Effects of Threshing Devices, Maize Varieties and Moisture Content of Grains on the Percentage of Maize Grains Broken in Harvesting

Abstract

:1. Introduction

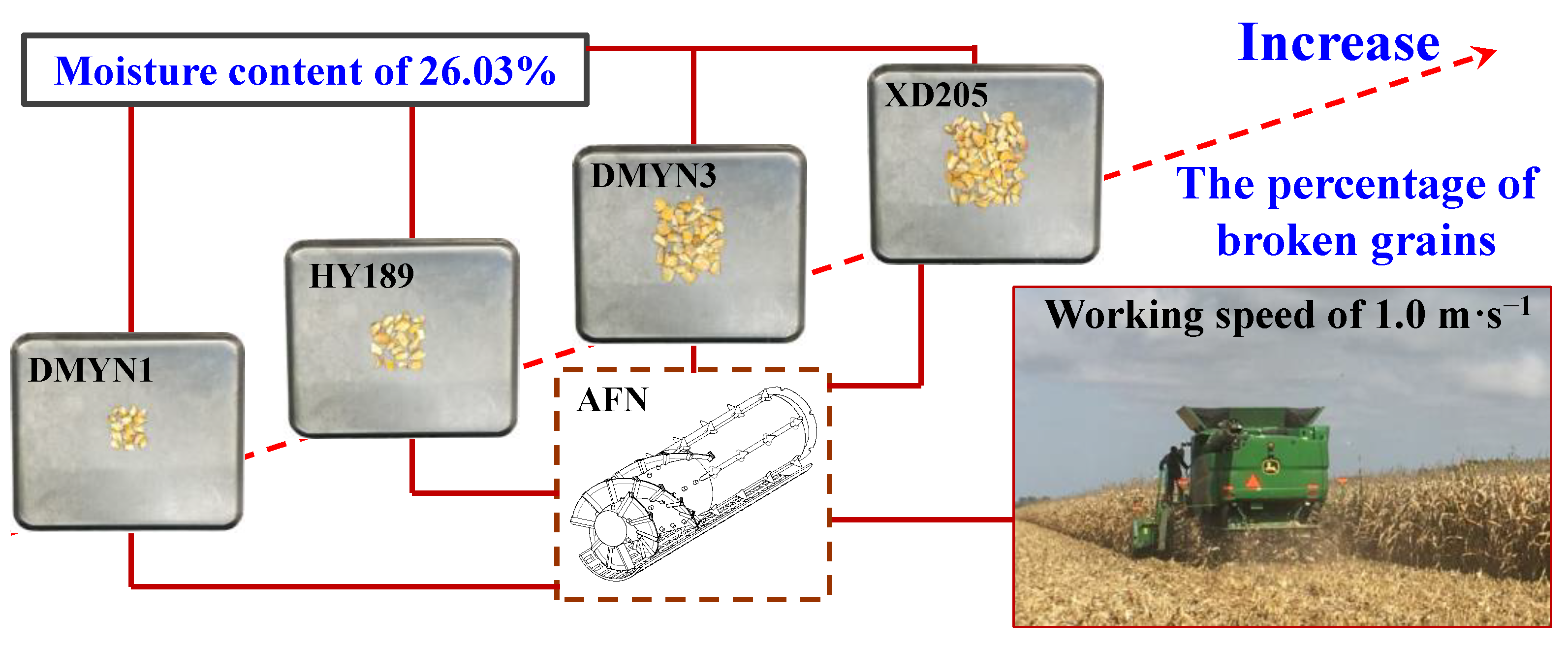

2. Materials and Methods

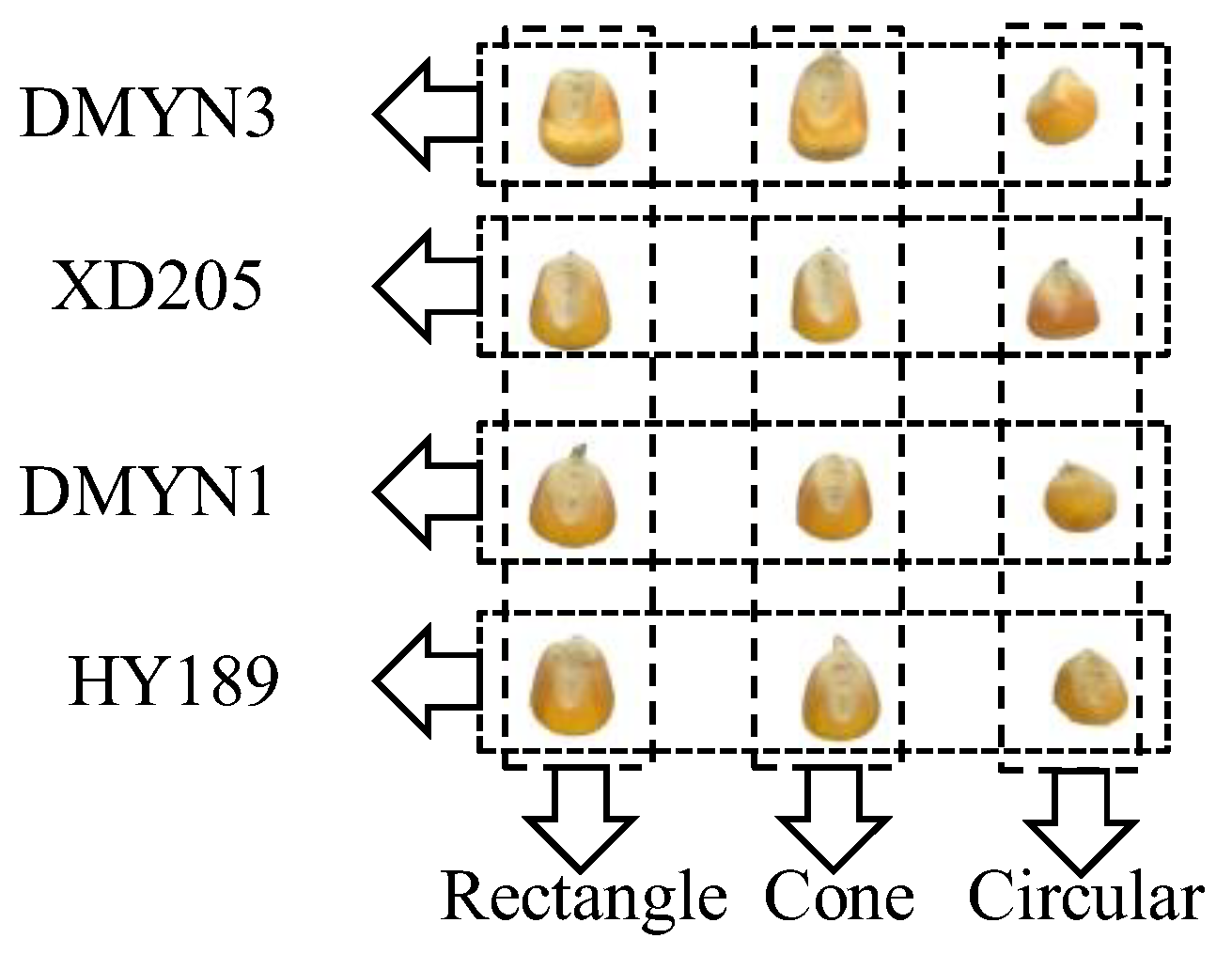

2.1. Materials

2.2. Devices

2.3. Methods

2.4. Index

3. Results and Analysis

3.1. Effect of Threshing Devices on the POGB

3.2. Effect of Maize Varieties on the POGB

3.3. Effect of the Moisture Content of Maize Grains on the POGB

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, L.Q.; Wang, W.Z.; Zhang, H.M.; Li, L.H.; Wang, M.M.; Hou, M.H. Improved Design and Bench Test Based on Tangential Flow-Transverse Axial Flow Maize Threshing System. Trans. Chin. Soc. Agric. Eng. 2018, 34, 35–43. (In Chinese) [Google Scholar]

- Yang, L.; Cui, T.; Qu, Z.; Li, K.H.; Yin, X.W.; Han, D.D.; Yan, B.X.; Zhao, D.Y.; Zhang, D.X. Development and Application of Mechanized Maize Harvesters. Int. J. Agric. Biol. Eng. 2016, 9, 15–28. [Google Scholar] [CrossRef]

- Hao, J.F.; Han, Z.D.; Liu, G.M.; Li, X.D. Research Status and Development Trend of Cleaning Device of Corn Thresher. J. Anhui Agric. Sci. 2016, 44, 322–324. (In Chinese) [Google Scholar] [CrossRef]

- Chen, Y.J.; Wang, Q.Q.; Xiang, Y. Analysis on the Status, Superiority and Self-Sufficiency Ratio of Maize in China. Chin. J. Agric. Resour. Reg. Plan. 2019, 40, 7–16. (In Chinese) [Google Scholar]

- Guo, Y.Q.; Xu, W.J.; Wang, K.R.; Chai, Z.W.; Xie, R.Z.; Hou, P.; Ming, B.; Li, S.K. Actuality and Factors Influencing Farmer Adoption of Mechanized Harvesting in Typical Maize Ecoregions. Chin. J. Eco-Agric. 2021, 29, 1964–1972. (In Chinese) [Google Scholar] [CrossRef]

- Wang, K.R.; Li, L.L.; Gao, S.; Wang, L.Z.; Huang, Z.F.; Xie, R.Z.; Ming, B.; Hou, P.; Xue, J.; Zhang, G.Q.; et al. Analysis of Main Quality Index of Corn Harvesting with Combine in China. Acta Agron. Sin. 2021, 47, 2440–2449. (In Chinese) [Google Scholar]

- Cui, T.; Fan, C.L.; Zhang, D.X.; Yang, L.; Li, Y.B.; Zhao, H.H. Research Progress of Maize Mechanized Harvesting Technology. Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–13. (In Chinese) [Google Scholar] [CrossRef]

- Song, J.Q.; Lu, D.W.; Zhang, Y.Y.; Li, Y.J.; Dong, W.H.; Sun, H.C.; Lu, L.Y.; Niu, Y.F.; Zhang, X.H.; Zhang, P. Relationship Between Corn Grain Moisture and Grain Breaking Rate Threshed by Machine. J. Hebei Agric. Sci. 2018, 22, 27–31. (In Chinese) [Google Scholar] [CrossRef]

- Yang, W.; Li, J.D.; Fang, X.F.; Shang, S.Q.; Du, W.W. Domestic and Foreign Current Situation and Development Trend of Seeding Mechanization in Maize Breeding. J. Agric. Eng. 2018, 8, 9–15. (In Chinese) [Google Scholar]

- Wang, K.R.; Li, S.K. Progresses in Research on Grain Broken Rate by Mechanical Grain Harvesting. Sci. Agric. Sin. 2017, 50, 2018–2026. (In Chinese) [Google Scholar] [CrossRef]

- Gu, R.L.; Huang, R.; Jia, G.Y.; Yuan, Z.P.; Ren, L.S.; LI, L.; Wang, J.H. Effect of Mechanical Threshing on Damage and Vigor of Maize Seed Threshed at Different Moisture Contents. J. Integr. Agric. 2019, 18, 1571–1578. [Google Scholar] [CrossRef]

- Waree, S.; Somchai, C.U.; Khwantri, S. Effects of Operating Factors for An Axial-Flow Corn Shelling Unit on Losses and Power Consumption. Agric. Nat. Resour. 2016, 50, 421–425. [Google Scholar] [CrossRef]

- Fan, G.C.; Wang, H.X.; Ji, J.J.; Cao, W.H.; Liu, H.X.; Hao, J.K.; Chen, D.R.; Zhou, Z.E.; Wang, S.H. Analysis of Influence Factor on Seed Damage Rate and Loss Rate during Picking Corn-Cob. Trans. Chin. Soc. Agric. Eng. 2002, 18, 72–74. (In Chinese) [Google Scholar] [CrossRef]

- Byg, D.M.; Hall, G.E. Corn Losses and Kernel Damage in Field Shelling of Corn. Trans. ASAE 1968, 11, 164–166. [Google Scholar] [CrossRef]

- Gao, L.X.; Li, F.; Zhang, X.W.; Zhang, Y.L.; Liu, X.; Jiao, W.P. Mechanism of Moisture Content Affect on Corn Seed Threshing. Trans. Chin. Soc. Agric. Mach. 2011, 42, 92–96. (In Chinese) [Google Scholar]

- Qu, Z.; Zhang, D.X.; Yang, L.; Zhang, T.L.; Wang, Z.D.; Cui, T. Experiment on Feed Rate and Cylinder Speed of Longitudinal Axial Flow Threshing and Separating Device for Maize. Trans. Chin. Soc. Agric. Mach. 2018, 49, 58–65. (In Chinese) [Google Scholar] [CrossRef]

- Valdas, K.; Dainius, S.; Albinas, A.; Aurelija, K.; Darius, J. Corn Ear Threshing Performance of Filler-Plate-Covered Threshing Cylinders. Mechanics 2017, 23, 714–722. [Google Scholar] [CrossRef] [Green Version]

- Qian, Z.J.; Jin, C.J.; Zhang, D.G. Multiple Frictional Impact Dynamics of Threshing Process between Flexible Tooth and Grain Kernel. Comput. Electron. Agric. 2017, 141, 276–285. [Google Scholar] [CrossRef]

- Yu, Y.J.; Fu, H.; Yu, J.Q. DEM-Based Simulation of the Corn Threshing Process. Adv. Powder Technol. 2015, 26, 1400–1409. [Google Scholar] [CrossRef]

- Petkevichiusa, S.; Shpokasa, L.; Kutzbachb, H.D. Investigation of the Maize Ear Threshing Process. Biosyst. Eng. 2008, 99, 532–539. [Google Scholar] [CrossRef]

- Pužauskas, E.; Steponavičius, D.; Jotautienė, E.; Petkevičius, S. Substantiation of Concave Crossbars Shape for Corn Ears Threshing. Mechanics 2016, 22, 553–561. [Google Scholar] [CrossRef]

- Miu, P.I.; Kutzbach, H. Mathematical Model of Material Kinematics in An Axial Threshing Unit. Comput. Electron. Agric. 2007, 58, 93–99. [Google Scholar] [CrossRef]

- Miu, P.I.; Kutzbach, H. Modeling and Simulation of Grain Threshing and Separation in Threshing Units—Part I. Comput. Electron. Agric. 2008, 60, 96–104. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Goering, C.E.; Rohrbach, R.P.; Buckmaster, D.R. Engineering Principles of Agricultural Machines. Trans. ASABE 1993, 6, 403–435. [Google Scholar] [CrossRef]

- Stout, B.A.; Cheze, B.C. Handbook of Agricultural Engineering, Volume III: Plant Production Engineering. Trans. ASABE 1999, 311–347, 376–380. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Gu, J.; Shi, W.; Zhao, H.; Sun, C.; You, S. Mapping of Phenological Traits in Northeast China Maize (Zea mays L.). Agronomy 2022, 12, 2585. [Google Scholar] [CrossRef]

- He, K.; Wang, Q.; Geng, D.Y.; Jin, C.Q.; Zhu, J.G.; Zhang, M.Y. Simulation and Analysis of Flexible Threshing Cylinder of Corn. J. Chin. Agric. Mech. 2018, 39, 53–58. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, W.X.; Wang, K.R.; Xie, R.Z.; Hou, P.; Ming, B.; Liu, C.W.; Xiao, C.H.; Zhang, G.Q.; Chen, J.L.; Yang, J.J.; et al. Relationship between Maize Grain Broken Rate and Moisture Content as well as the Differences among Cultivars. J. Maize Sci. 2018, 26, 74–78. (In Chinese) [Google Scholar] [CrossRef]

- Liu, F.H.; Wang, K.R.; Li, J.; Wang, X.M.; Sun, Y.L.; Chen, Y.S.; Wang, Y.H.; Han, D.S.; Li, S.K. Factors Affecting Corn Mechanically Harvesting Grain Quality. Crops 2013, 4, 116–119. (In Chinese) [Google Scholar] [CrossRef]

- Cai, C.J.; Chen, Z.; Han, Z.D.; Liu, G.M.; Zhang, Z.L.; Hao, J.F. Study on Relationship of Biomechanical Characteristics of Corn Seed and Threshing Performance. J. Agric. Mech. Res. 2017, 39, 192–196. (In Chinese) [Google Scholar] [CrossRef]

- Li, S.K.; Wang, K.R.; Xie, R.Z.; Li, L.L.; Ming, B.; Hou, P.; Chu, Z.D.; Zhang, W.X.; Liu, C.W. Grain Breakage Rate of Maize by Mechanical Harvesting in China. Crops 2017, 2, 76–80. (In Chinese) [Google Scholar] [CrossRef]

- Fan, C.L.; Zhang, D.X.; Yang, L.; Cui, T.; He, X.T.; Zhao, H.H.; Dong, J.Q. Development and Performance Evaluation of a Guide Vane Inclination Automatic Control System for Corn Threshing Unit Based on Feedrate Monitoring. Comput. Electron. Agric. 2022, 194, 106745. [Google Scholar] [CrossRef]

- Song, Z.C.; Diao, P.S.; Pang, H.X.; Zhao, D.B.; Miao, H.Q.; Li, X.W.; Yang, D.Z. Design and Experiment of Threshing and Separating Device of Corn Grain Harvester. J. Agric. Eng. 2022, 66, 182–190. [Google Scholar]

- Zhou, X.; Wang, Z.M.; Tian, L.Q.; Su, Z.; Ding, Z. Innovative Design and Performance Test of Threshing-separating Device for Horizontal Axial-flow Combine Harvester. J. Agric. Eng. 2022, 67, 497–508. [Google Scholar]

- Li, X.Y.; Du, Y.F.; Guo, J.L.; Mao, E.R. Design, Simulation, and Test of a New Threshing Cylinder for High Moisture Content Corn. J. Appl. Sci. 2020, 10, 4925. [Google Scholar] [CrossRef]

- Li, X.P.; Zhang, W.T.; Wang, W.Z.; Huang, Y. Design and Test of Longitudinal Axial Flow Staggered Millet Flexible Threshing Device. Agriculture 2022, 12, 1179. [Google Scholar] [CrossRef]

- Li, X.P.; Zhang, W.T.; Xu, S.D.; Du, Z.; Ma, Y.D.; Ma, F.L.; Liu, J. Low-Damage Corn Threshing Technology and Corn Threshing Devices: A Review of Recent Developments. Agriculture 2023, 13, 1006. [Google Scholar] [CrossRef]

| Planting Patterns and Physical Characteristics | XD205 | DMYN3 | HY189 | DMYN1 | ||||

|---|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| Row spacing (cm) | 64.20 | 3.03 | 67.50 | 3.00 | 67.10 | 6.74 | 66.70 | 1.41 |

| Plant spacing (cm) | 23.40 | 2.15 | 25.00 | 7.17 | 27.70 | 2.36 | 17.90 | 0.77 |

| Plant height (cm) | 250.40 | 12.43 | 281.60 | 13.49 | 256.80 | 17.77 | 236.00 | 9.34 |

| Minimum height of ear (cm) | 120.50 | 7.04 | 129.40 | 5.44 | 160.90 | 13.46 | 115.10 | 10.79 |

| Mass of grain in the ear (g) | 199.10 | 33.00 | 202.85 | 26.14 | 134.28 | 30.26 | 151.28 | 29.67 |

| Ear mass (with bract) (g) | 259.61 | 41.36 | 255.10 | 33.49 | 157.73 | 31.56 | 189.78 | 31.92 |

| Threshing Device | Tangential-Axial-Flow (TAF) | Axial-Flow with Nail-Tooth(AFN) | Axial-Flow with Rasp Bar in Big Space (AFRBBS)  | Axial-Flow with Rasp Bar in Small Space (AFRBSS) |

|---|---|---|---|---|

| Length × diameter (mm × mm) | Tangential-flow cylinder: 1700 × 600 Axial-flow cylinder: 4200 × 445 | Axial-flow cylinder: 3816 × 762 | Axial-flow cylinder: 3816 × 762 | Axial-flow cylinder: 3168 × 834 |

| Threshing part | Rasp bar | Nail-tooth | Rasp bar | Rasp bar |

| Position of cylinder and counter-bumper | Parallel | Parallel | Parallel | Parallel |

| Type of concave-bumper | Grid concave | Grid concave | Grid concave | Grid concave |

| Counter-bumper opening (°) | Tangential-flow cylinder: 84 Axial-flow cylinder: 142 | 210 | 180 | 155 |

| Type of sieve | Scale screen | Scale screen | Scale screen | Stepped woven screen |

| Beveled angle of sieve (°) | 8 | 8 | 8 | 8 |

| Type of fan | Cross-flow | Cross-flow | Cross-flow | Cross-flow |

| Group | Working Speed 1.0 m·s−1 | Working Speed 1.5 m·s−1 | Working Speed 2.0 m·s−1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AFN | AFRBSS | AFRBBS | TAF | AFN | AFRBSS | AFRBBS | TAF | AFN | AFRBSS | AFRBBS | TAF | |

| 1 | 6.6 | 5.8 | 7.0 | 5.7 | 7.2 | 7.3 | 6.6 | 5.9 | 8.5 | 7.5 | 7.4 | 8.6 |

| 2 | 6.3 | 5.7 | 7.2 | 5.1 | 6.8 | 6.8 | 7.0 | 6.1 | 8.1 | 7.0 | 7.7 | 8.4 |

| 3 | 5.9 | 6.3 | 6.7 | 5.5 | 7.3 | 6.7 | 7.3 | 6.4 | 8.7 | 6.9 | 7.3 | 8.8 |

| Mean | 6.3 ± 0.29 B | 5.9 ± 0.26 BC | 7.0 ± 0.21 A | 5.4 ± 0.25 C | 7.1 ± 0.22 A | 6.9 ± 0.26 A | 7.0 ± 0.29 A | 6.1 ± 0.21 B | 8.4 ± 0.25 A | 7.1 ± 0.26 B | 7.5 ± 0.17 B | 8.6 ± 0.16 A |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value (Prob > F) | Significance |

|---|---|---|---|---|---|---|

| Model | 29.14 | 11 | 2.65 | 31.07 | <0.0001 | *** |

| A—Threshing Devices | 2.39 | 3 | 0.80 | 9.36 | 0.0003 | *** |

| B—Working Speed | 19.03 | 2 | 9.52 | 111.60 | <0.0001 | *** |

| AB | 7.72 | 6 | 1.29 | 15.08 | <0.0001 | *** |

| Pure Error | 2.05 | 24 | 0.085 | |||

| Cor Total | 31.19 | 35 |

| Mass Fed (kg·s−1) | Working Speed 1.0 m·s−1 | Working Speed 1.5 m·s−1 | Working Speed 2.0 m·s−1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XD 205 | DMY N3 | HY 189 | DMY N1 | XD 205 | DMY N3 | HY 189 | DMY N1 | XD 205 | DMY N3 | HY 189 | DMY N1 | |

| 1 | 12.12 | 8.4 | 3.22 | 8.57 | 11.5 | 11.92 | 13.12 | 12.47 | 14.71 | 20.62 | 8.43 | 16.61 |

| 2 | 8.16 | 10.58 | 3.10 | 9.9 | 15 | 16.51 | 5.96 | 14.5 | 21.87 | 15.02 | 17.31 | 18.97 |

| 3 | 10.86 | 11.62 | 8.84 | 8.85 | 17.13 | 14.44 | 3.64 | 14.0 | 19.5 | 19.47 | 4.53 | 19.08 |

| Mean | 10.38 ± 1.65 A | 10.20 ± 1.34 A | 5.05 ± 2.68 B | 9.11 ± 0.57 AB | 14.54 ± 2.32 A | 14.29 ± 1.88 A | 7.57 ± 4.03 B | 13.66 ± 0.86 AB | 18.69 + 2.98 A | 18.37 ± 2.41 A | 10.09 ± 5.35 A | 18.22 ± 1.14 A |

| Group | Working Speed 1.0 m·s−1 | Working Speed 1.5 m·s−1 | Working Speed 2.0 m·s−1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| XD 205 | DMY N1 | DMY N3 | HY 189 | XD 205 | DMY N1 | DMY N3 | HY 189 | XD 205 | DMY N1 | DMY N3 | HY 189 | |

| 1 | 6.6 | 2.4 | 4.7 | 2.4 | 7.2 | 3.6 | 5.6 | 4.0 | 8.5 | 4.3 | 6.5 | 4.7 |

| 2 | 6.3 | 1.9 | 5.1 | 2.1 | 6.8 | 3.3 | 6.1 | 3.1 | 8.1 | 5.2 | 7.0 | 5.0 |

| 3 | 5.9 | 1.8 | 4.5 | 2.5 | 7.3 | 2.6 | 6.4 | 3.0 | 8.7 | 4.9 | 6.6 | 5.6 |

| Mean | 6.3 ± 0.29 A | 2.0 ± 0.28 C | 4.8 ± 0.25 B | 2.3 ± 0.17 C | 7.1 ± 0.22 A | 3.2 ± 0.42 C | 6.0 ± 0.33 B | 3.4 ± 0.45 C | 8.4 ± 0.25 A | 4.8 ± 0.37 C | 6.7 ± 0.22 B | 5.1 ± 0.37 C |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value (Prob > F) | Significance |

|---|---|---|---|---|---|---|

| Model | 131.41 | 11 | 11.95 | 82.08 | <0.0001 | *** |

| A—Variety | 95.13 | 3 | 31.71 | 217.85 | <0.0001 | *** |

| B—Working Speed | 34.95 | 2 | 17.48 | 120.06 | <0.0001 | *** |

| AB | 1.33 | 6 | 0.22 | 1.53 | 0.2115 | N |

| Pure Error | 3.49 | 24 | 0.15 | |||

| Cor Total | 134.91 | 35 |

| Order | Working Speed 1.0 m·s−1 | Working Speed 1.5 m·s−1 | Working Speed 2.0 m·s−1 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Moisture Content of Maize Grains | |||||||||

| 22.61 ± 0.8% | 26.03 ± 0.9% | 30.49 ± 0.9% | 22.61 ± 0.8% | 26.03 ± 0.9% | 30.49 ± 0.9% | 22.61 ± 0.8% | 26.03 ± 0.9% | 30.49 ± 0.9% | |

| 1 | 3.5 | 6.6 | 6.4 | 5.2 | 7.2 | 8.8 | 6.9 | 8.5 | 9.8 |

| 2 | 3.7 | 6.3 | 7.7 | 5.1 | 6.8 | 8.7 | 7.1 | 8.1 | 10.0 |

| 3 | 3.2 | 5.9 | 7.5 | 4.4 | 7.3 | 7.8 | 6.6 | 8.7 | 11.2 |

| Mean | 3.5 ± 0.21 B | 6.3 ± 0.29 A | 7.2 ± 0.57 A | 4.9 ± 0.36 C | 7.1 ± 0.22 B | 8.4 ± 0.45 A | 6.9 ± 0.21 C | 8.4 ± 0.25 B | 10.3 ± 0.62 A |

| Source | Sum of Squares | df | Mean Square | F Value | p-Value (Prob > F) | Significance |

|---|---|---|---|---|---|---|

| Model | 98.16 | 8 | 12.27 | 56.06 | <0.0001 | *** |

| A—Moisture Content | 58.56 | 2 | 29.28 | 133.77 | <0.0001 | *** |

| B—Working Speed | 38.33 | 2 | 19.16 | 87.55 | <0.0001 | *** |

| AB | 1.27 | 4 | 0.32 | 1.42 | 0.2580 | N |

| Pure Error | 3.94 | 18 | 0.22 | |||

| Cor Total | 102.10 | 26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, X.; Wang, L.; Bi, S.; Wang, B.; Ma, Z.; Gao, Y. Effects of Threshing Devices, Maize Varieties and Moisture Content of Grains on the Percentage of Maize Grains Broken in Harvesting. Agronomy 2023, 13, 1615. https://doi.org/10.3390/agronomy13061615

Feng X, Wang L, Bi S, Wang B, Ma Z, Gao Y. Effects of Threshing Devices, Maize Varieties and Moisture Content of Grains on the Percentage of Maize Grains Broken in Harvesting. Agronomy. 2023; 13(6):1615. https://doi.org/10.3390/agronomy13061615

Chicago/Turabian StyleFeng, Xin, Lijun Wang, Shengying Bi, Bo Wang, Zhao Ma, and Yunpeng Gao. 2023. "Effects of Threshing Devices, Maize Varieties and Moisture Content of Grains on the Percentage of Maize Grains Broken in Harvesting" Agronomy 13, no. 6: 1615. https://doi.org/10.3390/agronomy13061615

APA StyleFeng, X., Wang, L., Bi, S., Wang, B., Ma, Z., & Gao, Y. (2023). Effects of Threshing Devices, Maize Varieties and Moisture Content of Grains on the Percentage of Maize Grains Broken in Harvesting. Agronomy, 13(6), 1615. https://doi.org/10.3390/agronomy13061615