Evaluating Sustainable Options for Valorization of Rice By-Products in Sri Lanka: An Approach for a Circular Business Model

Abstract

:1. Introduction

Circular Business Model

- I.

- “Take-back system”, which incorporates the concept of “material loops,” in which items, parts, or substances are recovered from consumers and then reused.

- II.

- “Adoption factors”, which assume that multiple existing management skills and external (technical, political, societal, and economic) elements are necessary for a successful shift towards circular business models.

2. Materials and Methods

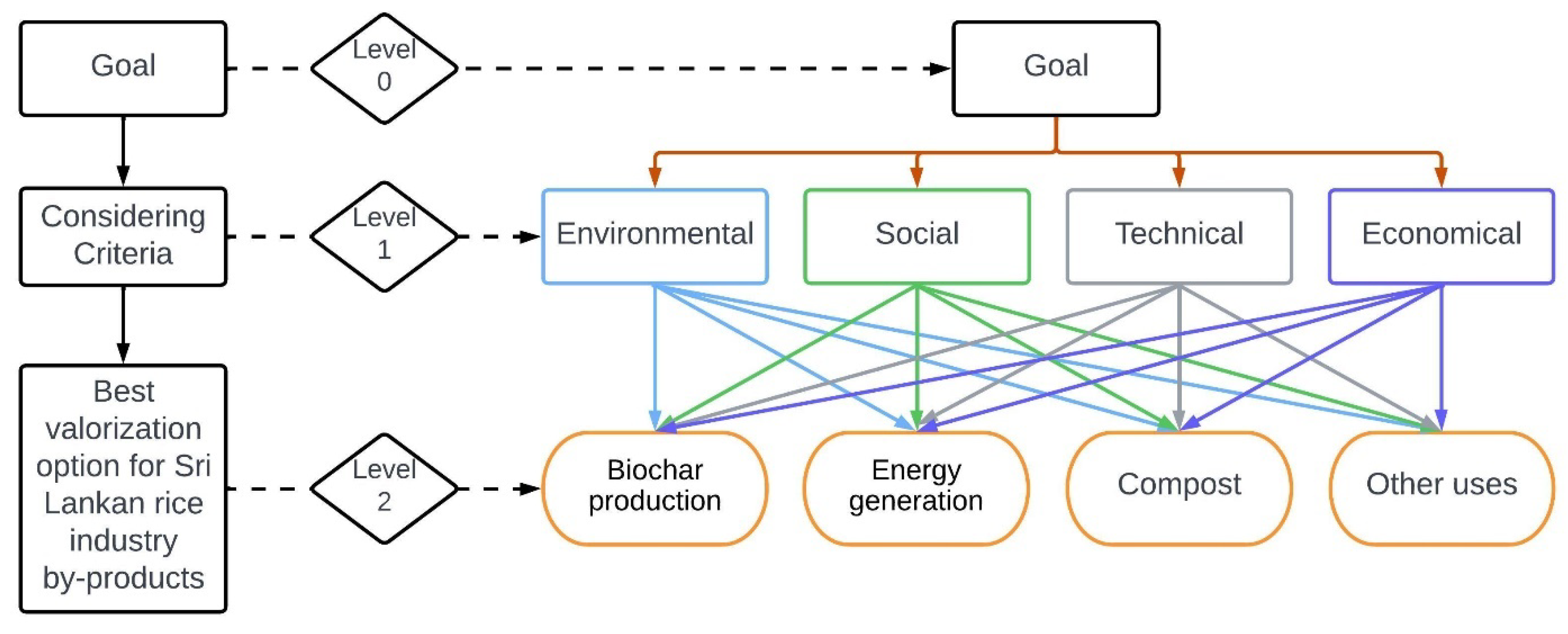

2.1. Hierarchy Model

2.2. Make a Pair-Wise Comparison to Generate a Matrix

Consistency Check

2.3. AHP Model Development

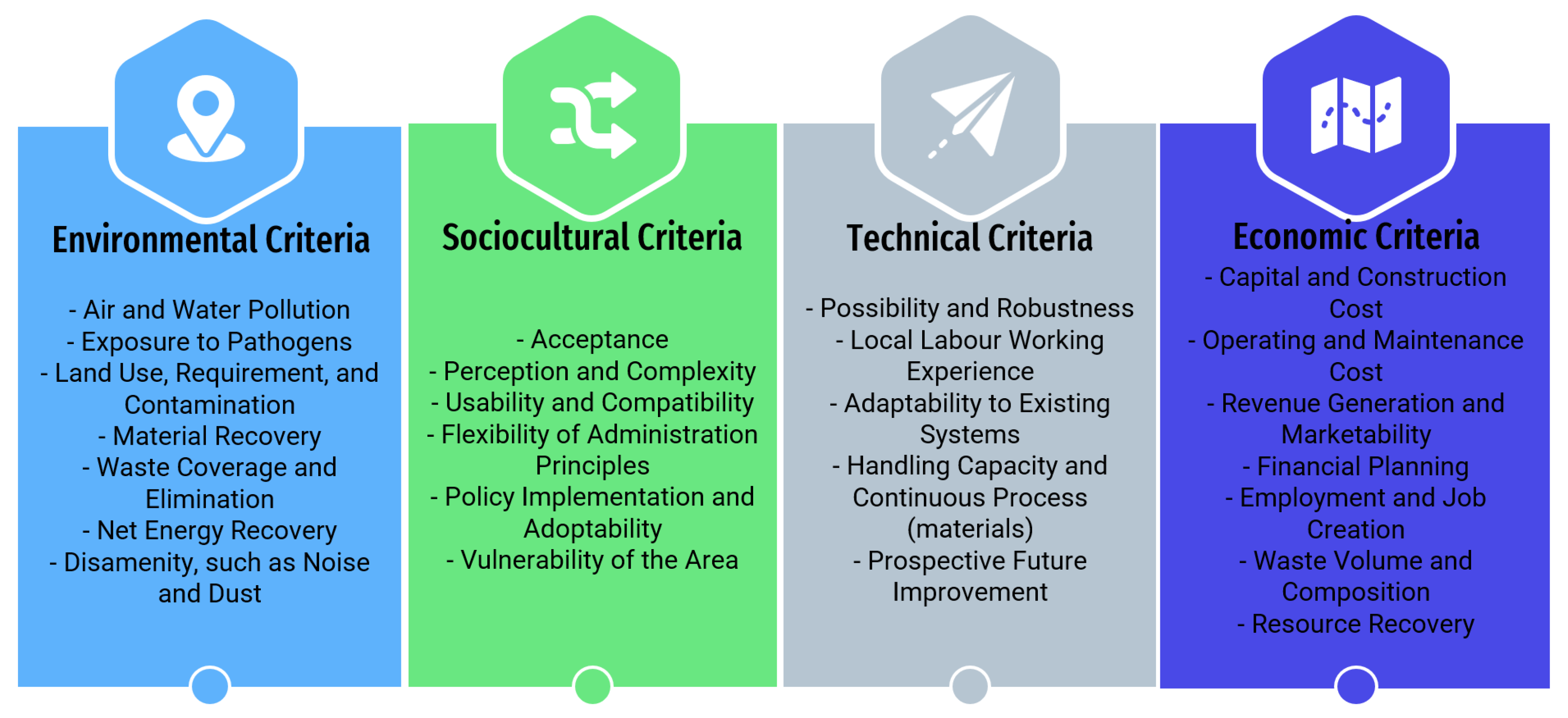

Definitions of Criteria: To Be Shorten and Made without Repetitions

- Regarding the object of the study: “What factors are considered significantly robust criteria in implementing and proposing the best valorization option for the Sri Lankan agricultural waste management system”?

- Four main criteria were considered for each of the four valorizing options according to their level of significance. The interrogation was (for each valorizing option): “How much more robust or highly significant are one considered criteria over another in the valorizing options for agricultural management”?

2.4. Circular Business Model

3. Results and Discussion

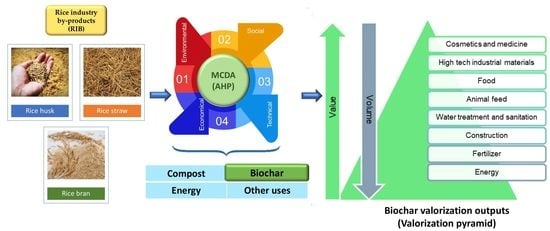

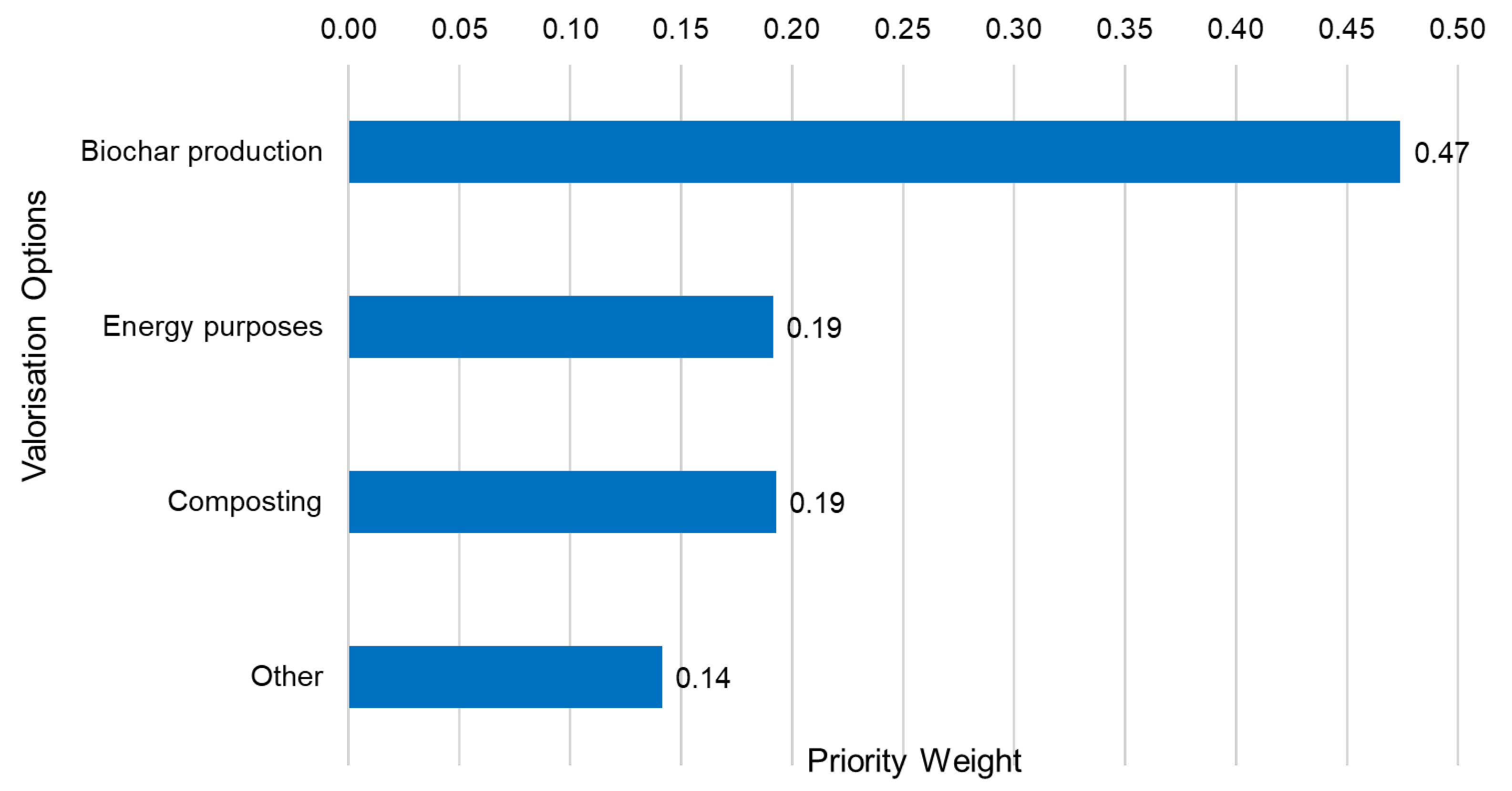

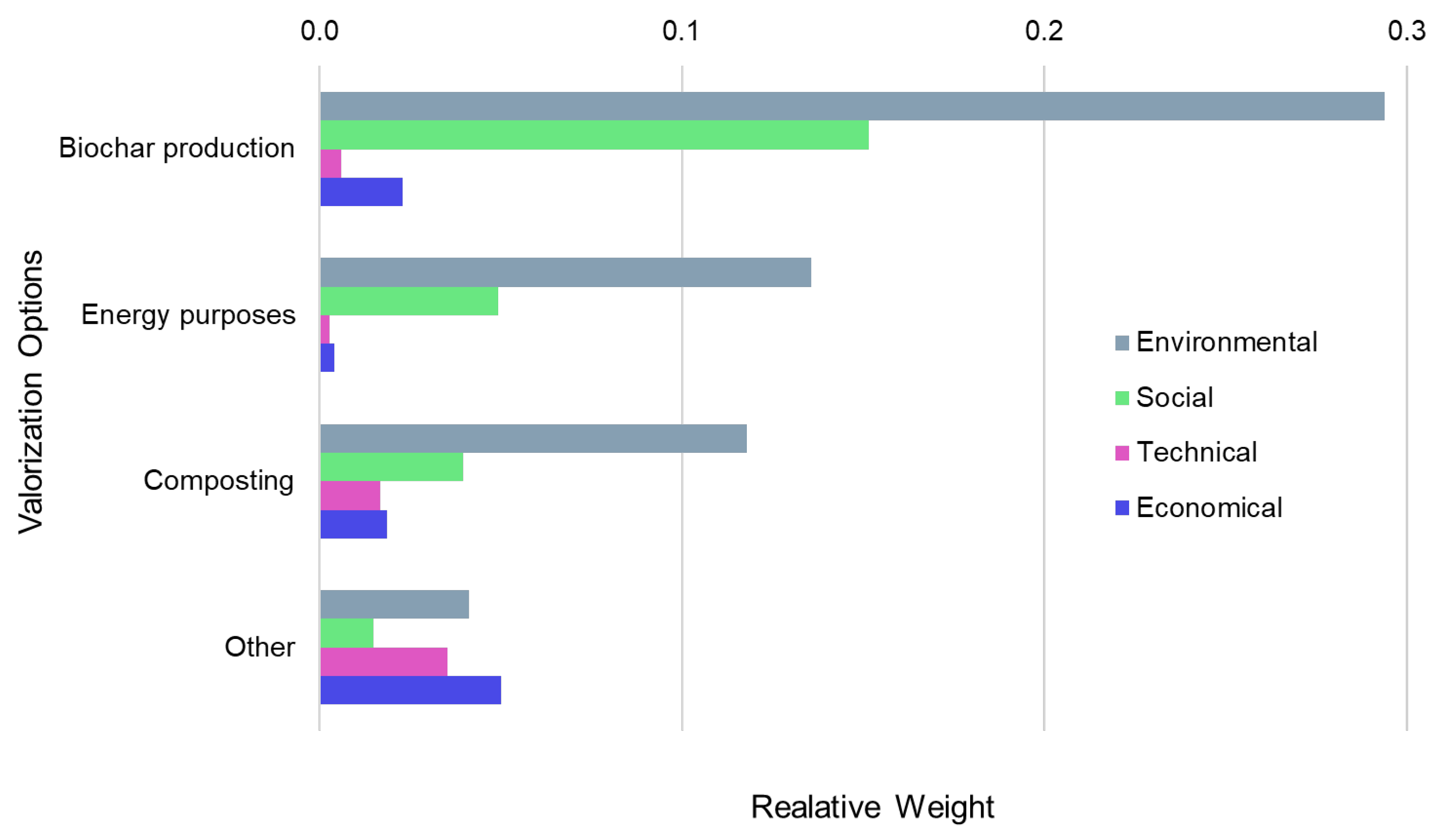

3.1. Preference Order of Valorization Options

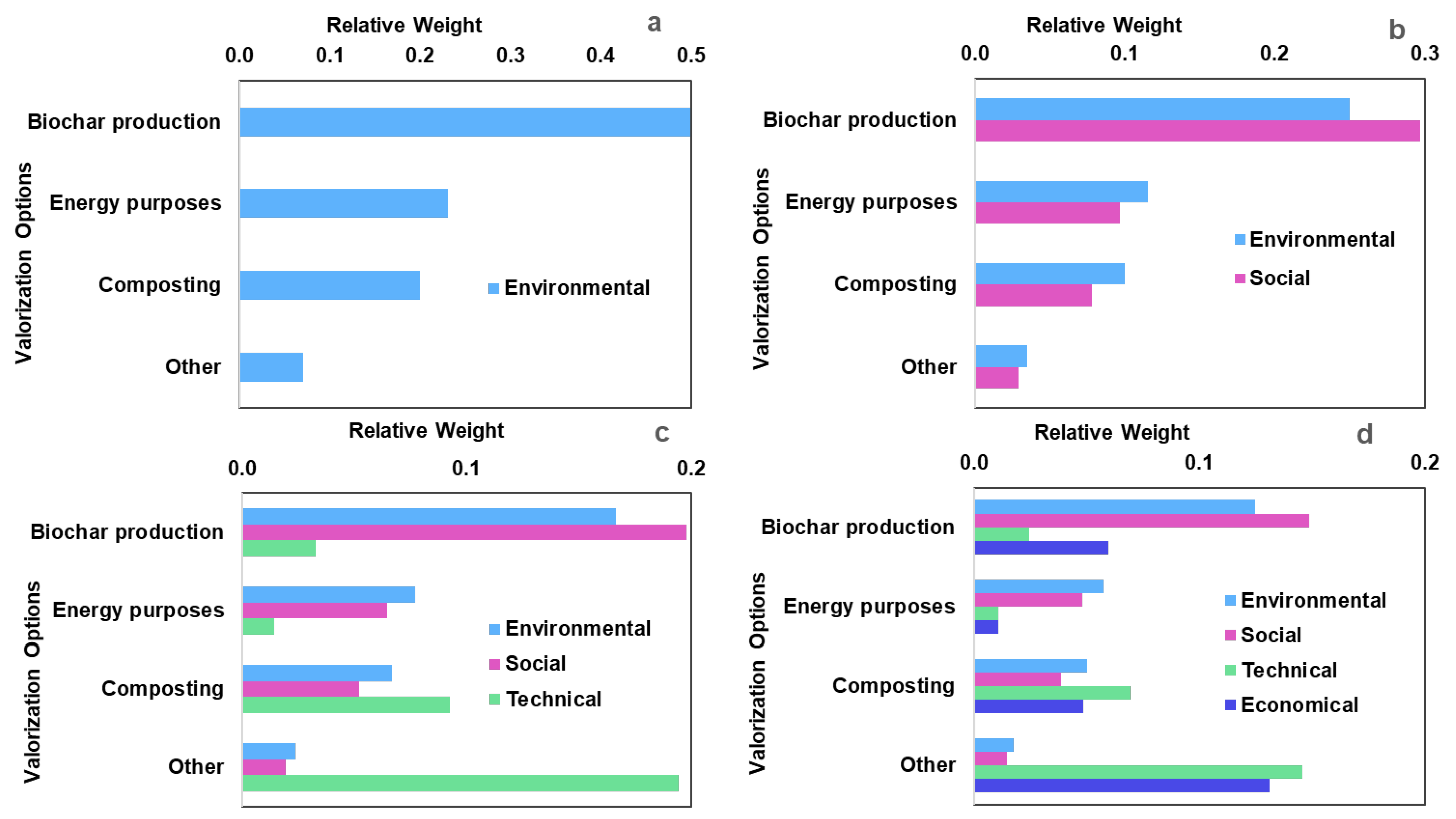

Sensitivity Analysis

- In the first of these four scenarios, three criteria are allocated no relative weight (0), while the remaining criterion receives the full weight (1). Figure 7a displays the analysis results, demonstrating that biochar production is the most effective method for managing rice waste, followed by composting and energy generating via combustion and incineration, and other miscellaneous activities being the least effective method.

- In the third scenario, three of the four criteria are each given a relative weight of 0.33. In contrast, the remaining criterion is given a relative weight of zero (0), as shown in Figure 7c. Findings also indicate that biochar production, followed by composting, and energy generation, is the most effective strategy, whereas other miscellaneous activities are the least desirable alternative.

- In the last case, as seen in Figure 7d, all four criteria have an equal weight of 0.25. While both biochar production and other miscellaneous activities were significant in this study, biochar production was found to be somewhat greater than other activities. However, in the Sri Lankan context, producing biochar is the most appropriate use for rice industry by-products, followed by composting and energy generation.

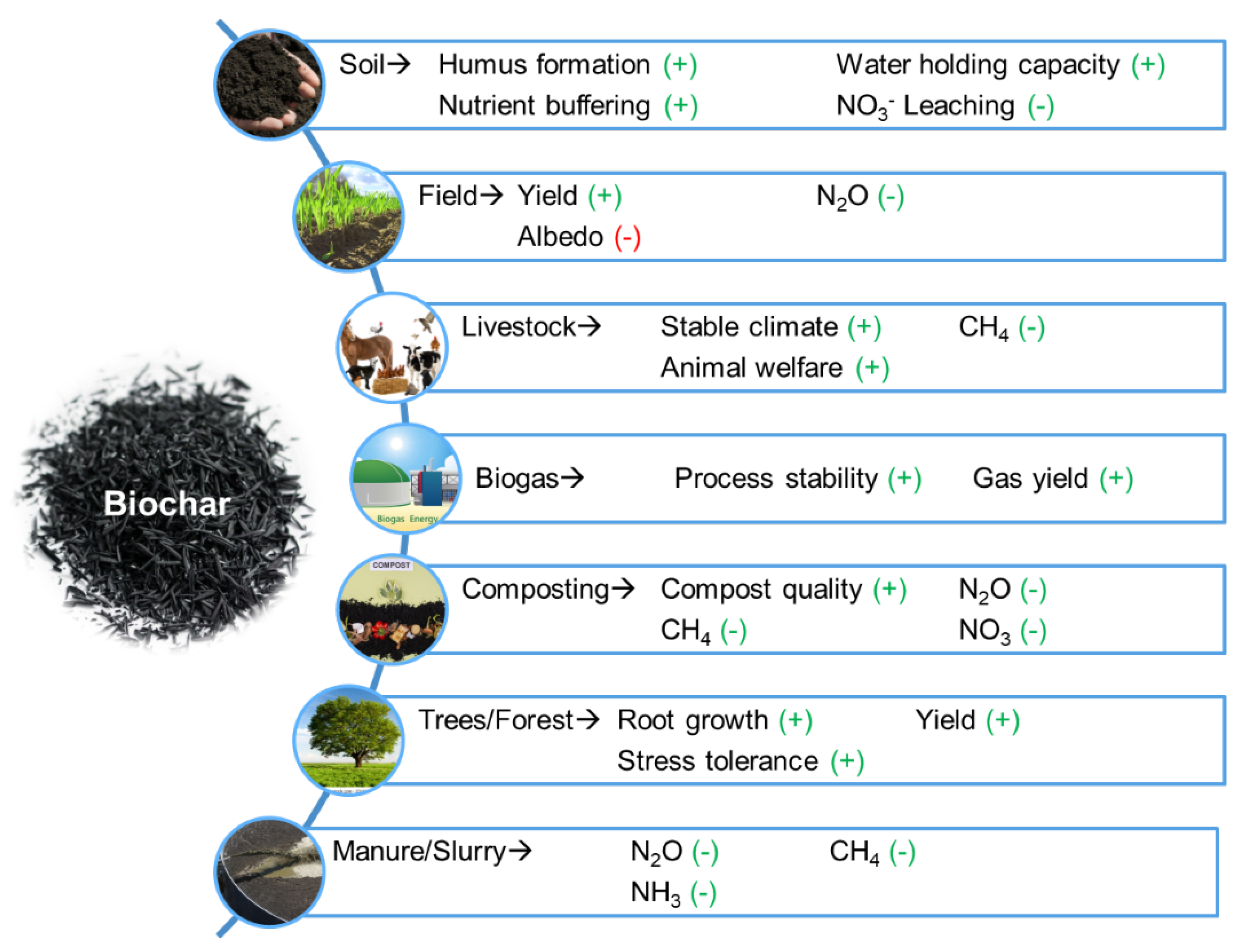

3.2. Development of Circular Business Model for Biochar Production in Sri Lankan Context

- Decrease in the production and emissions of carbon dioxide and other greenhouse gases.

- Cost savings in waste collection and disposal positively affect the economy.

3.2.1. Economic Feasibility of Biochar System

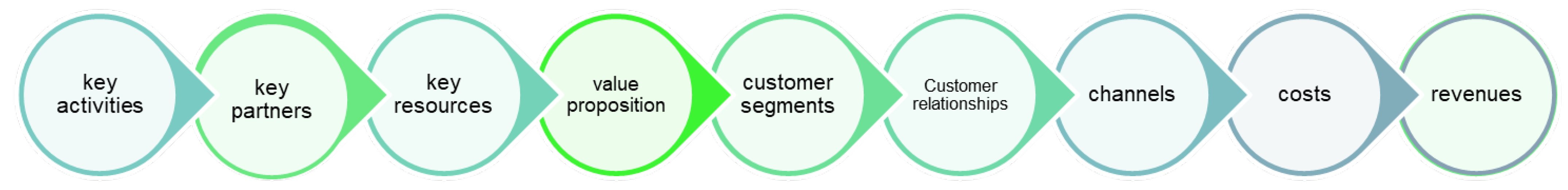

3.2.2. Characterization of Biochar Production According to the Business Canvas Model

4. Key Insights of the Study

- I.

- Public commitment to the environment in the context of wasted and unsustainable waste management in the rice industry is the primary motivator for implementing by-product valorization initiatives in the sector. In South Asia, Sri Lanka is also a major rice husk and straw producer.

- II.

- It is common for companies to focus primarily on the value addition of rice industry by-products. However, the value-adding process may also be a great side business for rice producers.

- III.

- Although some businesses operate as unions, organizations, or public–private alliances, the overwhelming majority is run by sole proprietors who may be either small-scale rice millers, entrepreneurs, or global corporations with specific specializations.

- IV.

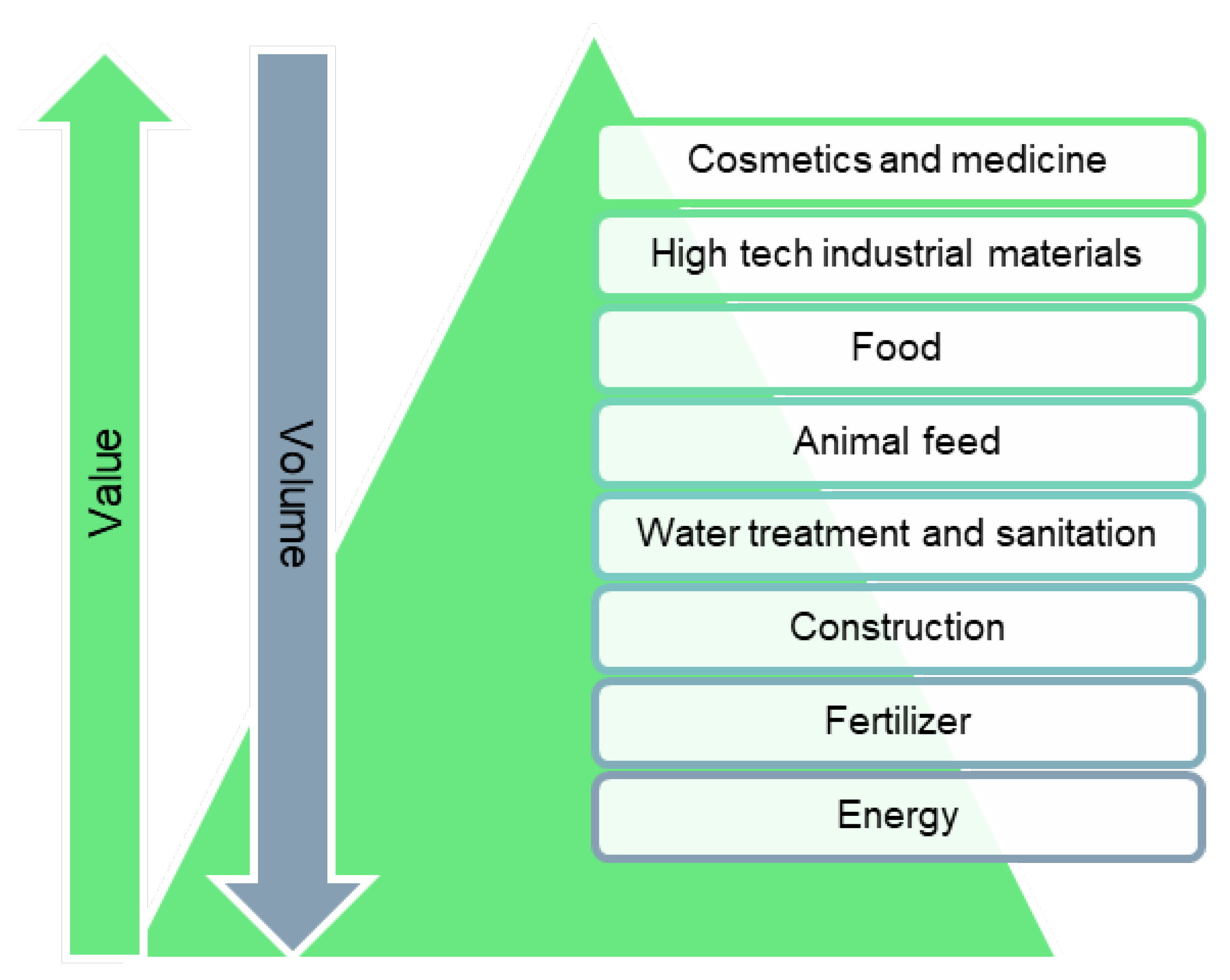

- All rice industry by-products have valorization potentials, but complete value-addition activities are often confined to just one or a few resources and practices, only a few valuation options.

- V.

- While there is more potential for effectively marketing high-value-added goods, most rice sector by-products are now turned into low-value-added products (bioenergy or fertilizers).

- VI.

- Appropriate technology is required for environmentally friendly, high-quality biochar production with minimum specific operational and technical requirements that can efficiently operate under field and household conditions.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Illankoon, W.A.M.A.N.; Milanese, C.; Girella, A.; Rathnasiri, P.G.; Sudesh, K.H.M.; Llamas, M.M.; Collivignarelli, M.C.; Sorlini, S. Agricultural Biomass-Based Power Generation Potential in Sri Lanka: A Techno-Economic Analysis. Energies 2022, 15, 8984. [Google Scholar] [CrossRef]

- Illankoon, W.A.M.A.N.; Milanese, C.; Karunarathna, A.K.; Alahakoon, A.M.Y.W.; Rathnasiri, P.G.; Medina-Llamas, M.; Collivignarelli, M.C.; Sorlini, S. Development of a Dual-Chamber Pyrolizer for Biochar Production from Agricultural Waste in Sri Lanka. Energies 2023, 16, 1819. [Google Scholar] [CrossRef]

- Maheshi, D.; Steven, V.P.; Karel, V.A. Environmental and Economic Assessment of ‘Open Waste Dump’ Mining in Sri Lanka. Resour. Conserv. Recycl. 2015, 102, 67–79. [Google Scholar] [CrossRef]

- Peiris, A.P.T.S. Peiris Feasibility Study of Production of Bio Methane from Bio Wastes in Sri Lanka and Develop Cost Model for the Production Process. Master’s Thesis, KTH School of Industrial Engineering and Management, Beijing, China, 2016. [Google Scholar]

- Illankoon, W.A.M.A.N. Sabrina Sorlini A Technical, Economical, and Environmental Comparison of Composting and Anaerobic Digestion of Organic Waste Fraction of Municipal Solid Waste in Sri Lanka. In Proceedings of the Waste-to-Resources 2021, 9th International Symposium Circular Economy, MBT, MRF and Recycling, Virtual, 18 May 2021. [Google Scholar]

- Hoang, A.T.; Varbanov, P.S.; Nižetić, S.; Sirohi, R.; Pandey, A.; Luque, R.; Ng, K.H.; Pham, V.V. Perspective Review on Municipal Solid Waste-to-Energy Route: Characteristics, Management Strategy, and Role in Circular Economy. J. Clean. Prod. 2022, 359, 131897. [Google Scholar] [CrossRef]

- Jang, S.M.; Seo, D. Environmental Impact Assessment (Eia) Report of the Proposed Waste to Energy Project at Sri Lanka Board of Investment Land; Dompe: Pittakotte, Sri Lanka, 2016. [Google Scholar]

- Weerakoon, W.M.W.; Mutunayake, M.M.P.; Bandara, C.; Rao, A.N.; Bhandari, D.C.; Ladha, J.K. Direct-Seeded Rice Culture in Sri Lanka: Lessons from Farmers. Field Crops Res. 2011, 121, 53–63. [Google Scholar] [CrossRef]

- Senanayake, S.; Premaratne, S.P. An Analysis of the Paddy/Rice Value Chains in Sri Lanka. Asia Pac. J. Rural. Dev. 2016, XXVI, 105–126. [Google Scholar] [CrossRef] [Green Version]

- Wilson, R.T.; Lewis, I. The RICE Value Chain in Tanzania; FAO: Rome, Italy, 2015. [Google Scholar]

- Soullier, G.; Demont, M.; Arouna, A.; Lançon, F.; Mendez del Villar, P. The State of Rice Value Chain Upgrading in West Africa. Glob. Food Sec. 2020, 25, 100365. [Google Scholar] [CrossRef]

- Michele, A.; Angela, D.; Franck, D. Biorefinery; Aresta, M., Dibenedetto, A., Dumeignil, F., Eds.; De Gruyter: Berlin, Germany, 2012; ISBN 978-3-11-026023-6. [Google Scholar]

- Zaccheria, F.; Mariani, M.; Ravasio, N. The Use of Rice Bran Oil within a Biorefinery Concept. Chem. Biol. Technol. Agric. 2015, 2, 23. [Google Scholar] [CrossRef] [Green Version]

- Rambo, M.K.D.; Schmidt, F.L.; Ferreira, M.M.C. Analysis of the Lignocellulosic Components of Biomass Residues for Biorefinery Opportunities. Talanta 2015, 144, 696–703. [Google Scholar] [CrossRef]

- Zhou, Q.; Le, Q.V.; Yang, H.; Gu, H.; Yang, Y.; Sonne, C.; Tabatabaei, M.; Lam, S.S.; Li, C.; Chen, X.; et al. Sustainable Conversion of Agricultural Biomass into Renewable Energy Products: A Discussion. Bioresources 2022, 17, 3489–3508. [Google Scholar] [CrossRef]

- Sannigrahi, P.; Ragauskas, A.J.; Tuskan, G.A. Poplar as a Feedstock for Biofuels: A Review of Compositional Characteristics. Biofuels Bioprod. Biorefin. 2010, 4, 209–226. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Sorlini, S.; Milanese, C.; Illankoon, W.A.M.A.N.; Caccamo, F.M.; Calatroni, S. Rice Industry By-Products as Adsorbent Materials for Removing Fluoride and Arsenic from Drinking Water—A Review. Appl. Sci. 2022, 12, 3166. [Google Scholar] [CrossRef]

- Abbas, A.; Ansumali, S. Global Potential of Rice Husk as a Renewable Feedstock for Ethanol Biofuel Production. Bioenergy Res. 2010, 3, 328–334. [Google Scholar] [CrossRef]

- Saddhananda, K.W.S. Paddy Statistics 2021/2022 Maha Season; Department of Census and Statistics, Ministry of National Policies and Economic Affairs: Battaramulla, Sri Lanka, 2022. [Google Scholar]

- Rodrigo, A.S.; Perera, S. Potential and Viability of Rice Husk Based Power Generation in Sri Lanka. Eng. J. Inst. Eng. Sri Lanka 2013, 46, 9. [Google Scholar] [CrossRef]

- Mardani, A.; Zavadskas, E.K.; Khalifah, Z.; Zakuan, N.; Jusoh, A.; Nor, K.M.; Khoshnoudi, M. A Review of Multi-Criteria Decision-Making Applications to Solve Energy Management Problems: Two Decades from 1995 to 2015. Renew. Sustain. Energy Rev. 2017, 71, 216–256. [Google Scholar] [CrossRef]

- Pieratti, E.; Paletto, A.; de Meo, I.; Fagarazzi, C.; Rillo Migliorini, M.G. Assessing the Forest-Wood Chain at Local Level: A Multi-Criteria Decision Analysis (MCDA) Based on the Circular Bioeconomy Principles. Ann. For. Res. 2019, 62, 123–138. [Google Scholar] [CrossRef]

- Niero, M.; Kalbar, P.P. Coupling Material Circularity Indicators and Life Cycle Based Indicators: A Proposal to Advance the Assessment of Circular Economy Strategies at the Product Level. Resour Conserv. Recycl. 2019, 140, 305–312. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural Waste: Review of the Evolution, Approaches and Perspectives on Alternative Uses. Glob Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Antikainen, M.; Valkokari, K. A Framework for Sustainable Circular Business Model Innovation. Technol. Innov. Manag. Rev. 2016, 6, 5–12. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Schaltegger, S.; Lüdeke-Freund, F.; Hansen, E.G. Business Models for Sustainability. Organ Environ. 2016, 29, 264–289. [Google Scholar] [CrossRef]

- Boons, F.; Lüdeke-Freund, F. Business Models for Sustainable Innovation: State-of-the-Art and Steps towards a Research Agenda. J. Clean. Prod. 2013, 45, 9–19. [Google Scholar] [CrossRef]

- Stubbs, W.; Cocklin, C. Conceptualizing a “Sustainability Business Model”. Organ Environ. 2008, 21, 103–127. [Google Scholar] [CrossRef]

- Jonker, J.; Faber, N. Business Models for Multiple Value Creation: Exploring Strategic Changes in Organisations Enabling to Address Societal Challenges; Springer: Berlin/Heidelberg, Germany, 2019; pp. 151–179. [Google Scholar]

- Mentink, B. Circular Business Model Innovation: A Process Framework and a Tool for Business Model Innovation in a Circular Economy. Master’s Thesis, Delft University, Mekelweg, The Netherlands, 2014. [Google Scholar]

- Jurgilevich, A.; Birge, T.; Kentala-Lehtonen, J.; Korhonen-Kurki, K.; Pietikäinen, J.; Saikku, L.; Schösler, H. Transition towards Circular Economy in the Food System. Sustainability 2016, 8, 69. [Google Scholar] [CrossRef] [Green Version]

- Trollman, H.; Colwill, J.; Jagtap, S. A Circularity Indicator Tool for Measuring the Ecological Embeddedness of Manufacturing. Sustainability 2021, 13, 8773. [Google Scholar] [CrossRef]

- Let’s Build a Circular Economy. Available online: https://ellenmacarthurfoundation.org/ (accessed on 8 December 2022).

- Donner, M.; Radić, I. Innovative Circular Business Models in the Olive Oil Sector for Sustainable Mediterranean Agrifood Systems. Sustainability 2021, 13, 2588. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A New Sustainability Paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Barros, M.V.; Salvador, R.; de Francisco, A.C.; Piekarski, C.M. Mapping of Research Lines on Circular Economy Practices in Agriculture: From Waste to Energy. Renew. Sustain. Energy Rev. 2020, 131, 109958. [Google Scholar] [CrossRef]

- Rodias, E.; Aivazidou, E.; Achillas, C.; Aidonis, D.; Bochtis, D. Water-Energy-Nutrients Synergies in the Agrifood Sector: A Circular Economy Framework. Energies 2020, 14, 159. [Google Scholar] [CrossRef]

- Esposito, B.; Sessa, M.R.; Sica, D.; Malandrino, O. Towards Circular Economy in the Agri-Food Sector. A Systematic Literature Review. Sustainability 2020, 12, 7401. [Google Scholar] [CrossRef]

- Urbinati, A.; Chiaroni, D.; Chiesa, V. Towards a New Taxonomy of Circular Economy Business Models. J. Clean. Prod. 2017, 168, 487–498. [Google Scholar] [CrossRef]

- Scarpellini, S.; Valero-Gil, J.; Moneva, J.M.; Andreaus, M. Environmental Management Capabilities for a “Circular Eco-innovation”. Bus. Strategy Environ. 2020, 29, 1850–1864. [Google Scholar] [CrossRef]

- Donner, M.; de Vries, H. How to Innovate Business Models for a Circular Bio-economy? Bus. Strategy Environ. 2021, 30, 1932–1947. [Google Scholar] [CrossRef]

- Bocken, N.; Strupeit, L.; Whalen, K.; Nußholz, J. A Review and Evaluation of Circular Business Model Innovation Tools. Sustainability 2019, 11, 2210. [Google Scholar] [CrossRef] [Green Version]

- Whalen, K.A. Three Circular Business Models That Extend Product Value and Their Contribution to Resource Efficiency. J. Clean. Prod. 2019, 226, 1128–1137. [Google Scholar] [CrossRef]

- Nußholz, J. Circular Business Models: Defining a Concept and Framing an Emerging Research Field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef] [Green Version]

- Enes, Ü.; Andrea, U.; Davide, C. Managerial Practices for Designing Circular Economy Business Models: The Case of an Italian SME in the Office Supply Industry. J. Manuf. Technol. Manag. 2018, 30, 561–589. [Google Scholar]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product Design and Business Model Strategies for a Circular Economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Raut, R.D.; Jagtap, S.; Choubey, V.K. Circular Economy Adoption Challenges in the Food Supply Chain for Sustainable Development. Bus. Strategy Environ. 2022, 1–23. [Google Scholar] [CrossRef]

- Helen, M.; Franck, A.; Innovation Environnementale et Création de Valeur. Innovation Environnementale et Création de Valeur: Emergence et Conditions de Développement de BM Circulaires Dans La Filière DEEE; HAL: Lyon, France, 15 September 2016. [Google Scholar]

- Stål, H.I.; Corvellec, H. A Decoupling Perspective on Circular Business Model Implementation: Illustrations from Swedish Apparel. J. Clean. Prod. 2018, 171, 630–643. [Google Scholar] [CrossRef]

- Babalola, M.A. A Multi-Criteria Decision Analysis of Waste Treatment Options for Food and Biodegradable Waste Management in Japan. Environments 2015, 2, 471–488. [Google Scholar] [CrossRef] [Green Version]

- Saaty, R.W. The Analytic Hierarchy Process—What It Is and How It Is Used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef] [Green Version]

- Thomas, L.S. Decision Making with the Analytic Hierarchy Process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar]

- Abba, A.H.; Noor, Z.Z.; Aliyu, A.; Medugu, N.I. Assessing Sustainable Municipal Solid Waste Management Factors for Johor-Bahru by Analytical Hierarchy Process. Adv. Mater. Res. 2013, 689, 540–545. [Google Scholar] [CrossRef]

- Yaghoubi, H.; Allahyari, M.S.; Firouzi, S.; Damalas, C.A.; Marzban, S. Identifying Sustainable Options for Rice Husk Valorization Using the Analytic Hierarchy Process. Outlook Agric. 2019, 48, 117–125. [Google Scholar] [CrossRef]

- Kirch, T.; Medwell, P.R.; Birzer, C.H.; van Eyk, P.J. Small-Scale Autothermal Thermochemical Conversion of Multiple Solid Biomass Feedstock. Renew Energy 2020, 149, 1261–1270. [Google Scholar] [CrossRef]

- Rutherford, D.W.; Wershaw, R.L.; Rostad, C.E.; Kelly, C.N. Effect of Formation Conditions on Biochars: Compositional and Structural Properties of Cellulose, Lignin, and Pine Biochars. Biomass Bioenergy 2012, 46, 693–701. [Google Scholar] [CrossRef]

- Liu, W.-J.; Jiang, H.; Yu, H.-Q. Emerging Applications of Biochar-Based Materials for Energy Storage and Conversion. Energy Environ. Sci. 2019, 12, 1751–1779. [Google Scholar] [CrossRef]

- Lu, L.; Yu, W.; Wang, Y.; Zhang, K.; Zhu, X.; Zhang, Y.; Wu, Y.; Ullah, H.; Xiao, X.; Chen, B. Application of Biochar-Based Materials in Environmental Remediation: From Multi-Level Structures to Specific Devices. Biochar 2020, 2, 1–31. [Google Scholar] [CrossRef] [Green Version]

- Tan, G.; Mao, Y.; Wang, H.; Junaid, M.; Xu, N. Comparison of Biochar- and Activated Carbon-Supported Zerovalent Iron for the Removal of Se(IV) and Se(VI): Influence of PH, Ionic Strength, and Natural Organic Matter. Environ. Sci. Pollut. Res. 2019, 26, 21609–21618. [Google Scholar] [CrossRef] [PubMed]

- Leach, M.; Fairhead, J.; Fraser, J. Green Grabs and Biochar: Revaluing African Soils and Farming in the New Carbon Economy. J. Peasant. Stud. 2012, 39, 285–307. [Google Scholar] [CrossRef] [Green Version]

- Verma, M.; M’hamdi, N.; Dkhili, Z.; Brar, S.K.; Misra, K. Thermochemical Transformation of Agro-Biomass into Biochar: Simultaneous Carbon Sequestration and Soil Amendment. In Biotransformation of Waste Biomass into High Value Biochemicals; Springer: New York, NY, USA, 2014; pp. 51–70. [Google Scholar]

- Guo, J.; Chen, B. Insights on the Molecular Mechanism for the Recalcitrance of Biochars: Interactive Effects of Carbon and Silicon Components. Environ. Sci. Technol. 2014, 48, 9103–9112. [Google Scholar] [CrossRef] [PubMed]

- Peng, P.; Lang, Y.-H.; Wang, X.-M. Adsorption Behavior and Mechanism of Pentachlorophenol on Reed Biochars: PH Effect, Pyrolysis Temperature, Hydrochloric Acid Treatment and Isotherms. Ecol. Eng. 2016, 90, 225–233. [Google Scholar] [CrossRef]

- Peng, X.; Ye, L.L.; Wang, C.H.; Zhou, H.; Sun, B. Temperature- and Duration-Dependent Rice Straw-Derived Biochar: Characteristics and Its Effects on Soil Properties of an Ultisol in Southern China. Soil Tillage Res. 2011, 112, 159–166. [Google Scholar] [CrossRef]

- Lee, J.W.; Kidder, M.; Evans, B.R.; Paik, S.; Buchanan, A.C., III; Garten, C.T.; Brown, R.C. Characterization of Biochars Produced from Cornstovers for Soil Amendment. Environ. Sci. Technol. 2010, 44, 7970–7974. [Google Scholar] [CrossRef] [Green Version]

- Windeatt, J.H.; Ross, A.B.; Williams, P.T.; Forster, P.M.; Nahil, M.A.; Singh, S. Characteristics of Biochars from Crop Residues: Potential for Carbon Sequestration and Soil Amendment. J. Environ. Manag. 2014, 146, 189–197. [Google Scholar] [CrossRef]

- Alexandri, M.; López-Gómez, J.P.; Olszewska-Widdrat, A.; Venus, J. Valorising Agro-Industrial Wastes within the Circular Bioeconomy Concept: The Case of Defatted Rice Bran with Emphasis on Bioconversion Strategies. Fermentation 2020, 6, 42. [Google Scholar] [CrossRef]

- Kalderis, D.; Kotti, M.S.; Méndez, A.; Gascó, G. Characterization of Hydrochars Produced by Hydrothermal Carbonization of Rice Husk. Solid Earth 2014, 5, 477–483. [Google Scholar] [CrossRef] [Green Version]

- Elliott, D.C.; Biller, P.; Ross, A.B.; Schmidt, A.J.; Jones, S.B. Hydrothermal Liquefaction of Biomass: Developments from Batch to Continuous Process. Bioresour. Technol. 2015, 178, 147–156. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Xu, C.; Champagne, P. Overview of Recent Advances in Thermo-Chemical Conversion of Biomass. Energy Convers. Manag. 2010, 51, 969–982. [Google Scholar] [CrossRef]

- Chen, X.; Chen, G.; Chen, L.; Chen, Y.; Lehmann, J.; McBride, M.B.; Hay, A.G. Adsorption of Copper and Zinc by Biochars Produced from Pyrolysis of Hardwood and Corn Straw in Aqueous Solution. Bioresour. Technol. 2011, 102, 8877–8884. [Google Scholar] [CrossRef] [PubMed]

- Kalkanis, K.; Alexakis, D.E.; Kyriakis, E.; Kiskira, K.; Lorenzo-Llanes, J.; Themelis, N.J.; Psomopoulos, C.S. Transforming Waste to Wealth, Achieving Circular Economy. Circ. Econ. Sustain. 2022, 2, 1541–1559. [Google Scholar] [CrossRef]

- Fan, Y.V.; Klemeš, J.J.; Lee, C.T.; Perry, S. Anaerobic Digestion of Municipal Solid Waste: Energy and Carbon Emission Footprint. J. Environ. Manag. 2018, 223, 888–897. [Google Scholar] [CrossRef]

- Davidsson, Å.; la Cour Jansen, J.; Appelqvist, B.; Gruvberger, C.; Hallmer, M. Anaerobic Digestion Potential of Urban Organic Waste: A Case Study in Malmö. Waste Manag. Res. J. A Sustain. Circ. Econ. 2007, 25, 162–169. [Google Scholar] [CrossRef] [PubMed]

- Haque, S.; Singh, R.; Pal, D.B.; Harakeh, S.; Alghanmi, M.; Teklemariam, A.D.; Abujamel, T.S.; Srivastava, N.; Gupta, V.K. Recent Update on Anaerobic Digestion of Paddy Straw for Biogas Production: Advancement, Limitation and Recommendations. Environ. Res. 2022, 215, 114292. [Google Scholar] [CrossRef] [PubMed]

- Cecchi, F.; Cavinato, C. Anaerobic Digestion of Bio-Waste: A Mini-Review Focusing on Territorial and Environmental Aspects. Waste Manag. Res. J. A Sustain. Circ. Econ. 2015, 33, 429–438. [Google Scholar] [CrossRef]

- Matin, H.H.A.; Hadiyanto, H. Biogas Production from Rice Husk Waste by Using Solid State Anaerobic Digestion (SSAD) Method. E3S Web Conf. 2018, 31, 02007. [Google Scholar] [CrossRef]

- Illankoon, W.A.M.A.N.; Chiara, M.; Girella, A.; Maria, M.-L.; Giacomo, M.; Daniele, P.; Mauro, R.; Maria, C.C. Sabrina Sorlini biochar derived from the rice industry by-products as sustainable energy storage material. In Proceedings of the 30th European Biomass Conference and Exhibition (Eubce), Virtual, 9–12 May 2022; Chevet, P.-F., Scarlat, N., Grassi, A., Eds.; ETA-Florence Renewable Energies: Florence, Italy, 2022. [Google Scholar]

- Chieng, S.; Kuan, S.H. Harnessing Bioenergy and High Value–Added Products from Rice Residues: A Review. Biomass. Convers. Biorefin. 2022, 12, 3547–3571. [Google Scholar] [CrossRef]

- Taherzadeh, M.; Karimi, K. Pretreatment of Lignocellulosic Wastes to Improve Ethanol and Biogas Production: A Review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef] [Green Version]

- Amonette, J.E.; Blanco-Canqui, H.; Hassebrook, C.; Laird, D.A.; Lal, R.; Lehmann, J.; Page-Dumroese, D. Integrated Biochar Research: A Roadmap. J. Soil Water Conserv. 2021, 76, 24A–29A. [Google Scholar] [CrossRef]

- Yrjälä, K.; Ramakrishnan, M.; Salo, E. Agricultural Waste Streams as Resource in Circular Economy for Biochar Production towards Carbon Neutrality. Curr. Opin. Environ. Sci. Health 2022, 26, 100339. [Google Scholar] [CrossRef]

- Schulz, H.; Dunst, G.; Glaser, B. Positive Effects of Composted Biochar on Plant Growth and Soil Fertility. Agron. Sustain. Dev. 2013, 33, 817–827. [Google Scholar] [CrossRef] [Green Version]

- Agegnehu, G.; Srivastava, A.K.; Bird, M.I. The Role of Biochar and Biochar-Compost in Improving Soil Quality and Crop Performance: A Review. Appl. Soil Ecol. 2017, 119, 156–170. [Google Scholar] [CrossRef]

- Guo, X.; Liu, H.; Zhang, J. The Role of Biochar in Organic Waste Composting and Soil Improvement: A Review. Waste Manag. 2020, 102, 884–899. [Google Scholar] [CrossRef]

- Tibor, S.T.; Grande, C.A. Industrial Production of Activated Carbon Using Circular Bioeconomy Principles: Case Study from a Romanian Company. Clean Eng. Technol. 2022, 7, 100443. [Google Scholar] [CrossRef]

- Singh, E.; Mishra, R.; Kumar, A.; Shukla, S.K.; Lo, S.-L.; Kumar, S. Circular Economy-Based Environmental Management Using Biochar: Driving towards Sustainability. Process Saf. Environ. Prot. 2022, 163, 585–600. [Google Scholar] [CrossRef]

- Campbell, R.M.; Anderson, N.M.; Daugaard, D.E.; Naughton, H.T. Financial Viability of Biofuel and Biochar Production from Forest Biomass in the Face of Market Price Volatility and Uncertainty. Appl. Energy 2018, 230, 330–343. [Google Scholar] [CrossRef]

- Haeldermans, T.; Campion, L.; Kuppens, T.; Vanreppelen, K.; Cuypers, A.; Schreurs, S. A Comparative Techno-Economic Assessment of Biochar Production from Different Residue Streams Using Conventional and Microwave Pyrolysis. Bioresour. Technol. 2020, 318, 124083. [Google Scholar] [CrossRef]

- Zhou, Q.; Houge, B.A.; Tong, Z.; Gao, B.; Liu, G. An In-Situ Technique for Producing Low-Cost Agricultural Biochar. Pedosphere 2018, 28, 690–695. [Google Scholar] [CrossRef]

- Cornelissen, G.; Pandit, N.R.; Taylor, P.; Pandit, B.H.; Sparrevik, M.; Schmidt, H.P. Emissions and Char Quality of Flame-Curtain “Kon Tiki” Kilns for Farmer-Scale Charcoal/Biochar Production. PLoS ONE 2016, 11, e0154617. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Weight of Pairwise Comparison | Status |

|---|---|

| 1 | Equally: Two technologies contribute to equal weight |

| 3 | Slightly favor: One technology is slightly more important than another |

| 5 | Strongly favor: One technology is more strongly important than another |

| 7 | Very strongly favor: One technology is more strongly important than another |

| 9 | Extremely favor: Evidence proof of importance over another |

| 2, 4, 6, 8 | Intermediate values: When further analysis is needed |

| Number of Options | 1 | 2 | 3 | 4 | 5 | 6 | 7 | n |

| Number of comparisons | 0 | 1 | 3 | 6 | 10 | 15 | 21 |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| RI | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 | 1.51 | 1.48 | 1.56 | 1.57 | 1.59 |

| Criteria | Environmental | Social | Technical | Economical | Priority Vector |

|---|---|---|---|---|---|

| Environmental | 1 | 3 | 7 | 7 | 0.5887 |

| Social | 0.33 | 1 | 5 | 3 | 0.2552 |

| Technical | 0.14 | 0.20 | 1 | 0.33 | 0.0606 |

| Economical | 0.14 | 0.33 | 3 | 1 | 0.0955 |

| Note: λmax = 4.1177 | CI = (λmax − n)/(n − 1) = 0.0392 | CR = CI/RI = 0.0436 ˂ 0.1 | |||

| Criteria | Biochar Production | Energy Purposes | Composting | Other | Priority Vector |

|---|---|---|---|---|---|

| Biochar production | 1 | 3 | 3 | 5 | 0.4994 |

| Energy purposes | 0.33 | 1 | 2 | 3 | 0.2306 |

| Composting | 0.33 | 5 | 1 | 5 | 0.2001 |

| Other | 0.2 | 0.33 | 0.2 | 1 | 0.0699 |

| Note: λmax = 4.2666 | CI = (λmax − n)/(n − 1) = 0.0888 | CR = CI/RI = 0.0987 ˂ 0.1 | |||

| Criteria | Biochar Production | Energy Purposes | Composting | Other | Priority Vector |

|---|---|---|---|---|---|

| Biochar production | 1 | 5 | 3 | 9 | 0.5444 |

| Energy purposes | 0.2 | 1 | 2 | 3 | 0.0688 |

| Composting | 0.33 | 0.5 | 1 | 3 | 0.1934 |

| Other | 0.11 | 0.33 | 0.33 | 1 | 0.1934 |

| Note: λmax = 4.2039 | CI = (λmax − n)/(n − 1) = 0.068 | CR = CI/RI = 0.0755 ˂ 0.1 | |||

| Criteria | Biochar Production | Energy Purposes | Composting | Other | Priority Vector |

|---|---|---|---|---|---|

| Biochar production | 1 | 3 | 0.33 | 0.14 | 0.0974 |

| Energy purposes | 0.33 | 1 | 0.11 | 0.11 | 0.0425 |

| Composting | 3.00 | 9 | 1 | 0.33 | 0.2772 |

| Other | 7.00 | 9 | 3 | 1 | 0.5829 |

| Note: λmax = 4.1954 | CI = (λmax − n)/(n − 1) = 0.0651 | CR = CI/RI = 0.072376897 ˂ 0.1 | |||

| Criteria | Biochar Production | Energy Purposes | Composting | Other | Priority Vector |

|---|---|---|---|---|---|

| Biochar production | 1 | 5 | 2 | 0.33 | 0.2251 |

| Energy purposes | 0.2 | 1 | 0.14 | 0.11 | 0.0354 |

| Composting | 0.5 | 7 | 1 | 0.33 | 0.2251 |

| Other | 3 | 9 | 3 | 1 | 0.5145 |

| Note: λmax = 4.1981 | CI = (λmax − n)/(n − 1) = 0.0660 | CR = CI/RI = 0.0733 ˂ 0.1 | |||

| Valorization Options | Criteria | ||||

|---|---|---|---|---|---|

| Environmental | Social | Technical | Economical | Overall Priority | |

| Biochar production | 0.2940 | 0.1516 | 0.0059 | 0.0227 | 0.4742 |

| Energy purposes | 0.1357 | 0.0492 | 0.0026 | 0.0041 | 0.1917 |

| Composting | 0.1178 | 0.0396 | 0.0168 | 0.0185 | 0.1927 |

| Other | 0.0412 | 0.0148 | 0.0353 | 0.0501 | 0.1414 |

| Note: | = 0.0646 ˂ 0.1 | ||||

| Options | Normalized Priority | Idealized Priority |

|---|---|---|

| Biochar production | 0.47 | 1 |

| Energy purposes | 0.19 | 0.4042 |

| Composting | 0.19 | 0.4065 |

| Other | 0.14 | 0.2982 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Illankoon, W.A.M.A.N.; Milanese, C.; Karunarathna, A.K.; Liyanage, K.D.H.E.; Alahakoon, A.M.Y.W.; Rathnasiri, P.G.; Collivignarelli, M.C.; Sorlini, S. Evaluating Sustainable Options for Valorization of Rice By-Products in Sri Lanka: An Approach for a Circular Business Model. Agronomy 2023, 13, 803. https://doi.org/10.3390/agronomy13030803

Illankoon WAMAN, Milanese C, Karunarathna AK, Liyanage KDHE, Alahakoon AMYW, Rathnasiri PG, Collivignarelli MC, Sorlini S. Evaluating Sustainable Options for Valorization of Rice By-Products in Sri Lanka: An Approach for a Circular Business Model. Agronomy. 2023; 13(3):803. https://doi.org/10.3390/agronomy13030803

Chicago/Turabian StyleIllankoon, W. A. M. A. N., Chiara Milanese, A. K. Karunarathna, Kumuditha D. Hikkaduwa Epa Liyanage, A. M. Y. W. Alahakoon, Puhulwella G. Rathnasiri, Maria Cristina Collivignarelli, and Sabrina Sorlini. 2023. "Evaluating Sustainable Options for Valorization of Rice By-Products in Sri Lanka: An Approach for a Circular Business Model" Agronomy 13, no. 3: 803. https://doi.org/10.3390/agronomy13030803

APA StyleIllankoon, W. A. M. A. N., Milanese, C., Karunarathna, A. K., Liyanage, K. D. H. E., Alahakoon, A. M. Y. W., Rathnasiri, P. G., Collivignarelli, M. C., & Sorlini, S. (2023). Evaluating Sustainable Options for Valorization of Rice By-Products in Sri Lanka: An Approach for a Circular Business Model. Agronomy, 13(3), 803. https://doi.org/10.3390/agronomy13030803