Abstract

The use of rootstocks and clones with different vigor and sensitivity to water deficit is an important and useful agronomic tool for vineyard management. It is essential to search for systems and strategies that maximize efficiency and productivity in the use of water. The objective of this work was to carry out a comparative economic and environmental evaluation, using the life cycle cost (LCC) and life cycle assessment (LCA) methodology, of the organic cultivation of seven Monastrell clones under two irrigation strategies, as well as to evaluate the productivity of water. The grape production depended significantly on the clone and the irrigation treatment, but the interaction between these factors was not significant. The differentiating effect of the °Brix on the price and gross receipts was very insignificant. Thus, the most important differences in productivity were those that determined the differences in economic productivity; clones 188 and 94 stood out for their high profitability. In relation to water, the most productive, water-use-efficient clones (94 and 188) showed very high WUE values. The combination of the selected plant material with the application of controlled deficit irrigation programs is a strategy with relevant economic and environmental effects on the sustainability of wine grape cultivation, especially in semi-arid areas with limited water resources.

1. Introduction

In the Mediterranean basin, viticulture is essential for the socioeconomic development of the producing regions, which often lack other viable economic alternatives. In addition to its economic weight, it has significant social value, due to the population dependent on this activity, which maintains the rural areas and plays a key role in the preservation of the environment [1,2]. The climate projections for Europe and, specifically, Spain [3,4,5] show the regions of Southern Europe and the Mediterranean arc, especially the south and east of the Iberian Peninsula, to be those that would need to make the greatest adaptation efforts at the highest costs to maintain the quality and productivity of their vineyards, since these regions will experience more severe water stress and changes of greater magnitude than other viticultural areas [4].

In the southeast of Spain, the vine is of great importance as an agroforestry crop; the removal of vineyards can lead to the abandonment of cultivated lands and the consequent problems of erosion and desertification [6,7]. The situation regarding vineyards is especially serious in regions with very limiting weather conditions, such as low rainfall [8,9]. At the national level, in the period 2011–2020, the area of vineyards decreased by 3.42% (32,000 ha), with a greater relative decrease in rain-fed cultivation (up to 14.86% in this period) [10]. In the Region of Murcia, representative of Southeastern Spain, the vineyard area has declined by 27%, the loss being particularly marked in rain-fed and insufficiently irrigated land [10]. This substantial difference verifies the vulnerability of this peninsular area, from both a productive perspective and a climatological one. This is a semi-arid area in which water resources are highly limiting [11,12,13], in terms of both availability and cost.

In these areas with large production limitations, the need to lower costs to maintain economic viability has led to production systems that are closely controlled in terms of inputs (water, fertilizers, and phytosanitary products) [14]. This has been possible largely due to the rusticity and adaptability of the main grape variety used, Monastrell. Moreover, the low consumption of inputs in vineyards in the southeast of Spain means that the potential environmental impacts evaluated through life cycle analysis are among the lowest recorded worldwide, including the global warming potential [2]. In these highly vulnerable regions, two of the main adaptations to climate change are the combination of a selection of vine varieties, clones, and rootstocks that are more tolerant of drought and high temperatures and the increase in the availability of water through irrigation [4,15]. The use of rootstocks and clones with different vigor and sensitivity to water deficit is an important and useful agronomic tool for vineyard management when deficit irrigation strategies are applied; all these measures are aimed at maximizing efficiency and improving berry and wine quality [16,17]. In such limiting situations, it is essential to search for systems and strategies that maximize efficiency and productivity in the use of water [8], in order to make cultivation viable from the socioeconomic and environmental perspectives [2]. There are studies on the productivity of irrigation water, at both a technical and economic level [18,19,20], but those that integrate productivity in both economic and social terms (employment generation) are less common [8]. Regulated deficit irrigation (RDI) and alternative techniques based on it, such as partial rootzone drying (PRD), have been widely tested in various territories of the Region of Murcia and on Monastrell in particular [8,21,22,23]. A significant improvement in grape and wine quality, mainly an increase in polyphenol content, is frequently associated with the RDI and PRD techniques [16,23,24,25,26].

The exploration of grapevine intracultivar variability (e.g., clones) is particularly interesting because there is consistent evidence of significant interclonal variability in water use efficiency (WUE), stomatal regulation, photosynthetic capacity, and biomass/yield traits [27,28,29,30]. Therefore, the identification of new clones with superior drought tolerance would provide genetic material that has greater WUE, thereby reducing the reliance on supplemental irrigation and making vineyards more sustainable [31].

In recent work, Romero et al. [17] studied the effects of deficit irrigation with very low amounts of water on the agronomic and physiological behavior of different traditional clones of Monastrell in the semi-arid conditions of Southeastern Spain, showing high variability among clones in water relations, productivity, and productive efficiency in water use. As a complementary analysis, the objective of this work was to carry out a comparative economic and environmental evaluation, using the life cycle cost (LCC) and life cycle assessment (LCA) methodology, of the organic cultivation of seven Monastrell clones under two irrigation strategies, as well as to evaluate the technical, social, and economic productivity of water.

2. Materials and Methods

For the socioeconomic and environmental evaluation of the combined strategies of clonal selection and irrigation in organic vineyards, the following work scheme was followed:

- Experimental evaluation of the grape production of seven clones in two deficit irrigation situations;

- The establishment of an organic trellised vineyard model based on the information available in the area [2,7,14] regarding the production process, investment and cost structure, and income;

- Analysis, through LCC and LCA, of the different scenarios defined by the productive behavior of the combined clonal selection and irrigation strategies.

2.1. Experiment: Grape Production as a Function of the Clone and the Amount of Irrigation

The experiment was carried out in a 0.10-ha plot of trellised adult grapevines (Vitis vinifera L., var. Monastrell, syn. Mourvedre) in an experimental vineyard located in Cehegín (Murcia) (38°6′38.13″ N, 1°40′50.41″ W, 432 m a.s.l.), during the years 2018–2021. The vines were 20+ years old and the clones studied were 4, 94, 188, 276, 360, 372, and 373, grafted on rootstock 110R. The planting density was 3333 vines ha−1, with 3 m between rows and 1 m between plants. The soil of the plot was clayey (>40% clay, 36–38% silt) and had organic matter content of 0.82–1.05%, pH of 7.39–7.40, electrical conductivity of 0.13 mS cm−1, 17–19% active limestone (CaCO3), a cation exchange capacity of 18 meq (100 g)−1, a C/N ratio between 7.1 and 8.1, total N of 0.067–0.078%, and available P of 10.7–14.7 mg kg−1. The irrigation water used came from a well and had a pH of 7.96 and electrical conductivity of 0.68–0.81 dS m−1. The climate was Mediterranean semi-arid, with hot and dry summers and scarce annual rainfall (around 300 mm year−1) [17]. The training system was a bilateral cordon trellised to a three-wire vertical system. The vine rows ran NW–SE. Six two-bud spurs (12 nodes) were left after pruning and, in May, green non-productive shoots were removed from each vine in the same manner for all treatments, according to the grower’s practice in the area [17].

Crop evapotranspiration (ETc = ETo × Kc) was estimated using varying crop coefficients (Kc)—based on those proposed by the FAO [32], adjusted for the Mediterranean area—and reference evapotranspiration (ETo) values. The Kc values used were 0.35 in April, 0.45 in May, 0.52 in June, 0.75 in July–mid-August, 0.60 in mid-August–early September, and 0.45 in mid-September–October. The ETo was calculated weekly from the mean values of the preceding 12–15 years, using the Penman–Monteith FAO method [32] and the daily climatic data collected in the meteorological station (Campbell mod. CR 10X) located at the experimental vineyard and belonging to the Servicio de Información Agraria de Murcia (SIAM, IMIDA) [17].

Each clone was irrigated from April to October using high-frequency drip irrigation (2–5 times per week during late evening (20:00–23:00), depending on the phenological period), applying an optimized RDI strategy throughout this period (control treatment) and a severe deficit irrigation strategy in which no irrigation was applied from fruit set to the end of the cycle (stress treatment, Table 1). All clones were irrigated with similar annual water volumes, applying the same control and DI strategies from 2018 to 2020 (Table 1). To perform a homogeneous socioeconomic analysis, in the present work, we evaluated the period 2018–2020. The plant material, irrigation system, irrigation treatments, and experimental design were described in detail by Romero et al. [17].

Table 1.

Water volume (mm) applied for each treatment (control and stress) in each phenological period and the total for every year of the experiment (2018–2020).

A completely randomized design was used in the vineyard with two factors, clone (7 clones) and irrigation conditions (control and stress treatments), with 15 repetitions per combination. Therefore, each clone had 15 control vines and 15 stressed vines arranged in the same trellis row. Due to its small size and to the high soil homogeneity (there were no significant differences in soil characteristics, such as texture, organic matter, pH, or cation exchange capacity), the experimental design was elaborated without repetitions of complete blocks. To cut off irrigation in plants with stress treatment, a key in the drip line was provided to open or close when irrigation or drought had to be applied. Inter-row and under-vine weeds were removed mechanically during the season, soil management was no tillage, and vineyard management and all of the phytosanitary treatments were applied following the rules of organic production.

Each year at harvest, the yield components were measured for 15 vines per clone–treatment combination. The yield per vine, number of clusters per vine, cluster weight, berry number per cluster, and berry weights were calculated. The productive water use efficiency (WUE) was expressed as the mass of fresh grapes produced per m3 of applied water.

Samples of mature berries were collected from each grapevine in September 2018, 2019, and 2020, when the maturity was around 23–24° Brix (coinciding with harvest), and transported to the laboratory. The harvest dates were determined on the basis of weekly analyses of the grape composition (TSS and acidity) during ripening. The samples consisted of 800–900 g of berries, randomly collected from different clusters in each vine. The berries were crushed by an automatic blender (Coupe 550 G T), avoiding seed breakage. A first sub-sample of this crushed sample of grapes was centrifuged and the juice was used for the analysis of TSS (°Brix), as described in detail in [17,22].

A general linear model (factorial ANOVA) was applied for production and °Brix as dependent variables to detect differences due to the clone and irrigation treatment factors. Next, the Tukey honest significant differences (HSD) post hoc test of multiple comparisons of means was performed (95% confidence level). In addition, for each clone, the means of the irrigation treatments (control and stress) were compared by one-way ANOVA. For all analyses, the R Commander software (GNU GPL license) was used.

2.2. Establishment of the Organic Vineyard Model

The organic vineyard model was based on the information published for the study area in different studies [2,7,14,33]. Hence, the Monastrell red grape variety was cultivated on trellises, with 3 × 1 m spacing and one dripper (2 dm3 h−1) per plant, considering a 10-ha trellis vineyard under an organic regime and expressing the results per hectare. The characteristics of this vineyard model are shown in Table 2.

Table 2.

Characteristics of the organic trellis vineyard model (Monastrell grape).

2.2.1. Investment and Fixed Assets

The standard farm has a 40-m2 warehouse for the irrigation head and storage of inputs. The irrigation installation consists of an irrigation head with a flow rate of 25 m3 h−1, as well as PE BD pipes with integrated self-compensating drippers (2 dm3 h−1) at a distance of 40 cm apart (1 dripper/plant). The existence of a regulating reservoir with sufficient capacity to satisfy the demand in the month of maximum requirements is also considered. Preparation and planting include preparation with a 100-HP tractor, manual setting up of the supports, and planting of the grafted vines. The supporting structure is a trellis with three wires, all of galvanized steel (Table 2).

2.2.2. The Process and Means of Production

The processes are described in relation to cost chapters. The costs are grouped so that the economic analysis (LCC) is analogous to the environmental one (LCA).

- Winter pruning. Manual winter pruning on a trellis formed with a double cordon.

- Pruning of green growth. Manual summer pruning to thin the vegetation, facilitating the entry of light.

- Machinery. This includes the use of machinery and implements in various activities: shredding of pruning waste, tillage and weed removal, phytosanitary treatments, and transport of the harvested grapes to the winery.

- Phytosanitary tasks. Four phytosanitary treatments are carried out with active substances accepted in organic farming (Table 2).

- Organic fertilization. Liquid organic fertilizer admitted in organic production is supplied through fertigation.

- Irrigation water. This includes the water consumed by the irrigation programmed for the production cycle. The irrigation strategy and the amounts of water are described in the experimental procedure.

- Electrical power. This is consumed by the irrigation head in the distribution of water and organic fertilizers (fertigation).

- Harvest. The harvesting is manual, with the support of a tractor and trailer for loading and subsequent transport to the winery.

2.3. Life Cycle Costs (LCC): Socioeconomic Analysis and Water Productivity

We established the productive structure of the costs and income of the crop, using indicators for the evaluation [2,8,34]. A methodology in line with the so-called life cycle cost (LCC) was followed [2,35,36,37,38].

Both the costs and the income were those of one year of production. To carry out this analysis, the costs of the operation were identified; later, they were grouped and classified into fixed costs and variable costs.

- Fixed costs. The fixed costs were calculated as the annual amortization cost, applying the linear or constant installments method.

- Variable costs. These included the costs of the inputs, services, and activities used in the course of one production cycle. They were calculated taking as a reference the cost of the inputs used and the activities carried out in the production process. For each of the costs, both fixed and variable, the corresponding opportunity cost was calculated; namely, the alternative use of money in bank savings accounts without risk was taken into account.

- Income. Revenue was calculated from the average price of the product. The price was established based on the weighted average prices, over the last three years, for Monastrell grapes in this area of production (Table 3). The income was calculated from the annual average sale price of Monastrell grapes in the 2018–2020 period in the Region of Murcia, obtained from the Statistical Service of the Regional Ministry of Water and Agriculture and the Rosario de Bullas cooperative (Murcia).

Table 3. Annual prices and average price of water and grapes for the period 2018–2020.

Table 3. Annual prices and average price of water and grapes for the period 2018–2020.

To analyze the viability/profitability conditions of the activity, the net margin (NM) was first calculated, as the difference between total income and total cost (TC), based on the following formula:

NM = Income − (Fixed Costs + Variable Costs + Opportunity Costs).

From the NM, the following socioeconomic indicators were calculated [2,39]:

- NM/TC (%)—this shows the overall profitability of the activity;

- Average cost (EUR kg−1)—this indicates the minimum sale price at the origin of the product for the activity to be viable;

- Breakeven point (kg ha−1)—this indicates the minimum production, for the mid-market sale price, for the activity to be viable;

- Employment/ha (AWU ha−1)—this is an indicator of direct employment generation linked to the rural environment; the agricultural work unit (AWU) corresponds to the work carried out by a person employed full-time on a farm [2,39].

Other indexes used in the analysis of the socioeconomic productivity of irrigation water were also calculated, due to the importance of this resource in the southeast of Spain [8]. In the literature, various indicators related to the productivity of water as a production factor have been used for various crops [8,19,40]. The following indicators were used: gross economic irrigation water productivity per m3 or income per m3, as an indicator of the gross income generated by each m3 consumed; net economic irrigation water productivity (EUR m−3), as the NM generated per m3 of water, equivalent to the profit per m3; crop water productivity (kg m−3) or water use efficiency (WUE), as an indicator of the kg of grapes produced for each m3 consumed in the crop. We also analyzed the social importance of each treatment according to the level of employment per cultivated hectare (AWU ha−1) and per cubic hectometer (AWU hm−3). Finally, we calculated the maximum price of irrigation water compatible with the economic viability of the activity (water viability threshold, WVT), i.e., the price at which income and costs are equal.

2.4. Life Cycle Analysis: Global Warming Potential

The LCA was developed according to the protocol standardized by ISO 14040/14044 [41,42]. The functional unit (FU) was 1 kg of grapes harvested in the field. The scope of the LCA, therefore, focused solely on the cultivation phase of the grapes for winemaking. As the system only produced grapes, it was treated as a monofunctional system, so environmental load allocation procedures were not applied. The SimaPro 9.4 software was used to carry out the LCA [43]. The background data (energy, fuel, materials, products, etc.) were obtained from the Ecoinvent 3.6 database that is available in the SimaPro 9.4 software. The following components of the system were taken into account.

- Infrastructure. This corresponds to the investment and fixed assets of the LCC. It includes the elements related to fertigation (the reservoir, irrigation head, and irrigation network) as well as the elements that make up the trellis.

- Machinery. The fuel consumed by the agricultural machinery in the different tasks, as well as its emissions.

- Fertigation. The electrical energy consumed by the water booster pumps in the fertigation.

- Fertilizers. The production of organic fertilizers, their transport and packaging, and their emissions into the air due to the application of nitrogenous compounds to the soil.

- Phytosanitary products. The production of the phytosanitary products and their transport and packaging.

The foreground data of this LCA are those set out in Section 2.2. However, Table 4 shows the inputs in relation to the FU. The background data (energy, fuel, materials, products, and transport) were obtained from the Ecoinvent 3.6 database available in SimaPro. The emissions into the atmosphere resulting from the consumption of diesel by agricultural vehicles were estimated based on the emission factors established by the EEA [44]. Direct and indirect N2O emissions into the atmosphere due to the application of organic nitrogen fertilizers were estimated as described by del Hierro et al. [45] and according to the IPCC [46]. For the characterization of the global warming potential (GWP100a), the CML-IA methodology available in SimaPro was used.

Table 4.

Inputs for the organic trellis vineyard model. Functional unit: 1 kg of grape. For the infrastructures, the useful life is taken into account.

3. Results and Discussion

3.1. Grape Production

The factorial ANOVA showed that, in the experimental period analyzed, the grape production depended significantly on the clone and the irrigation treatment, but the interaction between these factors was not significant (Table 5). However, the °Brix did not depend on these factors. In the control irrigation treatment, the production values were highest in clones 94 and 188, although there were no significant differences from 276, 372, or 373, and they were lowest in clone 360.

Table 5.

ANOVA results and mean values (±sd) of grape production and °Brix depending on the clone and the irrigation treatment (control and stress).

In all the clones, the production value was lower in the stress treatment, except in clone 4, for which the difference was negligible. However, the differences were only significant in clones 276 and 373, where the effect of the stress treatment was greater. The clone effect gave important differences in productivity (kg ha−1), depending on whether the irrigation system was control or stress.

3.2. Cost and Revenue Structure

Table 6 shows the calculations aimed at establishing the cost of the fixed assets, which was the same in all cases. For its part, Table 7 shows the structure of all the combinations analyzed (clone and irrigation strategy). In relation to income, Table 3 shows the average prices paid to viticulturists in the study period, while Table 8 shows the corresponding gross income per hectare and year. The form of payment for grapes in the area continues to be mostly EUR per kilo and °Baumé, as stated in various works [2,7,14]. As verified by previous works [8,16] and this one (Table 8), neither the clone nor the rootstock determine relevant differences in °Brix and consequently in °Baumé. In Table 5, we can see that the results grouped by clone are in a very narrow band of values (22.56 to 23.41 °Brix). Therefore, the differentiating effect of the °Brix on the price and gross receipts is very insignificant. Thus, the most important differences in productivity (kg ha−1) are those that determine the differences in economic productivity, through the income (EUR ha−1) and its effect on profitability, as we will see in the next section of indicators.

Table 6.

Investment and annual depreciation in vineyard Monastrell trellis system.

Table 7.

Cost accounting (EUR ha−1) for all combinations (clone × irrigation method) during the experimental period 2018–2020.

Table 8.

Average incomes (2018–2020) for each treatment clone–irrigation method.

As shown in Table 6, all the systems analyzed required the same investment and therefore carried the same fixed costs per hectare (EUR 722 ha−1, Table 7). The relative importance of the fixed costs was determined by the current costs. In this way, the fixed costs were less important than the variable costs. In all cases, the fixed costs were between 21.6% and 27.7% of the total cost of production. These values are high relative to other crops in the same area (Southeastern Spain) and are mainly due to the preparation/planting and the irrigation infrastructure (head + network + reservoir), which represent 52% and 43.6% of the fixed costs, respectively. Within the preparation and planting, an important aspect is the supporting structure, i.e., the trellis.

In relation to the cost structure, the differences between the clones were mainly due to their vigor and productivity, i.e., the greatest difference was due to the cost of harvesting, which was directly proportional to the productivity. Irrigation had a much weaker effect on the costs (the sum of the cost of the water and that of the electrical energy for irrigation). Thus, in the range of costs, from EUR 2606 (373S) to EUR 3347 per hectare (188C), 86% of this difference was due to harvesting; in absolute values, of the EUR 741 differential margin, EUR 637 was linked to the cost of harvesting. This relationship between the accounting structure and vigor–productivity was also verified when we analyzed combined irrigation and rootstock strategies [8].

3.3. Socioeconomic Indexes

3.3.1. Results Grouped by Clone

Clones 188 and 94 stood out for their high profitability, with an NM/C of 33.77% and 27.06%, respectively (Table 9), as already indicated, due to their high productivity. The rest of the clones showed negative returns, making them economically unviable. Only in the case of clone 4 was the NM/C very close to 0 (−0.62%). The case of clone 360 was the most unfavorable, for both production and the corresponding profitability. The differences were mainly due to productivity (in kg ha−1) and consequently to gross income (in EUR ha−1), because the °Baumé was very similar in all cases and its effect on income was not relevant (Table 4).

Table 9.

Productive, economic, and social parameters calculated in the cost/benefit analysis for different clones (C), irrigation strategies (IS), and the interaction (C × IS) for the period 2012–2017.

The breakeven point indicates that the minimum productivities for viability are around 7000–9000 kg ha−1, which are the productivities established as the maximum by the Denominaciones de Orígen (DOs) of Southeastern Spain. It is advisable to increase the maximum productivity of the regional DOs, since, with combined rootstock–clone–irrigation strategies, very high productivities can be achieved, especially in relation to water resources. Therefore, future research into the use of combinations of high-WUE, drought-tolerant rootstocks (e.g., 140Ru) [16] and these high-WUE, drought-tolerant Monastrell clones (e.g., clones 4 or 188) under deficit irrigation/rain-fed conditions is necessary, because it could reduce the reliance on supplemental irrigation and make vineyards more sustainable and water-use-efficient in semi-arid areas, even for rain-fed crops [17].

The average cost of production shows clones 188 and 94 to be the most efficient, with a low average value (EUR 0.27 kg−1). All the clones had values in the range of EUR 0.27 kg−1–EUR 0.43 kg−1, with the exception of 360, which had a high production cost, very different from the rest of the clones (EUR 0.72 kg−1) (Table 9).

In relation to water, gross productivity (kg m−3) was very high for all clones. The most productive, water-use-efficient clones (94 and 188, Table 9) showed very high WUE values (approximately 28 kg m−3), similar to the highest found in cv. Gaglioppo in Italy (9–29 kg m−3) [47]. These results indicate that these clones are very productive when supplied with very little irrigation water, suggesting greater drought tolerance and WUE in high-vigor clones (94, 188) than in low-vigor clones [17].

The socioeconomic effect in social and territorial terms achieved by the water resource is very important. In 94 and 188, the gross economic value generated on the land was around EUR 10 m−3 (Table 9). The vineyard in general, and the Monastrell variety in particular, adapted well to deficit irrigation, with high water productivity values. The value reached was higher than that of other woody trees in Southeastern Spain, such as the peach tree, in which values between EUR 3.75 m−3 and EUR 4.51 m−3 were reached in deficit treatments [48]. In terms of microeconomics, the profit obtained at the exploitation level, measured as the net productivity of water, reached values in the clones highlighted previously of EUR 2.15 m−3 (clone 188) and EUR 1.74 m−3 (clone 94).

The employment generated per m3 (AWU hm−3) was very high, reaching 269 AWU hm−3 in the cultivation phase in clone 188 (Table 9). All the clones had very high values of this indicator (between 195 and 269 AWU hm−3), making water a very productive factor in social terms—more so than for highly productive, intensive crops in the same area, such as lemon (89 AWU hm−3) or even greenhouse pepper (224 AWU hm−3) [49].

The water threshold price (WVT) in clones 188 and 94 was far above the market price of water in the southeast of Spain, which has shown an upward trend in recent years. This value is highly variable depending on the areas and specific sources of water involved, reaching values between EUR 0.350 m−3 and EUR 0.508 m−3 [9,49], but, in any case, the WVT values for clones 188 and 94 were much higher (EUR 2.18 m−3 and EUR 1.76 m−3, respectively). For clone 4, the WVT value was below the current market price of water in most areas of Murcia, making its cultivation unviable.

3.3.2. Results by Clone and Irrigation Strategy

For all the clones, the results show the control treatment to be more profitable than the stress treatment (Table 9). There is an exception in the case of clone 4, with 4 control being unviable and 4 stress practically at the threshold of economic viability, with NM/TC = 0.71%. As in the analysis grouped by clone, both 188 and 94 stand out, the control showing a much higher profitability value. For example, 188 control had an NM/TC of 48.11%, compared to 19.43% in the case of 188 stress.

For some of the clones, viability and economic profitability were found only with the control water supply: 276 (MN/TC 12.69%), 373 (14.68%), and 372 (8.66%). This confirms that with the deficit irrigation (stress) water supply, the production and income were not enough to make the crop profitable, when the necessary infrastructure of the irrigated production system (irrigation infrastructure and metal trellis) was taken into account. In these conditions of very low irrigation allocations, it could be a better option, from an economic profitability standpoint, to make the vineyard rain-fed and adapt it to climate change through the more sustainable management of the soil, to increase the efficiency of rainwater.

The analysis also verified that the worst clone from an economic point of view was, as seen in the aggregated results, clone 360 (unviable in any case, control or stress). Clone 4, so close to the viability threshold, could be economically viable with a slightly greater water supply.

The breakeven point in the control treatment for clones 188 and 94 exceeded 9000 kg ha−1 (Table 9), outside the productive limitation range of the regional DOs. Thus, the proposed strategies combining clones and irrigation, already so tight in terms of water supply, could be somewhat more restrictive (lower water consumption), especially if some quality premium were paid [21]. The high productivity of clones 188 and 94 would make it possible to further reduce irrigation, with more restrictive RDI strategies, to better adapt to the productions allowed by the DOs of Southeastern Spain.

The values of the gross water productivity indicators were higher for the stress treatments (Table 9), but only the profitable ones showed positive net productivities. In terms of social water productivity, the values reached by clones 188 and 94 in the stress treatment were extremely high (reaching 577 AWU hm−3 in clone 94), even compared to highly productive, intensive, protected crops [50]. For the combination of clone 4 and stress, more irrigation water could be bought, perhaps improving its productivity. Several of the clones assayed (373, 372, and 276) would be profitable even with higher water prices, since their WVT values were higher than the current market price of water (with control irrigation).

The qualitative analysis of the grapes and musts revealed improvements in grape quality (both technological and phenolic) in medium–low-vigor (360, 372, 276, 373) and high-vigor (188) clones, compared to clones 94 and 4, which showed worse grape and wine quality [17]. These authors recommended the application of low-water-volume RDI strategies under semi-arid conditions for clone 188, to try to achieve a balance between high yield, efficiency, and optimum berry and wine quality.

3.3.3. Global Warming Potential (GWP)

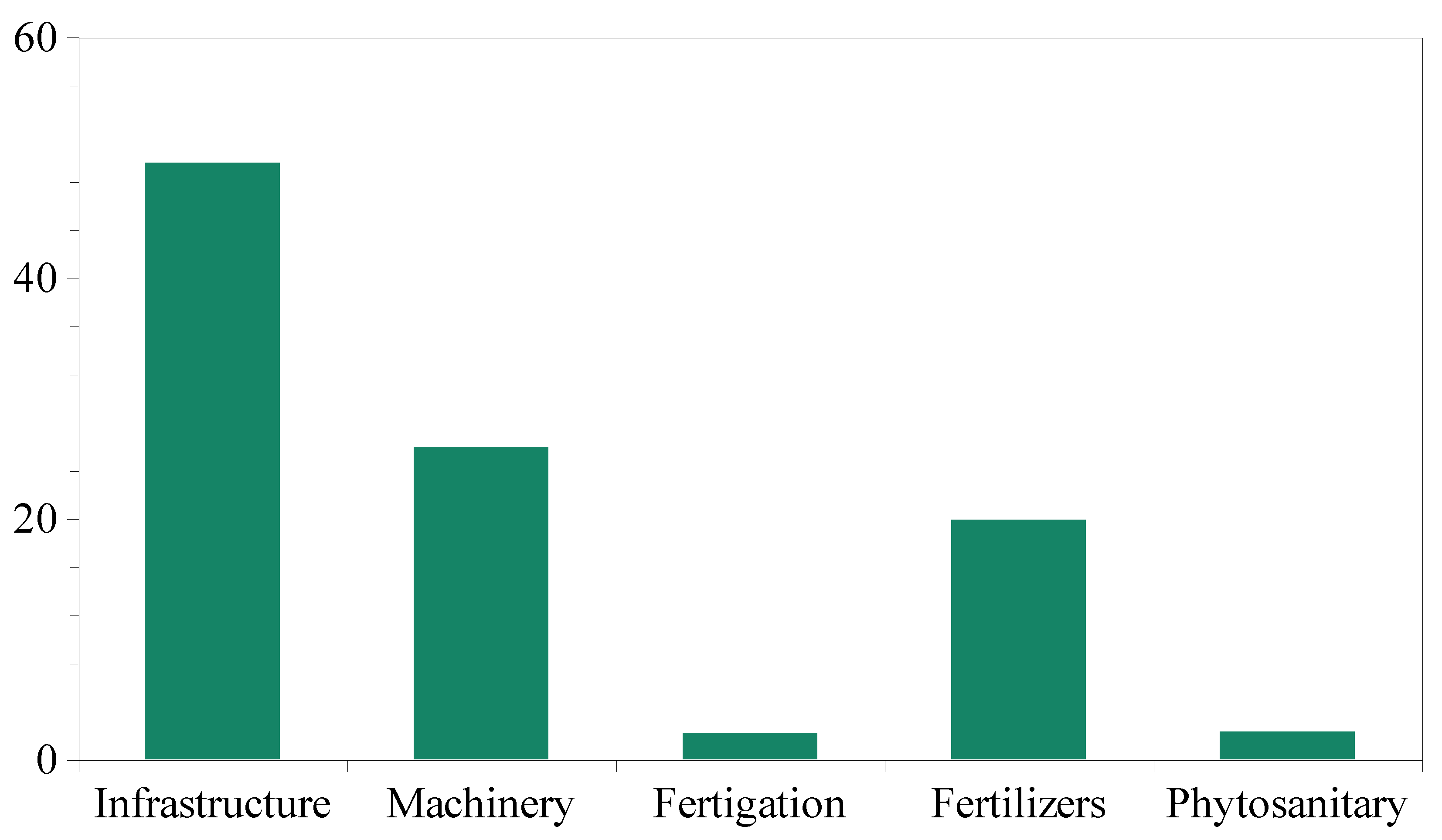

The values of the contributions of the system components to GWP were the same for all control clones, since the only variable was production; the inputs were the same. Infrastructure was the component that contributed the most (49.65%) to GWP, followed by fertilizers (25.99%), machinery (19.91%), phytosanitary products (2.28%), and fertigation (2.17%) (Figure 1). This pattern of the contributions of the system components to GWP is similar to that described in trellised vineyards by García-Castellanos et al. [2], with the contribution of the infrastructure being very relevant. In the cultivation of pepper in a greenhouse with fertigation, the infrastructure also made a very important contribution [49]. In general, labor and fertilizers seem to be the components of the system that contribute the most to GWP [51] in the production of grapes for wine. However, this is the case when the vine is trained in the form of a goblet, without localized irrigation, or the infrastructure has not been considered. Likewise, the contribution of phytosanitary products has been shown to be significant [51], but here it was very low. This is because, as indicated by Navarro et al. [52], in dry climates, the application of fungicides is minimized, since the incidence of fungi in vineyards is lower than in damp climates.

Figure 1.

Contribution (%) of system components to GWP in the vineyard model.

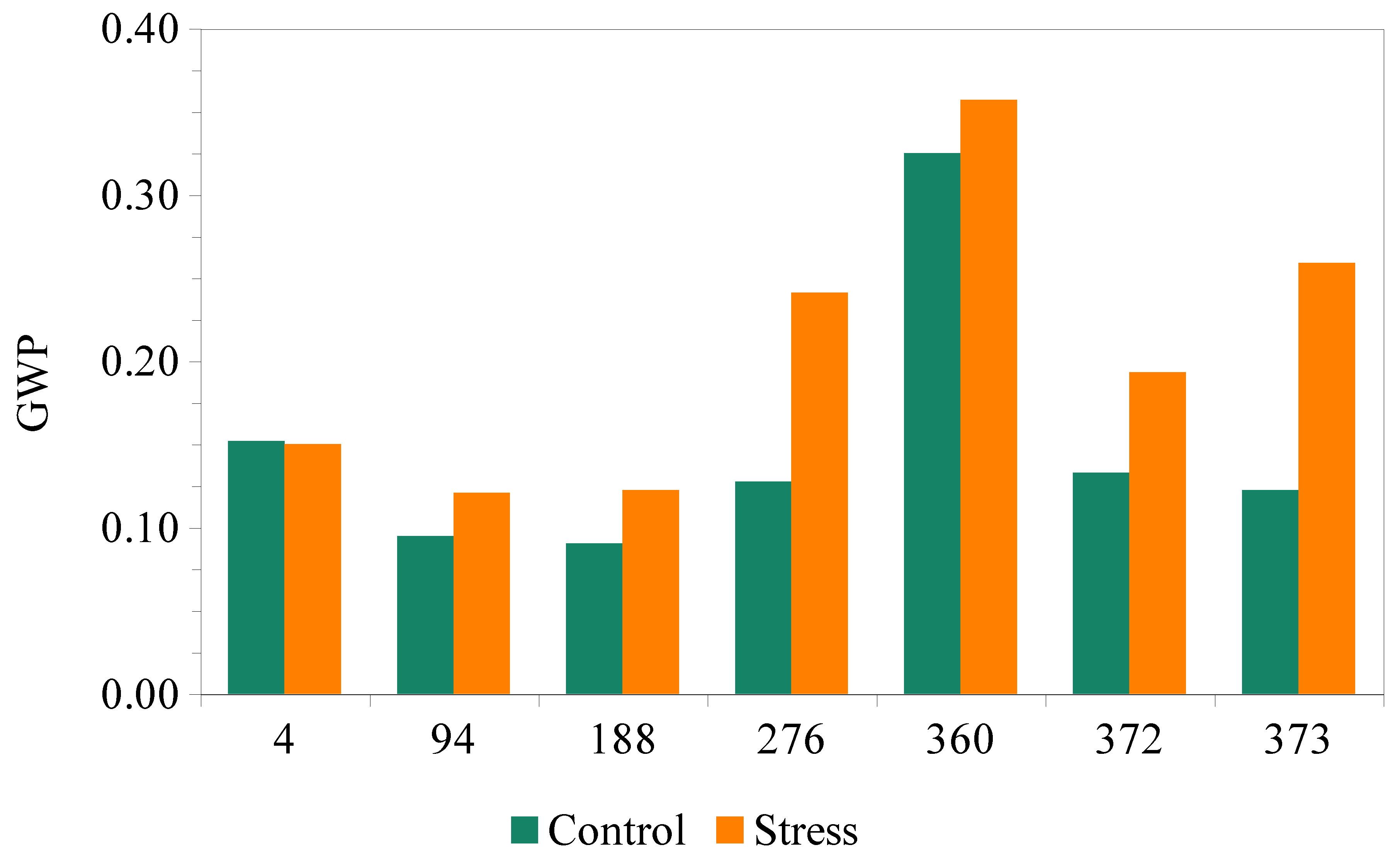

The GWP values (Table 10) were, for all clones, inversely proportional to the production obtained with each of them (Table 5), as the inputs were the same in all cases except when comparing the control and stress treatments, since the electrical energy associated with localized irrigation was lower in the latter.

Table 10.

GWP values (kg CO2-eq per kg of grape) for the different clones and treatments, and relative differences (RD%).

The values for the different clones grown under control conditions (Table 10) vary from 0.090 (clone 188) to 0.325 kg CO2-eq (clone 360). For the stressed clones, the values are generally higher, ranging from 0.121 (clone 94) to 0.357 (clone 360), except for clone 4, where stress gave a slightly lower value with a relative difference of only 1.19%. In any case, the values are within the ranges recorded by different authors [51,52]. Ferrara and De Feo [51], in an extensive bibliographical review of vineyards around the world, found values per kg of grapes from 0.1 to 2.1 kg CO2-eq. Navarro et al. [52] analyzed 18 vineyards in Spain and France and the GWP varied between 0.08 and 0.70 kg CO2-eq, with a mean value of 0.23 kg CO2-eq. For red grape vineyards in the Mediterranean area, different authors reported values between 0.12 and 0.50 kg CO2-eq [36,53,54,55]. Given these ranges, the values registered here can be considered low, except perhaps for the one obtained for clone 360 (both control and stress). These low GWP values confirm what has been indicated in various works in Southeastern Spain in relation to the rusticity of the Monastrell variety and its adaptation to the limiting edaphoclimatic conditions typical of semi-arid areas, as well as in relation to the low use of inputs and, therefore, to the high efficiency in their use [2,7,14].

The greatest differences between the treatments were obtained in clone 276 and clone 373, of −89.21% and −111.85%, respectively (Figure 2, Table 10), since the stress treatment caused a significant decrease in grape production (Table 5). However, the difference in clone 4 was negligible, with production being around 8 t ha−1; in clone 360, the difference was also slight (−9.83%) but the production was lower, less than 4 t ha−1.

Figure 2.

Global warming potential (GWP, kg CO2-eq) of the different clones and for the two irrigation strategies.

4. Conclusions

The combination of selected clones of a variety, with the application of controlled deficit irrigation programs, is a strategy with relevant economic and environmental effects on the sustainability of wine grape cultivation, especially in semi-arid areas with limited water resources. The selected clone of a variety determines the viability and economic profitability, especially due to the effect on productivity, in technical and economic terms, since the differences in costs are insignificant and directly related to gross production. In the same way, this effect on productivity has repercussions for environmental indicators, such as global warming; with greater vigor and productivity, the impact per unit of production is lower. A balance between quality and productivity must be sought to guarantee the sustainability of viticulture for the production of quality wines.

Faced with increasingly limiting climatic conditions regarding production, these adaptation strategies may well be decisive for the viability of viticulture in semi-arid environments.

Author Contributions

J.G.G. and P.R.A. conceived and designed the present study. The role of each of the authors was as follows: P.R.A., P.B. and J.M.N. carried out the experimental evaluation of the grape production of seven clones in two deficit irrigation situations. J.G.G. and B.G.G. established the organic trellised vineyard model. J.G.G. and B.G.C. performed the life cycle cost analysis. B.G.G. and B.G.C. performed the life cycle assessment. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the AGL2017-83738-C3-2-R project of the Ministry of Science, Innovation, and Universities within the program “Challenges of Society” and by the FEDER 1420-24 project (operating program of the Region of Murcia 2014-2020), co-financed at 80% by the European Regional Development Fund.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ferrer, J.R.; Abella-Garcés, S.; Maza-Rubio, M.T. Human Resource Practices and Performance in Small Spanish Wineries, and Their Evolution with Age and Size. Ciência Téc. Vitiv. 2020, 35, 107–119. [Google Scholar] [CrossRef]

- García Castellanos, B.; García García, B.; García García, J. Evaluation of the Sustainability of Vineyards in Semi-Arid Climates: The Case of Southeastern Spain. Agronomy 2022, 12, 3213. [Google Scholar] [CrossRef]

- Fraga, H.; García de Cortazar, I.; Malheiro, A.C.; Santos, J.A. Modelling Climate Change Impacts on Viticultural Yield, Phenology and Stress Conditions in Europe. Glob. Chang. Biol. 2016, 22, 3774–3788. [Google Scholar] [CrossRef]

- Resco, P.; Iglesias, A.; Bardají, I.; Sotés, V. Exploring Adaptation Choices for Grapevine Regions in Spain. Reg. Environ. Chang. 2016, 16, 979–993. [Google Scholar] [CrossRef]

- Guiot, J.; Cramer, W. Climate Change: The 2015 Paris Agreement Thresholds and Mediterranean Basin Ecosystems. Science 2016, 354, 465–468. [Google Scholar] [CrossRef]

- García García, J. Actualización de la contabilidad de costes del cultivo de viña en la Región de Murcia. Enoviticultura 2016, 39, 2–9. [Google Scholar]

- García García, J.; García García, B. Aspectos socioeconómicos y ambientales del cultivo de la uva Monastrell. In El libro de la Monastrell; Riquelme, F., Martínez-Cutillas, A., Eds.; Consejería de Agua, Agricultura, Ganadería y Pesca de la Región de Murcia: Murcia, Spain, 2018; pp. 71–88. ISBN 978-84-09-06249-2. [Google Scholar]

- Romero Azorín, P.; García García, J. The Productive, Economic, and Social Efficiency of Vineyards Using Combined Drought-Tolerant Rootstocks and Efficient Low Water Volume Deficit Irrigation Techniques under Mediterranean Semiarid Conditions. Sustainability 2020, 12, 1930. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Martínez-Alvarez, V.; Maestre-Valero, J.F.; Gallego-Elvira, B. Influence of the Water Source on the Carbon Footprint of Irrigated Agriculture: A Regional Study in South-Eastern Spain. Agronomy 2021, 11, 351. [Google Scholar] [CrossRef]

- MAPA. Anuario de Estadística 2021; Ministerio de Agricultura, Pesca y Alimentación (MAPA): Madrid, Spain, 2021. [Google Scholar]

- Arcas Lario, N.; Alcón Provencio, F. Contribución de Las Entidades de “Economía Social” a La Gestión Eficiente Del Agua Para Uso Agrícola: Situación En La Región de Murcia. Rev. Estud. Coop. 2007, 91, 7–33. [Google Scholar]

- Soto García, M.; Martínez Álvarez, V.; Martín Górriz, B. El regadío en la Región de Murcia. Caracterización y Análisis Mediante Indicadores de Gestión; Sindicato Central de Regantes del Acueducto Tajo-Segura: Murcia, Spain, 2014; ISBN 978-84-697-0372-4. [Google Scholar]

- Maestre Valero, J.F.; Martín Górriz, B.; Alarcón, J.J.; Nicolás, E.; Martínez Álvarez, V. Economic Feasibility of Implementing Regulated Deficit Irrigation with Reclaimed Water in a Grapefruit Orchard. Agric. Water Manag. 2016, 178, 119–125. [Google Scholar] [CrossRef]

- García-Castellanos, B.; García-García, B.; García-García, J. Evaluación de la sostenibilidad de tres sistemas de cultivo de viña característicos de la Región de Murcia. ITEA 2021, 118, 137–157. [Google Scholar] [CrossRef]

- Iglesias, A.; Garrote, L. Adaptation Strategies for Agricultural Water Management under Climate Change in Europe. Agric. Water Manag. 2015, 155, 113–124. [Google Scholar] [CrossRef]

- Romero, P.; Botía, P.; Navarro, J.M. Selecting Rootstocks to Improve Vine Performance and Vineyard Sustainability in Deficit Irrigated Monastrell Grapevines under Semiarid Conditions. Agric. Water Manag. 2018, 209, 73–93. [Google Scholar] [CrossRef]

- Romero, P.; Botía, P.; Gil-Muñoz, R.; del Amor, F.M.; Navarro, J.M. Evaluation of the Effect of Water Stress on Clonal Variations of Cv. Monastrell (Vitis vinifera L.) in South-Eastern Spain: Physiology, Nutrition, Yield, Berry, and Wine-Quality Responses. Agronomy 2023, 13, 433. [Google Scholar] [CrossRef]

- De, C. Teixeira, A.H.; Bastiaanssen, W.G.M.; Bassoi, L.H. Crop Water Parameters of Irrigated Wine and Table Grapes to Support Water Productivity Analysis in the São Francisco River Basin, Brazil. Agric. Water Manag. 2007, 94, 31–42. [Google Scholar] [CrossRef]

- Fernández, J.E.; Alcón, F.; Díaz-Espejo, A.; Hernández-Santana, V.; Cuevas, M.V. Water Use Indicators and Economic Analysis for On-Farm Irrigation Decision: A Case Study of a Super High Density Olive Tree Orchard. Agric. Water Manag. 2020, 237, 106074. [Google Scholar] [CrossRef]

- Vita Serman, F.; Orgaz, F.; Starobinsky, G.; Capraro, F.; Fereres, E. Water Productivity and Net Profit of High-Density Olive Orchards in San Juan, Argentina. Agric. Water Manag. 2021, 252, 106878. [Google Scholar] [CrossRef]

- García García, J.; Martínez-Cutillas, A.; Romero, P. Financial Analysis of Wine Grape Production Using Regulated Deficit Irrigation and Partial-Root Zone Drying Strategies. Irrig. Sci. 2012, 30, 179–188. [Google Scholar] [CrossRef]

- Romero, P.; Gil Muñoz, R.; Fernández-Fernández, J.I.; del Amor, F.M.; Martínez-Cutillas, A.; García-García, J. Improvement of Yield and Grape and Wine Composition in Field-Grown Monastrell Grapevines by Partial Root Zone Irrigation, in Comparison with Regulated Deficit Irrigation. Agric. Water Manag. 2015, 149, 55–73. [Google Scholar] [CrossRef]

- Romero, P.; García García, J.; Fernández-Fernández, J.I.; Gil Muñoz, R.; del Amor Saavedra, F.; Martínez-Cutillas, A. Improving Berry and Wine Quality Attributes and Vineyard Economic Efficiency by Long-Term Deficit Irrigation Practices under Semiarid Conditions. Sci. Hortic. 2016, 203, 69–85. [Google Scholar] [CrossRef]

- Intrigliolo, D.S.; Castel, J.R. Response of Plum Trees to Deficit Irrigation under Two Crop Levels: Tree Growth, Yield and Fruit Quality. Irrig. Sci. 2010, 28, 525–534. [Google Scholar] [CrossRef]

- Castellarin, S.D.; Pfeiffer, A.; Sivilotti, P.; Degan, M.; Peterlunger, E.; Di Gaspero, G. Transcriptional Regulation of Anthocyanin Biosynthesis in Ripening Fruits of Grapevine under Seasonal Water Deficit. Plant Cell Environ. 2007, 30, 1381–1399. [Google Scholar] [CrossRef] [PubMed]

- Castellarin, S.D.; Matthews, M.A.; Di Gaspero, G.; Gambetta, G.A. Water Deficit Accelerate Ripening and Induce Changes in Gene Expression Regulating Flavonoid Biosynthesis in Grape Berries. Planta 2007, 227, 101–112. [Google Scholar] [CrossRef] [PubMed]

- Tortosa, I.; Douthe, C.; Pou, A.; Balda, P.; Hernández-Montes, E.; Toro, G.; Escalona, J.M.; Medrano, H. Variability in Water Use Efficiency of Grapevine Tempranillo Clones and Stability over Years at Field Conditions. Agronomy 2019, 9, 701. [Google Scholar] [CrossRef]

- Tortosa, I.; Escalona, J.M.; Toro, G.; Douthe, C.; Medrano, H. Clonal Behavior in Response to Soil Water Availability in Tempranillo Grapevine Cv: From Plant Growth to Water Use Efficiency. Agronomy 2020, 10, 862. [Google Scholar] [CrossRef]

- Pagliarani, C.; Boccacci, P.; Chitarra, W.; Cosentino, E.; Sandri, M.; Perrone, I.; Mori, A.; Cuozzo, D.; Nerva, L.; Rossato, M.; et al. Distinct Metabolic Signals Underlie Clone by Environment Interplay in “Nebbiolo” Grapes Over Ripening. Front. Plant Sci. 2019, 10, 1575. [Google Scholar] [CrossRef]

- Buesa, I.; Escalona, J.M.; Tortosa, I.; Marín, D.; Loidi, M.; Santesteban, L.G. Intracultivar Genetic Diversity in Grapevine: Water Use Efficiency Variability within Cv. Grenache. Physiol. Plant 2021, 173, 2226–2237. [Google Scholar] [CrossRef]

- Pagay, V.; Furlan, T.S.; Kidman, C.M.; Nagahatenna, D. Long-Term Drought Adaptation of Unirrigated Grapevines (Vitis vinifera L.). Theor. Exp. Plant Physiol. 2022, 34, 215–225. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration—Guidelines for Computing Crop Water Requirements; FAO: Rome, Italy, 1998; ISBN 92-5-104219-5. [Google Scholar]

- García García, J. Estructura de Costes de las Orientaciones Productivas Agrícolas de la Región de Murcia: Frutos Secos, Frutales de Pepita, Vid y Olivo; Técnica; Consejería de Agua, Agricultura, Ganadería y Pesca de la Región de Murcia: Murcia, Spain, 2019. [Google Scholar]

- García García, J. Estructura de Costes de las Orientaciones Productivas Agrícolas de la Región de Murcia: Horticultura al Aire Libre y Bajo Invernadero; Técnica; Consejería de Agua, Agricultura, Ganadería y Pesca de la Región de Murcia: Murcia, Spain, 2020; Volume 1, ISBN MU 466-2020. [Google Scholar]

- Strano, A.; De Luca, A.I.; Falcone, G.; Iofrida, N.; Stillitano, T.; Gulisano, G. Economic and Environmental Sustainability Assessment of Wine Grape Production Scenarios in Southern Italy. Agric. Sci. 2013, 4, 12–20. [Google Scholar] [CrossRef]

- Falcone, G.; De Luca, A.I.; Stillitano, T.; Strano, A.; Romeo, G.; Gulisano, G. Assessment of Environmental and Economic Impacts of Vine-Growing Combining Life Cycle Assessment, Life Cycle Costing and Multicriterial Analysis. Sustainability 2016, 8, 793. [Google Scholar] [CrossRef]

- Zhang, C.; Rosentrater, K.A. Estimating Economic and Environmental Impacts of Red-Wine-Making Processes in the USA. Fermentation 2019, 5, 77. [Google Scholar] [CrossRef]

- Noguera-Muñoz, F.A.; García García, B.; Ponce-Palafox, J.T.; Wicab-Gutierrez, O.; Castillo-Vargasmachuca, S.G.; García García, J. Sustainability Assessment of White Shrimp (Penaeus vannamei) Production in Super-Intensive System in the Municipality of San Blas, Nayarit, Mexico. Water 2021, 13, 304. [Google Scholar] [CrossRef]

- MAPA. Resultados Técnico-Económicos de Frutales 2017; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2019. [Google Scholar]

- Martínez-Granados, D.; Marín-Membrive, P.; Calatrava, J. Economic Assessment of Irrigation with Desalinated Seawater in Greenhouse Tomato Production in SE Spain. Agronomy 2022, 12, 1471. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management-Life Cycle Assessment: Principles and Framework. International Organization for Standards (ISO): Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management–Life Cycle Assessment: Requirements and Guidelines. International Organization for Standards (ISO): Geneva, Switzerland, 2006.

- PRé. Introduction to LCA with SimaPro; PRé: Amersfoort, The Netherlands, 2016. [Google Scholar]

- EEA. EMEP/EEA Air Pollution Emission Inventory Guidebook 2019. Technical Guidance to Prepare National Emission Inventories; EEA Report; Publications Office of the European Union: Luxenbourg, 2019; ISBN 978-92-9213-806-6. [Google Scholar]

- Del Hierro, Ó.; Gallejones, P.; Besga, G.; Artetxe, A.; Garbisu, C. A Comparison of IPCC Guidelines and Allocation Methods to Estimate the Environmental Impact of Barley Production in the Basque Country through Life Cycle Assessment (LCA). Agriculture 2021, 11, 1005. [Google Scholar] [CrossRef]

- IPCC. Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas. Inventories; Calvo Buendia, E., Tanabe, K., Kranjc, A., Baasansuren, J., Fukuda, M., Ngarize, S., Osako, A., Pyrozhenco, Y., Shermanau, P., Federici, S., Eds.; IPCC: Geneva, Switzerland, 2019; ISBN 978-4-88788-232-4. [Google Scholar]

- Chitarra, W.; Perrone, I.; Avanzato, C.G.; Minio, A.; Boccacci, P.; Santini, D.; Gilardi, G.; Siciliano, I.; Gullino, M.L.; Delledonne, M.; et al. Grapevine Grafting: Scion Transcript Profiling and Defense-Related Metabolites Induced by Rootstocks. Front. Plant Sci. 2017, 8, 654. [Google Scholar] [CrossRef] [PubMed]

- García García, J.; García Brunton, J. Economic Evaluation of Early Peach (Prunus persica L. Batsch) Commercial Orchard under Different Irrigation Strategies. O. J. Acct 2013, 2, 99–106. [Google Scholar] [CrossRef]

- García García, J.; García García, B. Sustainability Assessment of Greenhouse Pepper Production Scenarios in Southeastern Spain. Agronomy 2022, 12, 1254. [Google Scholar] [CrossRef]

- García García, J. Estructura de Costes de los Principales Cultivos en Agricultura Ecológica de la Región de Murcia; Técnica; Consejería de Agua, Agricultura, Ganadería y Pesca de la Región de Murcia: Murcia, Spain, 2023; ISBN MU 132-2023. [Google Scholar]

- Ferrara, C.; De Feo, G. Life Cycle Assessment Application to the Wine Sector: A Critical Review. Sustainability 2018, 10, 395. [Google Scholar] [CrossRef]

- Navarro, A.; Puig, R.; Kılıç, E.; Penavayre, S.; Fullana-i-Palmer, P. Eco-Innovation and Benchmarking of Carbon Footprint Data for Vineyards and Wineries in Spain and France. J. Clean. Prod. 2017, 142, 1661–1671. [Google Scholar] [CrossRef]

- Rinaldi, S.; Bonamente, E.; Scrucca, F.; Merico, M.C.; Asdrubali, F.; Cotana, F. Water and Carbon Footprint of Wine: Methodology Review and Application to a Case Study. Sustainability 2016, 8, 621. [Google Scholar] [CrossRef]

- Bosco, S.; Di Bene, C.; Galli, M.; Remorini, D.; Massai, R.; Bonari, E. Greenhouse Gas Emissions in the Agricultural Phase of Wine Production in the Maremma Rural District in Tuscany, Italy. Ital. J. Agron. 2011, 6, 15. [Google Scholar] [CrossRef]

- Gazulla, C.; Raugei, M.; Fullana-i-Palmer, P. Taking a Life Cycle Look at Crianza Wine Production in Spain: Where Are the Bottlenecks? Int. J. Life Cycle Assess. 2010, 15, 330–337. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).