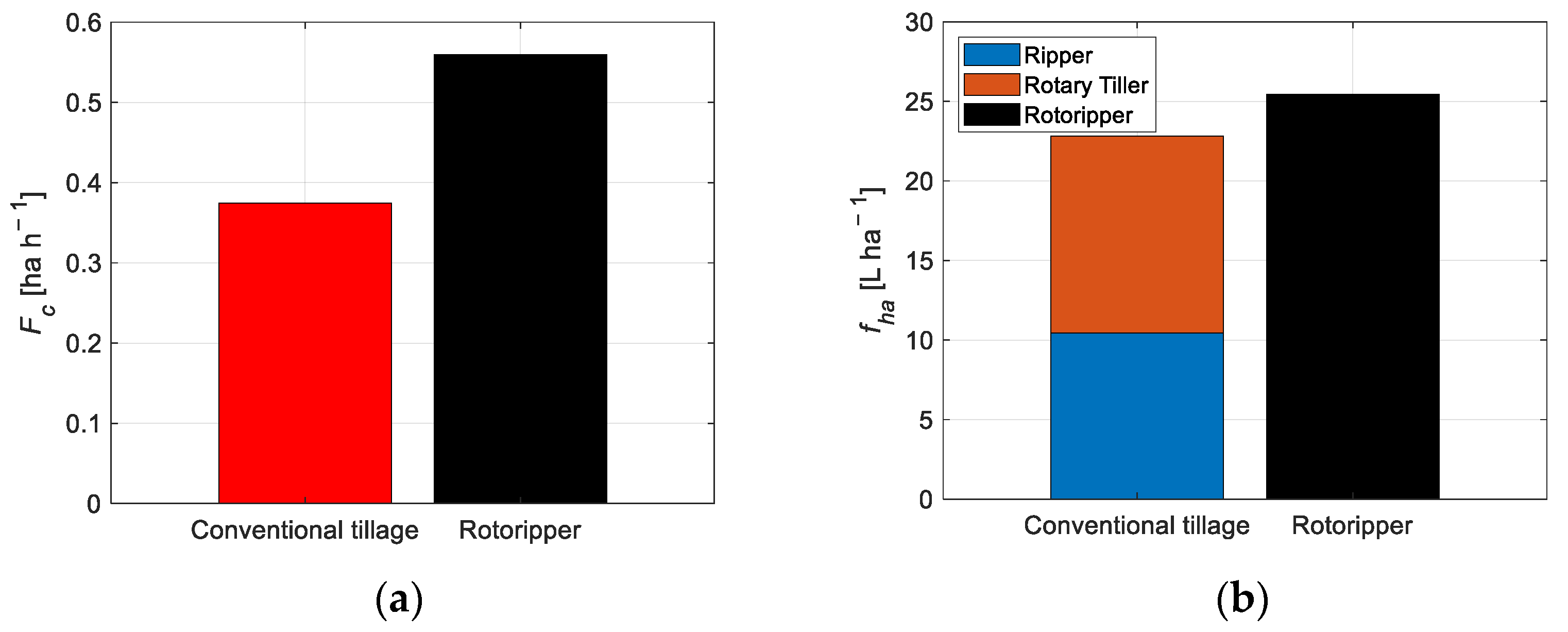

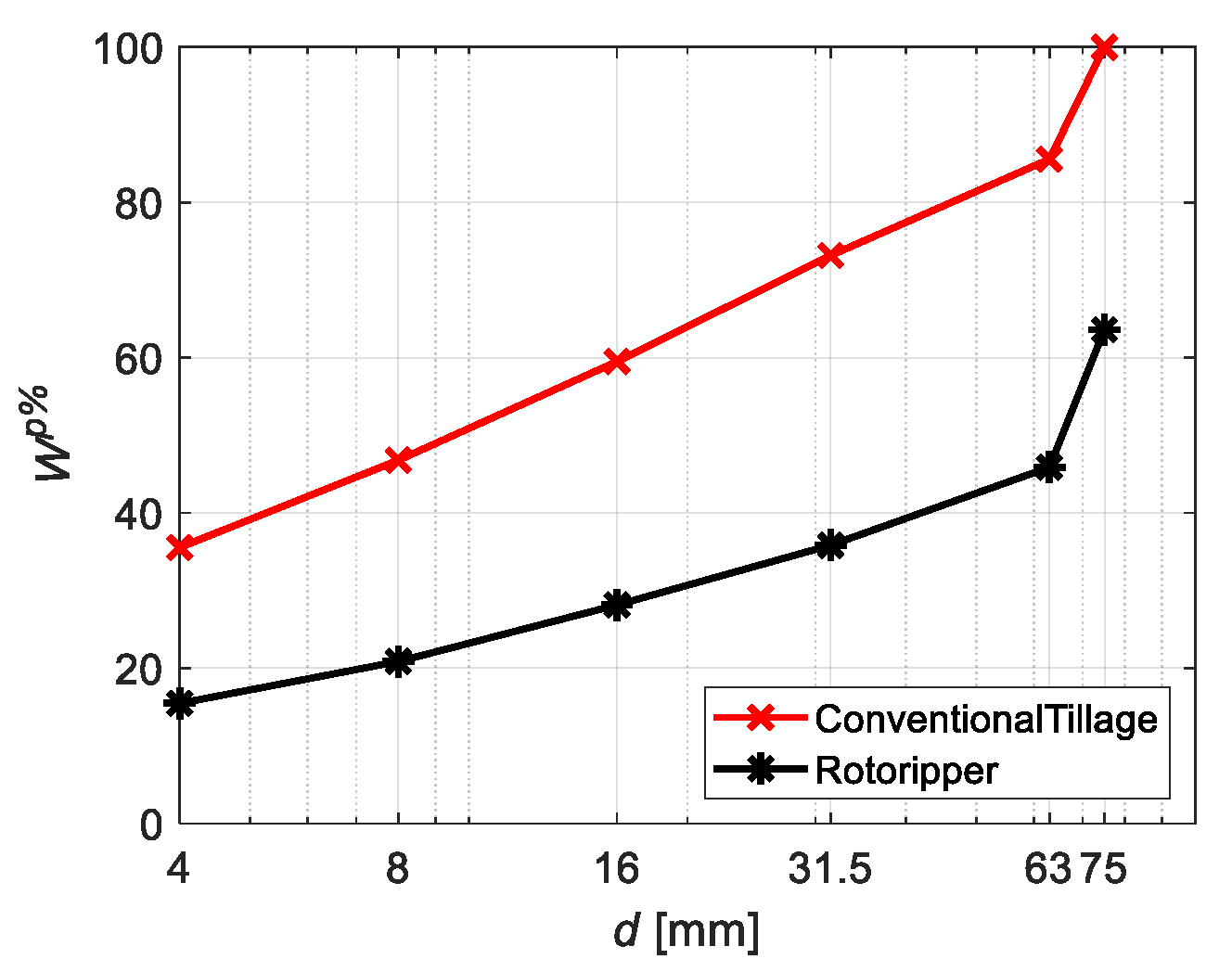

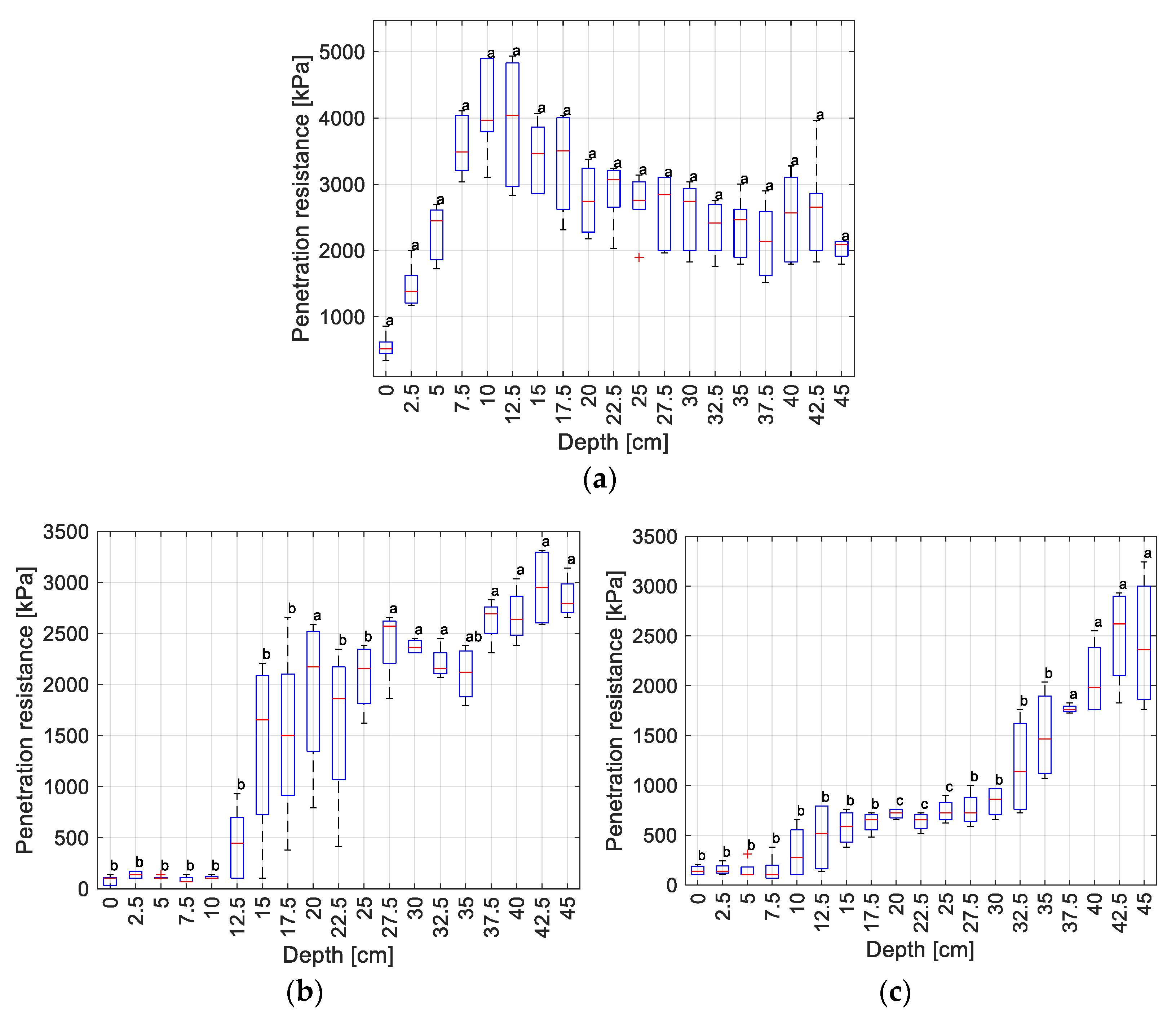

3.1. Field Tests Results

3.2. Economic Evaluation

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beckman, J.; Ivanic, M.; Jelliffe, J.L.; Baquedano, F.G.; Scott, S.G. Economic and Food Security Impacts of Agricultural Input Reduction Under the European Union Green Deal’s Farm to Fork and Biodiversity Strategies; Economic Research Service: Washington, DC, USA, 2020. [Google Scholar]

- Garnett, T.; Appleby, M.C.; Balmford, A.; Bateman, I.J.; Benton, T.G.; Bloomer, P.; Burlingame, B.; Dawkins, M.; Dolan, L.; Fraser, D.; et al. Sustainable Intensification in Agriculture: Premises and Policies. Science 2013, 341, 33–34. [Google Scholar] [CrossRef]

- Balázs, B.; Kelemen, E.; Centofanti, T.; Vasconcelos, M.W.; Iannetta, P.P.M. Integrated policy analysis to identify transformation paths to more sustainable legume-based food and feed value-chains in Europe. Agroecol. Sustain. Food Syst. 2021, 45, 931–953. [Google Scholar] [CrossRef]

- Zanin, A.; Dal Magro, C.B.; Bugalho, D.K.; Morlin, F.; Afonso, P.; Sztando, A. Driving Sustainability in Dairy Farming from a TBL Perspective: Insights from a Case Study in the West Region of Santa Catarina, Brazil. Sustainability 2020, 12, 6038. [Google Scholar] [CrossRef]

- Singh, S.; Srivastava, S.K. Decision support framework for integrating triple bottom line (TBL) sustainability in agriculture supply chain. Sustain. Account. Manag. Policy J. 2021. ahead of print. [Google Scholar] [CrossRef]

- Elkington, J. Towards the Sustainable Corporation: Win-Win-Win Business Strategies for Sustainable Development. Calif. Manag. Rev. 1994, 36, 90–100. [Google Scholar] [CrossRef]

- Borin, M.; Menini, C.; Sartori, L. Effects of tillage systems on energy and carbon balance in north-eastern Italy. Soil Tillage Res. 1997, 40, 209–226. [Google Scholar] [CrossRef]

- Choudhary, S.; Upadhyay, G.; Patel, B.; Sihag, N.; Jain, M. Energy Requirements and Tillage Performance Under Different Active Tillage Treatments in Sandy Loam Soil. J. Biosyst. Eng. 2021, 46, 353–364. [Google Scholar] [CrossRef]

- Balsari, P.; Biglia, A.; Comba, L.; Sacco, D.; Alcatrão, L.E.; Varani, M.; Mattetti, M.; Barge, P.; Tortia, C.; Manzone, M.; et al. Performance analysis of a tractor—Power harrow system under different working conditions. Biosyst. Eng. 2020, 202, 28–41. [Google Scholar] [CrossRef]

- Godwin, R. A review of the effect of implement geometry on soil failure and implement forces. Soil Tillage Res. 2007, 97, 331–340. [Google Scholar] [CrossRef]

- Mattetti, M.; Varani, M.; Molari, G.; Morelli, F. Influence of the speed on soil-pressure over a plough. Biosyst. Eng. 2017, 156, 136–147. [Google Scholar] [CrossRef]

- Natsis, A.; Papadakis, G.; Pitsilis, J. The Influence of Soil Type, Soil Water and Share Sharpness of a Mouldboard Plough on Energy Consumption, Rate of Work and Tillage Quality. J. Agric. Eng. Res. 1999, 72, 171–176. [Google Scholar] [CrossRef]

- OECD. Environmental Indicators for Agriculture—Volume 3: Methods and Results; OECD Publishing: Berlin, Germany, 2001. [Google Scholar]

- Biswas, M.R. Agricultural Production and Environment: A Review. Environ. Conserv. 1984, 11, 253–259. [Google Scholar] [CrossRef]

- Varani, M.; Mattetti, M.; Maraldi, M.; Molari, G. Mechanical Devices for Mass Distribution Adjustment: Are They Really Convenient? Agronomy 2020, 10, 1820. [Google Scholar] [CrossRef]

- Varani, M.; Mattetti, M.; Molari, G. Performance Evaluation of Electrically Driven Agricultural Implements Powered by an External Generator. Agronomy 2021, 11, 1447. [Google Scholar] [CrossRef]

- Scarlett, A.J. Integrated control of agricultural tractors and implements: A review of potential opportunities relating to cultivation and crop establishment machinery. Comput. Electron. Agric. 2001, 30, 167–191. [Google Scholar] [CrossRef]

- Mohammadi, F.; Maleki, M.R.; Khodaei, J. Control of variable rate system of a rotary tiller based on real-time measurement of soil surface roughness. Soil Tillage Res. 2021, 215, 105216. [Google Scholar] [CrossRef]

- Riegler-Nurscher, P.; Moitzi, G.; Prankl, J.; Huber, J.; Karner, J.; Wagentristl, H.; Vincze, M. Machine vision for soil roughness measurement and control of tillage machines during seedbed preparation. Soil Tillage Res. 2019, 196, 104351. [Google Scholar] [CrossRef]

- Knowler, D.; Bradshaw, B. Farmers’ adoption of conservation agriculture: A review and synthesis of recent research. Food Policy 2007, 32, 25–48. [Google Scholar] [CrossRef]

- Holland, J.M. The environmental consequences of adopting conservation tillage in Europe: Reviewing the evidence. Agric. Ecosyst. Environ. 2004, 103, 1–25. [Google Scholar] [CrossRef]

- Lal, R. Carbon emission from farm operations. Environ. Int. 2004, 30, 981–990. [Google Scholar] [CrossRef]

- Rusu, T. Energy efficiency and soil conservation in conventional, minimum tillage and no-tillage. Int. Soil Water Conserv. Res. 2014, 2, 42–49. [Google Scholar] [CrossRef] [Green Version]

- Hunt, D.; Wilson, D. Farm Power and Machinery Management, 11th ed.; Waveland Press: Long Grove, IL, USA, 2015; ISBN 978-1-4786-3177-4. [Google Scholar]

- Vozka, P. Comparison of Alternative Tillage Systems. Master’s Thesis, Cranfield University School of Applied Sciences, Cranfield, UK, 2007. [Google Scholar]

- Weersink, A.; Walker, M.; Swanton, C.; Shaw, J. Economic Comparison of Alternative Tillage Systems under Risk. Can. J. Agric. Econ. Can. d′Agroeconomie 1992, 40, 199–217. [Google Scholar] [CrossRef]

- Sijtsma, C.H.; Campbell, A.J.; McLaughlin, N.B.; Carter, M.R. Comparative tillage costs for crop rotations utilizing minimum tillage on a farm scale. Soil Tillage Res. 1998, 49, 223–231. [Google Scholar] [CrossRef]

- Soane, B.D.; Ball, B.C.; Arvidsson, J.; Basch, G.; Moreno, F.; Roger-Estrade, J. No-till in northern, western and south-western Europe: A review of problems and opportunities for crop production and the environment. Soil Tillage Res. 2012, 118, 66–87. [Google Scholar] [CrossRef] [Green Version]

- Pagliai, M.; Vignozzi, N.; Pellegrini, S. Soil structure and the effect of management practices. Soil Tillage Res. 2004, 79, 131–143. [Google Scholar] [CrossRef]

- Chen, Y.; Cavers, C.; Tessier, S.; Monero, F.; Lobb, D. Short-term tillage effects on soil cone index and plant development in a poorly drained, heavy clay soil. Soil Tillage Res. 2005, 82, 161–171. [Google Scholar] [CrossRef]

- Rotoripper—Ripuntatore Rotativo | SELVATICI Srl. Available online: https://www.selvatici.com/ita/products/rotoripper---ripuntatore-rotativo-cat-14.html (accessed on 22 December 2022).

- Köppen, W. Das Geographische System Der Climate; Gebrü der Borntraeger: Berlin, Germany, 1936. [Google Scholar]

- ASTM. ASTM D3441-16 Standard Test Method for Mechanical Cone Penetration Testing of Soils; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- USDA. Soil Mechanichs Level I.; U.S. Department of Agriculture: Washington, DC, USA, 1987.

- ASTM. ASTM D4318-17e1 Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; ASTM International: Washington, DC, USA, 2018. [Google Scholar]

- Geerlings, H.; van Duin, R. A new method for assessing CO2-emissions from container terminals: A promising approach applied in Rotterdam. J. Clean. Prod. 2011, 19, 657–666. [Google Scholar] [CrossRef]

- Mattetti, M.; Beltramin, A.; Estevez, M.A.P.; Varani, M.; Renzi, M.; Alberti, L. Start and stop systems on agricultural tractors as solution for saving fuel and emissions. Biosyst. Eng. 2022, 216, 108–120. [Google Scholar] [CrossRef]

- ASTM. D2488—Practice for Description and Identification of Soils (Visual-Manual Procedure); ASTM International: Washington, DC, USA, 2009. [Google Scholar]

- ASTM. ASTM D6913/D6913M-17—Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis; ASTM International: Washington, DC, USA, 2021. [Google Scholar]

- BS ISO 3310-2:2013 Test Sieves—Technical Requirements and Testing. Civ. Environ. Res. 2013, 14, 7.

- Van Bavel, C.H.M. Mean Weight-Diameter of Soil Aggregates as a Statistical Index of Aggregation. Soil Sci. Soc. Am. J. 1950, 14, 20–23. [Google Scholar] [CrossRef] [Green Version]

- Bodria, L.; Pellizzi, G.; Piccarolo, P. Meccanica agraria; Edagricole: Bologna, Italy, 2006; ISBN 978-88-506-5131-3. [Google Scholar]

- ASAE. D497.7 Agricultural Machinery Management Data; American Society of Association Executives: Washington, DC, USA, 2015. [Google Scholar]

- Edwards, W. Machinery Management: Estimating Farm Machinery Costs. Ag Decis. Mak. 2015, A3–29. [Google Scholar]

- Medici, M.; Canavari, M. Addressing Risk Associated to ICT-Based Technology: Estimation of Financial Parameters; IGI Global: Hershey, PA, USA, 2021; pp. 174–184. ISBN 978-1-79984-850-9. [Google Scholar]

- Kay, R.; Edwards, W.; Duffy, P. Farm Management, 9th ed.; McGraw-Hill Education: New York, NY, USA, 2020; ISBN 978-1-260-00219-5. [Google Scholar]

- ASAE. ASAE D496.3—Agricultural Machinery Management; ASAE Standard: St. Joseph, MI, USA, 2006. [Google Scholar]

- Kheiralla, A.; Yahya, A.; Zohadie, M.; Ishak, W. Modelling of power and energy requirements for tillage implements operating in Serdang sandy clay loam, Malaysia. Soil Tillage Res. 2004, 78, 21–34. [Google Scholar] [CrossRef]

- Fanigliulo, R.; Pochi, D.; Servadio, P. Conventional and Conservation Seedbed Preparation Systems for Wheat Planting in Silty-Clay Soil. Sustainability 2021, 13, 6506. [Google Scholar] [CrossRef]

- Smith, L.A.; Williford, J.R. Power Requirements of Conventional, Triplex, and Parabolic Subsoilers. Trans. Am. Soc. Agric. Eng. 1988, 31, 1685–1688. [Google Scholar] [CrossRef]

- ASAE. ASAE D497.7—Agricultural Machinery Management Data; ASAE Standard: St. Joseph, MI, USA, 2011; pp. 1–15. [Google Scholar]

- Weise, G.; Engelhardt, D. The Use of Trucks for Agricultural Transport. In Proceedings of the 2000 ASAE Annual International Meeting, Milwaukee, WI, USA, 9–12 July 2000; Volume 1, pp. 2527–2540. [Google Scholar]

- Adam, K.M.; Erbach, D.C. Secondary Tillage Tool Effect on Soil Aggregation. Trans. ASAE 1992, 35, 1771–1776. [Google Scholar] [CrossRef]

- Braunack, M.V.; Dexter, A.R. Soil aggregation in the seedbed: A review. I. Properties of aggregates and beds of aggregates. Soil Tillage Res. 1989, 14, 259–279. [Google Scholar] [CrossRef]

- Osunbitan, J.A.; Oyedele, D.J.; Adekalu, K.O. Tillage effects on bulk density, hydraulic conductivity and strength of a loamy sand soil in southwestern Nigeria. Soil Tillage Res. 2005, 82, 57–64. [Google Scholar] [CrossRef]

- Hamza, M.A.; Anderson, W.K. Soil compaction in cropping systems: A review of the nature, causes and possible solutions. Soil Tillage Res. 2005, 82, 121–145. [Google Scholar] [CrossRef]

- Weersink, A.; Walker, M.; Swanton, C.; Shaw, J.E. Costs of Conventional and Conservation Tillage Systems. J. Soil Water Conserv. 1992, 47, 328–334. [Google Scholar]

- Šařec, O.; Šařec, P.; Hájek, P. Evaluation of Different Soil Tillage Technologies of Grain Maize Production; Swedish University of Agricultural Sciences: Uppsala, Sweden, 2013; pp. 562–566. [Google Scholar]

- Wang, X.-B.; Cai, D.-X.; Hoogmoed, W.B.; Oenema, O.; Perdok, U.D. Potential Effect of Conservation Tillage on Sustainable Land Use: A Review of Global Long-Term Studies1 1Project Supported by the National Natural Science Foundation of China (No 40571151), the Beijing Key Lab of Resources Environment and GIS at Capital Normal University, and the National High Technology Research and Development Program of China (863 Program) (Nos. 2002AA2Z4311 and 2002AA2Z4021). Pedosphere 2006, 16, 587–595. [Google Scholar] [CrossRef]

- Mattetti, M.; Medici, M.; Canavari, M.; Varani, M. CANBUS-enabled activity-based costing for leveraging farm management. Comput. Electron. Agric. 2022, 194, 106792. [Google Scholar] [CrossRef]

- Varani, M.; Mattetti, M.; Molari, G.; Biglia, A.; Comba, L. Correlation between power harrow energy demand and tilled soil aggregate dimensions. Biosyst. Eng. 2023, 225, 54–68. [Google Scholar] [CrossRef]

| Specification | Conventional Tillage | Rotoripper | |

|---|---|---|---|

| Ripper | Rotary Tiller | ||

| Mass (kg) | 450 | 600 | 950 |

| Width (bim) (m) | 2.1 | 1.8 | 1.8 |

| Nominal working depth (mm) | Up to 400 | Up to 200 | From 200 up to 400 |

| Linkage category | Cat. 2 | Cat. 2 | Cat. 2 |

| Nominal PTO speed (rpm) | 540 + 540E | 540 + 540E | 540 + 540E |

| Purchase cost (Vi) (euros) | 2600 | 7000 | 12,000 |

| Specification | Value/Description |

|---|---|

| Manufacturer | CNH Industrial N.V. (Amsterdam, Netherlands) |

| Model | New Holland T5.140 |

| Nominal engine power (kW) | 96 @ 2200 rpm |

| Max torque (Nm) | 630 @1300 rpm |

| Unballasted mass (kg) | 5500 |

| Rear PTO transmission ratio in 540E mode (τPTO) | 2.86 |

| Parameter | Conventional Tillage | Rotoripper | |

|---|---|---|---|

| Ripper | Rotary Tiller | ||

| Engine Speed () (rpm)’ | 1805 (24) a | 1554 (6) b | 1574 (24) b |

| PTO speed () (rpm) | - | 543 (2) a | 550 (8) a |

| Tractor speed () (km/h)’ | 7.3 (0.03) a | 3.6 (0.13) b | 3.4 (0.06) c |

| Engine Power () (kW)’ | 66.1 (6.0) a | 29.1 (1.3) b | 69.0 (2.4) a |

| Hourly Fuel Consumption ) (L h−1) | 16.6 (1.4) a | 7.8 (0.3) b | 16.6 (0.6) a |

| Combined 24.4 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varani, M.; Mattetti, M. Rotary Ripper: A Possible Solution to Increase the Efficiency of Tillage Operations. Agronomy 2023, 13, 365. https://doi.org/10.3390/agronomy13020365

Varani M, Mattetti M. Rotary Ripper: A Possible Solution to Increase the Efficiency of Tillage Operations. Agronomy. 2023; 13(2):365. https://doi.org/10.3390/agronomy13020365

Chicago/Turabian StyleVarani, Massimiliano, and Michele Mattetti. 2023. "Rotary Ripper: A Possible Solution to Increase the Efficiency of Tillage Operations" Agronomy 13, no. 2: 365. https://doi.org/10.3390/agronomy13020365

APA StyleVarani, M., & Mattetti, M. (2023). Rotary Ripper: A Possible Solution to Increase the Efficiency of Tillage Operations. Agronomy, 13(2), 365. https://doi.org/10.3390/agronomy13020365